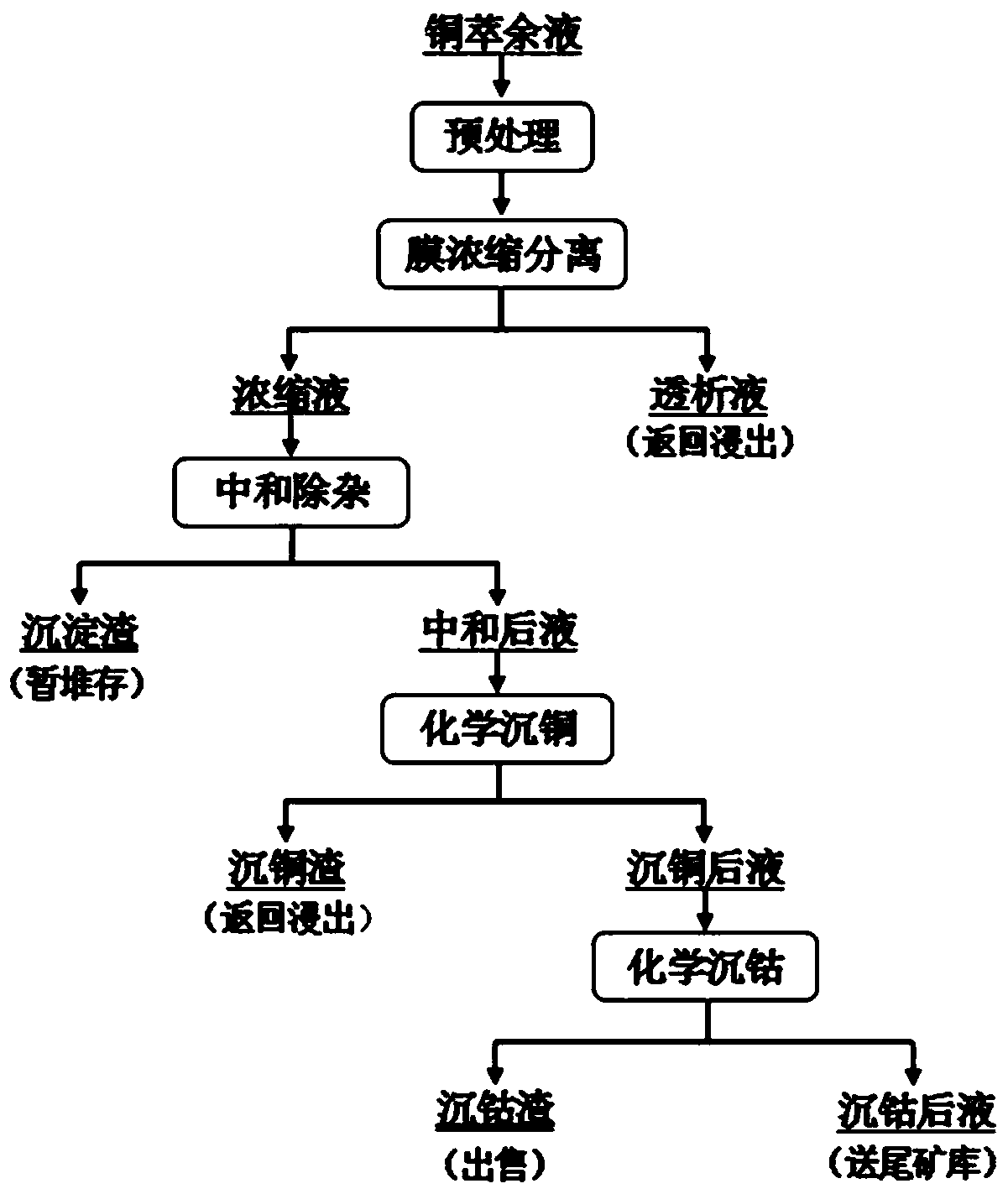

A method for recovering copper and cobalt in copper raffinate by using nanofiltration membrane concentration separation-neutralization precipitation

A nanofiltration membrane and raffinate technology, applied in the field of hydrometallurgy, can solve problems such as poor operating environment, high operating pressure, and small processing capacity, achieve significant environmental and economic benefits, increase recycling value, and reduce waste water The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The cobalt-containing copper raffinate to be treated is centrally stored in the raw material liquid storage tank, and the raw material liquid is pretreated by an air flotation degreaser, a multi-media filter, and a security filter to remove oil, organic extractant, Colloidal and granular impurities; the treated feed liquid enters the nanofiltration membrane component through the pressure boosting system for 3 times concentration to obtain the acid-containing 10.5g / L dialysate and copper-rich and cobalt-rich concentrated liquid; return the dialysate to the leaching process ; The copper-rich and cobalt concentrated solution is placed in the neutralization reaction stirring tank, and the mass concentration is 15% lime milk is added under normal temperature conditions, and the pH value of the neutralization reaction of the concentrated solution is adjusted and controlled to be 3, and the solid-liquid separation is carried out after 90 minutes of reaction ; put the neutralize...

Embodiment 2

[0044] The cobalt-containing copper raffinate to be treated is centrally stored in the raw material liquid storage tank, and the raw material liquid is pretreated by air flotation degreaser, multi-media filter, security filter, etc. to remove oil and organic extractant contained in the solution , colloid, and granular impurities; the treated feed liquid is concentrated into the nanofiltration membrane component through the pressure lifting system for 3.5 times concentration, and the acid-containing 11.5g / L dialysate and copper-rich and cobalt-rich concentrated liquid are obtained; the dialysate is returned to leaching Process: Copper-rich and cobalt-rich concentrates are placed in a neutralization reaction stirring tank, and milk of lime with a mass concentration of 15% is added at room temperature to adjust and control the pH value of the neutralization reaction of the concentrate to 3, and carry out solid-liquid reaction after 120 minutes of reaction. Separation; put the neut...

Embodiment 3

[0051] The cobalt-containing copper raffinate to be treated is centrally stored in the raw material liquid storage tank, and the raw material liquid is pretreated by an air flotation degreaser, a multi-media filter, and a security filter to remove oil, organic extractant, Colloidal and granular impurities; the treated feed liquid enters the nanofiltration membrane component through the pressure boosting system for 4-fold concentration, and obtains a dialysate containing 11.8g / L sulfuric acid and a concentrated solution rich in copper and cobalt; returns the dialysate to the leaching process ; Copper-rich and cobalt concentrates are placed in the neutralization reaction stirring tank, and the mass concentration is 15% milk of lime is added under normal temperature conditions, and the pH value of the neutralization reaction of the concentrated solution is adjusted and controlled to be 3.2, and the solid-liquid separation is carried out after 90 minutes of reaction ; put the neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com