Negative pressure leachate raising method for in-situ lixiviation of tailing for re-dressing

A technology for leaching liquid and tailings dam, which is applied in the field of in-situ leaching tailings dam, re-selected tailings, negative pressure lifting leachate, and collection of tailings leaching liquid, achieving the effect of easy operation, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

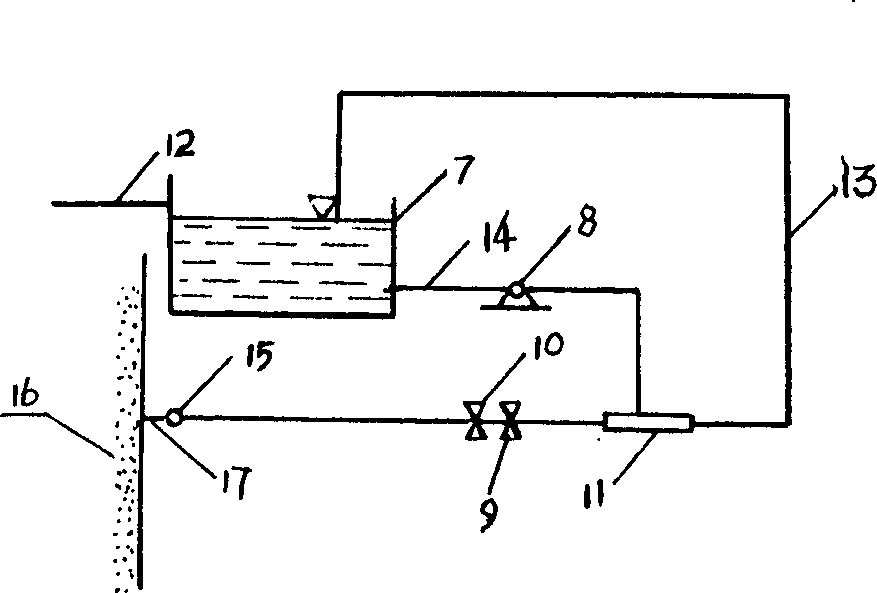

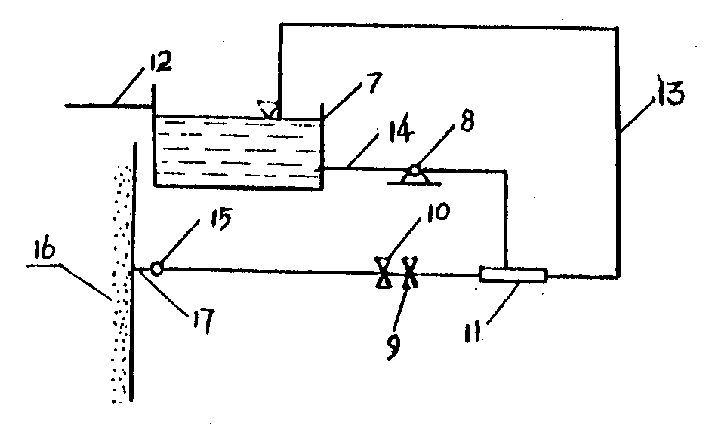

[0012] In-situ leaching of tailings dam re-election tailings negative pressure lifting leachate method is to inject a chemical leaching agent suitable for leaching a certain useful component into the tailings heap of the tailings dam to soak the tailings ;After soaking the tailings for a period of time, use a negative pressure lifting device to use negative pressure to extract the leaching solution containing useful components from the tailings heap to the surface and inject it into the liquid storage tank; before extracting the leaching solution under negative pressure, use a plastic film Cover the tailings area 16 so that the tailings under the plastic film are in a sealed area. When using the negative pressure lifting device to extract the leachate, it should be ensured that the vacuum value in this area is greater than 80Kpa.

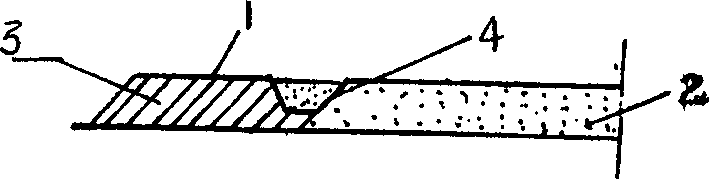

[0013] In order to ensure the airtightness, the plastic film 1 should be laid in two to three layers, and the periphery of the plastic film 1 should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com