Patents

Literature

36results about How to "Reduce roasting energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

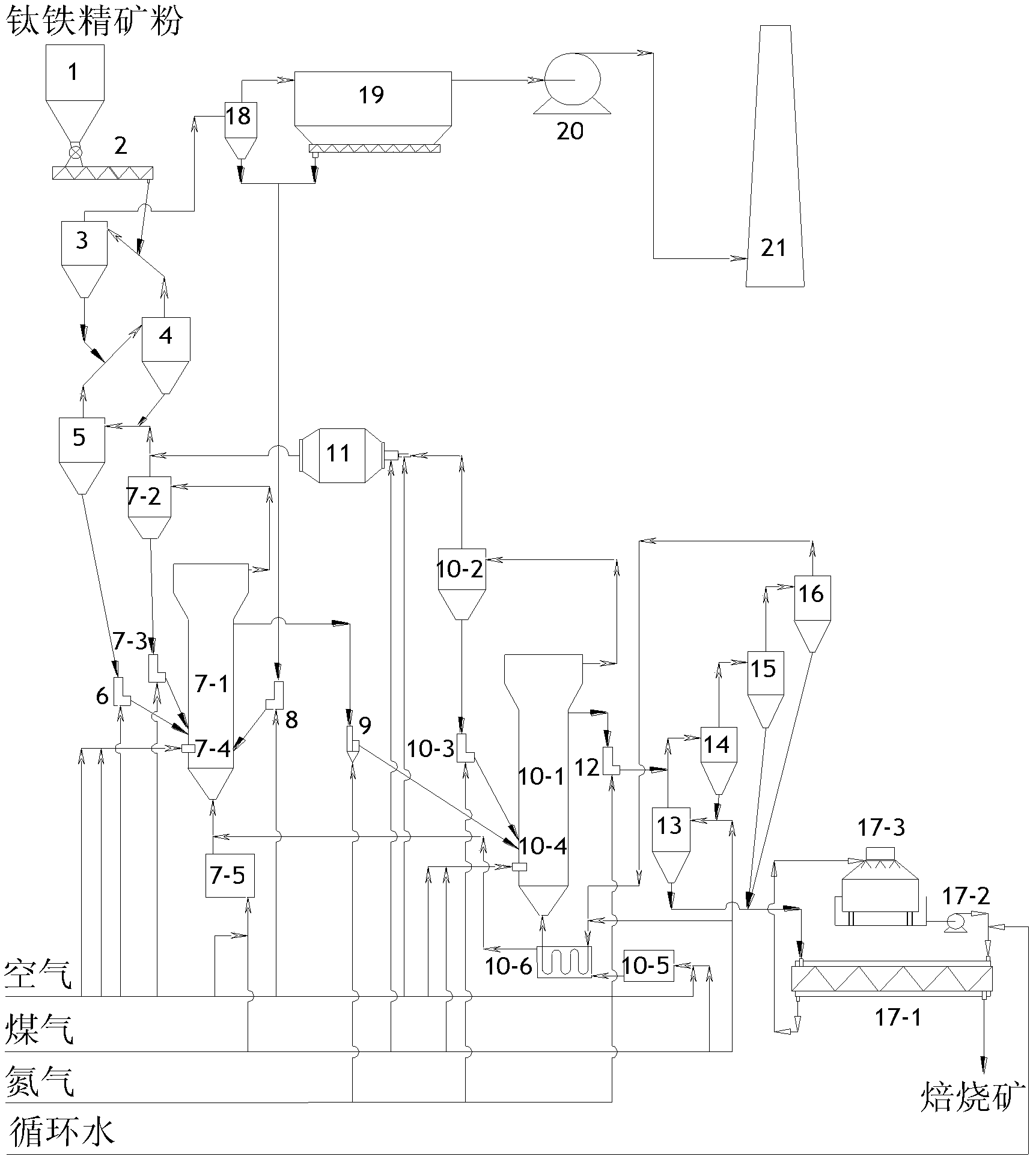

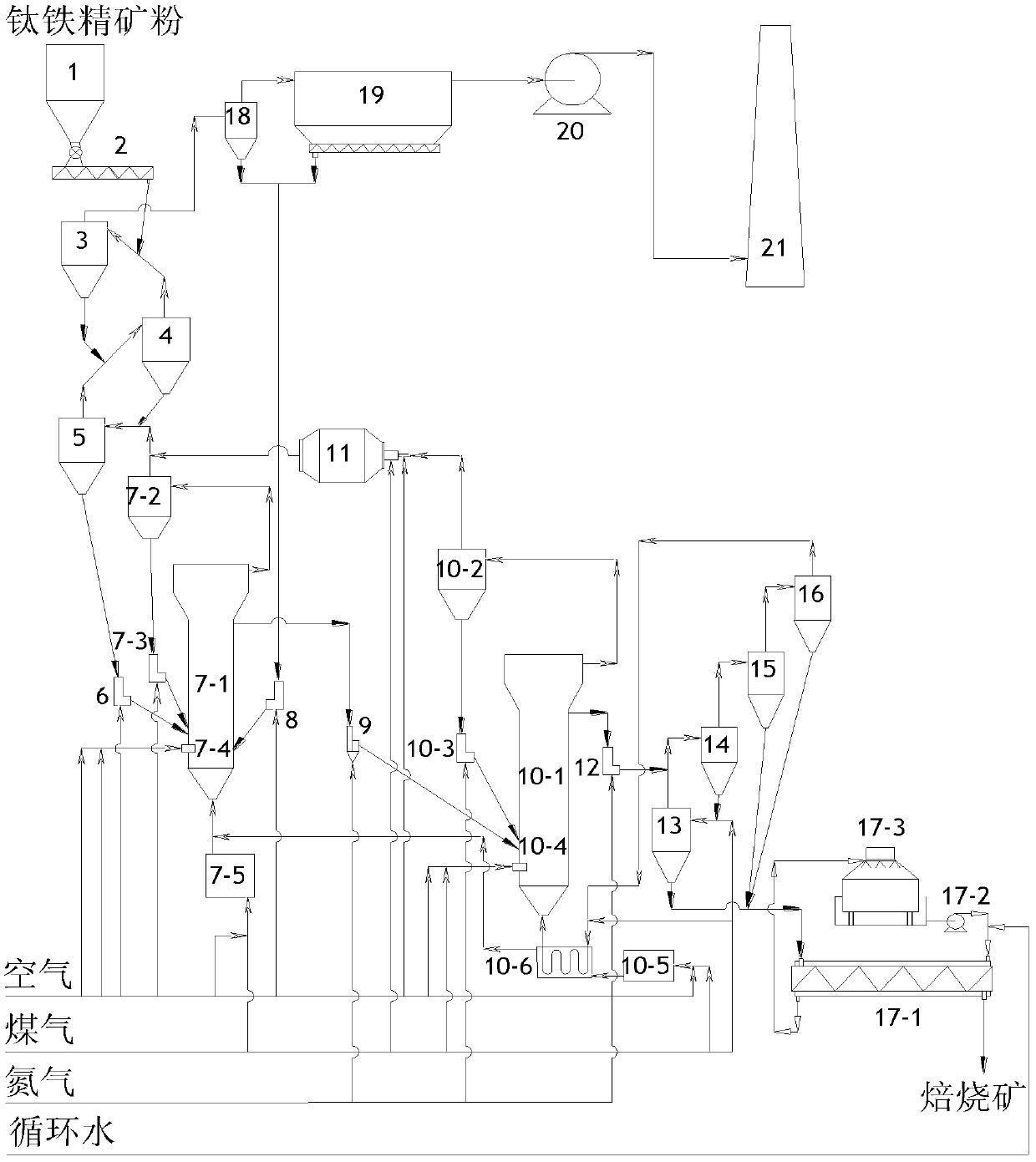

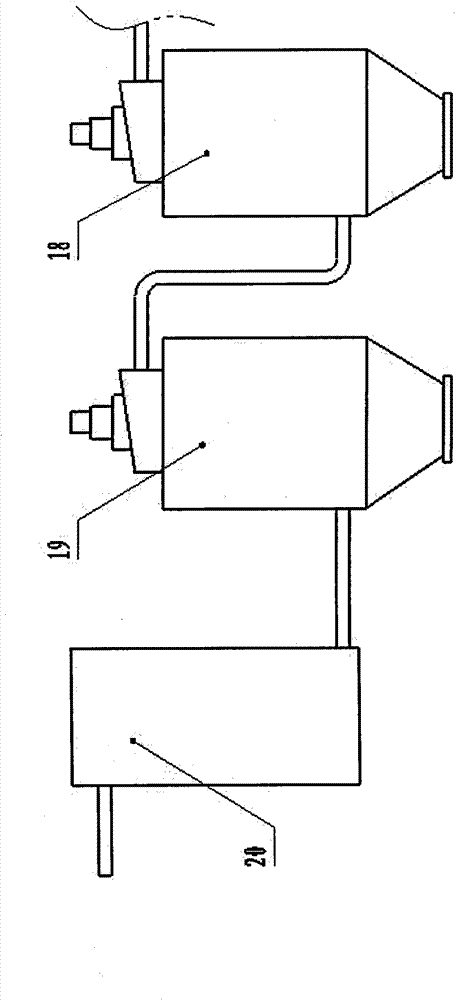

System for oxidizing roasting-reducing roasting of titaniferous iron concentrate and roasting process

The invention discloses a system for oxidizing roasting-reducing roasting of titaniferous iron concentrate and a roasting process. A fluidized bed oxidation reactor is adopted for the oxidizing roasting of the titaniferous iron concentrate; the oxidized titaniferous iron concentrate enters a fluidized bed reduction reactor for reducing roasting; the reduced titaniferous iron concentrate is sequentially and spirally cooled by a cyclone cooler and water cooling and then enters a downstream section; and reduced coal gas is firstly subjected to heat exchange by the cyclone cooler, then preheated by a coal gas preheater, and enters a reducing furnace, latent heat of unreacted reducing gas in tail gas exhausted from the fluidized bed reduction reactor is firstly released through combustion in a combustion chamber, and hot flue gas generated by the combustion is mixed with the tail gas exhausted by the fluidized bed oxidation reactor and then enters a multi-stage cyclone preheater to exchange heat with the titaniferous iron concentrate for heat recovery. The system disclosed by the invention has the advantages of high reaction efficiency, full heat utilization, good economical efficiency in the roasting process and the like, and is suitable for large-scale continuous industrial production.

Owner:深圳中科九台资源利用研究院有限公司

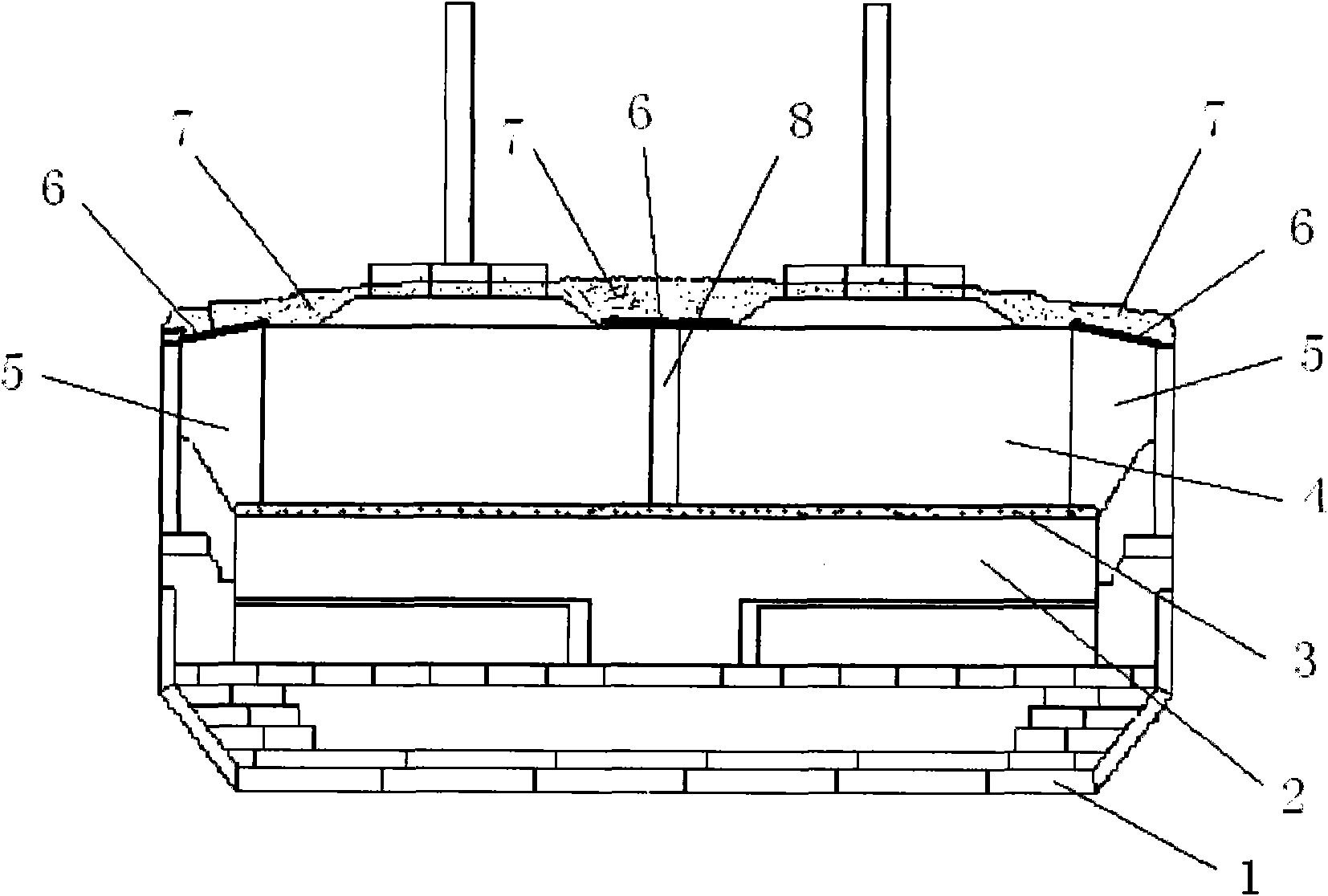

Electrolyzer circumfluence calcination method

The present invention provides electrolyzer circumfluence calcination method, when installing the electrolyzer, between the anode seam, center seam and inside edge cavity are provided with no materials, installing the electrolyzer in full cavity mode, then using the medium generated heat to calcine cathode lining of the electrolyzer in multiple heat transferring modes of radiation, convection and heat transmission etc, smoke generated by pressure difference during calcination circumfluence in the electrolyzer to make sure calcination temperature of all the sections is uniform, and avoids problem of heat stress centralization and sodium enriching in part effectively; a high-temperature insulation thermal insulating layer is lay in anode seam cavity, center seam cavity and top of edge cavity in the electrolyzer for reducing heat loss effectively, improving warming speed, shorting calcination time, saving energy sources and helpful for earlier regular production of the electrolyzer, meanwhile can reduce calcination energy consumption effectively and improve affect of radiation on operation environment; and the most important is that, using full electrolytes powder to instead of cryolite can reduce calcination startup cost greatly.

Owner:YUNNAN RUNXIN ALUMINUM

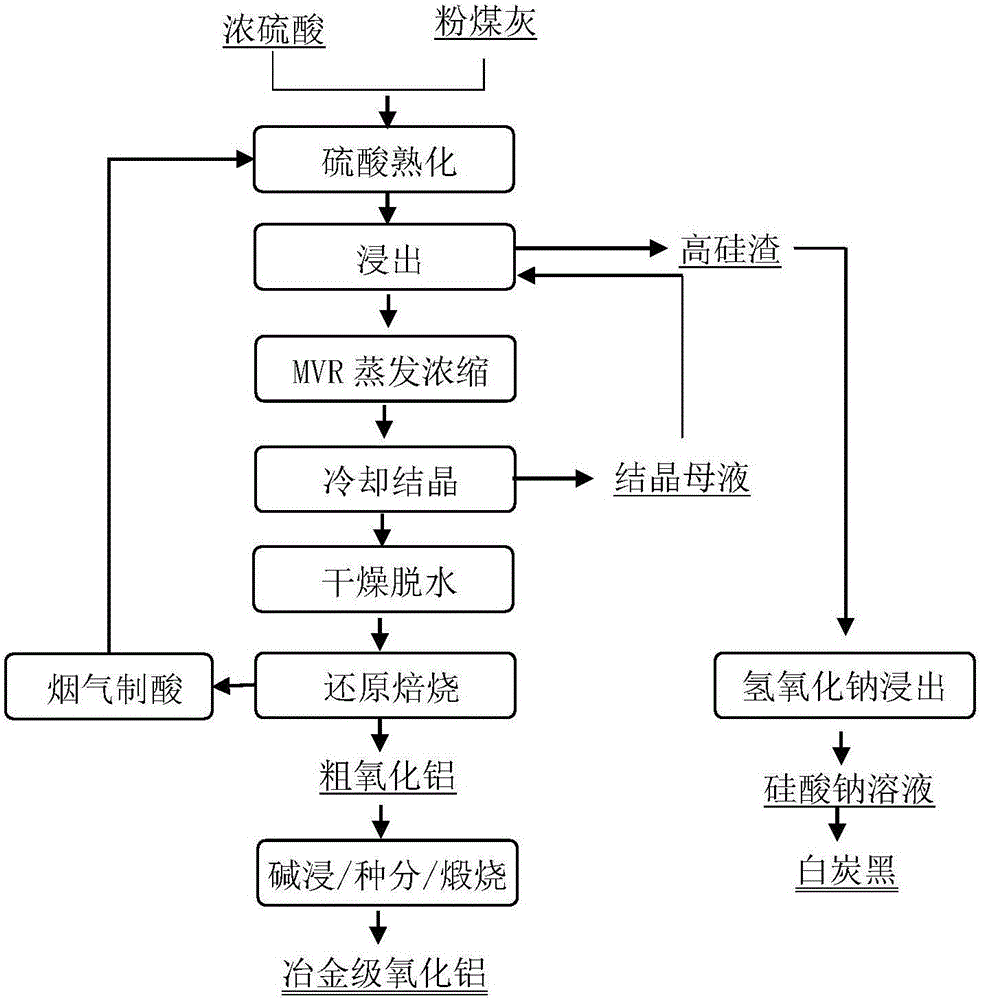

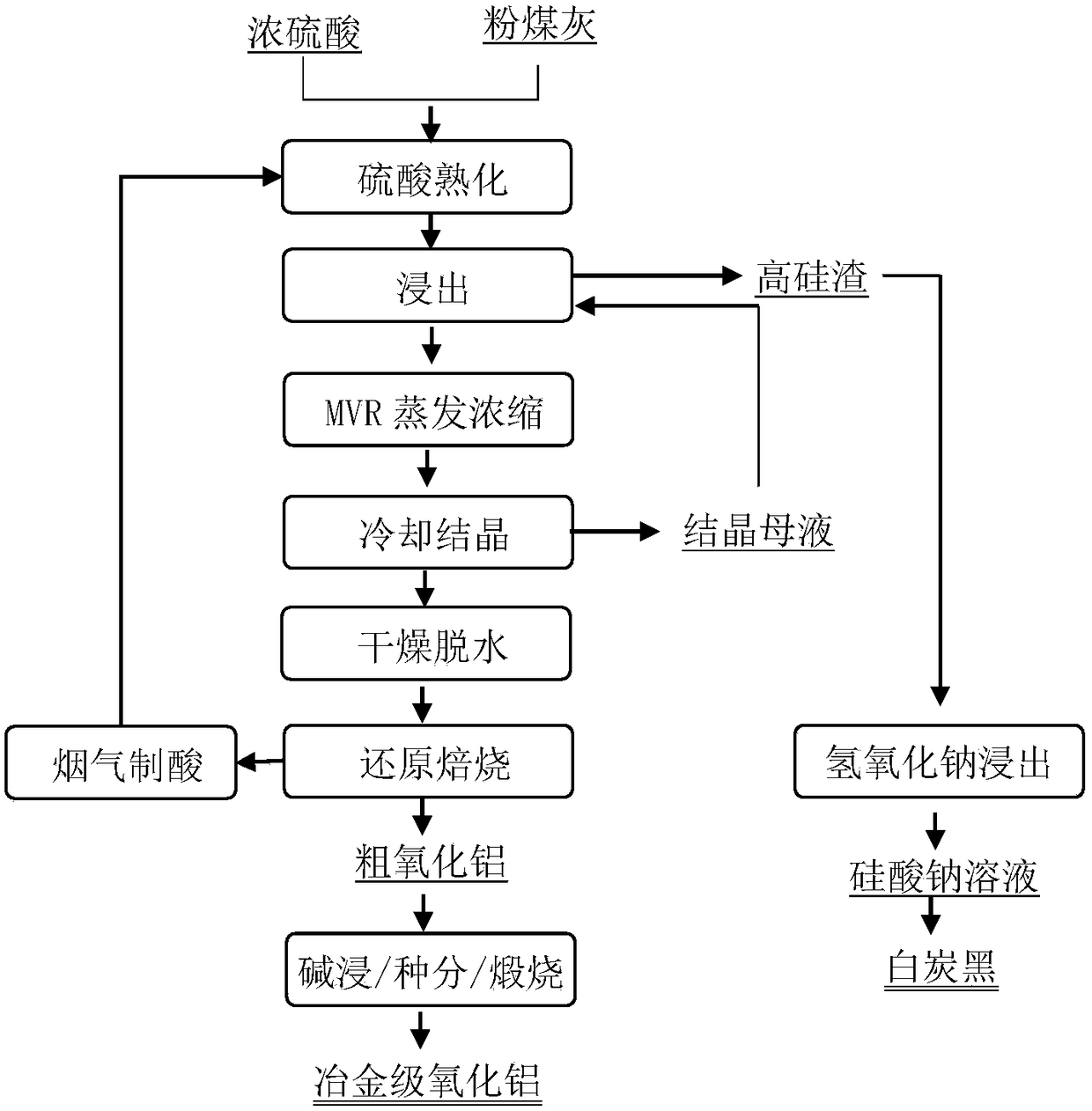

Method for producing alumina by curing fly ash with sulphuric acid

ActiveCN106477609AHigh recovery rateReduce energy consumptionAluminium compoundsSilicaCalcium silicateSlag

The invention discloses a method for producing alumina by curing fly ash with sulphuric acid, belonging to the technical field of comprehensive utilization of the fly ash. The method comprises the following steps: uniformly mixing a proper amount of concentrated sulfuric acid and the fly ash, then carrying out curing so as to obtain a sulfated clinker, then leaching the clinker with an aluminum sulfate crystallized mother liquor or water so as to obtain an aluminum sulfate and high-silicon slag, subjecting the aluminum sulfate solution to evaporation, concentration, crystallization, drying and dehydration so as to obtain aluminum sulfate, subjecting obtained aluminum sulfate and a proper amount of a reducing agent to rapid reduction and calcination so as to obtain crude alumina, then treating the crude alumina by adopting a low-temperature Bayer process so as to produce metallurgical-grade alumina, wherein the obtained high-silicon slag can be leached by sodium hydroxide to produce white carbon black or active calcium silicate. The method provided by the invention has the advantages of high aluminum recovery rate, easily-available equipment and materials, good alumina product quality, etc.; and the slag obtained by leaching of aluminum is the high-silicon slag with good alkali-soluble activity, and can be used for further production of a variety of high-value-added silicon products.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

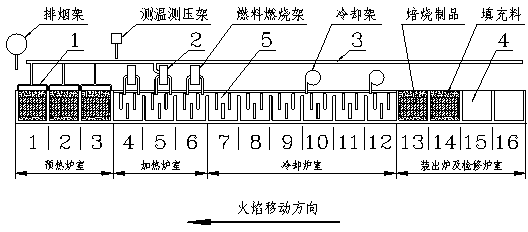

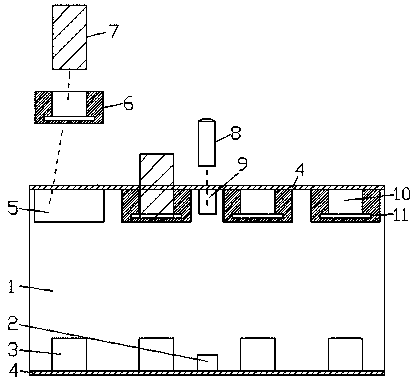

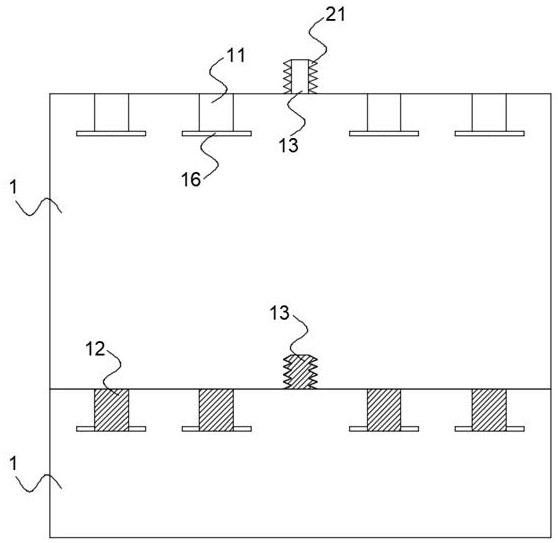

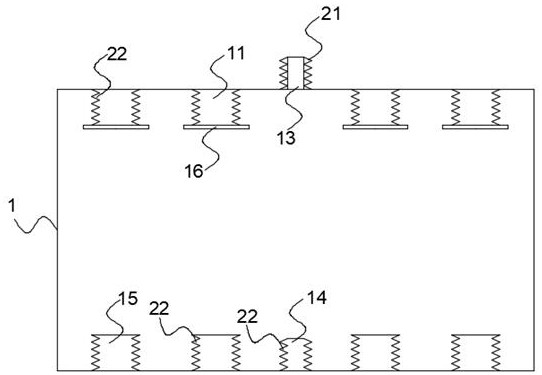

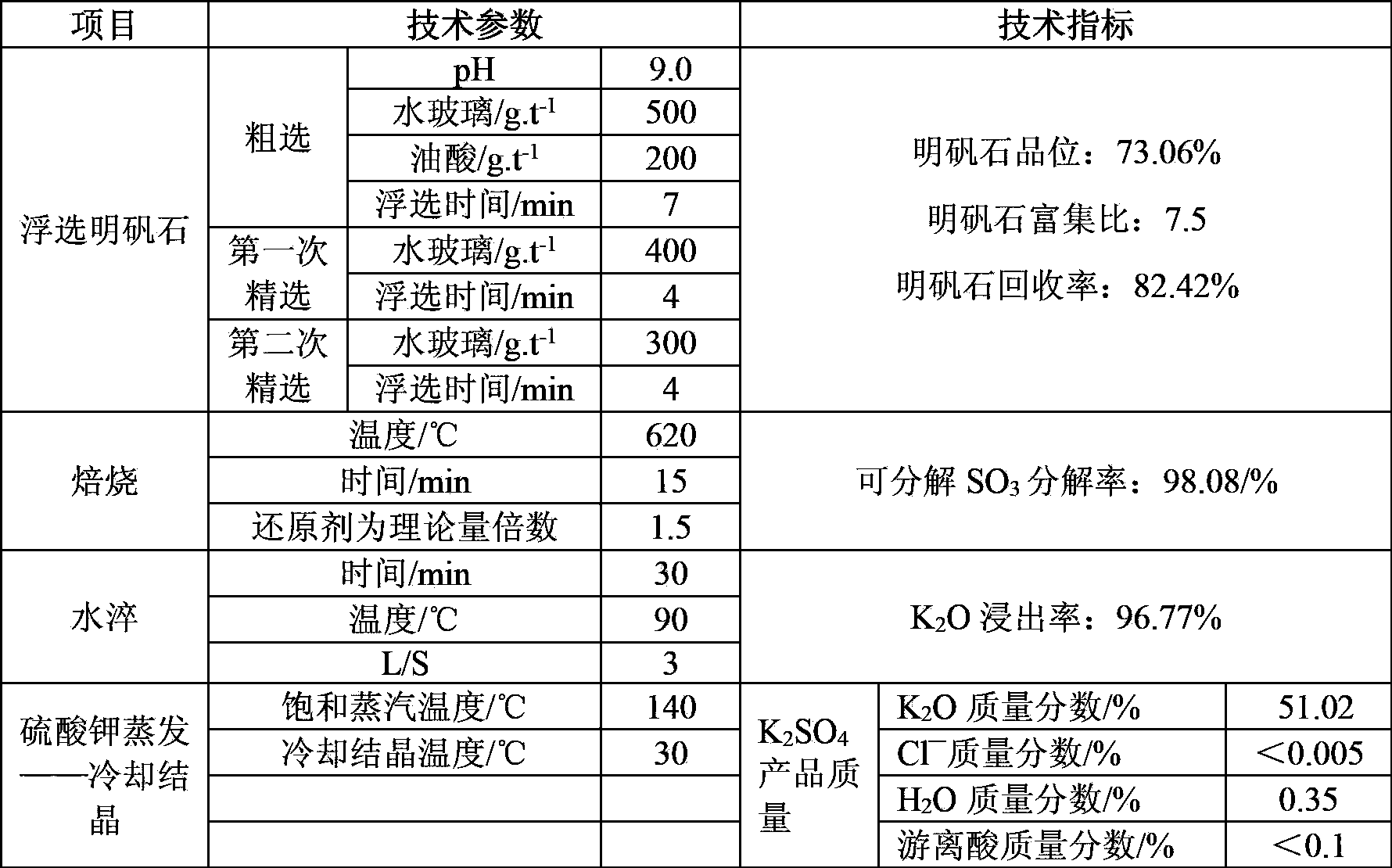

Energy-saving tunnel kiln used for gangue sintered brick production

InactiveCN103423992AReduce lossesFast roastingFurnace typesCeramic materials productionTunnel kilnAutomatic control

The invention belongs to the technical field of gangue sintered brick production, in particular to an energy-saving tunnel kiln used for gangue sintered brick production. The energy-saving tunnel kiln comprises a drying kiln and a calcining kiln, wherein the calcining kiln comprises a kiln body extending along the horizontal direction, and a light kiln car, the kiln body comprises a kiln top, a kiln wall and a working passage, the working passage comprises a preheating section, a calcining section, a holding section and a cooling section in sequence along the extending direction, the cooling section at a kiln tail is provided with a cooling system, an under-kiln balance cooling system and a bootstrap system, a kiln temperature and kiln pressure monitoring and controlling system is also arranged on the kiln body, and the kiln temperature and kiln pressure monitoring and controlling system is provided with a computer automatic control system in a connected way. The energy-saving tunnel kiln has the beneficial effects that above-thermal calcining and fast calcining are realized, the calcining period is shortened, the calcining energy consumption is reduced, and the heat utilization rate is improved, so that the goal of energy saving is achieved.

Owner:郑州鹏泰高新建材制品有限公司

Production method of polishing powder for liquid crystal display device

InactiveCN101381586AHigh crystallinityAccelerated settlementPolishing compositionsNon-linear opticsComing outTunnel kiln

The invention relates to a method for producing polishing powder used for a liquid crystal display device. The method comprises the following steps: at the room temperature, 30 to 40 percent of fluorosilicic acid is added into rare earth chloride solution with REO of between 80 and 100 gram / litre and CeO2 / REO of more than or equal to 70 percent under the stirring; after five minutes, an additive A is added into the mixture, is heated to the temperature of between 70 and 80 DEG C, is kept at the temperature and is added with mixed precipitant solution till the reaction ends; the PH value of the mixture is 7; the mixture is stirred for 10 minutes, is kept stand for 3 to 5 hours and supernatant fluid of the mixture is removed through siphonage; under the stirring, cold water is added to nearly fill a groove fully; before the stirring is stopped, flocculant solution is added till appearing the flocculating effect; the mixture is kept stand, is deposited and the supernatant fluid of the mixture is removed through siphonage for three times; the mixture is washed, is heated up to 98 DEG C, is kept at the temperature for 10 minutes and is discharged to a stainless steel sieve with 120 meshes; the mixture is subjected to solid-liquid separation, vacuum extraction and filtering and dewatering by a centrifuge; a filter cake is transferred to a quartz material sagger; the charging thickness is less than or equal to 9 centimeters; the filter cake is transported to a muffle tunnel kiln at the temperature of 900 DEG C, is subjected to dehydration in a preheating section and decomposition and transformation at certain degree, is roasted for 3 to 4 hours at high temperature of 900 DEG C, is cooled to the temperature of less than 400 DEG C in a cooling section and comes out from the kiln; a roasted material is cooled to the room temperature and is subjected to stage treatment; and a quality part is the product.

Owner:SHANGHAI JIELONG RARE EARTCH FINE ABRASIVE MATERIAL

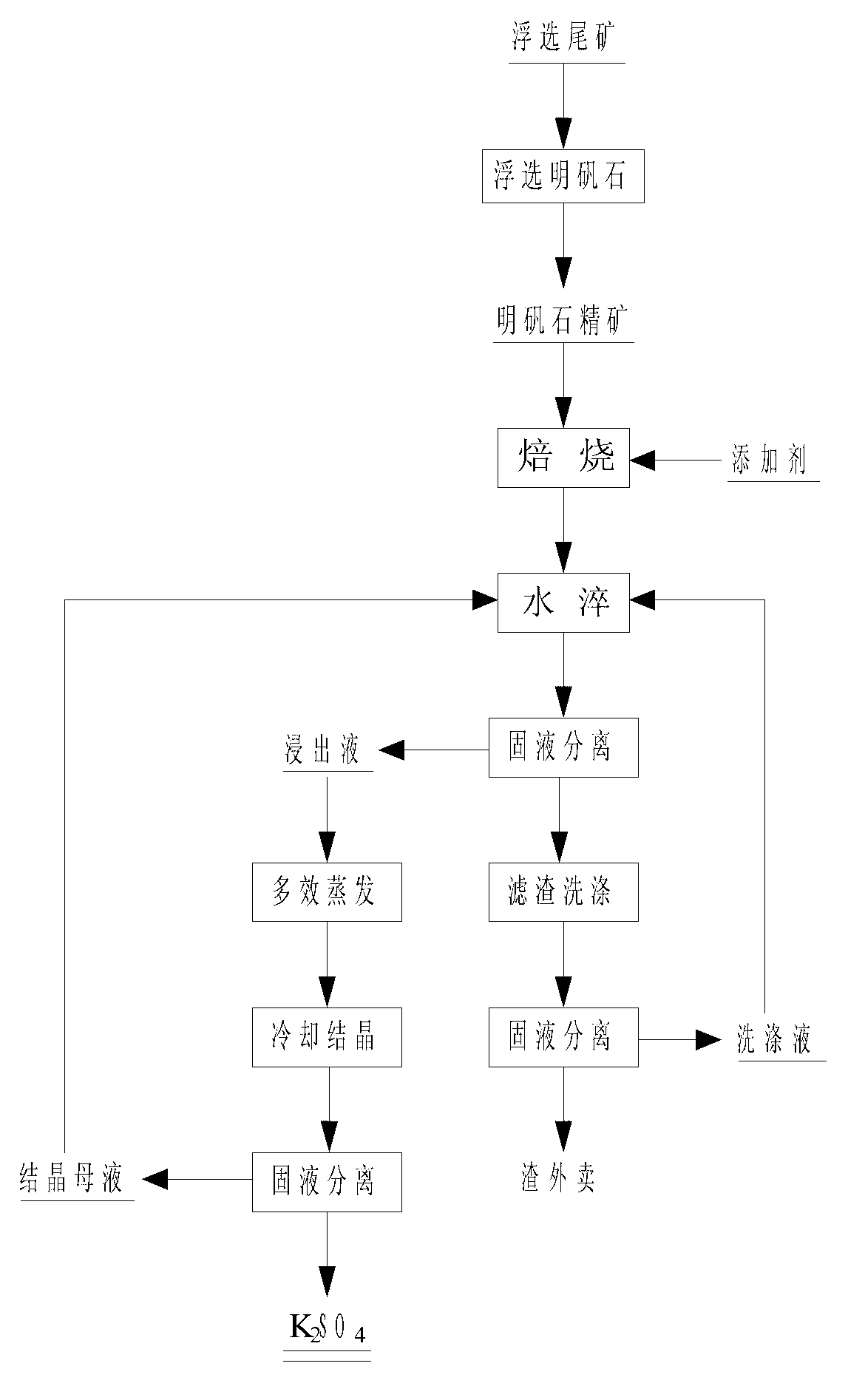

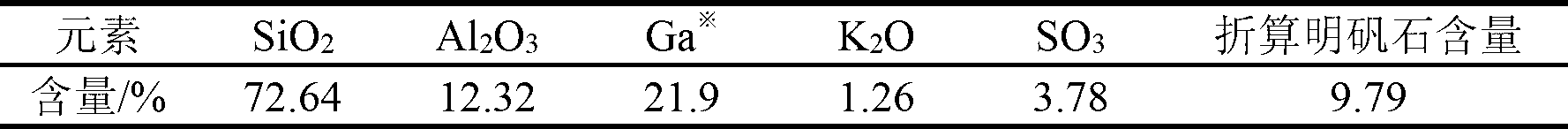

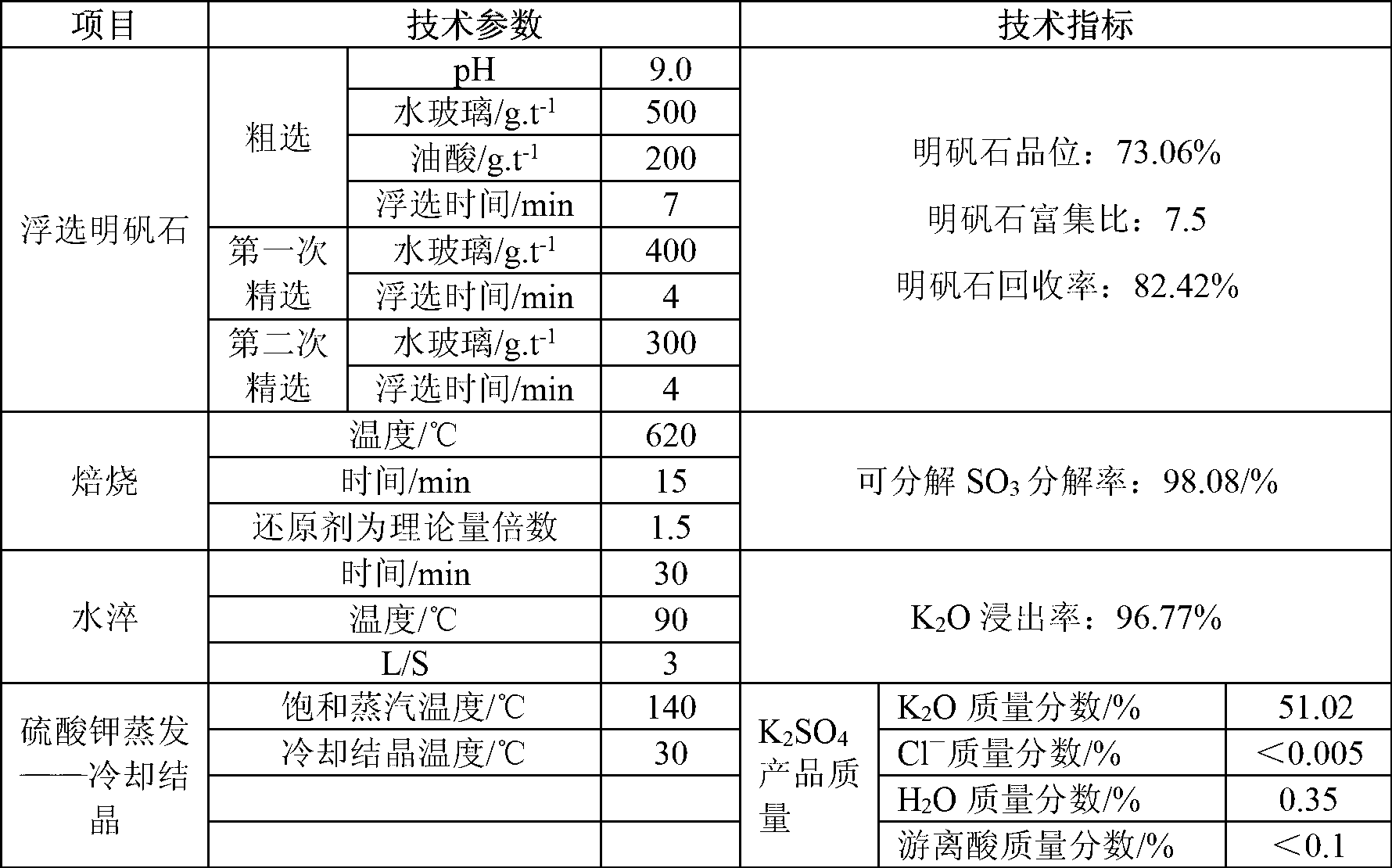

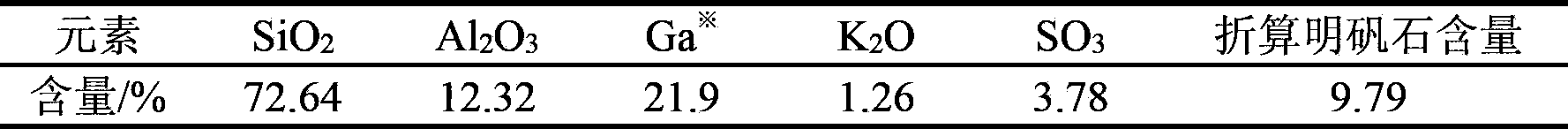

Method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof

ActiveCN103011206AImprove the level of comprehensive utilizationAlleviate the contradiction between supply and demandSulfate/bisulfate preparationEngineeringPotassium sulfate

The invention provides a method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof. The method fully utilizes secondary resources, changes waste into treasure, achieves minimizing, harmlessness and recycling of solid waste, improves comprehensive utilizing level of tailings in China, relieves an acute contradiction of supply and demand of potassium sulfate, reduces loss on foreign exchange caused by mass importation of the potassium sulfate, improves guarantee age limit of kalium and the international competitiveness of the kalium salt industry, completely solves the key scientific and technical problem of economic, clean efficient and comprehensive utilization of the alunite in flotation, the tailings are utilized as resources, establishes tailing comprehensive utilization technical demonstration project, and promotes the development of the comprehensive utilization technique of the tailing in China.

Owner:ZIJIN MINING GROUP

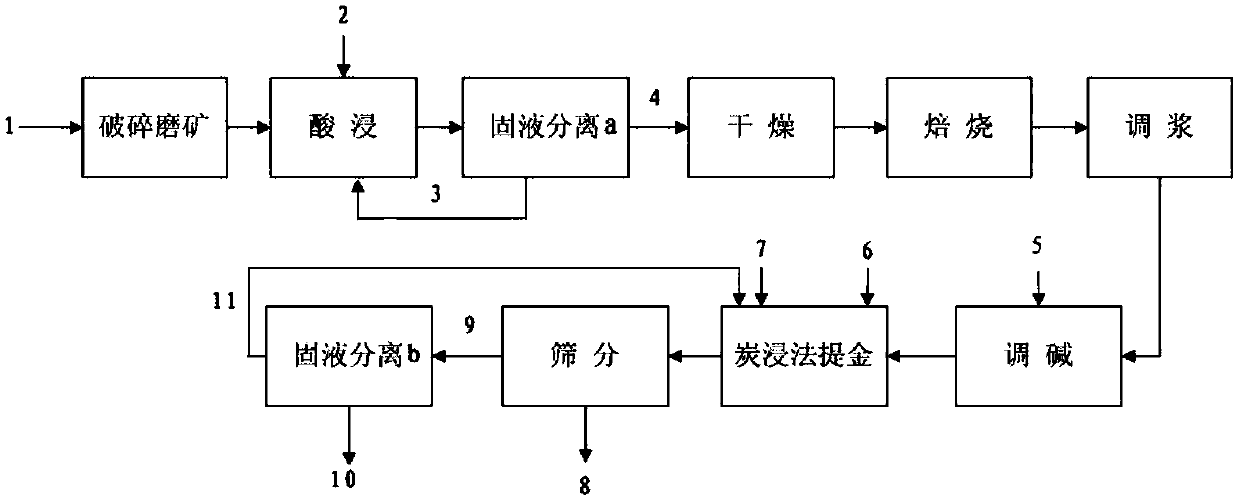

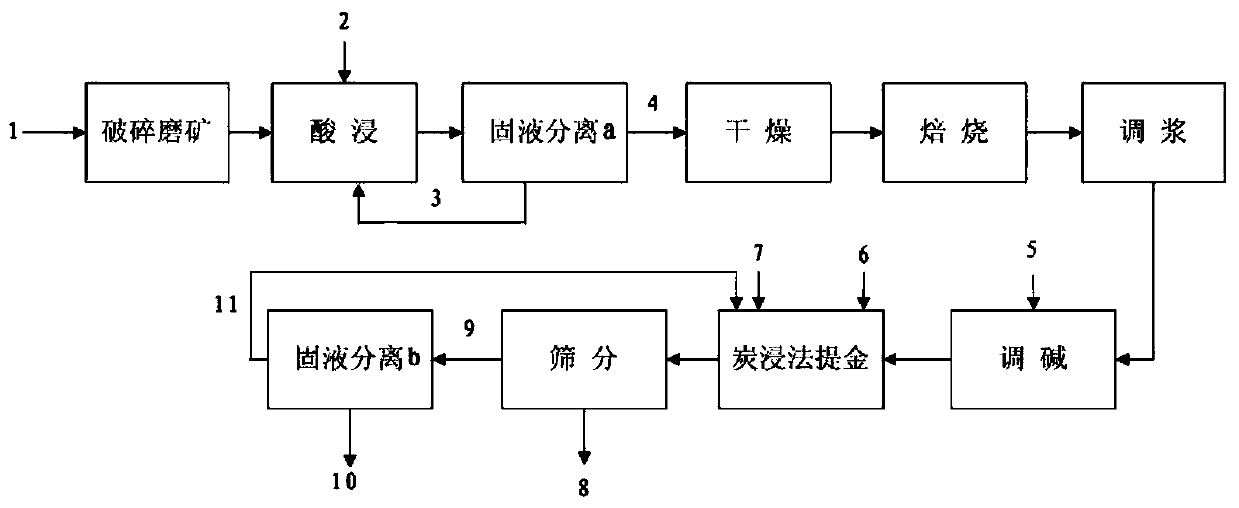

Method for recycling gold for gold-bearing washing mud of gold ore cyaniding system

ActiveCN107815552AImprove leaching ratePrevent the problem of secondary packagingProcess efficiency improvementSulfateGold ore

The invention relates to a method for recycling gold for gold-bearing washing mud of a gold ore cyaniding system. The method includes the following wet process-pyrogenic process combined technologicalsteps of crushing and grinding, acid leaching, solid-liquid separation, roasting, size mixing, alkali adjusting, gold extraction with a carbon-in-leach process and screening for solid-liquid separation b; and according to conditions, conventional sulfuric acid is replaced with hydrochloric acid for acid leaching, the weight of samples entering the roasting step can be reduced, the roasting energyconsumption is reduced, the problem of secondary gold wrapping caused by generation of calcium sulfate can be solved, the gold leaching efficiency is improved, the beneficial effects of being simplein process, low in production cost, high in gold leaching efficiency, capable turning waste into wealth, environment-friendly and the like are achieved, efficient recycling of gold-bearing washing mudvaluable resources can be achieved, and the method is suitable for recycling and application of the gold in the washing mud of the gold ore cyaniding system.

Owner:ZIJIN MINING GROUP +1

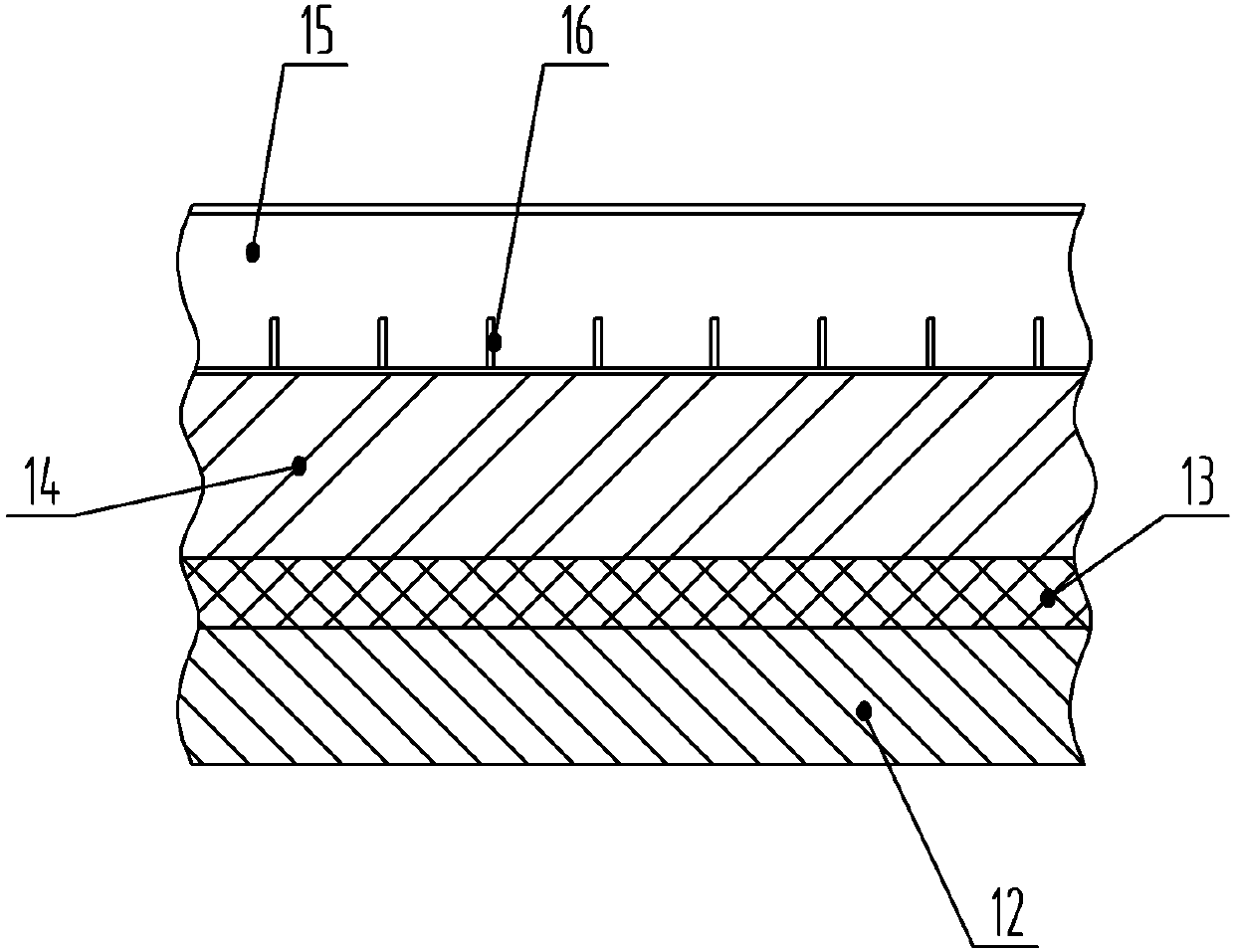

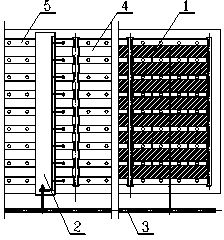

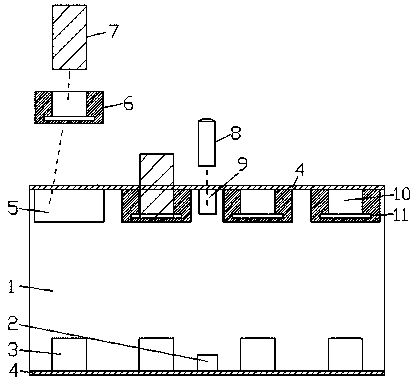

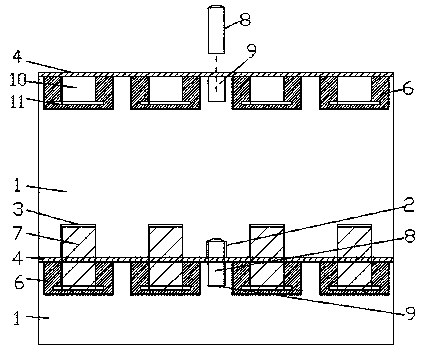

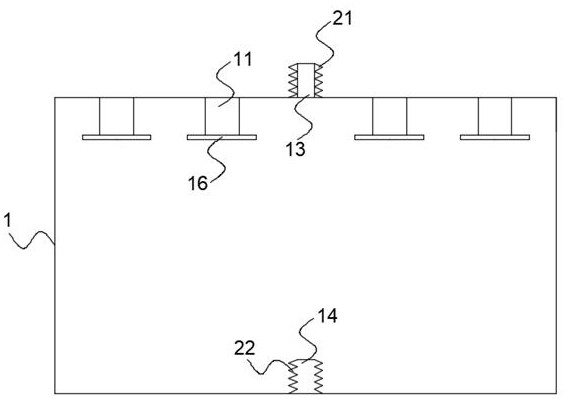

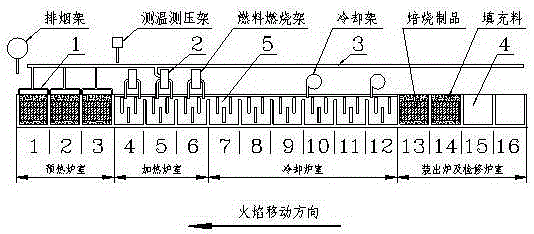

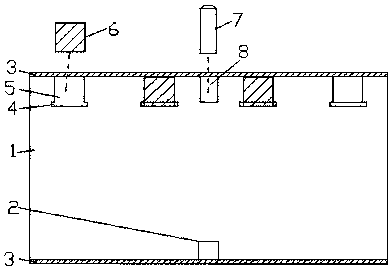

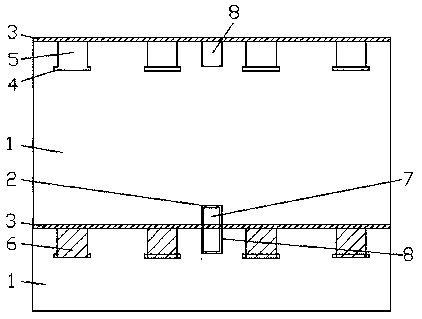

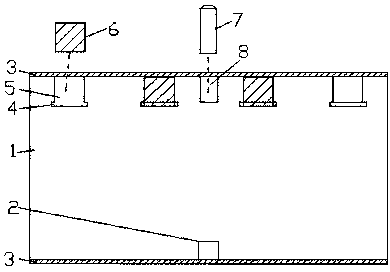

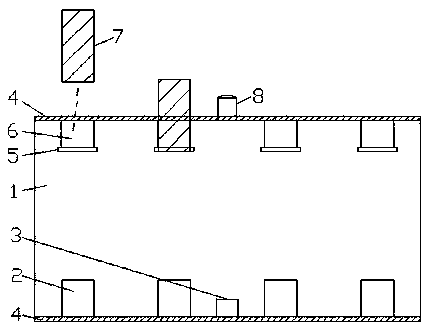

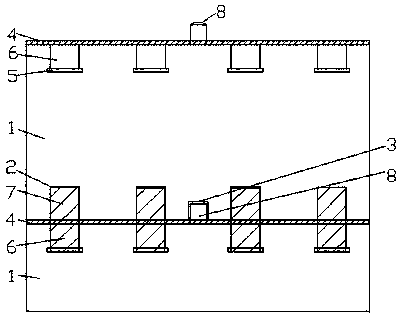

Ring-type baking furnace for carbon production

The present invention discloses a ring-type baking furnace for carbon production. According to the ring-type baking furnace, a plurality of furnace chambers are subjected to head-tail connection combination to form a ring; a material box (4) and a fire channel (5) are separately arranged; the upper portion of the preheat furnace chamber material box (4) is provided with a furnace cover (1); a volatilization component pipeline (3) is arranged between the two rows of the furnace chambers; the upper portion of a heat furnace chamber is provided with volatilization component combustion frames (2); the furnace cover (1) and the volatilization component combustion frames (2) are connected with the volatilization component pipeline (3); the volatilization component combustion frame (2) is connected with the fire channel (5) of the heat furnace chamber; the furnace cover (1) is provided with asphalt volatilization component discharge ports; and furnace cover volatilization component discharge ports and inlets of the volatilization component combustion frames (2) are connected through the volatilization component pipeline (3). With the present invention, the condition that harmful asphalt volatilization components enter baking flue gas so as to cause pollution can be avoided, baking energy consumption can be reduced, benzopyrene can be effectively treated, a clean production purpose can be achieved, and the condition that the too high temperature at the preheat stage causes the baking product to generate cracks can further be avoided.

Owner:GUIYANG AL-MG DESIGN & RES INST

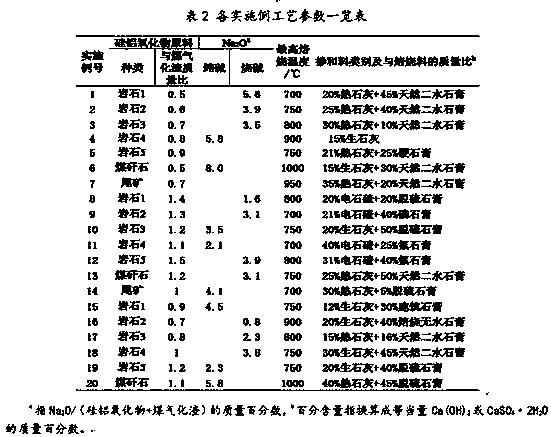

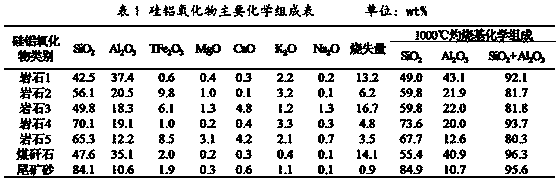

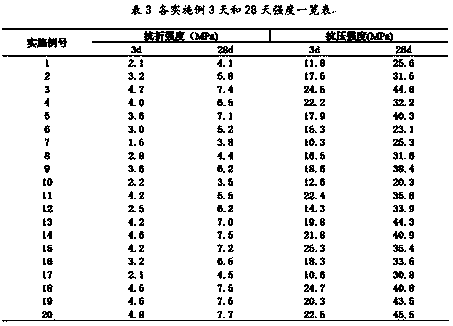

Method for preparing cementing material from suspended roasted coal gasifying slag

ActiveCN108275895AEmission reductionReduce energy consumptionCement productionSocial benefitsPolymer science

The invention discloses a method for preparing a gel material from suspended roasted coal gasifying slag. The method is characterized in that industrial alkaline, silicon-aluminum oxide and coal gasifying slag are uniformly mixed in proportion and are grinded to completely pass through a 100-mesh sieve; then, mixed powder is suspended and roasted in a temperature being 700-1000 DEG C in a pressurizing roasting furnace; and finally, lime and gypsum are added in proportion into the cooled roasted material, and are finally grinded until 200-mesh weight of screen residues is smaller than or equalto 10%. The method is used for preparing the gel material from the coal gasifying slag, and has economic and social benefits.

Owner:HUNAN UNIV OF SCI & TECH

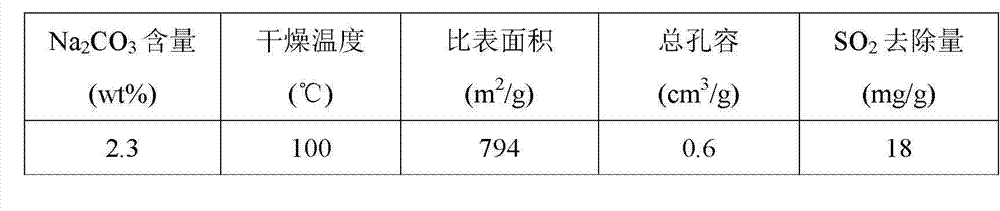

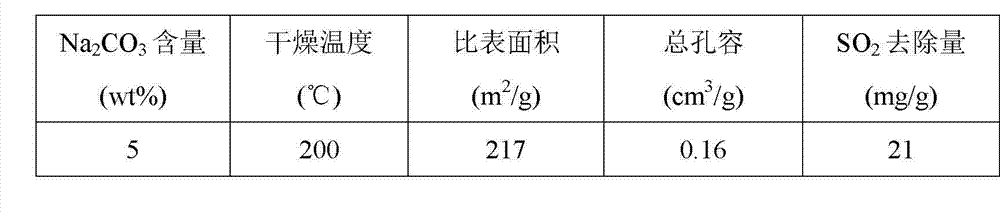

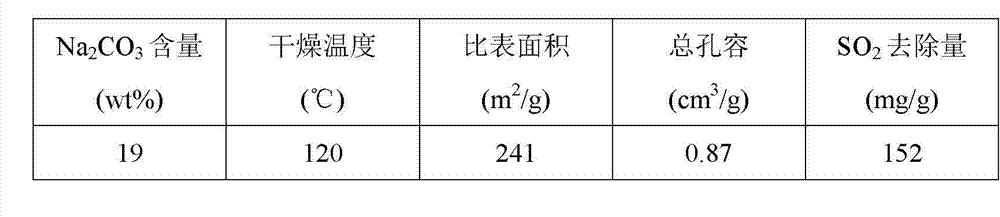

Carbonate/silicon oxide compound gel adsorbent and preparation method thereof

InactiveCN102773071AWide variety of sourcesThe production principle is simpleOther chemical processesSilicon compoundsSorbentChemisorption

The invention discloses a carbonate / silicon oxide compound gel adsorbent and a preparation method thereof, which belong to the technical field of preparation of chemical adsorbents. The method comprises the following steps of: adding carbonate at a condensation polymerization reaction phase according to the process characteristic of a porous adsorbent prepared with a sol-gel method for accelerating a reaction and introducing active ingredients specific to a target pollutant, i.e., SO2; and under the action of an acid catalyst, performing a hydrolysis reaction on a silicon source precursor to generate silicon oxide sol, adding a carbonate solution into the sol, stirring for gelling, aging, and drying under the normal pressure to obtain carbonate / SiO2 compound dry gel which can be taken as a chemical adsorbent for removing harmful gases such as SO2 and H2S. The preparation method has the advantages of wide source, low cost, simple process, easiness for operating, no need of baking at a high temperature and low energy consumption; and the prepared compound gel adsorbent has the advantages of high specific surface area, uniform dispersion of active ingredients and high removing efficiency on harmful gases.

Owner:TSINGHUA UNIV

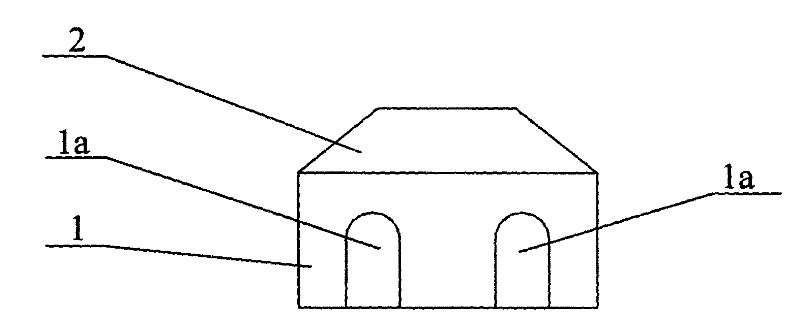

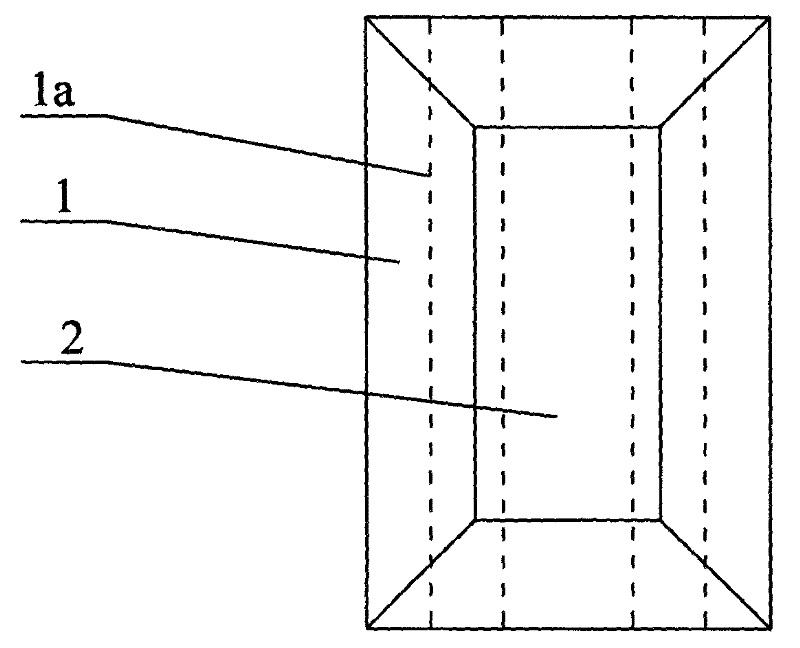

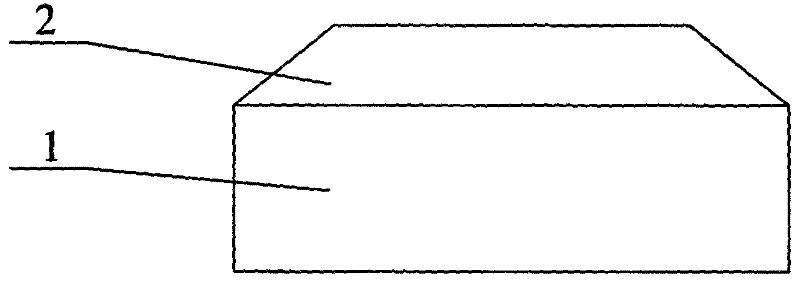

Continuous pre-baked anode carbon block with split type independent carbon bowl and ultra-long filling block structure

ActiveCN110029363ASimple structureHigh green block forming rateElectrical resistance and conductanceContinuous use

The invention discloses a continuous pre-baked anode carbon block with a split type independent carbon bowl and ultra-long filling block structure. The continuous pre-baked anode carbon block comprises a carbon block body, wherein carbon bowl assembly connecting pits are formed in the carbon block body, carbon bowl assemblies are arranged in the carbon bowl assembly connecting pits, carbon bowls are arranged on the carbon bowl assemblies, mechanical steel claw connecting ring grooves are formed in the positions, at the bottoms of the carbon bowls, of the charcoal bowl assemblies, and ultra-long carbon bowl filling blocks are movably arranged in the parts, on the carbon bowl assemblies, of the carbon bowls. The continuous pre-baked anode carbon block cooperates with casting-mechanical steelclaws so that the continuous use of a pre-baked anode can be realized, the time for connecting a new anode carbon block is short, the labor intensity is low, the use is convenient, the filling rate of the continuous pre-baked anode carbon block is improved, the connection strength of the carbon block is improved, the whole resistance of the anode carbon block is reduced, the service life of the single carbon block is prolonged, the production cost is low, moreover, manufacturing, roasting, transportation and use of the carbon block body, the split type independent carbon bowls, and the ultra-long filling blocks are all simple, and the characteristics of being high in manufacturing finished product rate, low in expense is low, low in cost and the like are achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

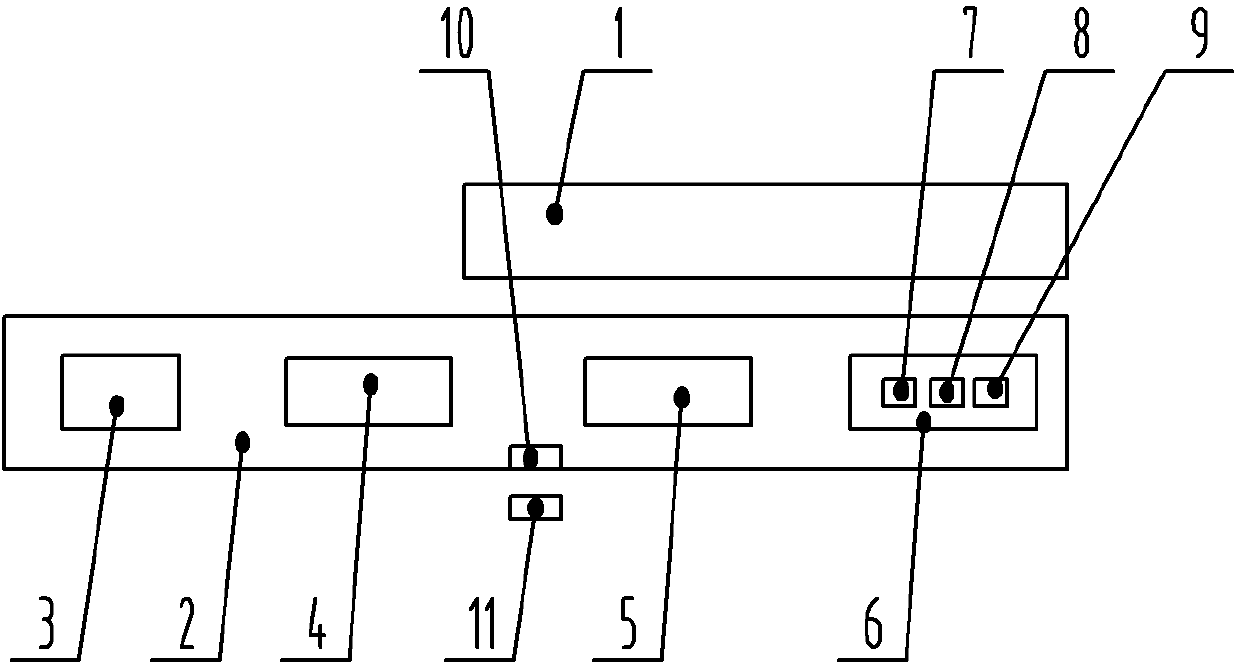

Method for reducing baking energy consumption of prebaked carbon anodes for aluminum electrolysis

InactiveCN102815687AReduce consumptionReduce anode costCarbon preparation/purificationElectrolysisTemperature difference

The invention discloses a method for reducing baking energy consumption of prebaked carbon anodes for aluminum electrolysis, and relates to an improved method for baking prebaked carbon anodes for aluminum electrolysis. The method is characterized in that in the baking process, the smoke exhaust frame total negative pressure is controlled to be 1,600-2,600 Pa; baking curve is controlled to be 26-48 h (250-620 DEG C, 7.5-14 DEG C, / h; 800-1,000 DEG C, 4-8 DEG C / h; 1,000-1,180 DEG C, 3.5-7 DEG C / h); temperature difference between different fire passages at 300-800 DEG C is controlled to be (-30)-30 DEG C; temperature difference between different fire passages at 1,000-1,180 DEG C is controlled to be (-5)-5 DEG C; and upper-lower temperature difference for the same fire passage is controlled to be 0-150 DEG C. The inventive method reasonably establishes baking curve, and reasonably controls exhaust frame total negative pressure to lower practical energy consumption; and effectively controls temperature difference of high-temperature zones and low-temperature zones between different fire passages, and upper-lower temperature difference for the same fire passage, so as to improve qualification rate of prebaked blocks, effectively lower baking energy consumption and reduce carbon anode cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

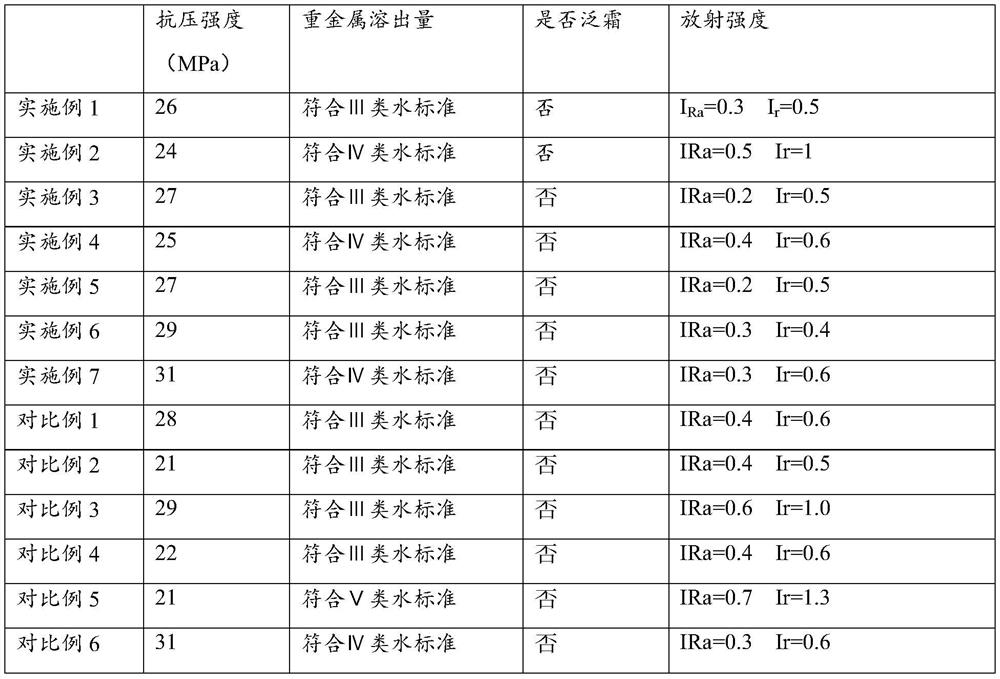

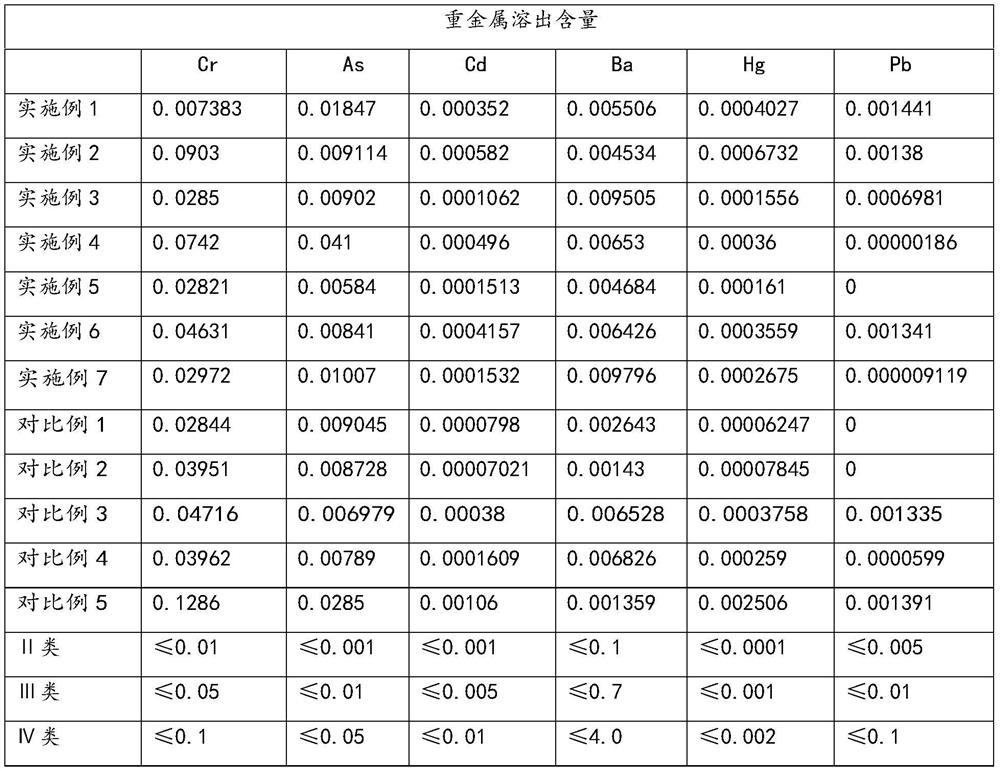

Semi-internal combustion type red mud sintered brick and production process and application

PendingCN112661490AIncrease dosageReduce radioactivity levelsCeramic materials productionClaywaresCompressive resistanceBrick

The invention provides a semi-internal combustion type red mud sintered brick and a production process and application thereof, and relates to the technical field of building materials, the semi-internal combustion type red mud sintered brick comprises the following components in parts by mass: 20-60 parts of Bayer process red mud, 5-15 parts of plastic clay, 15-20 parts of coal gangue, 10-40 parts of aggregate, 5-10 parts of a fluxing agent, 3-10 parts of a binder and 1-5 parts of a radioactivity shielding agent, wherein the sum of the parts by weight of the components is 100. According to the semi-internal combustion type red mud sintered brick provided by the invention, the doping amount of Bayer process red mud is greatly increased, through the synergistic cooperation of the components, the compressive strength reaches the MU30 standard, the problems of heavy metal dissolution pollution risk, scumming and the like are avoided in the use process, the radioactivity level is also greatly reduced, the national building main body material standard can be met, meanwhile, coal gangue is added into the raw materials, internal combustion and external combustion can be achieved in the production process, roasting energy consumption is remarkably reduced, and the production cost is effectively reduced.

Owner:SHANDONG UNIV OF TECH

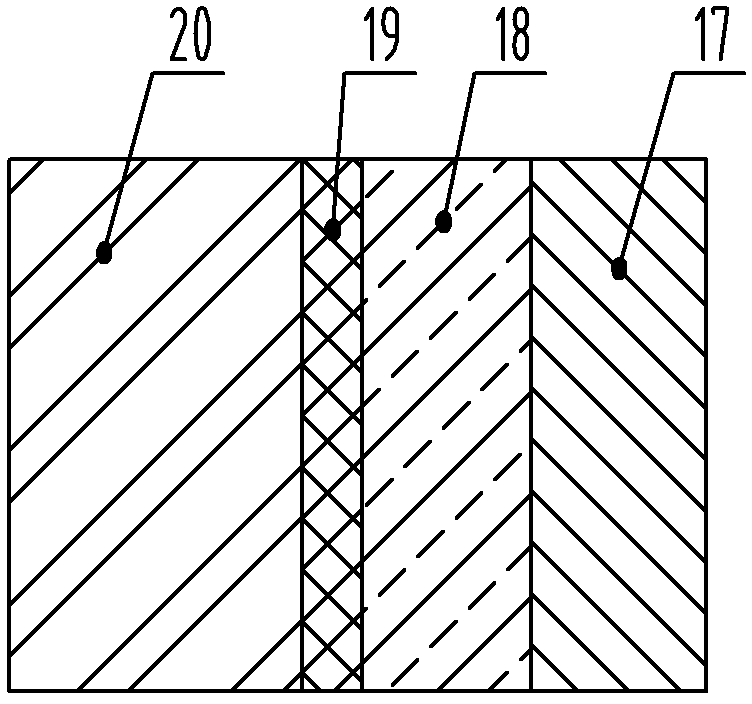

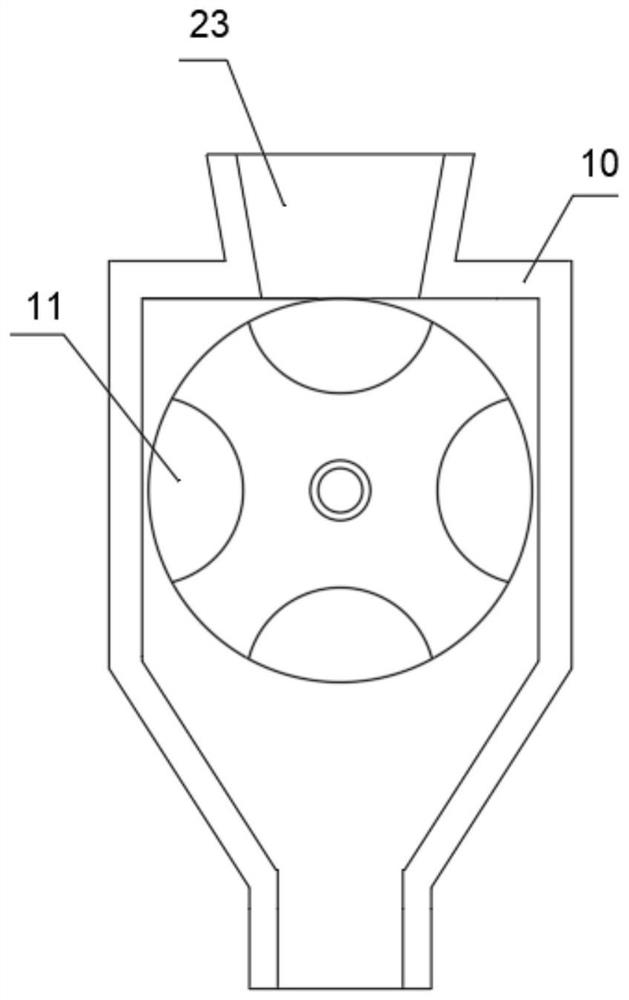

Novel anode carbon block for continuous prebaking

The invention provides a novel anode carbon block for continuous prebaking. The novel anode carbon block is characterized in that a carbon bowl is arranged at the top of a carbon block body; a carbon bowl filling block is movably arranged in the carbon bowl; a bump is arranged on the top surface of the carbon block body; a groove is formed in the bottom surface of the carbon block body and corresponds to the bump; a plurality of protrusions are arranged on one side face of the bump and distributed in the length direction of the bump, a plurality of recesses are formed in one side wall of the groove and distributed in the depth direction of the groove, the protrusions are matched with the recesses, and the distribution directions of the protrusions and the recesses are consistent, so that after the bump is inserted into the groove and the protrusions and the recesses are embedded in a one-to-one correspondence mode, the new carbon block body is connected with the old carbon block body. The continuous use of a prebaked anode is realized, the time for connecting new anode carbon block is short, the labor intensity is low, the use is convenient, the bonding area of the new and old carbon blocks is increased, the connection strength of the carbon blocks is improved, the service life of a single carbon block is prolonged, the production cost is low, the production efficiency is improved, and the product percent of pass is improved.

Owner:阿坝铝厂

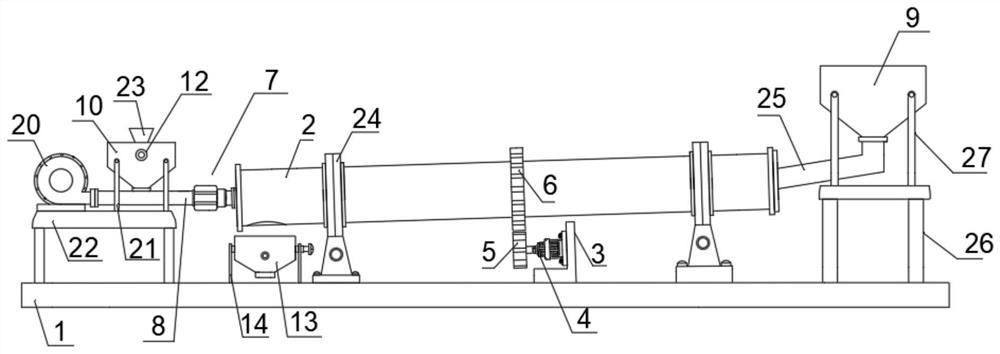

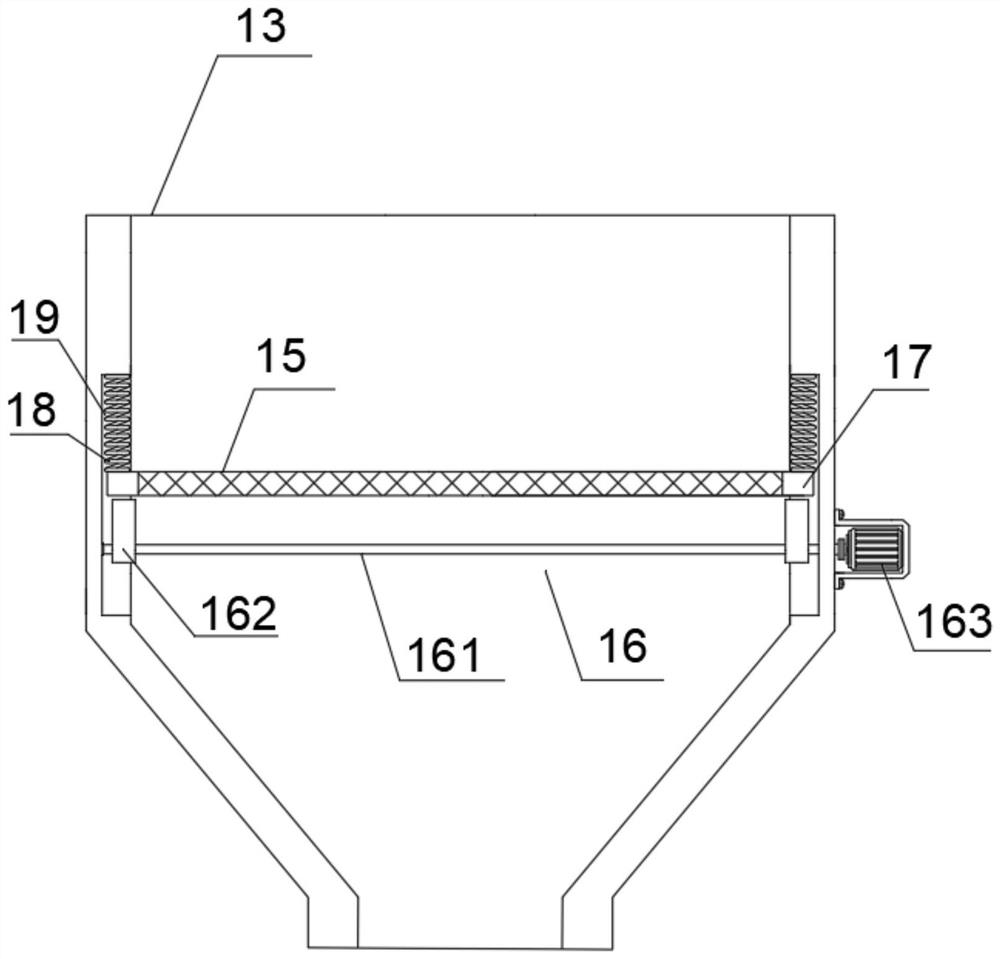

Rotary kiln roasting structure and roasting process thereof

InactiveCN112113419AGood roasting effectReduce roasting energy consumptionRotary drum furnacesEngineeringRotary kiln

The invention discloses a rotary kiln roasting structure and a roasting process thereof. The rotary kiln roasting structure comprises a bottom plate, wherein a rotary kiln body which is obliquely arranged is arranged above the bottom plate; a first motor is arranged at one side below the rotary kiln body; the output end of the first motor is fixedly connected with a drive gear; the middle part ofthe rotary kiln body is fixedly connected with a driven gear; one end of the rotary kiln body is connected with a coal injection mechanism; the coal injection mechanism comprises a combustor; one endof the rotary kiln body is rotatably connected with the middle part of the combustor; one end, far away from the rotary kiln body, of the combustor is fixedly connected with a connecting tube; the drive gear is engaged with the driven gear, the driven gear rotates, and the rotary kiln body fixedly connected with the driven gear rotates; the rotary kiln body is obliquely arranged, and the rotary kiln body rotates, so that materials move from the head end of the rotary kiln body to one end of the combustor while rotating; the closer the materials are to the combustor, the higher the temperatureis; and the materials are gradually roasted by flame sprayed out from a burner uniformly, so that the roasting effect is better, and roasting energy consumption is reduced.

Owner:JIANGSU HUIRAN IND CO LTD

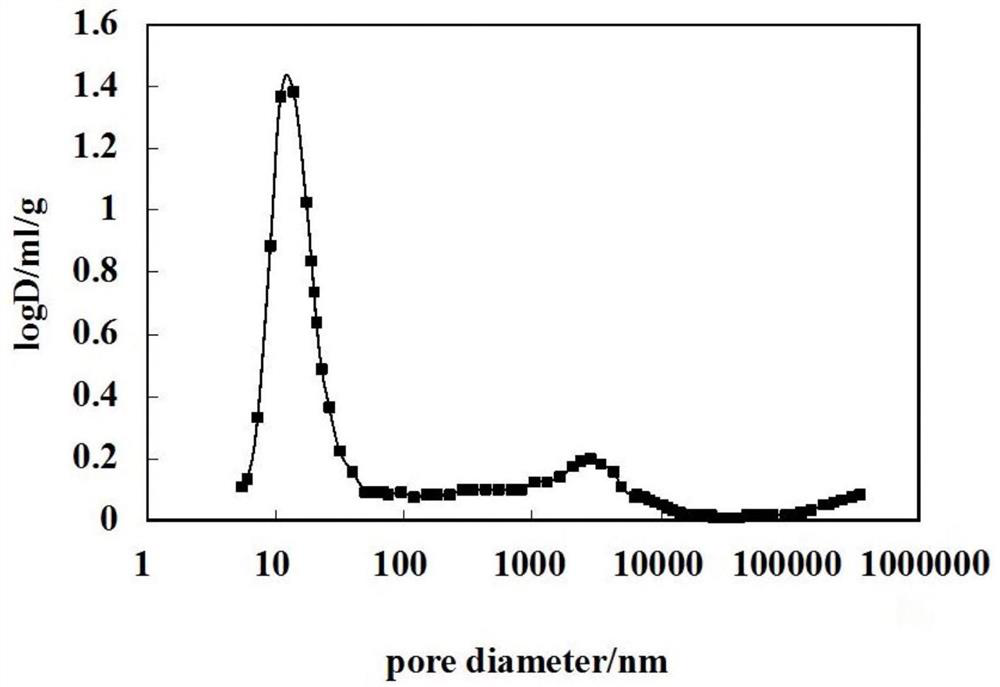

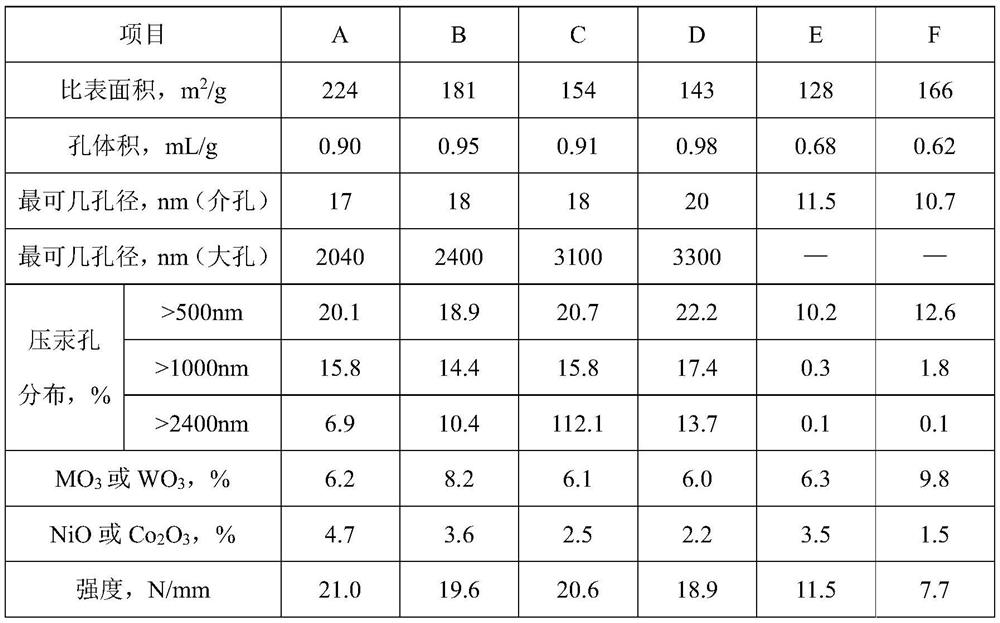

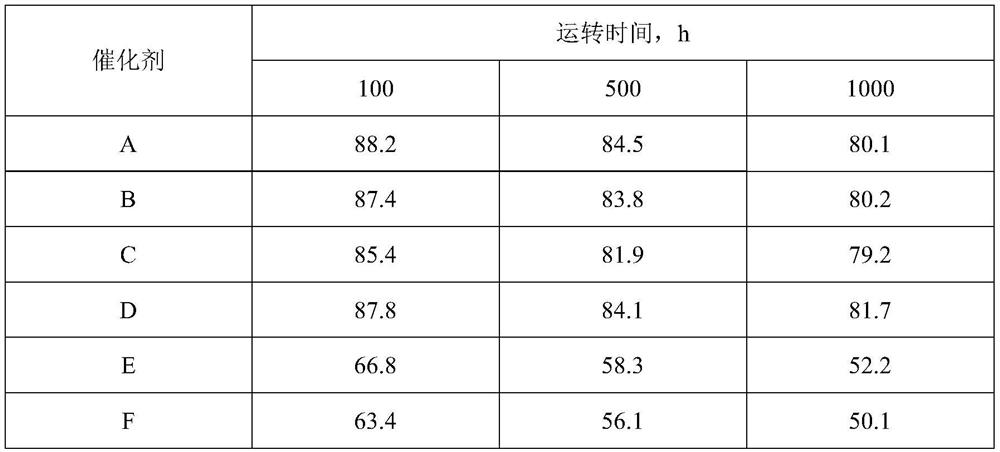

Coal tar bimodal pore structure hydrogenation pretreatment catalyst and preparation method thereof

ActiveCN111604074AImprove diffusivityProtect the pore structurePhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystEngineering

The invention discloses a coal tar bimodal pore structure hydrogenation pretreatment catalyst and a preparation method thereof. The pore volume of a coal tar bimodal pore structure hydrogenation pretreatment catalyst aluminum oxide carrier is 0.8-1.5 mL / g, the specific surface area is 120-350m < 2 > / g, the most probable pore size of mesopores is 15-30nm, the most probable pore size of macropores is 2000-4000nm, and the pore volume of macropores with the pore size of 2400nm or above accounts for 5-25% of the total pore volume. Aluminum oxide is used as a carrier, VIB and VIII metal elements areused as active components, a phosphorus element is used as an auxiliary agent, the weight content of the active components in the hydrogenation pretreatment catalyst is 0.4%-10% by metal, and the weight content of the auxiliary agent phosphorus in the hydrogenation pretreatment catalyst is 0.1%-10% by element. The coal tar bimodal pore structure hydrogenation pretreatment catalyst provided by theinvention has the advantages of large pore volume, large pore diameter, excellent diffusivity, and high demetallization and hydrogenolysis asphaltene activity.

Owner:CCTEG CHINA COAL RES INST

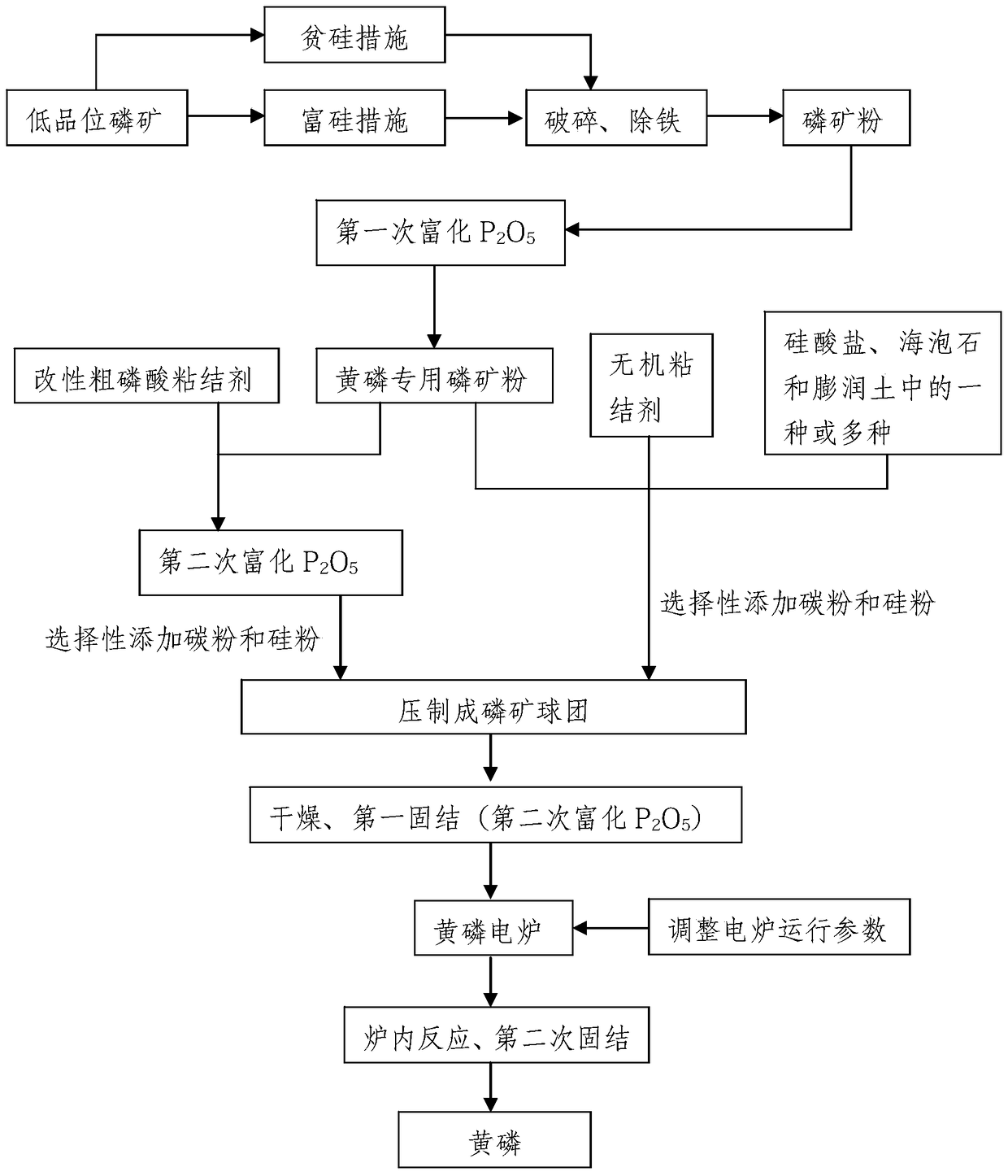

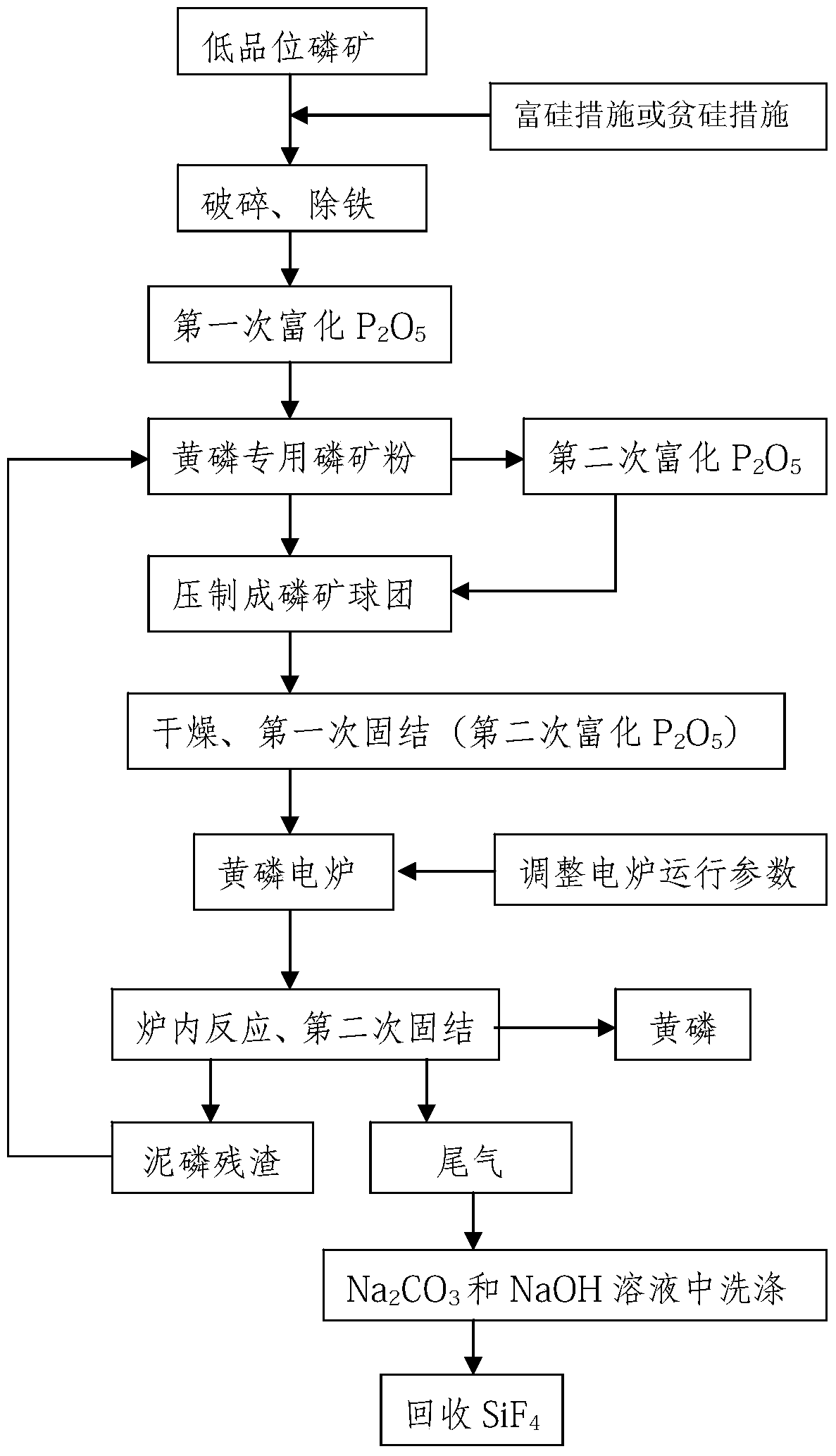

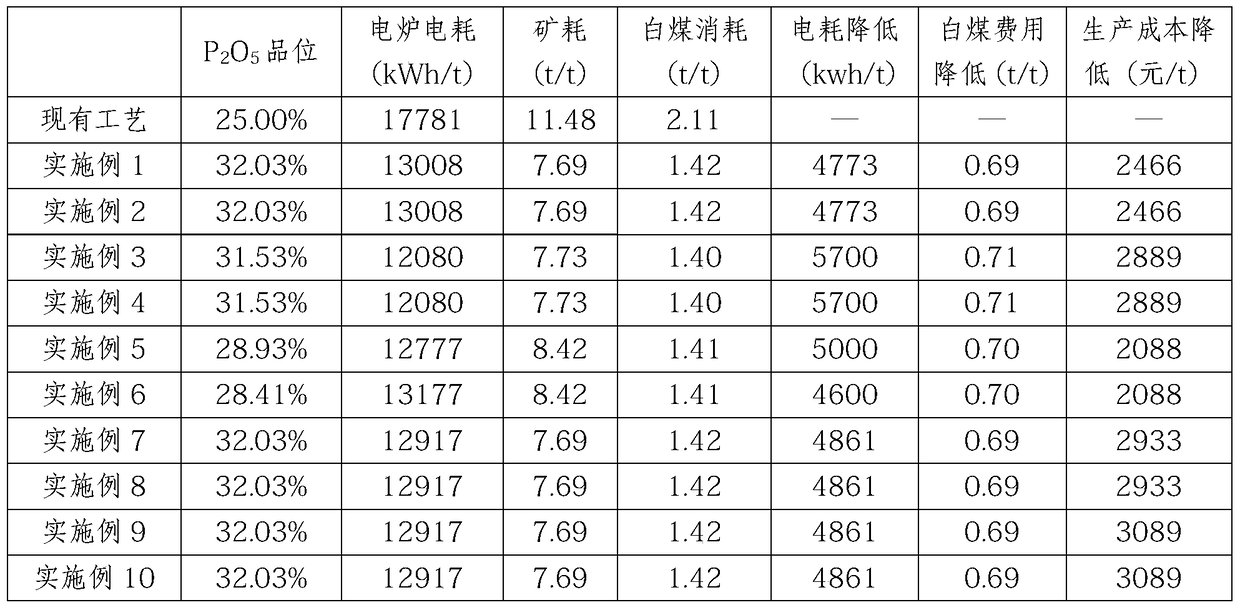

A method and preparation process for preparing yellow phosphorus from low-grade phosphate rock

ActiveCN105329865BSimple ingredientsReduce consumptionRaw phosphate material treatmentHalogenated silanesPhosphateYellow phosphorus

The invention relates to a method used for producing yellow phosphorus from low-grade phosphate ore. According to the method, phosphate ore powder with appropriate silicon content and low iron content is obtained via selectively adapting silicon concentrating or removing technology and removing iron-containing compounds in smashing period based on the difference of phosphate ores in mining period; a first time P2O5 enrichment and a second time P2O5 enrichment are carried out respectively via drying, roasting, or obverse flotation, or reverse flotation, drying,, curing, and obtaining of phosphate ore balls. The method is low in cost, high in efficiency, is friendly to the environment, is capable of improving yellow phosphorus quality, avoiding accidents or faults such as arch structure formation, material collapse, and electrode broken, and ensuring safe, stable, and high efficiency operation of electric furnaces.

Owner:成都天屿新磷科技有限公司

Method for producing alumina by sulfuric acid ripening of fly ash

ActiveCN106477609BHigh recovery rateReduce energy consumptionAluminium compoundsSilicaCalcium silicateSlag

The invention discloses a method for producing alumina by curing fly ash with sulphuric acid, belonging to the technical field of comprehensive utilization of the fly ash. The method comprises the following steps: uniformly mixing a proper amount of concentrated sulfuric acid and the fly ash, then carrying out curing so as to obtain a sulfated clinker, then leaching the clinker with an aluminum sulfate crystallized mother liquor or water so as to obtain an aluminum sulfate and high-silicon slag, subjecting the aluminum sulfate solution to evaporation, concentration, crystallization, drying and dehydration so as to obtain aluminum sulfate, subjecting obtained aluminum sulfate and a proper amount of a reducing agent to rapid reduction and calcination so as to obtain crude alumina, then treating the crude alumina by adopting a low-temperature Bayer process so as to produce metallurgical-grade alumina, wherein the obtained high-silicon slag can be leached by sodium hydroxide to produce white carbon black or active calcium silicate. The method provided by the invention has the advantages of high aluminum recovery rate, easily-available equipment and materials, good alumina product quality, etc.; and the slag obtained by leaching of aluminum is the high-silicon slag with good alkali-soluble activity, and can be used for further production of a variety of high-value-added silicon products.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

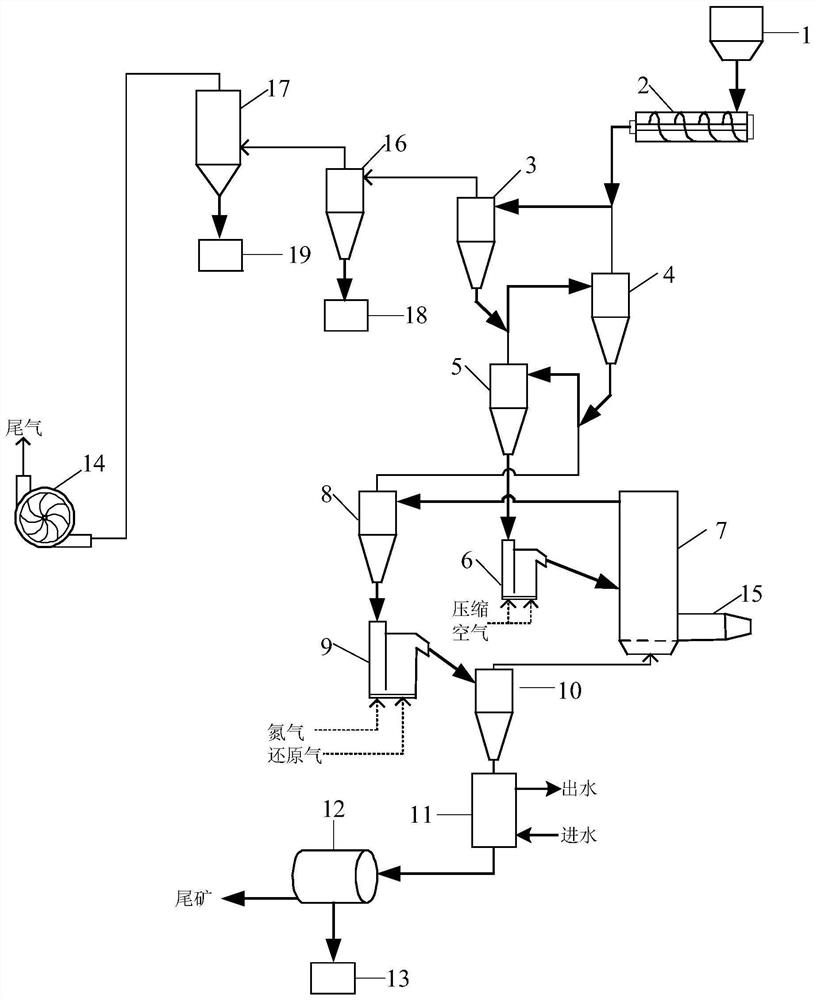

System for oxidizing roasting-reducing roasting of titaniferous iron concentrate and roasting process

ActiveCN103031431BImprove energy efficiencyReduce roasting energy consumptionCombustion chamberFlue gas

The invention discloses a system for oxidizing roasting-reducing roasting of titaniferous iron concentrate and a roasting process. A fluidized bed oxidation reactor is adopted for the oxidizing roasting of the titaniferous iron concentrate; the oxidized titaniferous iron concentrate enters a fluidized bed reduction reactor for reducing roasting; the reduced titaniferous iron concentrate is sequentially and spirally cooled by a cyclone cooler and water cooling and then enters a downstream section; and reduced coal gas is firstly subjected to heat exchange by the cyclone cooler, then preheated by a coal gas preheater, and enters a reducing furnace, latent heat of unreacted reducing gas in tail gas exhausted from the fluidized bed reduction reactor is firstly released through combustion in a combustion chamber, and hot flue gas generated by the combustion is mixed with the tail gas exhausted by the fluidized bed oxidation reactor and then enters a multi-stage cyclone preheater to exchange heat with the titaniferous iron concentrate for heat recovery. The system disclosed by the invention has the advantages of high reaction efficiency, full heat utilization, good economical efficiency in the roasting process and the like, and is suitable for large-scale continuous industrial production.

Owner:深圳市中科九台资源利用科技产业股份有限公司

Alumina carrier and preparation method thereof

ActiveCN111420711AExtend the start cycleAvoid damageCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses an alumina carrier of a coal tar hydrogenation catalyst and a preparation method thereof. The pore volume of the carrier is 1.0-1.5 mL / g, the specific surface area of the carrier is 200-300m<2> / g, the most probable pore diameter of the carrier is 15-30nm, and the pore volume of macropores with the pore size of 20-30nm or more accounts for 45-70% of the total pore volume. The alumina carrier provided by the invention has the advantages of large pore volume, large pore diameter and excellent diffusivity, and is suitable for being used as a hydrogenation catalyst carrier for treating colloid and heavy oil with high asphaltene content.

Owner:CCTEG CHINA COAL RES INST

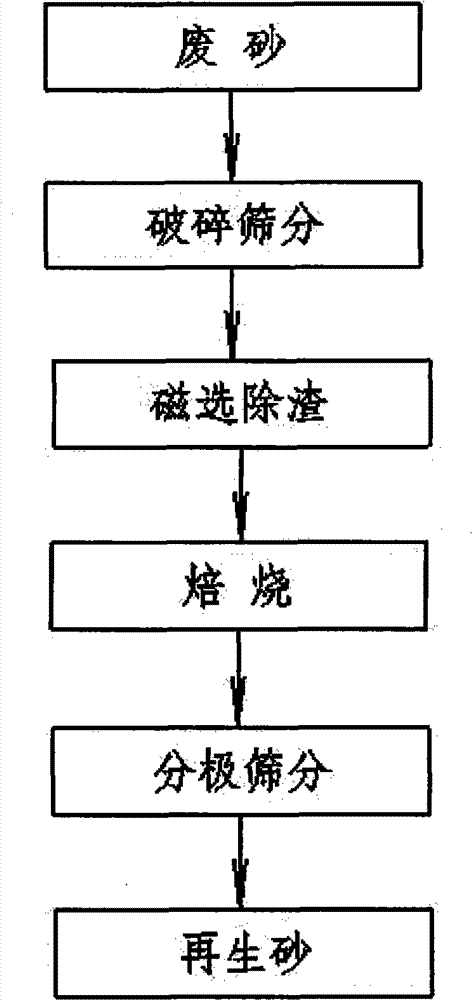

Waste foundry sand regenerating process method

InactiveCN102009122BReduce roasting energy consumptionMould handling/dressing devicesFoundryTemperature control

Owner:LIUZHOU AOKAI ENG MACHINERY

Manufacturing method of light-weight and high-strength water-permeable pavement brick

ActiveCN101633575BSufficient raw materialsPromote absorptionSolid waste disposalSidewalk pavingsPondingFire brick

The invention relates to a method for making sidewalk bricks with light weight, high strength and high water permeability. The production method comprises the following steps: preparation of mixture, molding of road bricks, drying, stacking kiln and roasting. The method has sufficient raw materials and can effectively Purify the environment, reduce pollution sources, quickly absorb the accumulated water on the brick surface, save external roasting energy consumption, and be more firmly combined with the cushion mortar during construction, not easy to loosen, and the weight of the fired bricks is lighter.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

Method for recovering gold from gold-bearing washing mud in gold ore cyanidation system

ActiveCN107815552BReduce weightReduce roasting energy consumptionProcess efficiency improvementSulfateGold ore

The invention relates to a method for recycling gold for gold-bearing washing mud of a gold ore cyaniding system. The method includes the following wet process-pyrogenic process combined technologicalsteps of crushing and grinding, acid leaching, solid-liquid separation, roasting, size mixing, alkali adjusting, gold extraction with a carbon-in-leach process and screening for solid-liquid separation b; and according to conditions, conventional sulfuric acid is replaced with hydrochloric acid for acid leaching, the weight of samples entering the roasting step can be reduced, the roasting energyconsumption is reduced, the problem of secondary gold wrapping caused by generation of calcium sulfate can be solved, the gold leaching efficiency is improved, the beneficial effects of being simplein process, low in production cost, high in gold leaching efficiency, capable turning waste into wealth, environment-friendly and the like are achieved, efficient recycling of gold-bearing washing mudvaluable resources can be achieved, and the method is suitable for recycling and application of the gold in the washing mud of the gold ore cyaniding system.

Owner:ZIJIN MINING GROUP +1

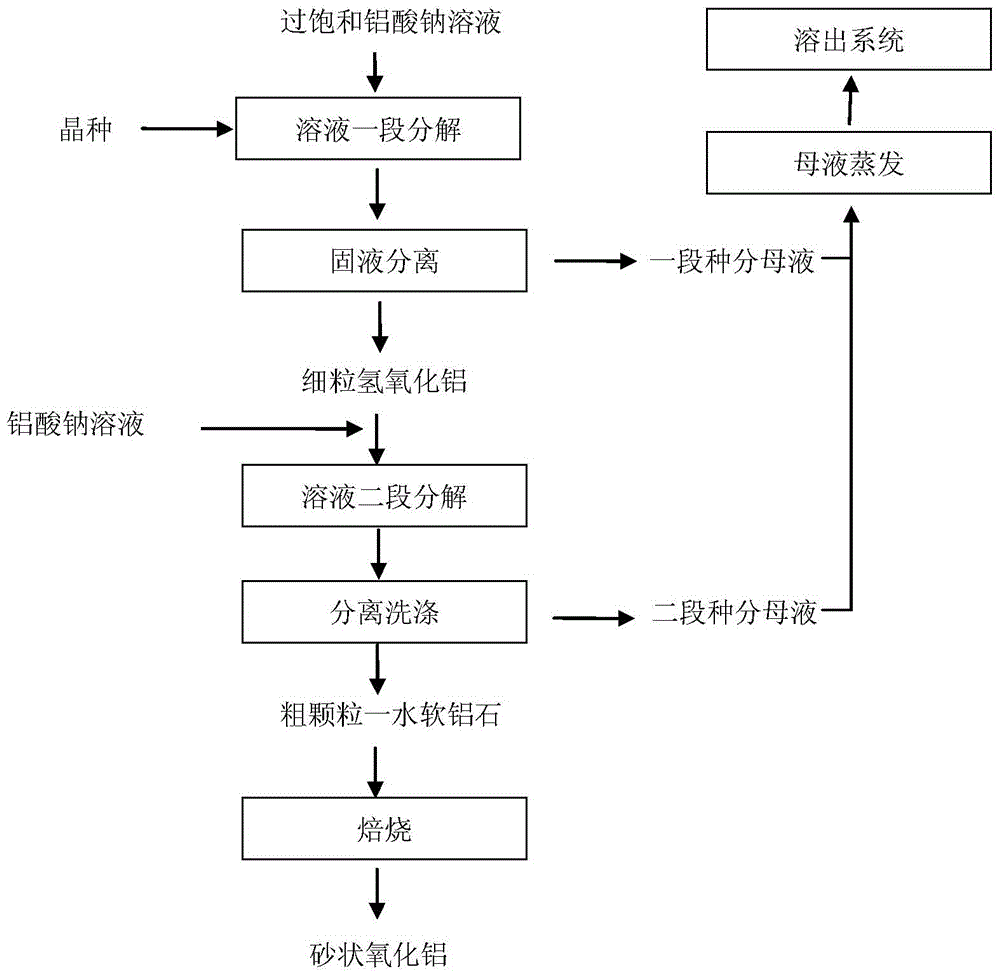

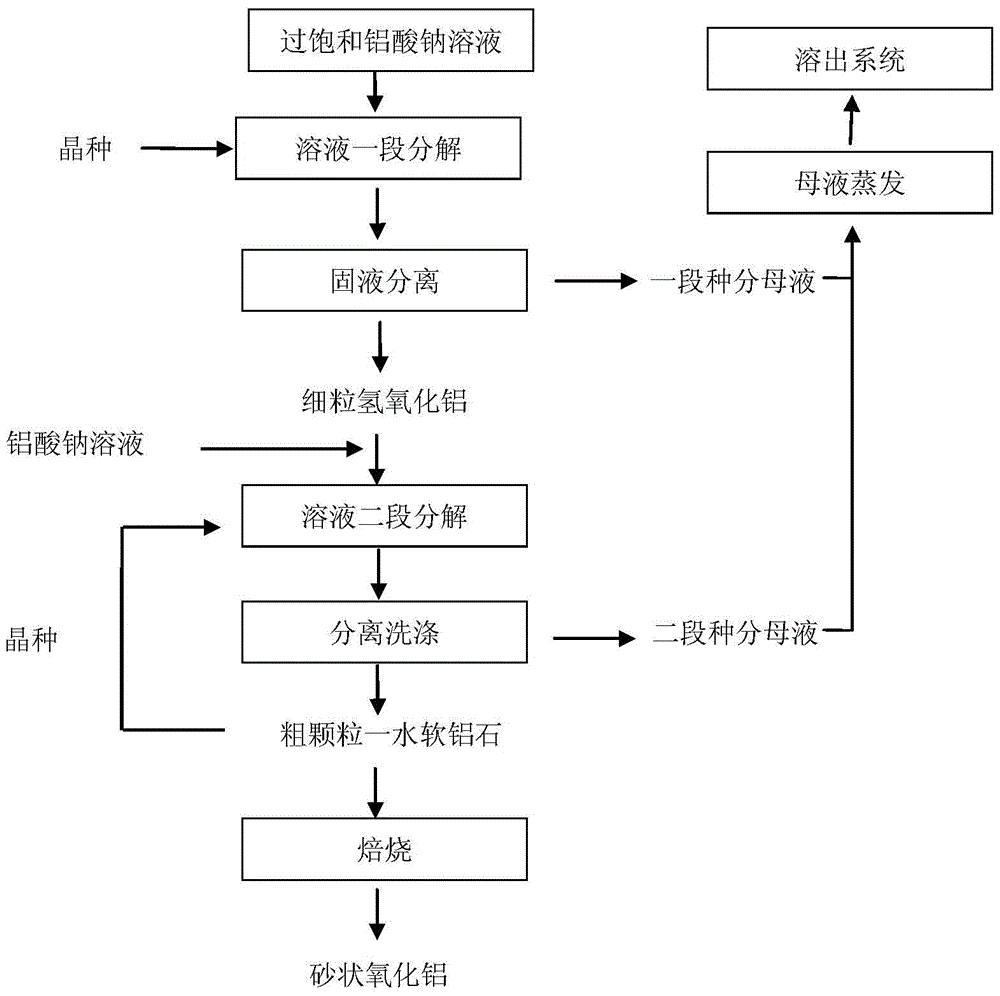

A method for preparing sandy alumina

ActiveCN104817100BImprove product qualityLow impurity contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideDecomposition

The invention discloses a method for preparing sand-shaped aluminum oxide. The method for preparing the sand-shaped aluminum oxide includes steps that 1) using supersaturated sodium aluminate solution as decomposition stock solution, and adding seed crystal to perform primary seed precipitation to obtain primary seed precipitation mother liquor and primarily decomposed aluminum hydroxide; 2) taking the primarily decomposed aluminum hydroxide and sodium aluminate solution to perform secondary seed precipitation to obtain secondary seed precipitation mother liquor and boehmite; 3) washing the boehmite and roasting to obtain the sand-shaped aluminum oxide. The sand-shaped aluminum oxide prepared by the method is featured with high decomposition rate, less impurity content, high product quality and the like, and meanwhile, the alpha-Al2O3 in the product is less, and the aluminum electrolysis is facilitated.

Owner:CENT SOUTH UNIV

Forming process for cathode carbon block with bottom groove for aluminum electrolytic cell

InactiveCN102699990AReduce inputUnique craftCeramic shaping apparatusStone-like material working toolsMetallurgyMaterials science

The invention relates to a forming process in production of a carbon material, and particularly relates to a forming process for a cathode carbon block with a bottom groove for an aluminum electrolytic cell. The forming process is characterized by comprising the steps of: vibrating and pre-slotting the cathode carbon block to shape and generate a block; roasting; and finally, machining a grooved milling face. The forming process provided by the invention is special; the cost is reduced; and the carbon block yield is improved.

Owner:QINGTONGXIA CITY QINGXIN CARBON

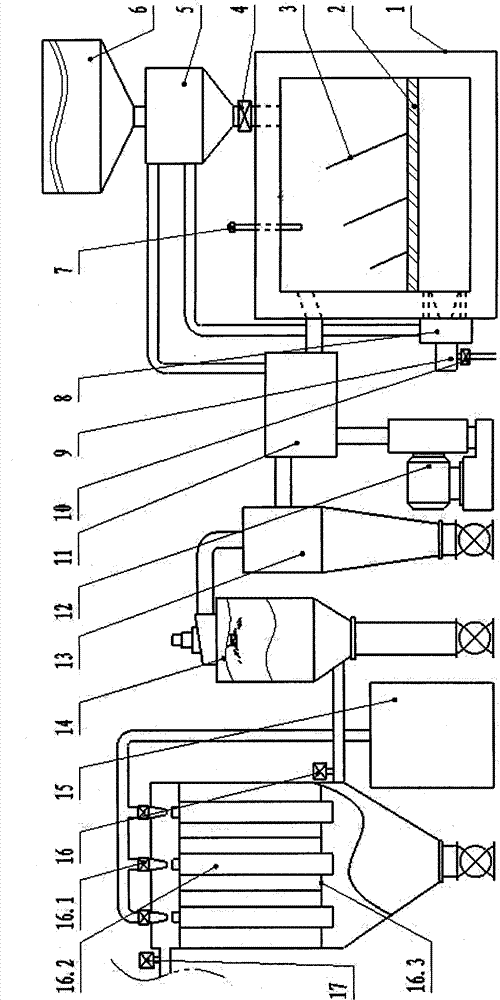

Device and method for selective roasting-magnetic separation of fine-grained ilmenite

ActiveCN112941306BEasy to chooseHigh efficiency of gas-solid mass transfer and heat transferMagnetic separationProcess efficiency improvementCyclonic separationEngineering

Owner:NORTHEASTERN UNIV LIAONING

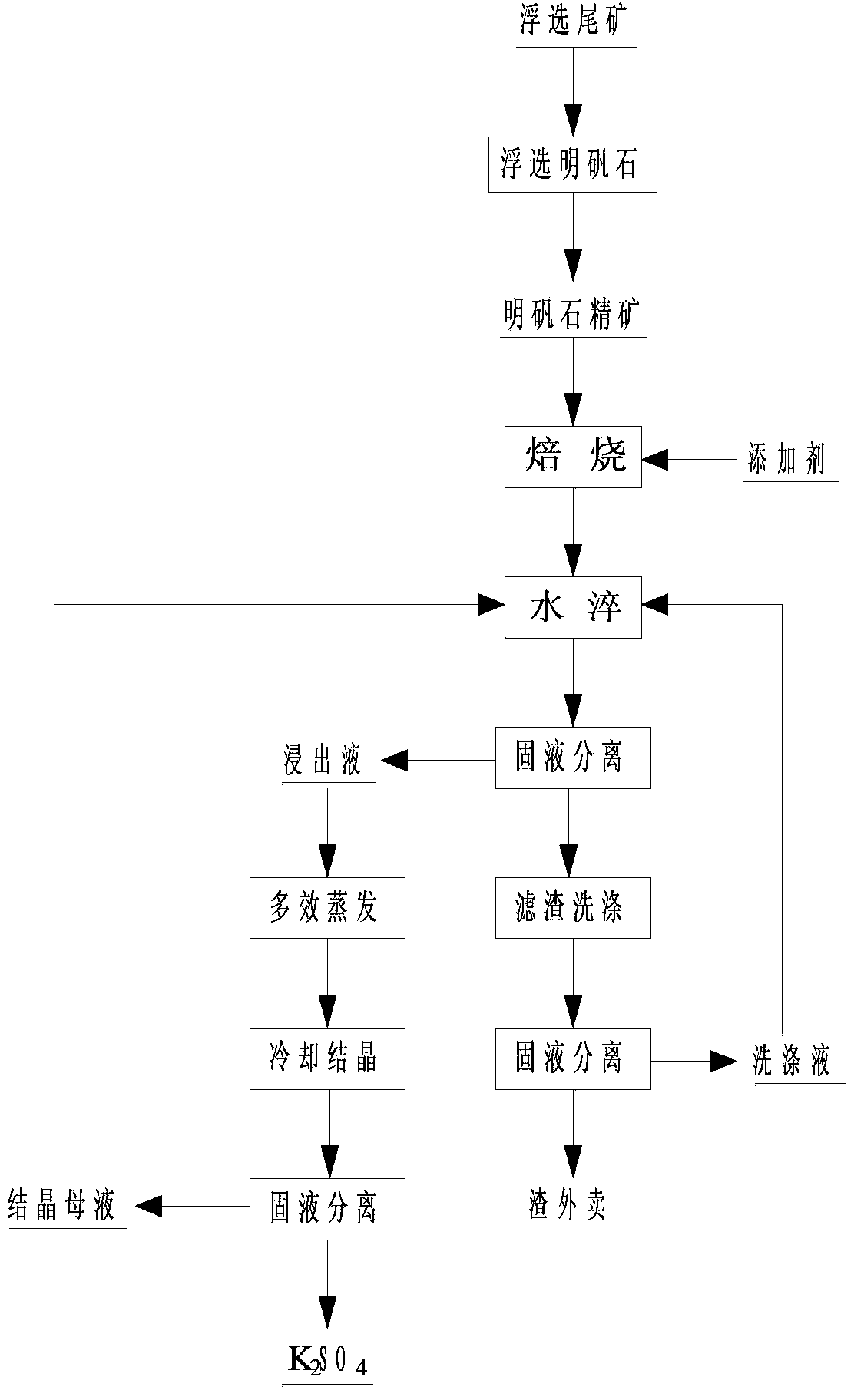

A method for producing potassium sulfate and its by-products using alunite in flotation tailings

ActiveCN103011206BImprove the level of comprehensive utilizationAlleviate the contradiction between supply and demandSolid waste disposalSulfate/bisulfate preparationPotassium sulfateAge limit

The invention provides a method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof. The method fully utilizes secondary resources, changes waste into treasure, achieves minimizing, harmlessness and recycling of solid waste, improves comprehensive utilizing level of tailings in China, relieves an acute contradiction of supply and demand of potassium sulfate, reduces loss on foreign exchange caused by mass importation of the potassium sulfate, improves guarantee age limit of kalium and the international competitiveness of the kalium salt industry, completely solves the key scientific and technical problem of economic, clean efficient and comprehensive utilization of the alunite in flotation, the tailings are utilized as resources, establishes tailing comprehensive utilization technical demonstration project, and promotes the development of the comprehensive utilization technique of the tailing in China.

Owner:ZIJIN MINING GROUP

Ring Roasters for Carbon Production

ActiveCN103159203BAvoid enteringAvoid crackingCarbon preparation/purificationCooking & bakingCombustion

Owner:GUIYANG AL-MG DESIGN & RES INST

A split-type filling block continuous prebaked anode carbon block

The invention discloses a continuous prebaked anode carbon block with split filling blocks. The continuous prebaked anode carbon block comprises a carbon block body, wherein carbon bowls are formed inthe carbon block body; the carbon bowl filling blocks are movably disposed in the carbon bowls; and the upper end face of each carbon bowl filling block in each carbon bowl flushes with the upper endface of the carbon bowl. The continuous prebaked anode carbon block disclosed by the invention has the beneficial effects that through fitting with a casting-mechanical compound steel claw, a prebaked anode can be used continuously; time spent on connection of a new anode carbon block is short and labor strength is low; use is convenient; an adhesion area between the new and old carbon blocks isincreased; connection strength of the carbon blocks is enhanced; overall resistance of the anode carbon block is reduced; production cost is low; with the carbon block body and the split filling blocks disclosed by the invention, production efficiency and a product percent of pass can be increased, unit product energy consumption and a rate of spoiled products are reduced, transportation, hoistingand installation are convenient and expense cost of each link is greatly reduced; and economic benefits and practical values are very high.

Owner:贵州铝城铝业原材料研究发展有限公司

A continuous prebaked anode carbon block with split super-long packing block structure

The invention discloses a continuous prebaked anode carbon block with a split-type ultralong filling block structure. The continuous prebaked anode carbon block comprises a carbon block body, whereincarbon bowls are arranged on the carbon block body; mechanical steel claw connecting ring slots are arranged on the carbon block body and positioned at the bottoms of the carbon bowls; and ultralong carbon bowl filling blocks are movably arranged in the carbon bowls. The continuous prebaked anode carbon block disclosed by the invention has the beneficial effects that through the cooperation with acasting and mechanical composite steel claw, the continuous use of a prebaked anode can be achieved; the time for the connection with a new anode carbon block is short, the labor intensity is low, and the use is convenient; the new carbon block and old carbon block bonding area can be increased, the carbon block connecting strength can be improved, the overall electrical resistance of the continuous prebaked anode carbon block can be reduced, the service life of a single carbon block can be prolonged, and the low product cost can be achieved; through the carbon block body and the split-type ultralong filling block structure, the production efficiency can be improved, the product qualification rate can be improved, the energy consumption per unit product can be reduced, the breakage rate can be reduced, and the conveying, hoisting and mounting processes can be simple and convenient; the cost of every link can be greatly reduced; and the great economic benefits and practical value can be achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com