Treatment method of copper smelting sludge

A copper smelting sludge and treatment method technology, which is applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as complex process, high cost, and unsatisfactory solidification effect. Achieve the effect of simple process and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

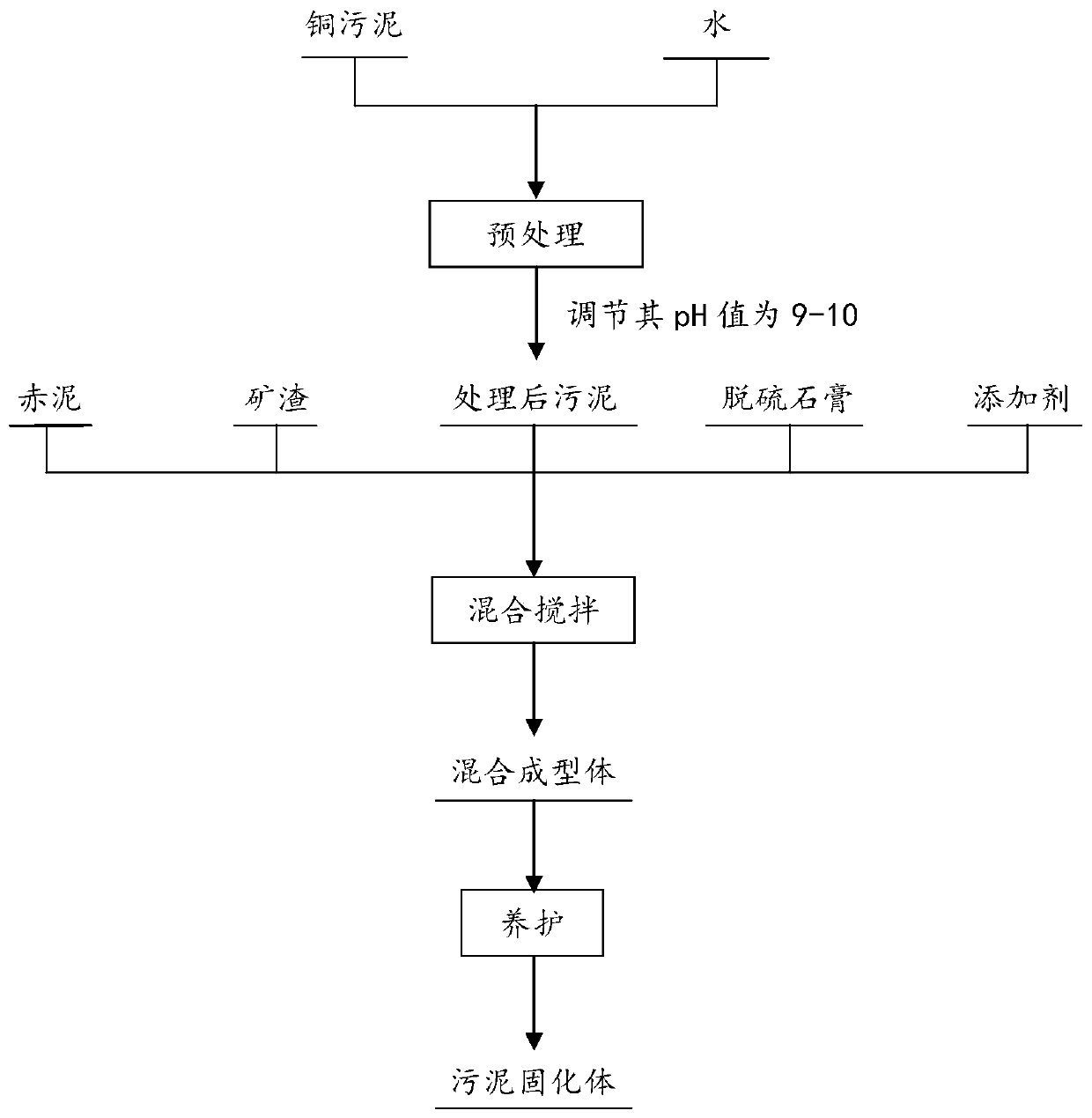

Method used

Image

Examples

Embodiment 1

[0043] For a non-ferrous metal company, the leaching toxicity test of copper smelting sludge before and after treatment is shown in Table 1:

[0044] Table 1 Sludge leaching toxicity of a non-ferrous metal company before and after treatment

[0045]

[0046] Dilute the sludge by 4 times, add red mud to adjust its pH to 9, add red mud at a ratio of 1:1.5, add slag and desulfurized gypsum at a ratio of 10:1, and add carboxymethyl cellulose at a ratio of 100:1 , press-molded with a pressure of 25mPa and maintained for 30 hours, and the leaching toxicity of heavy metals was detected. The leaching toxicity is reduced by 82%, and the Hg leaching toxicity is reduced by 95%.

Embodiment 2

[0048] For a copper smelting factory, the leaching toxicity test before and after treatment of the copper smelting factory is shown in Table 2:

[0049] Table 2 Toxicity of sludge leaching before and after treatment in a copper smelting plant

[0050]

[0051] Dilute the sludge by 3 times, add red mud to adjust its pH to 9.5, add red mud at a ratio of 1:1, add slag at a ratio of 5:1, add desulfurized gypsum at a ratio of 10:1, and add slag at a ratio of 150:1 Add polyvinyl alcohol in proportion, press molding with a pressure of 30mPa and maintain for 24 hours, and detect its heavy metal leaching toxicity. 59.95% reduction, Zn leaching toxicity reduction 80.90%, Cd leaching toxicity reduction 83.48%, Hg leaching toxicity reduction 42.86%.

Embodiment 3

[0053] For a copper smelting enterprise, the leaching toxicity test of copper smelting sludge before and after treatment is shown in Table 3:

[0054] Table 3 Sludge leaching toxicity of a copper smelting enterprise before and after treatment

[0055]

[0056] Dilute the sludge by 2 times, add red mud to adjust its pH to 10, add red mud at a ratio of 1:1, add slag and desulfurized gypsum at a ratio of 5:1, add cement at a ratio of 100:1, and use 20mPa The pressure was pressed and maintained for 20 hours, and the heavy metal leaching toxicity was detected. The results are shown in Table 3. It can be seen from the table that Cu leaching toxicity decreased by 59.91%, As leaching toxicity decreased by 93.17%, Pb leaching toxicity decreased by 85.19%, and Zn leaching toxicity decreased by 62.63%. %, Cd leaching toxicity decreased by 80.36%, and Hg leaching toxicity decreased by 89.66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com