An electric heating tube processing technology

A processing technology, electric heating tube technology, applied in the direction of the heating element shape, etc., can solve the problems of waste of raw materials, impact on the environment, dust pollution, etc., to achieve the effect of overcoming waste of materials, simplifying process steps, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

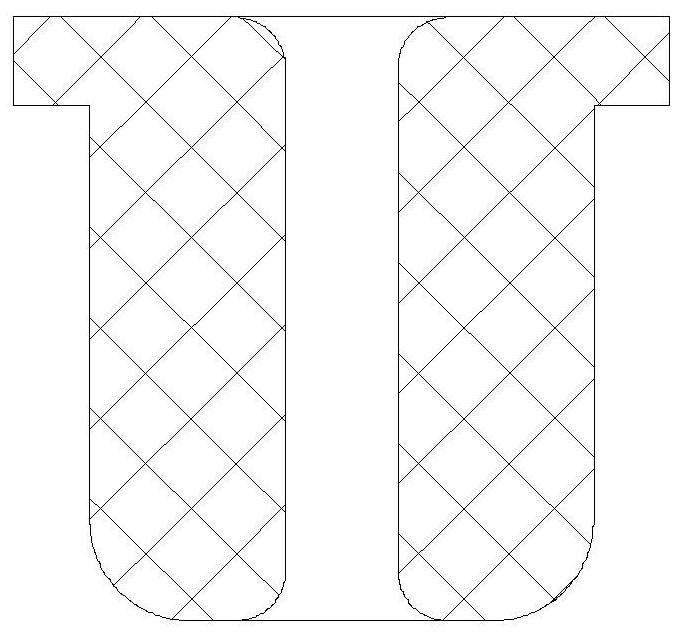

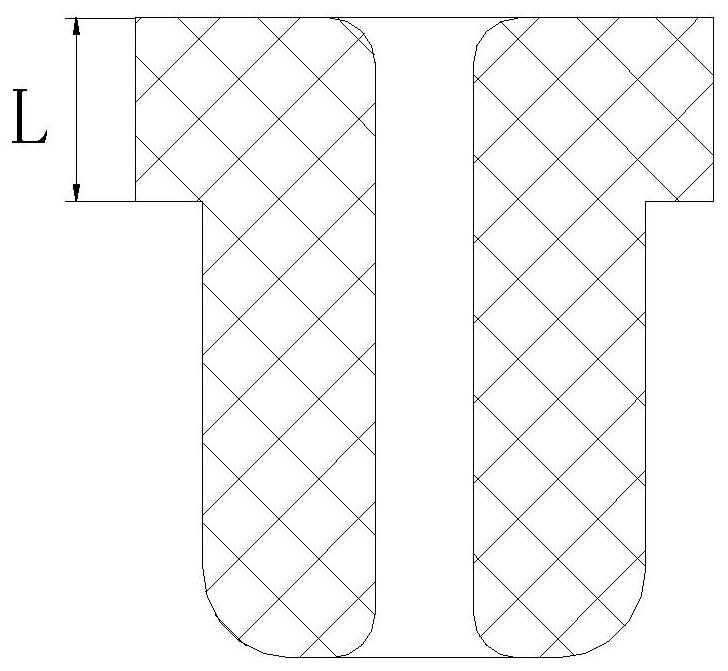

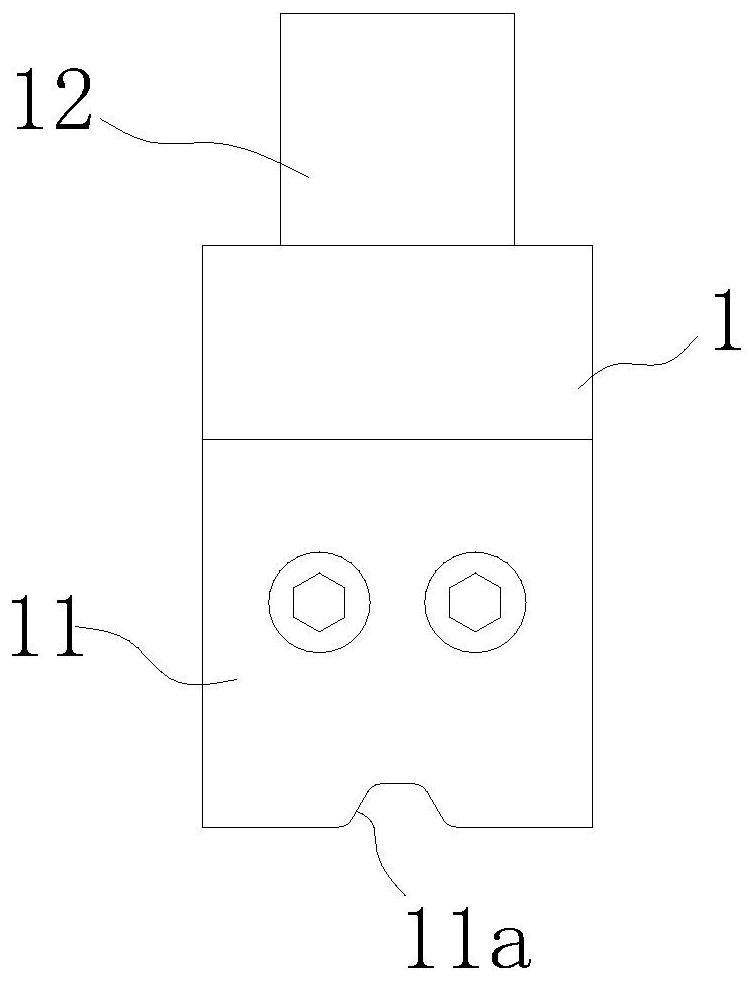

Image

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

[0021] An electric heating pipe processing technology, comprising the following steps:

[0022] Step 1: Process the heating wire, install the heating wire on the lead rod and perform spot welding; the details include:

[0023] 1. Use a wire winding machine to wind the heating wire into a spring shape to meet the specified wire diameter and resistance requirements;

[0024] 2. Clean the oil on the surface of the heating wire by an ultrasonic cleaning machine, and put it into an oven for drying;

[0025] 3. Drive the lower lead rod into the inner hole of the rubber pellet through the automatic rubber stopper machine to reach the specified exposed length;

[0026] 4. Use the automatic wire threading machine to thread the heating wire on the threading position of the upper and lower lead bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com