Patents

Literature

42results about How to "Improve economic and technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

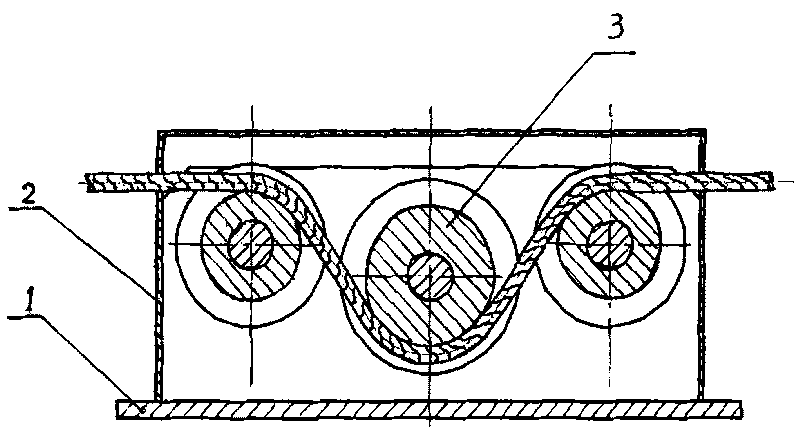

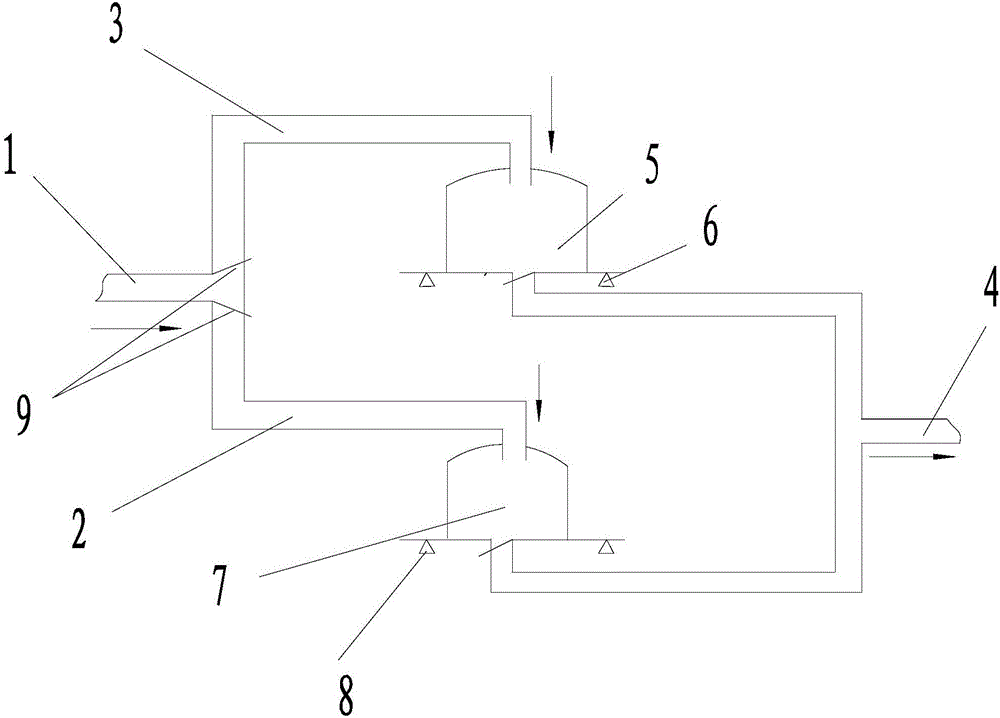

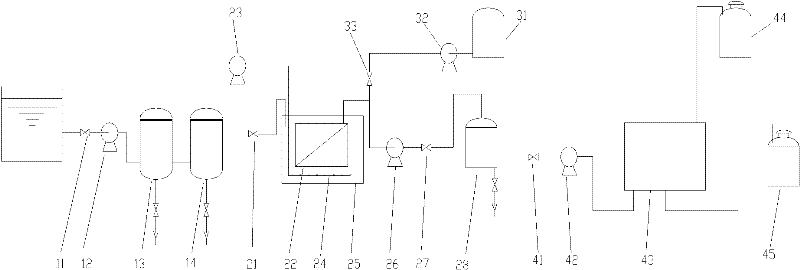

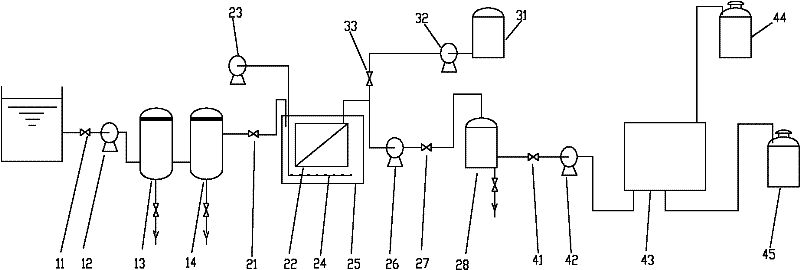

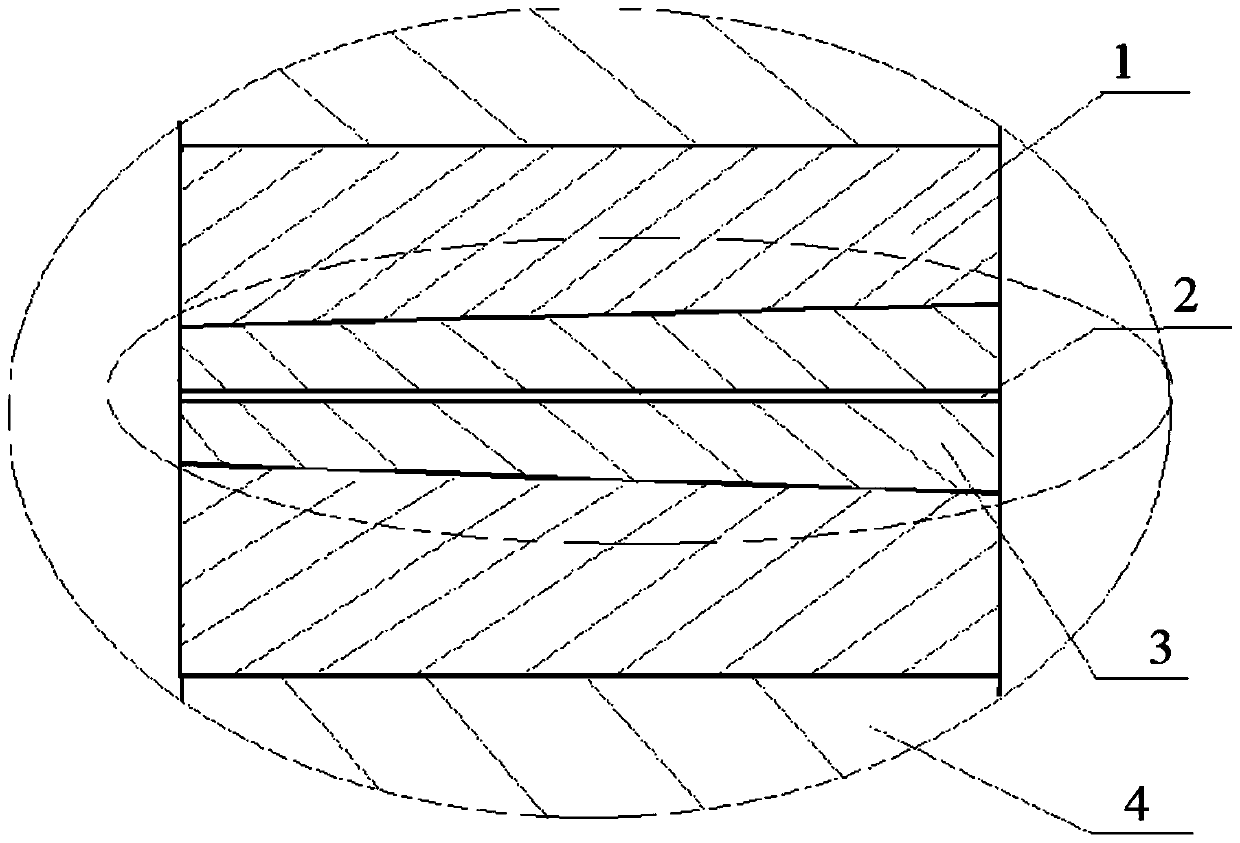

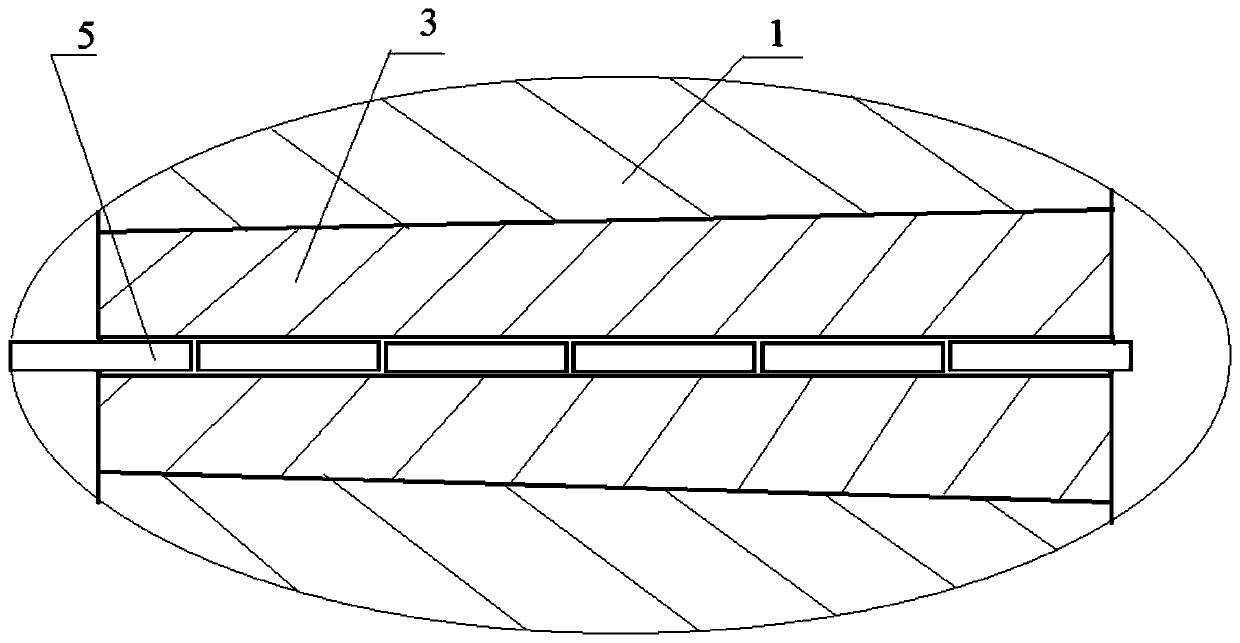

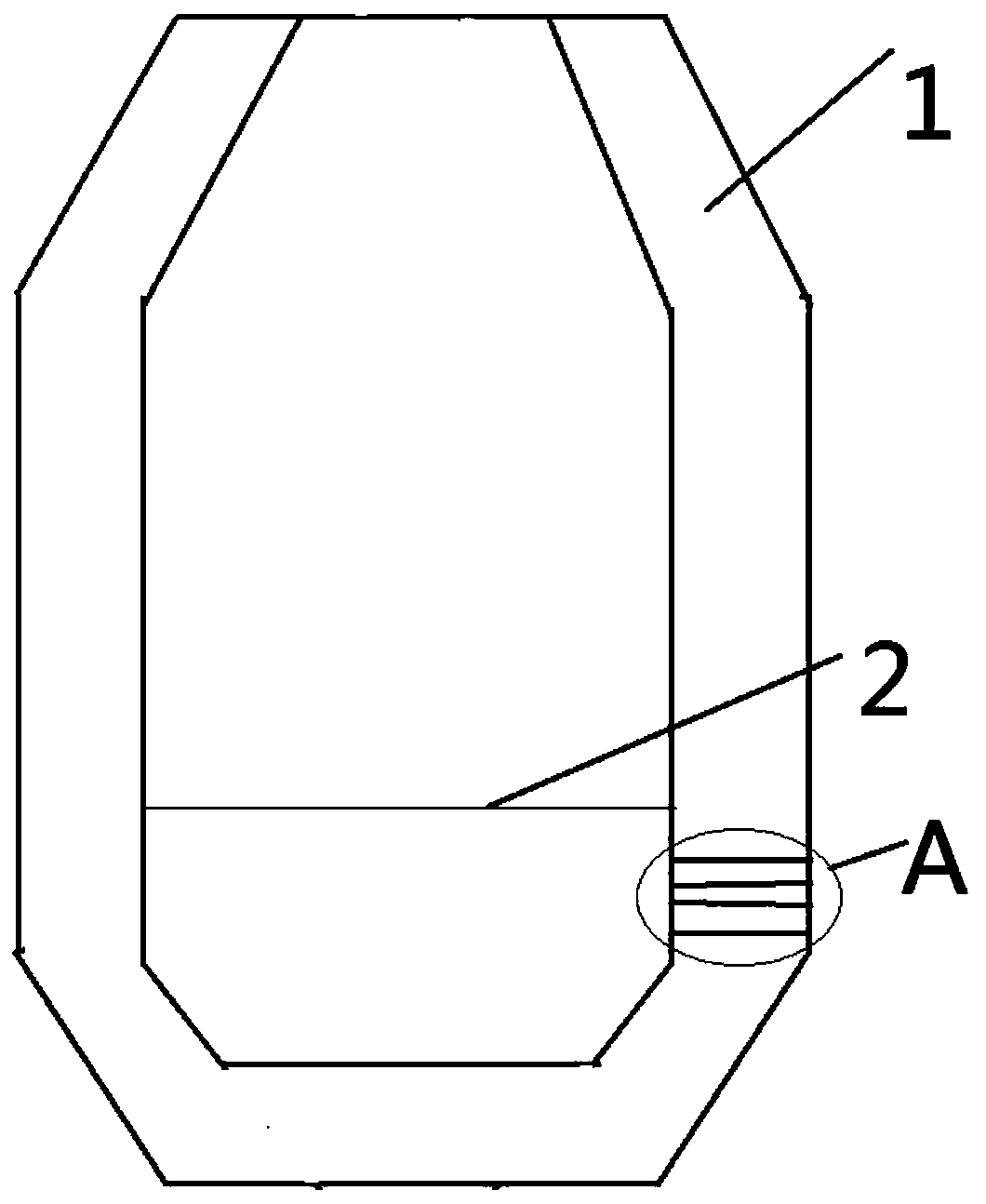

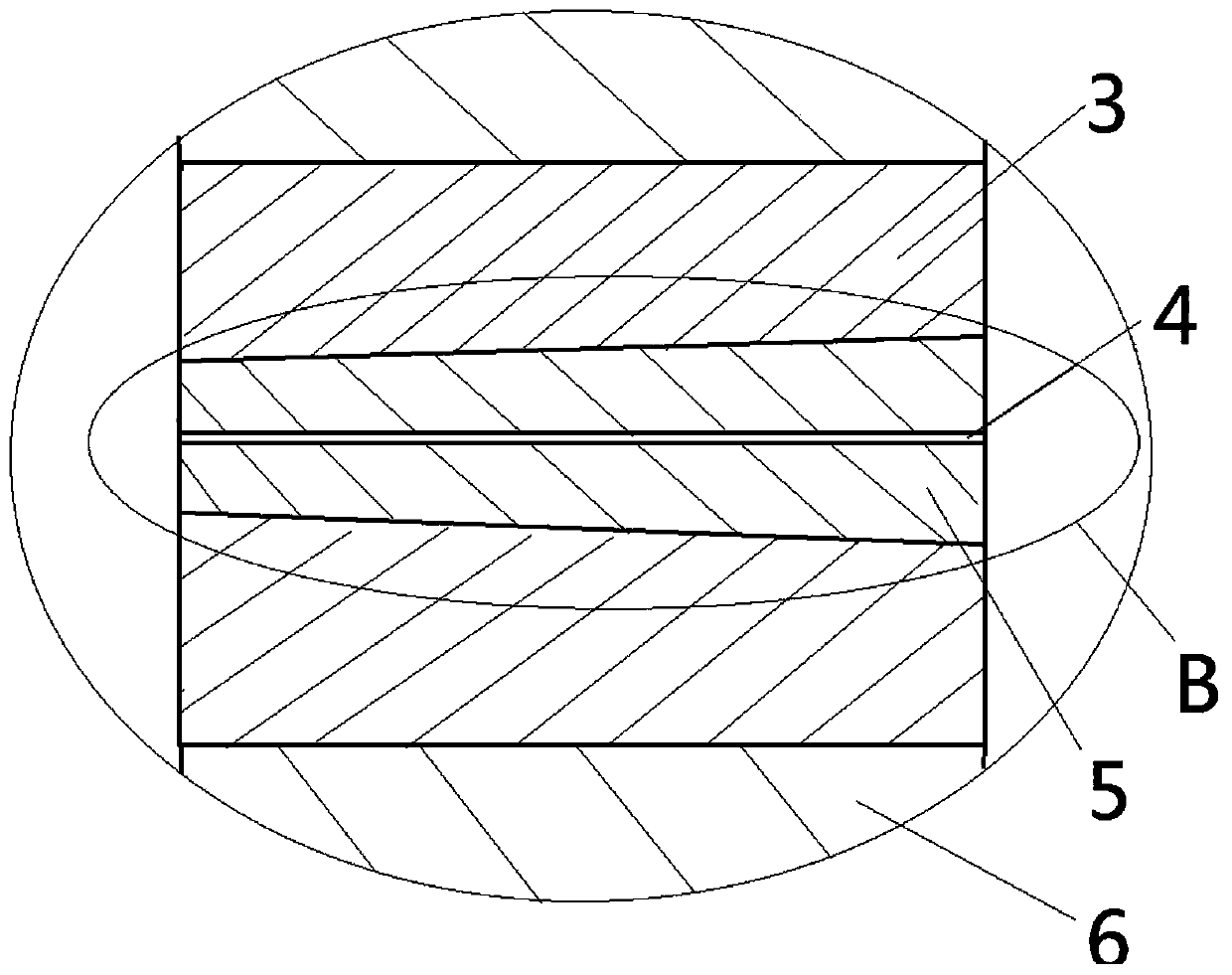

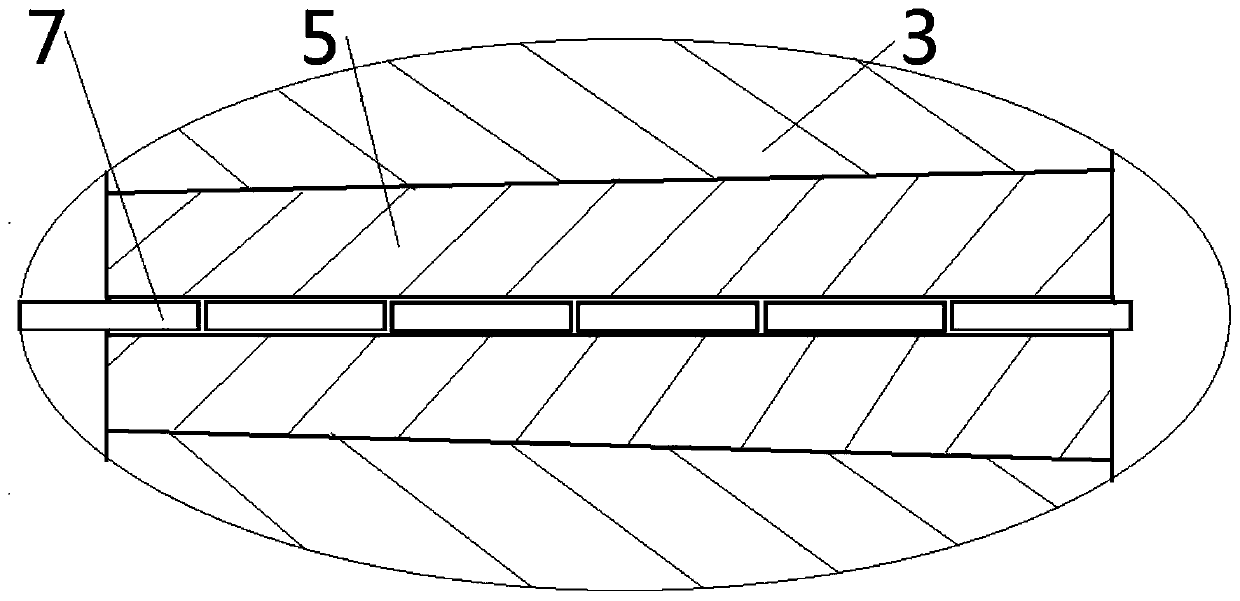

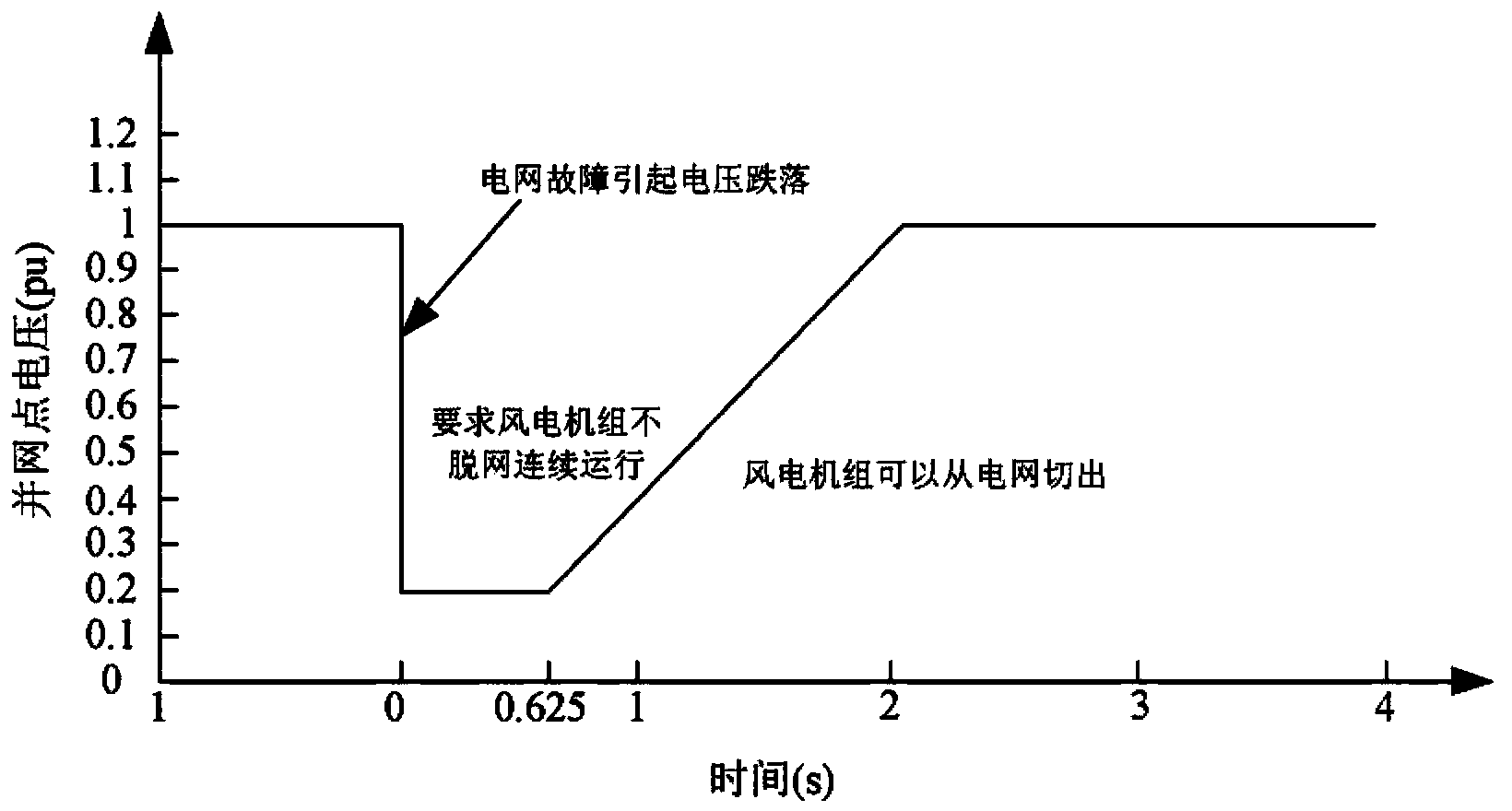

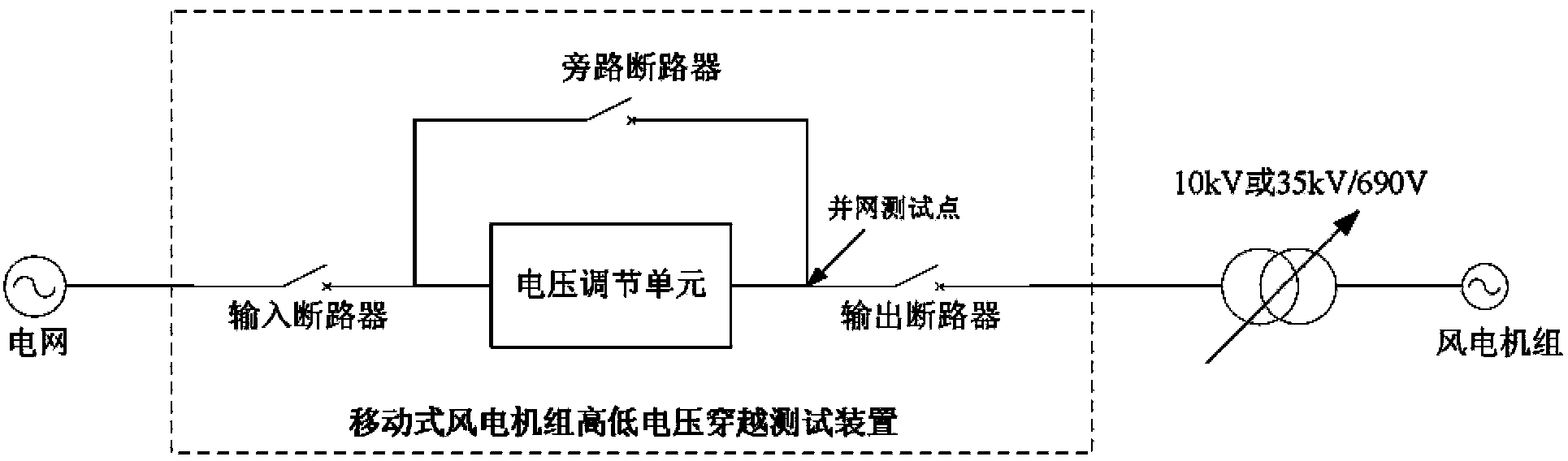

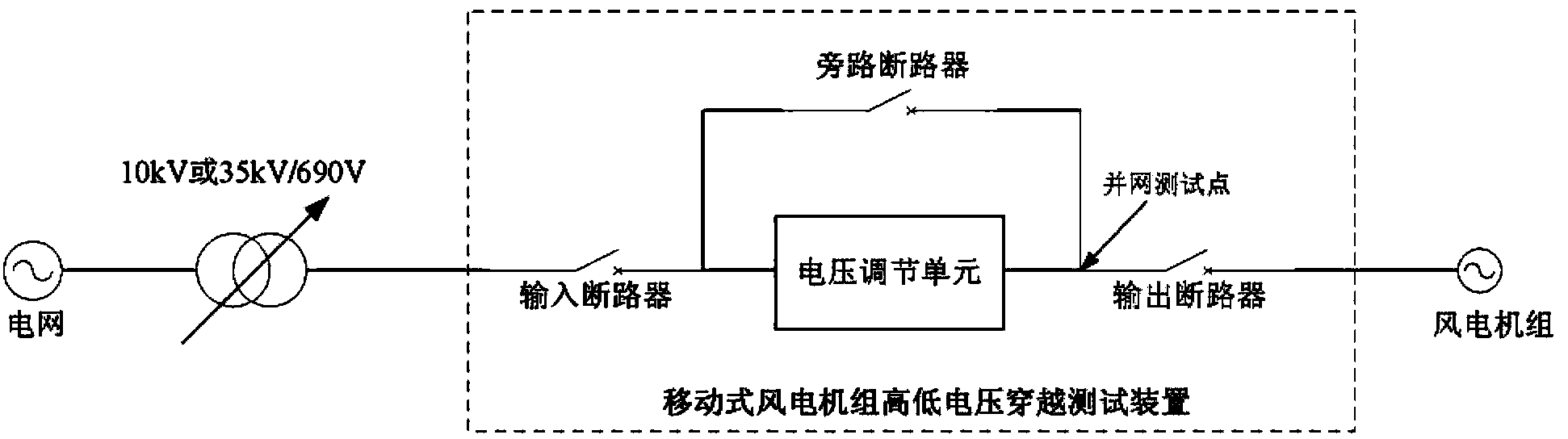

Mobile wind turbine generator system high-low voltage ride through test device

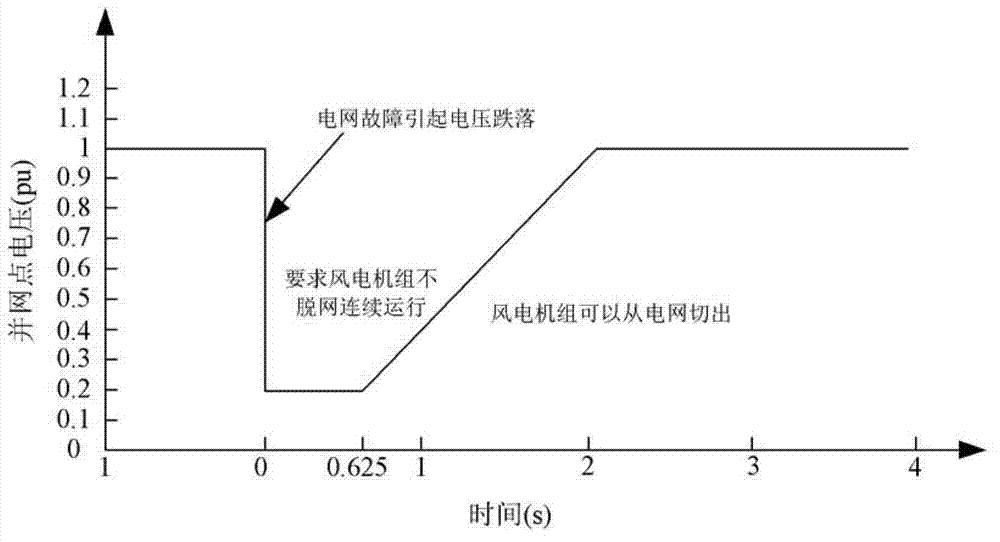

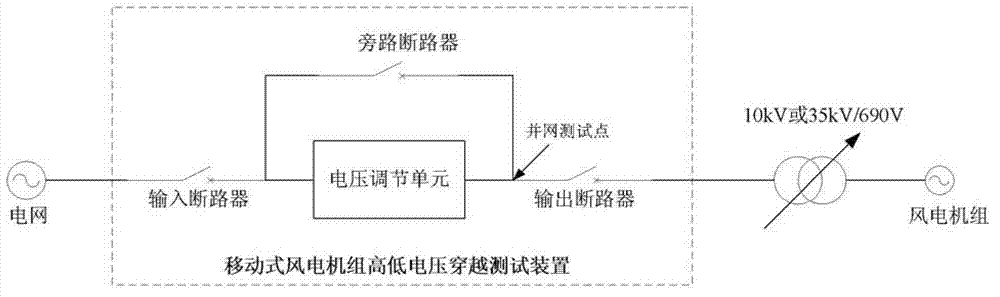

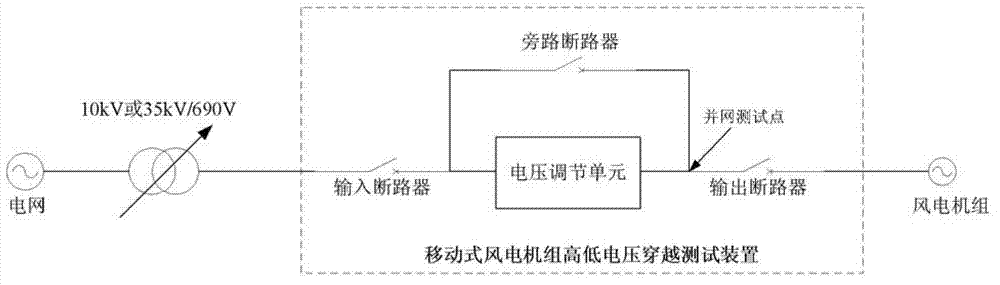

ActiveCN102736028AFlexible testingEasy to installDynamo-electric machine testingEngineeringHigh pressure

The invention provides a mobile wind turbine generator system high-low voltage ride through test device, which is applicable to high-voltage system tests and low-voltage system tests simultaneously, the test device is connected in series between a wind turbine generator system and a power network, and mainly comprises an input breaker, a voltage regulation unit, a bypass breaker and an output breaker. By adopting a transformer secondary side multi-tap voltage regulation mode, for thyristor high-speed switching control as well as a vehicle-mounted container structure, transformer output voltage is changed through controlling the on-ff of a thyristor, and thus a simulation test of different voltage class failures of a wind turbine generator system to be tested is achieved. By using the mobile wind turbine generator system high-low voltage ride through test device provided by the invention, high-low voltage ride through tests can be accomplished simultaneously, and the device has high integration, high reliability and highest economic and technical norms; the device can be applied to testing various types of wind generators, meet high-low voltage ride through test criteria in China as well as countries in Europe and America, and has a wide application range; and the device adopts a vehicle-mounted container structure, adopts a modular design, is convenient to transport and is flexible in testing.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

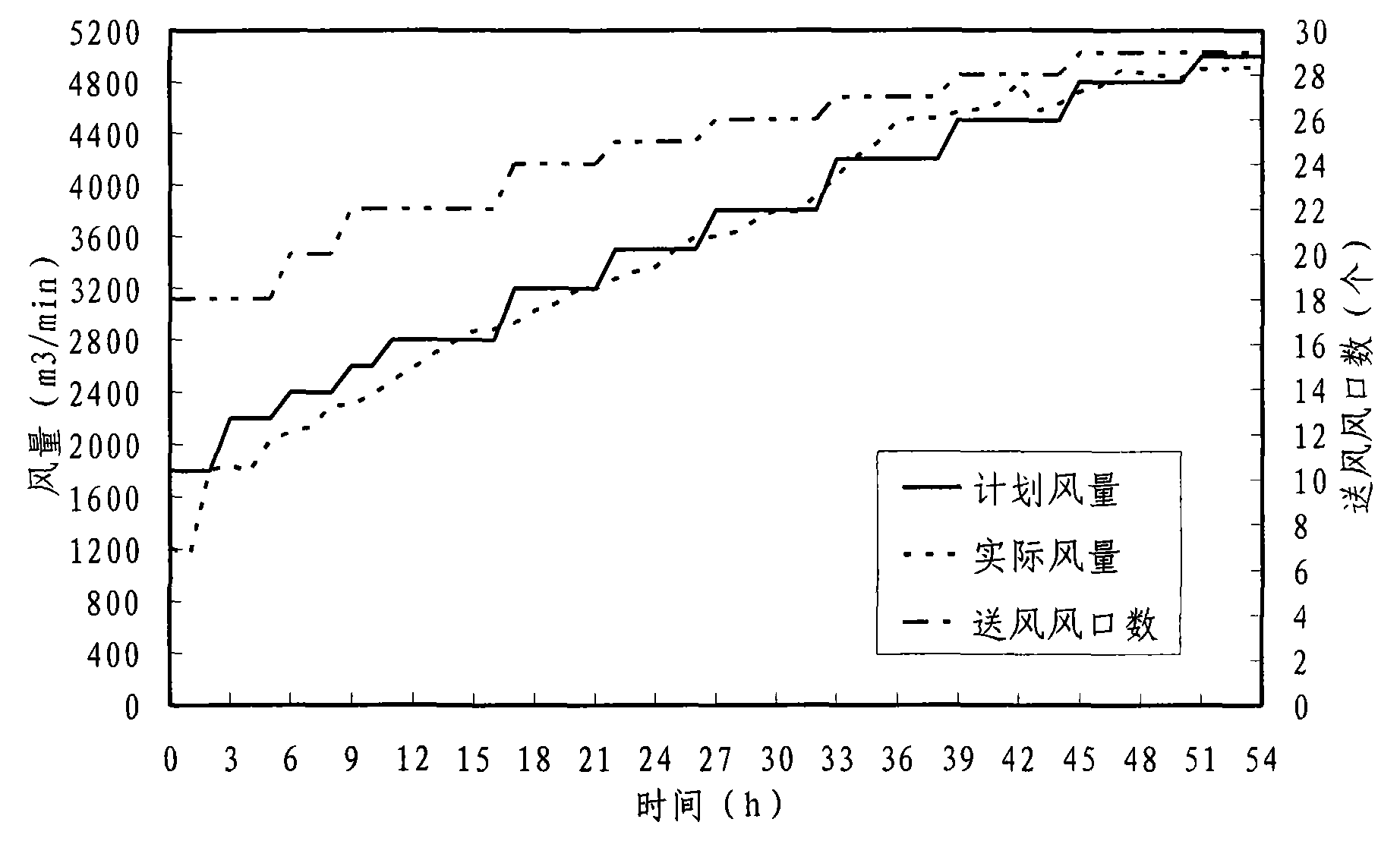

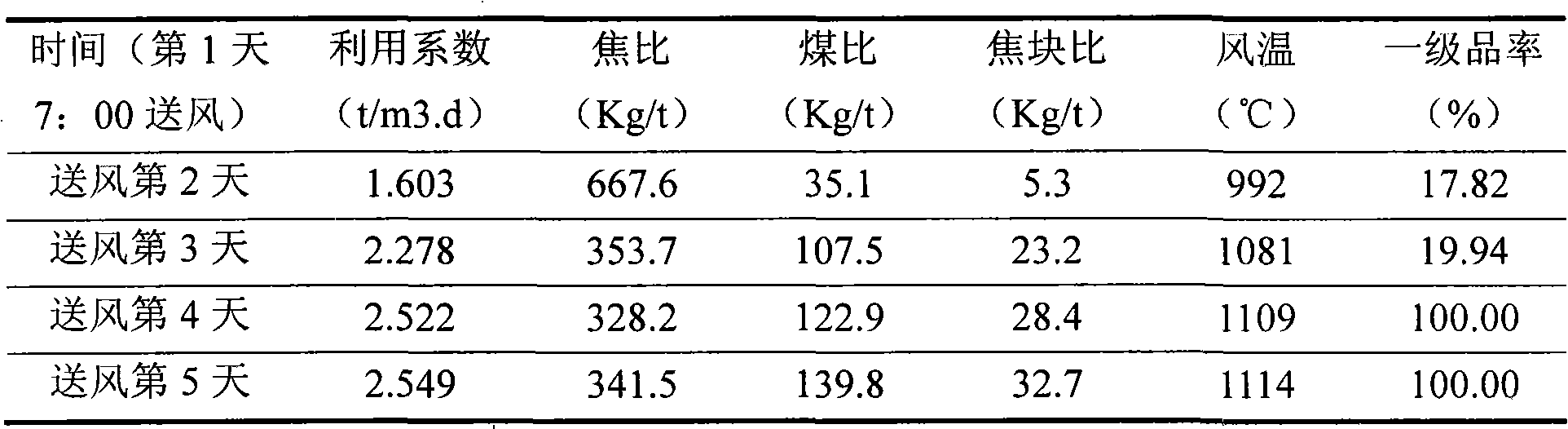

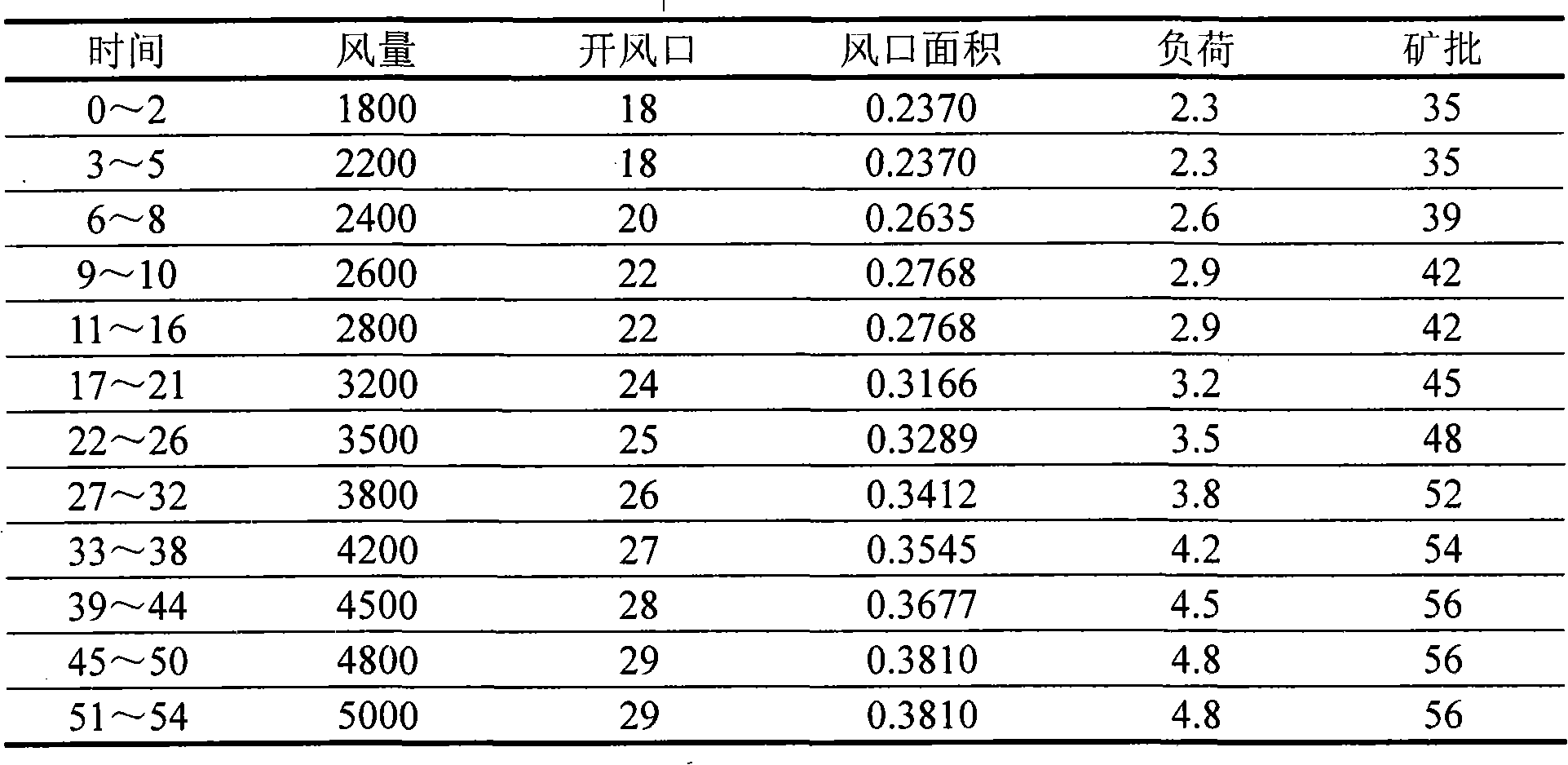

Quantification blow-in method for blast furnace

ActiveCN101671751ARefinement parametersImprove economic and technical indicatorsBlast furnace detailsParameter controlHeavy load

A quantification blow-in method for a blast furnace belongs to the technical field of blast furnace iron making. The blow-in process is divided into three phases, namely, a phase of forming a cohesivezone, a phase of taping adaptation, and a phase of mine batch and heavier load. Control standards for the phases and parameters of the blow-in process of the blast furnace are quantified, therefore,important jobs and quantification principles of the respective phase in the blow-in process can be defined. With a wind-adding curve as a core and in combination with actual conditions of blast furnace blow-in, the quantification blow-in technology details the parameters of the blow-in process; in addition, the practice of the technology in the blast furnace also shows that main parameters in theactual blow-in process conforms to the plan, and the blow-in process is smooth and high efficient, which lays the foundation for the quick improvement of economic technological indexes after the blow-in.

Owner:SHOUGANG CORPORATION

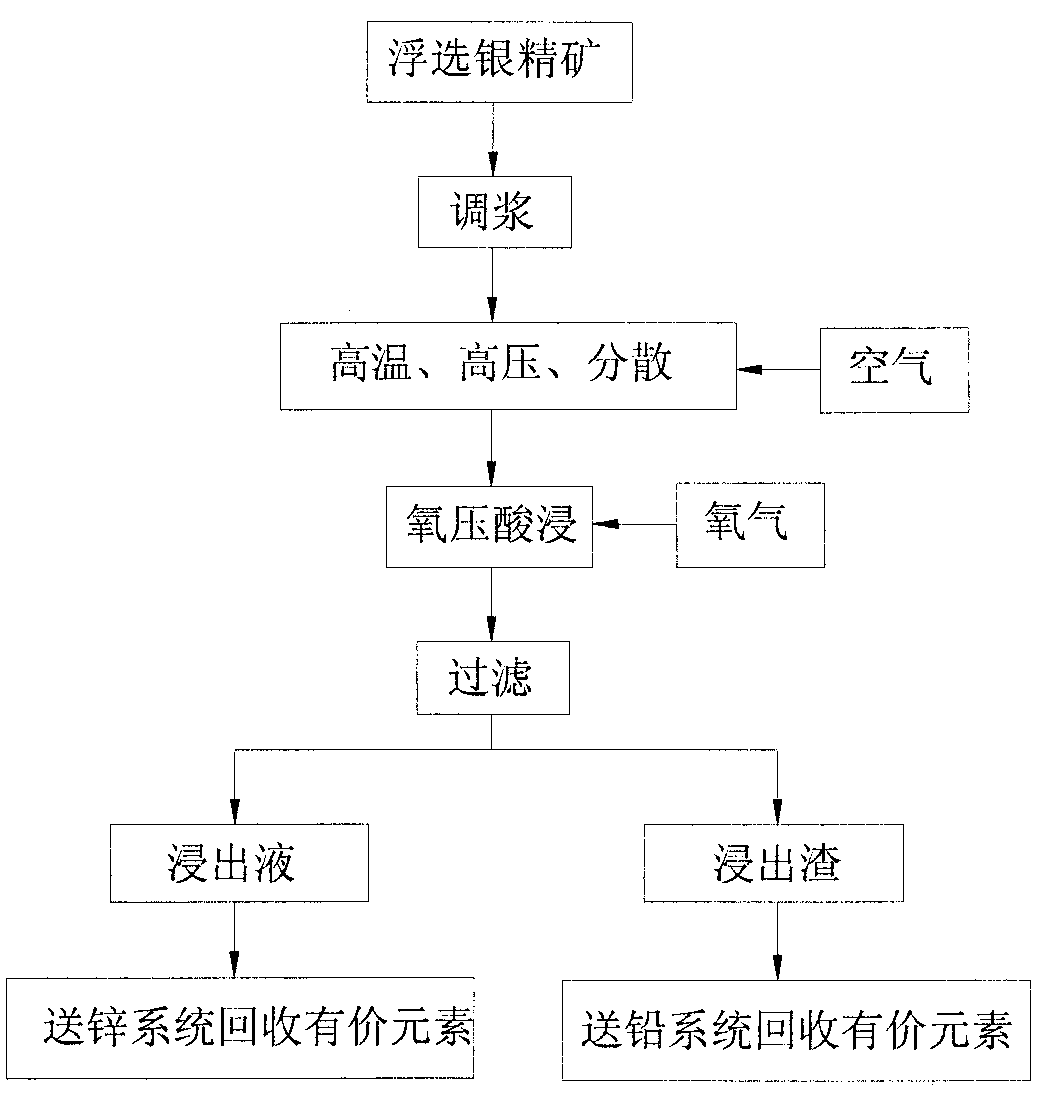

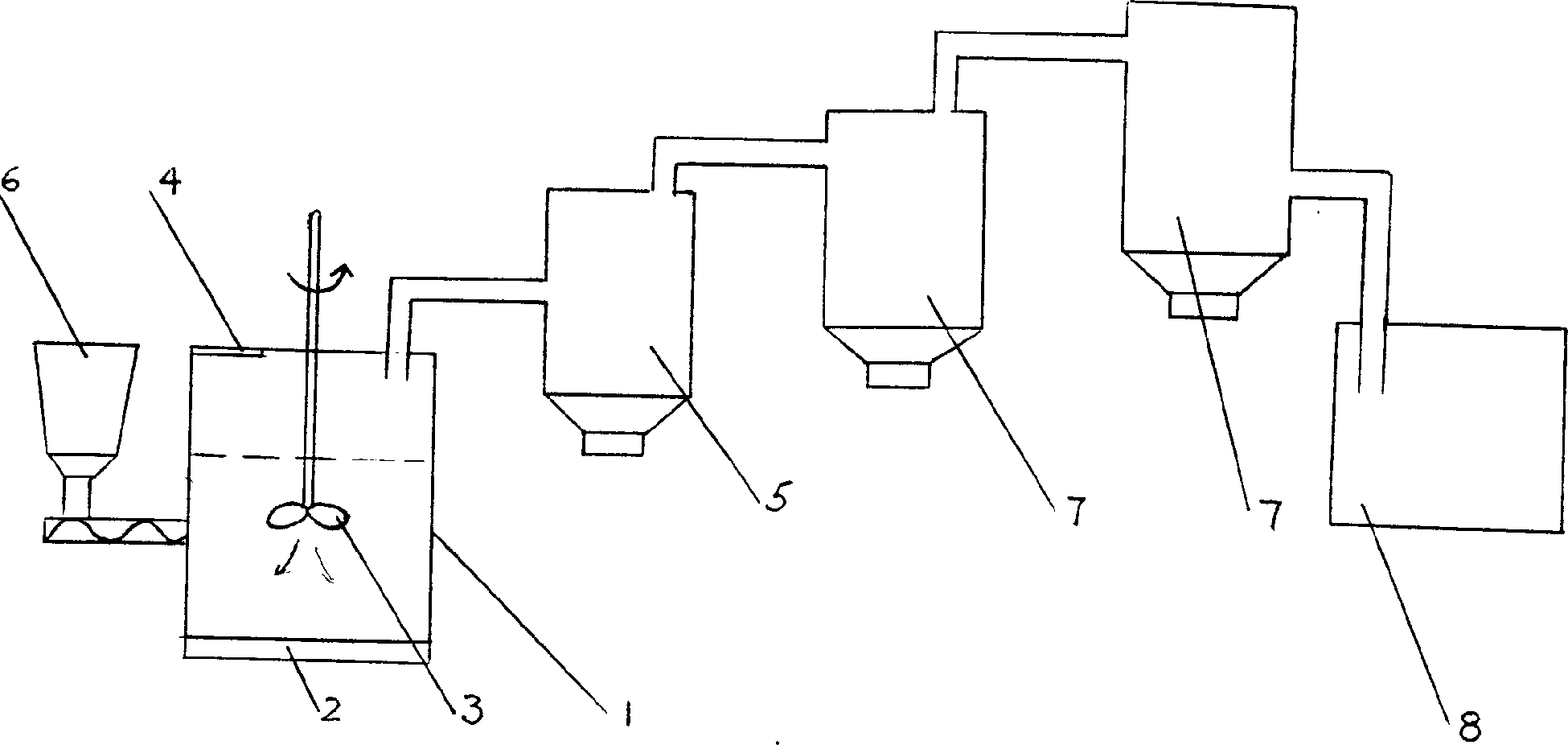

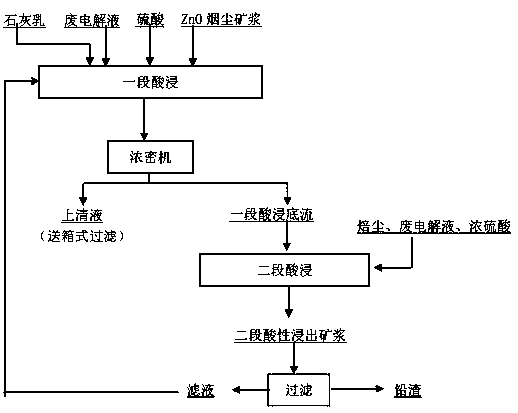

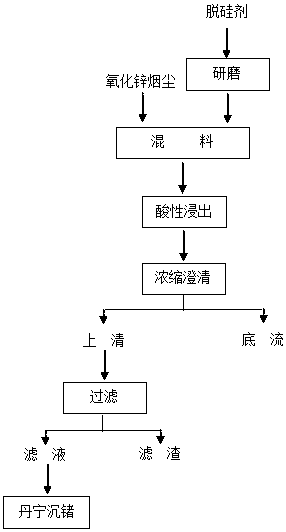

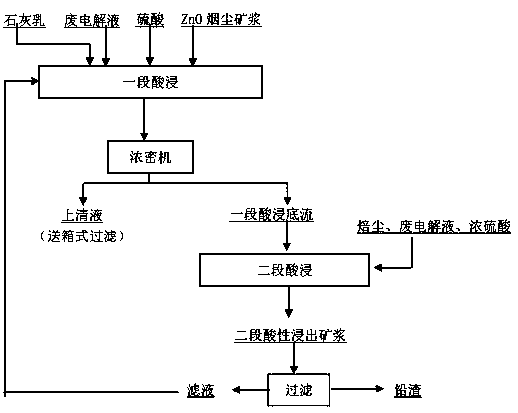

Method for comprehensively recycling zinc, copper, lead, gold, silver and sulfur from floatation silver concentrate

InactiveCN103215435AImprove economic and technical indicatorsReduce recycling production costsProcess efficiency improvementLiquid wastePregnant leach solution

The invention relates to a method for comprehensively recycling zinc, copper, lead, gold, silver and sulfur from floatation silver concentrate. The method comprises the following steps of: firstly carrying out size mixing on flotation silver concentrate, mixing the flotation silver concentrate and zinc electrolytic waste liquid for size mixing in the size mixing process, wherein the sulfuric acid concentration of the zinc electrolytic waste liquid is 180-250g / L, and the proportion of the flotation silver concentrate to the zinc electrolytic waste liquid is 1: (6-10); then adding the flotation silver concentrate subjected to size mixing to a high-pressure reactor for carrying out high-temperature high-pressure dispersion; after the high-temperature high-pressure dispersion is ended, carrying out oxygen pressure acid leaching on the flotation silver concentrate, then carrying out filtering separation on the flotation silver concentrate by a filter press, and filtering and separating to obtain leachate and leaching residues, wherein the leachate enters an electrolytic zinc system so as to recycle copper, zinc, lead, gold, silver, while elemental sulfur is enriched in the form of leaching residues, and finally returning to a bottom blowing furnace of a lead system for recycling.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

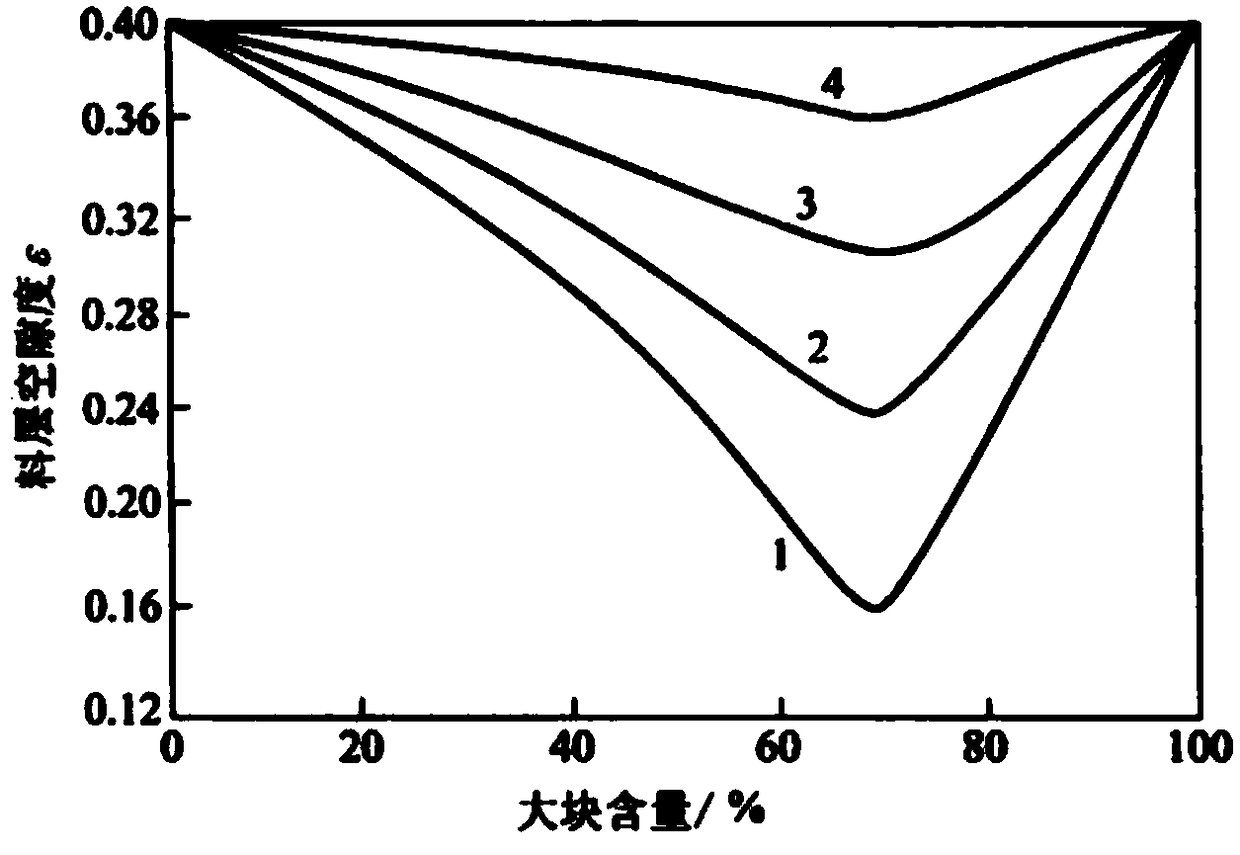

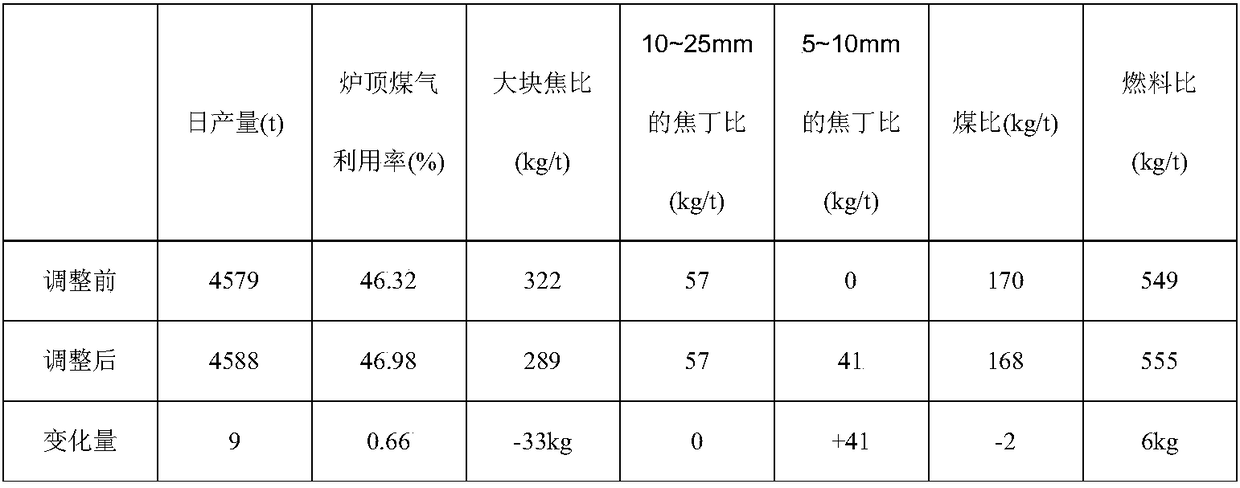

Burden distribution method for using small coke nuts by blast furnace

InactiveCN108611455AIncrease profitImprove overall utilizationBlast furnace detailsDistribution methodMaterials science

The invention discloses a burden distribution method for using small coke nuts by a blast furnace. By adopting the method, the utilization ratio of small-size coke nuts is greatly increased, the coking pressure brought by increase of the productivity is relieved, and the production cost of pig iron is lowered at the same time; and the limitation that the size of cokes of the traditional large blast furnace 2,000m<3> or more grade needs to be larger than or equal to 25mm is broken through, and small coke nuts with the size being 5-10mm are applied to a blast furnace fuel, so that the utilization ratio of small-size coke nuts is increased.

Owner:ANGANG STEEL CO LTD

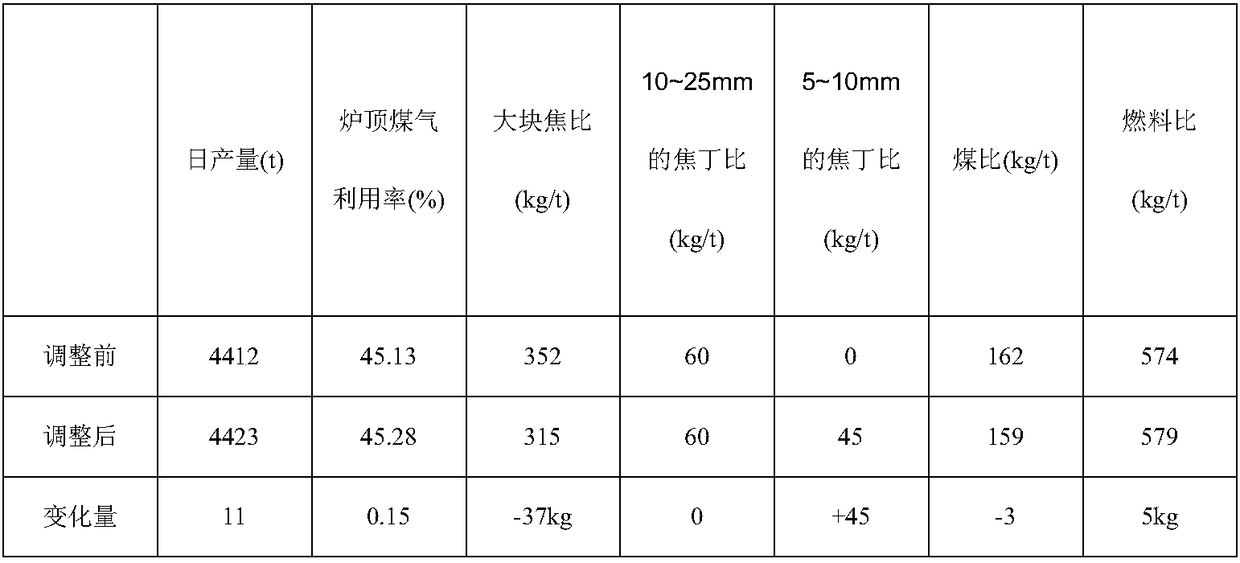

Electrolyzer circumfluence calcination method

The present invention provides electrolyzer circumfluence calcination method, when installing the electrolyzer, between the anode seam, center seam and inside edge cavity are provided with no materials, installing the electrolyzer in full cavity mode, then using the medium generated heat to calcine cathode lining of the electrolyzer in multiple heat transferring modes of radiation, convection and heat transmission etc, smoke generated by pressure difference during calcination circumfluence in the electrolyzer to make sure calcination temperature of all the sections is uniform, and avoids problem of heat stress centralization and sodium enriching in part effectively; a high-temperature insulation thermal insulating layer is lay in anode seam cavity, center seam cavity and top of edge cavity in the electrolyzer for reducing heat loss effectively, improving warming speed, shorting calcination time, saving energy sources and helpful for earlier regular production of the electrolyzer, meanwhile can reduce calcination energy consumption effectively and improve affect of radiation on operation environment; and the most important is that, using full electrolytes powder to instead of cryolite can reduce calcination startup cost greatly.

Owner:YUNNAN RUNXIN ALUMINUM

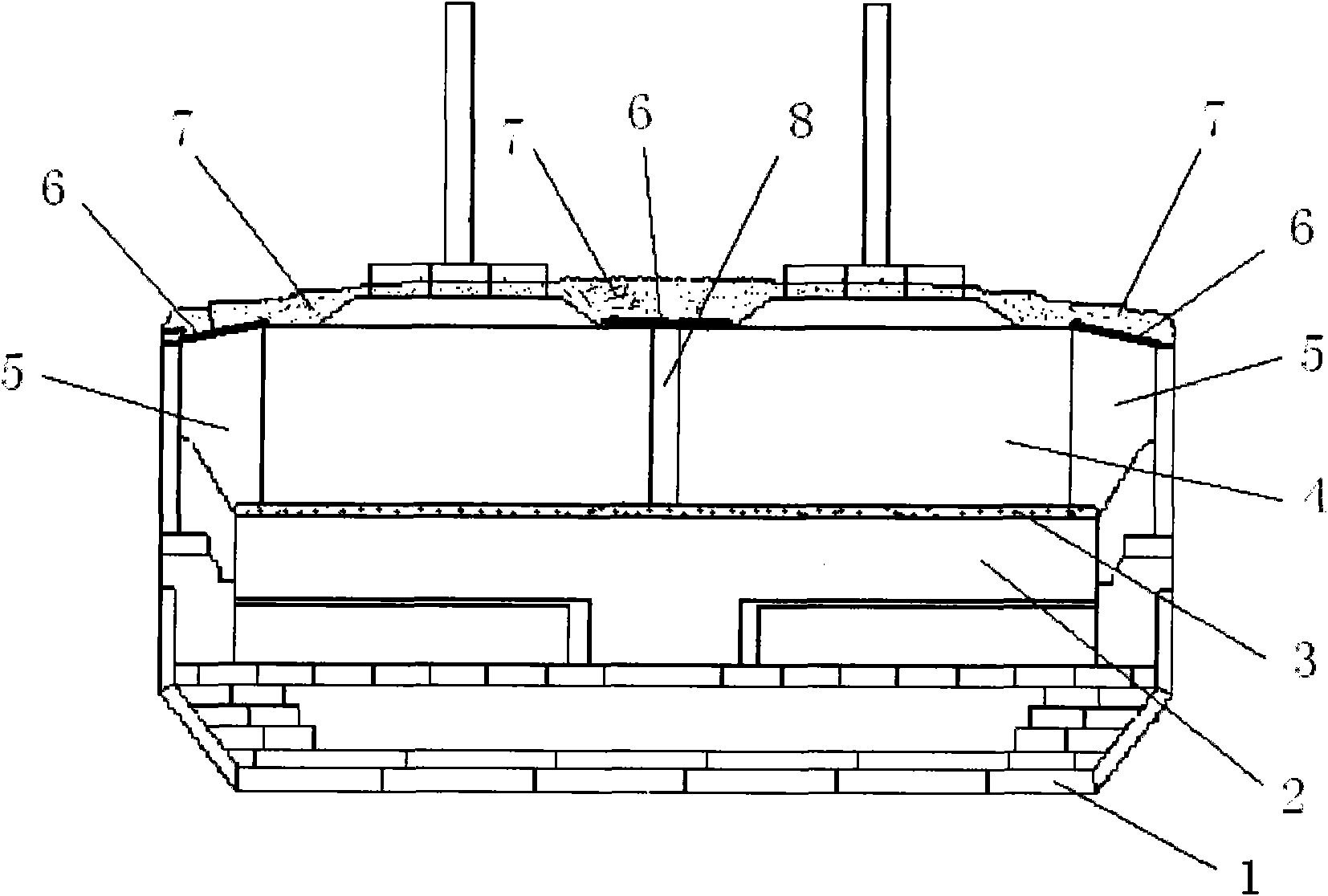

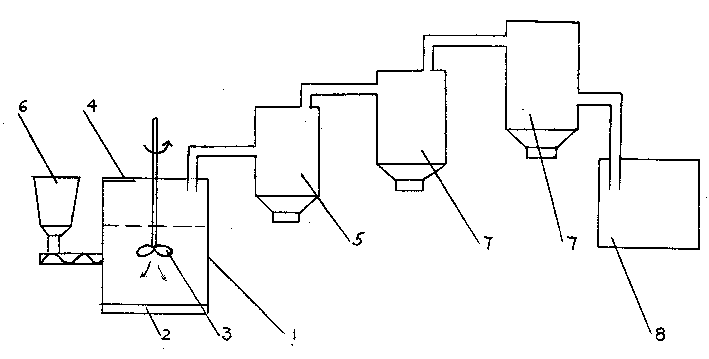

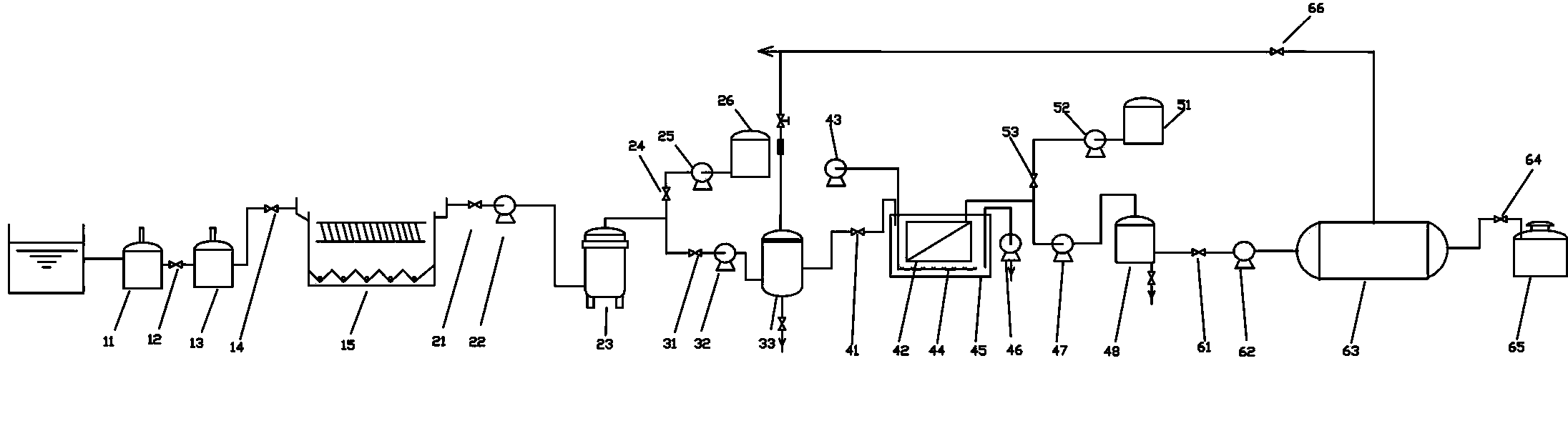

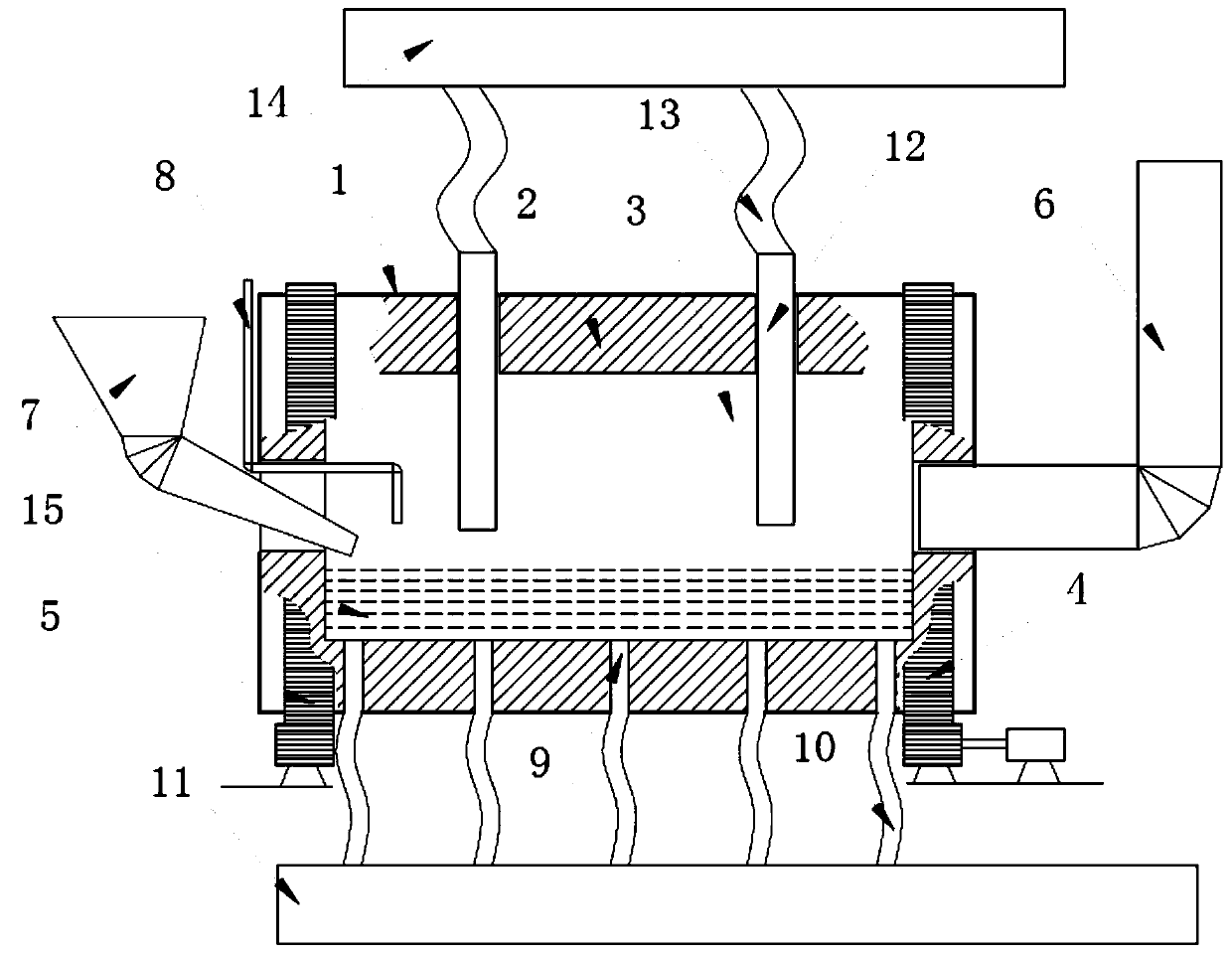

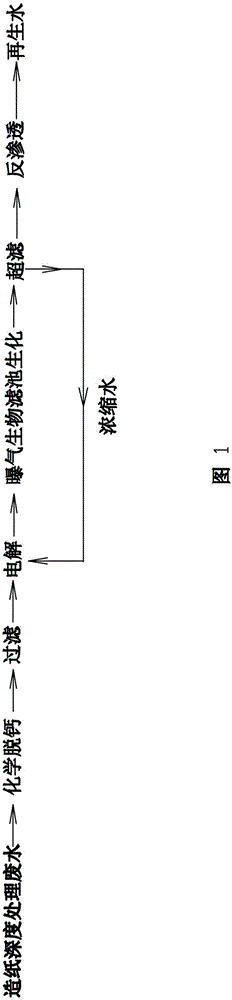

Recycling method of papermaking advanced treatment wastewater based on chemical decalcification

InactiveCN103265133AOvercoming processingOvercome costsGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

The invention discloses a recycling method of papermaking advanced treatment wastewater based on chemical decalcification. The recycling method comprises the following steps of chemical decalcification, filtering, electrolysis, membrane separation (ultra-filtration / MBR) and desalination. By combination of a chemical decalcification technology, an electrochemical technique and a membrane technology, 70-85% of papermaking advanced treatment wastewater can be recycled after being processed. Thus, wastewater emission is reduced; environmental pollution of the wastewater is avoided; waste of water resources is reduced; and the cost of regenerated circulating water is lower than the price of running water. Therefore, the recycling method is economical and reasonable; good economic benefit is generated; water consumption targets of tons of paper and wastewater discharge targets are greatly reduced; and the economic and technical indexes of enterprises are improved.

Owner:BOYING XIAMEN SCI & TECH

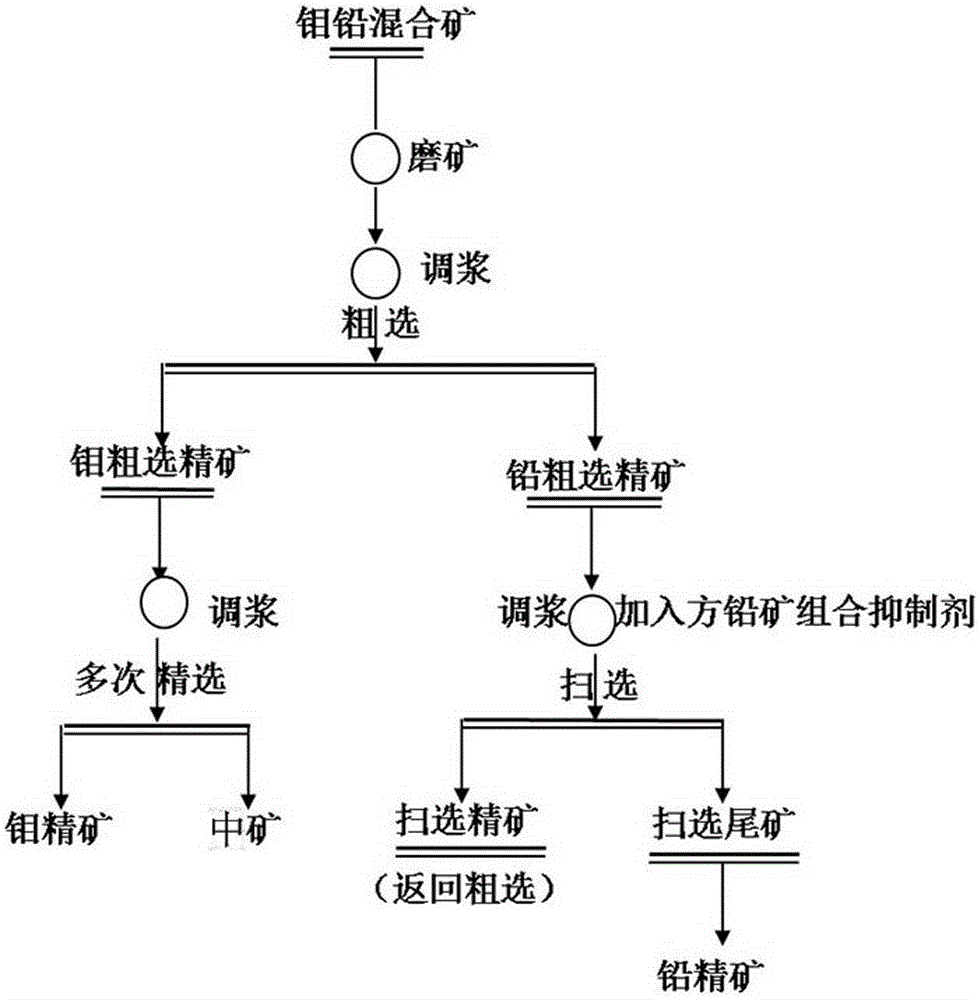

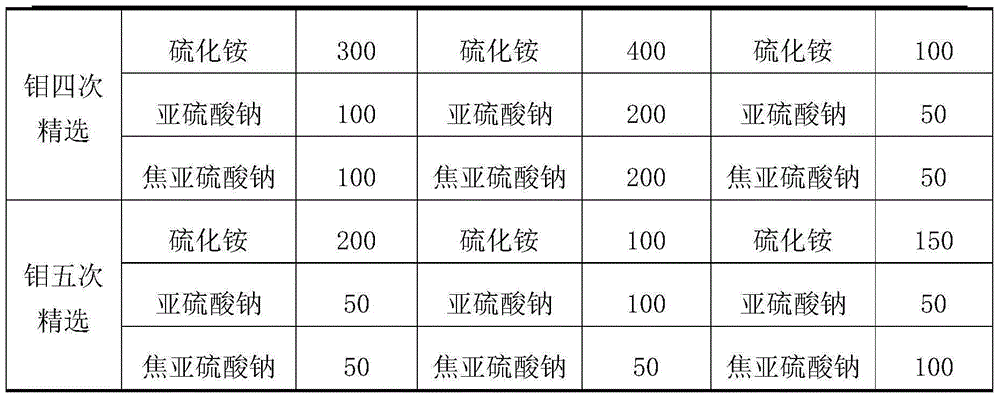

Separation mineral processing method for molybdenite and galena

The invention provides a separation mineral processing method for molybdenite and galena. The method is characterized in that molybdenum lead mixed ore, that is, raw ore is ground to be in the certain fineness, and the concentration and the PH of the slurry are adjusted; a galena combined inhibitor is added to restrain the galena, and a molybdenite collecting agent is added to achieve separation of the molybdenite and the galena; and the galena combined inhibitor is composed of ammonium sulfide, sodium sulfite and sodium pyrosulfite. A medicine agent used in the method is environment-friendly, and finally-obtained molybdenum concentrates and lead concentrates are high in grade. The mineral processing method is simple in technology, management and operation on site are easy, and the higher economic and technical indexes can be obtained through the technology.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Blow-in method for blast furnace to smelt high-titanium type vanadium titano-magnetite

InactiveCN102337360AImprove economic and technical indicatorsEasy to operateBlast furnace detailsMaterials preparationSlag

The invention provides a blow-in method for a blast furnace to smelt high-titanium type vanadium titano-magnetite, which comprises the steps of material loading, blast smelting, slag-out and tapping iron, wherein the material loading step comprises the process that before ignition smelting, hard coke is used for filling a hearth and the middle part and the lower part of a furnace bosh, hollow materials are filled at the upper part of the furnace bosh and a furnace waist, the hollow materials and normal materials are alternately filled into a furnace shaft, the hollow materials comprise the hard coke and lime stone but do not comprise iron-containing furnace materials, the normal materials comprise the hard coke, iron-containing lump ore and lime stone, and the normal materials are added into the blast furnace after the ignition smelting; in the blast smelting step, the air inlet area is reduced to 60 percent to 70 percent of the ordinary air inlet area: and the blow-in method also comprises a conversion material preparation step, and in the conversion material preparation step, high-titanium type vanadium-titanium magnet sinter is used for replacing the iron-containing lump ore in 1.5 to 2.0 smelting periods. The method can realize the effects of stable operation, high success ratio, high yield-reaching and efficiency-reaching speed, economic and technical index improvement of ironmaking production after blow-in and the like.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

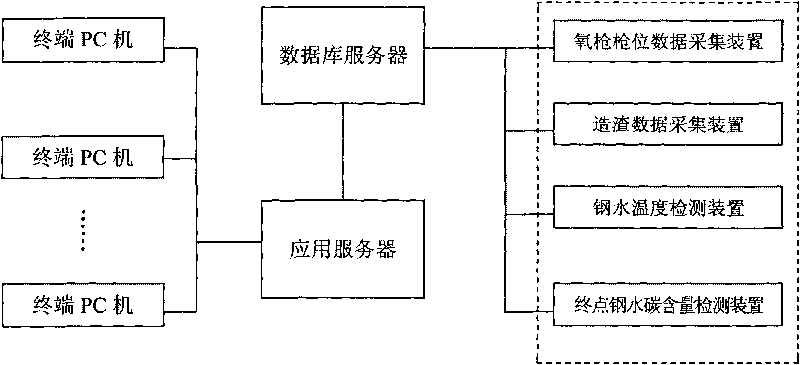

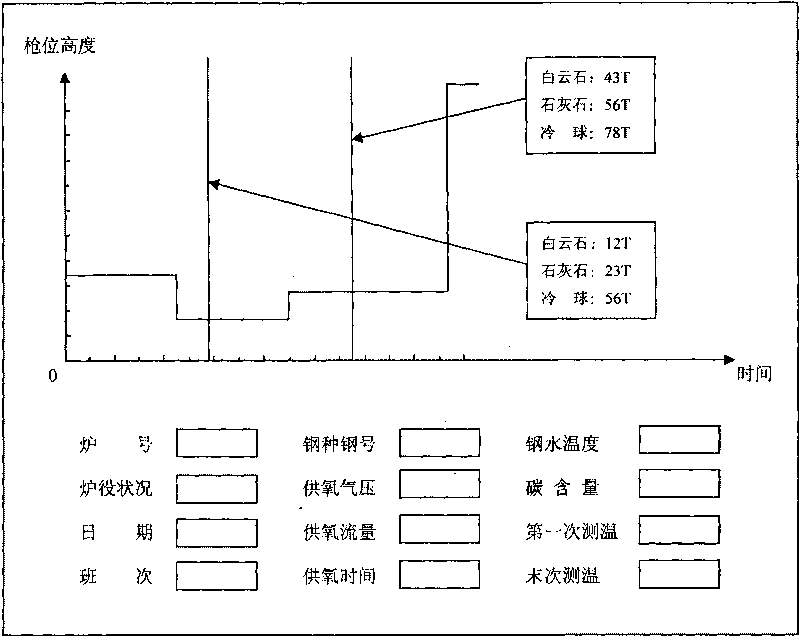

Converter smelting operation decision supporting system

InactiveCN101760578AReduce consumptionImprove inner qualityManufacturing convertersSpecial data processing applicationsOriginal dataData acquisition

The invention relates to a converter smelting operation decision supporting system of which the hardware system comprises a database server and a plurality of terminal personal computers (PC). The database server and the terminal PC are connected through a server to form a local area network; and an original data receiving module and a data storing module are arranged in the database server, and a real-time data curve generating module, an optimum proportioning module and a data optimum module. The hardware system also comprises an operation and final state data automatically collecting system comprising an oxygen lance position data collecting device, a slagging data collecting device, a molten steel temperature detecting device and a detecting device for carbon content in destination molten steel. The terminal PC displays a comprehensive real-time sign drawing for the process of converter smelting operation on line. The comprehensive real-time sign drawing comprises height identification of the oxygen lance position corresponding to the same time axis and added labels of slagging materials. The invention can direct the job operation of operators and support the operation decision of the operators.

Owner:TIANJUSHI ENG TECH GROUP

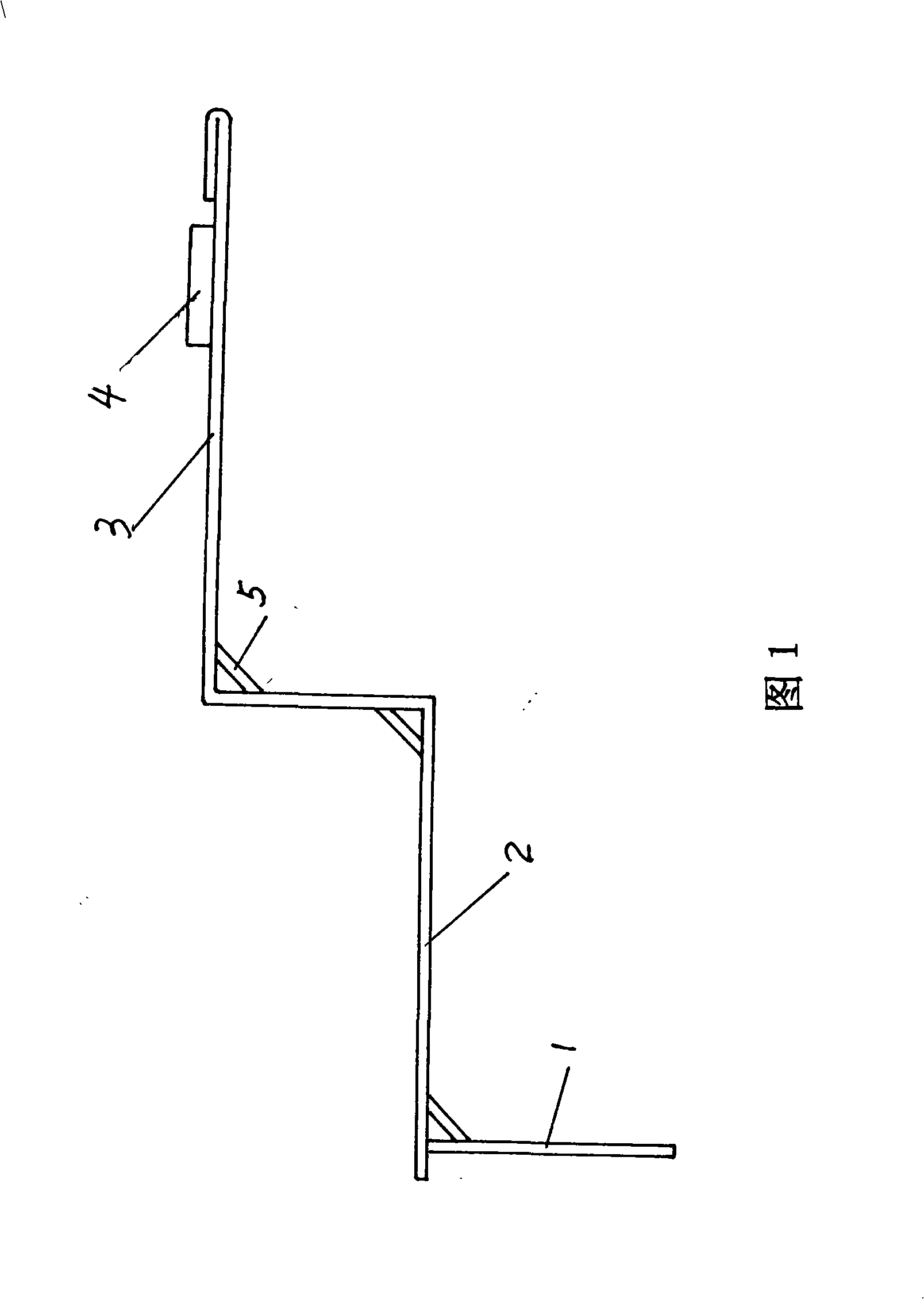

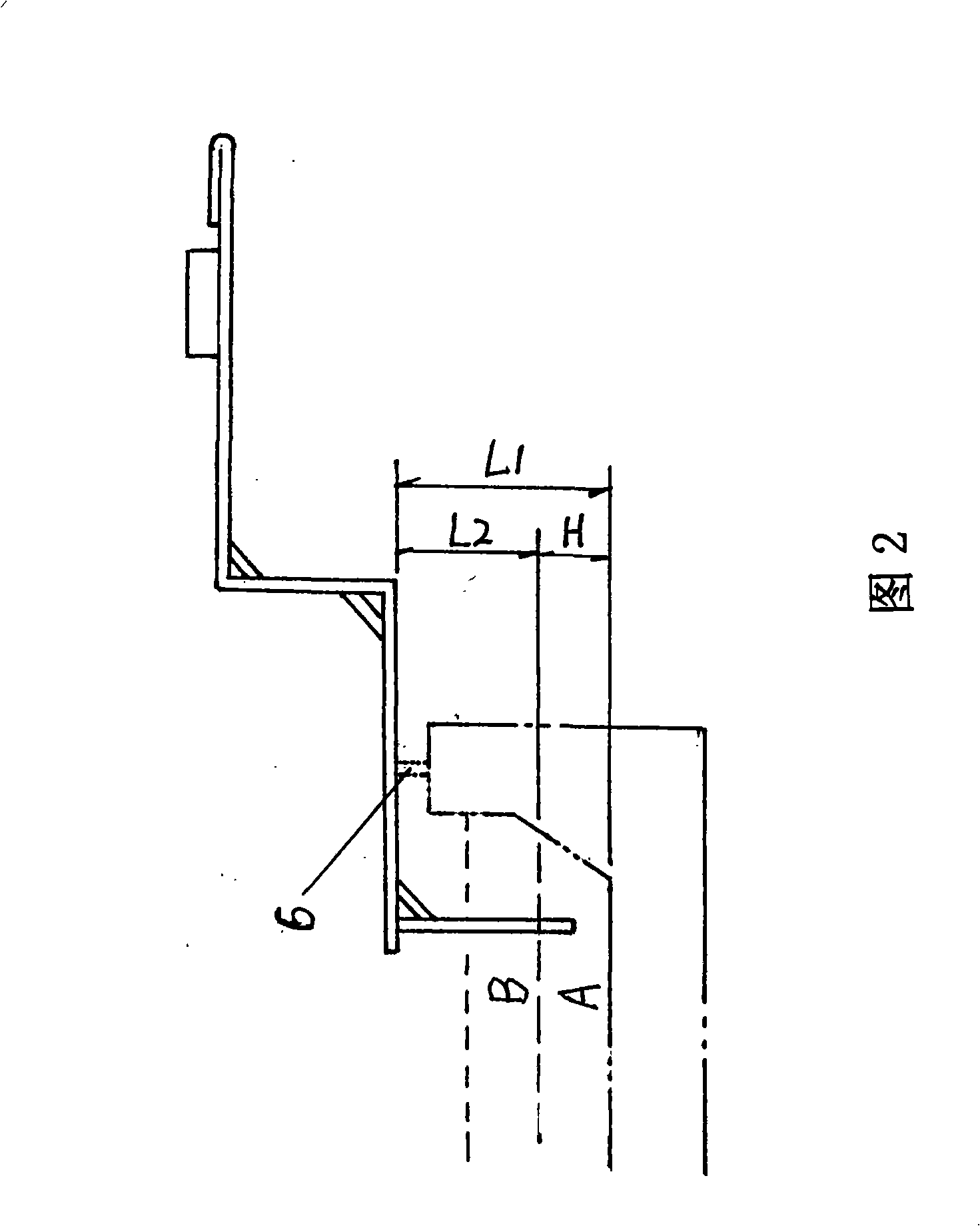

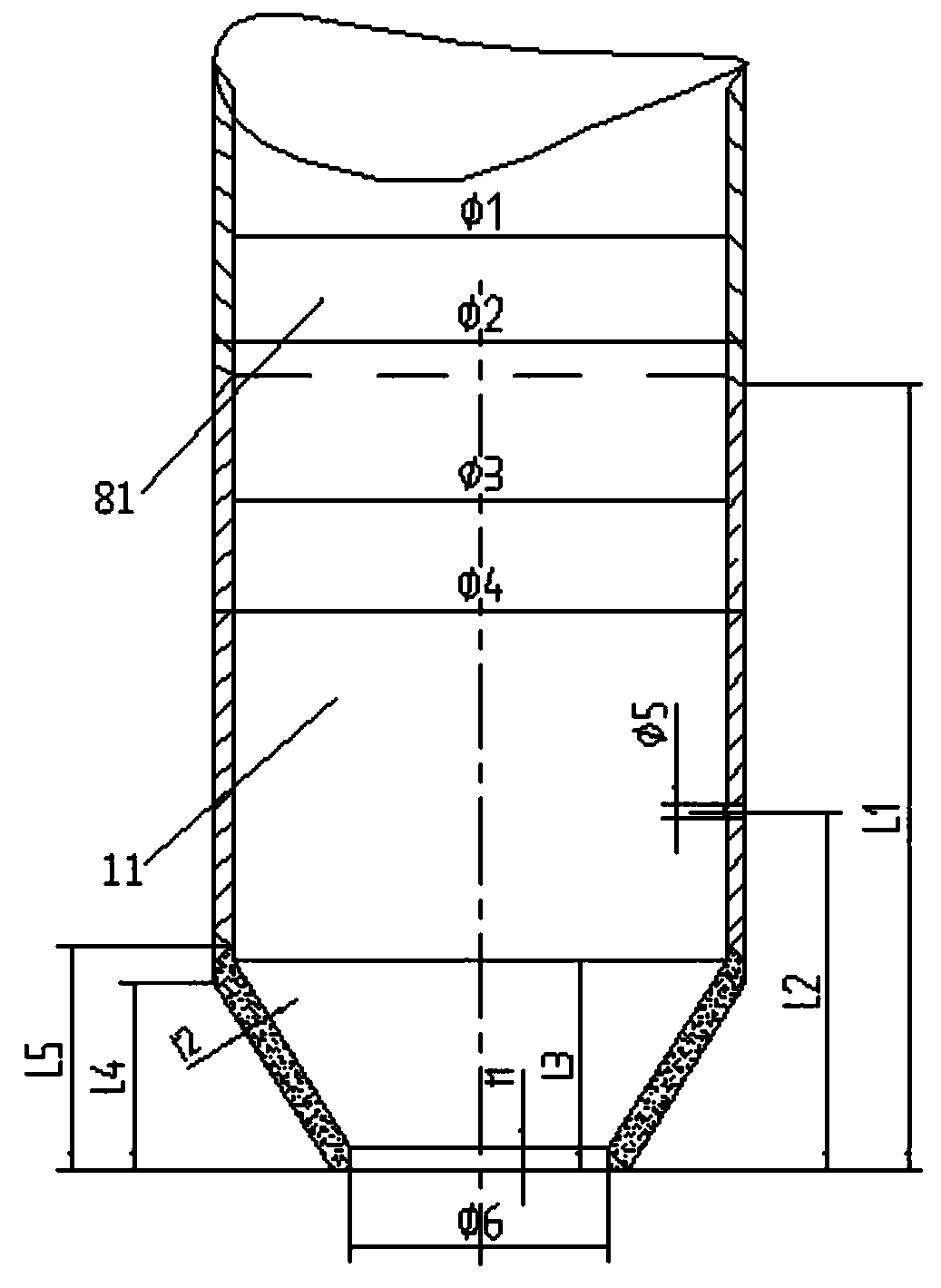

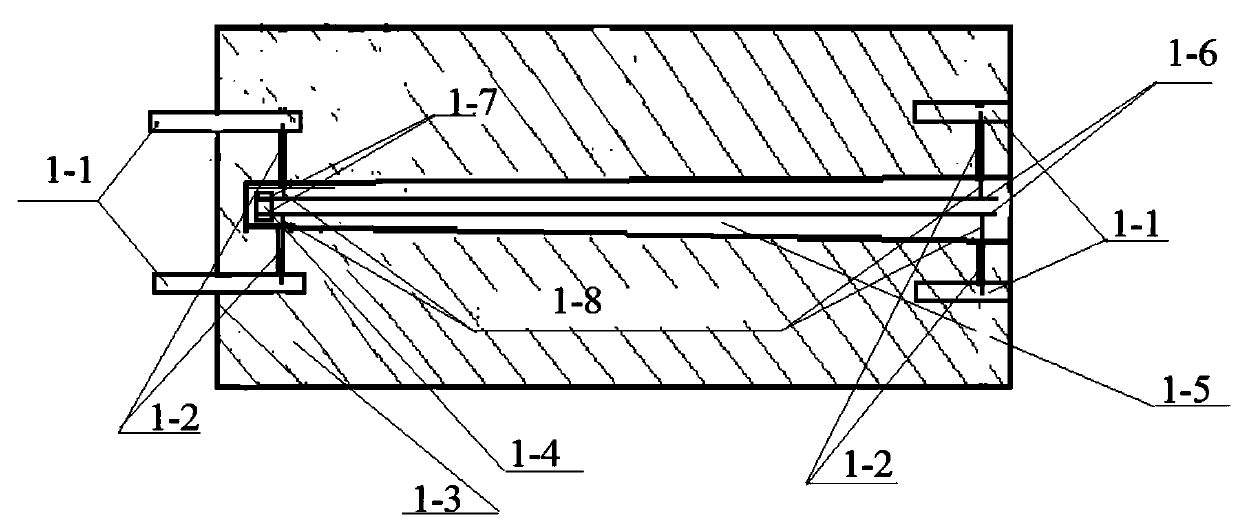

Aluminum liquid horizontal measurement method and tool

InactiveCN101329192ASimple structureReduce manufacturing costLevel indicators by physical variable measurementDemarcation pointEngineering

The invention relates to a measuring method and the measuring tool of aluminum liquid level in an electrolytic tank in the aluminum electrolytic production. The measuring method uses a standing edge board of the electrolytic tank with uneasy deformation as a reference plane and a reference zero point 0, the distance from the reference zero point 0 to the upper surface of a cathode carbon block inside the electrolytic tank is set to be L1, a reference level rod of the measuring tool is hanged over the reference plane, a measuring crooked chisel that is vertically fixed with the reference level rod is inserted into the aluminum liquid of the electrolytic tank and then pulled out, and consequently the distance L2 from the reference zero point to a level demarcation point between the electrolyte and the aluminum liquid is measured, and the level height of the aluminum liquid H is calculated by subtracting L2 from L1. The vertical measuring crooked chisel of the measuring tool has the length of H1, wherein, H1 is less than L1 and more than L2. The measuring method of the invention is convenient, simple and fast, uses the measuring tool with simple structure and low cost, is applicable to the production working of various aluminum electrolytic tanks, has high measurement precision, accurate measured data and reinforced guidance to the aluminum electrolytic production, and consequently improves each economic technical index of the aluminum electrolytic production.

Owner:FUSHUN ALUMINUM

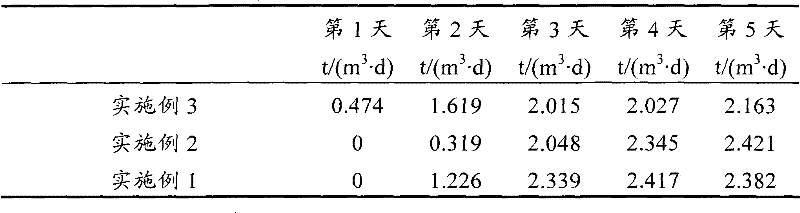

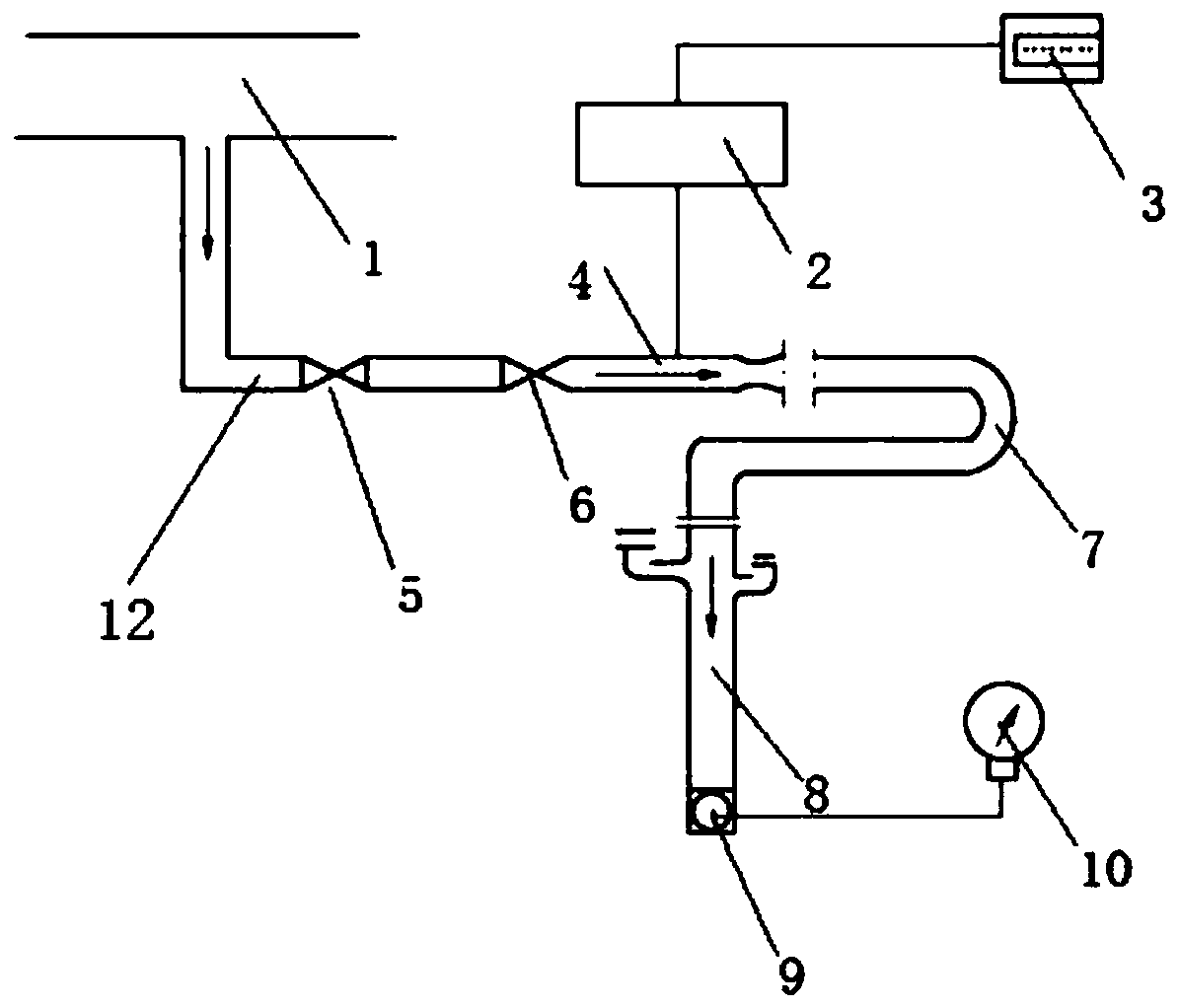

Method and device for measuring mass of solid in solid and liquid mixture

InactiveCN106404134AHigh measurement accuracyFew influence factors of errorVolume measurement apparatus/methodsWeighing apparatus for materials with special property/formChemistry

The invention relates to a method and device for measuring the mass of a solid in a solid and liquid mixture. The method comprises the following steps that a) the type of the solid in the solid and liquid mixture is determined, and the density Psolid of the solid is obtained by a table look-up or experiment method; b) the Volume Vmixutre and the mass Mmixture when the volume of the solid and liquid mixture equals Vm are measured; and c) according to that the volume of the solid and liquid mixture equals the sum of the volume of the solid and the volume of the liquid and that the mass of the of the solid and liquid mixture equals the sum of the mass of the solid and the mass of the liquid, an equation set is obtained, and values in the steps a) and b) are substituted into the equation set to obtain the Msolid. The method is simple and practical, realization approaches are diversified, both online measurement and static measurement can be realized, and the measuring precision is easy to control.

Owner:HUNAN CHENZHOU MINING CO LTD

Prepn of high-purity aluminium chloride

InactiveCN1436730ASolve and eliminate most of the problems of traditional production methodsImprove economic and technical indicatorsAluminium chloridesAluminium chlorideWastewater

The preparation process of high-purity aluminum chloride includes the following steps: adding NaCl, AlCl3 and sodium fluoride in the weight ratio of 30-40 to 50-60 to 1-10 into reactor to form the mixture mother liquid, heating the mother liquid to 800-830 deg.c; adding the mixture alumina and carbon blank in the weight ratio of 5.7:1 and chlorine in 11.8 units into the reactor while stirring for reaction with the mother liquid; sectionally condensating and recovering the produced gas and eliminating impurities in different temperature sections to obtain high-purity aluminum chloride; and treating and recovering tail gas. The said process has the advantages of easy-to-obtain material, low production cost, simple process, high product purity, no environmental pollution, etc.

Owner:黄建林

Converter gas recovery control method

InactiveCN107523663ACurrent frequency reductionEasy to recycleManufacturing convertersControl systemProcess engineering

The invention discloses a converter gas recovery control method. The converter gas recovery control method comprises the following steps: a converter gas recovery system controls gas recovery and diffusion through a control system; when the converter smelting time is less than or equal to 60 seconds, gas is diffused; when the converter smelting time is 60-240 seconds, gas is recovered when the CO concentration rises to be more than 6%, and gas is diffused when the CO concentration is reduced to be less than 4%; when the converter smelting time is 240-550 seconds, gas is recovered when the CO concentration rises to be more than 9%, and gas is diffused when the CO concentration is reduced to be less than 7%; and when the converter smelting time is more than or equal to 550 seconds, gas is recovered when the CO concentration rises to be more than 12%, and gas is diffused when the CO concentration is reduced to be less than 10%. According to the converter gas recovery control method, the relationship between the CO concentration and the recovery time is established, a recovery program no longer performs linkage according to only the gas concentration but performs linkage control according to both the steel-making time and gas recovery, and the gas recovery quantity can be increased to the maximum extent, so that gas can be recovered as much as possible on the basis of ensuring safe gas, the gas recovery quantity is increased, and energy saving and consumption reduction are realized.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

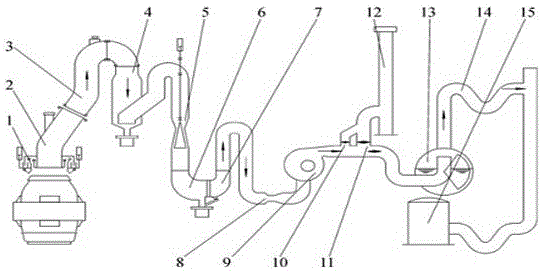

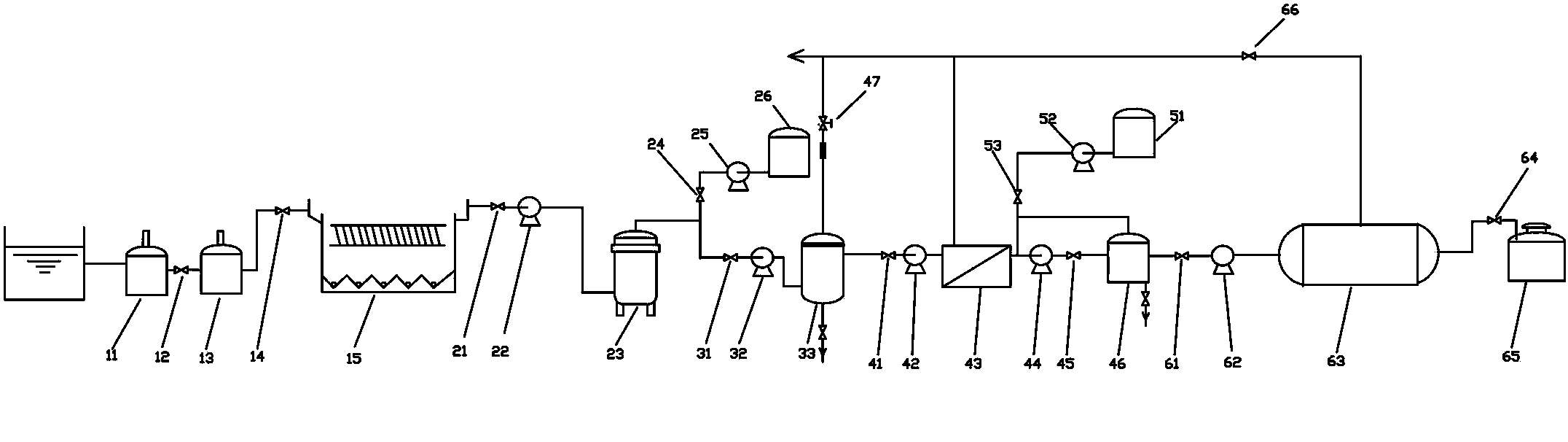

Papermaking wastewater recycling device and method based on electrochemical and electrodialysis technology

InactiveCN102295373AOvercoming Filtration Separation ProcessingOvercome the disadvantages of polluting the environmentGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

Provided is an electrochemistry and electrodialysis-based apparatus for recycling wastewater from papermaking. The recycling apparatus is provided with a nano-catalytic electrolysis system, a submerged ultrafiltration separation system, an ultrafiltration membrane cleaning system, and an electrodialysis system. Also provided is a method using the apparatus for recycling the wastewater from papermaking, comprising the following steps: extracting the wastewater from papermaking and introducing same into the nano-catalytic electrolysis system; flowing the wastewater from papermaking that is purified after processing into the submerged ultrafiltration separation system to acquire dialyzed water; then feeding the dialyzed water into the electrodialysis system for desalination by electrodialysis; and acquiring desalinated water and concentrated water.

Owner:BOYING XIAMEN SCI & TECH

Stagnation pressure measuring device and method of oxygen lance system

PendingCN110129515AOptimizing oxygen supply and slagging systemImprove economic and technical indicatorsManufacturing convertersThroatSlag

The invention discloses a stagnation pressure measuring device and method of an oxygen lance system and belongs to the technical field of steel smelting. The stagnation pressure measuring device comprises an oxygen main pipe which is connected with an oxygen branch pipe. A pressure taking point is arranged on the oxygen branch pipe. The output end of the oxygen branch pipe is connected with an oxygen soft pipe, and the output end of the oxygen soft pipe is connected with an oxygen lance. One end of the oxygen lance is an oxygen lance end portion, and an equivalent throat is installed at the end portion of the oxygen lance. The equivalent throat is composed of a cylinder barrel and a conical contraction section, a pressure taking hole is formed in the side wall of the cylinder barrel, and the pressure taking hole is connected with a standard pressure gauge through a pipeline. By means of the stagnation pressure measuring device and method, the relation between the pressure of the pressure taking point and the stagnation pressure before a spraying head is determined based on pipeline pressure loss measurement and according to the calculation of corresponding spraying head parametersand work conditions, a basis is provided for correcting the design of the oxygen lance spray head and determining the operation pressure of the oxygen lance, the oxygen supply and slag making system is optimized, and economic and technical indexes are improved.

Owner:MAANSHAN IRON & STEEL CO LTD

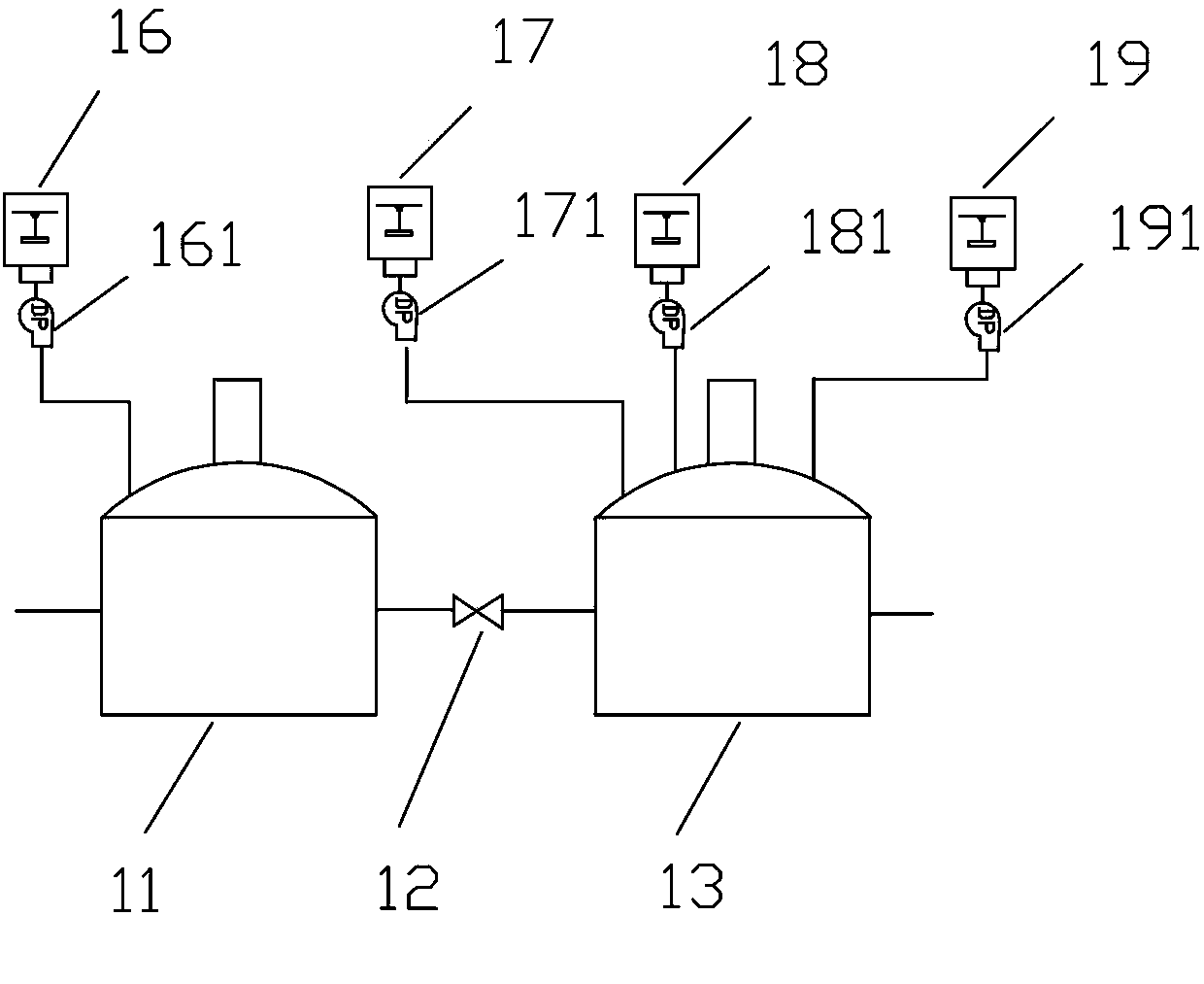

Method and device for continuously detecting ingredients and temperature of molten steel

InactiveCN110346059AContinuous temperature monitoringContinuous monitoring of ingredientsThermometer detailsThermometers using electric/magnetic elementsAdditive ingredientMolten steel

The invention discloses a method for continuously detecting ingredients and temperature of molten steel, and relates to the technical field of steel making detection equipment, structural improvementis performed on an existing detection probe to solve the continuous ingredient test problem and continuous temperature measurement problem necessary for intelligent steel making, therefore model intelligent steel making is realized, and intelligent dispatching and management of the temperature of an entire steel mill can also be achieved by the continuous temperature measurement of a steel refining furnace and a molten steel tank, so that various economic and technical indexes are greatly improved. Moreover, the method for continuously detecting ingredients and temperature of molten steel in the invention has the technical effects of less one-time investment, less maintenance cost, low probe cost, reliable detection result, no steel leakage doubt, and the problem in the prior art only continuous temperature measurement can be realized, but continuous detection data of ingredients such as carbon and phosphorus and the like that are necessary for intelligent steel making cannot be provided is solved. The device for continuously detecting ingredients and temperature of molten steel in the invention can realize continuous monitoring of the temperature and ingredients of molten steel.

Owner:连铸 +1

Detection system for continuous detection of molten steel temperature and composition for converter steelmaking

ActiveCN109897936AImprove economic and technical indicatorsTake convenienceManufacturing convertersSteelmakingBrick

The invention discloses a detection system for the continuous detection of the molten steel temperature and the composition for converter steelmaking, and relates to the technical field of steelmakingdetection equipment. By arranging a seating brick and a probe conveying pipe on the side wall of a converter, probes of various types are arranged in different detection through holes in the probe conveying pipe respectively, the molten steel temperature, the molten steel oxygen activity, and the low carbon and phosphorus content in the molten steel in the converter can be detected in real time,and an operator conveniently takes the corresponding operational means to reach the smelting end point in an optimized manner so as to improve various economic and technical indexes in steelmaking.

Owner:连铸 +1

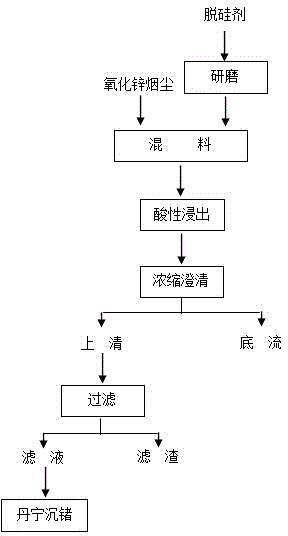

Method for improving filtration performance of zinc oxide leaching liquid

ActiveCN104928482AImprove filtering effectHarm reductionProcess efficiency improvementFiltrationSilicic acid

The invention relates to a method for improving filtration performance of zinc oxide leaching liquid, and belongs to the technical field of nonferrous metallurgy. According to the invention, zinc oxide smoke and a calcium aluminum composite desiliconization agent are mixed and added to a sulfuric acid dilute solution to conduct leaching for a period, and the leaching finish point acidity is kept to range from 0.8g / L to 2.5g / L. In the process of leaching of the zinc oxide smoke, an insoluble compound is generated by Ca2+ and Al3+ in a reaction between silicic acid and the calcium aluminum composite desiliconization agent in the leaching liquid, the content of the silicic acid, affecting filtration, in the solution is reduced, and therefore the filtration performance of the solution is improved. Compared with the prior art, the method has the advantages that an existing zinc oxide smoke leaching technology does not need to be changed, the operation that oxhide gelatin is added to improve the filtration performance of the solution is not required, and therefore the content of organic matter, generated after recycling of tannic acid, in the zinc electrowinning process of the sulfuric acid solution can be obviously reduced, the hazard caused by the organic matter to zinc electrowinning is reduced, the economic and technical indexes of zinc electrowinning are improved, the overall cost of production run is reduced, and the operation is easy and convenient.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

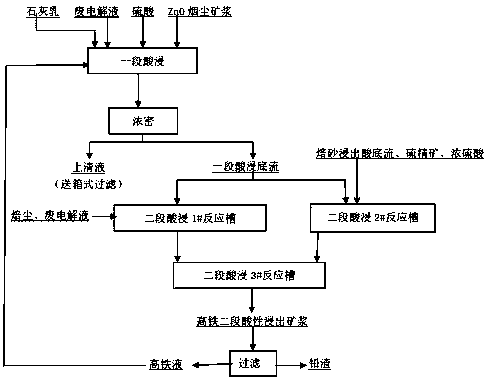

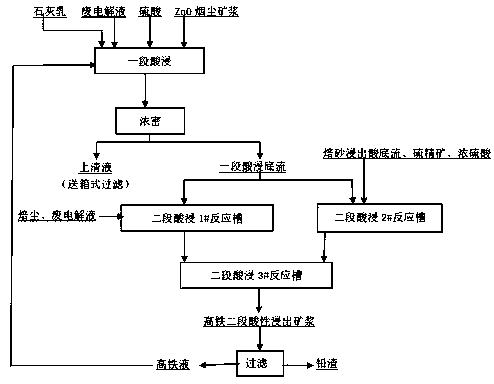

Method for improving content of ferrous iron in leaching liquid during zinc oxide smoke and dust leaching process

ActiveCN107746963AIncrease the content of ferrous ironIncrease contentProcess efficiency improvementSlagIron supplement

The invention relates to a method for improving the content of ferrous iron in leaching liquid during the zinc oxide smoke and dust leaching process, and belongs to the field of zinc hydrometallurgy.The method comprises the steps that in the second-stage acid leaching process of zinc oxide, first-stage acid leaching bottom flow is guided into a second-stage acid leaching 1# reaction tank and a second-stage acid leaching 2# reaction tank, roasted dust and waste electrolyte are added into the second-stage acid leaching 1# reaction tank, roasted sand leaching acid bottom flow, sulfur concentrateand concentrated sulfuric acid are added into the second-stage acid leaching 2# reaction tank, full reaction is conducted, then mixing is conducted, and a mixture is guided into a second-stage acid leaching 3# reaction tank for further reaction, obtained high-iron second-stage acid leaching ore pulp is filtered, so that lead slag and high iron liquid are obtained; and the high iron liquid returnsto a first-stage acid leaching process for first-stage acid leaching iron supplement. Through the method for improving the content of the ferrous iron in the leaching liquid during the zinc oxide smoke and dust leaching process, the content of Fe2+ in the high iron liquid is improved to 16000-22000 mg / L, so that it is ensured that the content of first-stage acid leaching Fe2+ is stably controlledto be 5000-6000 mg / L, and smoothing carrying out of the neutralizing and impurity removing process of subsequent stages is ensured.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

A mineral processing method for separating chalcopyrite from galena, sphalerite and pyrite

The invention discloses a flotation separation method for chalcopyrite, galena, zinc blende and ironpyrite by a composite inhibitor which comprises sodium pyrosulfite, sodium sulfite and ferrous sulfate, has an inhibition effect on the galena, the zinc blende and the ironpyrite under the condition of a natural pH value, and is easy to degrade and activate after inhibition during a separation process of the chalcopyrite, the galena, the zinc blende and the ironpyrite. According to the flotation separation method, the flotation is performed under the condition of a neutral medium, the adopted composite inhibitor has the inhibition effect on three metal sulphide ores of the galena, the zinc blende and the ironpyrite; environment pollution caused by adoption of heavy metal salt inhibitors is prevented; pipeline scaling caused by adoption of lime is prevented; and the inhibiting capacity of the composite medicament is relatively weaker and added segmentally, an activation difficulty of follow-up operation due to overinhibition in a flotation process is prevented, and the improvement of the metal recovery rate is further facilitated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

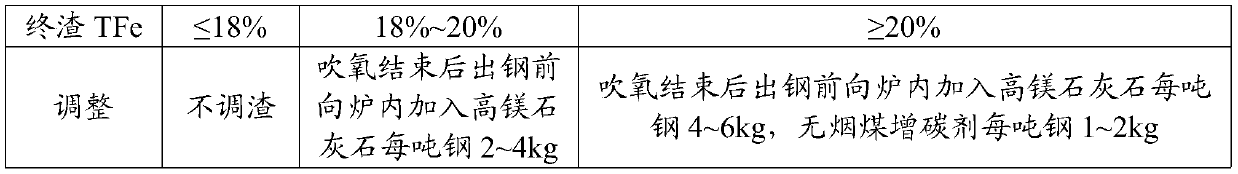

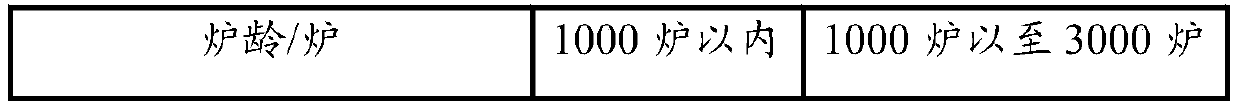

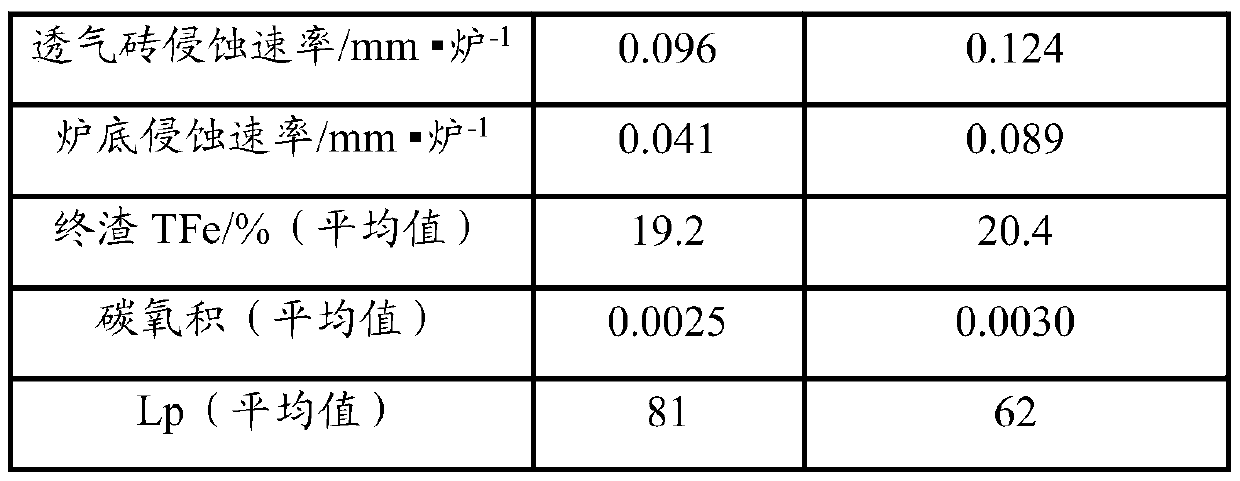

Method for controlling uniform erosion of bottom blowing bricks and furnace bottom of steel refining furnace

InactiveCN111440917AMitigation of bottom erosion rateImprove economic and technical indicatorsManufacturing convertersSlagProcess engineering

The invention provides a method for controlling uniform erosion of bottom blowing bricks and the furnace bottom of a steel refining furnace. The method comprises the following steps of in an earlier stage of furnace service, controlling the slag splashing time to be 1.5-2.5 minutes, the slag splashing gun position to be 0.8-1.5 m and the slag splashing pressure to be 0.8-0.9 MPa for each furnace slag splashing; in middle and later periods of furnace service, performing slag modification treatment according to the mass content of Fe in the slag, and then performing slag splashing for each furnace; and performing fettling maintenance. According to the method for controlling uniform erosion of the bottom blowing bricks and the furnace bottom of the steel refining furnace provided by the invention, the erosion rate of the bottom blowing bricks and the furnace bottom is controlled by means of adjustment of slag splashing schemes in different furnace service periods, steel slag quenching andtempering treatment and the fettling maintenance, so that the purposes of uniformly eroding the bottom blowing bricks and the furnace bottom, improving the bottom blowing stirring effect and guaranteeing the production safety are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification

InactiveCN103253838BOvercome defects such as polluting the environmentEmission reductionGeneral water supply conservationMultistage water/sewage treatmentElectrolysisFiltration

The invention discloses a papermaking advanced treatment waste water recycling device based on chemical decalcification, which includes a chemical decalcification system, a filtration system, an electrolysis system, a membrane separation system and a desalination system. The chemical decalcification system is equipped with a dosing system and a membrane separation system. It is one of ultrafiltration system and MBR system. The present invention combines chemical decalcification technology, electrochemical technology and membrane technology, and 70% to 85% of papermaking advanced wastewater treatment can be recycled and recycled, which not only reduces wastewater discharge, avoids environmental pollution of wastewater, but also reduces waste of water resources , It can also make the cost of regenerated circulating water lower than the price of tap water, which is economically reasonable, produces better economic benefits, greatly reduces the water consumption index and wastewater discharge index of tons of paper, and improves the economic and technical indicators of the enterprise.

Owner:BOYING XIAMEN SCI & TECH

A method for improving the filtration performance of zinc oxide leachate

ActiveCN104928482BImprove filtering effectHarm reductionProcess efficiency improvementFiltrationSilicic acid

The invention relates to a method for improving filtration performance of zinc oxide leaching liquid, and belongs to the technical field of nonferrous metallurgy. According to the invention, zinc oxide smoke and a calcium aluminum composite desiliconization agent are mixed and added to a sulfuric acid dilute solution to conduct leaching for a period, and the leaching finish point acidity is kept to range from 0.8g / L to 2.5g / L. In the process of leaching of the zinc oxide smoke, an insoluble compound is generated by Ca2+ and Al3+ in a reaction between silicic acid and the calcium aluminum composite desiliconization agent in the leaching liquid, the content of the silicic acid, affecting filtration, in the solution is reduced, and therefore the filtration performance of the solution is improved. Compared with the prior art, the method has the advantages that an existing zinc oxide smoke leaching technology does not need to be changed, the operation that oxhide gelatin is added to improve the filtration performance of the solution is not required, and therefore the content of organic matter, generated after recycling of tannic acid, in the zinc electrowinning process of the sulfuric acid solution can be obviously reduced, the hazard caused by the organic matter to zinc electrowinning is reduced, the economic and technical indexes of zinc electrowinning are improved, the overall cost of production run is reduced, and the operation is easy and convenient.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Mobile wind turbine generator system high-low voltage ride through test device

ActiveCN102736028BFlexible testingEasy to installDynamo-electric machine testingHigh pressureHigh voltage

The invention provides a mobile wind turbine generator system high-low voltage ride through test device, which is applicable to high-voltage system tests and low-voltage system tests simultaneously, the test device is connected in series between a wind turbine generator system and a power network, and mainly comprises an input breaker, a voltage regulation unit, a bypass breaker and an output breaker. By adopting a transformer secondary side multi-tap voltage regulation mode, for thyristor high-speed switching control as well as a vehicle-mounted container structure, transformer output voltage is changed through controlling the on-ff of a thyristor, and thus a simulation test of different voltage class failures of a wind turbine generator system to be tested is achieved. By using the mobile wind turbine generator system high-low voltage ride through test device provided by the invention, high-low voltage ride through tests can be accomplished simultaneously, and the device has high integration, high reliability and highest economic and technical norms; the device can be applied to testing various types of wind generators, meet high-low voltage ride through test criteria in China as well as countries in Europe and America, and has a wide application range; and the device adopts a vehicle-mounted container structure, adopts a modular design, is convenient to transport and is flexible in testing.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

A method for reducing impurity content in molten magnesium chloride for magnesium electrolysis

The invention belongs to the field of non-ferrous metal metallurgy, particularly relates to a method for reducing content of impurities in magnesium chloride melts for magnesium electrolysis and aimsto solve the technical problems to provide the method for reducing content of impurities in magnesium chloride melts for magnesium electrolysis. The method comprises steps as follows: (1) the magnesium chloride melts are put in a purification furnace to be heated to 750 DEG C plus / minus 10 DEG C, stirred and left to stand and settle until the mass percentage of upper clarified melts MgO is smallerthan or equal to 0.10%; (2) the clarified melts are extracted from the upper part of the purification furnace and added to a purification electrolytic bath, wherein the purification electrolytic bathadopts a KCl-NaCl-CaCl2 molten salt system, the temperature of the melts ranges from 690 DEG C to 730 DEG C, a graphite anode and a steel cathode are adopted, the electrolytic voltage is 2.8-5.5 V, the electrode distance is 30-60 mm and the current density is 0.2-0.8 A / cm<2>. By means of the method, the content of impurities such as MgO, Fe, Ti and the like in the magnesium chloride melts can beeffectively reduced, the purity of MgCl2 in the melts is improved, and the method has an important influence on improving the operation state and the current efficiency in the magnesium electrolysis process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

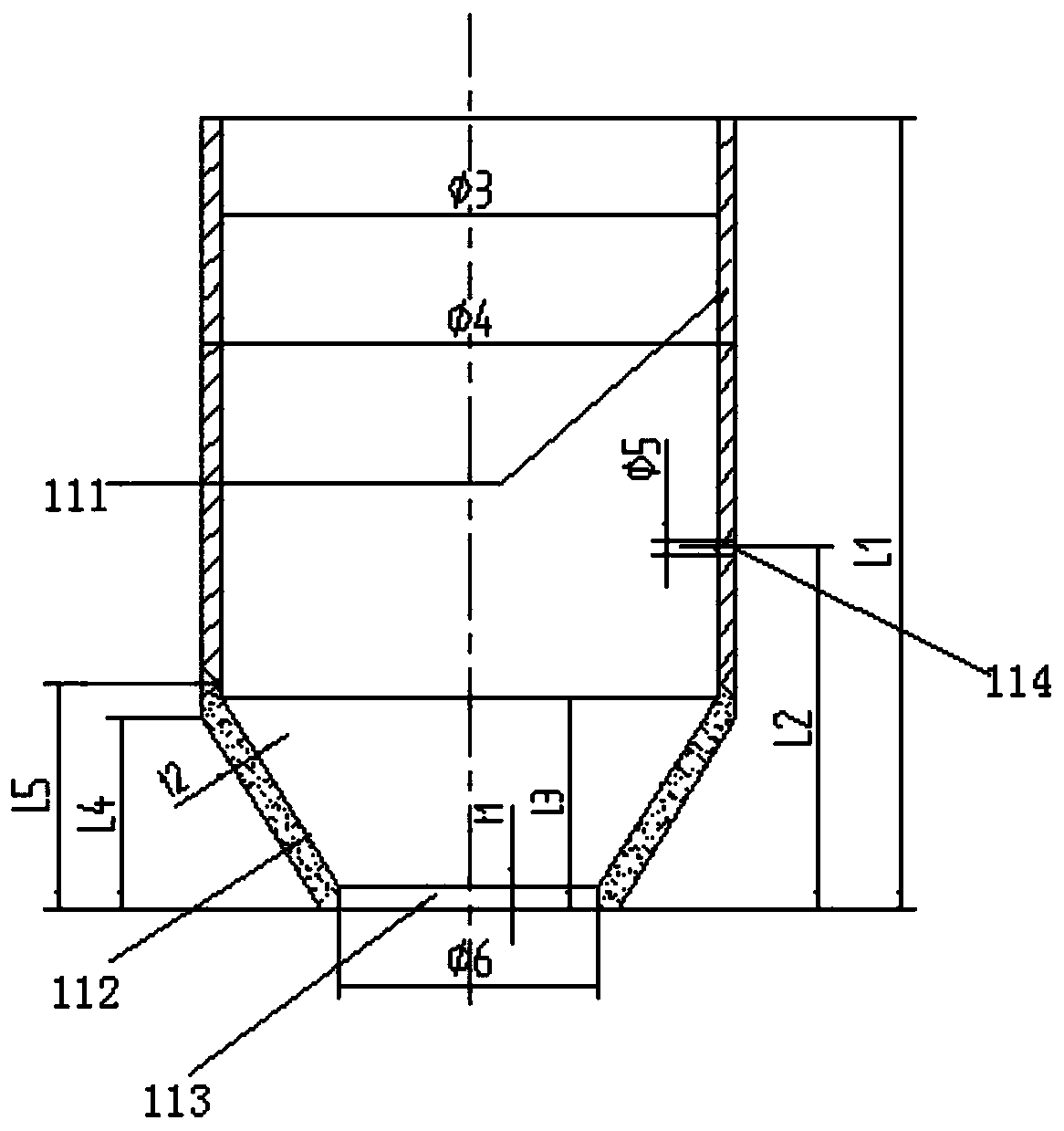

Molten pool smelting converter with antimony ore bottom blowing and top blowing mixed

InactiveCN110846522AIncrease production capacityReduce energy consumptionFurnace componentsGear wheelRefractory

The invention discloses a molten pool smelting converter with antimony ore bottom blowing and top blowing mixed. The molten pool smelting converter comprises a horizontal barrel-shaped converter body.The converter body comprises a converter body shell and a converter cavity arranged in the converter body shell. A refractory material is arranged between the converter body shell and the converter cavity. A walking gear used for controlling rotating is arranged at one end of the converter body shell, and a driven rotating gear is arranged at the other end of the converter body shell. A feeding opening is formed in the side face or one end face of the converter body shell, and a smoke discharge opening is formed in the other end face of the converter body shell and is in noncontact connectionwith a flue. One or more bottom blowing air holes and one or more top blowing inserting holes are formed in the converter body shell. The bottom blowing air holes and the top blowing inserting holespenetrate through the converter body shell and the refractory material to communicate with the interior of the converter cavity. According to the technical scheme, productivity can be effectively improved, energy consumption can be reduced, economic technology indexes can be improved, and production cost can be reduced.

Owner:广西万仕智稀贵金属科技有限公司

Regenerative cycle and utilization method for papermaking deep-treatment wastewater

InactiveCN103214153BOvercome defects such as polluting the environmentEmission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a regenerative cycle and utilization method for papermaking deep-treatment wastewater. The regenerative cycle and utilization method comprises the steps of chemical decalcification, filtration, electrolysis, biological aerated filter biochemical treatment, ultrafiltration and reverse osmosis. A chemical decalcification system can be used for effectively removing high-concentration calcium ions and magnesium ions in the papermaking deep-treatment wastewater, and the removal rate achieves 50%; the COD (chemical oxygen demand) is further reduced via nano-catalytic electrolysis; 70-85% of the papermaking deep-treatment wastewater can be regeneratively cycled and utilized via the treatment of the method disclosed by the invention, thus greatly reducing the water consumption index and the wastewater discharge index of per ton of paper, increasing the economic and technical indexes of enterprises, reducing the discharge of the wastewater, avoiding the pollution of the wastewater to environment, and reducing the waste of water resources; and the cost of the regenerated cycling water can be lower than the price of running water, so that the regenerative cycle and utilization method is economical, reasonable, and capable of generating good economic benefits.

Owner:BOYING XIAMEN SCI & TECH

A method for increasing the content of divalent iron in the leach solution during the leaching process of zinc oxide smoke and dust

ActiveCN107746963BIncrease the content of ferrous ironIncrease contentProcess efficiency improvementSlagIron supplement

The invention relates to a method for improving the content of ferrous iron in leaching liquid during the zinc oxide smoke and dust leaching process, and belongs to the field of zinc hydrometallurgy.The method comprises the steps that in the second-stage acid leaching process of zinc oxide, first-stage acid leaching bottom flow is guided into a second-stage acid leaching 1# reaction tank and a second-stage acid leaching 2# reaction tank, roasted dust and waste electrolyte are added into the second-stage acid leaching 1# reaction tank, roasted sand leaching acid bottom flow, sulfur concentrateand concentrated sulfuric acid are added into the second-stage acid leaching 2# reaction tank, full reaction is conducted, then mixing is conducted, and a mixture is guided into a second-stage acid leaching 3# reaction tank for further reaction, obtained high-iron second-stage acid leaching ore pulp is filtered, so that lead slag and high iron liquid are obtained; and the high iron liquid returnsto a first-stage acid leaching process for first-stage acid leaching iron supplement. Through the method for improving the content of the ferrous iron in the leaching liquid during the zinc oxide smoke and dust leaching process, the content of Fe2+ in the high iron liquid is improved to 16000-22000 mg / L, so that it is ensured that the content of first-stage acid leaching Fe2+ is stably controlledto be 5000-6000 mg / L, and smoothing carrying out of the neutralizing and impurity removing process of subsequent stages is ensured.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

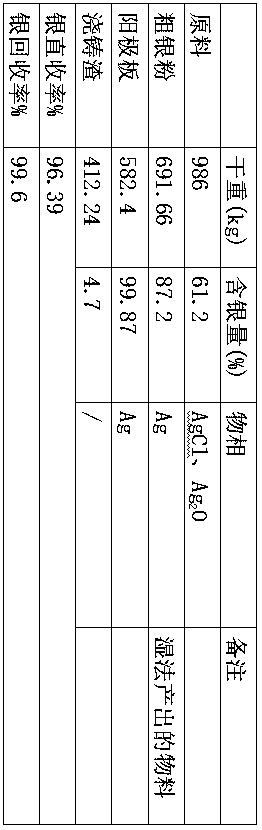

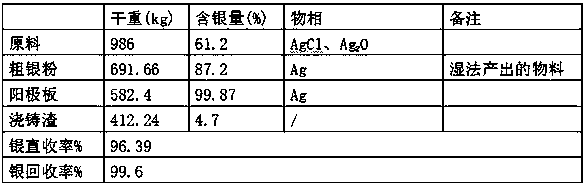

Comprehensive treatment process for silver-bearing material in silver nitrate production

InactiveCN110846501AEasy to handleSimple processPhotography auxillary processesProcess efficiency improvementMetallurgySilver nitrate

The invention discloses a comprehensive treatment process for a silver-bearing material in silver nitrate production. The comprehensive treatment process comprises the following steps of 1, liquid preparation; 2, reaction; 3, rinsing; 4, drying; 5, anode plate casting; 6, silver electrolysis; 7, finished product casting. According to the comprehensive treatment method, the treatment process of thesilver-bearing material generated in the silver nitrate production is effectively simplified, and the method has the advantages of being low in treatment cost and high in economic and technical index.

Owner:中科铜都粉体新材料股份有限公司

Blast furnace main runner repairing process

PendingCN114058755ASaving repair efficiencyImprove repair efficiencyDischarge devicesProcess efficiency improvementBrakeBlast furnace smelting

The invention discloses a blast furnace main runner repairing process, belongs to the technical field of blast furnace smelting, and provides a blast furnace main runner repairing process capable of remarkably shortening the main runner repairing time. The process comprises the following steps: a an iron notch is blocked and supply is cut off; b hoisting equipment is used for hoisting a special brake block, and the special brake block is put into the main runner, so that residual molten iron in the main runner is extruded, replaced and discharged, wherein the size of the special brake block matches that of the accommodating cavity of the main channel; c after the residual molten iron in the main runner is discharged, the special brake block is hoisted out by hoisting equipment, and then the residual molten iron residues in the main runner are cleaned; and d the part to be repaired in the main trench is repaired. According to the method, the special brake block is directly hung in the main runner, so that the residual molten iron in the main runner can be quickly replaced and discharged, and the residual molten iron can be discharged only in 10 to 15 minutes, so that the time can be greatly saved, the repairing efficiency of the main runner is improved, the economic and technical indexes of the blast furnace are improved, and the cost is saved.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com