Original-state soil borrowing press-grouting concrete pile exerted by prestress and construction method thereof

A technology of undisturbed soil borrowing and concrete pouring, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as low construction efficiency, mud discharge, waste of raw materials, etc., to prevent pile cracks, reduce project costs, overcome The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

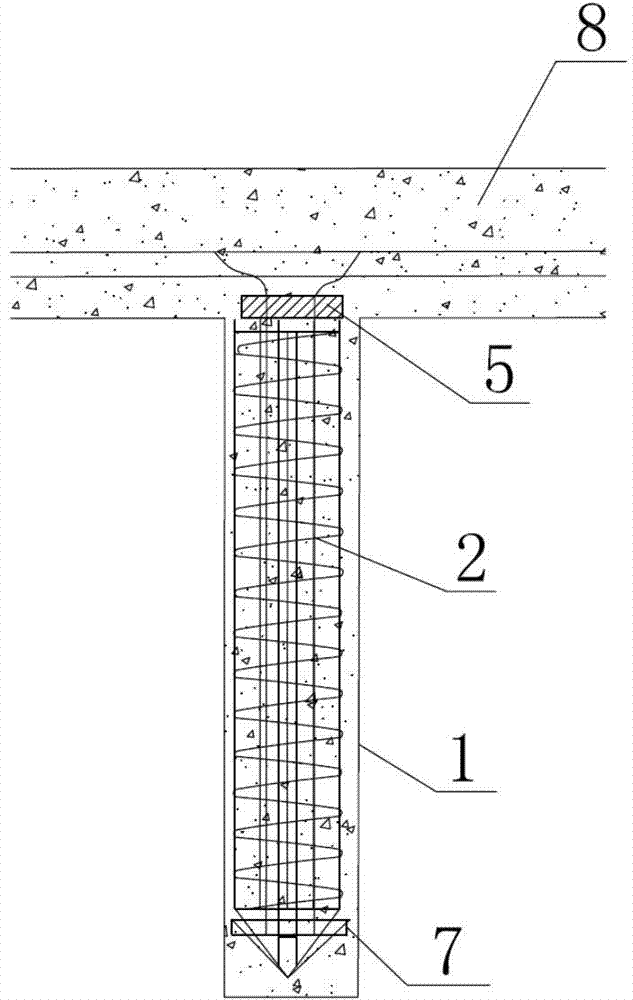

[0031] see Figure 1-Figure 3 , an undisturbed earth-extracted pressure-grown concrete pile with prestressing applied, comprising a concrete pile body 1 vertically poured on site, and the pile body 1 has a built-in reinforcement cage 2.

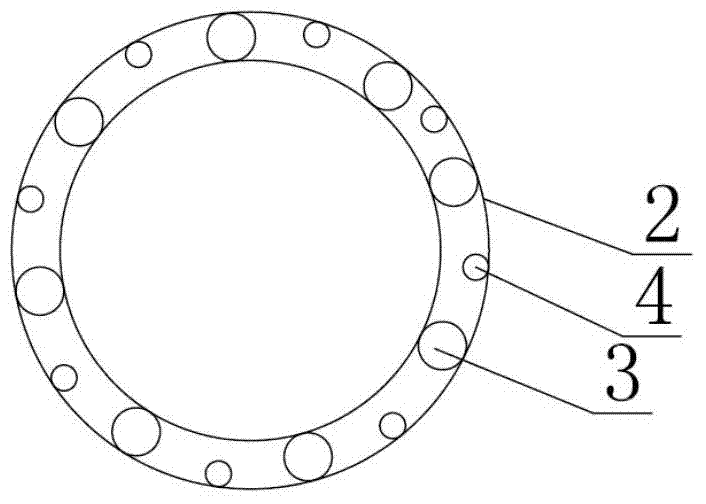

[0032] In the section direction, the reinforcement cage 2 has a plurality of vertical reinforcement bars 3 of conventional main reinforcement, and the vertical reinforcement bars 3 are hot-rolled steel bars or rebars, etc., and the main function of the hot-rolled steel bars is to meet the structural requirements of reinforced concrete.

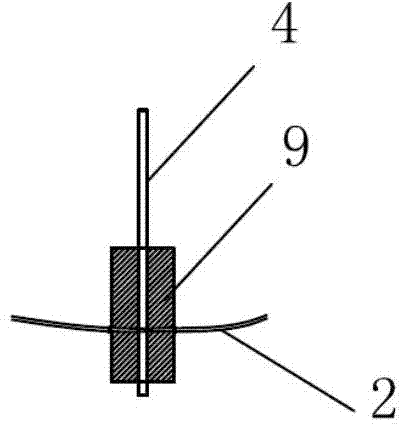

[0033] The reinforcement cage 2 is also provided with a plurality of evenly arranged vertical prestressed tendons 4 , and the prestressed tendons 4 are arranged at intervals wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com