Patents

Literature

34results about How to "Overcome the disadvantages of polluting the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slow release, long-acting urea manure and technique of manufacturing the same

InactiveCN101108781AFully functionExtend the fertilizer periodAgriculture gas emission reductionUrea compound fertilisersOrganic solventFluidized bed

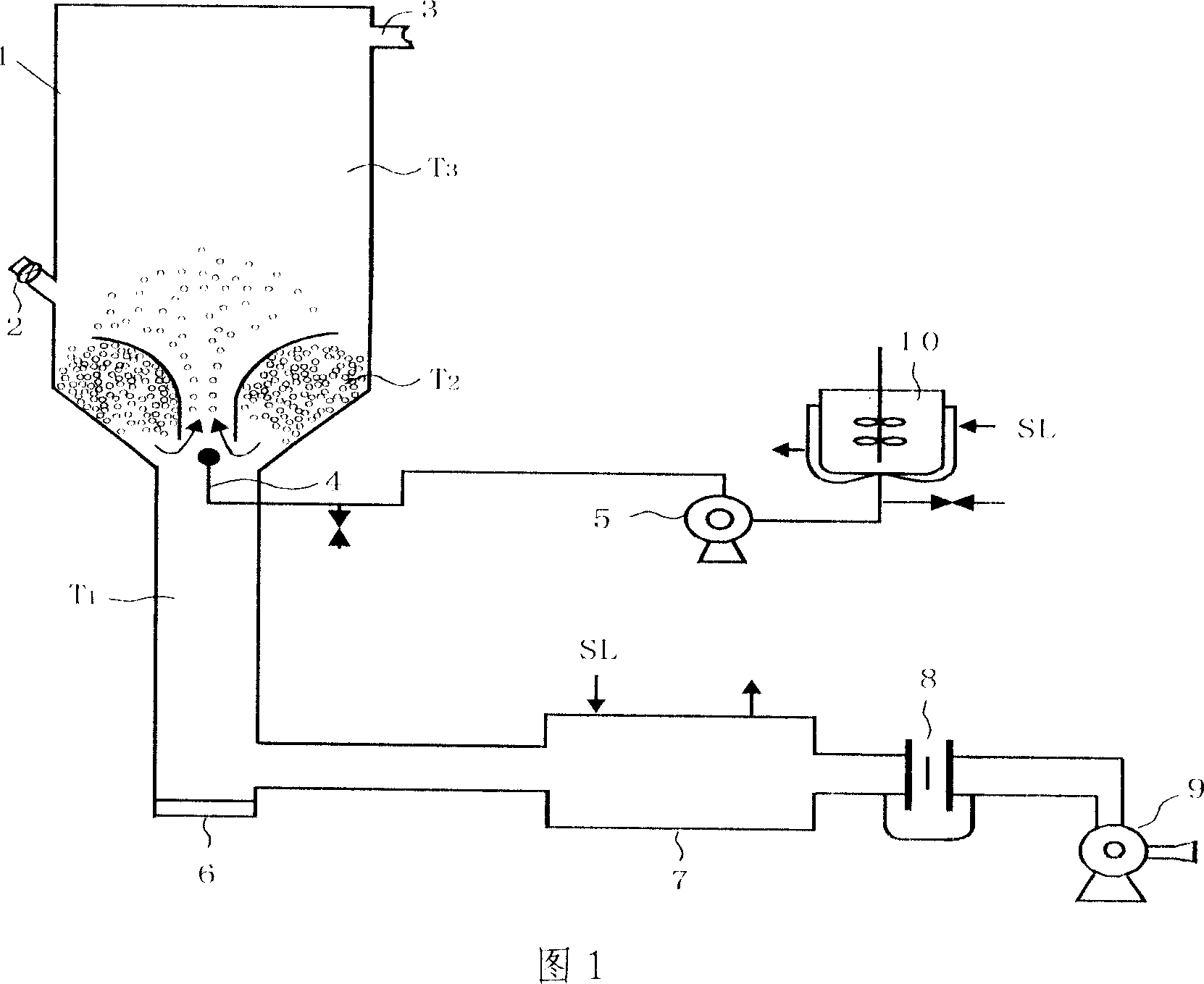

The invention relates to the nitrogen manure, in particular to the slow-release and long-effect urea fertilizer coating a layer of biochemical inhibitor on the urea surface and the preparation process. The fertilizer components are the urea, the biochemical inhibitor, the bond and the organic solvent. The process is that: the levitated solution mixed with the biochemical inhibitor, the bond and the organic solvent is sprayed and coated on the surface of the molding urea granule under the fluidized state through a fluidized bed to gain the slow-release urea fertilizer. The fertilizer of the invention makes full play of the functions and effects of two biochemical inhibitors, makes the fertilizer effect period prolonged obviously and realizes that once basal nitrogen fertilizer application can meet the requirement of whole growing seasons on the nitrogen. The agricultural production saves labor and time with low production cost and friendly environment. For the secondary processing of the urea, the preparation process of the invention has simple operation and easy realization and can carry out industrial production on a large scale.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

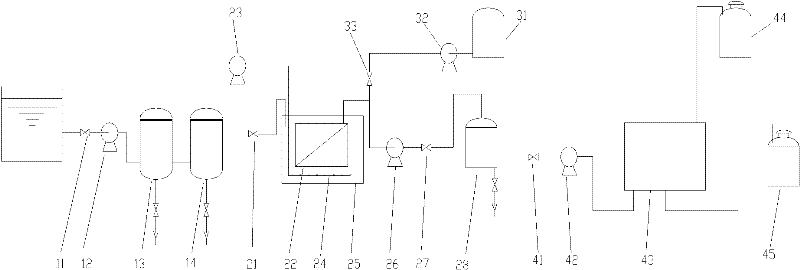

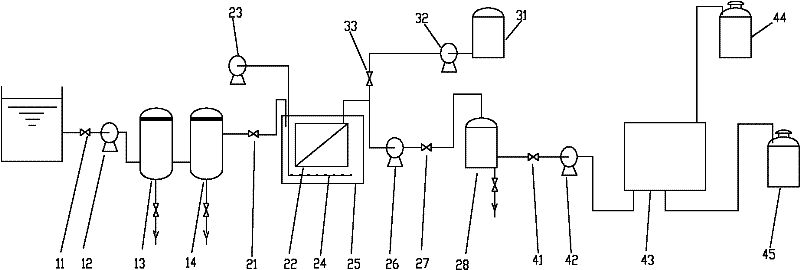

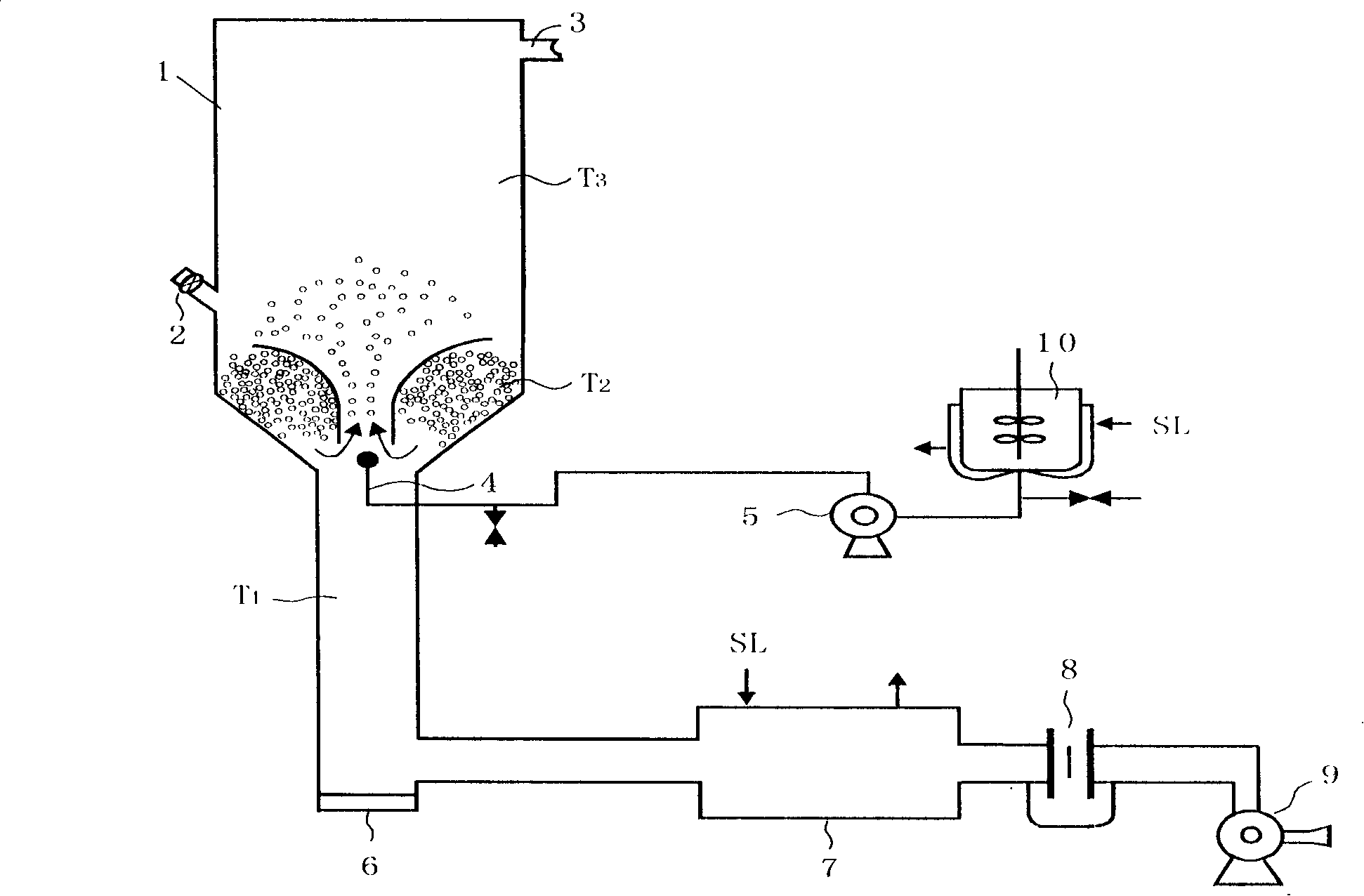

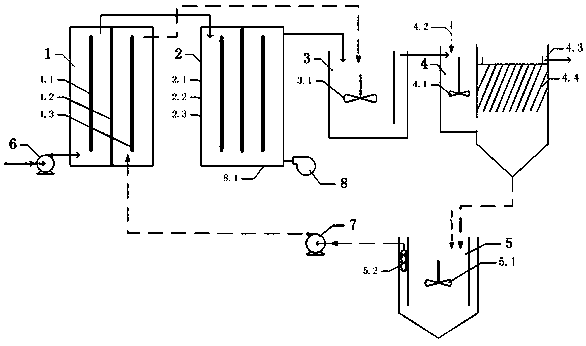

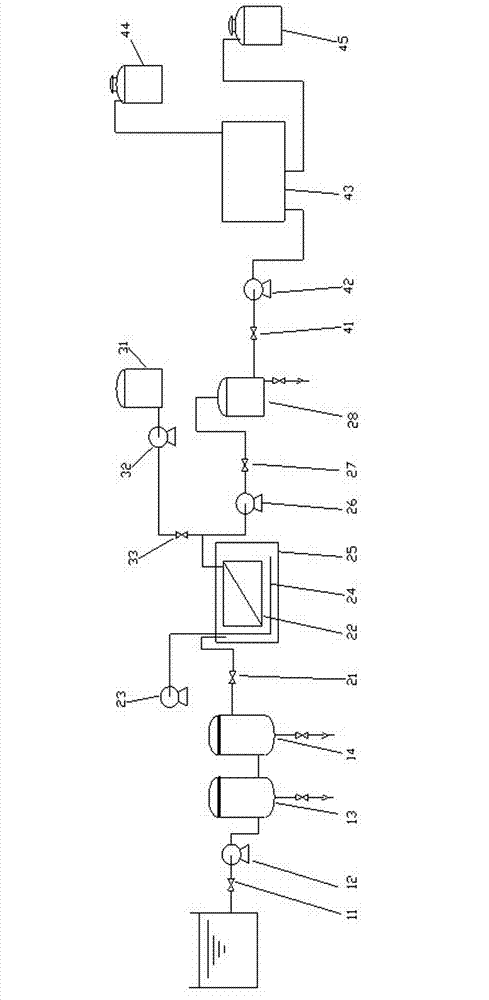

Wastewater treatment device with coupled Electro-Fenton and electrocatalytic oxidation without solid waste generation

ActiveCN105884091AAchieve recyclingOvercome the disadvantages of polluting the environmentWater contaminantsMultistage water/sewage treatmentFenton reactionAcid dissolution

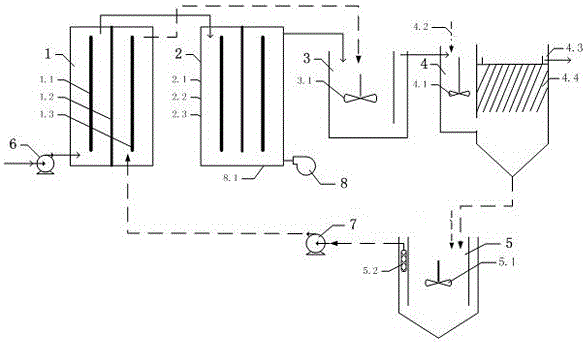

The invention relates to a wastewater treatment device with coupled Electro-Fenton and electrocatalytic oxidation without solid waste generation. The wastewater treatment device comprises a raw water pump, a first diaphragm electrolytic cell, a second diaphragm electrolytic cell, a Fenton reaction tank, a coagulating sedimentation tank and an iron cement dissolving tank which are connected in sequence, wherein the anode chambers of the first diaphragm electrolytic cell and the second diaphragm electrolytic cell are adopted for electrocatalytic oxidation reaction to dissolve organic pollutants; Fe<+3> generated after Fenton reaction is reduced into Fe<+2> in the cathode chamber of the first diaphragm electrolytic cell; H2O2 is generated through electrochemical synthesis in the cathode chamber of the second diaphragm electrolytic cell; the reduced Fe<+2>, the newly generated H2O2 and wastewater are fed into the reaction tank for Fenton reaction; the effluent is subjected to iron cement separation in the coagulating sedimentation tank; treated water is discharged; the sedimentary iron cement is Fe<+3> which is fed into the iron cement dissolving tank; after acid dissolution, the sedimentary iron cement is fed into the cathode chamber of the first diaphragm electrolytic cell and is circulated after electrochemical reduction; and therefore, solid waste production and emission are avoided.

Owner:南京赛佳环保实业有限公司

Method for electrolytically refining crude lead

InactiveCN102534660AImprove direct yieldOvercome the polluted environmentPhotography auxillary processesProcess efficiency improvementIonLead plate

The invention discloses a method for electrolytically refining crude lead. The method comprises the following steps of: adding sodium hydroxide and tartaric acid into water in turn, and stirring to dissolve at normal temperature to obtain a mixed solution; adding lead oxide powder into the mixed solution, dissolving and filtering to obtain filtrate, namely electrolyte; and adding the prepared electrolyte into an electrolytic cell, and switching on direct current for electrolysis by taking a stainless steel plate or a pure lead plate as a cathode and crude lead to be refined as an anode. By the method, smoke and middle slag generated in pyro-refining are avoided, the direct recovery rate of lead and comprehensive recovery rate of valued metals in the refining process are improved, volatile smoke or acid mist cannot be generated, and a defect that electrolyte in a silicofluoric acid system pollutes environment is overcome; meanwhile, the sodium hydroxide and the tartaric acid are added into the electrolyte, so that the sodium hydroxide and the tartaric acid can form a complex with the lead oxide, the concentration of lead ions in the electrolyte is greatly increased and the electrolysis efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

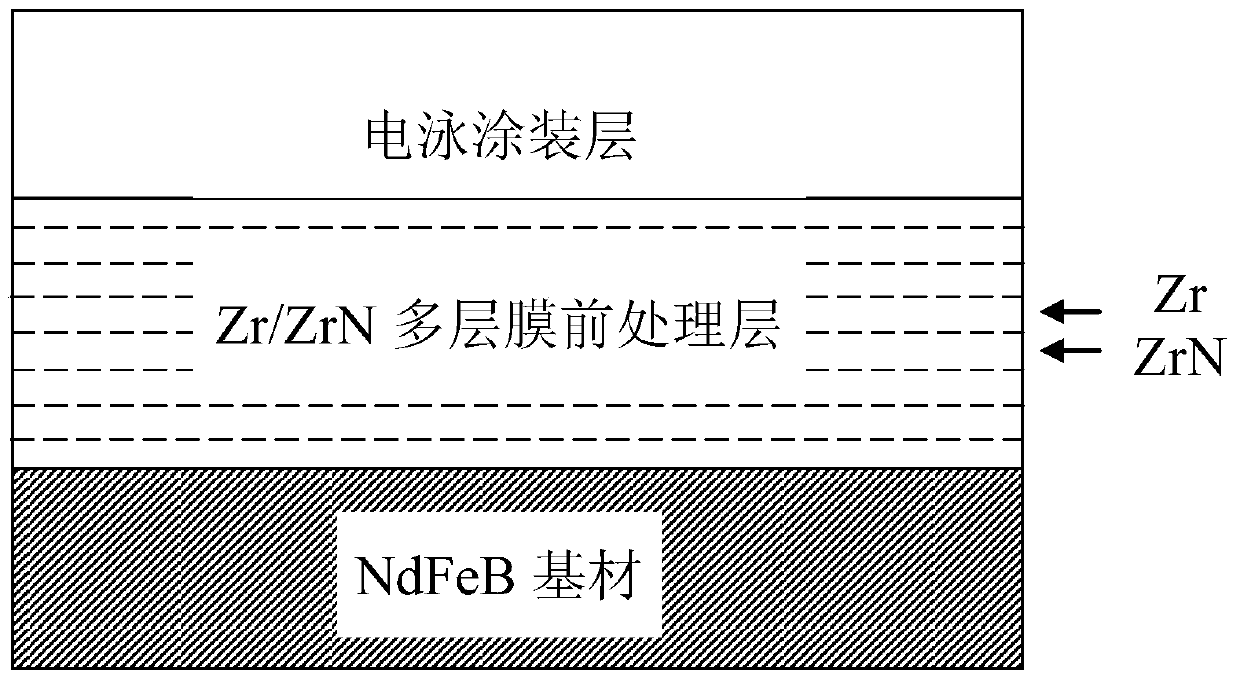

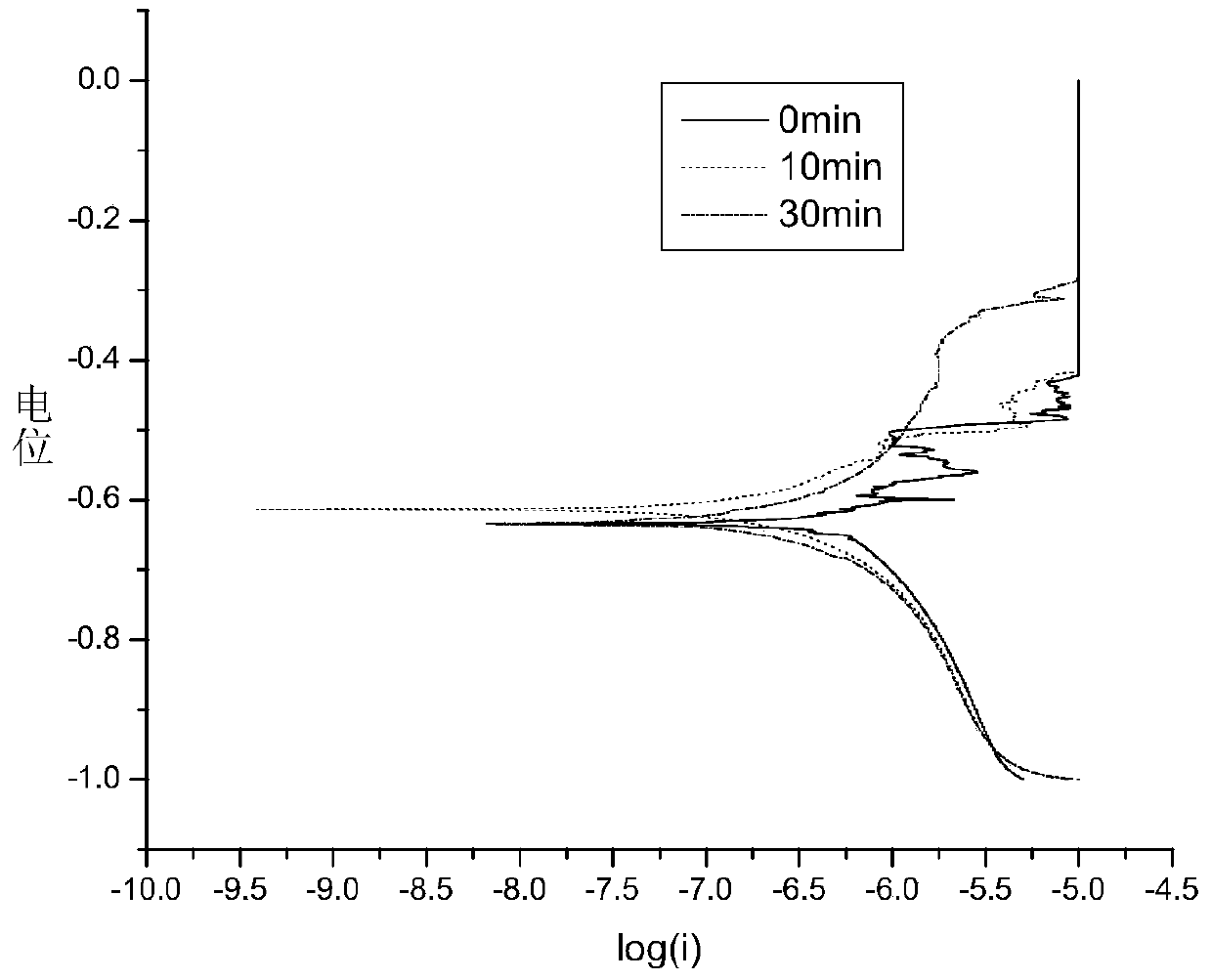

Vapor deposition method used for anticorrosion pretreatment of permanent magnet

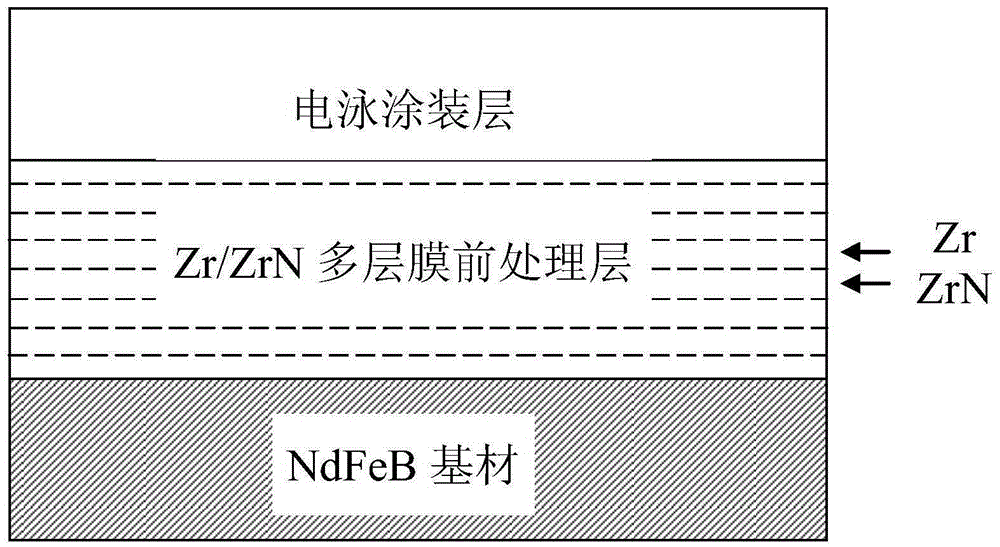

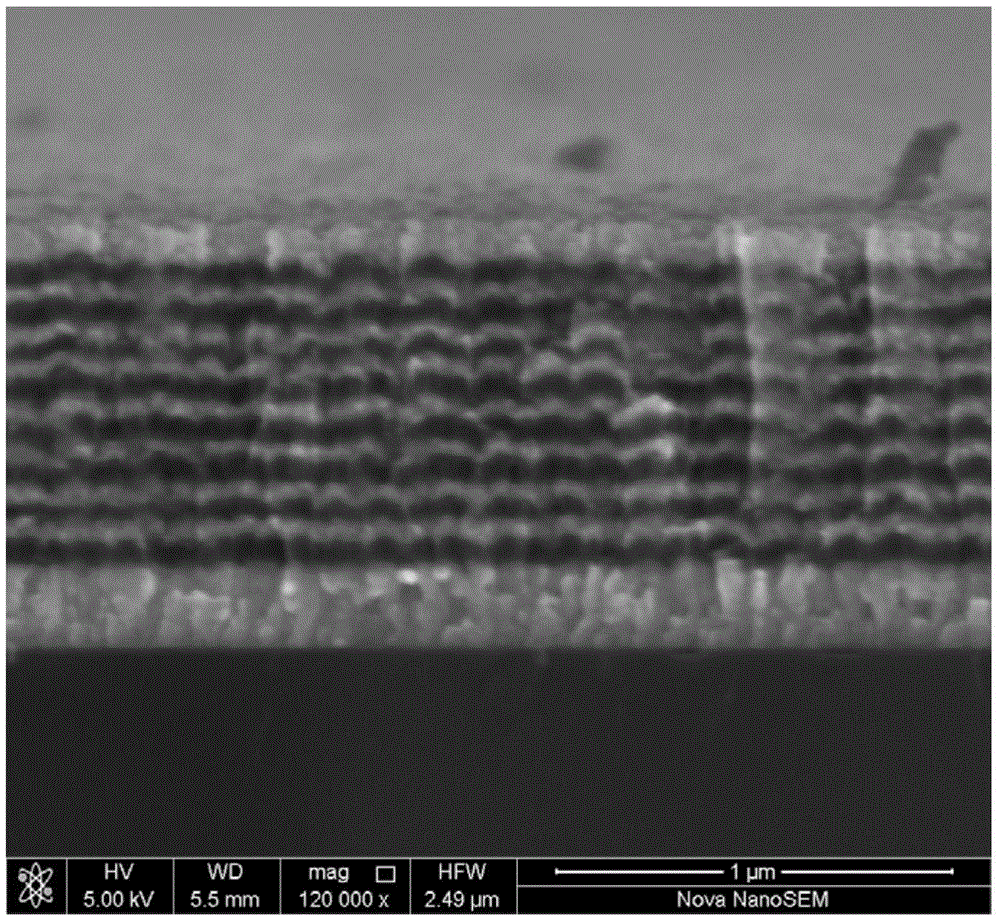

InactiveCN105420669ANo magnetic damageOvercome the disadvantage of magnetic damageVacuum evaporation coatingSputtering coatingGas phaseElectrophoresis

The invention discloses a vapor deposition method used for anticorrosion pretreatment of a permanent magnet, and relates to the field of surface treatment of materials. The physical vapor deposition technology is adopted, and a nano multi-layer structural thin film is deposited on a NdFeB surface; before the nano multi-layer structural thin film is deposited on the NdFeB surface, the NdFeB surface can be passivated; after the nano multi-layer structural thin film is deposited on the NdFeB surface, an electrophoretic method is adopted to carry out coating deposition; and the invention discloses a method for carrying out pretreatment on the magnetic material NdFeB so as to replace phosphorization; and through the technology, the NdFeB magnetic performance damage caused by a phosphorization technology can be overcome. The method is green, free of pollution and wide in application prospect, and technological parameters are easy to control; combination performance of a transition metal / nitride composite coating prepared through the method and the NdFeB permanent magnet is excellent, the method is matched with the electrophoresis or plating process, and the anticorrosion performance of the NdFeB permanent magnet can be obviously improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Novel halogen-free environment-friendly type flame-proof polypropylene material

ActiveCN101161775AOvercome the disadvantages of polluting the environmentSignificant progressFireproof paintsAntioxidantCooling down

The invention relates to a novel halogen-free environmental friendly fire retarding polypropylene material which comprises the following components (percentage by weight): 40 to 70 percent of polypropylene granules, 25 to 38 percent of halogen-free intumescent fire retardant, 0.5 to 1.5 percent of lubricant, 0.1 to 0.5 percent of antioxidant, 0.5 to 1.5 percent of coupling agent and filler surplus. The polypropylene material is made by the following method: polypropylene granules and other components are evenly mixed inside a high-speed mixer according to certain proportion and then are extruded by a twin screw extruder, cooled down and granulated under the conditions of routine feeding speed, temperature and screw stem rotary speed. With ideal flame retardant property and mechanical property, the polypropylene material is characterized by low smoke, low toxicity and no melt drip as compared with fire-retarding polypropylene, thereby reducing environmental pollution and doing less harm to human body.

Owner:浙江省化工产品质量检验站有限公司 +1

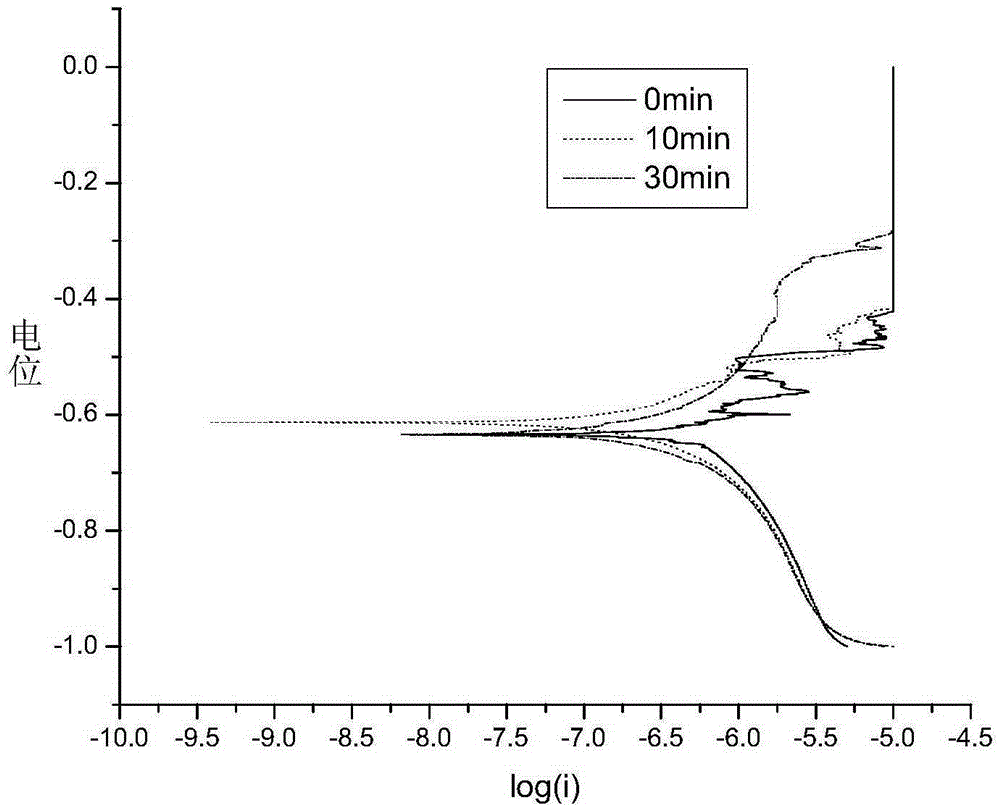

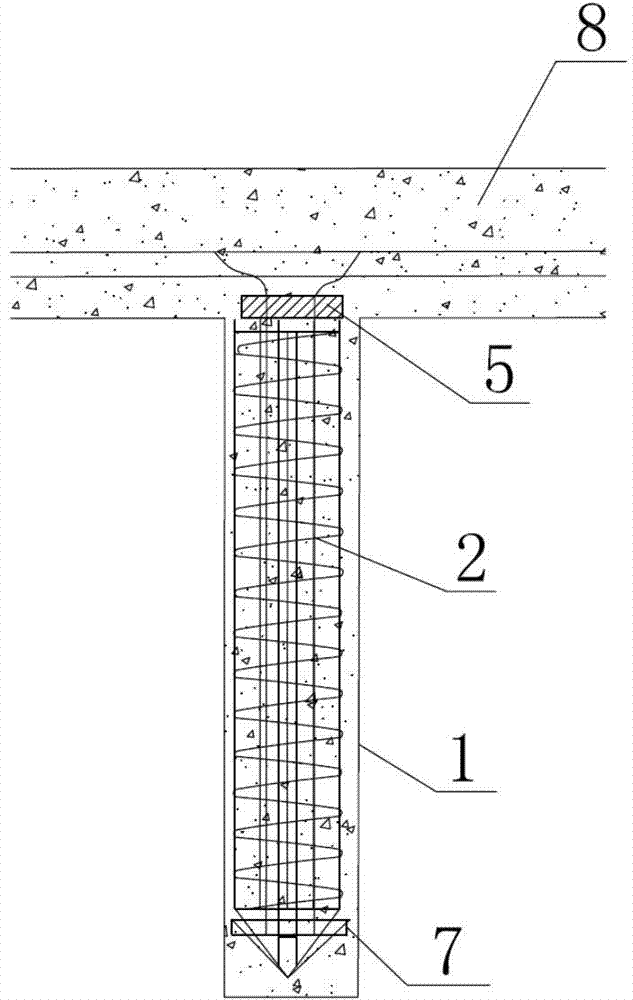

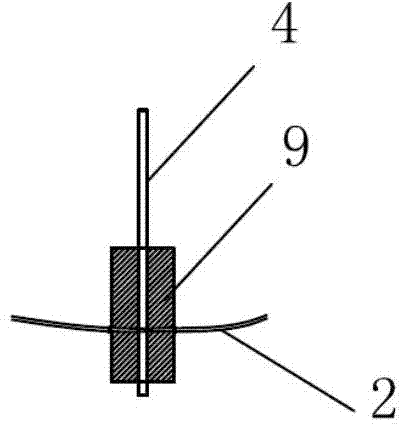

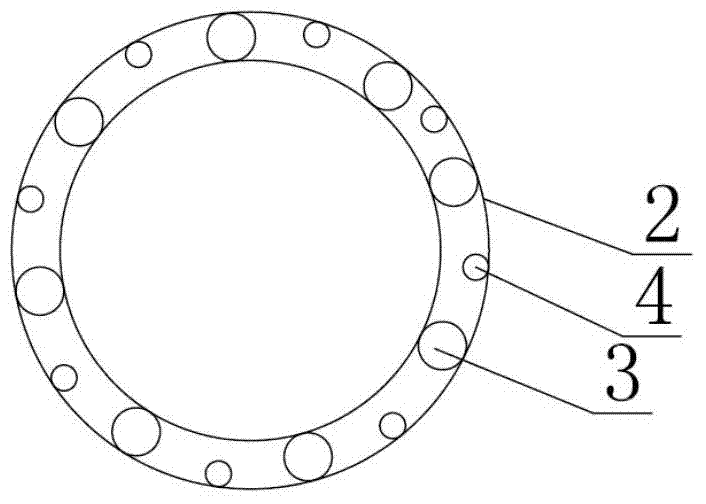

Original-state soil borrowing press-grouting concrete pile exerted by prestress and construction method thereof

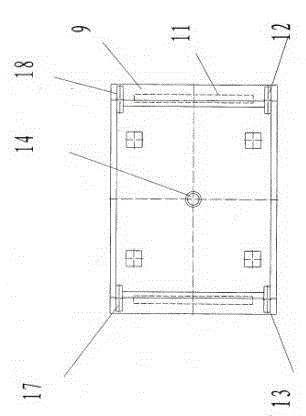

ActiveCN103882859AOvercome the disadvantages of polluting the environmentAvoid crackingBulkheads/pilesReinforced concretePre stress

The invention provides an original-state soil borrowing press-grouting concrete pile exerted by prestress. A steel reinforcement cage is internally arranged, so that the requirement for construction of reinforced concrete is met, prepressing ribs are arranged in the steel reinforcement cage, and prestress is exerted. Due to the fact that the original-state soil borrowing pile forming technology is adopted in a pile body, no slurry is discharged, the pile body is compact, and cracks can not be generated after prestress is exerted on the concrete pile body; the steel use amount is saved and the building cost of projects is reduced.

Owner:SHANGHAI STRONG FOUND ENG

Papermaking wastewater recycling device and method based on electrochemical and electrodialysis technology

InactiveCN102295373AOvercoming Filtration Separation ProcessingOvercome the disadvantages of polluting the environmentGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

Provided is an electrochemistry and electrodialysis-based apparatus for recycling wastewater from papermaking. The recycling apparatus is provided with a nano-catalytic electrolysis system, a submerged ultrafiltration separation system, an ultrafiltration membrane cleaning system, and an electrodialysis system. Also provided is a method using the apparatus for recycling the wastewater from papermaking, comprising the following steps: extracting the wastewater from papermaking and introducing same into the nano-catalytic electrolysis system; flowing the wastewater from papermaking that is purified after processing into the submerged ultrafiltration separation system to acquire dialyzed water; then feeding the dialyzed water into the electrodialysis system for desalination by electrodialysis; and acquiring desalinated water and concentrated water.

Owner:BOYING XIAMEN SCI & TECH

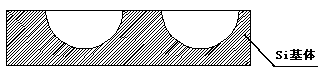

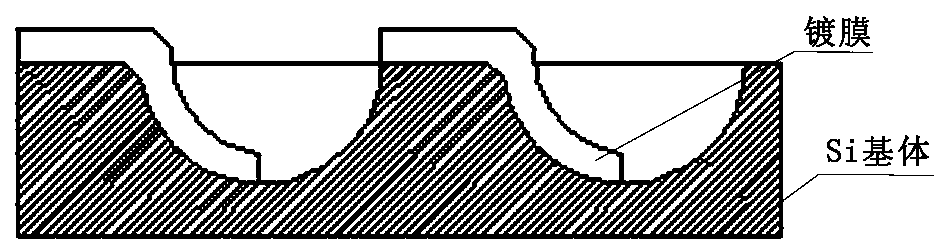

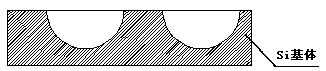

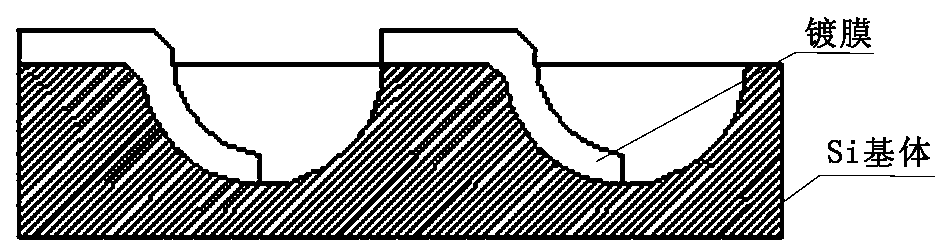

Preparation method of micro-nano suspension beam arm-structured elastic contactor

ActiveCN107565252ASimple preparation processNo pollutionTelevision system detailsContact member manufacturingMicro nanoSpherical shaped

The invention discloses a preparation method of a micro-nano suspension beam arm-structured elastic contactor. The preparation method specifically comprises the following steps of (1) photoetching: adopting a photoetching process to transfer a mask pattern to a Si substrate; (2) etching: etching a semispherical silicon groove in the Si substrate by an etching machine; (3) film coating: forming a hollow-out coated film in the semispherical silicon groove, wherein the film coating material is copper alloy; (4) brazing: brazing the hollow-out coated film on the other material substrate; and (5) removal of the Si substrate: removing the Si substrate by adopting a physical method or a chemical method to obtain the elastic contactor. The preparation method of the elastic sheet or the elastic contactor provided by the invention is simple in process, and adopts dry etching and film coating, so that environment pollution can be almost avoided, and the shortcoming of environment pollution causedby an electroplating process or a chemical corrosion process can be overcome; and in addition, by virtue of the preparation method, high processing efficiency is achieved, and dimensions and processing precision can be ensured.

Owner:河南明华智能系统研究院有限公司

A vapor deposition method for permanent magnet anti-corrosion pretreatment

InactiveCN105420669BNo magnetic damageOvercome the disadvantage of magnetic damageVacuum evaporation coatingSputtering coatingNano structuringGas phase

A vapor deposition method used for pre-treatment of permanent magnet anticorrosion relates to the field of surface treatment of materials. The invention adopts physical vapor deposition technology to deposit a nanometer multi-layer structure film on the surface of NdFeB. Before this step, the NdFeB surface can be passivated, and after this step, an electrophoretic method can be used to deposit a coating. The invention discloses a method for pre-treating magnetic material NdFeB by adopting gas phase deposition technology to replace phosphating. This technology can overcome the NdFeB magnetic performance damage caused by the phosphating process. The method is green and pollution-free, the process parameters are easy to control, and has broad application prospects. The transition group metal / nitride composite coating prepared by the method has excellent bonding performance with the NdFeB permanent magnet, and can significantly improve the corrosion resistance of the NdFeB permanent magnet when matched with an electrophoresis or electroplating process.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

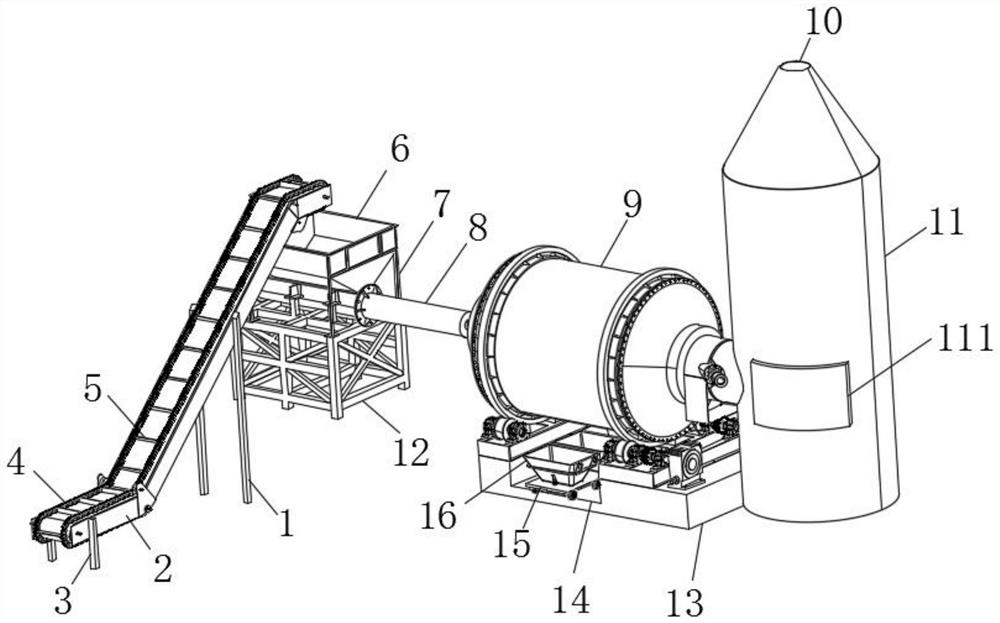

Crude lead refining process for lead-acid battery recovery

ActiveCN111996549AAchieve rotationImprove running stabilityPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentElectrical battery

The invention discloses a crude lead refining process for lead-acid battery recovery. The crude lead refining process comprises the following steps: stirring and dissolving at normal temperature to prepare a mixed solution, adding lead oxide powder and an additive into the mixed solution, stirring and dissolving at the temperature of 80-100 DEG C and the stirring speed of 800-1000r / min for 5-7 hours, and filtering to obtain an electrolyte; carrying out fire refining on crude lead through a refining device, and respectively casting the crude lead subjected to fire refining and electrodepositedrefined lead in a molten state into a crude lead anode and an electrodeposited lead cathode; and adding the prepared electrolyte into an electrolytic cell, introducing direct current for electrolysis,melting and casting the electrolytic lead obtained by cathode electrodeposition to obtain a pure lead ingot, washing and filter-pressing anode mud, and then sending the anode mud to a noble metal extraction process for treatment. The crude lead refining process disclosed by the invention improves the direct recovery rate of lead in the refining process and the comprehensive recovery rate of various valuable metals, and the electrolytic lead is higher in purity and lower in production cost.

Owner:太和县大华能源科技有限公司

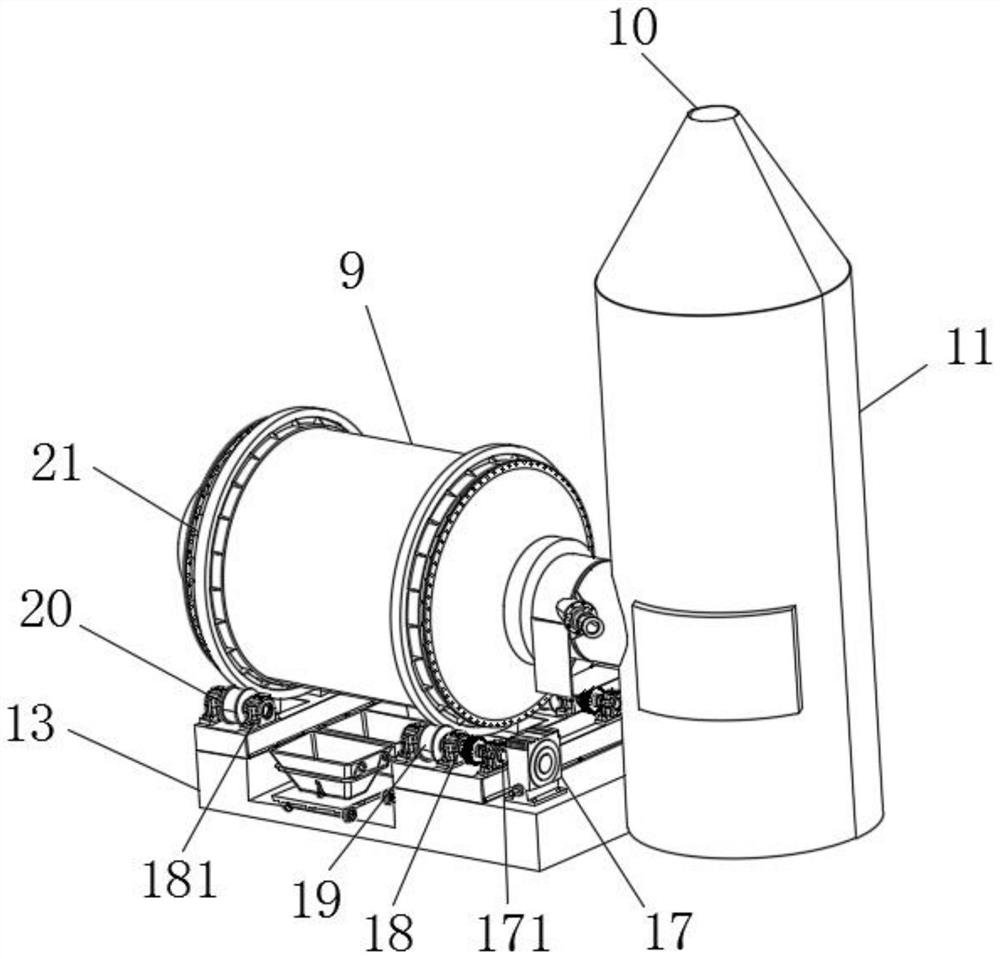

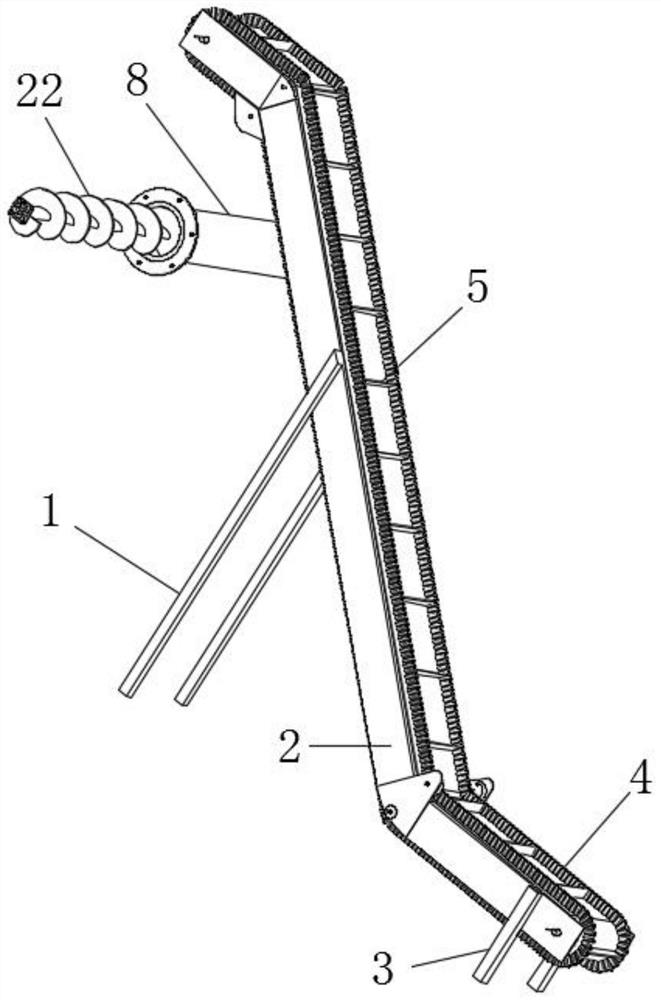

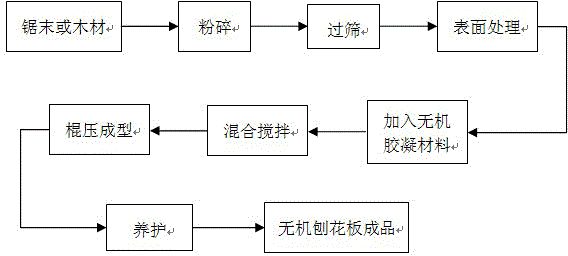

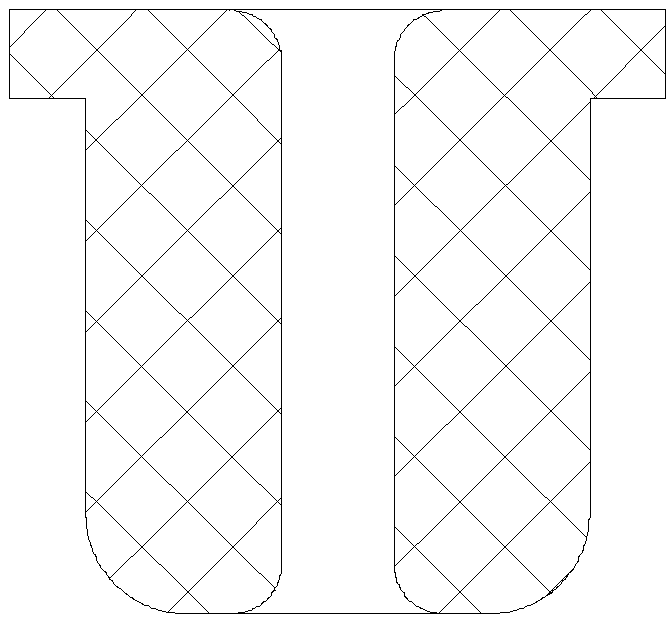

Novel shaving board and production technology thereof

The invention discloses a novel shaving board and a production technology of the novel shaving board. The novel shaving board is composed of saw powder or poor wood such as remaining edges, skin and ends formed by wood machining and inorganic bond materials,. The density of a product is controllable within the range of 0.6g / cm<3> to 1.2g / cm<3>. The production technology comprises the steps that the saw powder or the wood materials are smashed, and then are sieved, so that wooden particles with a certain mesh number can be selected; the sieved-out particles are conveyed to surface modification equipment, and therefore surface modification treatment can be carried out on the particles, and then the particles are manufactured into hydrophobic particles, and the inorganic bond materials and water are added into the hydrophobic particles to be mixed and stirred; stirred mixing materials are conveyed to a rolling machine to be rolled and formed; and finally the formed shaving board is conveyed to a curing chamber to be cured for a certain time, and a finished product is obtained. The shaving board has the advantages of being simple in production technology, rich in raw material source, low in production cost, high in product strength, free of formaldehyde, and resistant to flame; the utilization rate of the wood is greatly improved; and obvious social benefits and economic benefits are achieved.

Owner:NINGBO TIANJIN NEW MATERIAL

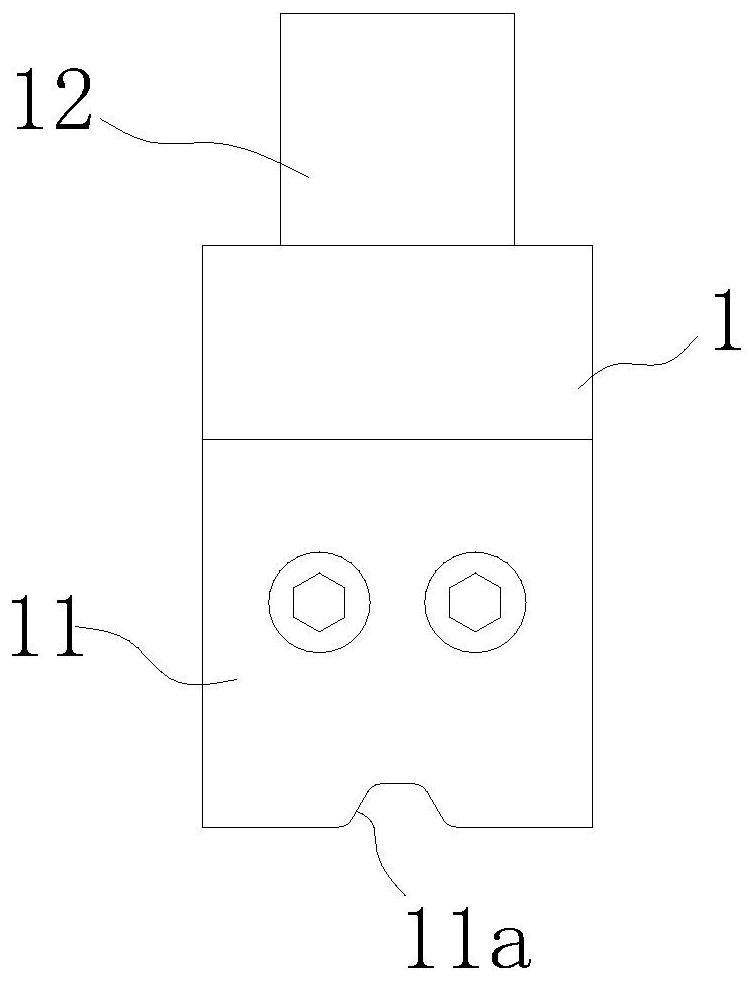

Processing technology for electric heating tube

ActiveCN109379791ASkip the shrink tubeSave the digging processHeating element shapesEngineeringSpot welding

The invention relates to a processing technology for an electric heating tube. The processing technology includes the following steps: step 1. processing a heating wire, namely a step of mounting theheating wire on a lead rod and performing spot welding; step 2. filling powder, namely a step of changing a rubber plug structure used in a powder filling process, and increasing the creepage distancebetween a rubber plug upper lead rod and a tube nozzle, making the heating wire penetrate into a hollow tube by utilizing a powder filling machine, and filling dense magnesium oxide powder between the heating wire and the hollow tube; step 3. performing riveted joint, namely a step of riveting a tube nozzle rubber plug and the electric heating tube into a hexagon, and tightly connecting the rubber plug and the electric heating tube; step 4. stretching, riveting the pipe nozzle rubber plug and the electric heating tube into the hexagon by utilizing a riveting die to make the rubber plug and the electric heating tube tightly connected; step 5. cutting the rod, namely a step of cutting the lead rod into the rod with the consistent exposed length; and step 6. bending the tube, namely a step of bending the electric heating tube into the tube with a specified shape by utilizing a pipe bender and to meet dimensional requirements of a drawing. The processing technology for the electric heating tube overcomes the shortcomings of wasting materials and polluting environment by dust caused by a traditional process, and has the advantages of simplifying process steps and improving the processing efficiency.

Owner:安徽苏立科技股份有限公司

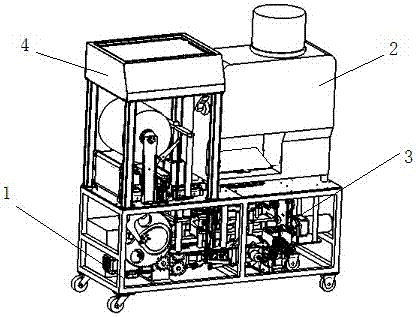

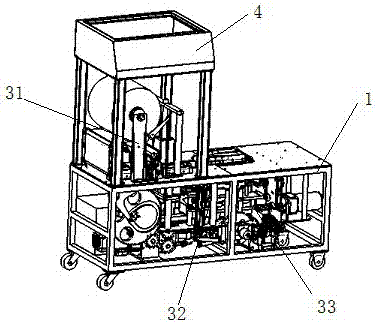

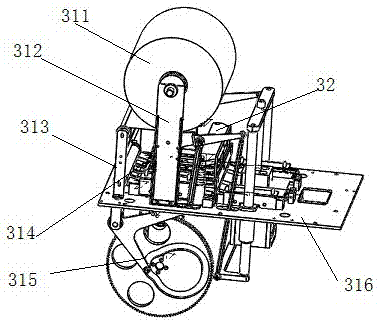

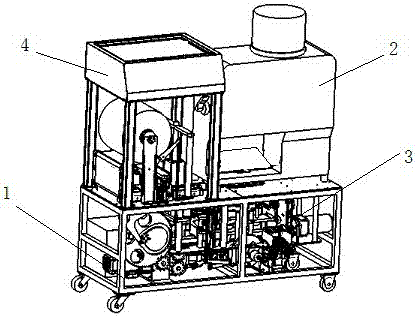

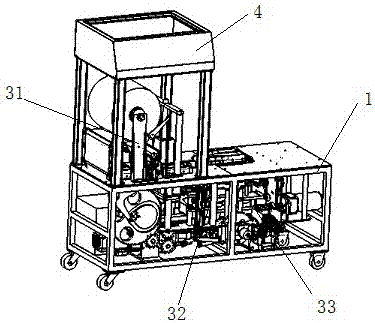

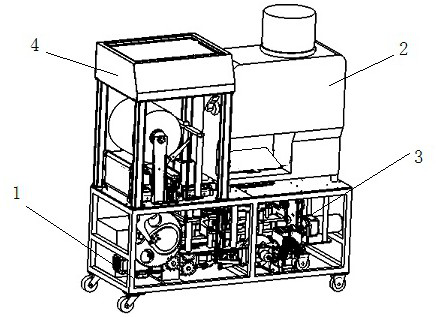

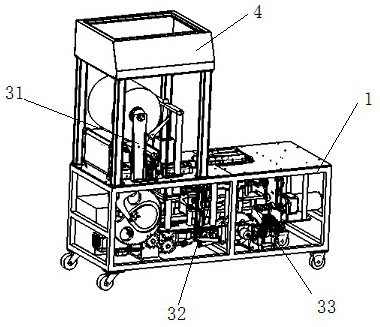

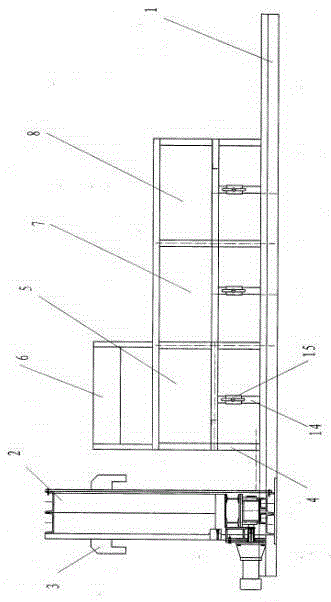

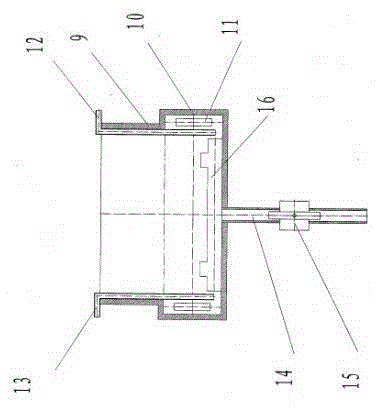

Machine for making and selling automatically-packaged fresh noodles

ActiveCN107027843ARealize automatic on-site production and salesOvercome the disadvantages of polluting the environmentMixing/kneading structural elementsWrapping material feeding apparatusControl systemPulp and paper industry

The invention relates to a small-scale machine for making and selling automatically-packaged fresh noodles, and belongs to the field of commercial equipment. The machine comprises a machine frame, a noodle making machine, a paper packaging machine and a control system, wherein the machine frame consists of a plurality of members; the noodle making machine is mounted on the machine frame; a noodle conveying device is mounted under a noodle cutting device; the paper packaging machine is mounted on the machine frame; and the control system is mounted on the machine frame and comprises a control box, a controller, a displayer, a paying system and an information acquisition system. The small-scale machine disclosed by the invention has the characteristics that fresh noodles can be automatically made and sold on site, paper package of the fresh noodles is realized, and the defects that conventional fresh noodle making and selling machine cannot realize automatic package, the package provided by the conventional fresh noodle making and selling machine cannot be matched with sold noodles and plastic bag packages pollute environment are overcome.

Owner:HENAN WANJIE INTELLIGENT TECH

Method for electrolytically refining crude lead

InactiveCN102534660BImprove direct yieldHigh recovery ratePhotography auxillary processesProcess efficiency improvementSlagCoordination complex

The invention discloses a method for electrolytically refining crude lead. The method comprises the following steps of: adding sodium hydroxide and tartaric acid into water in turn, and stirring to dissolve at normal temperature to obtain a mixed solution; adding lead oxide powder into the mixed solution, dissolving and filtering to obtain filtrate, namely electrolyte; and adding the prepared electrolyte into an electrolytic cell, and switching on direct current for electrolysis by taking a stainless steel plate or a pure lead plate as a cathode and crude lead to be refined as an anode. By the method, smoke and middle slag generated in pyro-refining are avoided, the direct recovery rate of lead and comprehensive recovery rate of valued metals in the refining process are improved, volatile smoke or acid mist cannot be generated, and a defect that electrolyte in a silicofluoric acid system pollutes environment is overcome; meanwhile, the sodium hydroxide and the tartaric acid are added into the electrolyte, so that the sodium hydroxide and the tartaric acid can form a complex with the lead oxide, the concentration of lead ions in the electrolyte is greatly increased and the electrolysis efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

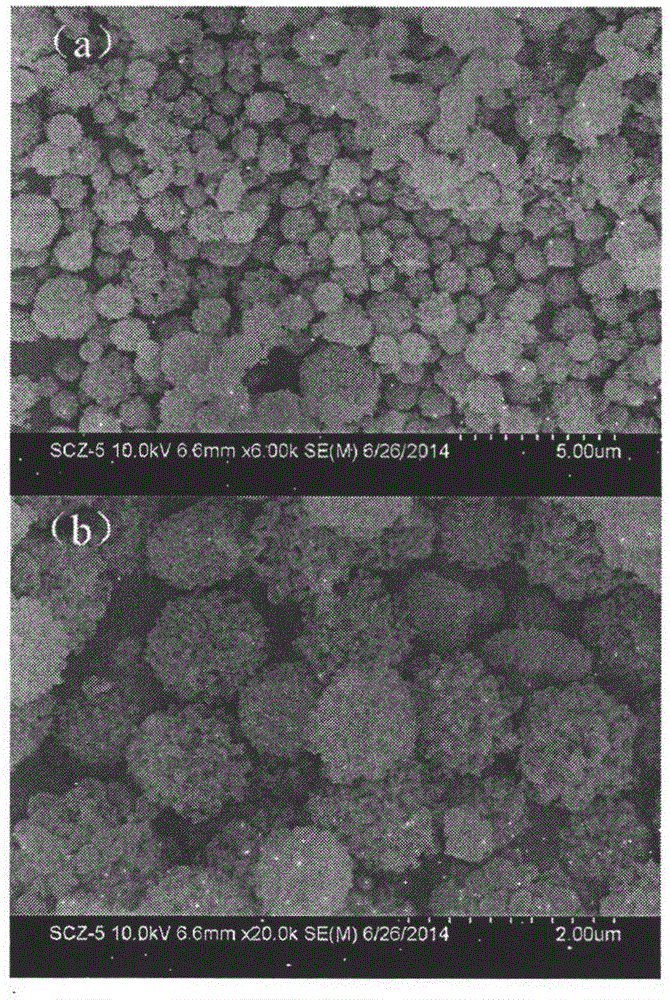

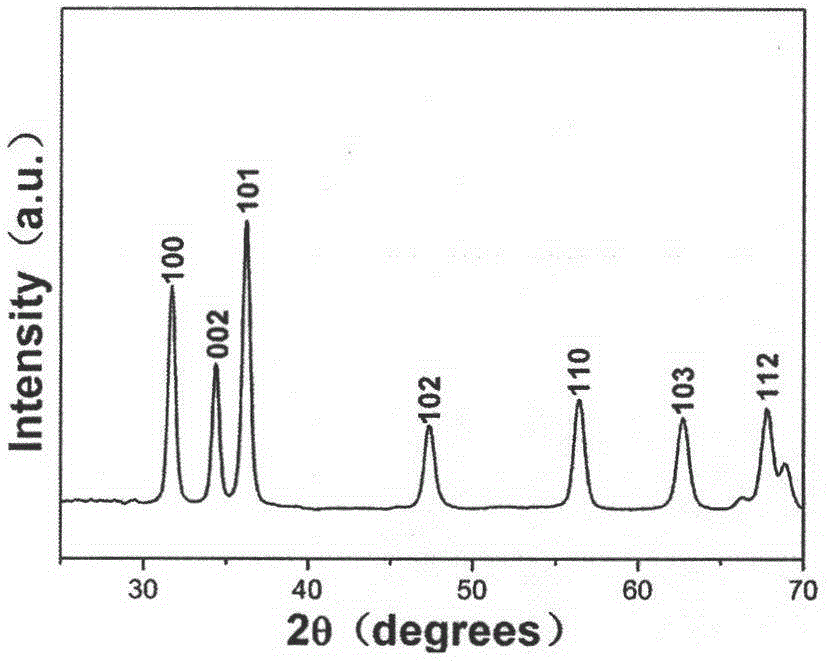

Preparation method of porous pompon-like zinc oxide material

InactiveCN105883899ALow costOvercome the polluted environmentMaterial nanotechnologyZinc oxides/hydroxidesPhotocatalytic degradationSolvent

The invention discloses a preparation method of a porous pompon-like zinc oxide material. The method comprises the following steps: zinc salt, acrylic acid and glucose or cane sugar which are used as a raw material undergoes a hydrothermal reaction by using distilled water as a solvent in a teflon autoclave at 160-180 DEG C for 6-12 h, so as to generate a zinc oxide microsphere precursor; and the precursor undergoes heat treatment in a muffle furnace at 500 DEG C for 5 h to obtain the porous pompon-like zinc oxide microspheres with diameter being 1-5 microns. The raw materials such as zinc salt, acrylic acid, glucose or cane sugar, etc. are cheap and easily-available and are low-cost. In addition, a surfactant organic additive is not used. Thus, environmental pollution is reduced. The prepared porous pompon-like zinc oxide material has large specific surface area, and has a broad application prospect in the fields of photocatalytic degradation of dyes, sensors, sewage adsorption, antibacterial materials, energy storage, lithium battery and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Slow release, long-acting urea manure and technique of manufacturing the same

InactiveCN101108781BFully functionExtend the fertilizer periodAgriculture gas emission reductionUrea compound fertilisersOrganic solventFluidized bed

The invention relates to the nitrogen manure, in particular to the slow-release and long-effect urea fertilizer coating a layer of biochemical inhibitor on the urea surface and the preparation process. The fertilizer components are the urea, the biochemical inhibitor, the bond and the organic solvent. The process is that: the levitated solution mixed with the biochemical inhibitor, the bond and the organic solvent is sprayed and coated on the surface of the molding urea granule under the fluidized state through a fluidized bed to gain the slow-release urea fertilizer. The fertilizer of the invention makes full play of the functions and effects of two biochemical inhibitors, makes the fertilizer effect period prolonged obviously and realizes that once basal nitrogen fertilizer application can meet the requirement of whole growing seasons on the nitrogen. The agricultural production saves labor and time with low production cost and friendly environment. For the secondary processing of the urea, the preparation process of the invention has simple operation and easy realization and can carry out industrial production on a large scale.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

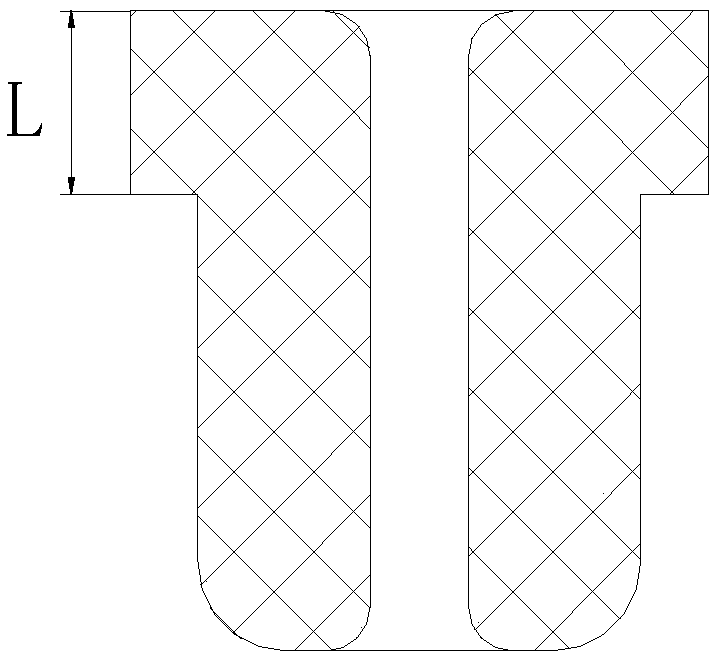

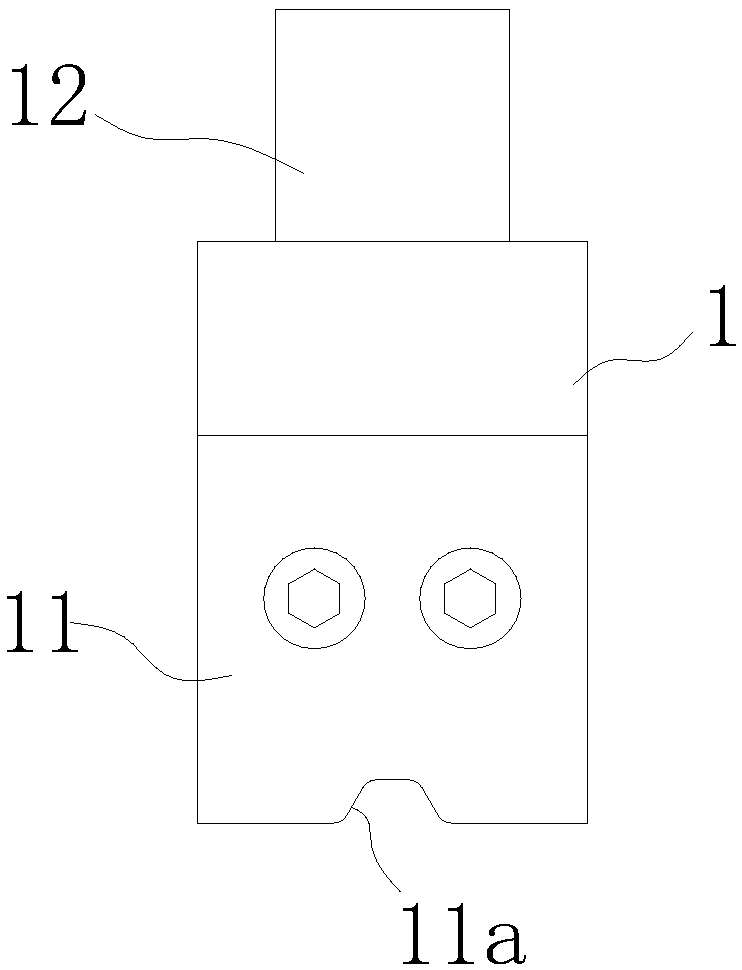

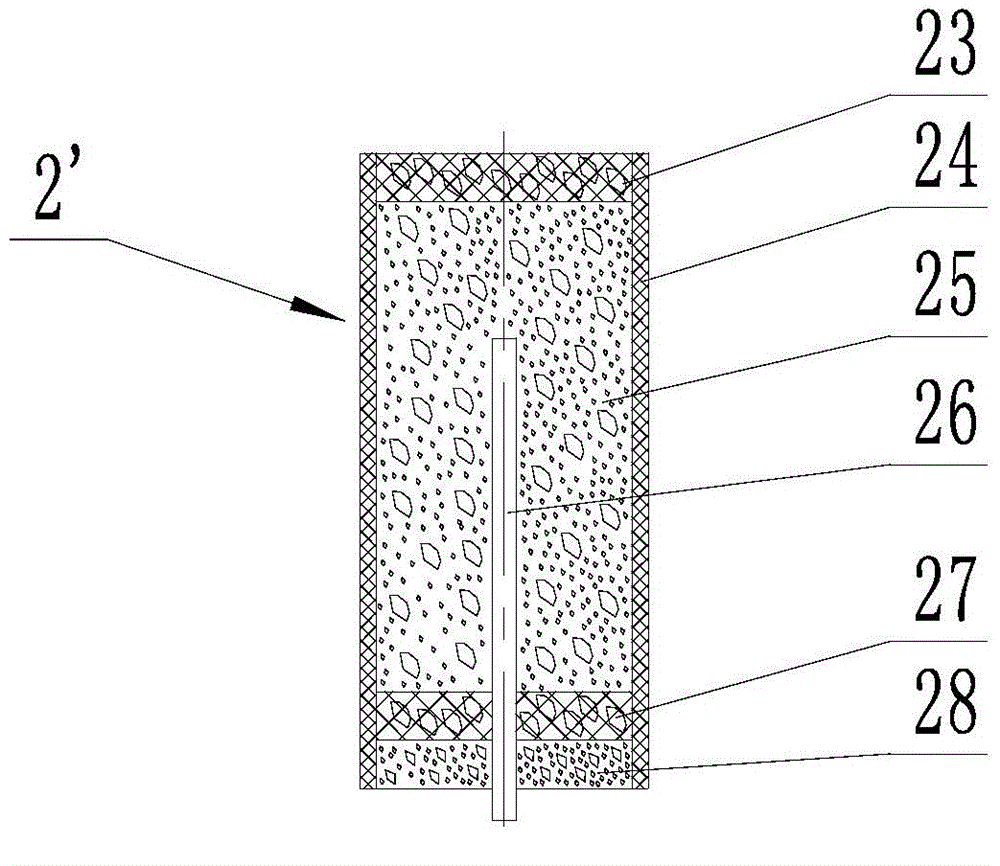

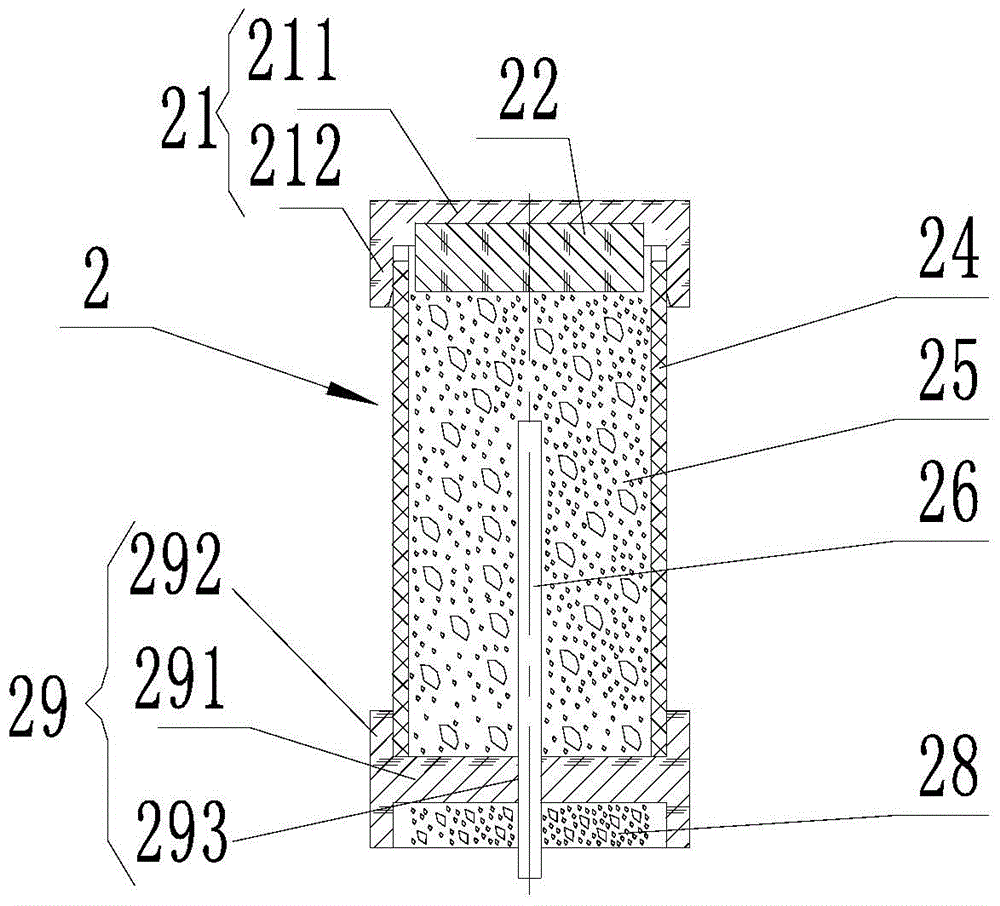

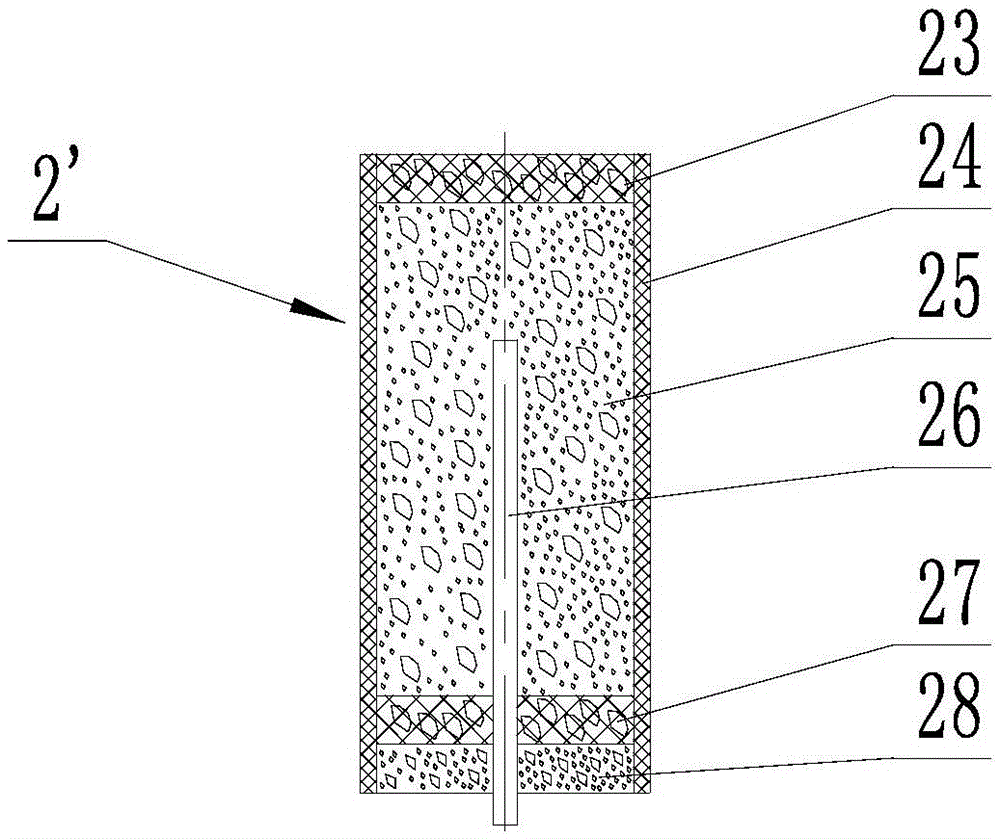

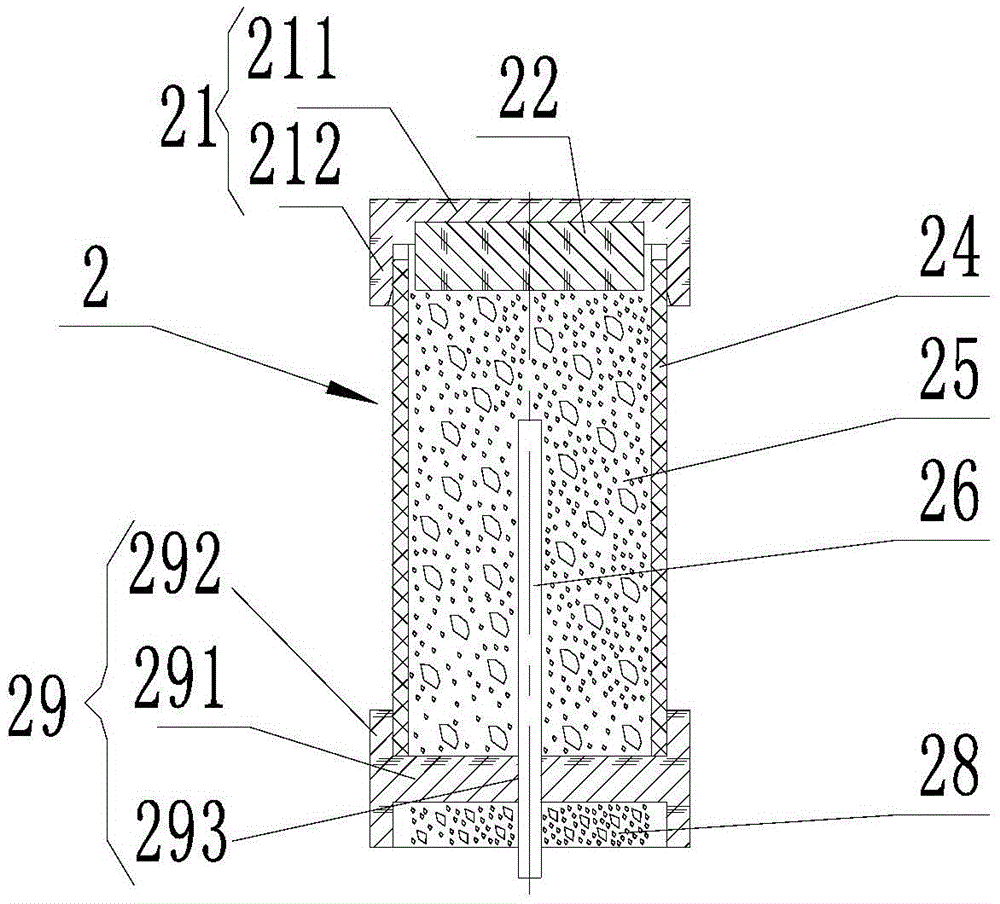

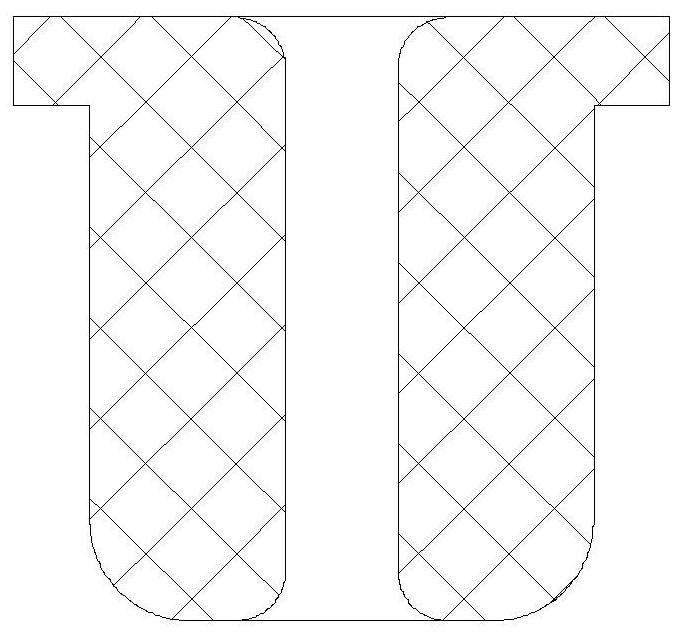

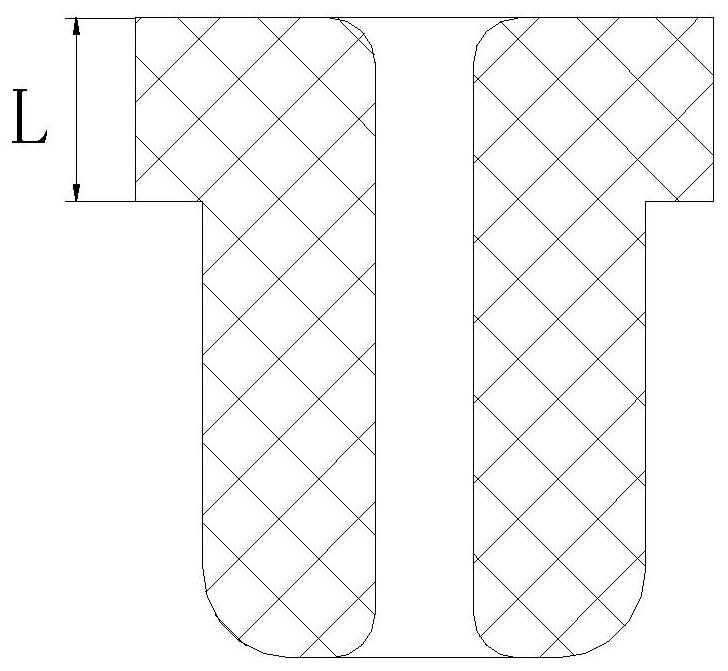

Inner fireworks barrel and fireworks with same

The invention discloses an inner fireworks barrel and fireworks with the inner fireworks barrel. The inner fireworks barrel comprises a cylindrical barrel body for storing an explosive mixture; a top cover is arranged at the upper end of the barrel body, and while a base is arranged at the lower end of the barrel body; the top cover comprises a cover body, and a first annular sidewall which is axially stretched along the outer round surface of the cover body; the inner wall surface of the first annular sidewall is in connection fitting with the outer round surface of the upper part of the barrel body; the base comprises a base body, and a second annular sidewall which is axially stretched along the outer round surface of the base body; the inner wall surface of the second annular sidewall is in connection fitting with the outer round surface of the lower part of the barrel body; a line guide hole is formed in the base body. According to the inner fireworks barrel, the processing technique is simplified; in addition, the top cover and the base can be conveniently produced by mass, and therefore, the cost is reduced, and the processing efficiency is increased; meanwhile, the structure that the inner wall surface of the annular sidewall is in connection fitting with the upper outer round surface and the lower outer round surface of the barrel body is adopted to reliably ensure the connection reliability of the top cover, the base and the barrel body.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

A wastewater treatment device coupled with electro-Fenton and electrocatalytic oxidation without solid waste generation

ActiveCN105884091BAchieve recyclingOvercome the disadvantages of polluting the environmentWater contaminantsMultistage water/sewage treatmentFenton reactionElectricity

The invention relates to a wastewater treatment device with coupled Electro-Fenton and electrocatalytic oxidation without solid waste generation. The wastewater treatment device comprises a raw water pump, a first diaphragm electrolytic cell, a second diaphragm electrolytic cell, a Fenton reaction tank, a coagulating sedimentation tank and an iron cement dissolving tank which are connected in sequence, wherein the anode chambers of the first diaphragm electrolytic cell and the second diaphragm electrolytic cell are adopted for electrocatalytic oxidation reaction to dissolve organic pollutants; Fe<+3> generated after Fenton reaction is reduced into Fe<+2> in the cathode chamber of the first diaphragm electrolytic cell; H2O2 is generated through electrochemical synthesis in the cathode chamber of the second diaphragm electrolytic cell; the reduced Fe<+2>, the newly generated H2O2 and wastewater are fed into the reaction tank for Fenton reaction; the effluent is subjected to iron cement separation in the coagulating sedimentation tank; treated water is discharged; the sedimentary iron cement is Fe<+3> which is fed into the iron cement dissolving tank; after acid dissolution, the sedimentary iron cement is fed into the cathode chamber of the first diaphragm electrolytic cell and is circulated after electrochemical reduction; and therefore, solid waste production and emission are avoided.

Owner:南京赛佳环保实业有限公司

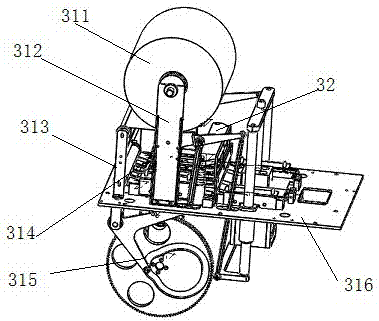

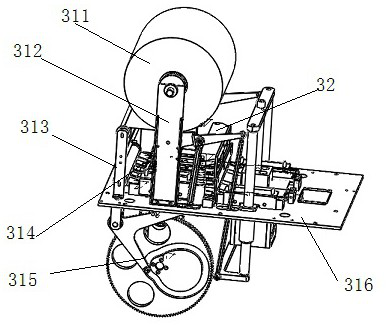

Paper packaging machine

PendingCN107336869AOvercoming the inability to automatically wrapRealize automatic on-site production and salesWrapping material feeding apparatusDough shaping and cutting apparatusProcess engineeringPlastic bag

The invention provides a paper packaging machine and belongs to the field of commercial equipment. The paper packaging machine comprises a roll paper feed device, a paperboard forming device and a packaging and output device. The roll paper feed device is mounted on a rack, located above the paperboard forming device and connected with the paperboard forming device. The paperboard forming device is mounted on the rack and located below the roll paper feed device. A paper inlet of the paperboard forming device is connected with a paper outlet of the roll paper feed device. A paperboard feed-out mechanism of the paperboard forming device is connected with the packaging and output device. The packaging and output device is mounted on the rack and located behind the paperboard forming device. A noodle inlet of the packaging and output device corresponds to an outlet of a noodle conveying device of a noodle maker. Power parts of all functional units of the paper packaging machine are connected with a control system. The paper packaging machine has the characteristics that automatic on-site making and selling of fresh noodles can be realized; paper packaging is realized; and the defects that an existing fresh noodle making and selling machine cannot conduct automatic packaging, packages cannot be matched with sold noodles, and plastic bag packages pollute the environment are overcome.

Owner:HENAN WANJIE INTELLIGENT TECH

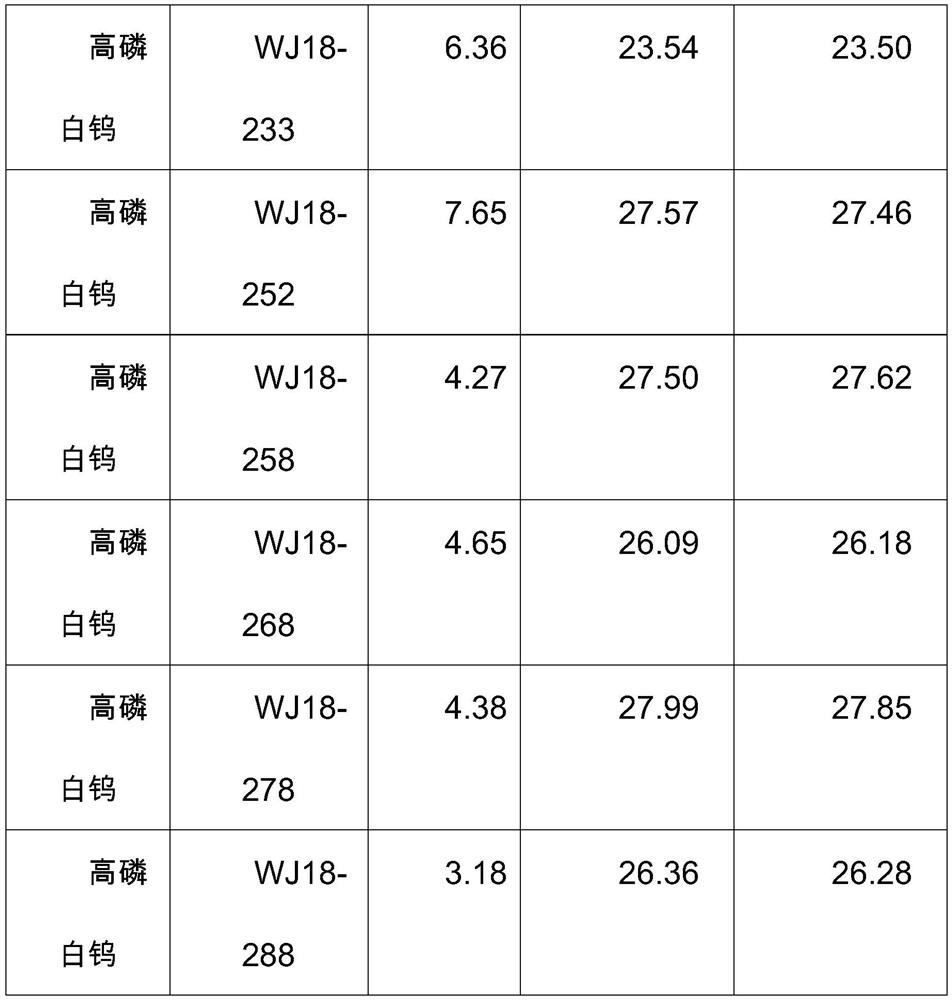

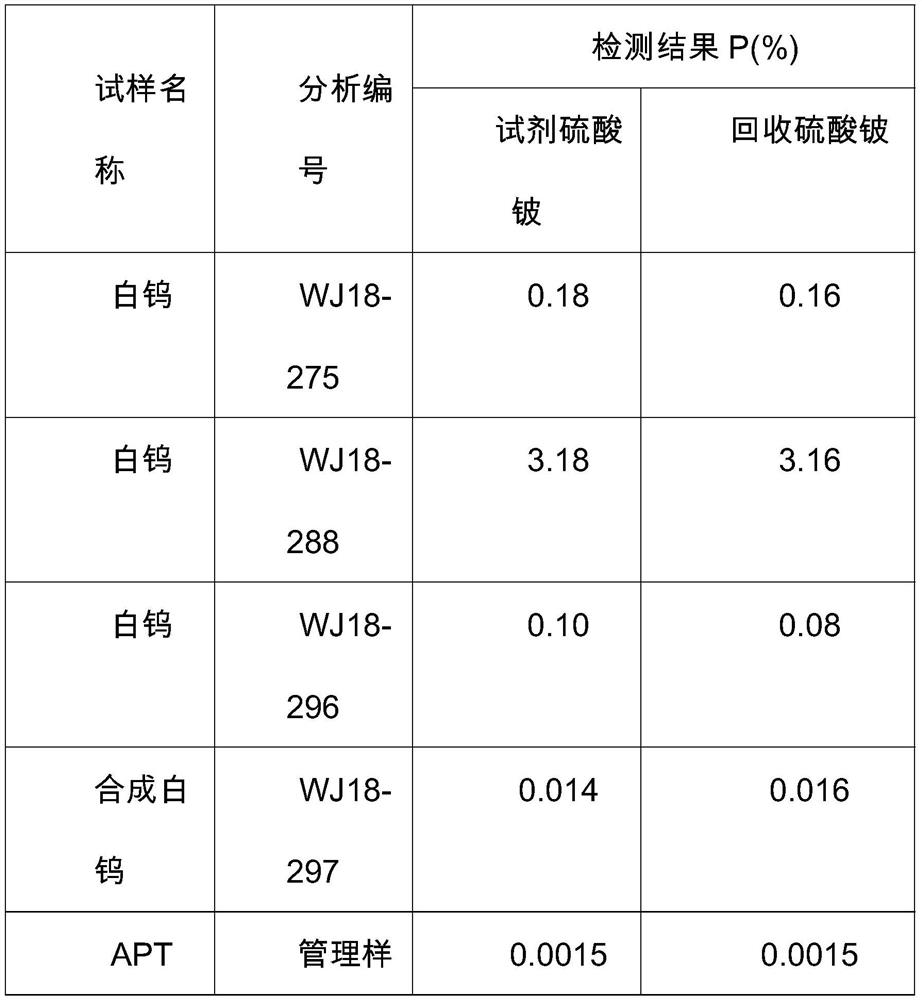

A kind of recycling method of beryllium in beryllium waste liquid measured by beryllium loading method

ActiveCN109319973BOvercome the disadvantages of polluting the environmentReduce pollutionTreatment involving filtrationMultistage water/sewage treatmentBüchner funnelBeryllium hydroxide

The invention discloses a method for recovering and reusing beryllium in the waste liquid of P measured by the beryllium loading method. The method comprises the following steps: placing the waste liquid containing beryllium after measuring P by the beryllium loading method in a 3000mL beaker, heating and concentrating on an electric furnace Volume, neutralized with alkali, then add ammonia water until beryllium hydroxide precipitates completely; filter with Buchner funnel, wash the precipitate with ammonia water-ammonium nitrate solution or ammonia water-ammonium sulfate solution for 10 times, transfer the precipitate into a beaker, add nitric acid or sulfuric acid Dissolve the precipitate; add ammonia water until the beryllium hydroxide precipitates completely, filter again with a Buchner funnel, wash the precipitate with ammonia water-ammonium nitrate solution or ammonia water-ammonium sulfate solution 10 times, transfer the precipitate into a beaker, add nitric acid or sulfuric acid to dissolve the precipitate. The invention is simple and easy to implement and low in cost. The beryllium salt is recovered and then used for the determination of P, or used for the phosphorus removal step of the determination of tungsten trioxide in high-phosphorus tungsten ore. The beryllium waste liquid is discharged outside, causing the disadvantage of beryllium polluting the environment, and greatly saving the cost of reagents.

Owner:江钨世泰科钨品有限公司

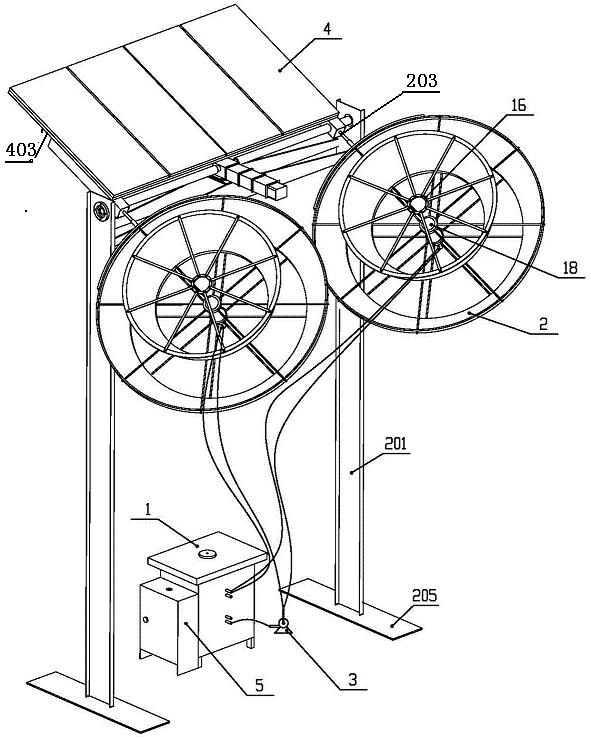

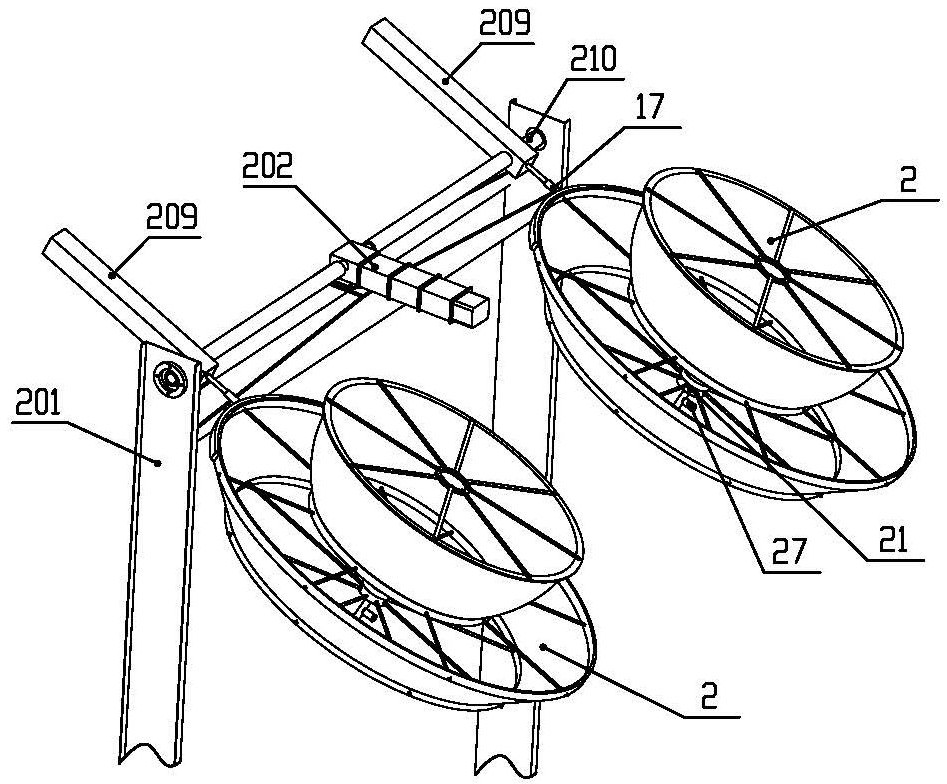

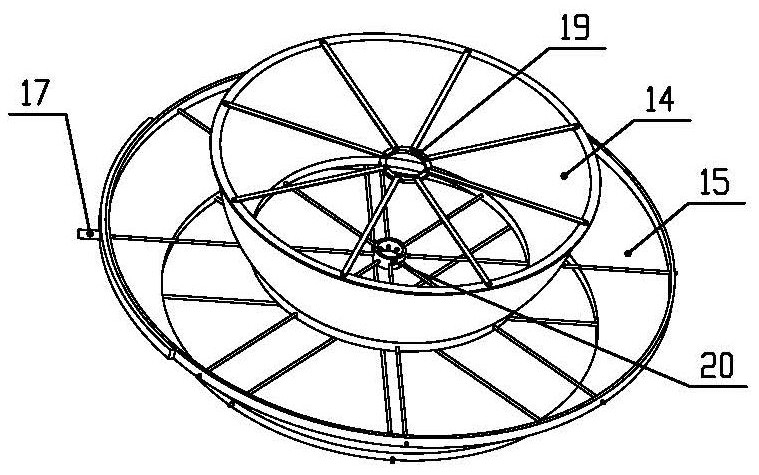

Combined heat and power solar cooker integrated solar device

InactiveCN114322331AEmission reductionImprove yard living conditionsSolar heating energySolar heat storageCogenerationSolar cooker

The invention provides a heat and power cogeneration solar cooker integrated solar device which comprises a coil base cooker, a light condensation-heat collection suite, a thermal medium circulation assembly, a photovoltaic power generation panel assembly, a power storage tracking control suite and a sun tracking suite. According to the solar motion trail tracking function and structure, sunlight focusing heat collection is achieved, heat needed by a high-temperature heat transfer medium is provided, the heat is provided for the heat storage type cooking bench, and then the effects and purposes that cooking can be conducted in the daytime and at night, and hot water is provided are achieved; the power generation and storage component meets the requirement for tracking the power consumption of a power station and also achieves the effect and purpose of external power supply, and has the advantages that the illumination space is fully utilized, the operation is simple, convenient and reliable, the total efficiency of solar energy is high, and the solar device adapts to the requirements of a cooking bench; according to the heat accumulating type cooking bench, the heat medium circulating assembly and the movable heat control core are matched for use, the requirements of cooking for adjusting and controlling the heat supply intensity can be met, and the heat accumulating type cooking bench has the advantages of being long in service life and high in energy efficiency.

Owner:PULIN TAIYANG ZHENGZHOU ENERGY POWER

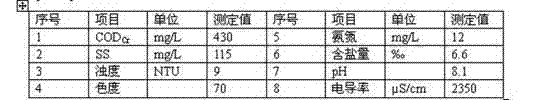

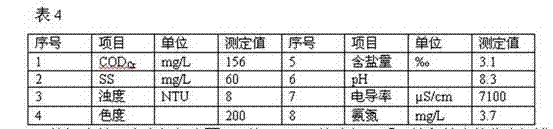

Cyclic utilization method of dyeing and printing advanced treatment wastewater

InactiveCN102086072BOvercoming unsatisfactory treatment effectsOvercome the disadvantages of polluting the environmentDispersed particle separationWater/sewage treatment bu osmosis/dialysisChemical oxygen demandElectrolysis

The invention relates to a cyclic utilization device of dyeing and printing advanced treatment wastewater and a method thereof. The cyclic utilization device contains a nanometer catalytic electrolysis system, an immersed ultrafiltration-membrane filtration separation system and an electrodialysis system which are connected in turn, wherein the dyeing and printing advanced treatment wastewater passes through the nanometer catalytic electrolysis system, the immersed ultrafiltration-membrane filtration separation system and the electrodialysis system in sequence to perform nanometer catalytic electrolysis, ultrafiltration and filtration, and electrodialysis treatment. The cyclic utilization device of the invention has the outstanding advantages that the recovery rate of water is high, the cost is low, the decoloring and deodorizing effects are good, the total discharge amount of wastewater chemical oxygen demand (COD) can be greatly reduced, the biological pollution of membrane can be eliminated, no secondary pollution is caused, the amount of sludge can be greatly reduced, the floor space is small, the quality of the reused water is high, the energy consumption is greatly reduced during the operation of the device, etc.

Owner:BOYING XIAMEN SCI & TECH

Novel halogen-free environment-friendly type flame-proof polypropylene material

ActiveCN101161775BOvercome the disadvantages of polluting the environmentSignificant progressAntioxidantCooling down

The invention relates to a halogen-free environmental friendly fire retarding polypropylene material which comprises the following components (percentage by weight): 40 to 70 percent of polypropylene granules, 25 to 38 percent of halogen-free intumescent fire retardant, 0.5 to 1.5 percent of lubricant, 0.1 to 0.5 percent of antioxidant, 0.5 to 1.5 percent of coupling agent and filler surplus. The polypropylene material is made by the following method: polypropylene granules and other components are evenly mixed inside a high-speed mixer according to certain proportion and then are extruded by a twin screw extruder, cooled down and granulated under the conditions of routine feeding speed, temperature and screw stem rotary speed. With ideal flame retardant property and mechanical property, the polypropylene material is characterized by low smoke, low toxicity and no melt drip as compared with fire-retarding polypropylene, thereby reducing environmental pollution and doing less harm to human body.

Owner:浙江省化工产品质量检验站有限公司 +1

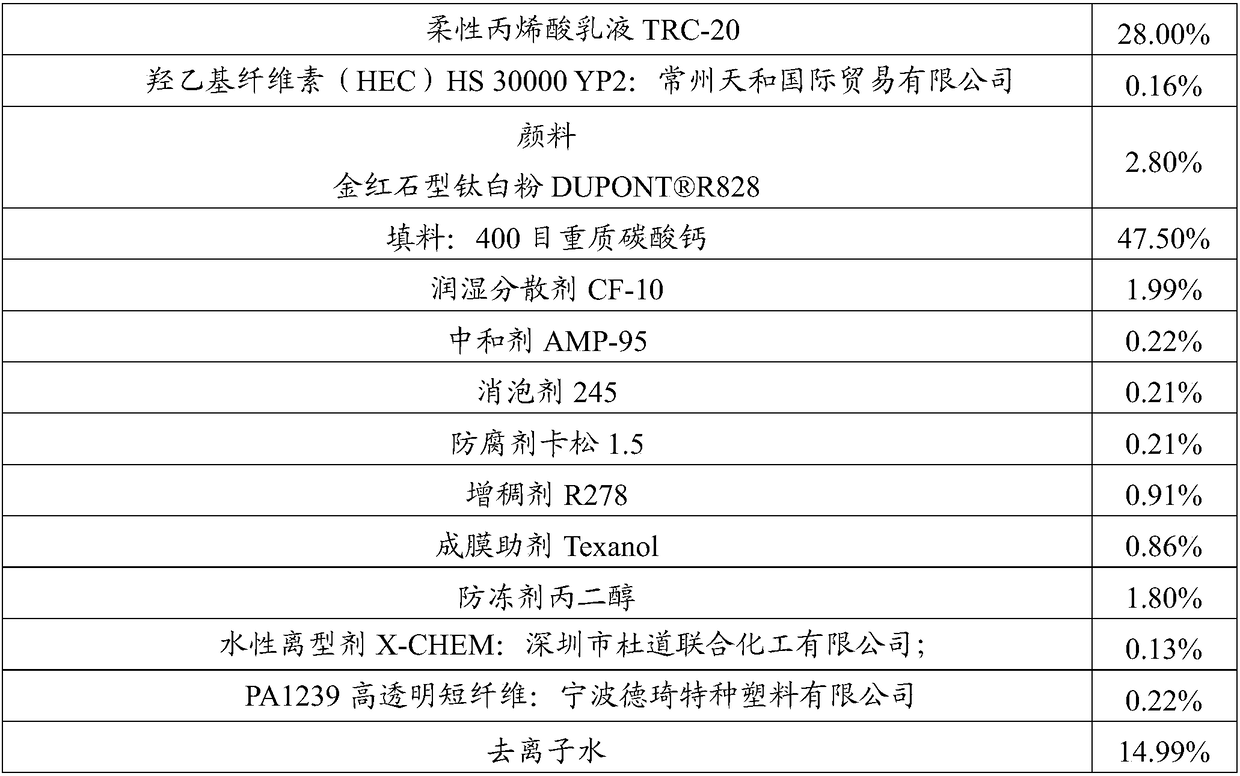

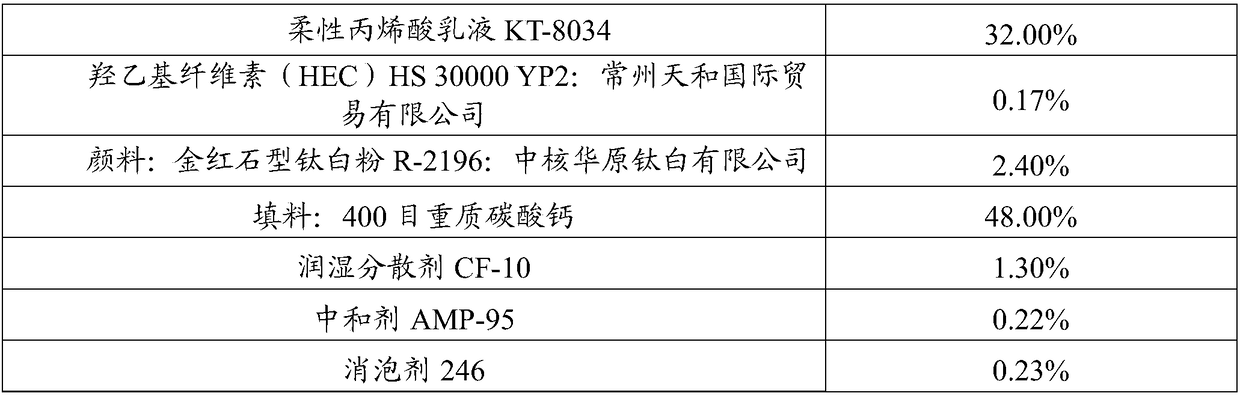

Bubble breaking type thick waterborne elastic middle coating and preparation method thereof

InactiveCN109233494AGood low temperature flexibilityGuaranteed crack resistanceAntifouling/underwater paintsPaints with biocidesFiberEmulsion

The invention relates to a bubble breaking type thick waterborne elastic middle coating. Raw materials of the coating in a formula comprise components in percentage by mass as follows: 28.00%-32.00% of flexible acrylic emulsion, 0.16%-0.17% of hydroxyethyl cellulose, 2.40%-3.00% of pigment, 46.00%-48.00% of filler, 1.30%-1.99% of a wetting dispersant, 0.21%-0.22% of a neutralizer, 0.08%-0.13% of awaterborne releasing agent, 0.21%-0.24% of an organosilicon defoamer, 0.21%-0.25% of a preservative, 0.90%-0.91% of a thickener, 0.86%-0.96% of a coalescing agent, 1.80%-2.20% of an antifreezing agent, 0.22%-0.43% of PA short fiber and 10.85%-15.53% of water. The invention further relates to a preparation method of the coating. With the adoption of the coating and the preparation method thereof,bubbles are broken quickly in a construction process, and modeling is stable.

Owner:上海三银涂料科技股份有限公司

An automatic packing fresh noodle making and selling machine

ActiveCN107027843BRealize automatic on-site production and salesOvercome the disadvantages of polluting the environmentMixing/kneading structural elementsWrapping material feeding apparatusCollection systemControl system

A small-sized fresh noodle making and selling machine for automatic packaging, belonging to the field of commercial equipment, including a frame, a noodle making machine, a paper packaging machine, and a control system; the frame is composed of multiple components; the noodle making machine is installed On the frame; the noodle conveying device is installed below the noodle cutting device; the paper packaging machine is installed on the frame; the control system is installed on the frame, including a control box, a controller, a display, Payment system, information collection system; it can realize automatic on-site production and sales of fresh noodles, and realize paper packaging, which overcomes the fact that the existing fresh noodle production and sales machines cannot be automatically packaged, and its packaging cannot match the noodles sold, and the pollution of plastic bag packaging The characteristics of the defects of the environment.

Owner:HENAN WANJIE INTELLIGENT TECH

Preparation method of a micro-nano cantilever arm structure elastic contactor

ActiveCN107565252BSimple preparation processNo pollutionTelevision system detailsContact member manufacturingMicro nanoChemical corrosion

Owner:河南明华智能系统研究院有限公司

Polycrystalline silicon ingot surface pretreatment device and its treatment method

ActiveCN103866397BAutomate processingImprove the quality of prescribingPolycrystalline material growthAfter-treatment detailsSurface cleaningIngot

The invention discloses a surface pretreatment device for a polycrystalline silicon ingot and a treatment method thereof. The problems of serious environmental dust pollution, and low surface cleaning quality and efficiency in the prior art are solved. The surface pretreatment device comprises a corrosion pool (5), an ultrasonic soaking pool (7) and a rinse spray pool (8) sequentially arranged on a pretreatment pool bracket (4), wherein a drainage pipeline (14) is arranged at the center of the bottom surface of a rectangular corrosion pool body (9) of the corrosion pool (5); a drainage control valve (15) is arranged on the drainage pipeline (14); pool bottom grooves (10) are arranged at the bottoms on the left side and the right side of the rectangular corrosion pool body (9); an electric heater (11) is arranged in each pool bottom groove (10); and an acid liquor input pipe (12), an alkali liquor input pipe (13), a purified water input pipe (17) and a compressed air input pipe (18) are respectively arranged on the inner lateral wall of the rectangular corrosion pool body (9). The extracting quality of the silicon ingot and the reuse rate of rim charge are improved.

Owner:山西中电科新能源技术有限公司

Inner cylinder of fireworks and fireworks with the inner cylinder of fireworks

The invention discloses an inner fireworks barrel and fireworks with the inner fireworks barrel. The inner fireworks barrel comprises a cylindrical barrel body for storing an explosive mixture; a top cover is arranged at the upper end of the barrel body, and while a base is arranged at the lower end of the barrel body; the top cover comprises a cover body, and a first annular sidewall which is axially stretched along the outer round surface of the cover body; the inner wall surface of the first annular sidewall is in connection fitting with the outer round surface of the upper part of the barrel body; the base comprises a base body, and a second annular sidewall which is axially stretched along the outer round surface of the base body; the inner wall surface of the second annular sidewall is in connection fitting with the outer round surface of the lower part of the barrel body; a line guide hole is formed in the base body. According to the inner fireworks barrel, the processing technique is simplified; in addition, the top cover and the base can be conveniently produced by mass, and therefore, the cost is reduced, and the processing efficiency is increased; meanwhile, the structure that the inner wall surface of the annular sidewall is in connection fitting with the upper outer round surface and the lower outer round surface of the barrel body is adopted to reliably ensure the connection reliability of the top cover, the base and the barrel body.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

Treatment method and application of using polymer waste to regenerate colloid polymer

InactiveCN106750514AAvoid and control secondary pollutionHigh purityPlastic recyclingOrganic fertilisersDecompositionResource recovery

The invention relates to a treatment method and application of using polymer waste to regenerate colloid polymer. The method comprises the steps of conducting water separation to collected garbage; conducting crushing and blow drying after washing and spin-drying; conducting constant temperature static soaking to obtain a free radical material; conducting mixing decomposition and synthesis; lastly sending the material in a granulating machine for granulating to obtain a gel body polymer. The treatment method overcomes the shortcoming that the traditional method causes pollution to the environment. The water collection is concentrated to enhance the purity, the separation selection effect is good, the process is simple, the resource recycling rate is high, the problem that garbage occupies large area of land and pollutes the environment is solved. The generated gel body polymer can be used in the application of building waterproof and heat insulation material, road asphalt material, colloid sheet material, colloid pipe material, colloid pipe fittings material and flexible concrete material, and has economical, social and environmental protection benefits, and effectively avoids and controls the secondary pollution to the environment.

Owner:韦罡

An electric heating tube processing technology

ActiveCN109379791BSkip the shrink tubeSave the digging processHeating element shapesProcess engineeringSpot welding

The invention relates to a processing technology of an electric heating tube, which comprises the following steps: 1. heating wire processing, installing the heating wire on the lead rod and performing spot welding; 2. filling powder, changing the structure of the rubber plug used in the powder filling process, adding glue Plug the creepage distance between the lead rod and the nozzle, and then use a powder filling machine to penetrate the heating wire into the empty tube and fill the gap with dense magnesium oxide powder; three: riveting, riveting the rubber plug of the nozzle and the electric heating tube into a hexagonal shape, tightly connecting the rubber plug and the electric heating tube; four: stretching, using a riveting mold to rive the nozzle rubber plug and the electric heating tube into a hexagonal shape, so that the rubber plug and the electric heating tube are tightly connected; five: cutting the rod, and The lead-out rods are cut into consistent exposed lengths; six: tube bending, use a tube bender to bend the electric heating tube into a specified shape and meet the size requirements of the drawing. The invention overcomes the disadvantages of wasting materials and dust polluting the environment caused by the traditional process, and has the advantages of simplifying process steps and improving processing efficiency.

Owner:安徽苏立科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com