Method for treating arsenical sludge by utilizing rotary cement kiln

A cement rotary kiln and rotary kiln technology, applied in the fields of comprehensive utilization of resources and environmental protection, can solve problems such as long residence time, achieve the effect of improving efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

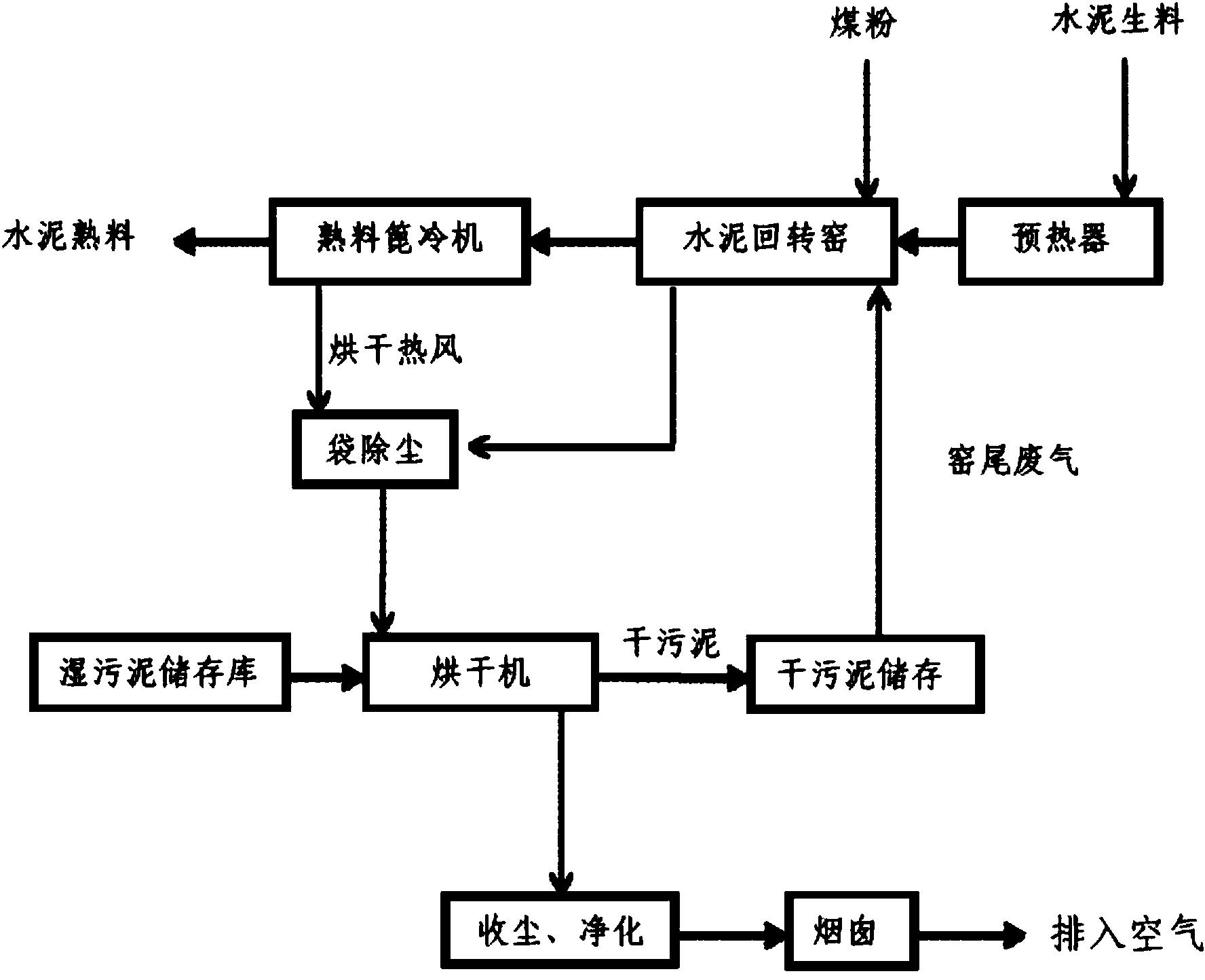

[0049] A method of utilizing a cement rotary kiln to treat arsenic-containing sludge, such as figure 1 shown, including the following steps:

[0050] The gas is extracted from the grate cooler and the tail of the rotary kiln, and after being treated by the dust collector, the gas is sent to the dryer to dry the arsenic-containing sludge;

[0051] The arsenic-containing sludge transported from the sewage treatment plant is put into the sludge storage, and according to the proportion of 80% (weight) arsenic-containing sludge with a water content of 80% (weight) according to the production of 1 ton of cement clinker mixed with burning, the arsenic-containing sludge The arsenic sludge is evenly sent to the dryer for drying, and the moisture content of the dried sludge after rough control is 25-35% (weight); the gas discharged from the dryer is collected and purified by the dust collector and then discharged from the chimney Discharged into the atmosphere, the obtained dry sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com