Method for stabilizing arsenic-calcium slag

A technology of calcium slag and waste slag is applied in the field of stabilization of arsenic calcium slag, which can solve the problems of low cost and achieve the effect of low cost and good stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

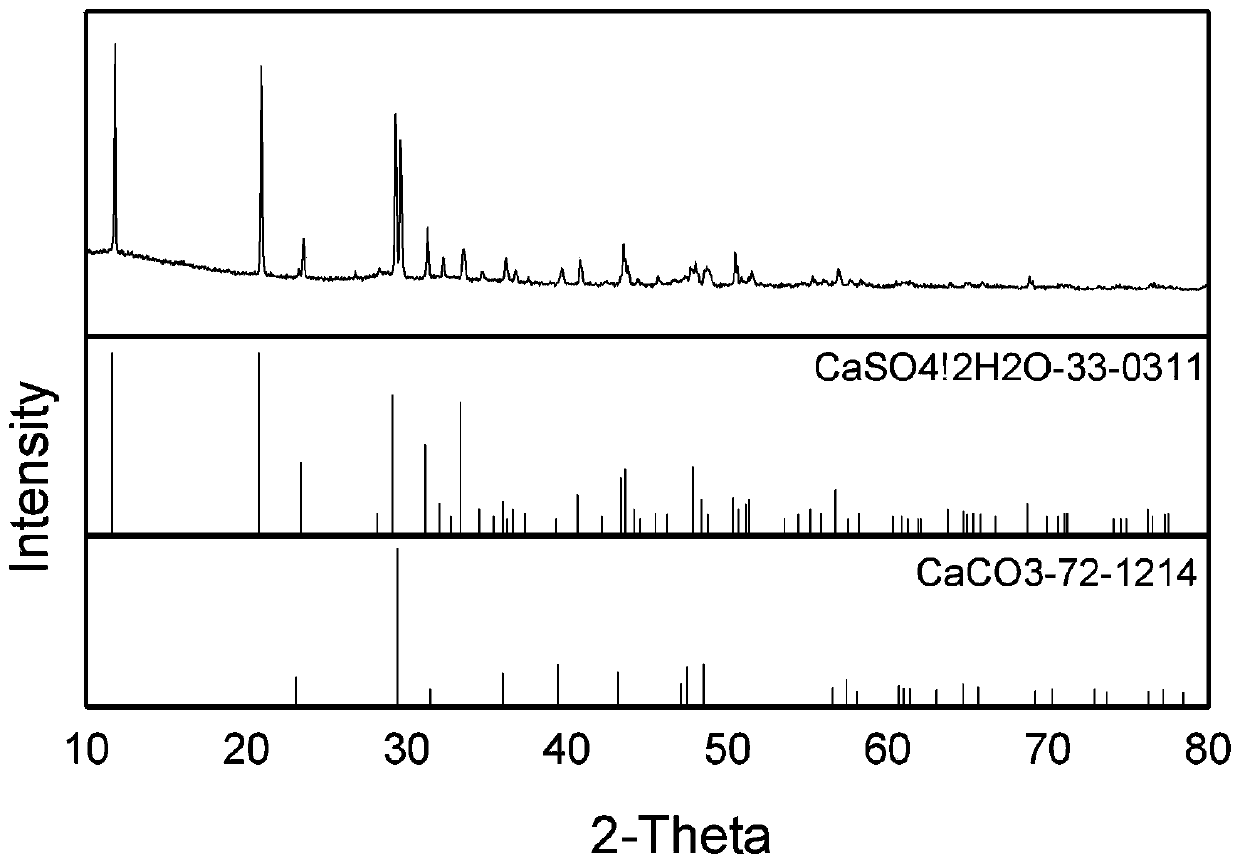

[0044] The arsenic-containing waste liquid is subjected to lime precipitation treatment to obtain arsenic-calcium slag. The treatment method is: adding calcium oxide to the arsenic-containing waste liquid, reacting for 10 hours, filtering, collecting solids, and obtaining arsenic-calcium slag.

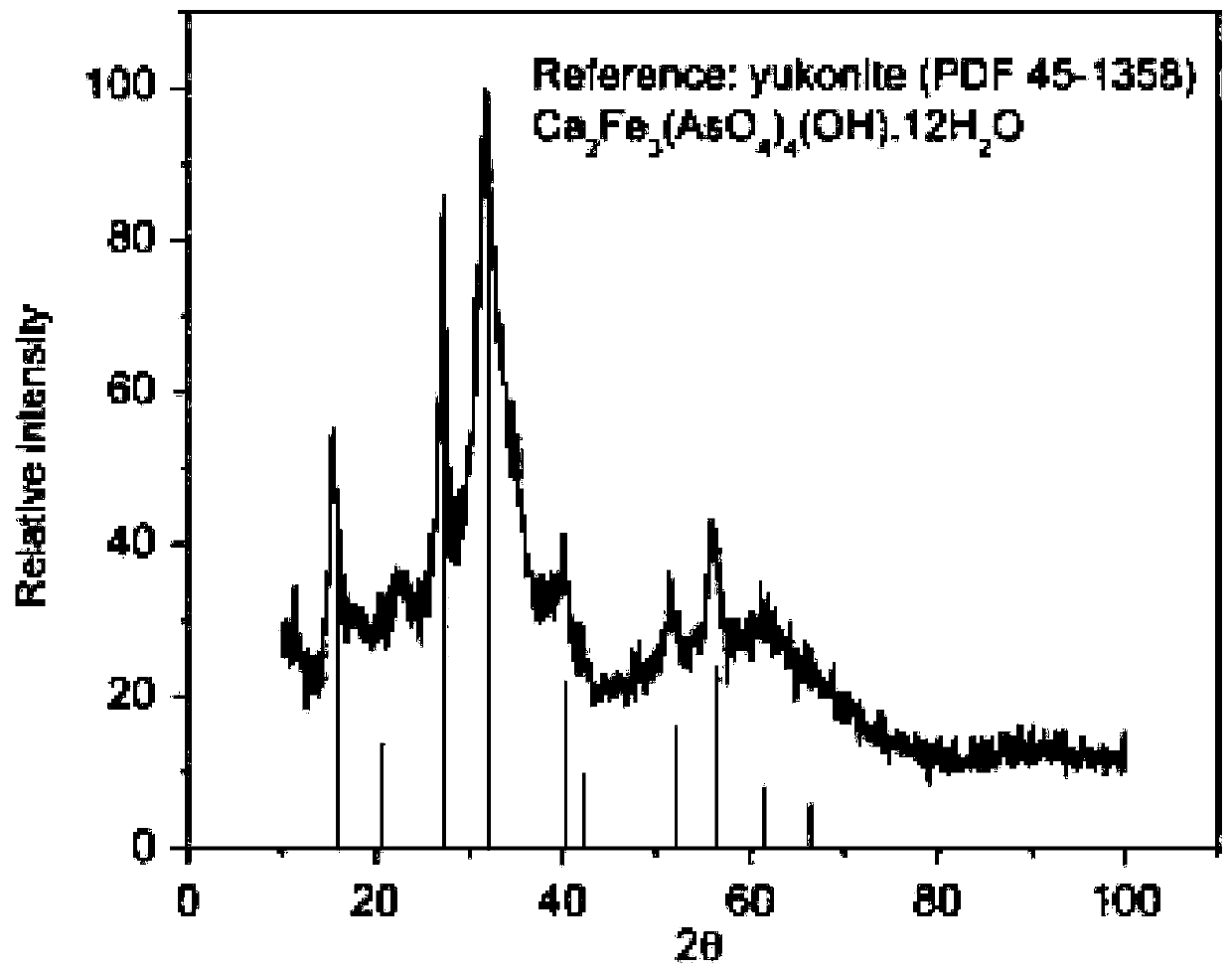

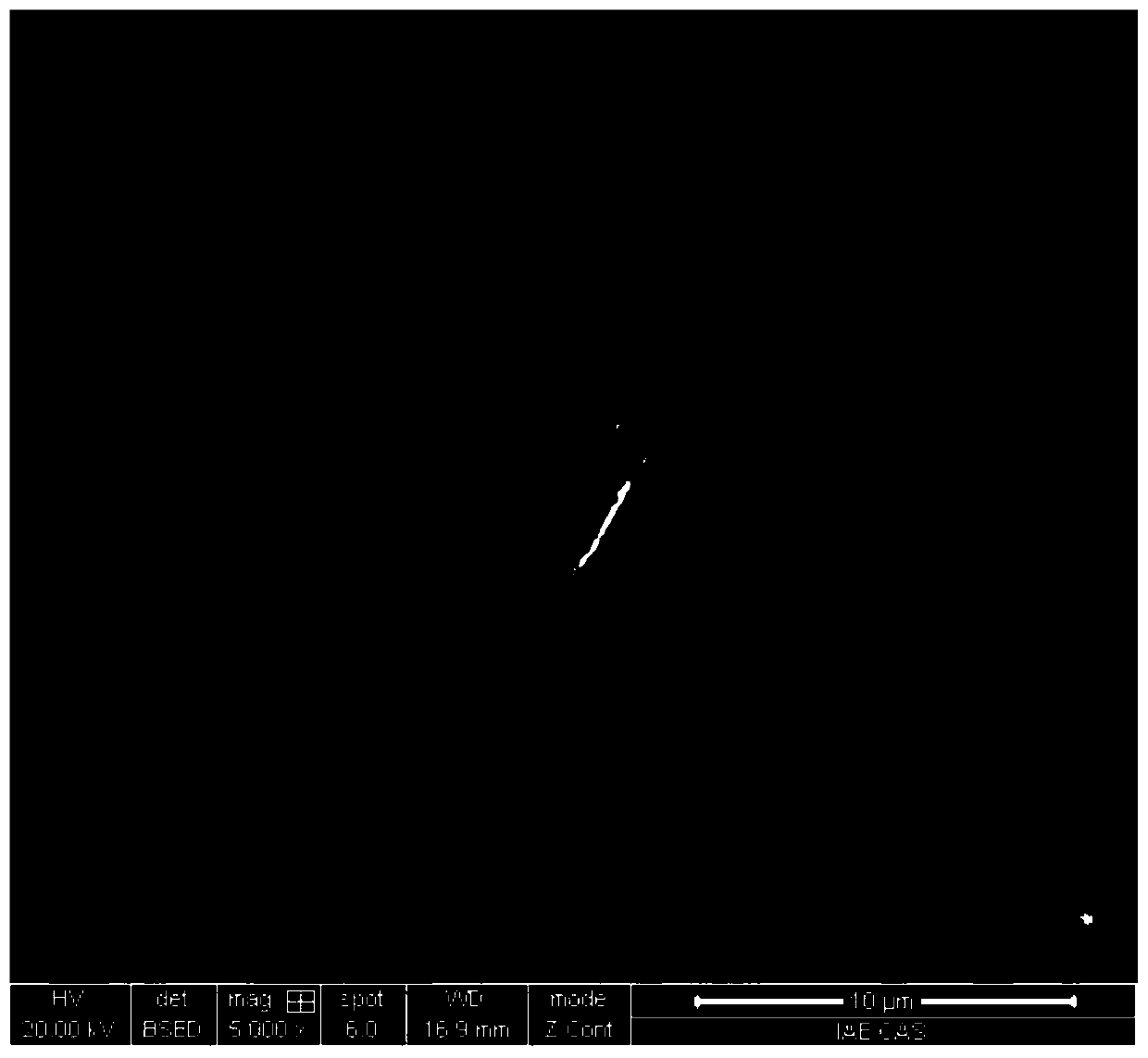

[0045] Mix 40 g of calcium arsenic slag with 400 ml of water to obtain a mixed slurry of calcium arsenic slag, wherein the content of arsenic in the calcium arsenic slag is 5.86wt.%; add 14 mL of ferric nitrate solution dropwise to the calcium arsenic slag mixed slurry under mechanical stirring, The molar ratio of the iron in the ferric nitrate solution to the arsenic in the arsenic-calcium slag is 0.7. After the dropwise addition is completed, the compounding reaction is continued, and the pH value of the compounding reaction process is always controlled at 7 by acid or alkali. Detect the arsenic content in the reaction system slurry (As content detection method is: use potassium boro...

Embodiment 2

[0054] Mix 40 g of calcium arsenic slag with 400 ml of water to obtain a mixed slurry of calcium arsenic slag, wherein the content of arsenic in the calcium arsenic slag is 5.86wt.%. Under mechanical stirring, 14 mL of ferric nitrate solution is added dropwise to the calcium arsenic slag mixed slurry, The molar ratio of the iron in the ferric nitrate solution to the arsenic in the arsenic-calcium slag is 0.7. After the dropwise addition is completed, the compounding reaction is continued, and the pH value of the compounding reaction process is always controlled at 8 by acid or alkali. According to the method in Example 1, the arsenic concentration of the slurry on the 15th day after the compounding reaction was detected, and the arsenic concentration was only 12.61 mg / L, indicating that the formation of calcium iron arsenate effectively reduced the leaching of arsenic. The changes of arsenic concentration before and after treatment when the pH value was 8 are shown in Table 3....

Embodiment 3

[0064] Mix 40 g of calcium arsenic slag with 400 mL of water to obtain a mixed slurry of calcium arsenic slag, wherein the content of arsenic in the calcium arsenic slag is 5.86 wt. %; add 14 mL of ferric nitrate solution dropwise to the calcium arsenic slag mixed slurry under mechanical stirring, The molar ratio of the iron in the ferric nitrate solution to the arsenic in the arsenic-calcium slag is 0.7. After the dropwise addition is completed, the compounding reaction is continued, and the pH value of the compounding reaction process is always controlled at 9 by acid or alkali. After stabilizing for a period of time, the filtered arsenic-calcium slag was tested according to the method in Example 1, and the obtained test results are shown in Table 5: according to the method in Example 1, the arsenic concentration of the slurry after the compounding reaction was detected, and it was obtained The arsenic concentration on the 15th day of the compounding reaction was only 14.56 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com