A method for treating arsenic-containing wastewater and solidifying arsenic

A wastewater treatment and wastewater technology, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as low efficiency, high requirements for bacterial culture, and long arsenic-fixing operation cycle for microorganisms. Achieve the effect of reducing cost, shortening response time and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

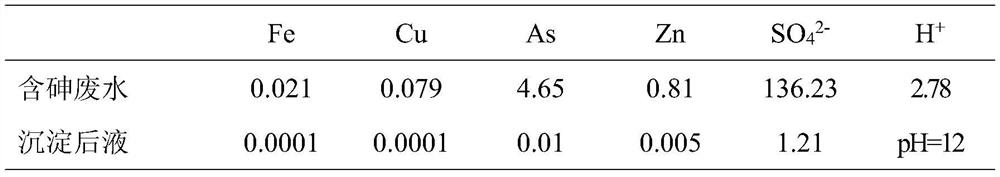

[0052] Take smelting flue gas to wash arsenic-containing wastewater 5m 3 , stir and add calcium iodide, I in the solution - The ion concentration is 0.002mg / L, with H 2 SO 3 As reducing agent, use I - Use ions as a catalyst to reduce As(V) to As(III). After reacting at room temperature for 0.5 h, add limestone powder to adjust the pH of the solution to 2.7, and filter to obtain a calcium sulfate filter cake containing 0.03% As and a deacidified liquid; Stir the resulting deacidification liquid into milk of lime, adjust the pH to 8.1, stir at room temperature for 1 hour, filter and separate the heavy metal precipitate, continue to add milk of lime, adjust the pH to 12, and stir at room temperature for 0.5 hour to precipitate the arsenic in it, and filter to obtain As content of 35.87% arsenic-calcium precipitation slag and precipitated liquid, the precipitated liquid is directly returned to the smelting flue gas washing process for recycling. The obtained arsenic-calcium pr...

Embodiment 2

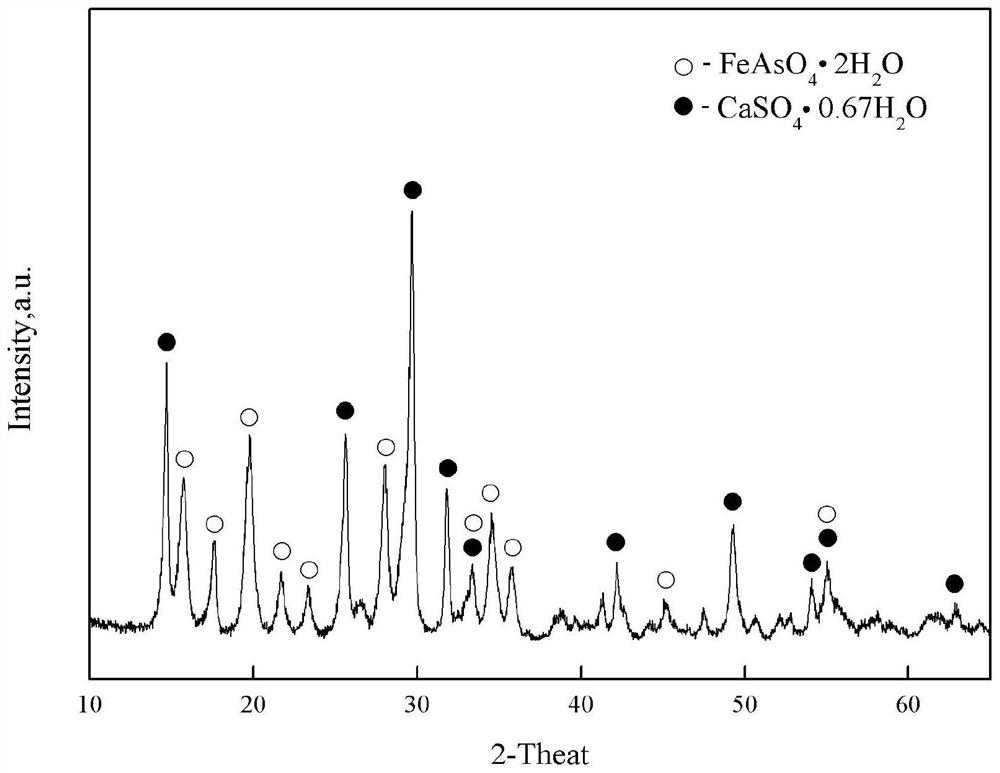

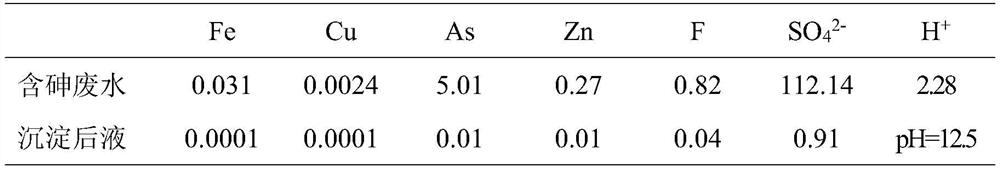

[0056] Take the smelting flue gas to wash the arsenic-containing wastewater 3m 3 , stir and add limestone powder, adjust the pH of the solution to 2.5, filter to obtain a calcium sulfate filter cake containing 0.1% As and the neutralized liquid, stir the obtained neutralized liquid, add lime milk, adjust the pH to 12.5, and stir at room temperature for 1.5h. The arsenic and heavy metals in it are precipitated together, and the mixed sedimentation residue and the precipitated liquid are obtained by filtration, and the precipitated liquid is returned to the reclaimed water for reuse. The obtained mixed sediment residue was slurried in a pressure reactor by adding water at a solid-to-liquid ratio of 1:2 g / mL, and adjusting the pH to 4.5 with dilute sulfuric acid, adding ferrous sulfate at a molar ratio of arsenic / iron of 1:1.2, and pressing the As( III) Oxidation to As(V) and Fe(II) to Fe(III) is 1.5 times the theoretical amount required to oxidize to Fe(III) Add hydrogen peroxid...

Embodiment 3

[0060] Take 3L of sodium arsenate solution with an As concentration of 35.8g / L obtained from the copper electrolyte indirect self-purification load accelerator regeneration process, stir and add lime at 95°C for causticization, filter to obtain calcium arsenate-containing precipitate residue and arsenic-removed liquid, After dearsenicization, the liquid is returned to continue to be used as a regeneration liquid for loading accelerators. The precipitated residue containing calcium arsenate is slurried by adding water at a solid-to-liquid ratio of 1:2g / mL, and the pH is adjusted to 2.5 by adding sulfuric acid. :1.15 Add ferric sulfate, stir to make the arsenic in it convert into amorphous iron arsenate precipitation, filter to obtain filter residue and filtrate, and the filtrate returns to continue to be used as the transformation liquid of calcium arsenate precipitate residue, and the filter residue is 1:2g according to the solid-liquid ratio / mL was added to the sodium bisulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com