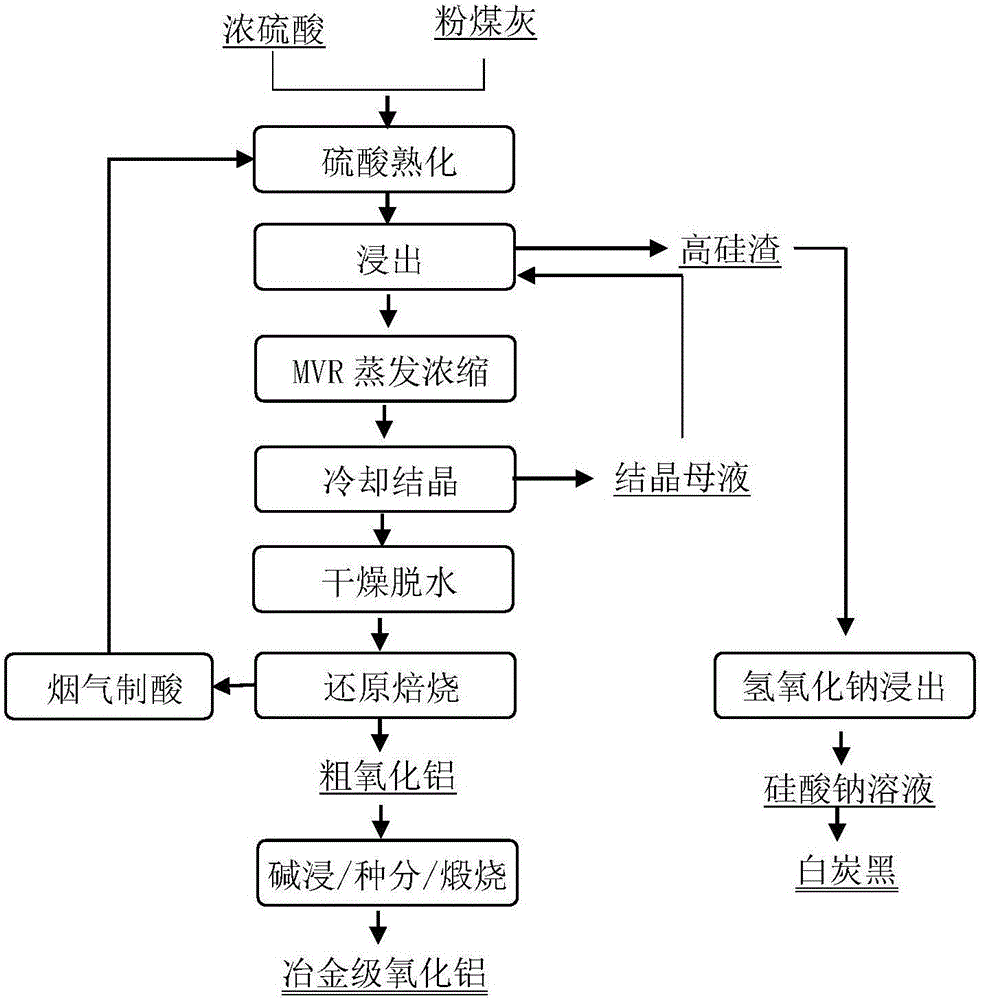

Method for producing alumina by curing fly ash with sulphuric acid

A technology of fly ash and aluminum sulfate, applied in the direction of chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problems of high equipment material requirements, high cost, low aluminum leaching rate, etc., to achieve equipment material resolution, equipment The effect of easy material and high aluminum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix the fly ash of the circulating fluidized bed boiler with concentrated sulfuric acid with a concentration of 93%, and then mature it at 200°C for 2 hours to obtain sulfated clinker. 2 SO 4 Al with fly ash 2 o 3 The molar ratio is 3.5:1, the clinker is leached with water, the leaching solution is evaporated and concentrated, crystallized, dried and dehydrated to obtain aluminum sulfate, and the aluminum sulfate is reduced and roasted to obtain crude alumina. The sodium aluminate solution is obtained by lower leaching, and the sodium aluminate solution is sorted and calcined to obtain metallurgical grade alumina.

Embodiment 2

[0035] Mix the fly ash of the circulating fluidized bed boiler with concentrated sulfuric acid with a concentration of 93% and then mature it in the rotary kiln. 2 SO 4 Al with fly ash 2 o 3 The molar ratio is 3.5:1, the residence time of the mixed material in the temperature range of 100-150°C is 1h, and the residence time in the temperature range of 200-250°C is 0.5h to obtain sulfated clinker, the clinker is leached with water, and the leachate is evaporated and concentrated. Crystallization, drying and dehydration to obtain aluminum sulfate, aluminum sulfate is reduced and roasted to obtain crude alumina, crude alumina is leached with 100g / L sodium hydroxide solution at 95°C to obtain sodium aluminate solution, and the sodium aluminate solution is seeded and calcined Metallurgical grade alumina is obtained.

Embodiment 3

[0037] Mix the fly ash of the circulating fluidized bed boiler with concentrated sulfuric acid with a concentration of 93% and then mature it in the rotary kiln. 2 SO 4Al with fly ash 2 o 3 The molar ratio is 3.5:1, the residence time of the mixed material in the temperature range of 100-150°C is 1h, and the residence time in the temperature range of 200-250°C is 0.5h to obtain sulfated clinker, and the aluminum sulfate obtained in Example 2 is used The clinker is leached with the crystallization mother liquor and an appropriate amount of supplementary water. The leaching solution is evaporated and concentrated, crystallized, dried and dehydrated to obtain aluminum sulfate, and the aluminum sulfate is reduced and roasted to obtain crude alumina. The crude alumina is leached at 95°C with 100g / L sodium hydroxide solution A sodium aluminate solution is obtained, and the sodium aluminate solution is sorted and calcined to obtain metallurgical grade alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com