Method for treating arsenic-containing waste copper slag

A technology for copper slag and black copper slag is applied in the field of processing black copper slag and arsenic-containing waste copper slag. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

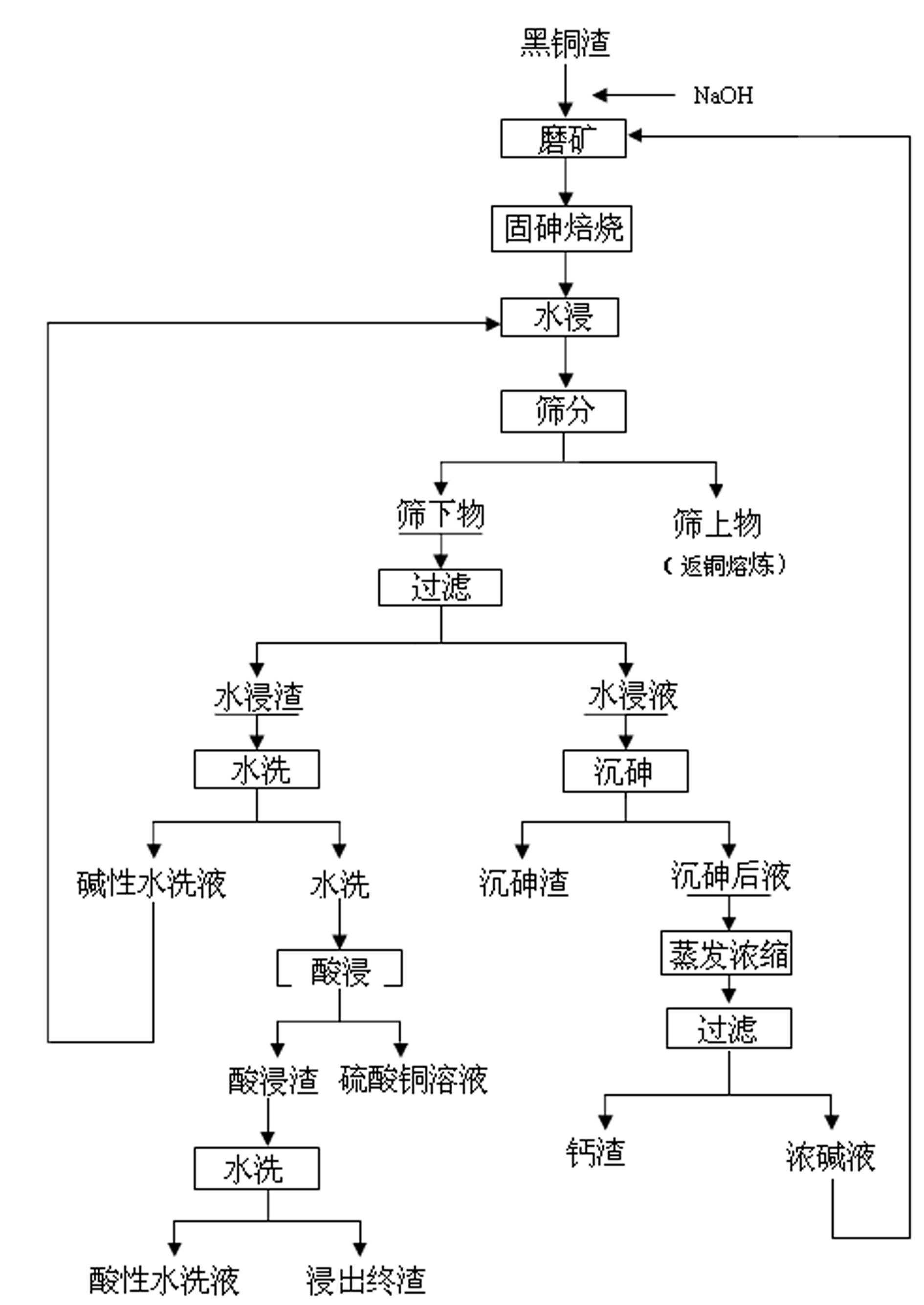

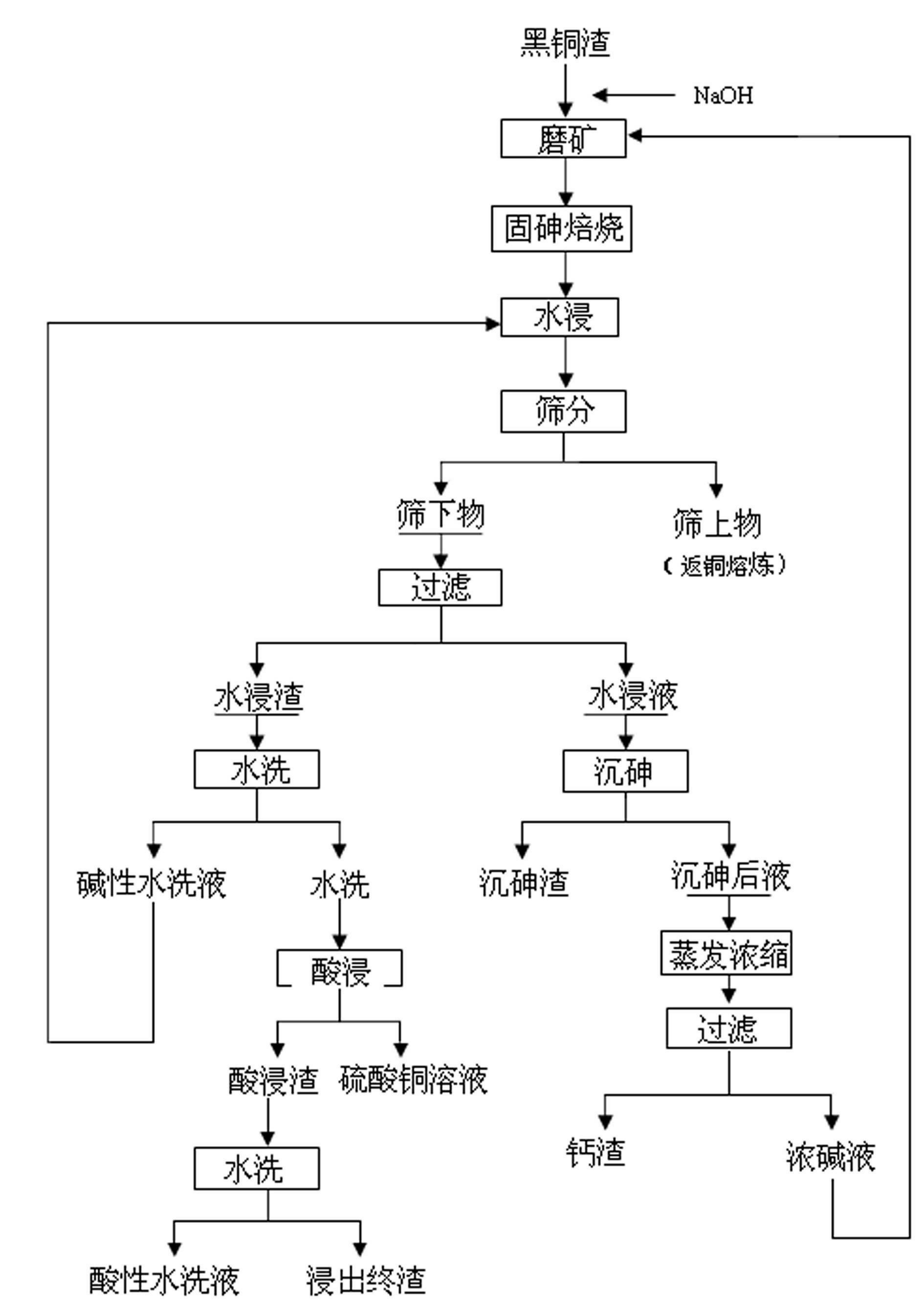

Method used

Image

Examples

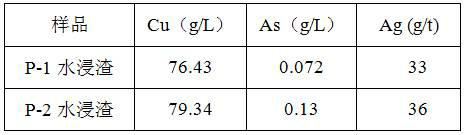

Embodiment 1

[0034] The composition of black copper slag produced by an electrolytic copper factory is Ni0.87%, Co0.0052%, Cu56.72%, Fe0.23%, Pb0.056%, Zn0.0034%, Mn0.022%, As5.18 %, Sb0.37%, Bi0.56%, S4.23%, Ag538.75 (g / t), SiO 2 1.0%. The black copper slag is fully mixed with sodium hydroxide, the alkali coefficient of the used sodium hydroxide is 2.0, and the ore is ground by a ball mill; the product after grinding is placed in a roasting kiln in a micro-oxidizing atmosphere and roasted at a temperature of 550 ° C for 2 hours. Roasted slag is obtained; the roasted slag is subjected to water leaching to remove arsenic, and the liquid-solid ratio during water leaching for arsenic removal is 5 1. The water immersion temperature is 60°C, and the water immersion time is 60 minutes; all the arsenic in the roasted slag is transferred into the leaching solution to obtain a water leaching pulp; during the water immersion process, the copper, antimony, bismuth, etc. in the roasted slag do not en...

Embodiment 2

[0055] The composition of black copper slag produced by an electrolytic copper factory is: Ni1.36%, Co0.015%, Cu41.48%, Fe0.066%, Pb0.064%, Zn0.0038%, Mn0.0041%, As4. 05%, Sb0.69%, Bi0.60%, S8.02%, Ag 666.25 (g / t). Fully mix the black copper slag with sodium carbonate, the alkali coefficient of all sodium carbonate is 1.5, grind the ore in a ball mill; place the ground product in a roasting kiln for 1.5 hours at 600°C in a slightly oxidizing atmosphere to obtain the roasted slag; the roasted slag is subjected to water leaching to remove arsenic, and the liquid-solid ratio during water leaching to remove arsenic is 6 1. The water immersion temperature is 65°C, and the water immersion time is 40 minutes, so that all the arsenic in the roasted slag is transferred into the leaching solution to obtain a water leaching pulp; during the water immersion process, the copper, antimony, bismuth, etc. in the roasted slag do not enter the water Leach ore pulp; screen and classify the wat...

Embodiment 3

[0067] Fully mix the black copper slag and calcium hydroxide, the alkali coefficient of the calcium hydroxide used is 1.75, grind the ore in a ball mill; place the ground product in a roasting kiln for 2.5 hours at 500°C in a micro-oxidizing atmosphere to obtain roasted After slag; the roasted slag is subjected to water leaching to remove arsenic, and the liquid-solid ratio during water leaching to remove arsenic is 5.5 1. The water immersion temperature is 62.5°C, and the water immersion time is 50 minutes, so that all the arsenic in the roasted slag is transferred into the leaching solution to obtain a water leaching pulp; during the water immersion process, the copper, antimony, bismuth, etc. in the roasted slag do not enter the water Leach slurry; sieve and classify the water leaching slurry to obtain coarse-grained slurry with a particle size greater than 0.2mm and fine-grade slurry with a particle size less than 0.2mm; the coarse-grained material is returned to the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com