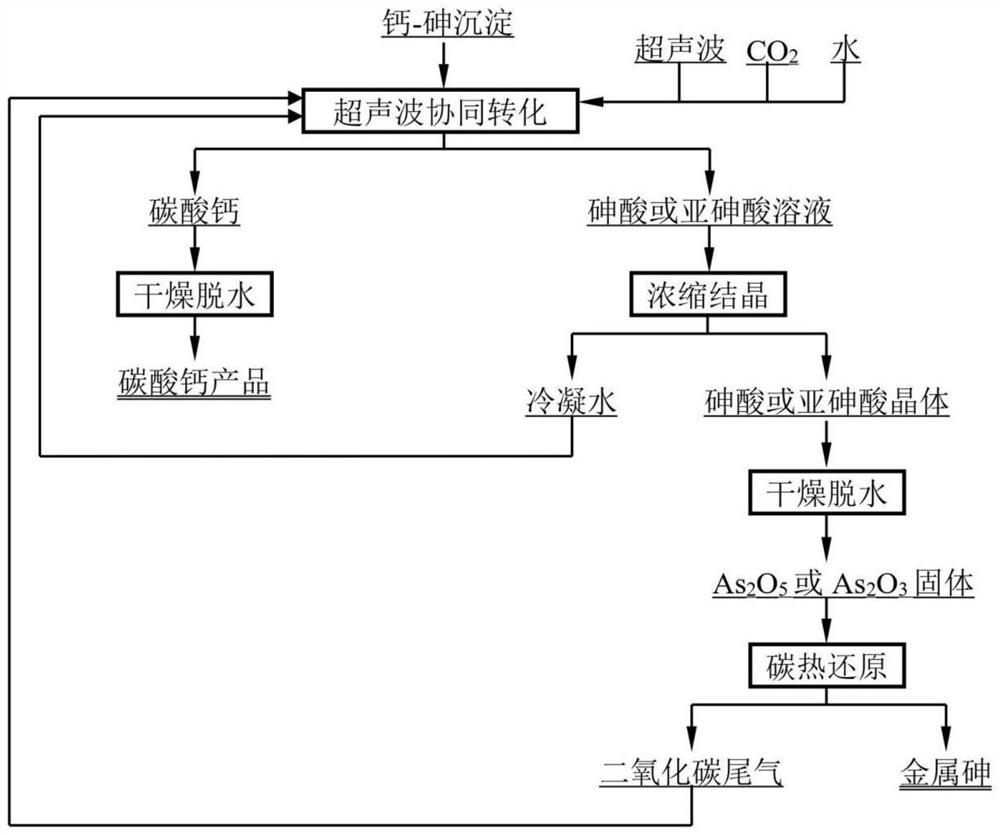

Method for synergistically converting and decomposing calcium-arsenic precipitate through ultrasonic waves

A sediment and ultrasonic technology, applied in the fields of metallurgy and environmental protection, can solve the problems of unstable chemical properties, harsh conditions, and high energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw material used in this embodiment is the calcium arsenate slag obtained by adding 1.2 times the theoretical amount of lime to the lead anode slime oxygen pressure alkaline immersion solution, and the calcium arsenate slag contains 29.98% of arsenic.

[0035] Add 100.00g of calcium arsenate slag to 1000mL of water, stir mechanically until a slurry is formed, and at a leaching temperature of 80°C, introduce carbon dioxide gas into a cavitation generating device, the molar ratio of carbon dioxide and calcium in calcium arsenate The ratio is 5:1, the carbon dioxide feed time is 360 minutes, and the cavitation effect time is 360 minutes. After the reaction is completed, the mixed slurry is subjected to liquid-solid separation to obtain calcium carbonate and arsenic-containing solution. The arsenic content in the calcium carbonate is 0.01%. After the arsenic solution is evaporated and crystallized, the carbothermal reduction is carried out at a temperature of 800°C, a t...

Embodiment 2

[0037] The raw material used in this example is a mixture containing calcium arsenite obtained by adding 1.5 times the theoretical amount of lime to arsenic-containing wastewater, and the mixture contains 14.56% arsenic.

[0038] Add 100.00g of the mixture containing calcium arsenite to 600mL of water, stir mechanically until a slurry is formed, and at a leaching temperature of 80°C, pass in carbon dioxide gas and introduce a cavitation generating device, carbon dioxide, calcium arsenate and arsenous The molar ratio of calcium element in the calcium carbonate is 5: 1, and the carbon dioxide feed time is 360min, and the cavitation effect time is 360min, and after the reaction is finished, the mixed slurry is subjected to liquid-solid separation to obtain calcium carbonate and arsenic-containing solution; The arsenic content in calcium carbonate is 0.04%. After the arsenic-containing solution is evaporated and crystallized, the carbothermal reduction is carried out at a temperatu...

Embodiment 3

[0040] The raw material used in this embodiment is a mixture containing calcium arsenite obtained by adding 1.2 times the theoretical amount of lime to the lead anode slime normal-pressure alkaline immersion solution, and the mixture contains 21.75% arsenic.

[0041] Add 100.00g of calcium arsenate slag to 800mL of water, stir mechanically until a slurry is formed, and at a leaching temperature of 80°C, pass in carbon dioxide gas and introduce a cavitation generating device, carbon dioxide and calcium arsenate and calcium arsenite The molar ratio of elements is 5: 1, the carbon dioxide feed time is 360min, and the cavitation effect time is 360min. After the reaction is finished, the mixed slurry is subjected to liquid-solid separation to obtain calcium carbonate and arsenic-containing solution; The arsenic content is 0.03%; after the arsenic-containing solution is evaporated and crystallized, the carbothermal reduction is carried out at a temperature of 1200°C, a time of 120 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com