A treatment process for copper smelting dust

A treatment process, copper smelting technology, applied in the field of copper smelting fume treatment process, can solve problems such as difficult treatment, lower conversion rate, deterioration of furnace condition, etc., achieve the effect of solving open circuit problem and improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

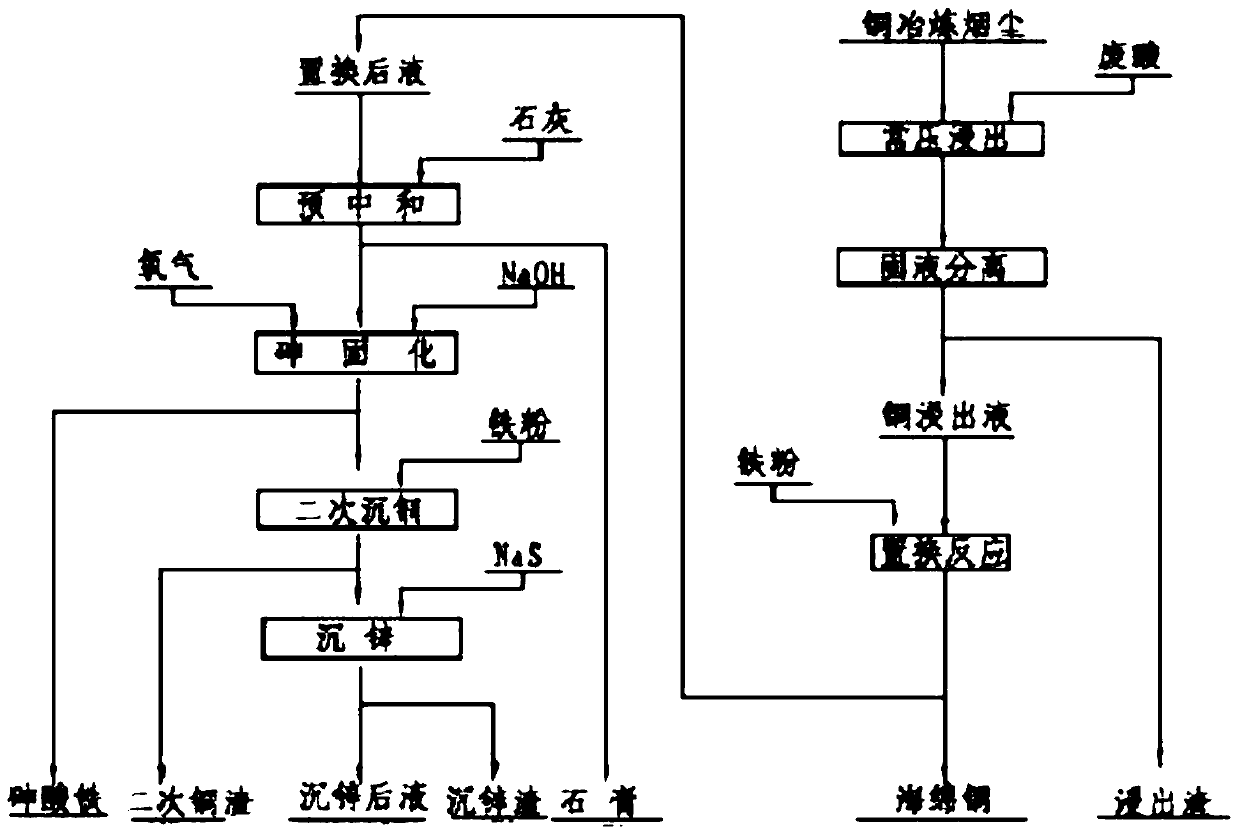

Method used

Image

Examples

Embodiment 1

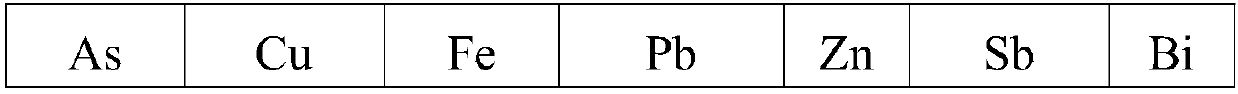

[0079] See Table 1-1 for the composition of copper smelting dust, which contains high arsenic and low copper; see Table 1-2 for the composition of waste acid.

[0080] Table 1-1 Composition of copper smelting dust

[0081] Element

[0082] Table 1-2 Composition of waste acid

[0083] As

[0084] 1. Pickling

[0085] Prepare the waste acid into an acid solution with an acid mass concentration of 12.5%, and prepare the solution according to the solid-to-liquid ratio of smoke and acid solution at a ratio of 1:4, add it to the reaction kettle, heat it to 80°C, and react for 3.5 hours. After 3.5 hours, it will be solid-liquid Separation and leaching results are shown in Table 1-3.

[0086] Table 1-3 Leaching results

[0087] project

[0088] The composition of acid leaching slag is shown in Table 1-4.

[0089] Table 1-4 Composition of acid leaching slag

[0090] As

[0091] Lead and bismuth are further recovered from the acid leaching sl...

Embodiment 2

[0121] The composition of copper smelting dust is shown in Table 2-1, and the dust contains high arsenic and low copper; the composition of waste acid is shown in Table 2-2.

[0122] Table 2-1 Composition of copper smelting dust

[0123] Element

[0124] Table 2-2 Composition of waste acid

[0125] As

[0126] 1. Pickling

[0127] Prepare the waste acid so that the acid concentration is 165g / l, make liquid according to the solid-to-liquid ratio of dust and acid liquid mass 1:6, add it to the reaction kettle, heat to 70°C, react for 5 hours, and separate the solid and liquid after 5 hours, see the leaching results Table 2-3.

[0128] Table 2-3 Leaching results

[0129]

[0130]

[0131] The components of the acid leaching slag are shown in Table 2-4.

[0132] Table 2-4 Composition of acid leaching slag

[0133] As

[0134] Lead and bismuth are further recovered from the acid leaching slag.

[0135] 2. Metal replacement sinking copper

...

Embodiment 3

[0162] The composition of copper smelting dust is shown in Table 3-1, the dust contains high arsenic and low copper; the composition of waste acid is shown in Table 3-2.

[0163] Table 3-1 Composition of copper smelting dust

[0164] Element

[0165] Table 3-2 Composition of waste acid

[0166] As

[0167] 1. Pickling

[0168] Prepare the waste acid into an acid solution with an acid mass concentration of 130g / l, and prepare the solution according to the solid-to-liquid ratio of smoke dust and acid solution at a ratio of 1:4.5, add it to the reaction kettle, heat to 80°C, and react for 3.5 hours. After 3.5 hours, it will solidify Liquid separation, leaching results are shown in Table 3-3.

[0169] Table 3-3 Leaching results

[0170]

[0171] The components of the acid leaching slag are shown in Table 3-4.

[0172] Table 3-4 Composition of acid leaching slag

[0173] As

[0174] Lead and bismuth are further recovered from the acid leaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com