Patents

Literature

37 results about "Calcium arsenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

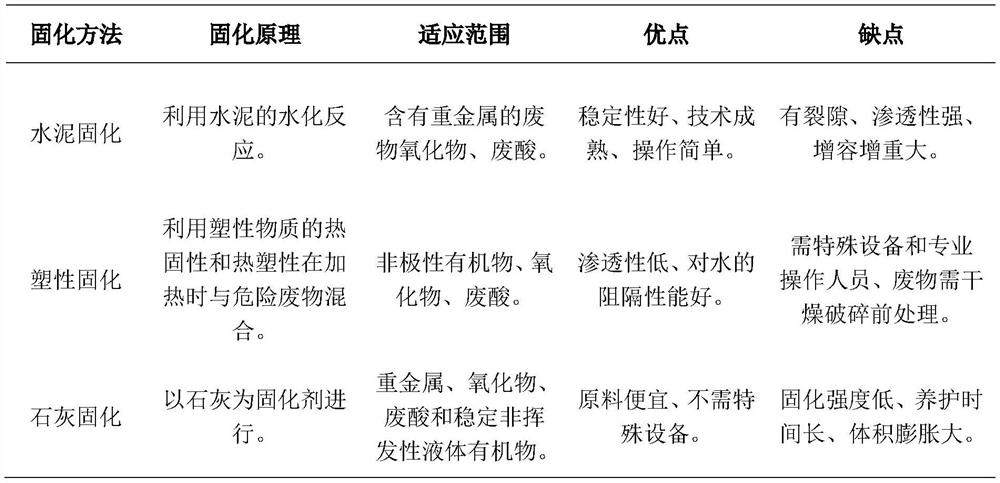

Calcium arsenate is the inorganic compound with the formula Ca₃(AsO₄)₂. A colourless solid, it was originally used as a pesticide and as a germicide. It is highly soluble in water, as compared with lead arsenate, which makes it more toxic. The minerals Rauenthalite Ca₃(AsO₄)₂·10H₂O and Phaunouxite Ca₃(AsO₄)₂·11H₂O are hydrates of calcium arsenate.

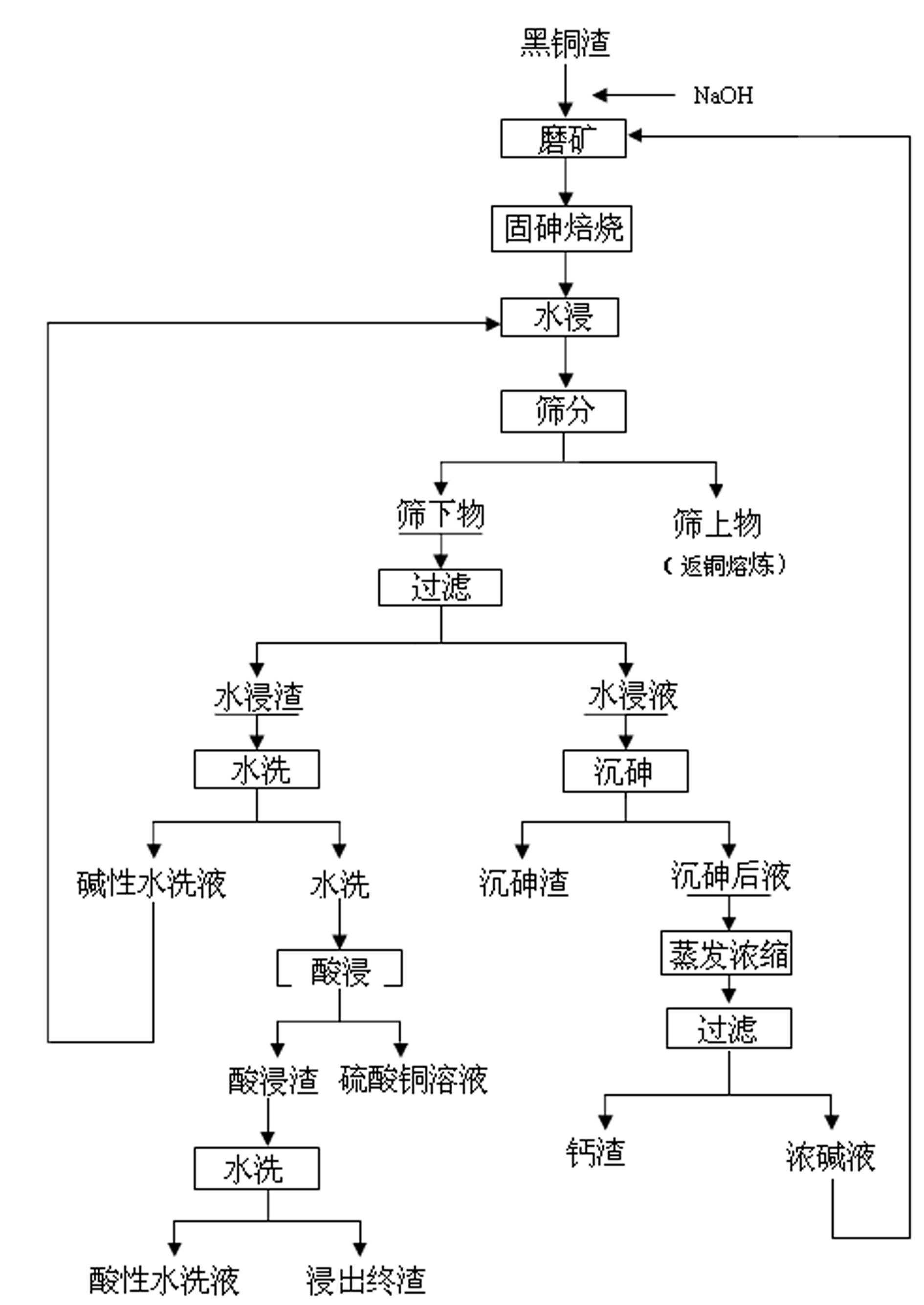

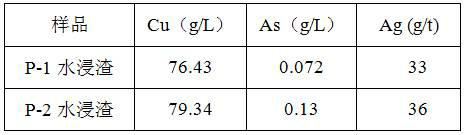

Method for treating arsenic-containing waste copper slag

InactiveCN102634672ASolve the open circuit problemHigh enrichment ratioProcess efficiency improvementArsenateEnvironmental engineering

The invention provides a method for treating arsenic-containing waste copper slag. The method comprises the following steps of: adding alkali and arsenic fixation roasting on the arsenic-containing waste copper slag from a copper electrolysis purification procedure to convert the arsenic into low-toxicity, water-soluble and nonvolatile arsenate, leaching the roasting slag into water to remove the arsenic, recovering copper and enriching antimony bismuth silver by virtue of acid leaching, and embedding calcium arsenate sediment converted from the arsenic in the water leaching solution; and comprehensively recovering valued metals such as copper, silver, antimony and bismuth in the black copper slag. The method is a safe and effective wet smelting method for recovering the valued metals in the black copper slag, and the arsenic and the copper are leached separately; the recovery rate of the copper in the black copper slag reaches 99.6 percent, and the removal rate of the arsenic reaches over 98 percent; over 95 percent of antimony and over 98 percent of bismuth enter the slag, and over 98 percent of silver also enters the acid leaching slag by adding trace chlorine radicals during acid leaching, so that the antimony, the bismuth and the silver are comprehensively recovered; and the method has the advantages of low equipment investment, short flow, low running cost and safe and reliable operating environment.

Owner:JINCHUAN GROUP LIMITED

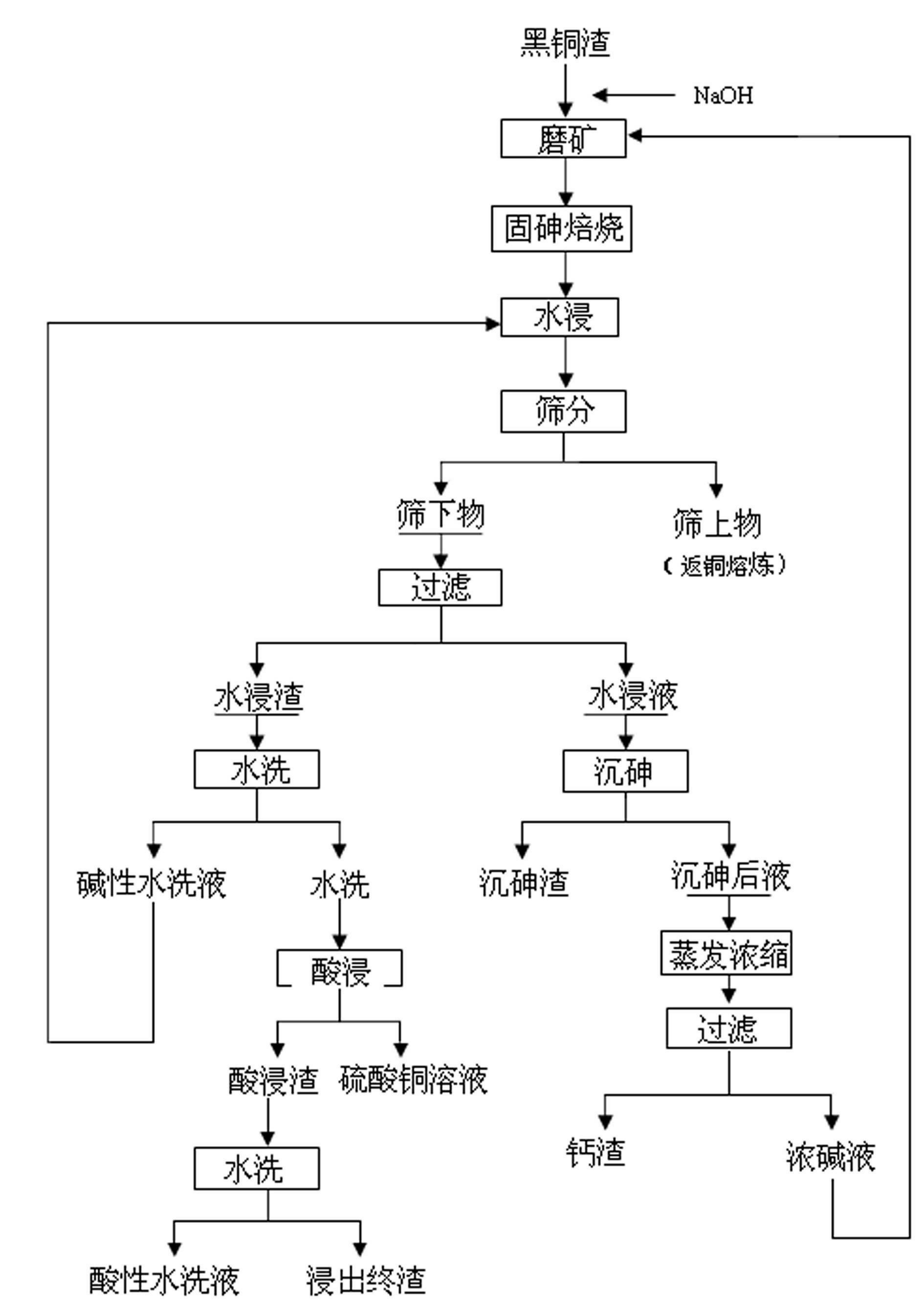

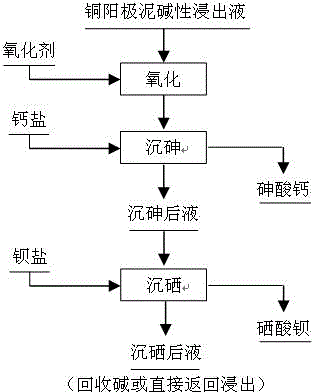

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

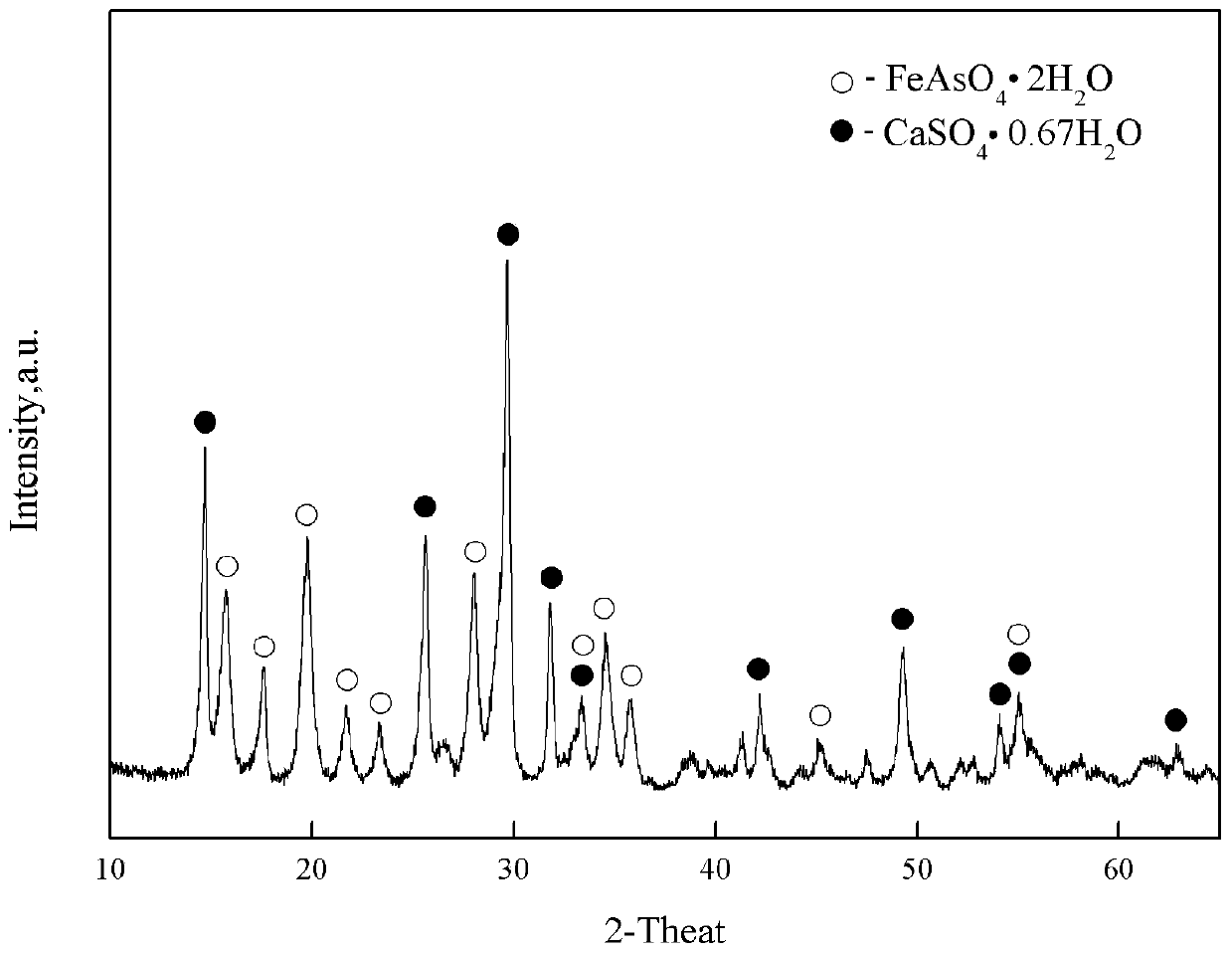

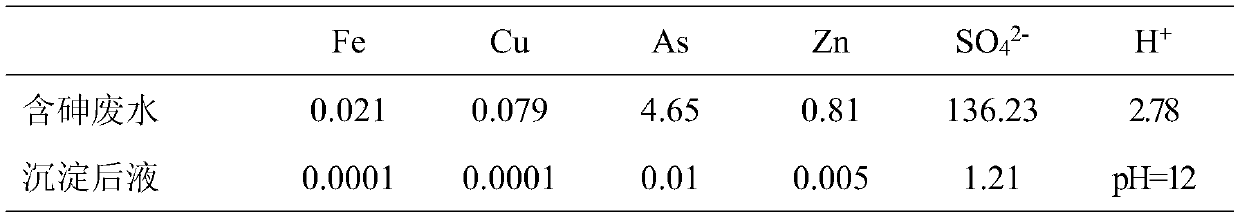

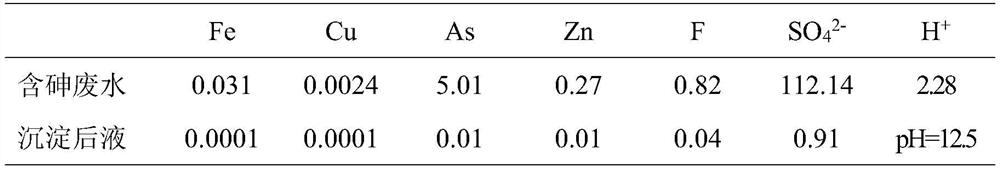

Method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

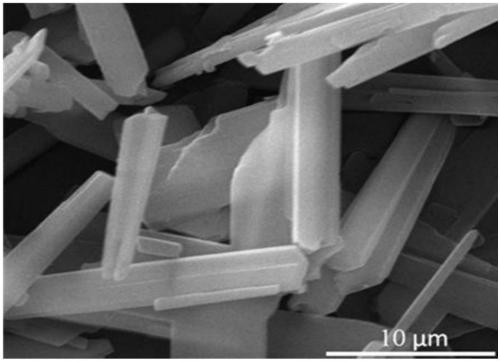

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

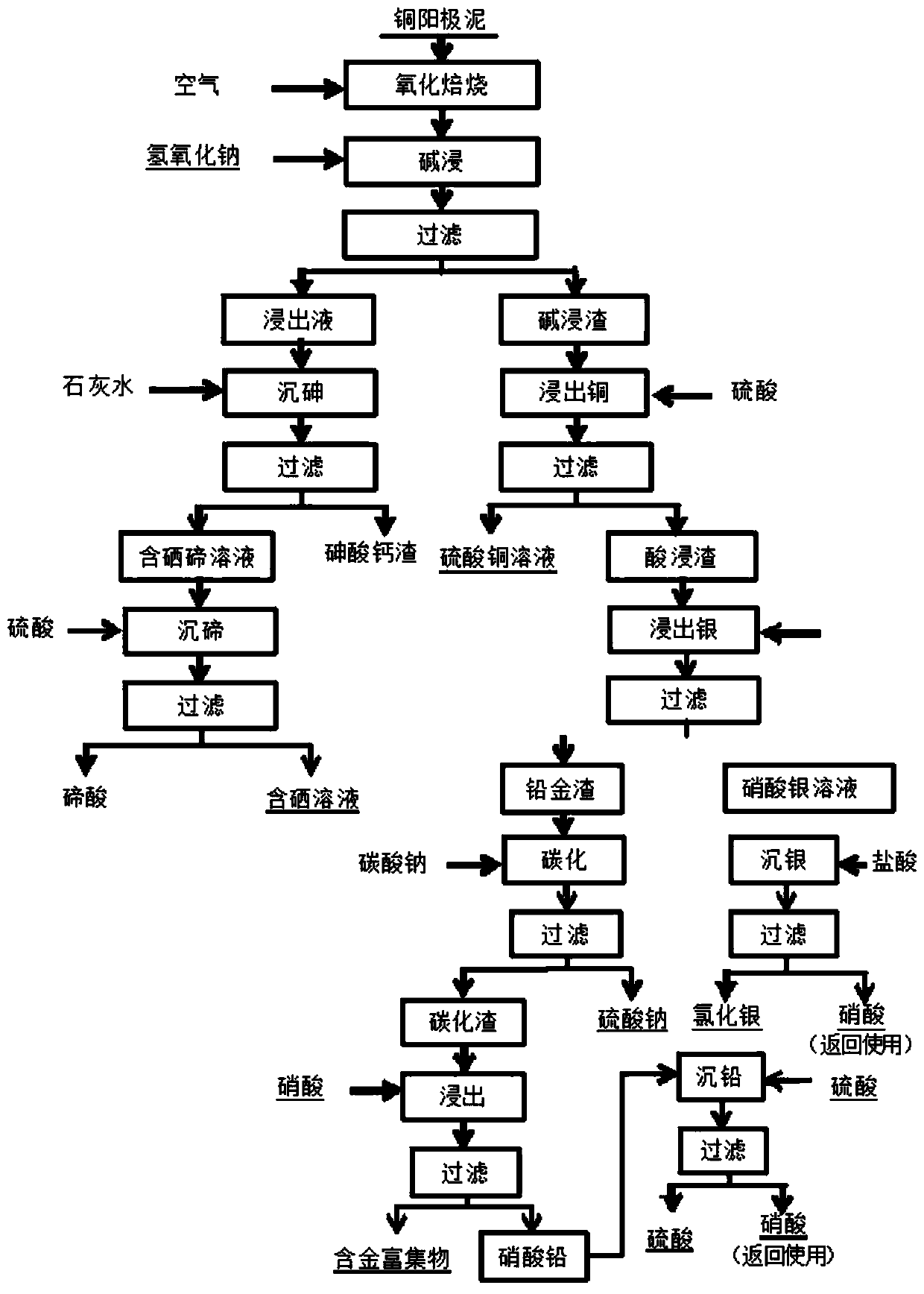

Method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud

ActiveCN111575483AAvoiding the problem of hard-to-leach telluriumAchieve recyclingProcess efficiency improvementSelenium/tellurium oxyacid saltsSlagLead nitrate

The invention discloses a method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud, and relates to the technical field of rare and preciousmetal metallurgy. The method comprises the following steps that roasted products obtained through low-temperature oxidization roasting of the copper anode mud and sodium hydroxide react to obtain selenium, tellurium and arsenic containing leaching liquor and alkaline leaching slag; the leaching liquor and whitewash react to obtain a selenium and tellurium containing solution and calcium arsenate slag; the alkaline leaching slag and sulfuric acid react to obtain copper sulfate and acid leaching slag; sulfuric acid and the selenium and tellurium containing solution react to obtain telluric acidand a selenium containing solution; the acid leaching slag and nitric acid react to obtain a silver nitrate solution and lead and gold slag; silver nitrate and hydrochloric acid react to obtain silverchloride and nitric acid; the lead and gold slag and a sodium carbonate solution react to obtain carbonization slag and a sodium sulfate solution; the carbonization slag and nitric acid react to obtain a lead nitrate solution and gold containing enrichment; and the lead nitrate solution and sulfuric acid react to obtain a lead sulfate and sulfuric acid solution. The method aims to solve the problems that existing methods for recycling metal from copper anode mud, the cost is high, recycled metal is single, and the comprehensive recovery effect is poor.

Owner:KUNMING BOREN PRECIOUS METALS +1

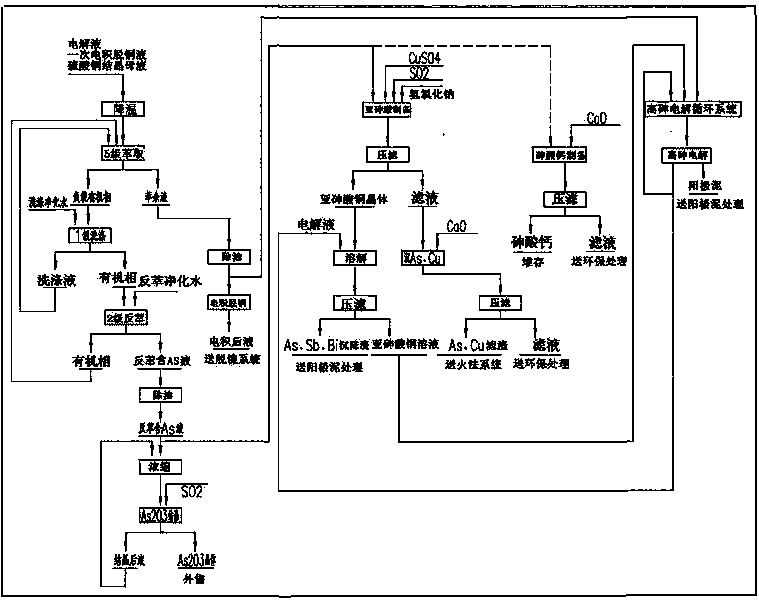

Compound technology for removing As, Sb, Bi by utilizing copper electrolyte

ActiveCN104018185AReduce power consumptionReduce energy consumptionElectrolysis componentsPhotography auxillary processesElectrolytic agentArsenic product

The invention discloses a compound technology for removing, Sb, Bi by utilizing copper electrolyte. A process for removing As by means of solvent extraction and a process of removing Sb and Bi by means of solution self-purification are combined; copper arsenite crystals are prepared by As in a back-extraction solution and is used as a high arsenic electrolytic additive; during high arsenic electrolysis, Sb and Bi in the solution can be effectively removed through As (III), and a majority of Sb and Bi in an anode plate enter anode mud. According to the compound technology, the aims of removing As, Sb and Bi can be fulfilled; meanwhile, an electro-deposition induced decoppering and dearsenification method is eliminated in the main process, and a small quantity of nickel removal liquid in the auxiliary process needs to be subjected to electro-deposition treatment. The compound technology is low in power consumption; the amount of H3As gas, black copper plates and black copper powder is obviously reduced; a dearsenification product is sold in a form of As2O3 or stacked in a form of calcium arsenate. According to the method, the operating environment is optimized, the defects that the As removal product contains a large amount of copper in the electro-deposition induced decoppering and dearsenification method and needs to be returned to a pyrogenic process system for separating copper and arsenic are overcome; the electro-deposition during the main impurity removal process is avoided, and the energy consumption is obviously reduced.

Owner:CHINA NERIN ENG

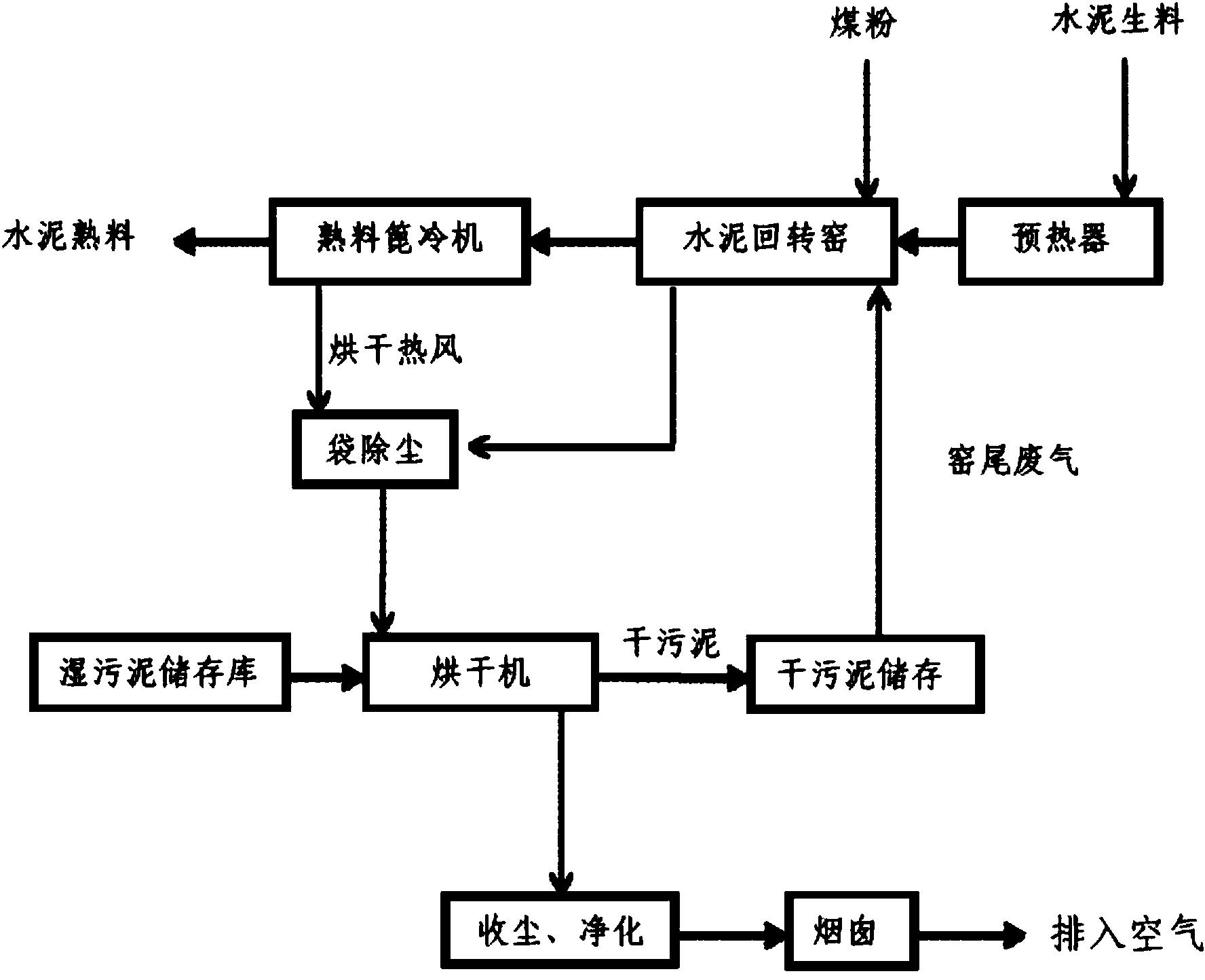

Method for treating arsenical sludge by utilizing rotary cement kiln

The invention discloses a method for treating arsenical sludge by utilizing a rotary cement kiln. According to the method, cooling hot air produced during clinker cooling by a grate cooler of dry process cement production equipment and high-temperature kiln tail gas of the rotary kiln are introduced into a dryer to dry wet sludge, and drying tail gas is exhausted from a chimney after dust removal; and the dried sludge with certain water content is fed into the rotary cement kiln and subjected to co-firing with a cement raw material, arsenic in the arsenical sludge and the cement raw material CaO form calcium arsenate in the high-temperature co-firing process, arsenic curing and stabilizing purposes are achieved, and the arsenical sludge is safely and reasonably treated. According to the method, heat produced during cement production can be sufficiently utilized to dry the wet sludge, energy loss is reduced, and the benefit is improved.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

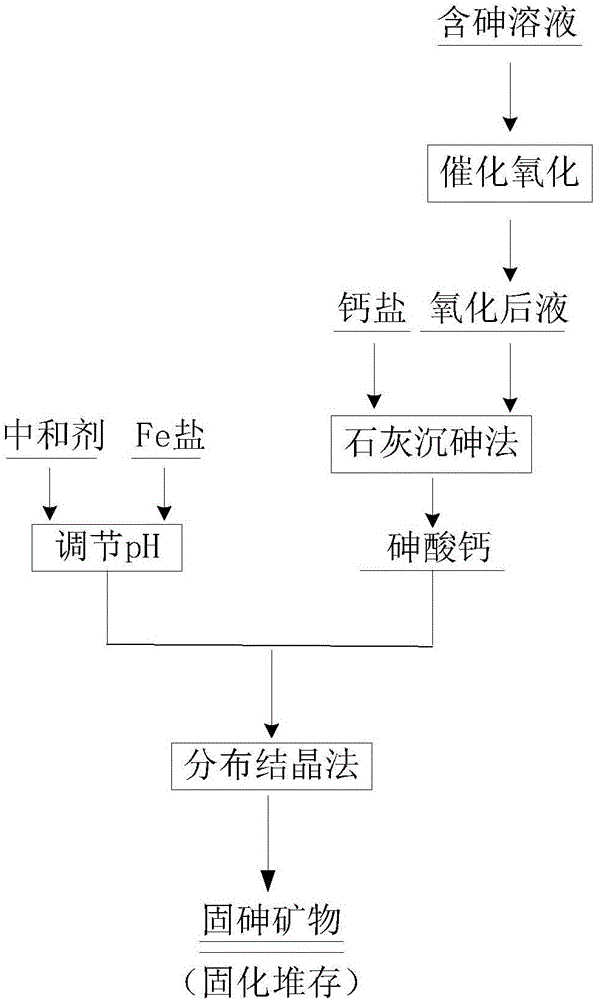

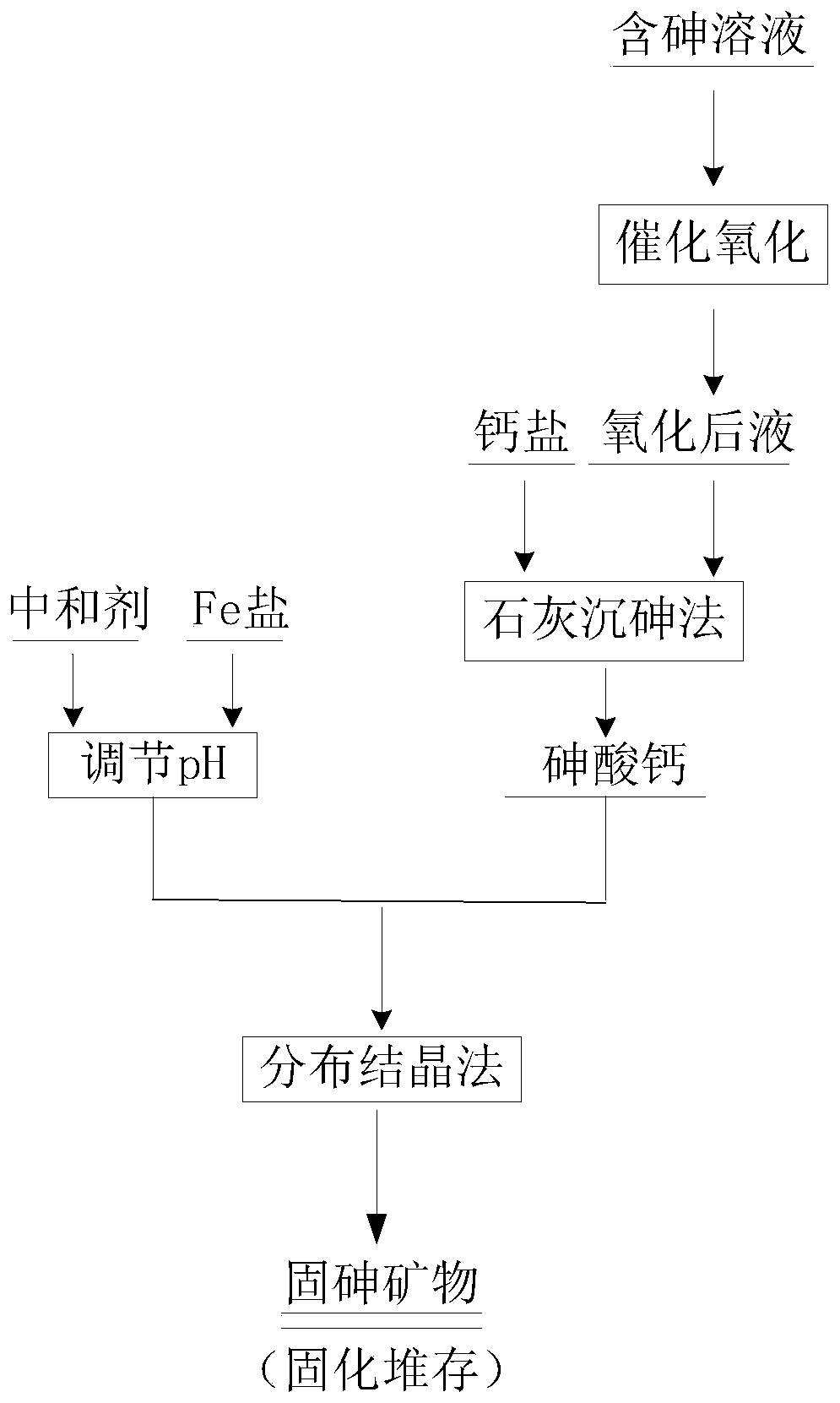

Method for preparing high-stability solid arsenic minerals through distributed crystallization method

ActiveCN106823233ASimple processEasy to operateChemical protectionCatalytic oxidationReduced properties

The invention relates to a method for preparing high-stability solid arsenic minerals through a distributed crystallization method. The method comprises the following steps: removing arsenic from a high-arsenic-content solution and curing the solution, so as to carry out harmless treatment on the arsenic-containing solution. According to the method disclosed by the invention, trivalent arsenic in the arsenic-containing solution is catalytically oxidized into pentavalent arsenic; and the oxidized solution is synthesized into the high-stability solid arsenic minerals through a lime arsenic settling method and the distributed crystallization method, and the high-stability solid arsenic minerals can be directly stockpiled. Calcium arsenate is obtained firstly through the lime arsenic settling method, and then the calcium arsenate is turned into the high-stability solid arsenic minerals through the distributed crystallization method; and toxicity extraction meets the specifications of GB5085.3-2007 (solid waste authentication standard-extraction toxicity authentication). The method is short in technological flow and good in arsenic settling effect; the solution subjected to arsenic settling can be directly discharged, and the synthesized solid arsenic minerals are high in stability and can be stably stockpiled within a wide pH range of 2 to 11 and under a strong reducing property condition.

Owner:CENT SOUTH UNIV

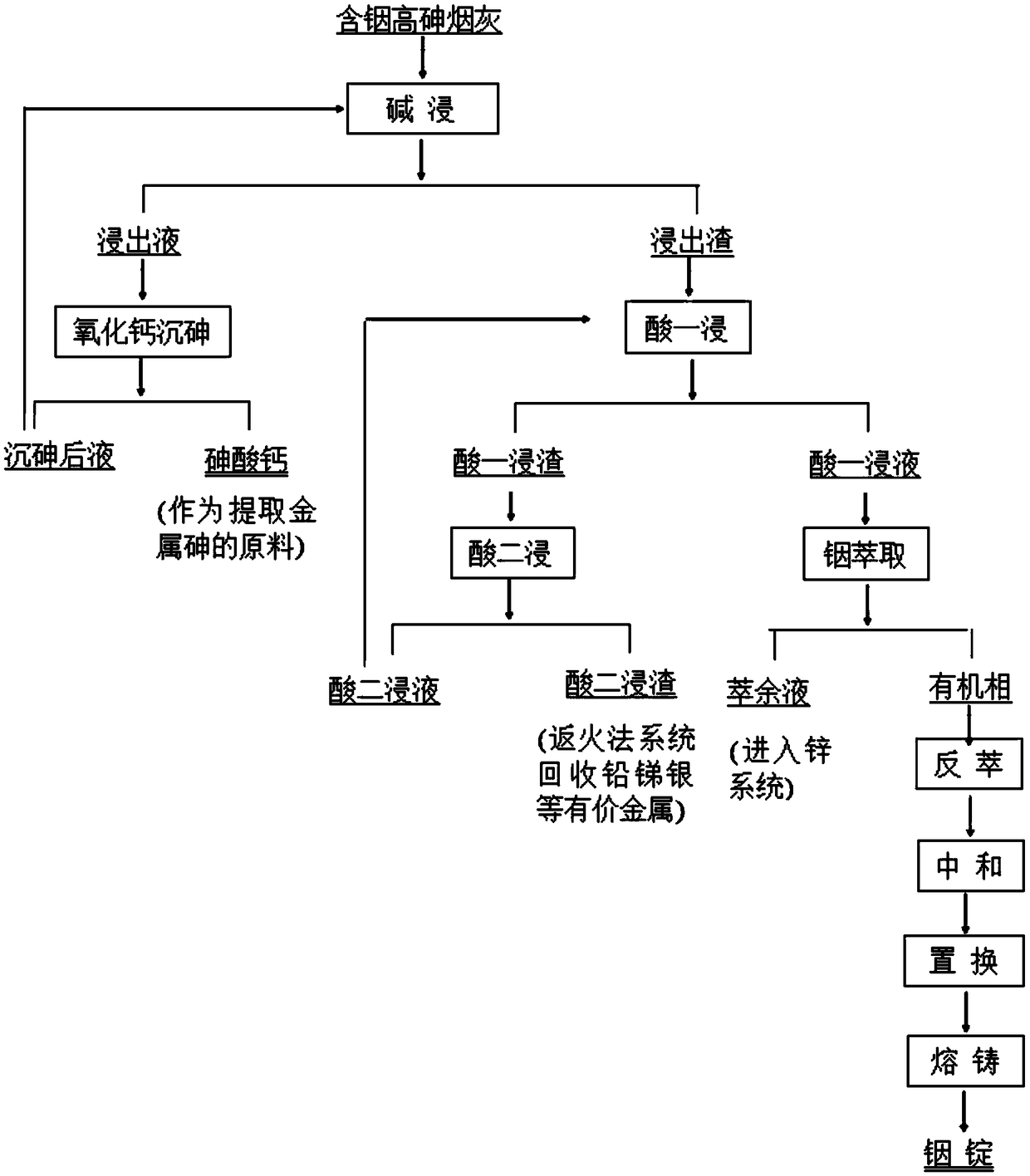

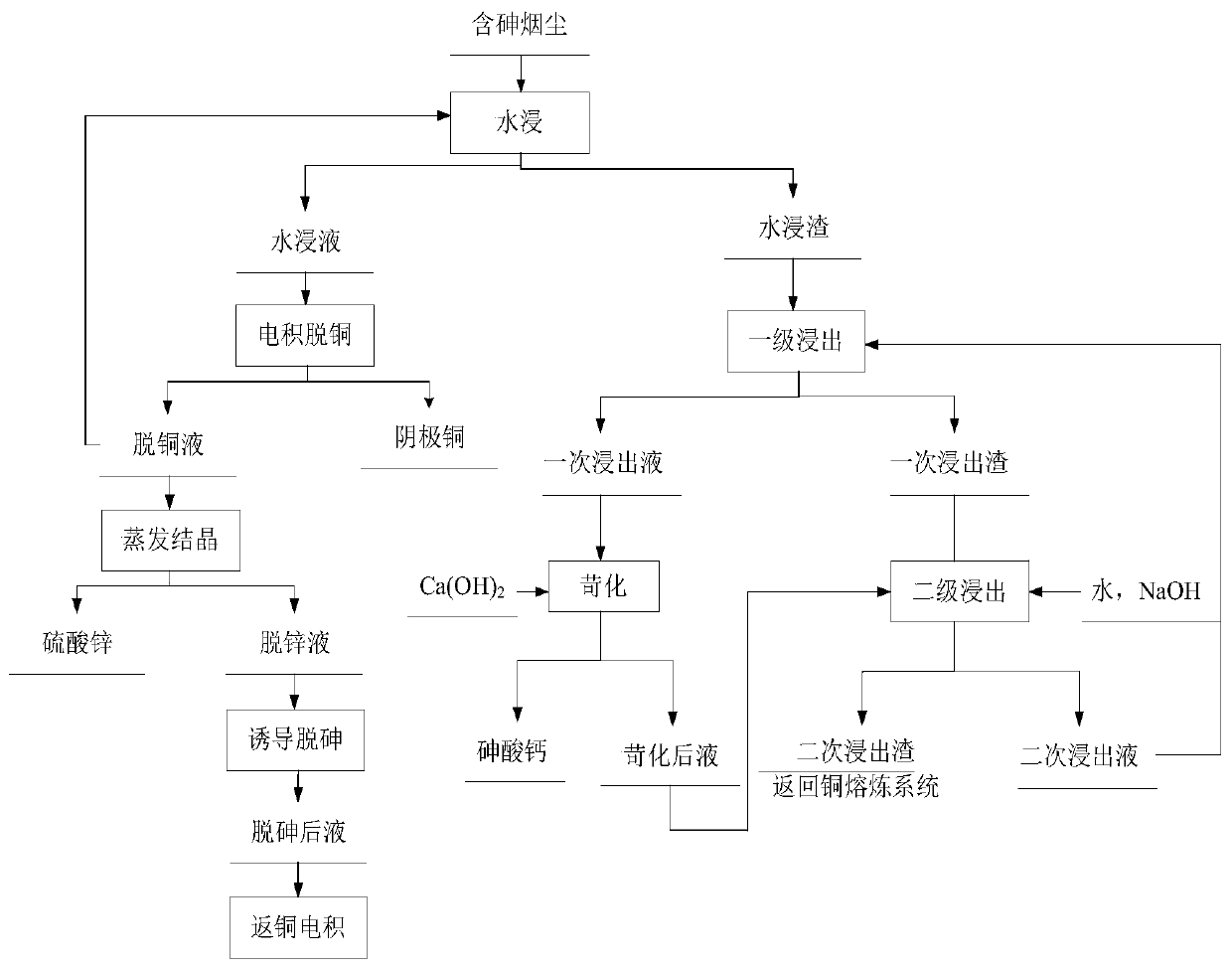

Method for treating indium-containing high-arsenic soot in wet method

InactiveCN108998677AAchieve separationEfficient recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisIndium

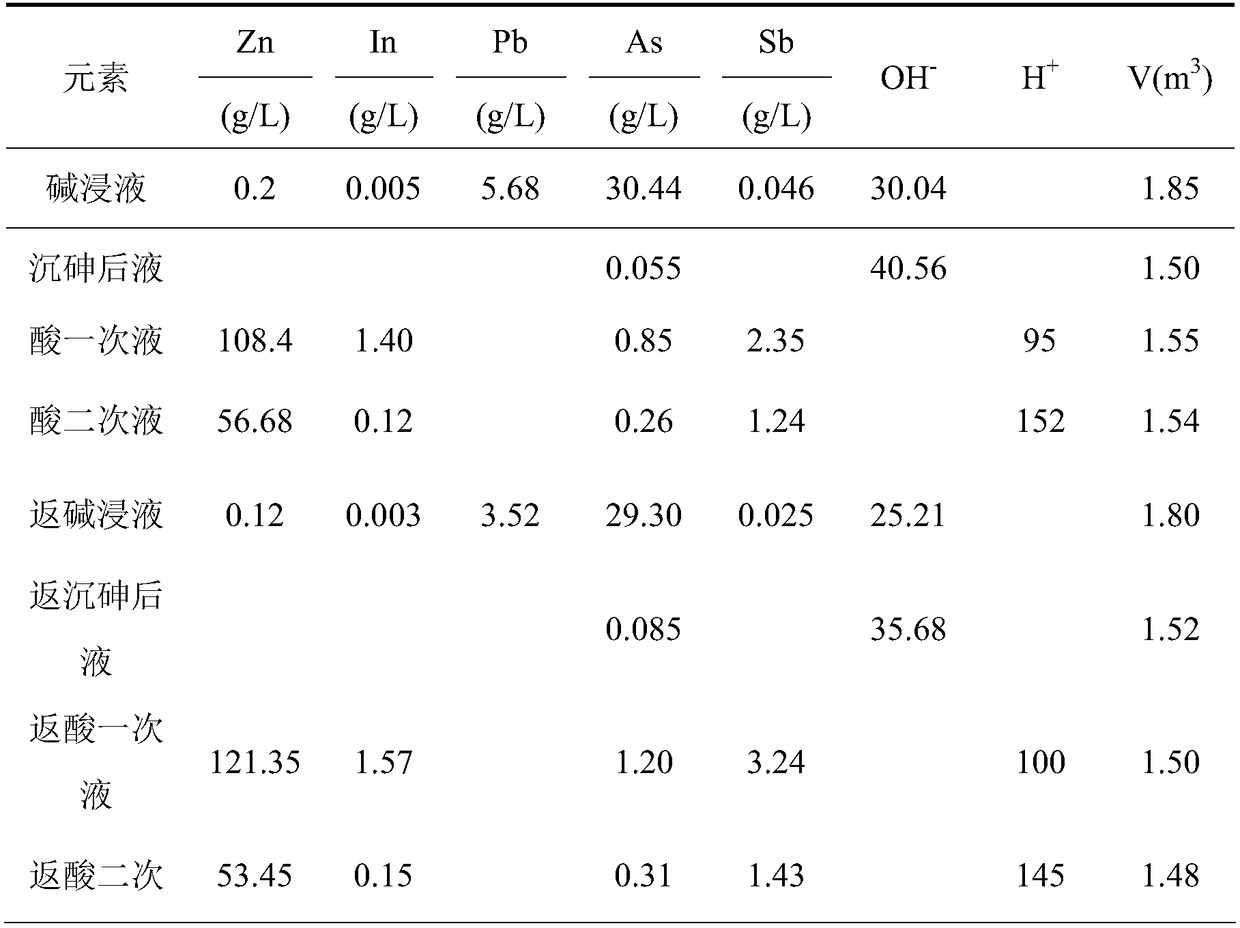

The invention belongs to the technical field of metal recycling and discloses a method for treating indium-containing high-arsenic soot in a wet method. The method includes the steps that the indium-containing high-arsenic soot is subjected to alkaline leaching, and leachate containing arsenate and leaching residues containing valuable metal such as antimony, lead, zinc and silver are obtained; calcium oxide is subjected to arsenic precipitation and arsenic precipitation post-liquid and calcium arsenate are obtained; the leaching residues are sequentially subjected to acid first-time leachingand acid second-time leaching through zinc electrolysis waste liquid, the indium leaching rate is 90% or above, acid first leaching liquid is subjected to P204 extraction, an organic phase and extraction raffinate are obtained, the organic phase is subjected to hydrochloric acid reverse extraction, caustic soda flake neutralization, zinc sheet replacement and fusion casting, indium ingots with purity being 99% or above are obtained, the extraction raffinate enters an electrolytic zinc system to recycle zinc, acid second leaching residues are subjected to lead pyrogenic process smelting, and valuable metal such as lead, antimony and silver in the residues is systematically recycled. The method is simple in procedure, separation of valuable metal such as arsenic and indium is achieved, and the valuable metal of indium and the like is effectively recycled.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

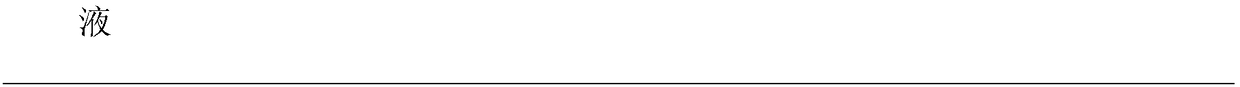

Method for producing a poorly soluble calcium-arsenic compound

The invention relates to a method for precipitating pentavalent calcium arsenate from an acidic solution, in which arsenic is at least partially in trivalent form. The acidic solution is neutralised before being routed to an arsenic oxidation stage,and a poorly soluble calcium-arsenic compound is precipitated from the solution, in which all the arsenic is pentavalent.

Owner:OUTOTEC OYJ

Method for treating waste residue by using arsenious wastewater in clean mode

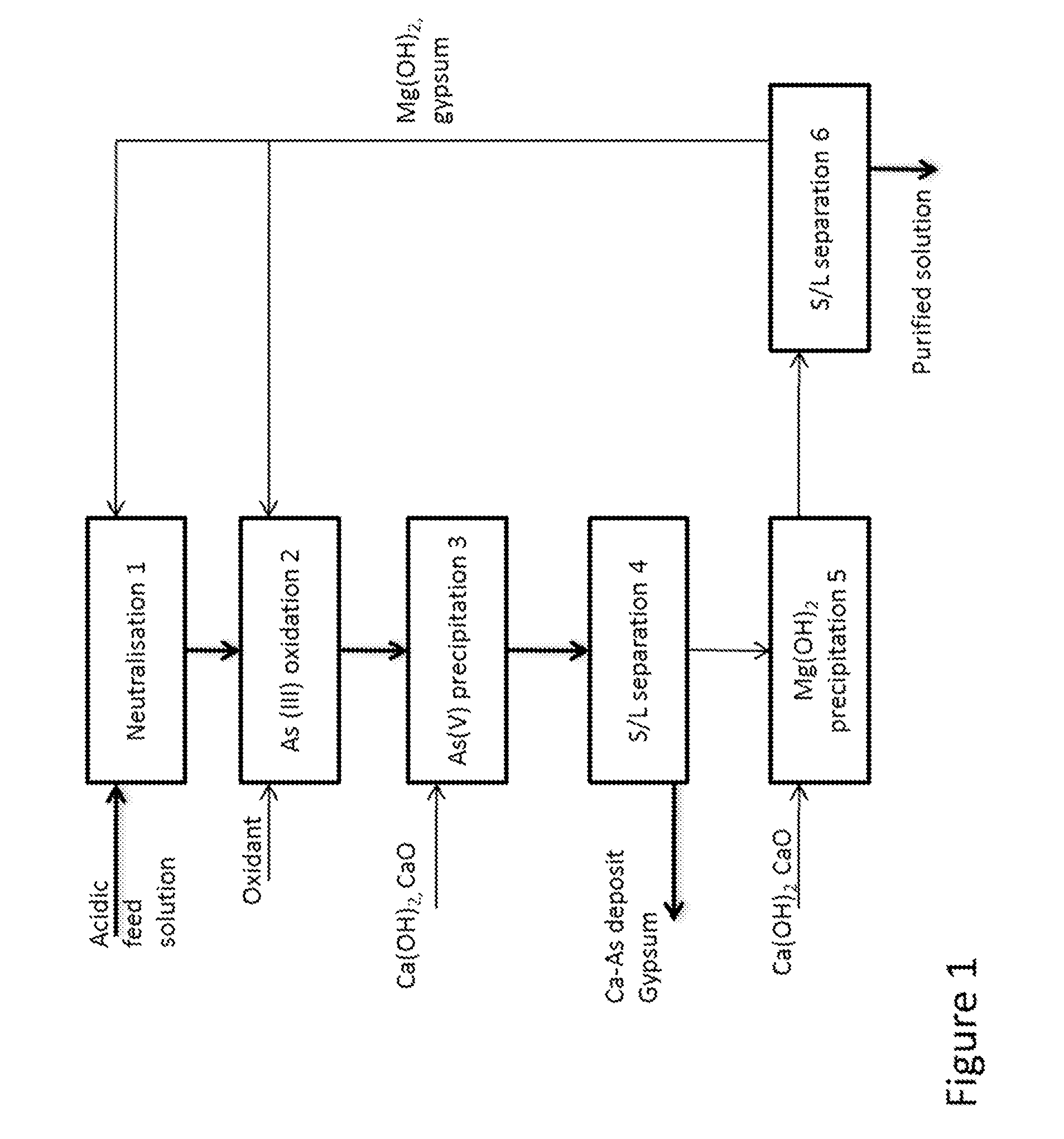

ActiveCN103215453ASolve the impact of secondary pollutionReach disposalWater contaminantsWaste water treatment from metallurgical processWastewaterCopper

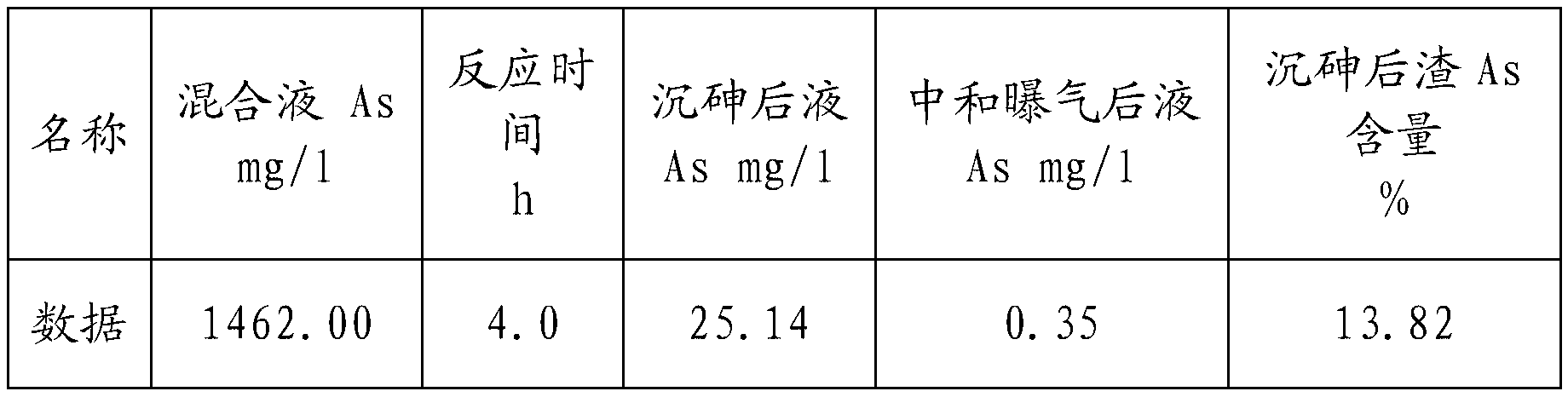

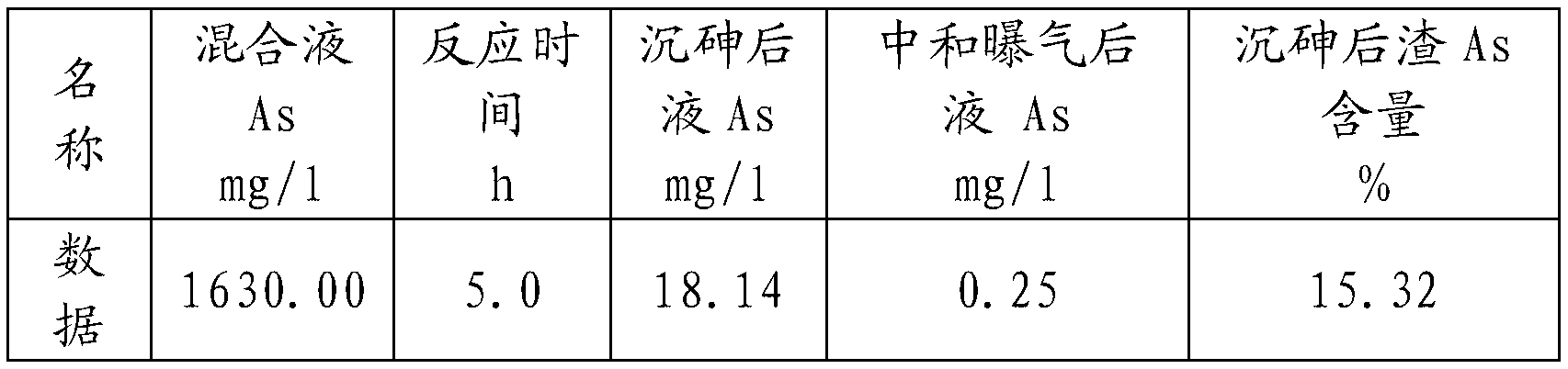

The invention relates to a method for treating waste residue by using arsenious wastewater in a clean mode. The method comprises the following steps of: carrying out roasting pretreatment on arsenious gold concentrate so as to generate dusty fume and roasting sand, recycling As2O3 from the dusty fume containing gas-state As2O3, CO2 and SO2 by using a cloth bag, and carrying out wet-method purification by using an acid-making system so as to generate arsenic dilute acid; extracting arsenic and copper from the generated roasting sand by using a 5-10% sulfuric acid solution, so as to generate an arsenic pickle liquid; carrying out neutralization reaction on a mixed solution of the arsenic dilute acid and the arsenic pickle liquid and lime so as to settle arsenic; at the end of the reaction, adding a flocculating agent for concentrating and settling, carrying out neutralization aeration treatment on the liquid after the arsenic is settled, so as to recycle the liquid; and after the arsenic is settled, returning the residue, namely calcium arsenate, to the processes of gold concentrate size mixing, roasting, spraying and condensation so as to generate an arsenic trioxide product. The arsenious dilute acid and the pickle liquid are directly neutralized by lime so as to generate the arsenious waste residue, namely calcium arsenate, and then the calcium arsenate is roasted to generate arsenic trioxide product, so that the secondary environment pollution of the arsenious dilute acid and the pickle liquid treatment waste residue is prevented, and the purpose of innocent treatment is reached.

Owner:SHANDONG GUODA GOLD

Method for immobilizing arsenic, and arsenic-containing vitrified waste

ActiveUS20180354840A1Stable storageEffectively utilize limited volumeSludge treatmentTransportation and packagingArsenateCalcium hydroxide

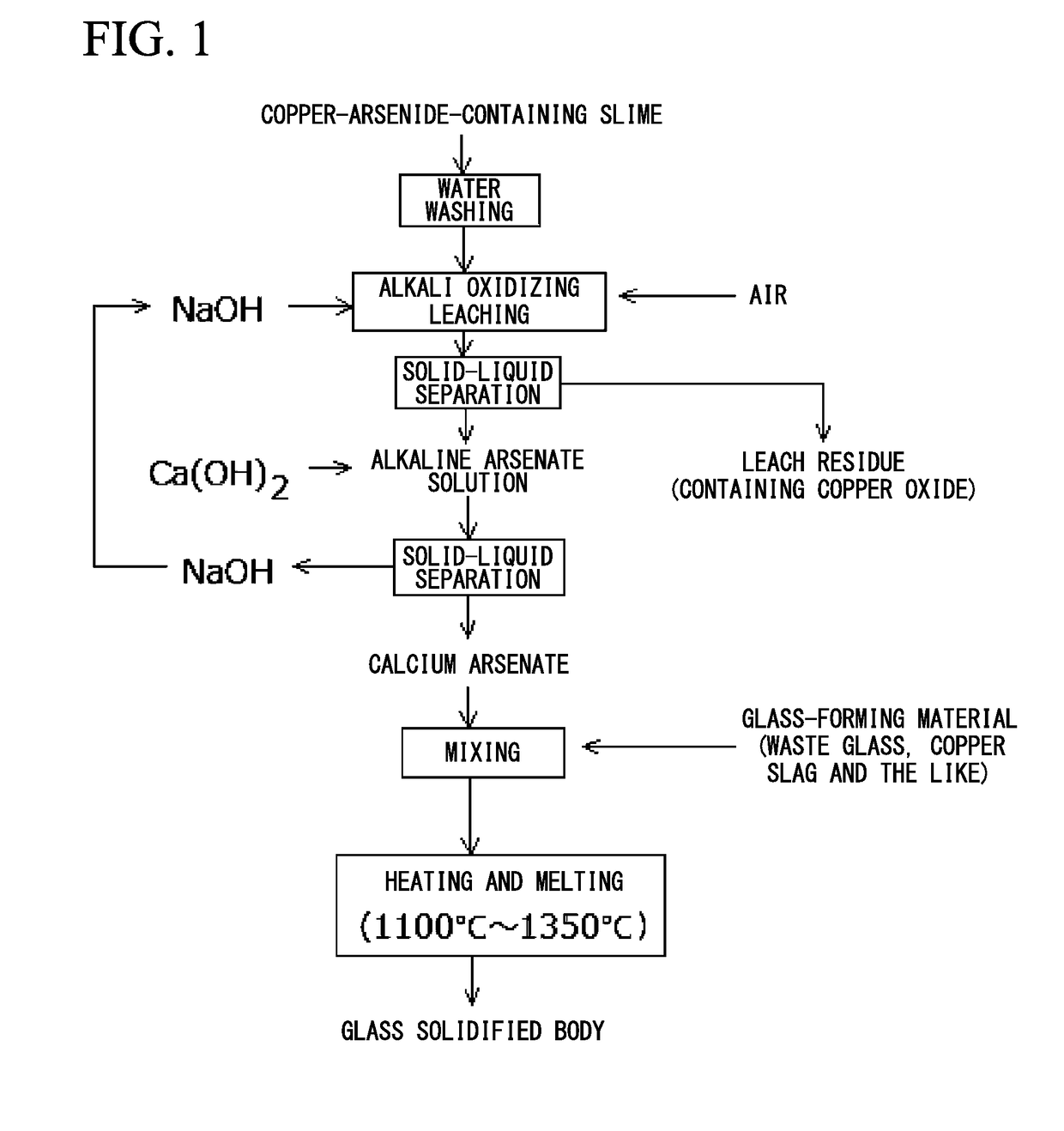

A method for immobilizing arsenic includes adding calcium arsenate to a glass-forming material containing iron, silica, and alkaline components so that an iron / silica weight ratio is in a range of 0.5 to 0.9 and an amount of alkaline components is in a range of 14 wt % to 26 wt %, and thereby incorporating the arsenic into a glass solidified body. For example, the method for immobilizing arsenic may include: adding an alkaline solution and an oxidizing agent to a copper-arsenic-containing substance, and thereby carrying out an oxidizing leaching; separating a leach residue by solid-liquid separation; adding calcium hydroxide to a recovered alkaline arsenate solution to generate calcium arsenate; and adding the glass-forming material to the recovered calcium arsenate so that the iron / silica weight ratio and the amount of alkaline components are in the above-mentioned ranges, and thereby incorporating the arsenic into the glass solidified body.

Owner:MITSUBISHI MATERIALS CORP

Comprehensive recovery process for antimony smelting arsenic alkali residues

ActiveCN112941312AMeet the requirements for arsenic content in general demandHarmlessAlkali metal oxidesProcess efficiency improvementCalcium hydroxideSlag

The invention discloses a comprehensive recovery process for antimony smelting arsenic alkali residues. The comprehensive recovery process comprises the following steps of (1) crushing and briquetting, specifically, firstly breaking the antimony smelting arsenic alkali residues, then mixing the broken antimony smelting arsenic alkali residues with a reducing agent, a slag former and fuel, finely grinding the mixture, adding water for mixing and preparing the mixture into a block mass; (2) arsenic and antimony pyrogenic volatilization, specifically, calcining and volatilizing to obtain alkaline residues and an antimony-containing arsenic trioxide crude product; (3) alkaline residue leaching, specifically, firstly breaking the alkaline residues, finely grinding the broken alkaline residues, after adding water, carrying out heating leaching, solid-liquid separation, and washing to obtain silicon dioxide residues and an arsenic-containing alkaline solution; and (4) arsenic removal and purification of the alkaline solution, specifically, adding an arsenic removal agent and a purifying agent into the arsenic-containing alkali solution, heating for deep arsenic removal reaction, carrying out solid-liquid separation to obtain calcium arsenate / calcium hydroxide mixed salt and arsenic-removed alkali solution, and concentrating and crystallizing the arsenic-removed alkali solution to obtain solid sodium hydroxide / sodium carbonate mixed alkali. The method is high in arsenic and antimony volatilization rate, high in alkali recovery rate and extremely low in arsenic content, byproducts can be efficiently recycled, no three wastes are discharged, the cost is low, harmlessness and recycling of the arsenic alkali residues are achieved, and the method is suitable for large-scale industrial treatment.

Owner:刘义冬

Method for stabilizing arsenic-calcium slag

The invention belongs to the technical field of arsenic-containing waste residue treatment, and provides a method for stabilizing arsenic-calcium slag, which comprises the following steps: mixing thearsenic-calcium slag, water-soluble ferric salt and water to obtain a mixture; adjusting the pH value of the mixture to 2-13; and carrying out a combination reaction on the mixture to generate iron calcium arsenate so as to complete stabilization treatment of the arsenic calcium slag, wherein the molar ratio of iron to arsenic in the mixture is 0.1-13:1. According to the method provided by the invention, the arsenic in the arsenic-calcium slag can be effectively stabilized by controlling the molar ratio of iron to arsenic and the pH value of the mixture, and the leaching rate of the arsenic inthe arsenic-calcium slag treated by the method is relatively low.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

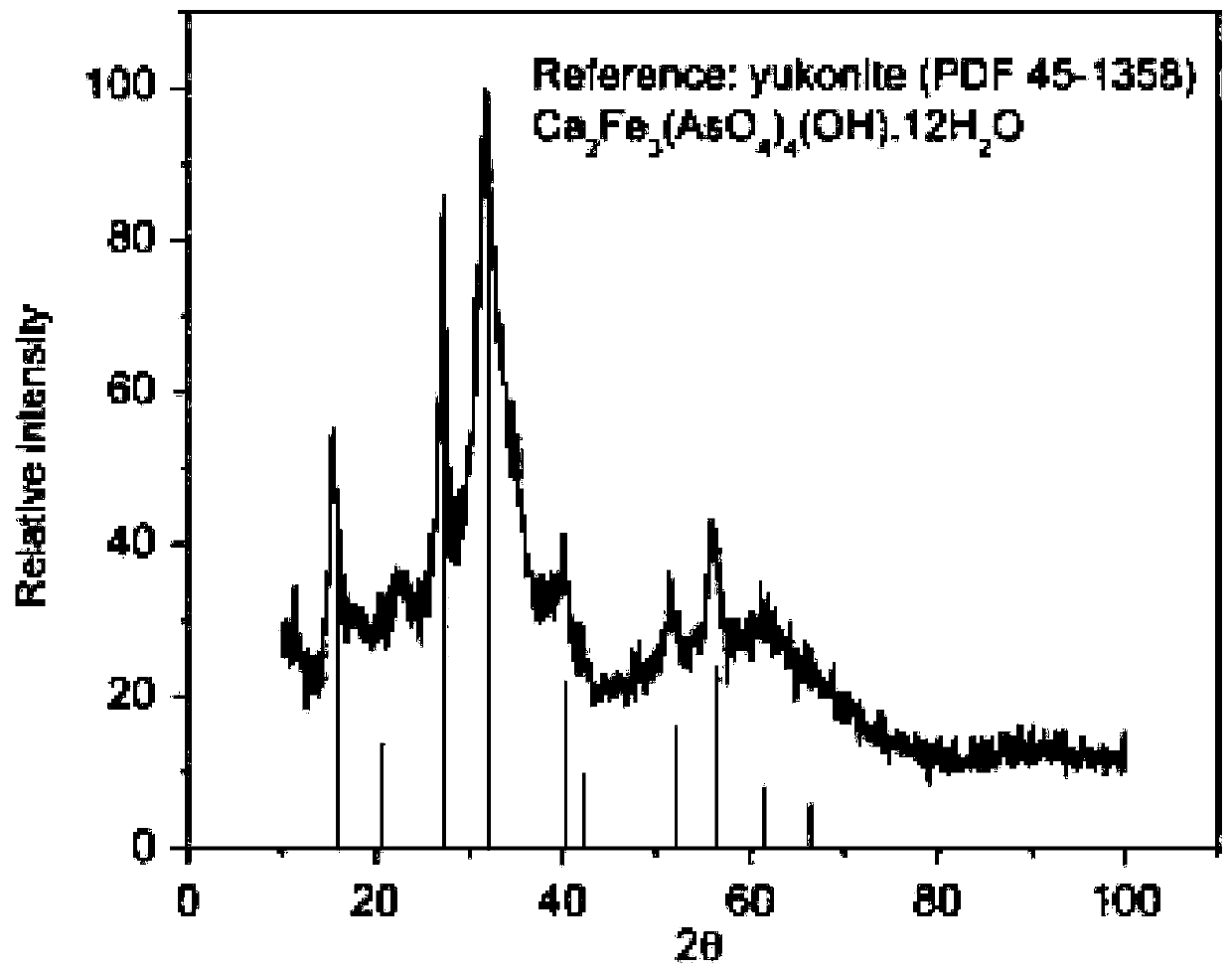

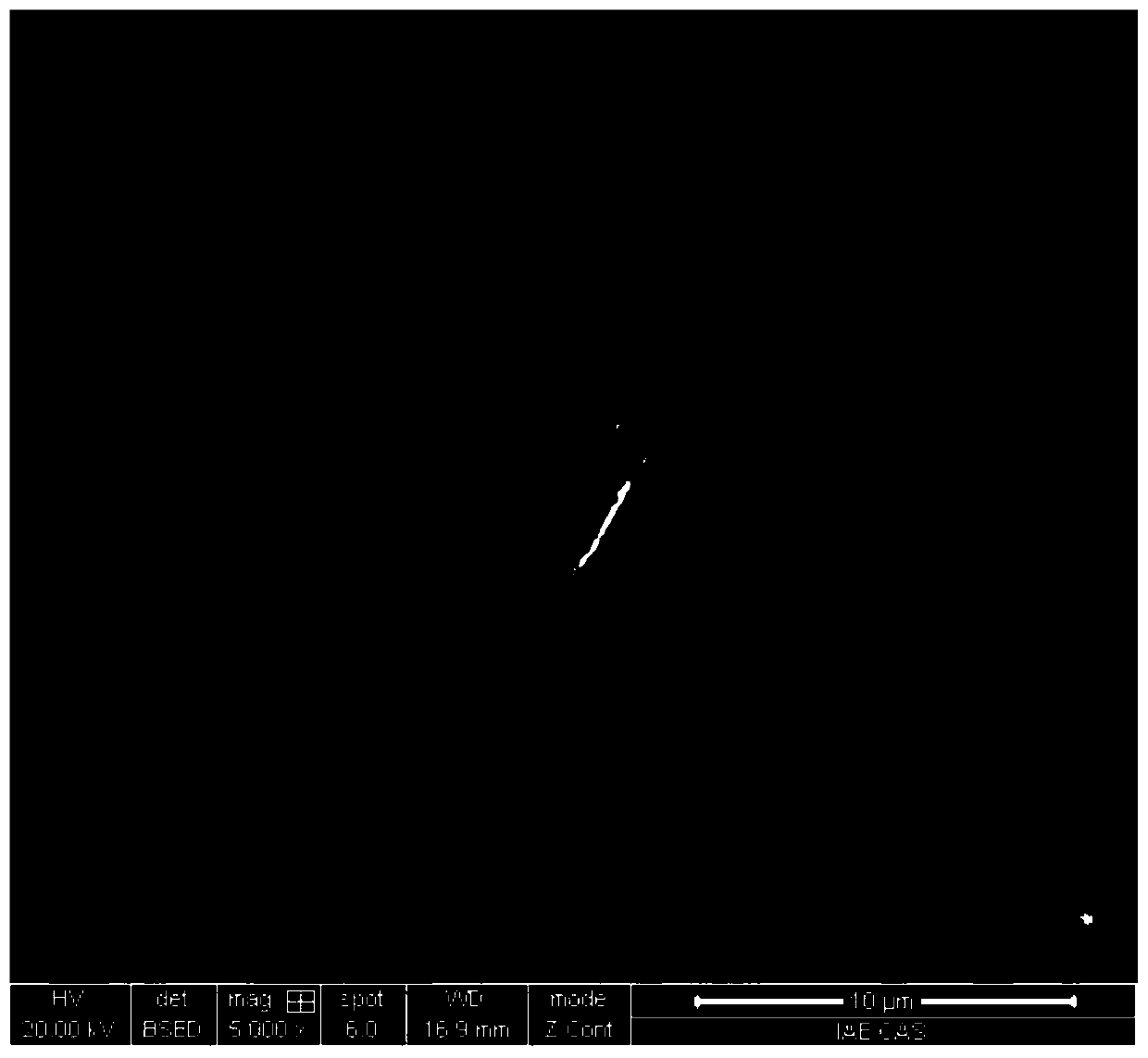

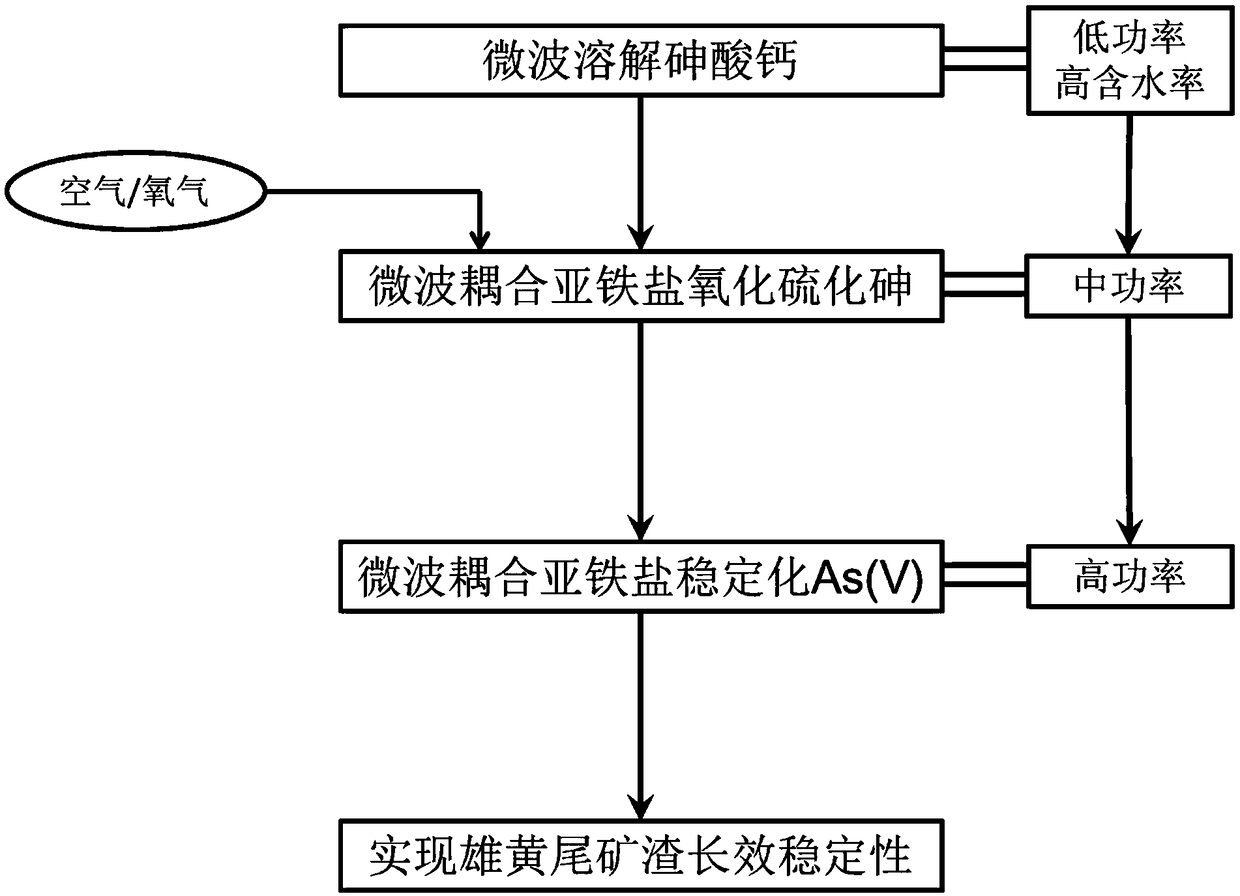

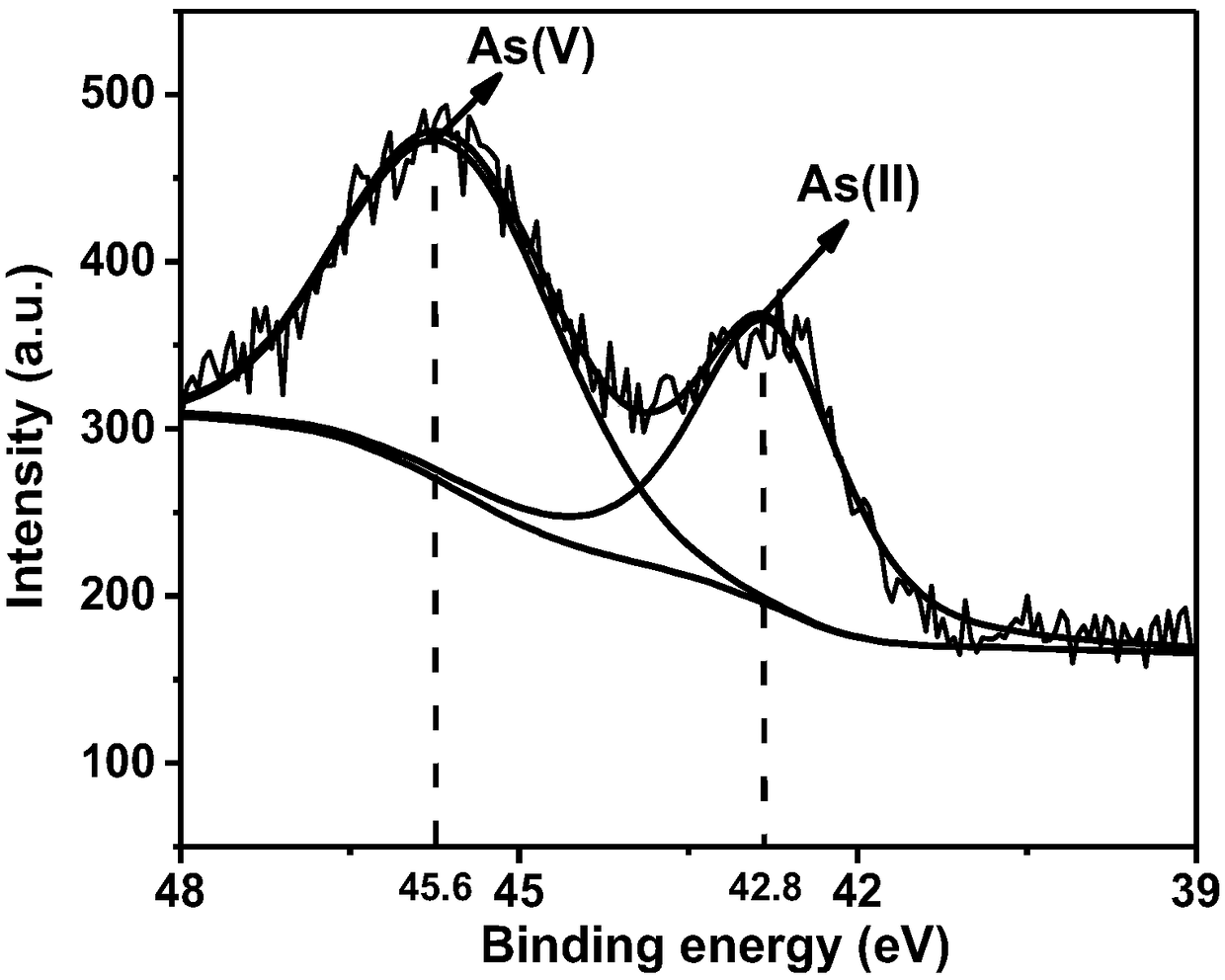

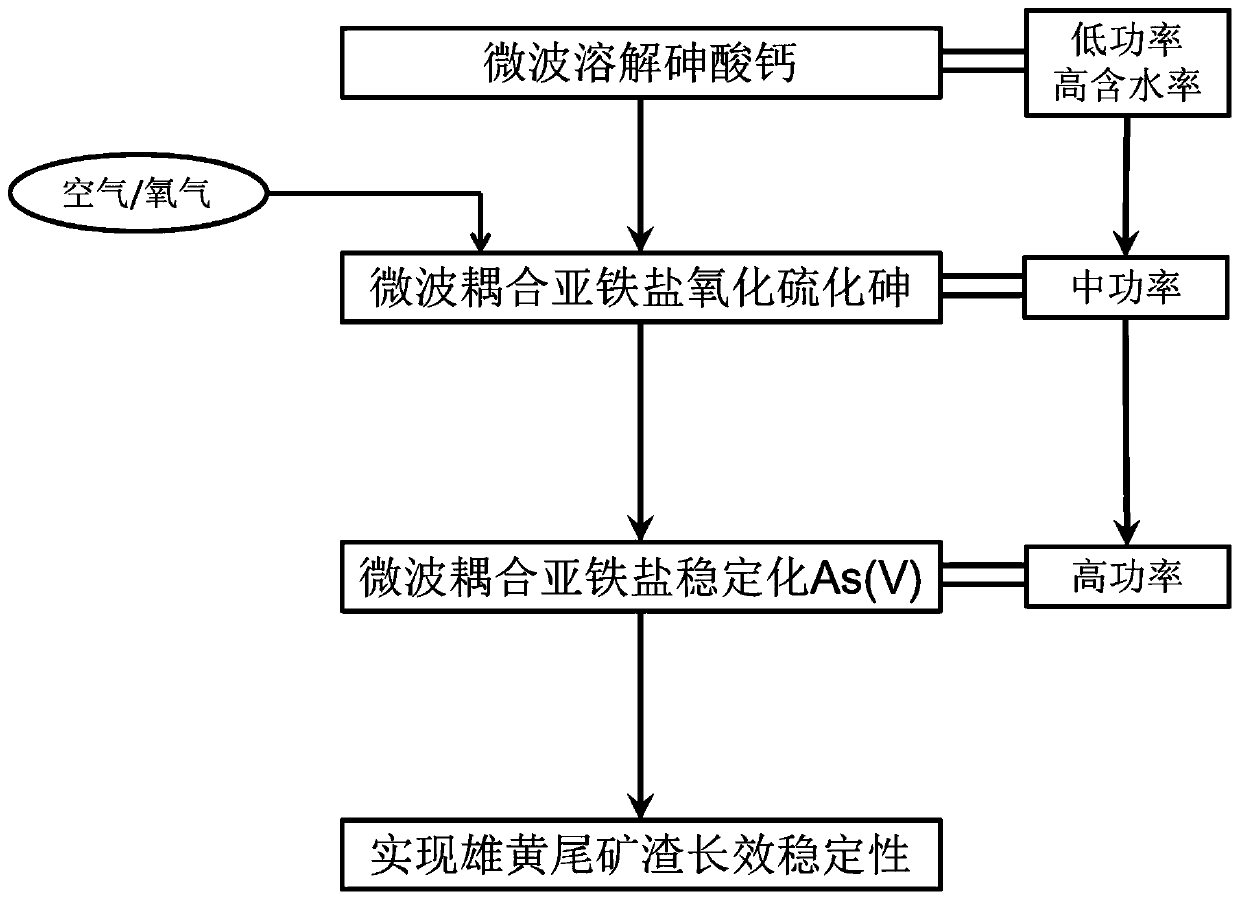

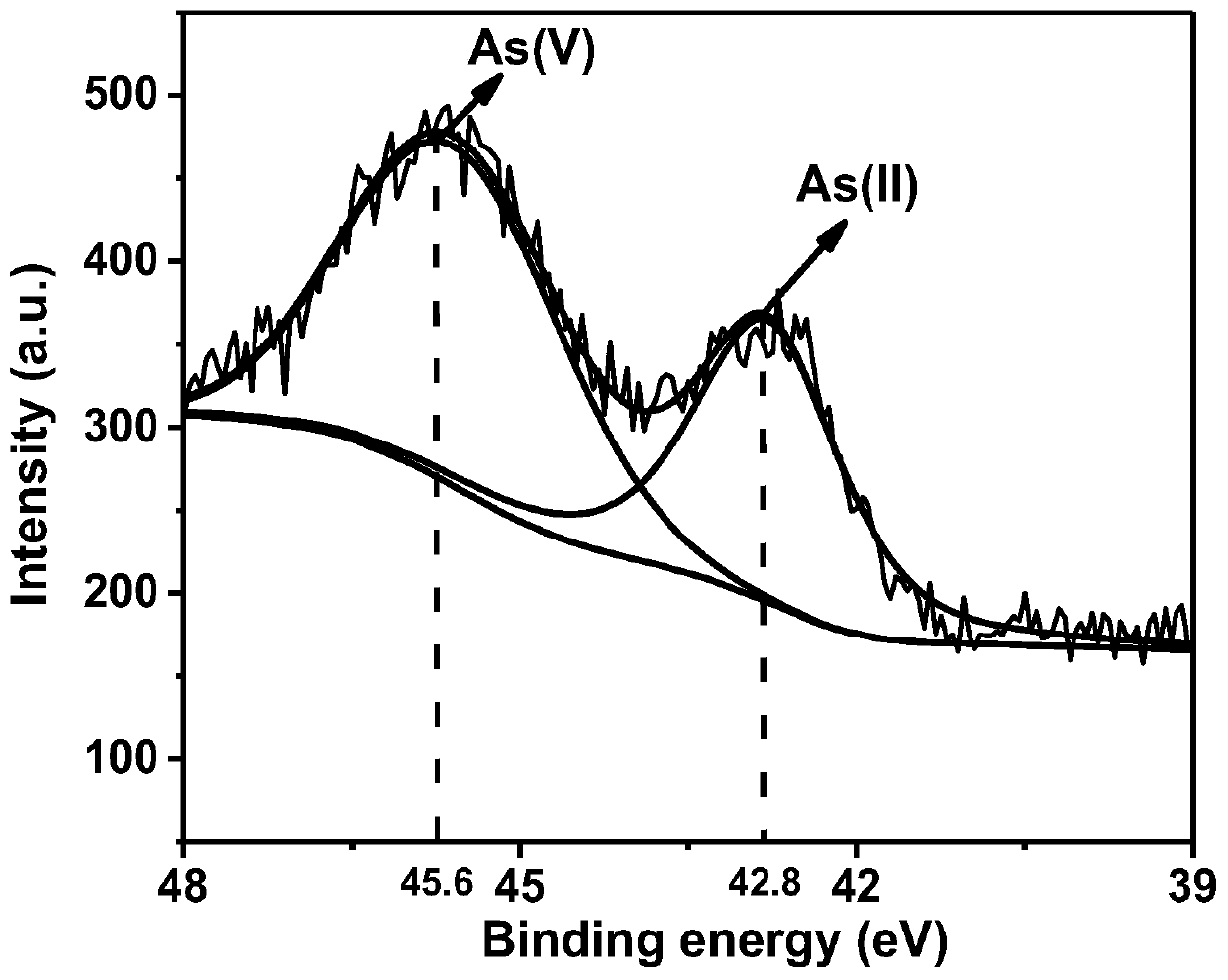

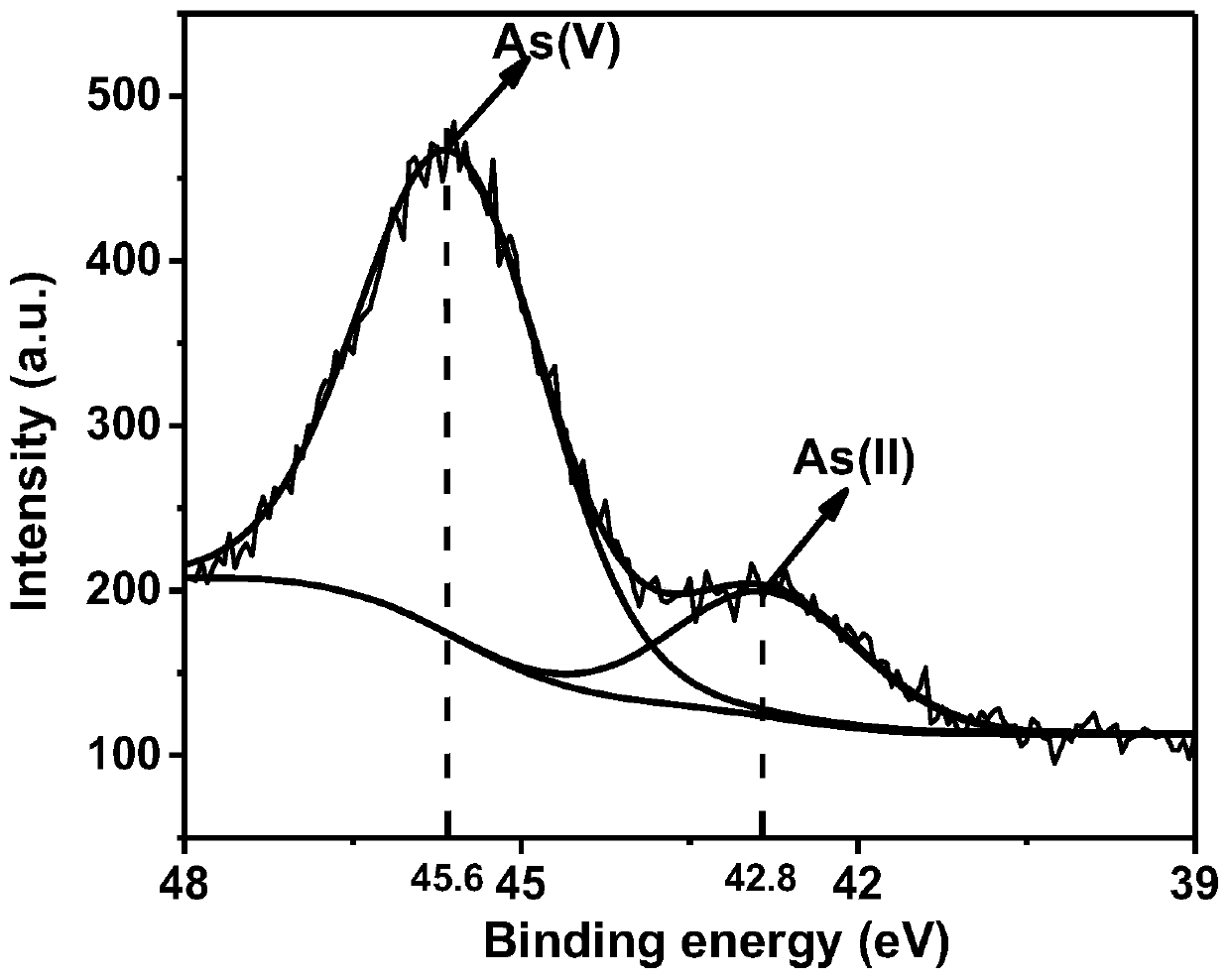

Stabilized treatment method for realgar tailing residues

The invention discloses a stabilized treatment method for realgar tailing residues. The stabilized treatment method for the realgar tailing residues comprises the following steps of (1) crushing the realgar tailing residues, adding water inside, uniformly stirring, and carrying out first-stage microwave treatment under the action of a microwave field at the power ranging from 100W to 300W; (2) adding water and ferrous salt inside, uniformly stirring, feeding air or oxygen, and meanwhile, carrying out second-stage microwave treatment under the action of a microwave field at the power ranging from 300W to 500W; and (3) carrying out third-stage microwave treatment under the action of a microwave field at the power ranging from 500W to 700W, so that the stabilization of the realgar tailing residues is realized. According to the stabilized treatment method for the realgar tailing residues provided by the invention, through designing a whole process technology of the method, especially improving parameters and conditions of a key microwave treatment process, and dissolving, oxidizing and stabilizing the realgar tailing residues for three stages, the problems of slow calcium arsenate dissolution rate, slow arsenic sulfide oxidation rate and insufficient product long-time stability can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Stabilization of hazardous materials

ActiveCN110944724ATransportation and packagingContaminated soil reclamationPhosphateFerrous Arsenate

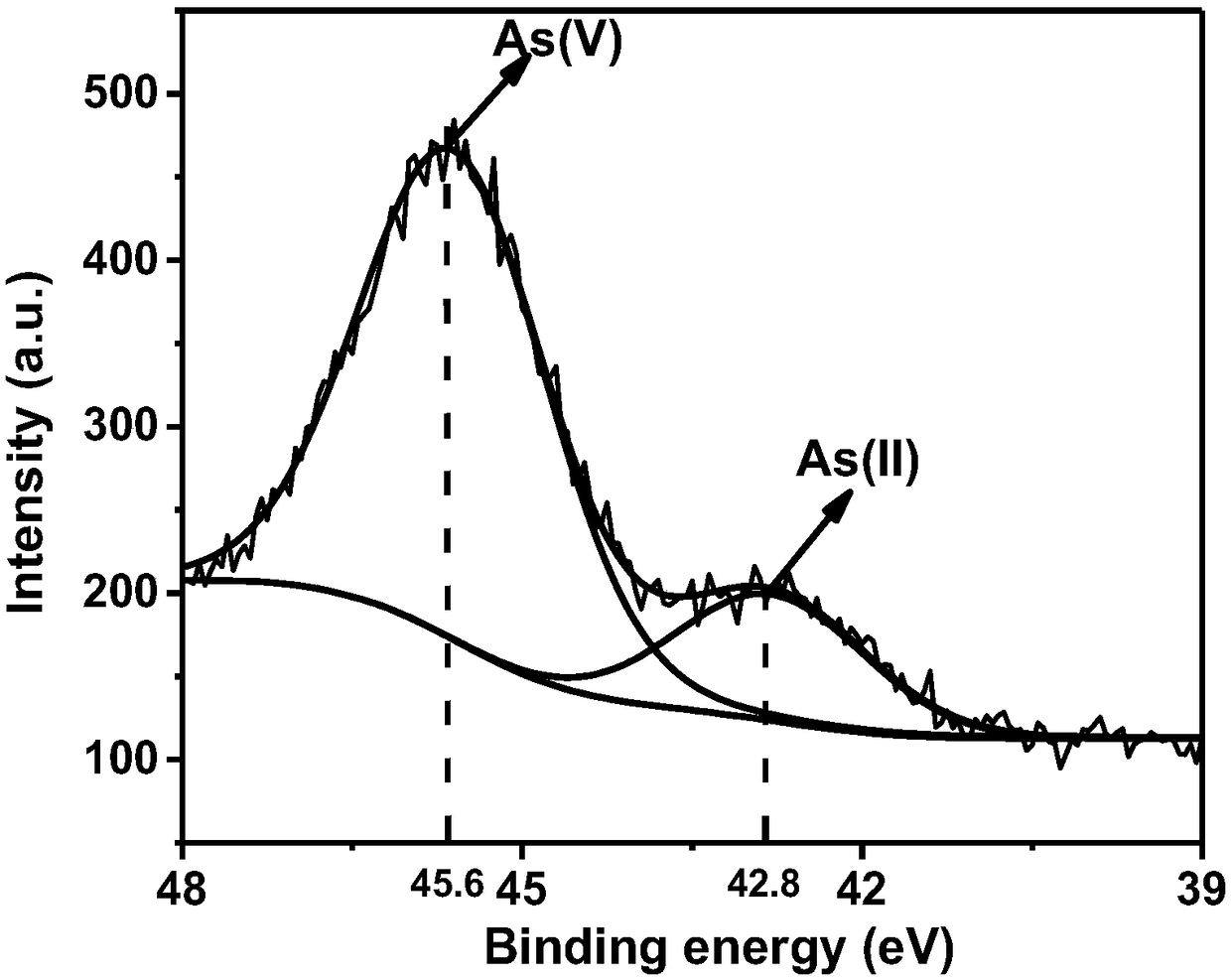

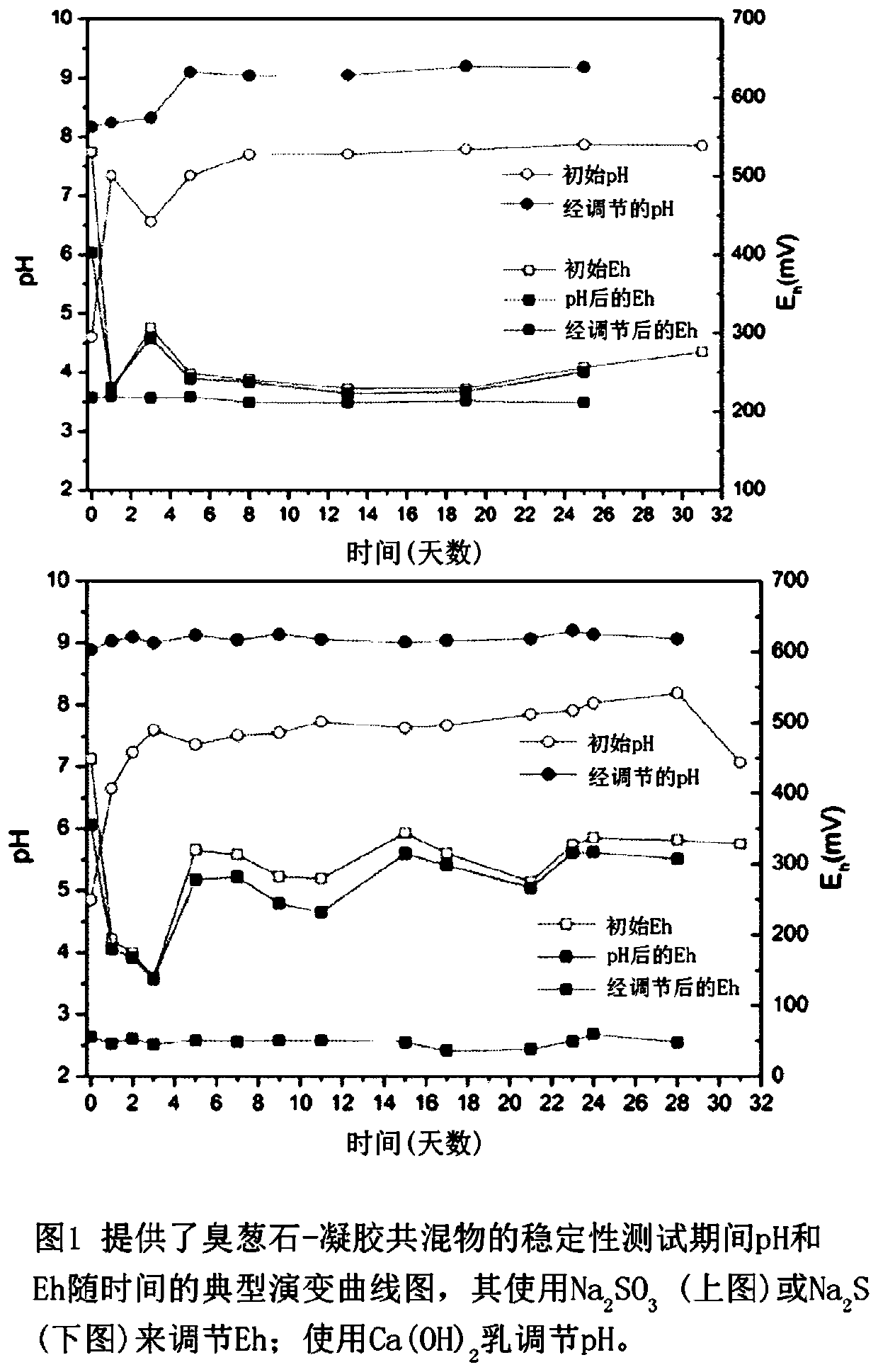

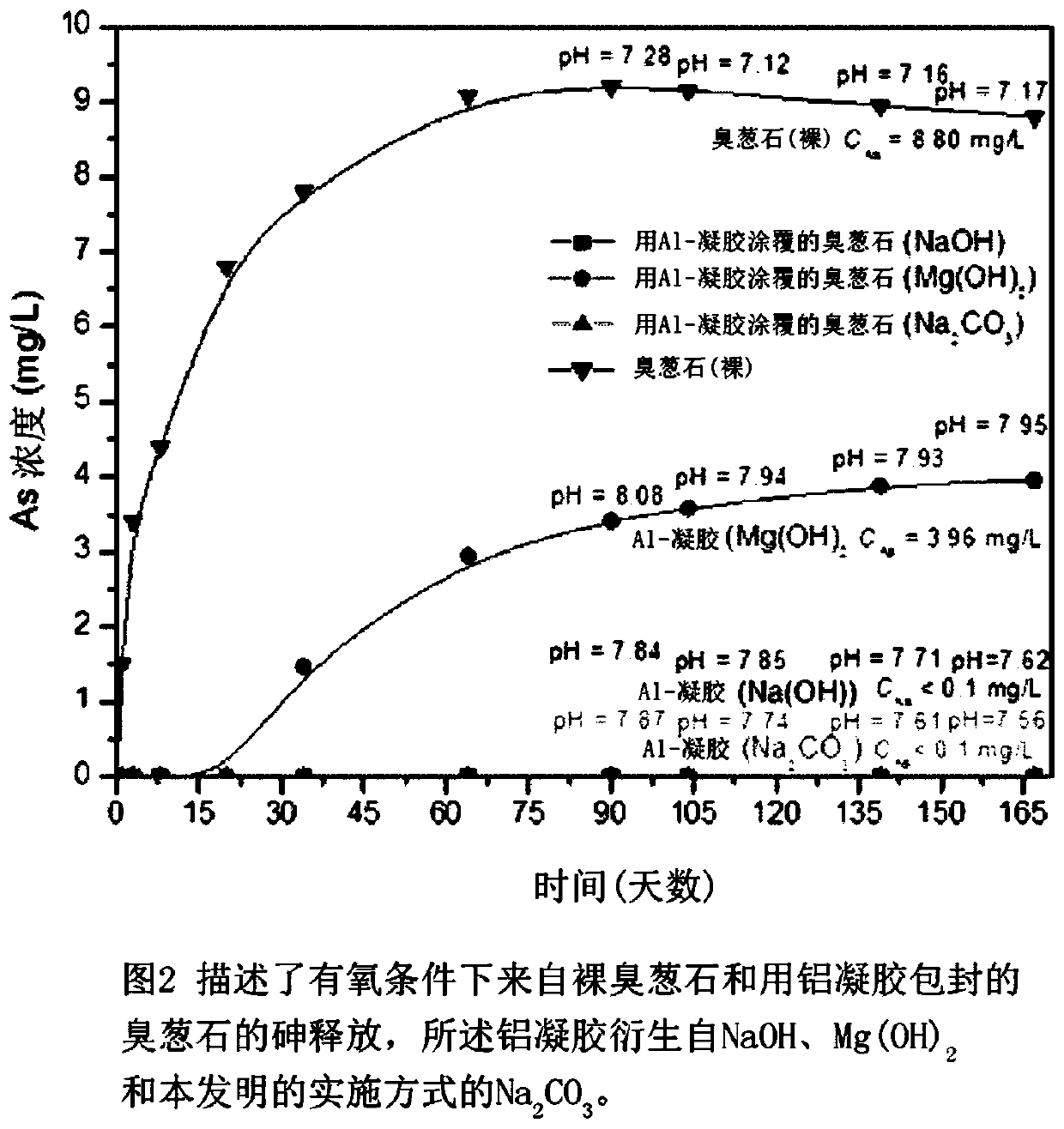

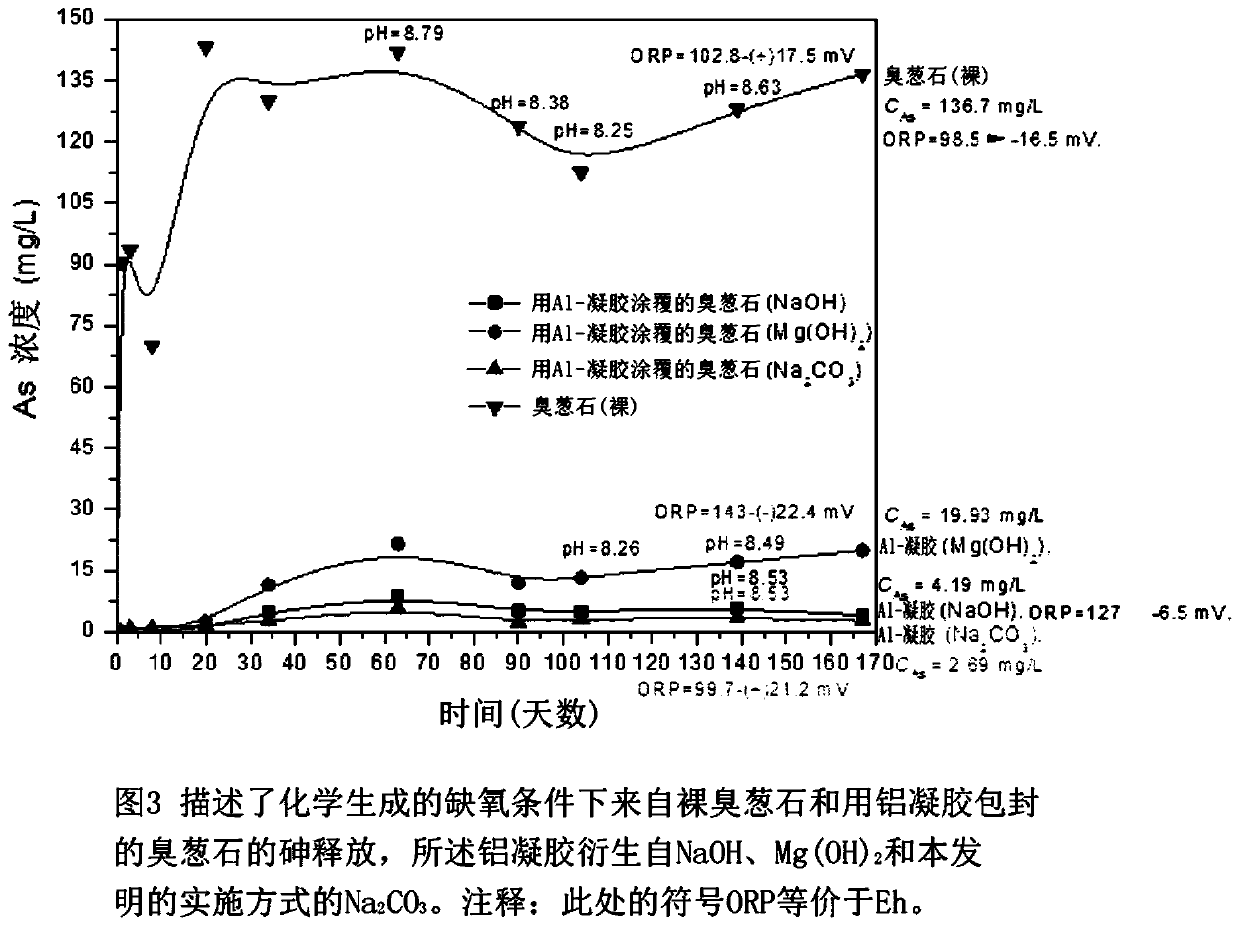

The invention relates to stabilization and / or solidification of hazardous materials which might be generated by activities like mining, milling or smelting industrial operations, such as arsenical wastes (such as scorodite, arsenic sulfides, calcium arsenates or arsenites, mixed calcium arsenates-phosphates, ferrous arsenate, ferric arsenite, or arsenic trioxide), antimony, mercury or selenium-containing wastes through the encapsulation of the arsenical wastes in the mineralized products of hydrolyzed aluminum gels created through the partial neutralization of A1(SO4)1.5 by a carbonate.

Owner:MCGILL UNIV

Method for recovery of valuable metal from white smoke and harmless treatment

InactiveCN106834704AEasy to separatePromote enrichmentArsenites/arsenatesProcess efficiency improvementBrickFiltration

The invention discloses a method for recovery of valuable metal from white smoke and harmless treatment. Sodium chlorate is used as an oxidizing agent; sulfuric acid is used for oxidation leaching for the white smoke; the filtration is performed; and acid leaching slag serves as a gold concentrate to feed in a copper concentrate, and is returned to a low blowing smelting furnace of a pyrogenic copper smelting system. Acid leaching liquid is added in iron powder for replacement; obtained arsenic-contained sponge copper is alkalinely leached by sodium hydroxide to remove arsenic; and the arsenic-removed sponge copper is returned to an anode furnace of the pyrogenic copper smelting system for refining. After liquid after replacement is mixed with alkali leaching liquid, the PH value is adjusted by lime milk; then, the mixture is fed in air for oxidation to generate a property-stable iron calcium arsenate compound; arsenic is cured as a stable compound; and a baking-free brick can be further prepared. The method is used for treating the white smoke; the copper recovery rate is higher than 93%; the copper content of sponge copper is higher than 90%; the leaching rate of arsenic is higher than 90%; and such precious metals as gold and silver of the acid leaching slag are highly enriched, can serve as gold concentrates to feed in the copper concentrate, and are returned to a bottom blowing smelting furnace of the pyrogenic copper smelting system.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

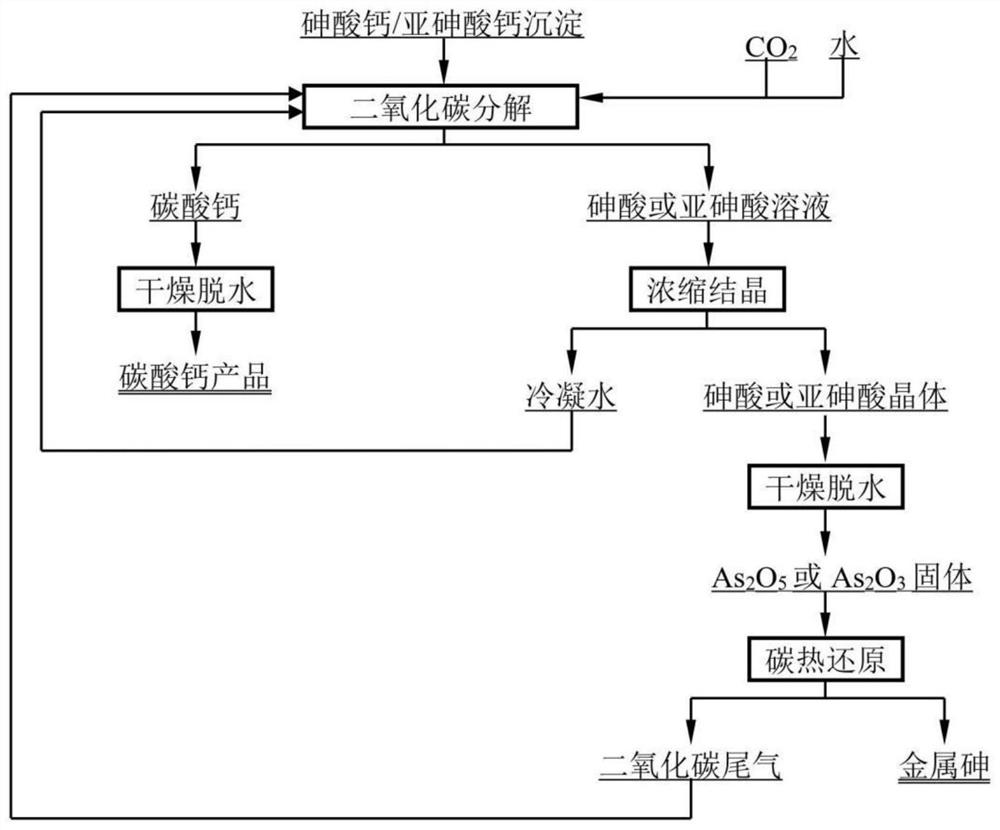

Method for comprehensively recovering calcium and arsenic from calcium arsenate/calcium arsenite precipitate

ActiveCN112609092ASmall footprintReduce hazardous waste disposal feesCalcium/strontium/barium carbonatesProcess efficiency improvementArsenous acidAqueous solution

The invention relates to a method for comprehensively recovering calcium and arsenic from calcium arsenate / calcium arsenite precipitate. The method comprises the following steps that (1) the calcium arsenate / calcium arsenite precipitate is mixed with water according to a liquid-solid ratio of (2-10):1 for size mixing, carbon dioxide gas is introduced at a leaching temperature of 25-100 DEG C, and the calcium and arsenic precipitate reacts with an aqueous solution of carbon dioxide to obtain mixed slurry; liquid-solid separation is performed on the mixed slurry to obtain a calcium carbonate solid and an arsenic-containing solution; the calcium carbonate solid is dried and dehydrated to obtain a calcium carbonate product; (2) the arsenic-containing solution is concentrated, crystallized and dried to obtain As2O5 or As2O3 solid; and (3) carbon is added into the obtained As2O5 or As2O3 solid for high-temperature carbon thermal reduction to obtain metal arsenic and carbon dioxide gas. Harmless, recycling and environment-friendly treatment of the calcium-arsenic precipitate is realized in the whole process.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

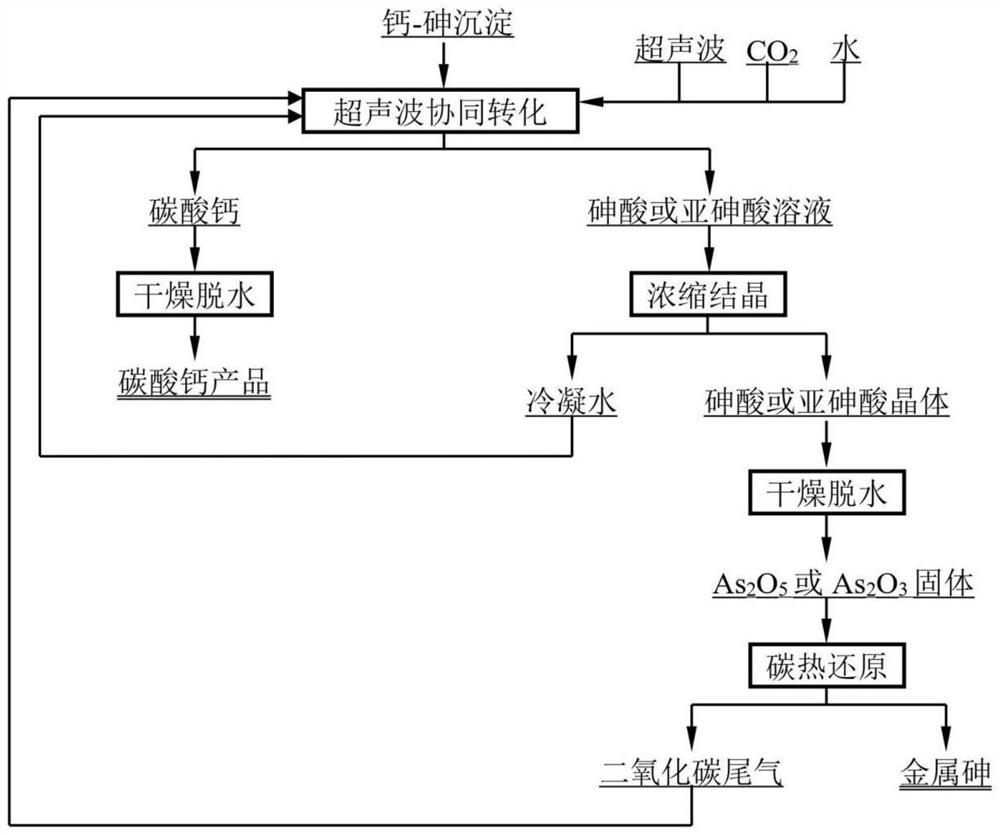

Method for synergistically converting and decomposing calcium-arsenic precipitate through ultrasonic waves

ActiveCN112813265AHarmlessRealize resourcesCalcium/strontium/barium carbonatesProcess efficiency improvementUltrasonic cavitationCalcium arsenite

The invention relates to a method for synergistically converting and decomposing a calcium-arsenic precipitate through ultrasonic waves. The method for synergistically converting and decomposing the calcium-arsenic precipitate through the ultrasonic waves comprises the following steps that (1), the calcium-arsenic precipitate and water are mixed according to a liquid-solid ratio of (2 to 10) to 1 for size mixing, carbon dioxide gas is introduced at a leaching temperature of 25-90 DEG C, a cavitation generation device is introduced, the calcium-arsenic precipitate is reacted with an aqueous solution of carbon dioxide, and mixed slurry is obtained; (2), liquid-solid separation is carried out on the mixed slurry to obtain calcium carbonate and an arsenic-containing solution; and (3), evaporative crystallization-carbon thermal reduction is carried out on the arsenic-containing solution to obtain metal arsenic. According to the method for synergistically converting and decomposing the calcium-arsenic precipitate through the ultrasonic waves, the calcium-arsenic precipitate (calcium arsenate, calcium arsenite or a mixture of the calcium arsenate and the calcium arsenite) can be quickly converted and decomposed, so that calcium carbonate with low arsenic content is obtained from the calcium-arsenic precipitate under the action of an ultrasonic cavitation effect, the conversion rate of the calcium-arsenic precipitate is effectively improved, the content of arsenic in the calcium carbonate is further reduced, and finally, the purposes of reducing the hazardous waste disposal cost of the arsenic of enterprises and performing harmless disposal are achieved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

A method for preparing highly stable arsenic-fixed minerals by distribution crystallization

ActiveCN106823233BSimple processEasy to operateChemical protectionCatalytic oxidationReduced properties

Owner:CENT SOUTH UNIV

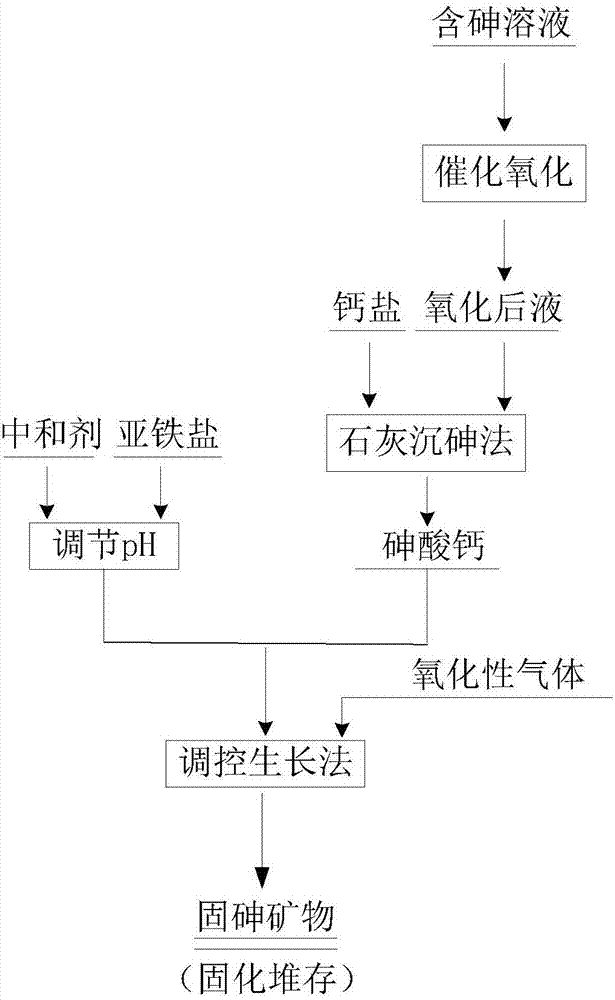

A method for preparing high-stability solid arsenic minerals by regulating growth method

The invention relates to a method for preparing high-stability arsenic fixing minerals through an adjusted and controlled growth process. The method comprises the step of removing arsenic from a high-arsenic solution and curing the high-arsenic solution, thereby realizing innocent treatment on an arsenic containing solution. According to the method, after trivalent arsenic in the arsenic-containing solution is converted into pentavalent arsenic through catalytic oxidation, the oxidized solution is synthesized into high-stability arsenic fixing minerals through a lime arsenic precipitation process-adjusted and controlled growth process, and the high-stability arsenic fixing minerals can be directly piled up. Calcium arsenate is firstly obtained through the lime arsenic precipitation process, and then calcium arsenate is converted into high-stability arsenic fixing minerals through the adjusted and controlled growth process, so that toxicity leaching meets regulations of GB5085.3-2007(solid waste identification standards-leaching toxicity identification). The method is short in technological process and is good in arsenic precipitation effect; the arsenic-precipitated solution can be directly exhausted, and the synthesized arsenic fixing minerals are high in stability, and can be stably piled up within a wide pH value range of 2-11 under strong reducing conditions.

Owner:CENT SOUTH UNIV

A kind of realgar tailing slag stabilization disposal method

ActiveCN108704239BAchieve dissolutionAchieve stabilizationChemical protectionFerrous saltsPhysical chemistry

The invention discloses a stabilized treatment method for realgar tailing residues. The stabilized treatment method for the realgar tailing residues comprises the following steps of (1) crushing the realgar tailing residues, adding water inside, uniformly stirring, and carrying out first-stage microwave treatment under the action of a microwave field at the power ranging from 100W to 300W; (2) adding water and ferrous salt inside, uniformly stirring, feeding air or oxygen, and meanwhile, carrying out second-stage microwave treatment under the action of a microwave field at the power ranging from 300W to 500W; and (3) carrying out third-stage microwave treatment under the action of a microwave field at the power ranging from 500W to 700W, so that the stabilization of the realgar tailing residues is realized. According to the stabilized treatment method for the realgar tailing residues provided by the invention, through designing a whole process technology of the method, especially improving parameters and conditions of a key microwave treatment process, and dissolving, oxidizing and stabilizing the realgar tailing residues for three stages, the problems of slow calcium arsenate dissolution rate, slow arsenic sulfide oxidation rate and insufficient product long-time stability can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Aromatic non-toxic insect repellent

InactiveCN103355347AImprove bad smellNo pollution in the processBiocideAnimal repellantsPaleontologyOctyl palmitate

The invention relates to an aromatic non-toxic insect repellent. The aromatic non-toxic insect repellent is mainly used for killing mosquitoes, flies, cockroaches, fleas, louses, ants and the like and improving unpleasant smell in humid environments in enclosed space. The aromatic non-toxic insect repellent is prepared by fully mixing and uniformly stirring sodium fluosilicate, permethrin, calcium arsenate, magnesium sulfate, octyl palmitate and essence in certain proportions. The finished product can be directly filled into bottles to be sprayed. The use amount of the aromatic non-toxic insect repellent is determined according to requirements.

Owner:陈巍

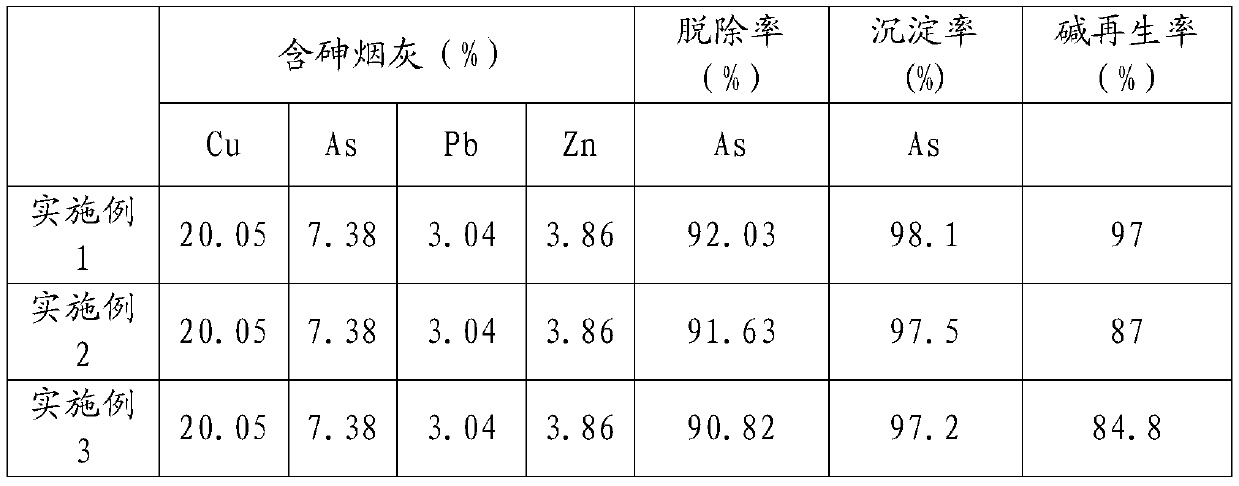

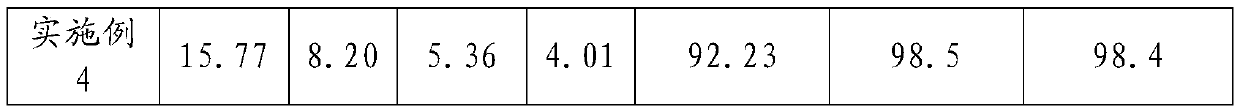

A low-cost method for removing arsenic from copper smelting high-arsenic soot

ActiveCN107779607BReduce alkali consumptionEffective enrichment of arsenicPhotography auxillary processesProcess efficiency improvementArsenic fumesPregnant leach solution

The invention discloses a method for low-cost dearsenification of copper smelting high-arsenic fume. The method comprises the following steps: A, performing neutral leaching on arsenic-containing fume, and after leaching is completed performing solid-liquid separation so as to obtain neutral leachate and natural leachate slag; B, performing primary normal-pressure alkali leaching on the natural leachate slag obtained in the step A, and after leaching is completed, performing solid-liquid separation so as to obtain primary leachate and primary leachate slag, wherein the final alkali concentration of the leachate is controlled to be less than 50g / L; C, performing secondary normal pressure alkali leaching on the primary leachate slag obtained in the step B, and after leaching is completed, performing solid-liquid separation so as to obtain secondary leachate and secondary leachate slag, wherein the NaOH concentration is 40-150g / L; D, performing rotational flow electrodeposition process copper removal by using the leachate obtained in the step A, wherein products are standard cathode copper and a copper removal after liquid; and E, performing lime causticization on the primary leachateobtained in the step B, and performing solid-liquid separation, thereby obtaining calcium arsenate and a causticization after liquid. The method is capable of low-cost high-efficiency dearsenification of c arsenic-containing fume and solving the influence of continuous increase of arsenic in copper concentrate to the copper smelting process, and has the advantages of environment protection, economy, energy conservation and resource utilization rates.

Owner:紫金铜业有限公司 +1

A method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510BHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateCalcium arsenite

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. First, the arsenic in the arsenic-containing wastewater is separated and enriched in the form of calcium arsenate or / and calcium arsenite precipitation, and then the obtained arsenic enrichment Oxidation in ferric sulfate or ferrous sulfate solution, through normal pressure reaction or pressurized hydrothermal reaction or normal pressure hydrothermal reaction, the arsenic in it is solidified in the form of scorodite crystals, and the obtained scorodite crystal grains Complete development, uniform distribution, stable structure under acidic conditions. The invention has the advantages of high operation efficiency, good arsenic fixation effect, convenient operation, low arsenic solidification treatment cost, etc., and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

Preparation method of industrial high-arsenic sludge treatment material

InactiveCN108751629AGood dispersionImprove stabilityWater contaminantsSludge detoxificationChloroacetic acidsReference function

The invention discloses a preparation method of an industrial high-arsenic sludge treatment material. The industrial high-arsenic sludge treatment material is prepared from egg shells, sodium chloride, acetic acid, calcium hypochlorite, stearic acid, chitosan, chloroacetic acid, silver nitrate, beta-cyclodextrin, polyacrylic acid and other raw materials. According to the preparation method, an arsenic stabilizer is prepared from the egg shells, and minerals such as calcium arsenate are formed by combining and fixing sodium hypochlorite and arsenic; high-toxicity trivalent arsenic is oxidized into pentavalent arsenic; the obtained silver particle-loaded chitosan, arsenic stabilizer and the like are embedded by the beta-cyclodextrin on the basis of the previous steps, and a stable fibrous membrane structure is formed through electrostatic spinning and thermal crosslinking. Therefore, an obtained fibrous membrane material is better in effect than a traditional stable curing agent, can well realize stabilizing up-to-standard treatment of arsenic-containing sludge, is convenient to recycle, and can be repeatedly used after being subjected to regeneration treatment; the high-arsenic sludge treatment cost is greatly reduced, and the industrial high-arsenic sludge treatment material has an extremely good reference function for stabilizing treatment engineering application of high-concentration arsenic-containing sludge.

Owner:WUHU EDISON AUTOMATION EQUIP

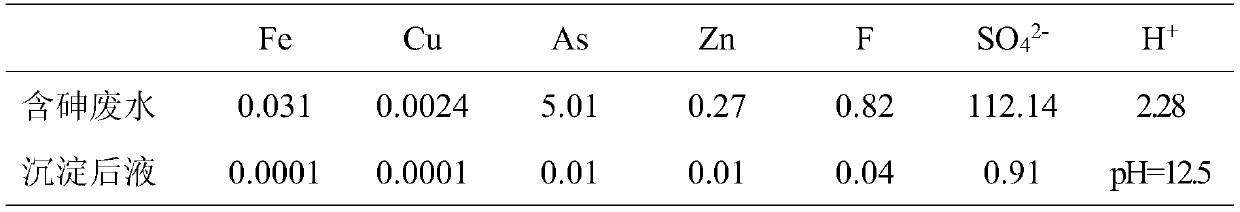

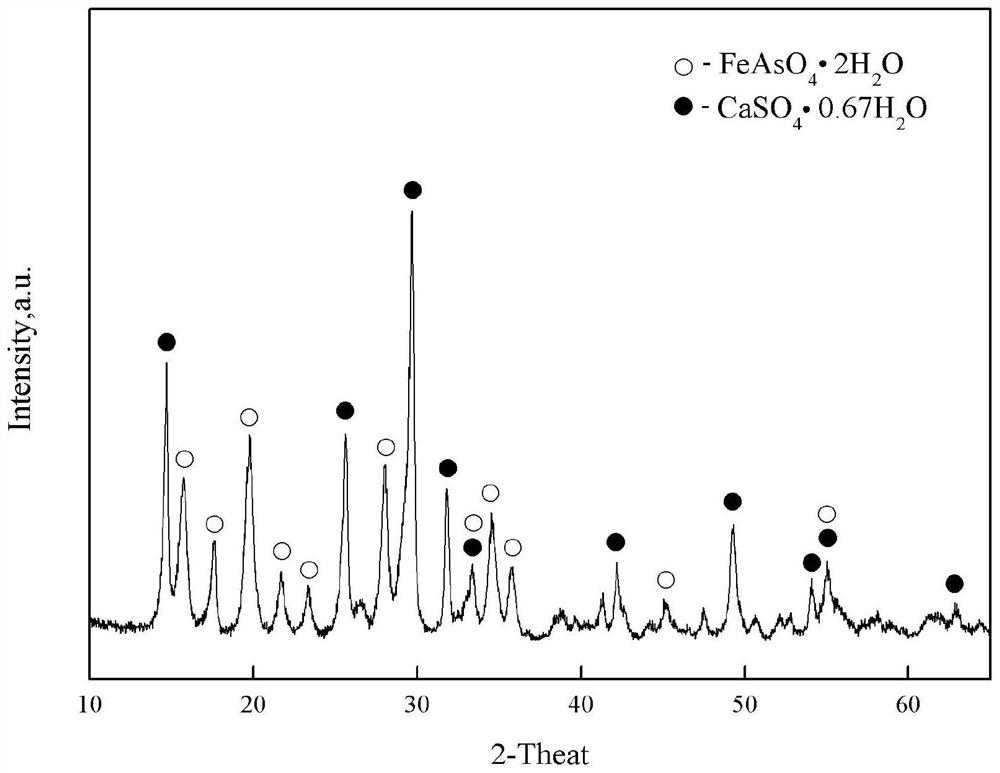

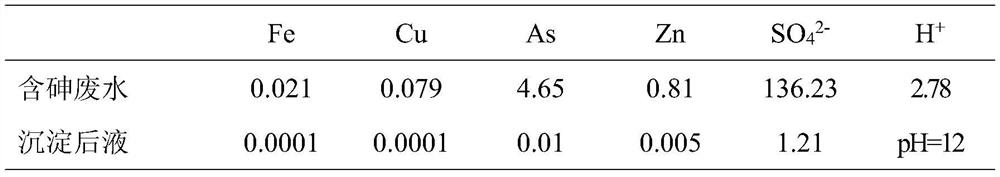

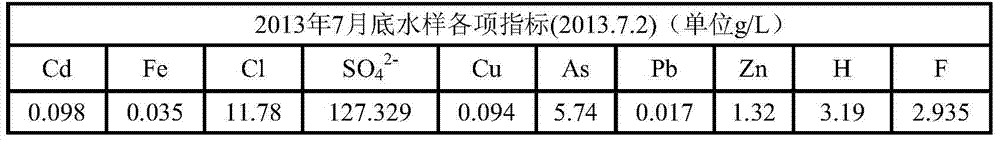

A method for treating arsenic-containing polluted acid wastewater produced by smelting flue gas

ActiveCN105152448BHigh removal rateReduce arsenic levelsWater contaminantsMultistage water/sewage treatmentSlagTherapeutic effect

The invention relates to a treatment method of arsenium-containing polluted acid wastewater generated by smelting flue gas, which comprises the following steps: pretreatment for sulfate removal; preneutralization; primary neutralization; secondary neutralization; tertiary neutralization; and circulating treatment. The pretreatment for sulfate removal, preneutralization and primary neutralization are sequentially operated to remove the sulfates and fluorine in the system in the precipitation form, wherein the removal rate is up to 95% or above, and the precipitate arsenium content is less than 0.1%. The secondary neutralization can enable more than 85% of the Cu, Fe, Pb, Zn and other metals to form a hydroxide precipitate, so that the high-content metals can be recycled. The tertiary neutralization can enable more than 95% of As to be enriched in the filter residue in the forms of calcium arsenate and calcium arsenite and to be recycled. The method can not generate unmanageable neutralization slag to form secondary pollution, and uses fewer reagents in the whole process; the calcium chloride only needs to be purchased at the time of starting; the operating process can be satisfied by circulation; and the method only consumes small amounts of lime and flocculant, is simple to operate, and has the advantages of low cost and favorable treatment effect.

Owner:JIANGXI UNIV OF SCI & TECH

A kind of separation method of antimony and arsenic in antimony arsenic material

ActiveCN108796234BHigh recovery ratePrevent volatilizationProcess efficiency improvementNitrogen oxideSodium nitrate

The invention discloses a separation method for antimony and arsenic in an antimony and arsenic material. The separation method comprises the following steps of uniformly mixing the antimony and arsenic material with sodium peroxide, calcining the mixture at 300-390 DEG C, adding water into the calcined product, stirring the calcined product, leaching the calcined product at 50-65 DEG C, filteringthe calcined product after leaching to obtain a lixivium; and adding calcium oxide into the lixivium, stirring the lixivium at a constant temperature, filtering the lixivium after full reaction to obtain filter residues and filtrate, and drying the filter residues to obtain a calcium arsenate product. By taking sodium peroxide as a primary raw material, the calcining temperature is relatively low, antimony and arsenic are prevented from being volatilized in the calcining process, and the antimony and arsenic recovery rates in later period are relatively high. Sodium peroxide which replaces sodium nitrate is taken as an oxidant, so that the material is oxidized more fully without generating oxynitride, and the environment is not polluted. As alkali is not added, the raw materials are low in cost and equipment is not corroded.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

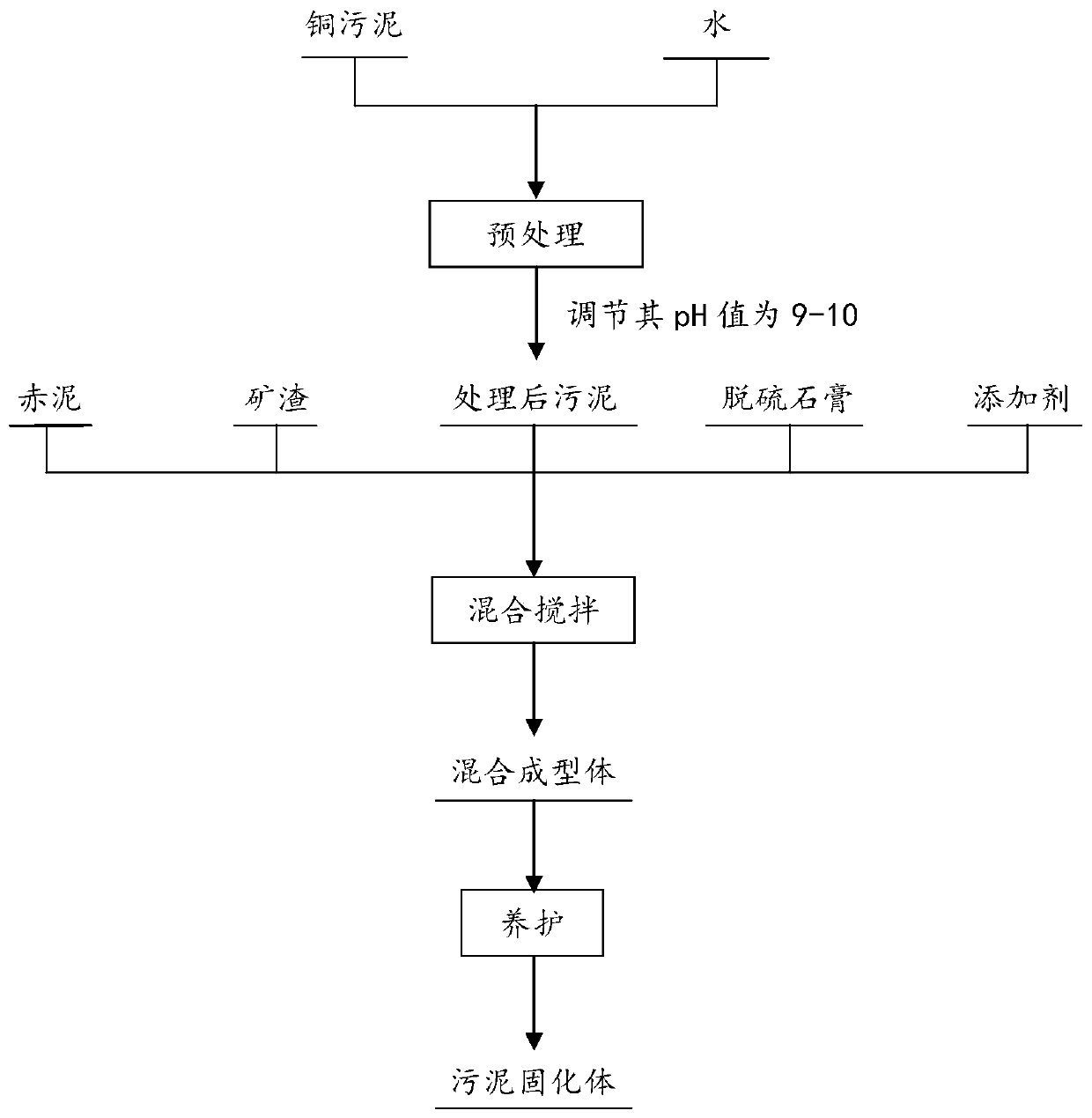

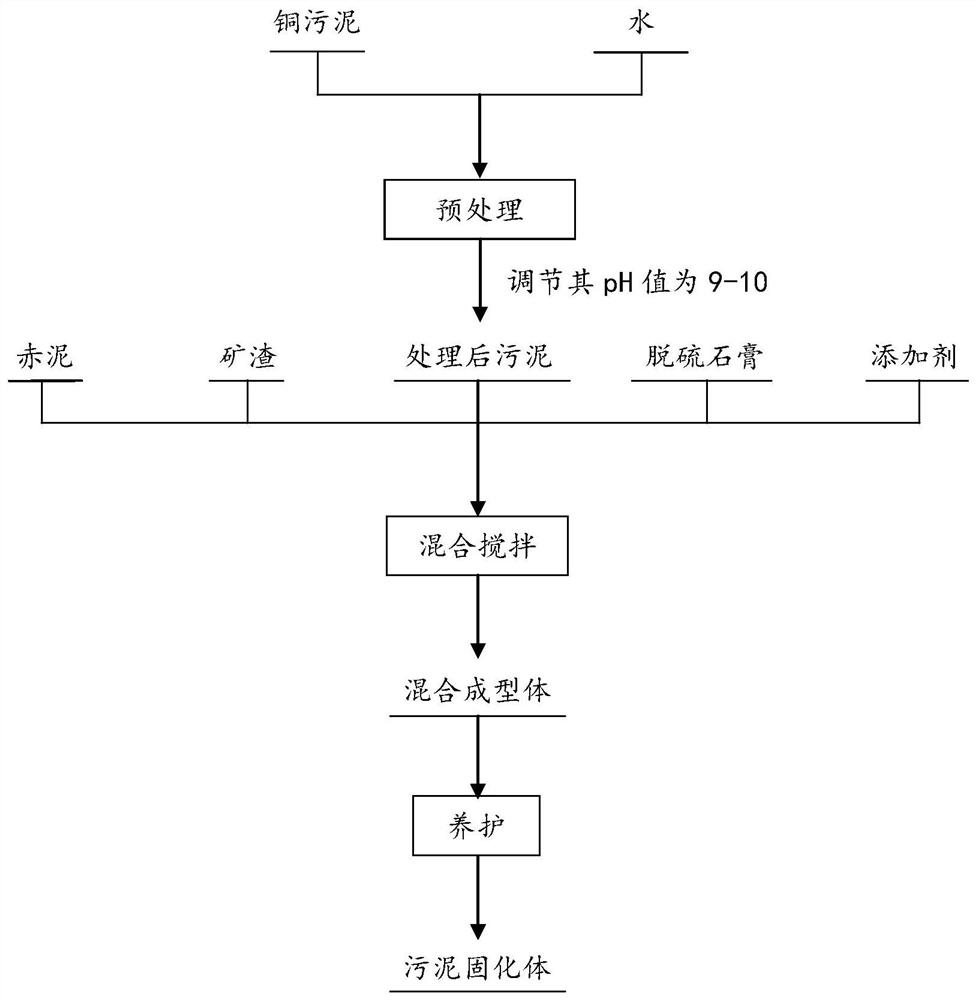

Treatment method of copper smelting sludge

InactiveCN111204940ASimple processReduce processing costsWater contaminantsFixation/solidifcation sludge treatmentSlagSludge

The invention discloses a treatment method of copper smelting sludge, and relates to a comprehensive utilization and environment-friendly treatment method of copper smelting sludge. The method is characterized in that in the treatment process, the copper smelting sludge is mixed with red mud, slag, desulfurized gypsum and an additive, and compression molding and maintenance are conducted to form asludge solidified body. According to the treatment method disclosed by the invention, the copper smelting sludge diluted by adding water is subjected to pH regulation pretreatment by utilizing strongbasicity of the red mud, and sludge slurry is regulated to be alkaline so as to precipitate most heavy metal ions; the viscosity, the adsorbability and the plasticity of the red mud are utilized, andare combined with the slag, desulfurized gypsum and the additive to solidify the pretreated copper smelting sludge, and heavy metals and arsenic in the sludge are subjected to innocent treatment in manners of forming hydroxides, adsorbing, physically wrapping, forming calcium arsenate and the like to finally obtain the sludge solidified body with certain mechanical strength. The purposes of solidifying arsenic ions and heavy metal ions such as Cu and Hg and converting the copper smelting sludge from dangerous solid waste into general solid waste are achieved, waste is treated with waste, andthe environmental protection cost is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

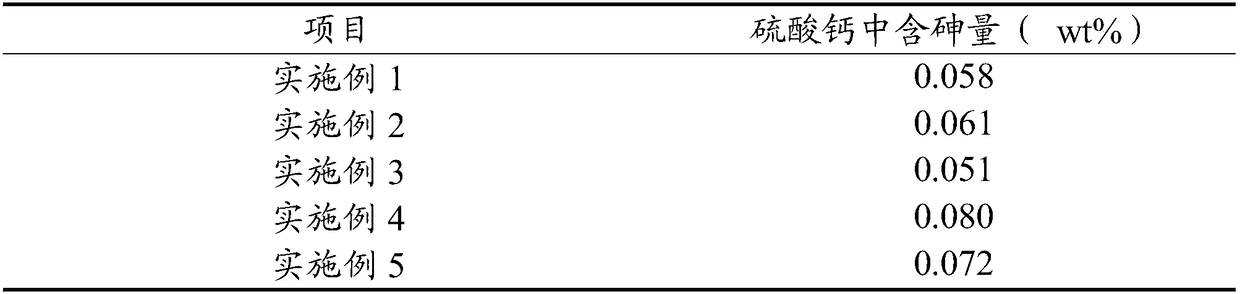

A method for acid hydrolysis of calcium arsenate and/or calcium arsenite

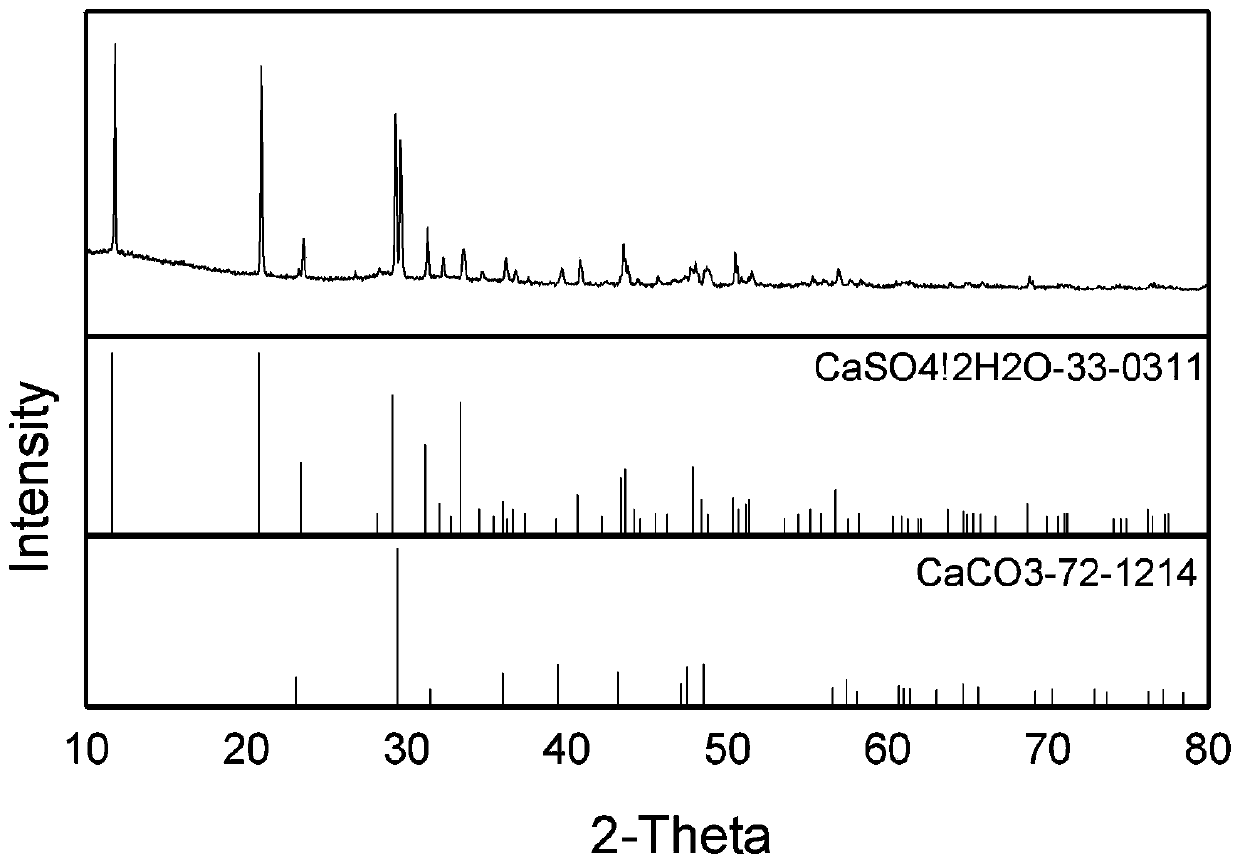

ActiveCN107151027BReduce arsenic levelsEmbedding lessCalcium/strontium/barium sulfatesSulfate radicalsDecomposition

The invention provides an acid hydrolysis method of calcium arsenate and / or calcium arsenite. The method comprises the following steps: (1) carrying out double decomposition reaction between calcium arsenate and / or calcium arsenite and a compound containing sulfate radicals in a solution to obtain a mixed system, wherein the pH value of the calcium arsenate and / or the calcium arsenite during the double decomposition reaction is less than or equal to 5.0; (2) carrying out solid-liquid separation of the mixed system to obtain calcium sulfate and an arsenic-containing solution. According to the acid hydrolysis method provided by the invention, the calcium sulfate is produced under a condition that the pH value of the calcium arsenate and / or the calcium arsenite is less than or equal to 5.0, so that a very small amount of arsenic can be embedded in to a calcium sulfate crystal lattice, and the calcium sulfate with low arsenic content can be obtained. An embodiment proves that the arsenic content in the calcium sulfate obtained by adopting the acid hydrolysis method is low to about 0.05 percent by weight, and the calcium sulfate can be used as a cement additive.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Treatment method of copper smelting sludge

ActiveCN112499919ASimple processReduce processing costsWater contaminantsFixation/solidifcation sludge treatmentSlagSludge

The invention discloses a treatment method of copper smelting sludge, and relates to a comprehensive utilization and environment-friendly treatment method of copper smelting sludge. The method is characterized in that in the treatment process, the copper smelting sludge is mixed with red mud, slag, desulfurized gypsum and an additive, compression molding and maintenance are conducted, and a sludgesolidified body is formed. According to the treatment method disclosed by the invention, the copper smelting sludge diluted by adding water is subjected to pH regulation pretreatment by utilizing strong basicity of the red mud, and sludge slurry is regulated to be alkaline so as to precipitate most heavy metal ions; the viscosity, the adsorbability and the plasticity of red mud are utilized, slag, desulfurized gypsum and additives are matched to solidify the pretreated copper smelting sludge, innocent treatment is conducted on heavy metal and arsenic in the sludge in the modes of hydroxide forming, adsorption, physical wrapping, calcium arsenate forming and the like, and finally the sludge solidified body with certain mechanical strength is formed. The purposes of solidifying arsenic ionsand heavy metal ions such as Cu and Hg and converting the copper smelting sludge from dangerous solid waste into general solid waste are achieved, waste is treated with waste, and the environmental protection cost is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com