Polycrystalline silicon ingot surface pretreatment device and its treatment method

A technology for surface pretreatment and polysilicon ingots, applied in post-processing, post-processing details, chemical instruments and methods, etc., can solve problems such as surface cleaning quality and low efficiency, environmental dust pollution, etc., to improve the quality of prescribing and overcome dust The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

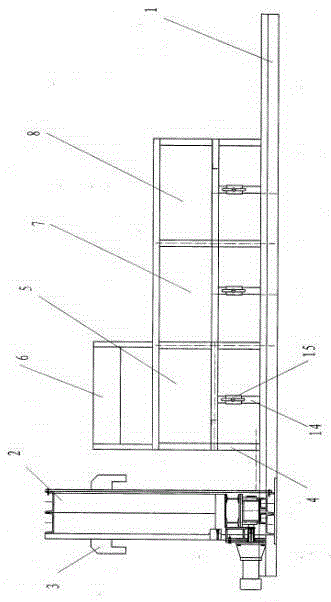

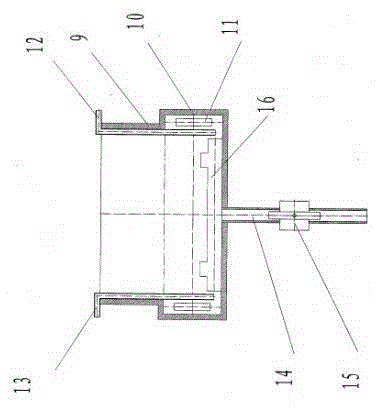

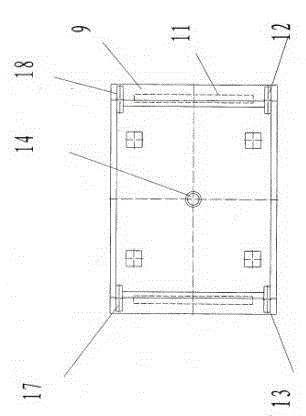

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] A polycrystalline silicon ingot surface pretreatment device, comprising a gantry crane guide rail 1, a gantry crane 2 is arranged on the gantry crane guide rail 1, a silicon ingot spreader 3 is arranged on the gantry crane 2, and a pretreatment pool support 4 is arranged on one side of the gantry crane guide rail 1 , a corrosion tank 5, an ultrasonic immersion tank 7 and a rinse spray tank 8 are sequentially arranged on the pretreatment tank support 4, and a drain pipeline 14 is arranged at the center of the bottom surface of the rectangular parallelepiped corrosion tank body 9 of the corrosion tank 5. A liquid discharge control valve 15 is provided on the liquid pipeline 14, and a pool bottom groove 10 is provided at the bottom of the left and right inner sides of the rectangular parallelepiped corrosion pool body 9, and an electric heater 11 is arranged in the pool bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com