Inductor and preparation method thereof, and preparation method of low-voltage integrally-formed inductor material

An integrated, inductive technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, and the magnetism of inorganic materials, can solve problems such as poor insulation, product open circuits, and low magnetic permeability, so as to improve molding density and solve open circuits. Problems, the effect of improving the magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

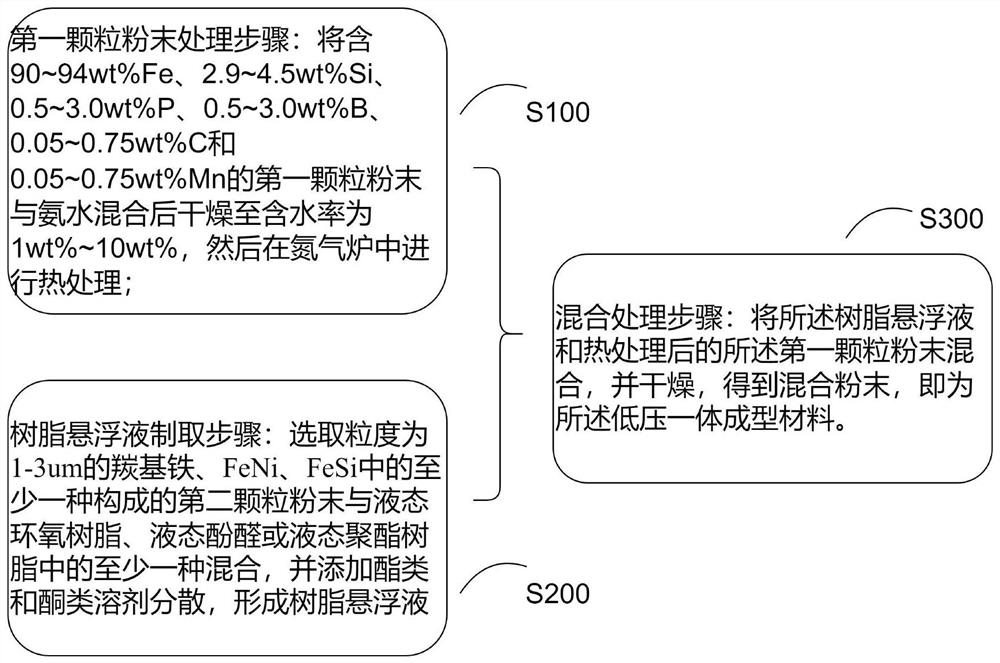

[0027] A preparation method of a low-voltage integrally formed inductor material, comprising the following steps:

[0028] The first particle powder processing step S100: the powder containing 90-94wt% Fe, 2.9-4.5wt% Si, 0.5-3.0wt%P, 0.5-3.0wt%B, 0.05-0.75wt%C and 0.05-0.75wt%Mn The first granular powder is mixed with ammonia water, dried to a moisture content of 1wt% to 10wt%, and then heat treated in a nitrogen furnace; the temperature of the heat treatment is between 250 ° C and 350 ° C, and the time is 2 to 6 hours .

[0029] Resin suspension preparation step S200: selecting the second particle powder composed of at least one of carbonyl iron, FeNi, FeSi with a particle size of 1-3um and at least one of liquid epoxy resin, liquid phenolic or liquid polyester resin Mix and add ester and ketone solvents to disperse to form a resin suspension; the mass ratio of the ester solvent and the ketone solvent is 1:10 to 1:12, and the resin suspension and the heat-treated The mass r...

Embodiment 1

[0037] A preparation method of a low-voltage integrally formed inductor material, comprising the following steps:

[0038] Preferably, metal spherical particle powder is used as the first particle powder, and its material composition is: 90wt% Fe, 4.5wt% Si, 3.0wt%P, 3.0wt%B, 0.75wt%C and 0.75wt%Mn. Wherein, the granular powder is composed of coarse particles and fine particles, the mass ratio of the coarse particles to the fine particles is 7:3, the particle size ratio of the coarse particles to the fine particles is 7:1, The particle size of the coarse particle powder is 35um.

[0039] The first granular powder was mixed with ammonia water, dried to a moisture content of 1 wt %, and then heat-treated in a nitrogen furnace at 250° C. for 6 hours. Wherein, the concentration of the ammonia water is 10 wt %, and the addition amount of the ammonia water is 50 wt % of the powder mass. The drying temperature during the heat treatment was 110°C.

[0040] Select 1-3um carbonyl iro...

Embodiment 2

[0044] A preparation method of a low-voltage integrally formed inductor material, comprising the following steps:

[0045] Preferably, metal spherical particle powder is used as the first particle powder, and its material composition is: 94wt% Fe, 2.9wt% Si, 0.5wt%P, 0.5wt%B, 0.05wt%C and 0.05wt%Mn. Wherein, the granular powder is composed of coarse particles and fine particles, the mass ratio of the coarse particles to the fine particles is 9:1, the particle size ratio of the coarse particles to the fine particles is 5:1, The particle size of the coarse particle powder is 20um.

[0046] The first granular powder was mixed with ammonia water, dried to a moisture content of 10 wt %, and then heat-treated in a nitrogen furnace at 350° C. for 2 hours. The concentration of the ammonia water is 3 wt %, the addition amount of the ammonia water is 20 wt % of the mass of the first particle powder, and the drying temperature of the heat treatment is 90°C.

[0047] Select 1-3um FeNi a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com