Patents

Literature

30results about "Selenium/tellurium oxyacid salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

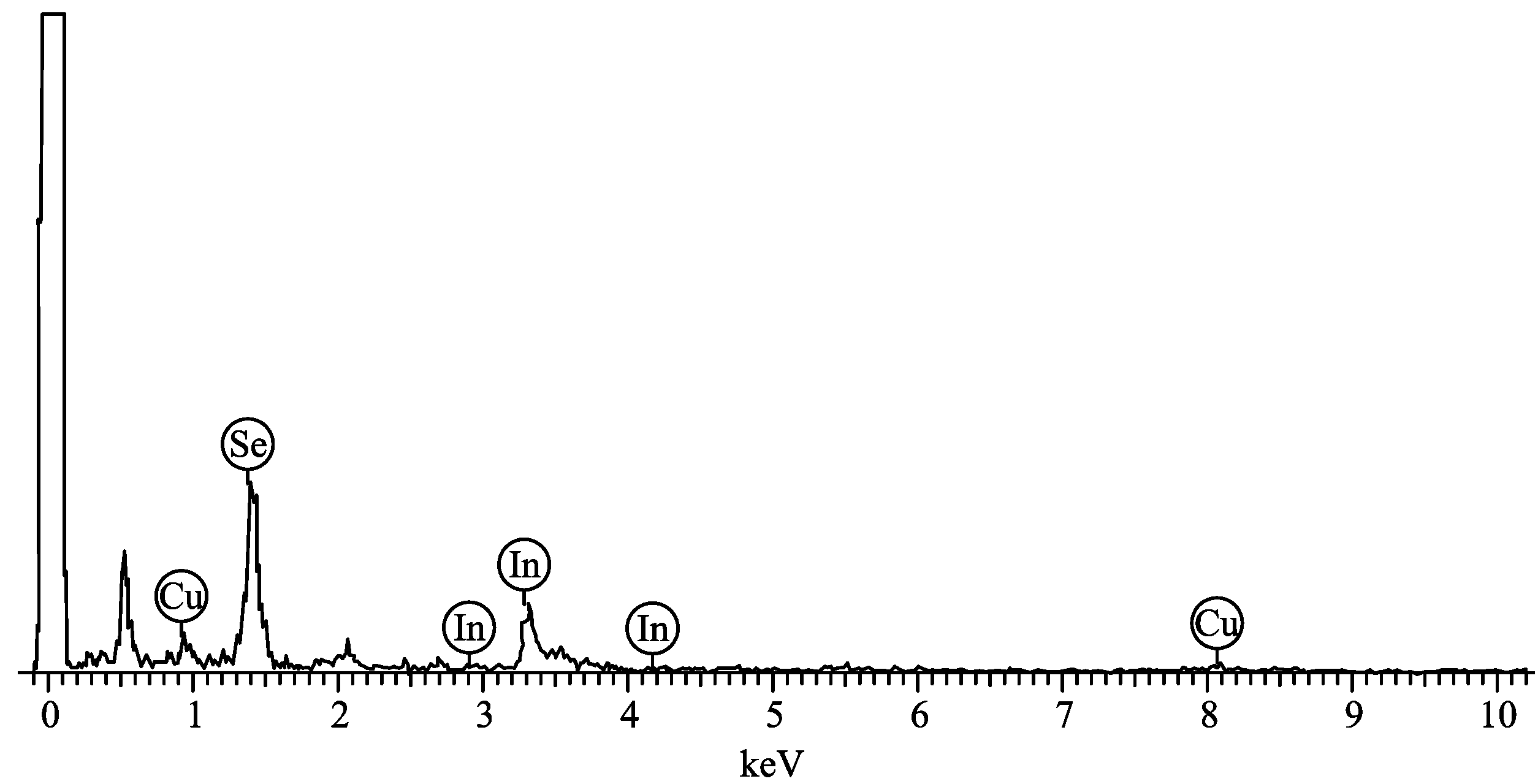

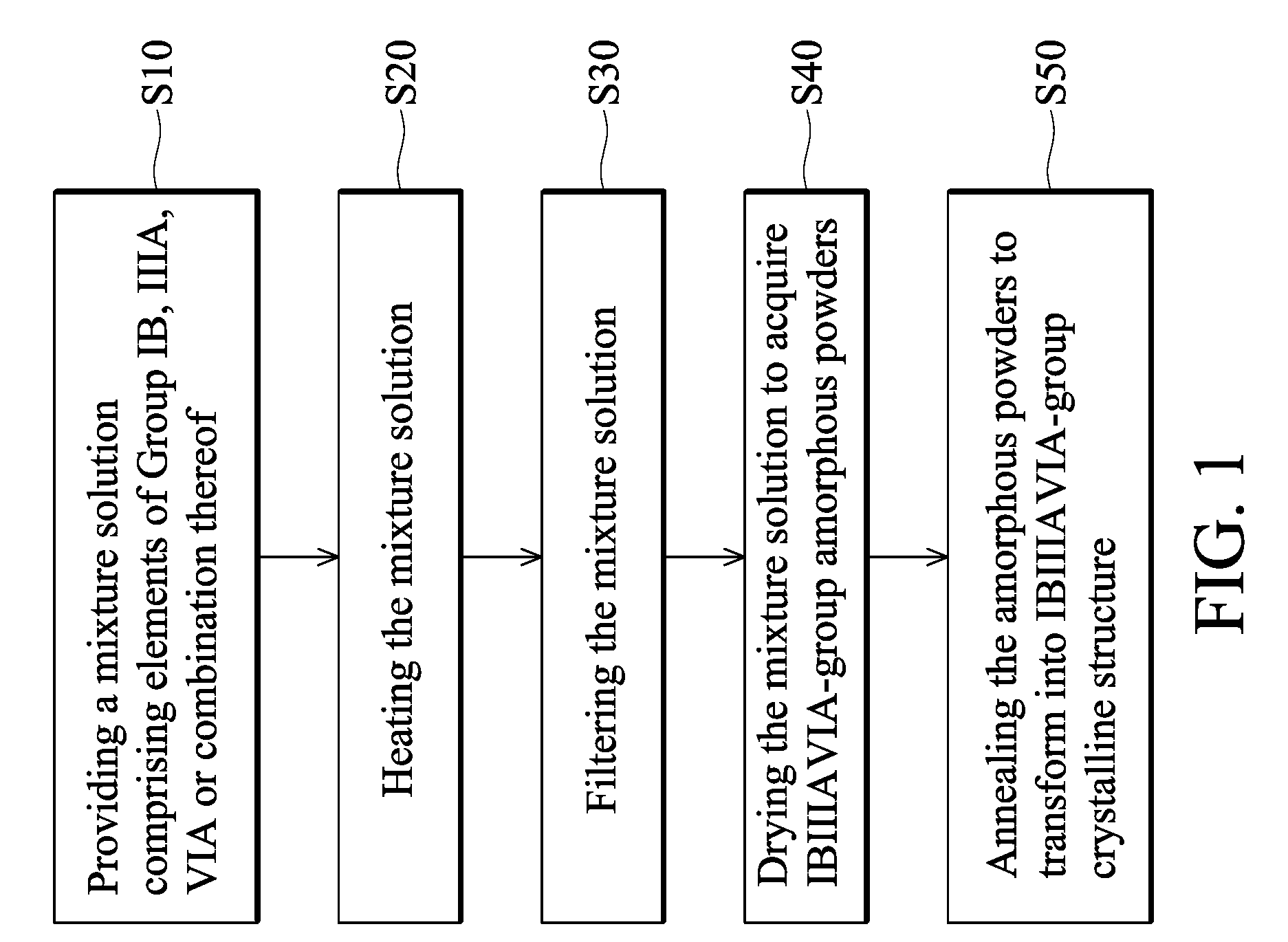

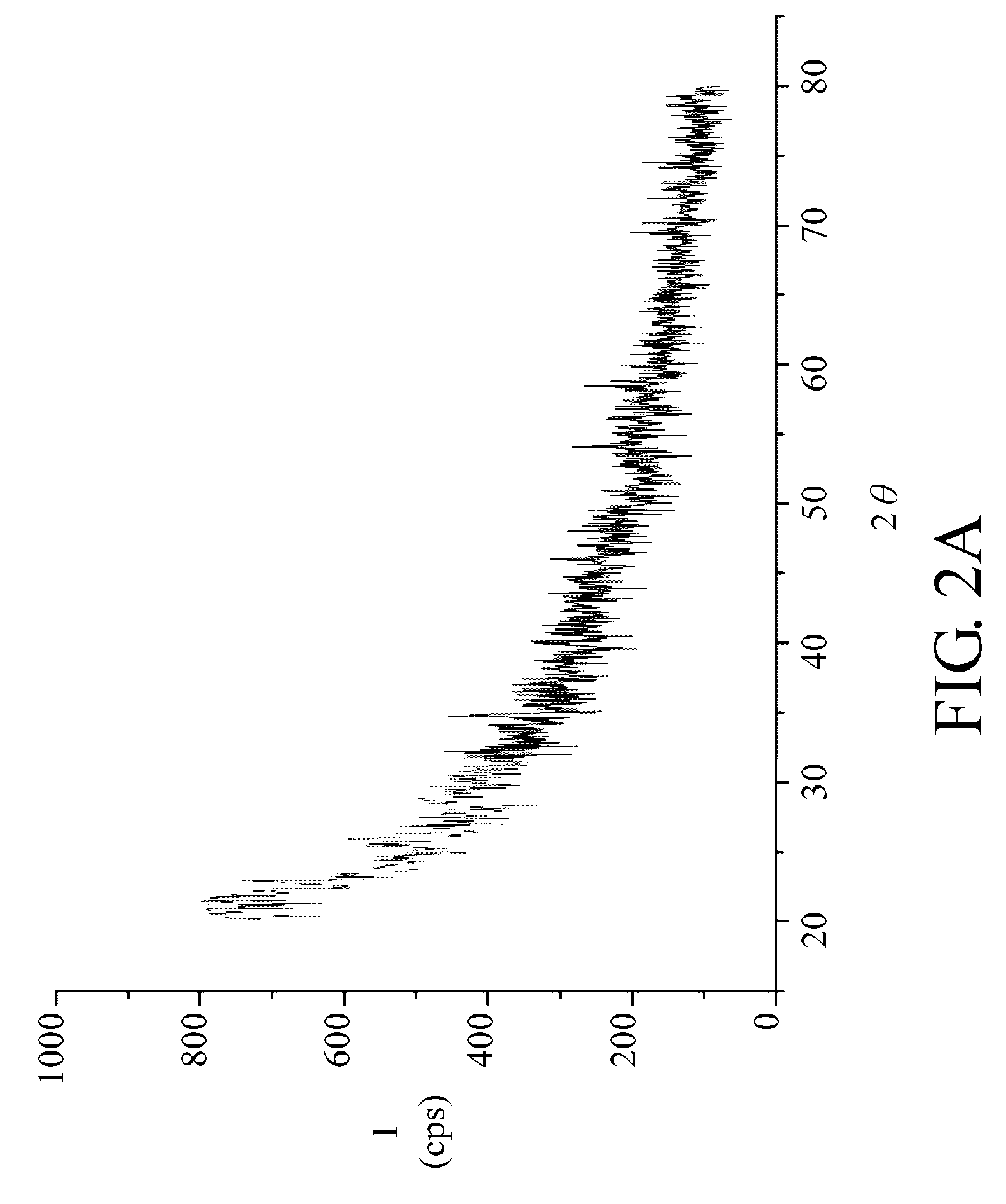

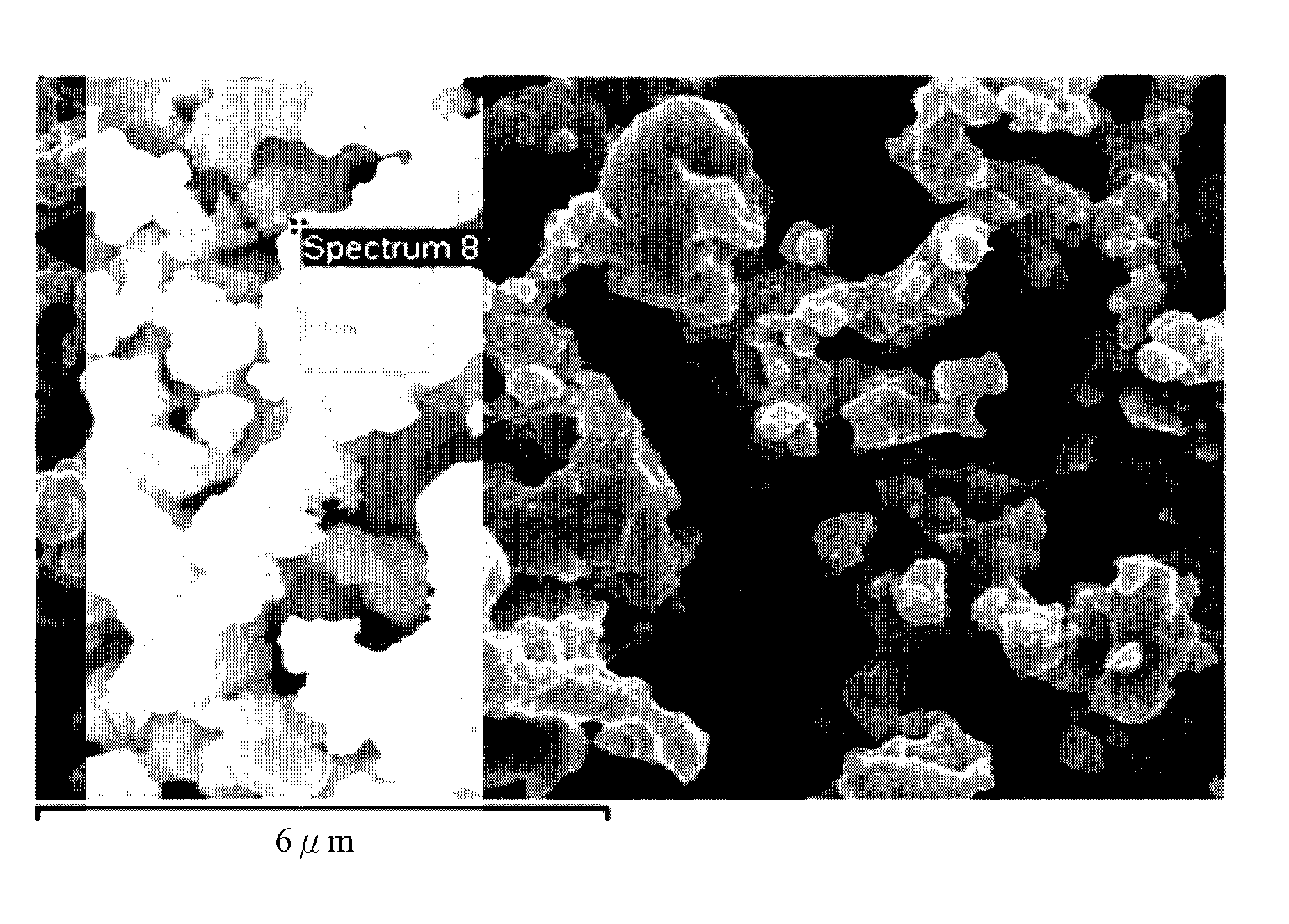

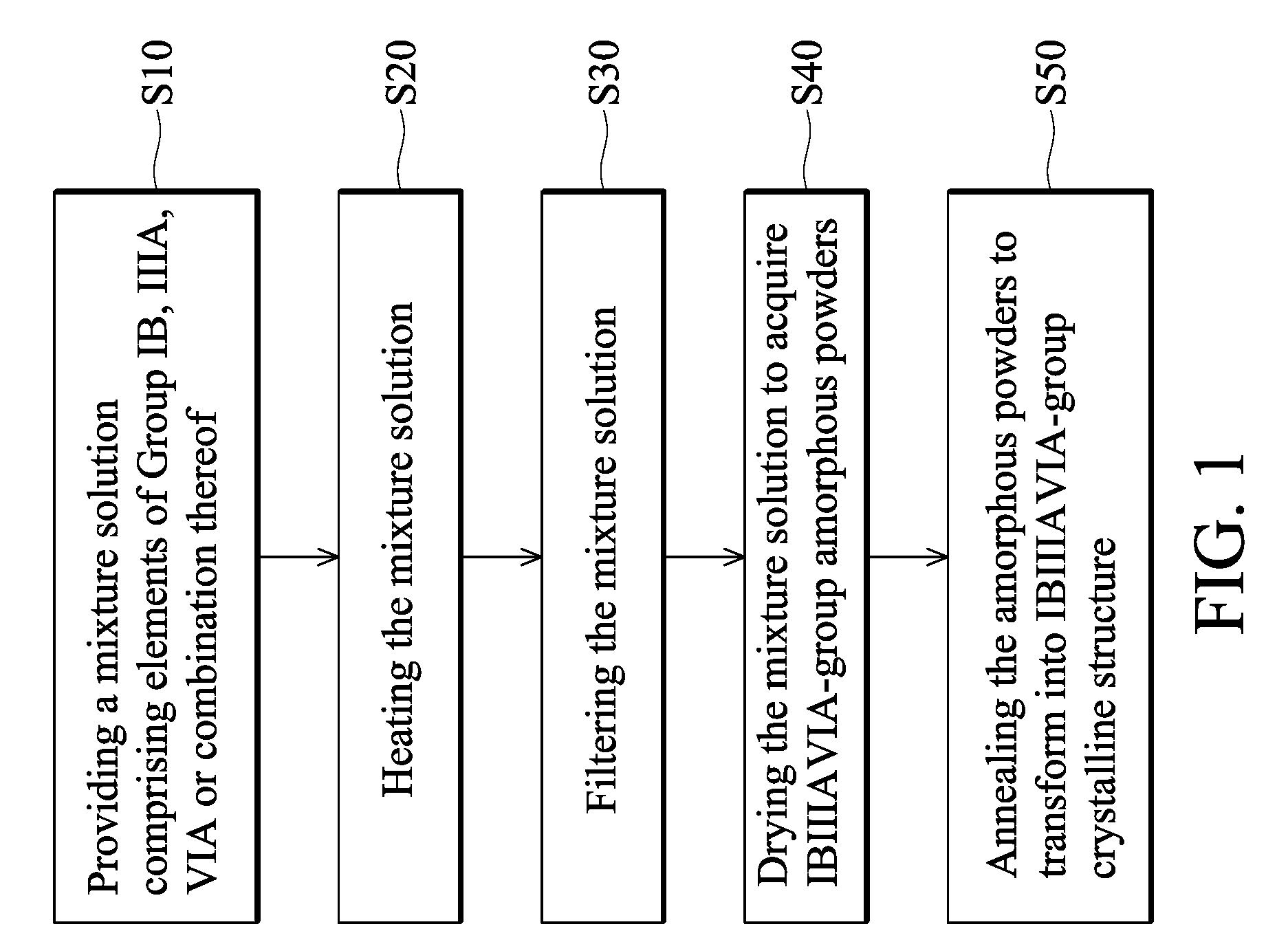

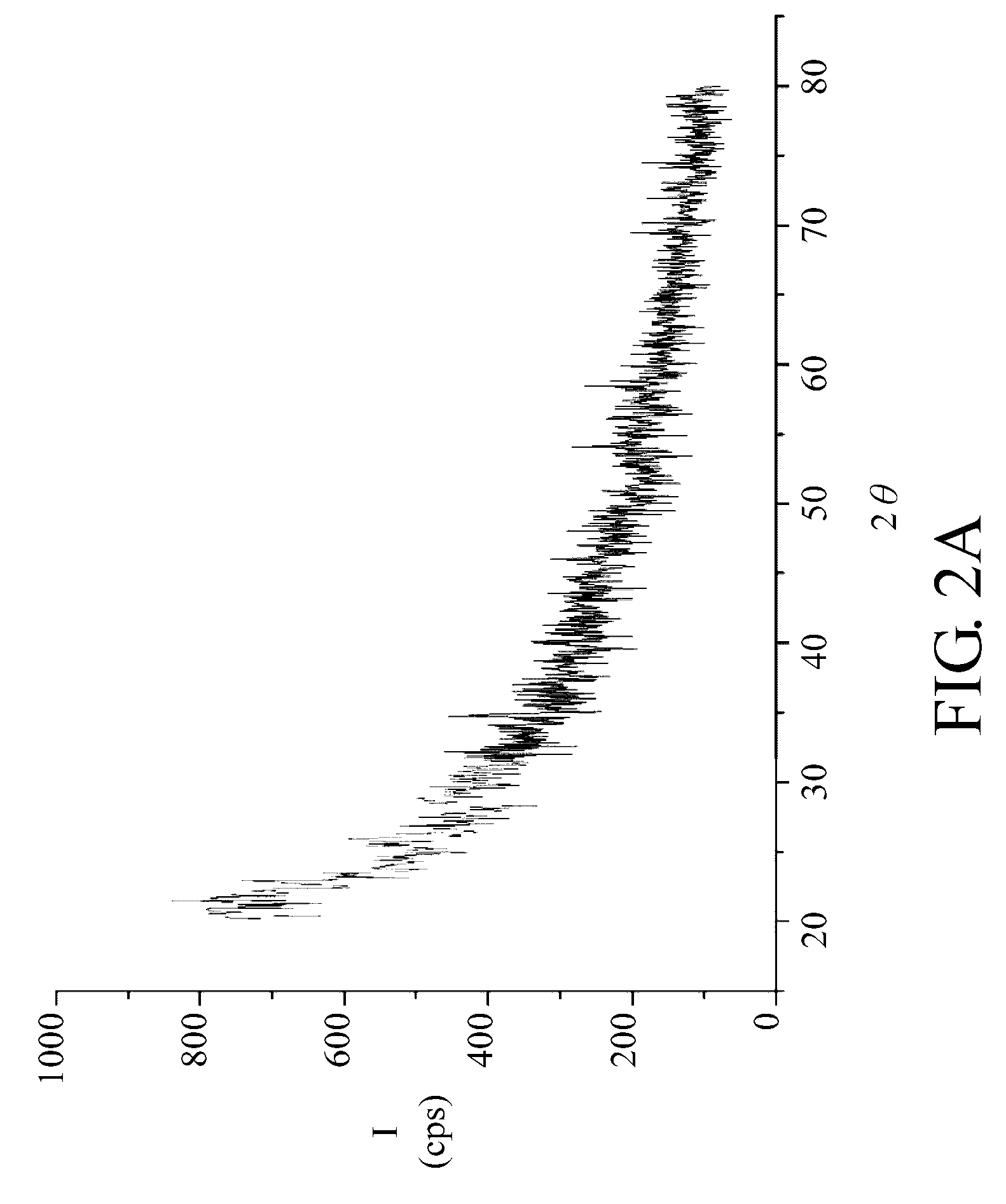

Fabrication method for ibiiiavia-group amorphous compound and ibiiiavia-group amorphous precursor for thin-film solar cells

ActiveUS20100133479A1Phosphorus sulfur/selenium/tellurium compoundsConductive materialCompound (substance)Materials science

A method for fabricating an IBIIIAVIA-group amorphous compound used for thin-film solar cells is provided. A mixture solution including elements of Group IB, IIIA, VIA or combinations thereof is provided. The mixture solution is heated and filtered. IBIIIAVIA-group amorphous powders are acquired after drying the heated and filtered mixture solution.

Owner:IND TECH RES INST

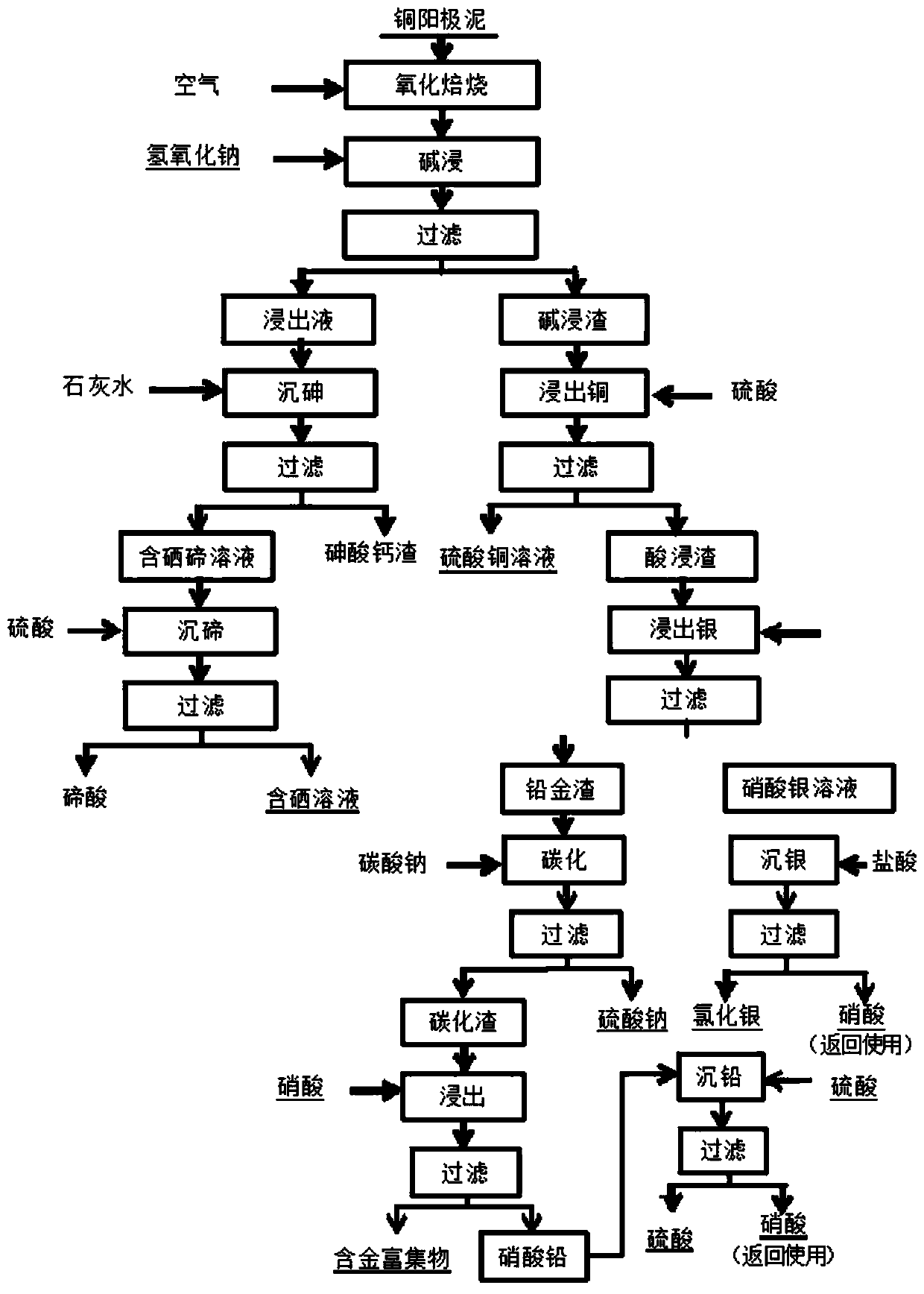

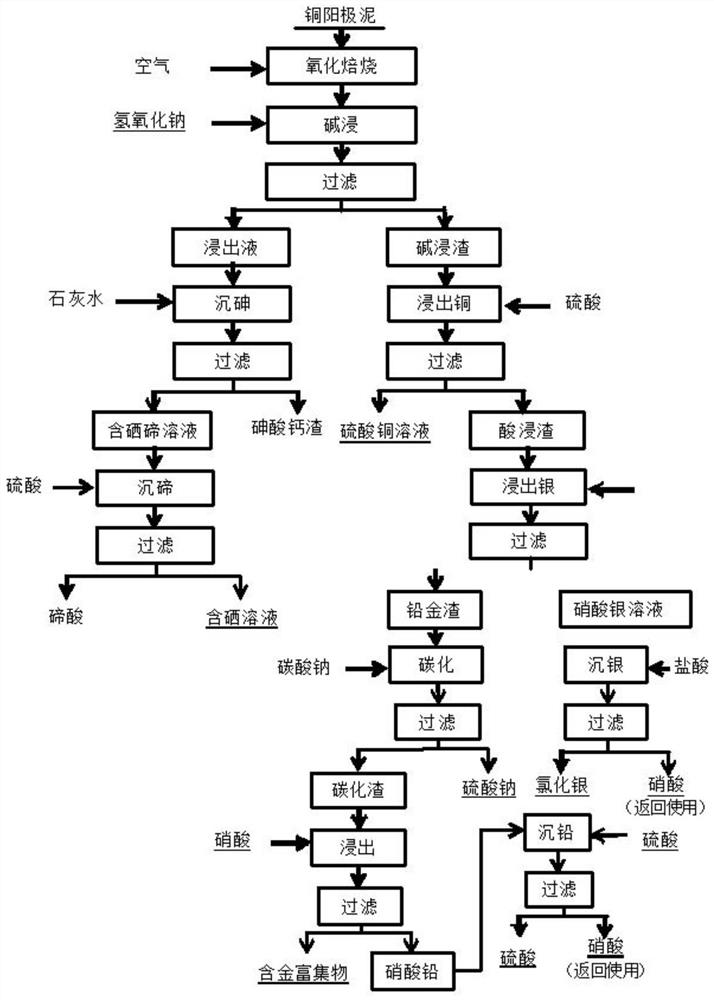

Method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud

ActiveCN111575483AAvoiding the problem of hard-to-leach telluriumAchieve recyclingProcess efficiency improvementSelenium/tellurium oxyacid saltsSlagLead nitrate

The invention discloses a method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud, and relates to the technical field of rare and preciousmetal metallurgy. The method comprises the following steps that roasted products obtained through low-temperature oxidization roasting of the copper anode mud and sodium hydroxide react to obtain selenium, tellurium and arsenic containing leaching liquor and alkaline leaching slag; the leaching liquor and whitewash react to obtain a selenium and tellurium containing solution and calcium arsenate slag; the alkaline leaching slag and sulfuric acid react to obtain copper sulfate and acid leaching slag; sulfuric acid and the selenium and tellurium containing solution react to obtain telluric acidand a selenium containing solution; the acid leaching slag and nitric acid react to obtain a silver nitrate solution and lead and gold slag; silver nitrate and hydrochloric acid react to obtain silverchloride and nitric acid; the lead and gold slag and a sodium carbonate solution react to obtain carbonization slag and a sodium sulfate solution; the carbonization slag and nitric acid react to obtain a lead nitrate solution and gold containing enrichment; and the lead nitrate solution and sulfuric acid react to obtain a lead sulfate and sulfuric acid solution. The method aims to solve the problems that existing methods for recycling metal from copper anode mud, the cost is high, recycled metal is single, and the comprehensive recovery effect is poor.

Owner:KUNMING BOREN PRECIOUS METALS +1

Method and Process of Treatment of Selenium Containing Material and Selenium Recovery

InactiveUS20160130144A1Remove completelyReadily availablePhosphorus sulfur/selenium/tellurium compoundsProcess efficiency improvementSludgeSorbent

The method and process of treatment of selenium containing materials, including, but not limited to, different adsorbents, membranes, filters, bioreactor sludge obtained from water treatment, waste electronic devices, material obtained from mineral processing, different industrial wastes, metallurgical wastes, which allow reduction of total selenium content in the material and selenium recovery have been developed.

Owner:TAIROVA GIOULCHEN +1

Method for extracting mercury from heavy-metal-related acid mud

ActiveCN106893865AEfficient separationAvoid pollutionProcess efficiency improvementSelenium/tellurium oxyacid saltsPotassium chlorateSediment

The invention particularly relates to a method for extracting mercury from heavy-metal-related acid mud, belonging to the technical field of resources and environment. The method comprises the following steps that step 1, the heavy-metal-related acid mud and hydrochloric acid are added into water and are heated; then potassium chlorate is added; reaction is performed at certain temperature to obtain a mixed liquid containing mercuric chloride; step 2, alkali is added in for neutralization to control pH, so that a mixed solution containing mercuric oxide sediment and Na2SeO3 is obtained; solid-liquid separation is performed, and a selenium-containing solution enters a selenium separation system for recycling selenium; step 3, the mercury oxide sediment obtained through separation in the step 2 is dried and is rectified by adopting a continuous vacuum rectification method; and generated mercury steam is condensed and recycled to obtained refined mercury. According to the method, a wet technique is adopted for processing, so that high-efficient separation of mercury and selenium is realized; then the high-purity mercury product is manufactured through continuous vacuum rectification; and smoke pollution caused by direct roasting of the acid mud is avoided.

Owner:湖南省环境保护科学研究院 +1

Preparation method for silver tellurite, crystalline solar cell positive pole silver paste and preparation method therefor

InactiveCN105858623AAvoid high temperature conditionsIntegrity guaranteedNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOhmic contact

The invention discloses a preparation method for preparing silver tellurite through subjecting a silver ammonia solution to a reaction with tellurite as well as provides novel crystalline solar cell positive pole silver paste by means of directly adding the silver tellurite prepared by the method and improved inorganic glass powder based on original raw materials and a method for preparing the crystalline solar cell positive pole silver paste. According to the invention, the design is ingenious; and through directly adding the silver tellurite and the high-selection-ratio corrosive inorganic glass powder, conditions are created for ohmic contact for silver and silicon, meanwhile, high-temperature conditions required for precipitating adequate silver tellurite from the glass powder are avoided, and the integrity of PN junctions cannot be affected by high temperatures, so that the contradiction is solved, and the window for sintering temperatures is widened.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

Compound effecting on hepatitis B virus

InactiveCN104208082AImprove immunityBreakthroughOrganic chemistryDigestive systemChronic hepatitisHbv replication

Owner:SHANGHAI AI QI ECOLOGICAL TECH

Method for leaching selenium from cadmium selenide waste

ActiveCN106744725AImprove leaching rateHigh recovery rateCadmium compoundsSelenium/tellurium oxyacid saltsCadmium selenideHigh pressure

The invention relates to a method for leaching selenium from cadmium selenide waste. The method adopts two-section oxygen pressure alkaline leaching; the cadmium selenide waste is subjected to first-section oxygen pressure alkaline leaching, and the leaching residue of the first-section oxygen pressure alkaline leaching is used as the raw material of second-section oxygen pressure alkaline leaching; the leaching liquid of the second-section oxygen pressure alkaline leaching returns to a leaching agent of the first-section oxygen pressure alkaline leaching; and the first-section oxygen pressure alkaline leaching and second-section oxygen pressure alkaline leaching are both performed in a high-pressure reaction kettle, and oxygen is introduced to both as an oxidizing agent. In the method provided by the invention, selenium in the cadmium selenide waste exists in the leachate totally in a form of sodium selenite, thereby being safe and environment-friendly; and the selenium recovery rate is high, and the cost is low.

Owner:FIRST RARE MATERIALS CO LTD

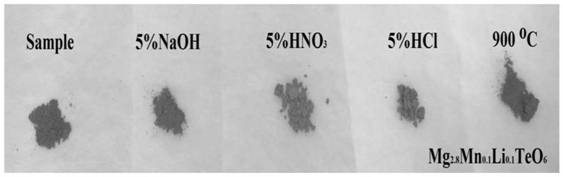

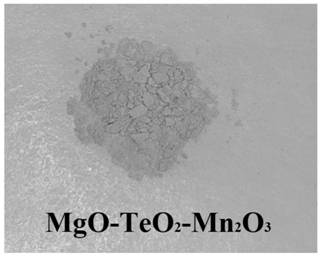

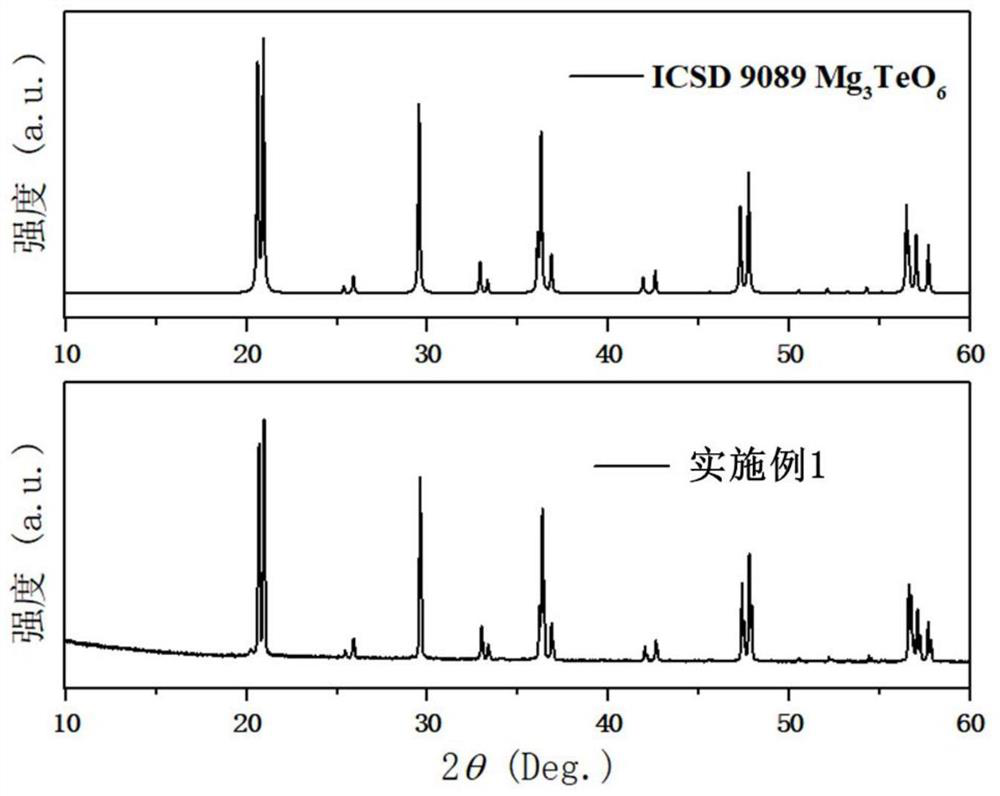

Purple inorganic pigment based on Mg3TeO6 structure and preparation method and application thereof

ActiveCN112758900AKeep the same colorThe preparation method is simple and environmentally friendlySelenium/tellurium oxyacid saltsPhysical chemistryManganese

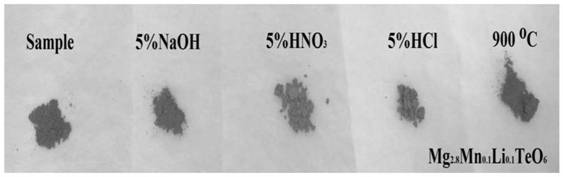

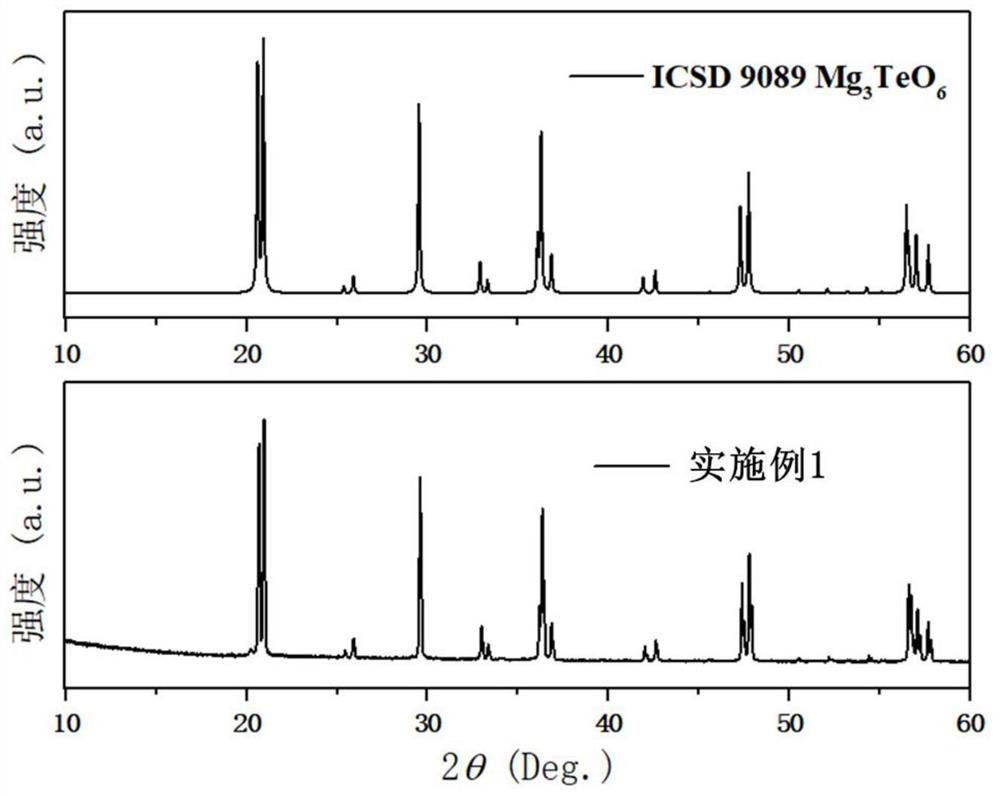

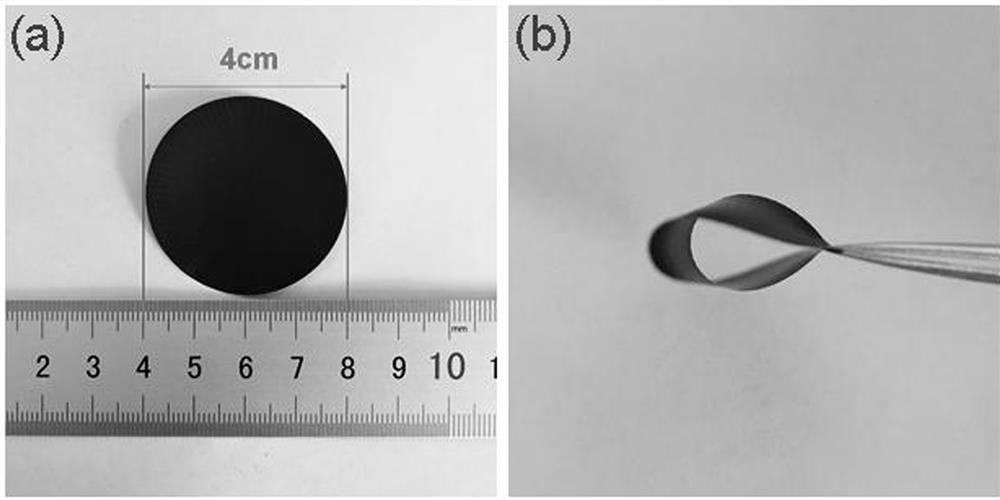

The invention discloses a purple inorganic pigment based on a Mg3TeO6 structure as well as a preparation method and application thereof, the molecular formula of the purple inorganic pigment is Mg<3-2x>MnxLixTeO6, and x is more than or equal to 0.02 and less than or equal to 0.15; and the preparation method of the purple inorganic pigment comprises the following steps: mixing and grinding a magnesium-containing compound, a tellurium-containing compound, a manganese-containing compound and Li2CO3 in proportion, calcining at 750-900 DEG C, and cooling to obtain the purple inorganic pigment. The purple inorganic pigment is resistant to acid, alkali and high temperature, the preparation method is environmentally friendly, the raw materials are cheap and non-toxic, and the purple inorganic pigment can be applied to chemical production of paint, coatings, paintings, plastics and rubber.

Owner:SUN YAT SEN UNIV

Flexible Bi2O2Se-based electrode material and preparation method and application thereof

ActiveCN114148994AImprove cycle performanceExcellent rate performanceSelenium/tellurium oxyacid saltsSemiconductor devicesNew energySodium-ion battery

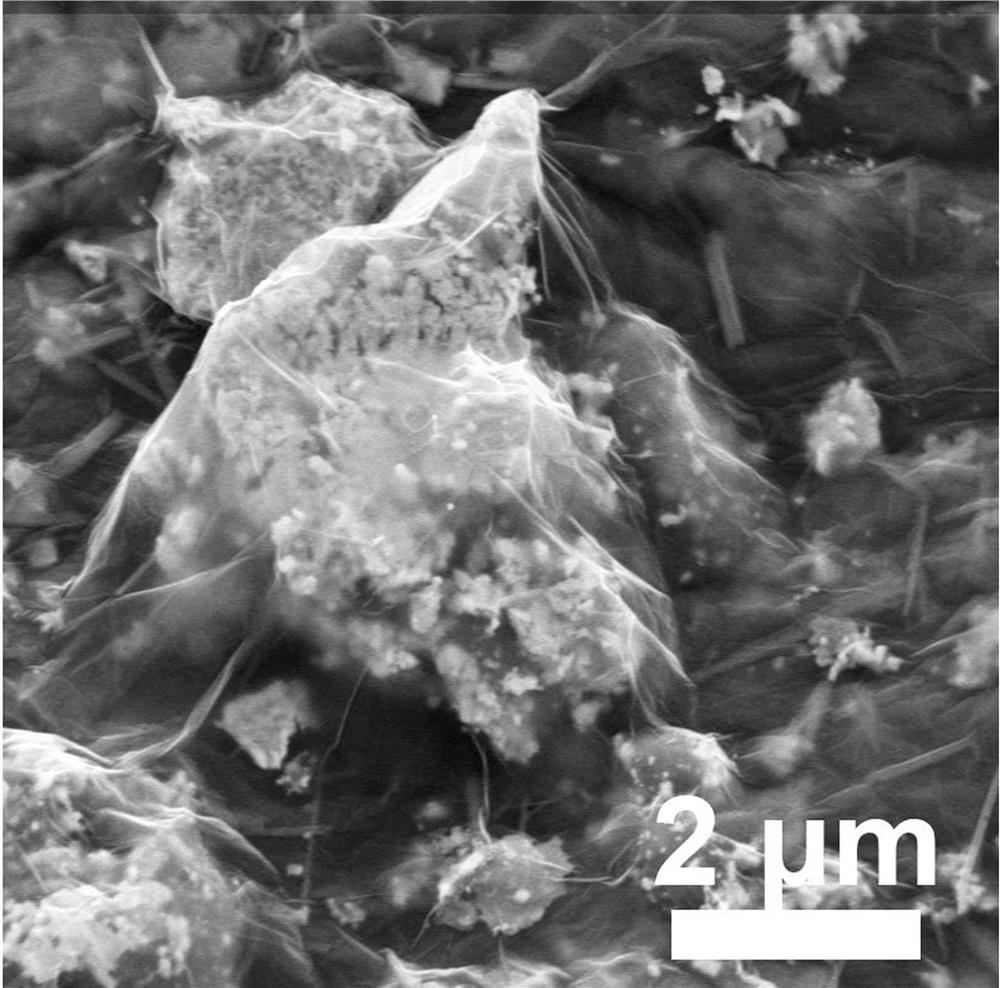

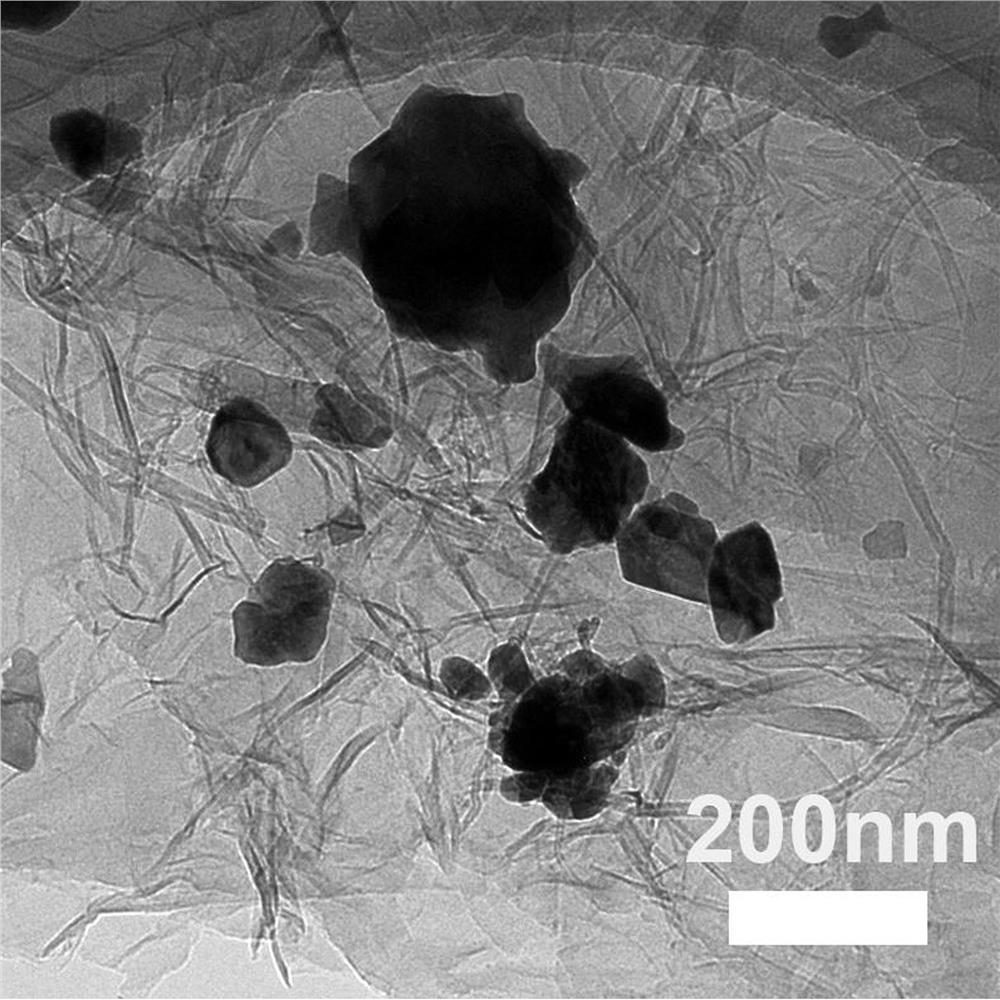

The invention belongs to the technical field of new energy materials, and provides a flexible Bi2O2Se-based electrode material as well as a preparation method and application thereof in order to solve the problem that a Bi2O2Se flexible material and a Bi2O2Se flexible material serving as a negative electrode material cannot be applied to a flexible battery at present. The preparation method comprises the following steps: mixing and dissolving carbon nanotubes, bismuth salt and a selenium source, carrying out a liquid-phase oil bath heating reaction, drying to obtain powder, dispersing the powder and graphene in an ethanol aqueous solution for a composite reaction, carrying out suction filtration to form a film, and sintering to obtain the flexible Bi2O2Se-based electrode material. The flexible electrode material is prepared through liquid phase reaction and carbonization treatment, and has high reversible capacity, stable cycle performance and excellent rate capability. The flexible electrode can be directly used as a battery negative electrode without adding a binder, a conductive agent and a current collector, the process is simplified, and the development of the flexible electrode is facilitated. The prepared flexible sodium-ion battery negative electrode material has excellent flexibility, high specific capacity, high rate capability, excellent cycling stability and high yield, and can be used for electrodes of sodium-ion batteries, and is suitable for flexible sodium-ion battery negative electrode materials.

Owner:ZHONGBEI UNIV

Copper indium gallium diselenide treatment method

InactiveCN108893610ASimple processPurification and high purityProcess efficiency improvementSelenium/tellurium oxyacid saltsIndiumCopper indium gallium selenide solar cells

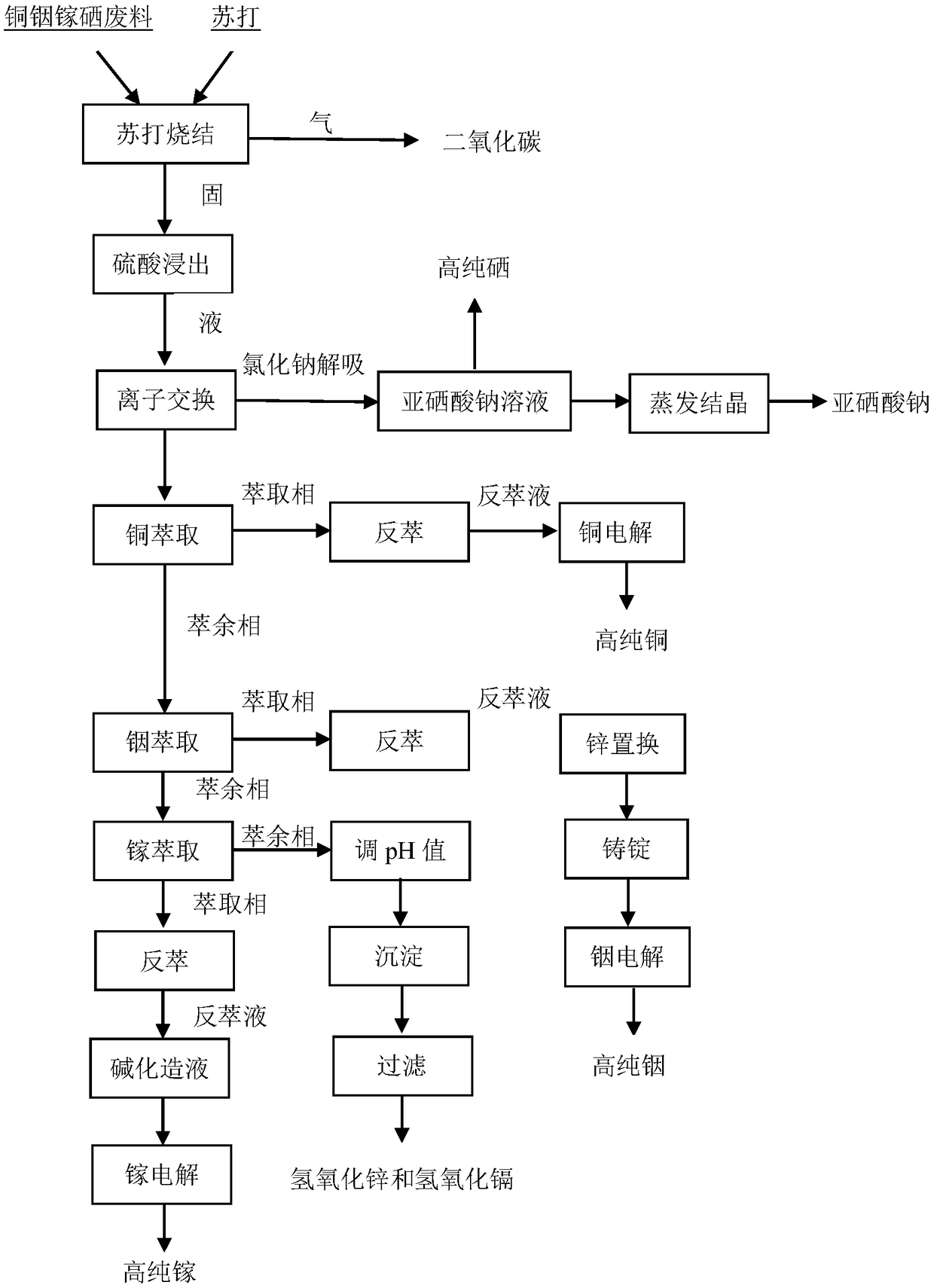

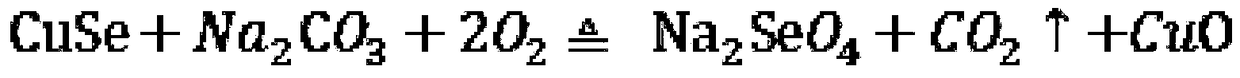

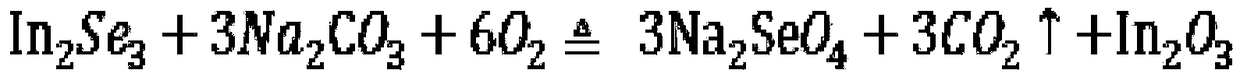

The application discloses a copper indium gallium diselenide treatment method, comprising the steps of adding sodium carbonate into copper indium gallium diselenide for sintering to obtain carbon dioxide and a sintered material, wherein the sintered material is a mixture of sodium selenite and copper indium gallium oxide; adding sulfuric acid to the sintered material for leaching, and filtering toobtain a mixed solution containing copper sulfate, gallium sulfate, indium sulfate and sodium selenite; subjecting the mixed solution containing copper sulfate, gallium sulfate, indium sulfate and sodium selenite to ion exchange through anion exchange resin to obtain copper indium gallium solution; desorbing the anion exchange resin to obtain high-purity selenium; treating the copper indium gallium solution to obtain copper, indium and gallium. The copper indium gallium waste mainly includes selenides; sodium carbonate sintering is performed to convert copper indium gallium diselenide into anoxide easily soluble in an acid; the consumption of acids and strong antioxidants is reduced.

Owner:HANERGY NEW MATERIAL TECH CO LTD

Method for reextracting tellurium by using alkali liquor

PendingCN108264028AIncrease profitSimple process routeSelenium/tellurium preparationSelenium/tellurium oxides/hydroxidesOil phaseTe element

The invention discloses a method for reextracting tellurium by using an alkali. The problem that the utilization rate of a raw material is low when a method in the prior art is applied to the tellurium extraction in tellurium ore is solved. The method comprises the following steps of (1), obtaining iron removed hydrochloric acid immersion liquor; (2), adding TBP (Tributyl Phosphate) with the volume fraction of 55 to 65 percent into the hydrochloric acid immersion liquor, extracting, and separating out an oil phase; (3), adding a sodium hydroxide solution with the concentration of 1.5mol / L to 2.5mol / L into the oil phase, and reextracting, so as to obtain a tellurium-containing product; (4), drying the tellurium-containing product to subsequently obtain a finished product. The method has theadvantages that the process route is relatively simple, the utilization rate of the raw material is high, the purity reaches 98 percent or above, the yield reaches 90 percent or above and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

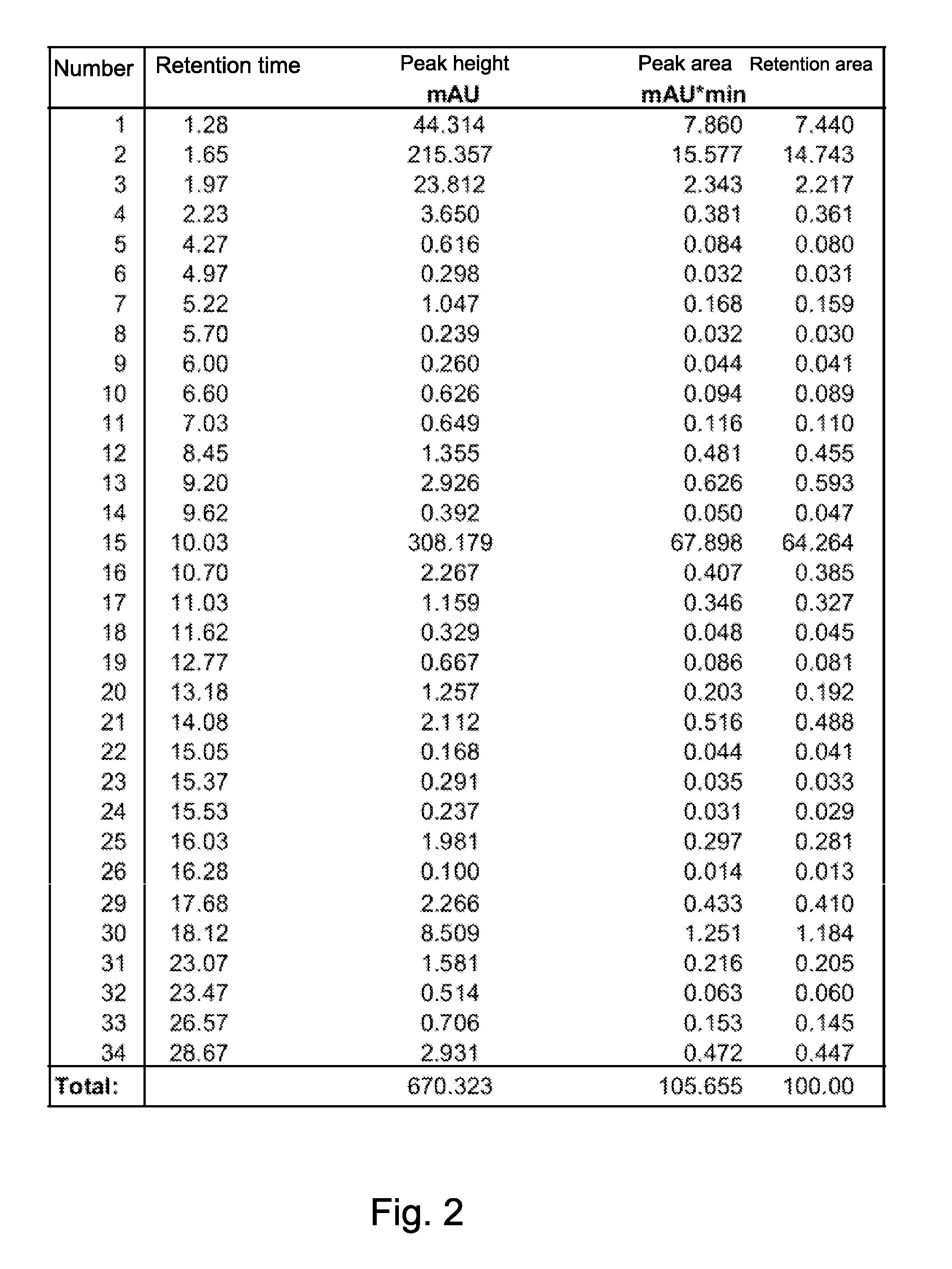

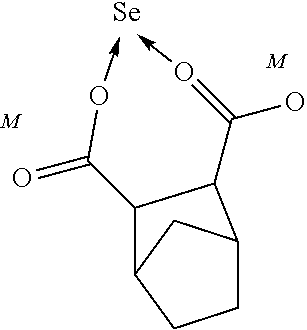

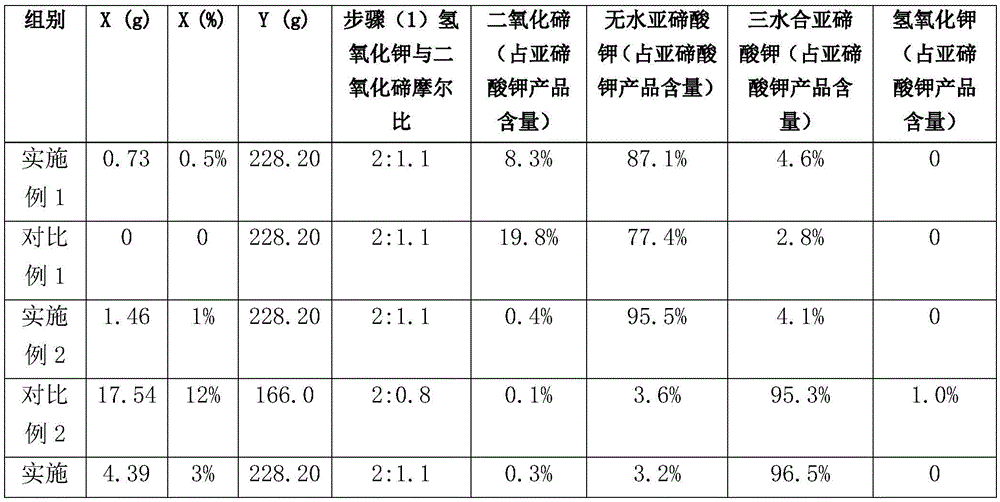

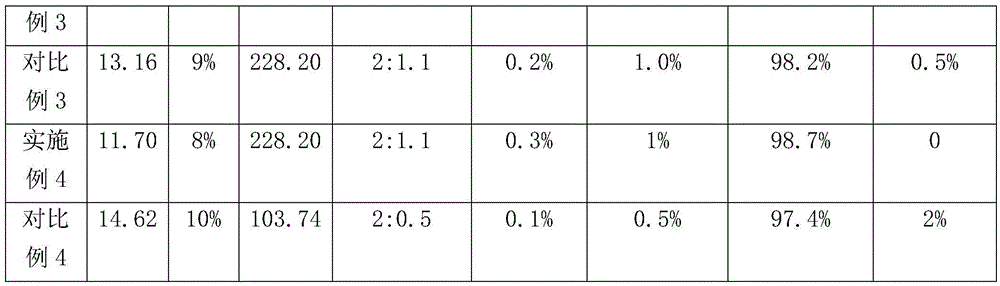

A method for controlling the content of tellurium dioxide and tellurite in tellurite products

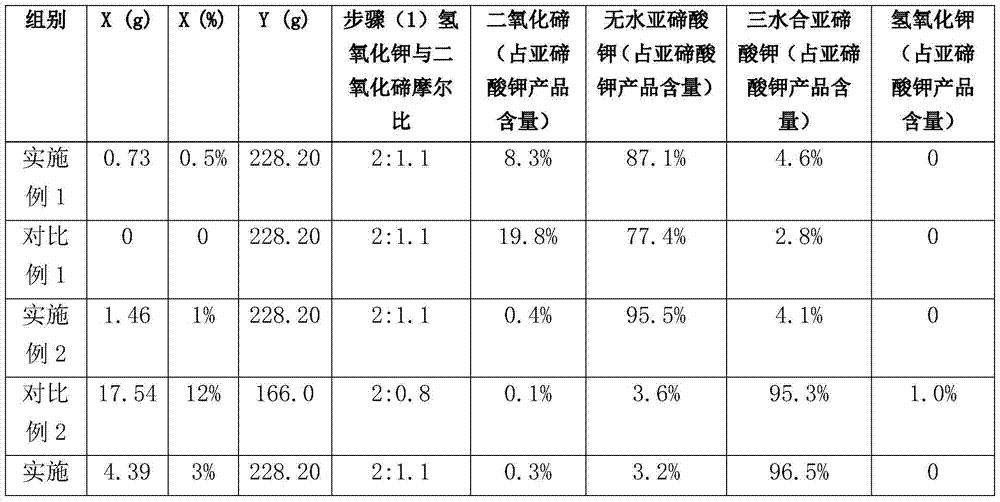

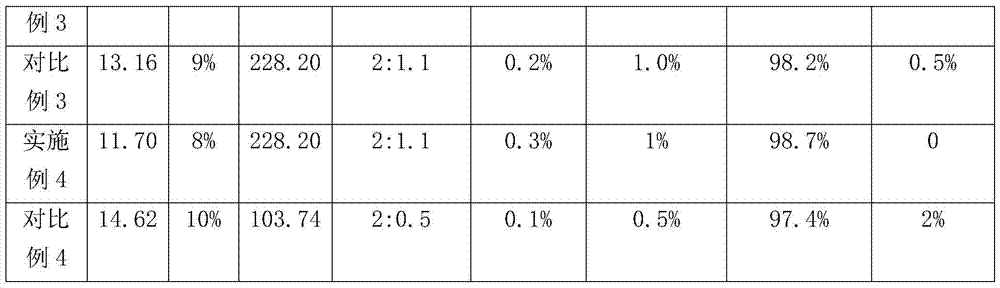

ActiveCN105480956BControl of tellurite trihydrate contentAvoid decompositionSelenium/tellurium oxyacid saltsMetalTellurium dioxide

The invention discloses a method for controlling the content of tellurium dioxide, the content of anhydrous tellurite and the content of trihydrate tellurite in a tellurite product. The method comprises the following steps that firstly, alkali metal hydroxide and tellurium dioxide are reacted in an aqueous solution with the mole ratio of 2.00:(1.00-1.15) to obtain a tellurite solution; secondly, alkali metal hydroxide is added in the tellurite solution, wherein the adding amount of alkali metal hydroxide accounts for X of alkali metal hydroxide in the first step by weight, different numerical value ranges are selected from X to control the content of tellurium dioxide, the content of anhydrous tellurite and the content of trihydrate tellurite in the tellurite product, and X is larger than zero and smaller than or equal to 8.00%. By means of the method, high-purity potassium tellurite can be prepared, and high-purity needle-like trihydrate potassium tellurite can also be prepared in an industrialized mode.

Owner:广东先导稀贵金属材料有限公司

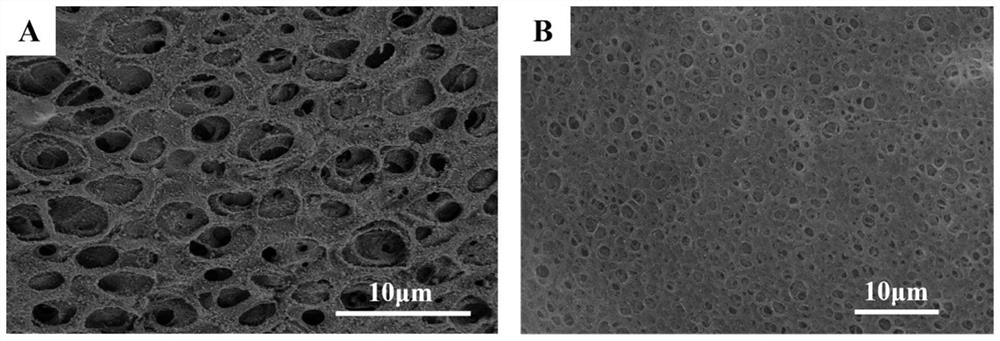

Preparation method of cellulose acetate-based composite membrane and application of cellulose acetate-based composite membrane in dynamic separation and extraction of tellurium

PendingCN113634139AImprove separation efficiencyImprove cycle performanceSemi-permeable membranesSelenium/tellurium compundsCellulose acetatePolyethylene glycol

The invention belongs to the field of chemical separation, and relates to a preparation method of a cellulose acetate-based composite membrane. The method comprises the steps of preparing a metal salt and a precipitant into a solution according to a molar volume ratio of the metal salt to the precipitant to water being 1 mol: (1-2) mol: (50-80) mL, carrying out a hydrothermal reaction at the temperature of 70-150 DEG C for 8-12 h, cooling to room temperature, carrying out precipitate centrifugal washing, drying at the temperature of 60-80 DEG C for 5-12 h, and calcining in air at the temperature of 300-600 DEG C for 1-5 h; and then mixing the metal oxide, cellulose acetate, polyvinylpyrrolidone and polyethylene glycol, stirring at the temperature of 50-80 DEG C for 4-9 hours, standing and cooling, casting the mixed solution on the surface of a glass plate, and immersing the glass plate into a non-solvent, thereby obtaining the product. The prepared composite membrane is applied to dynamic separation and recovery of tellurium in a tellurium-containing solution. The preparation method disclosed by the invention is low in cost and simple to operate, and the obtained composite membrane has high separation efficiency, circularity, pollution resistance and stability, is applied to the field of chemical separation, and has important significance on recycling of scattered element resources and environmental protection.

Owner:JIANGSU UNIV

Method for removing radioactive element thorium in rare earth mineral

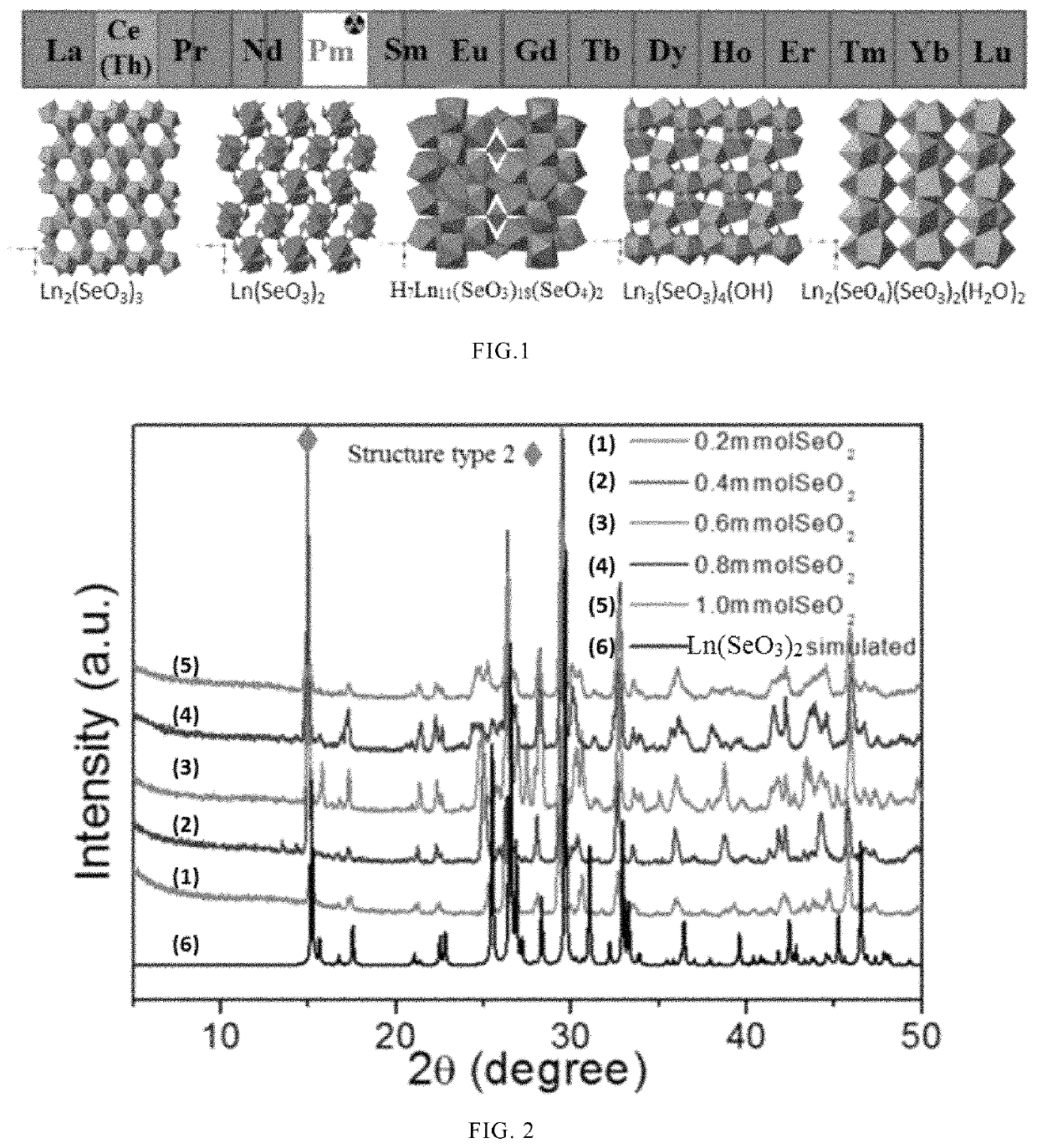

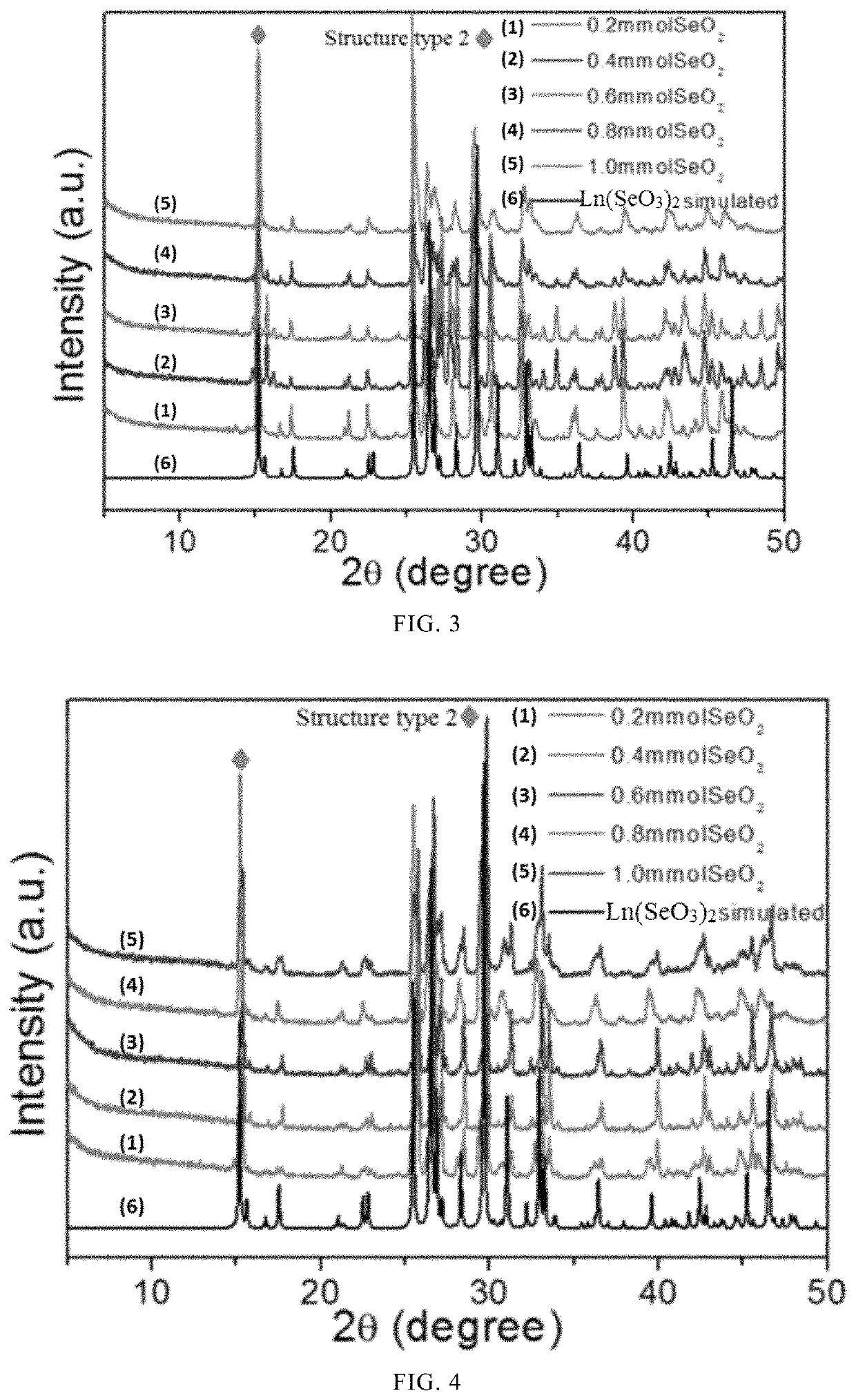

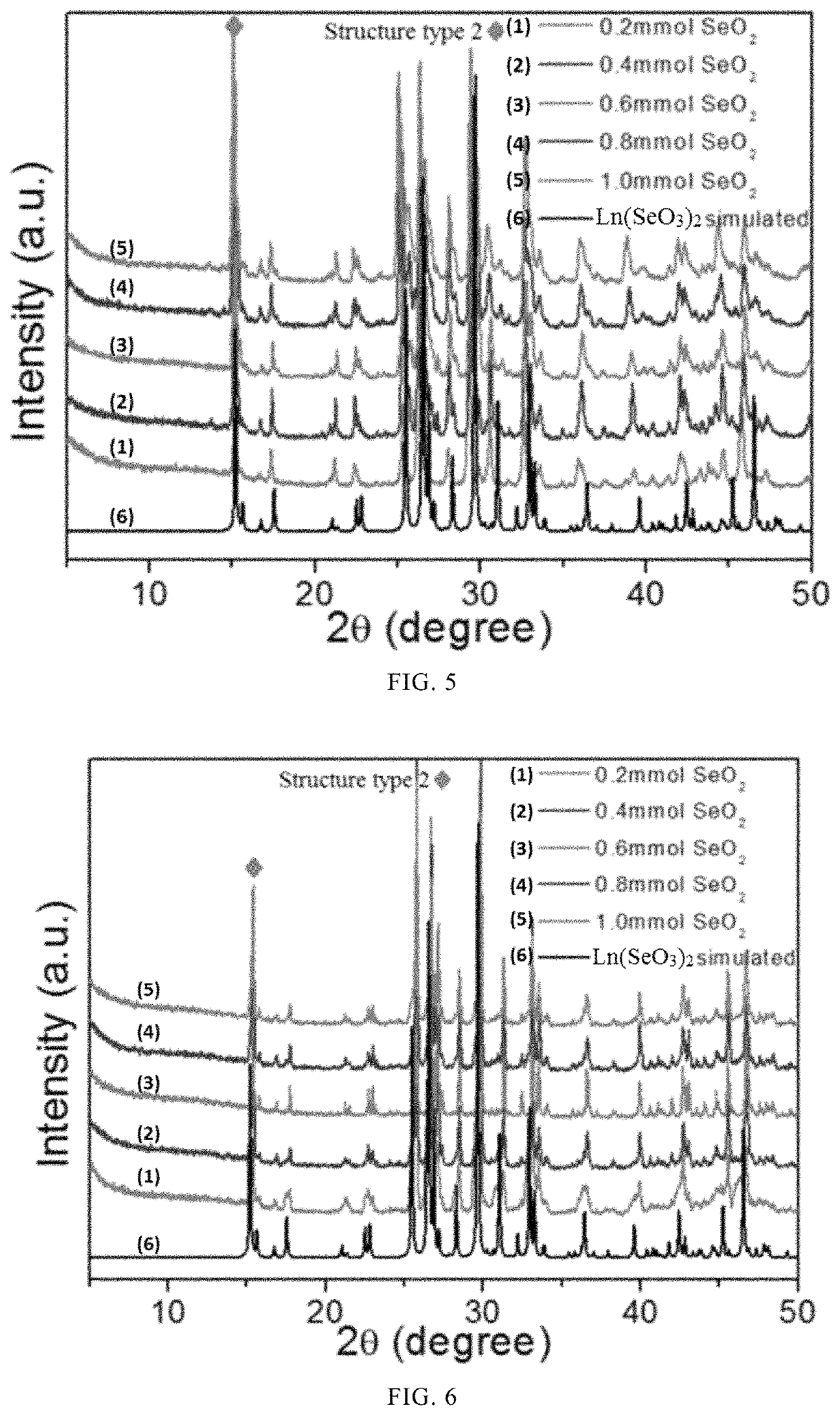

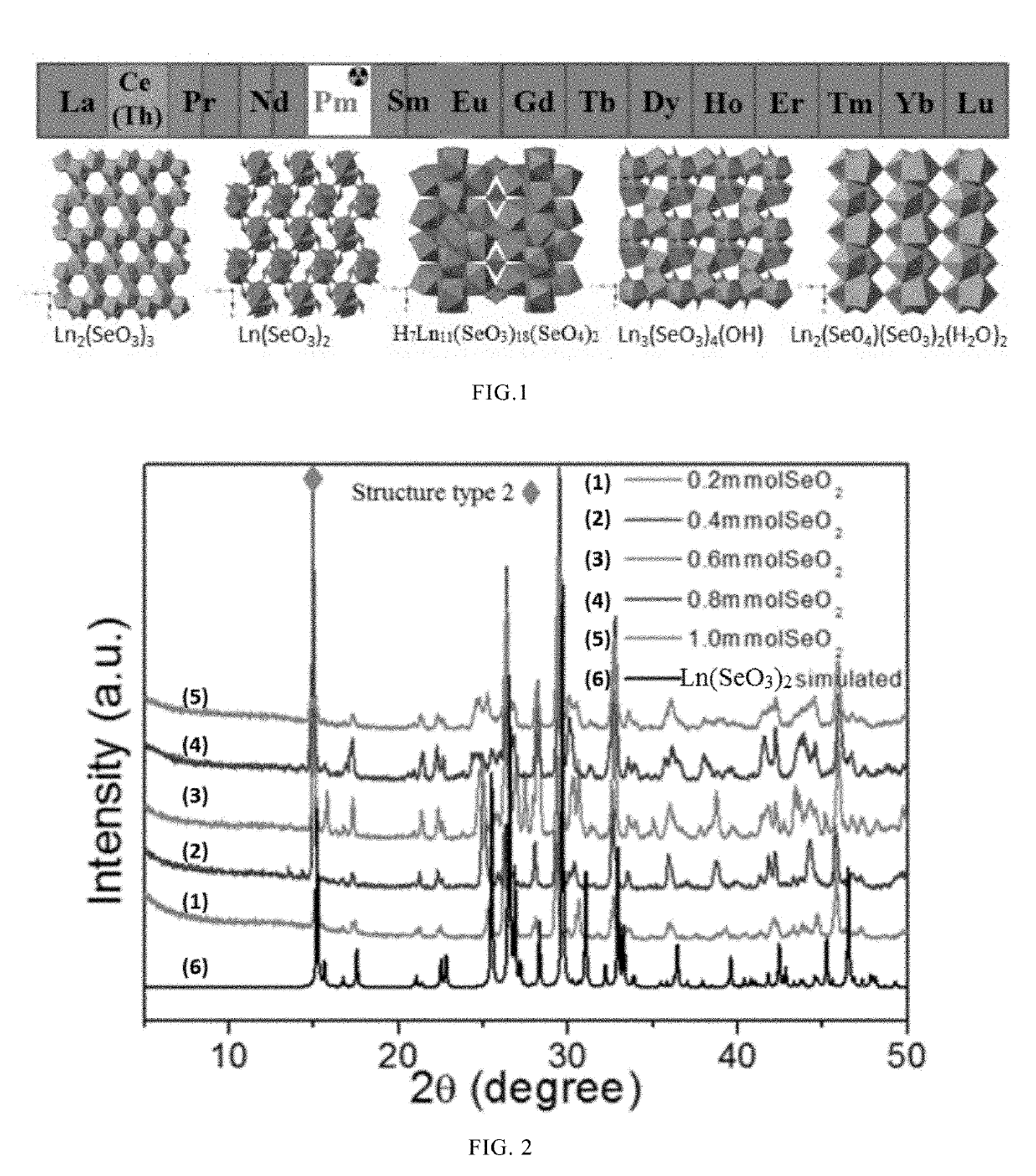

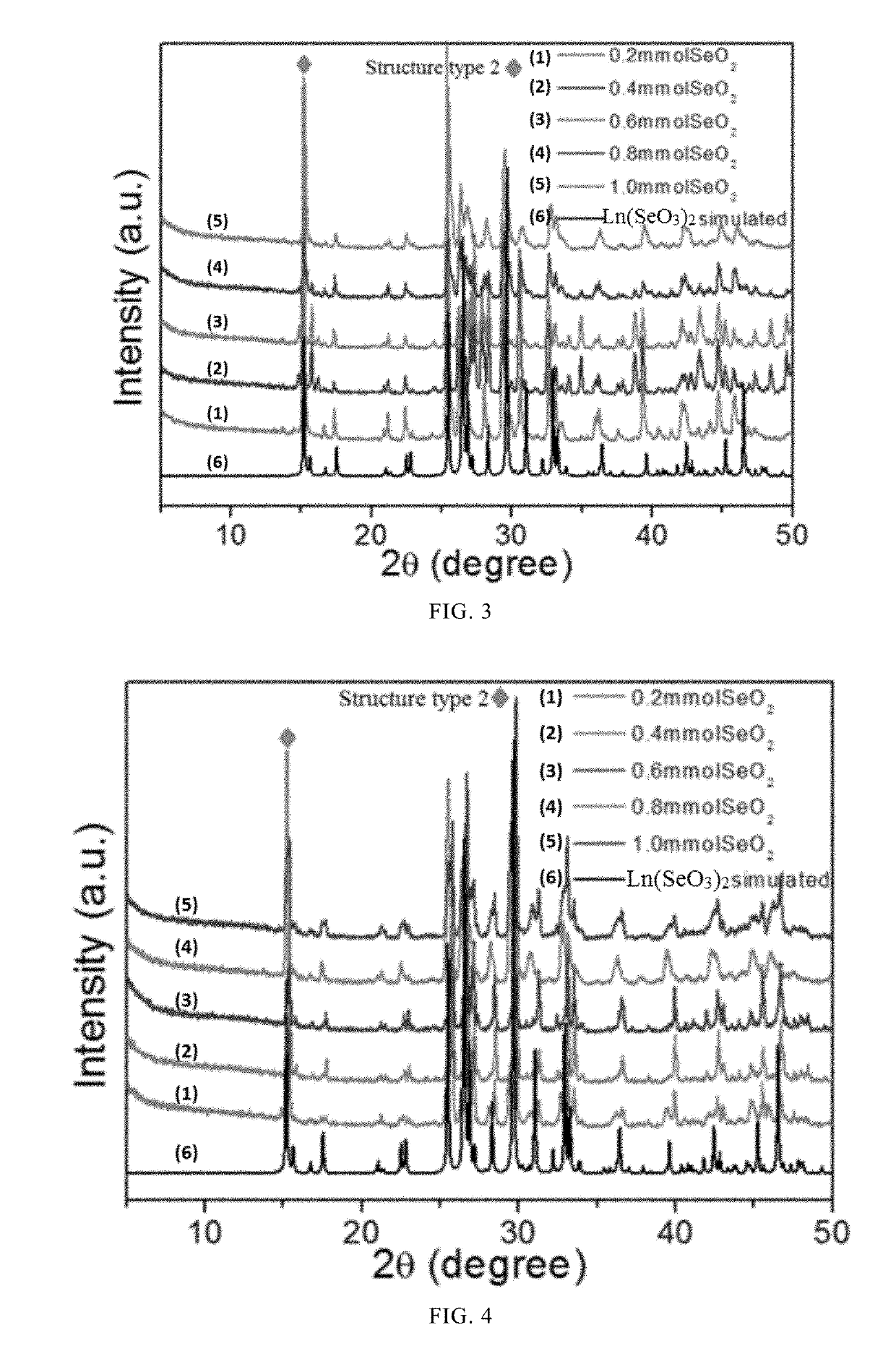

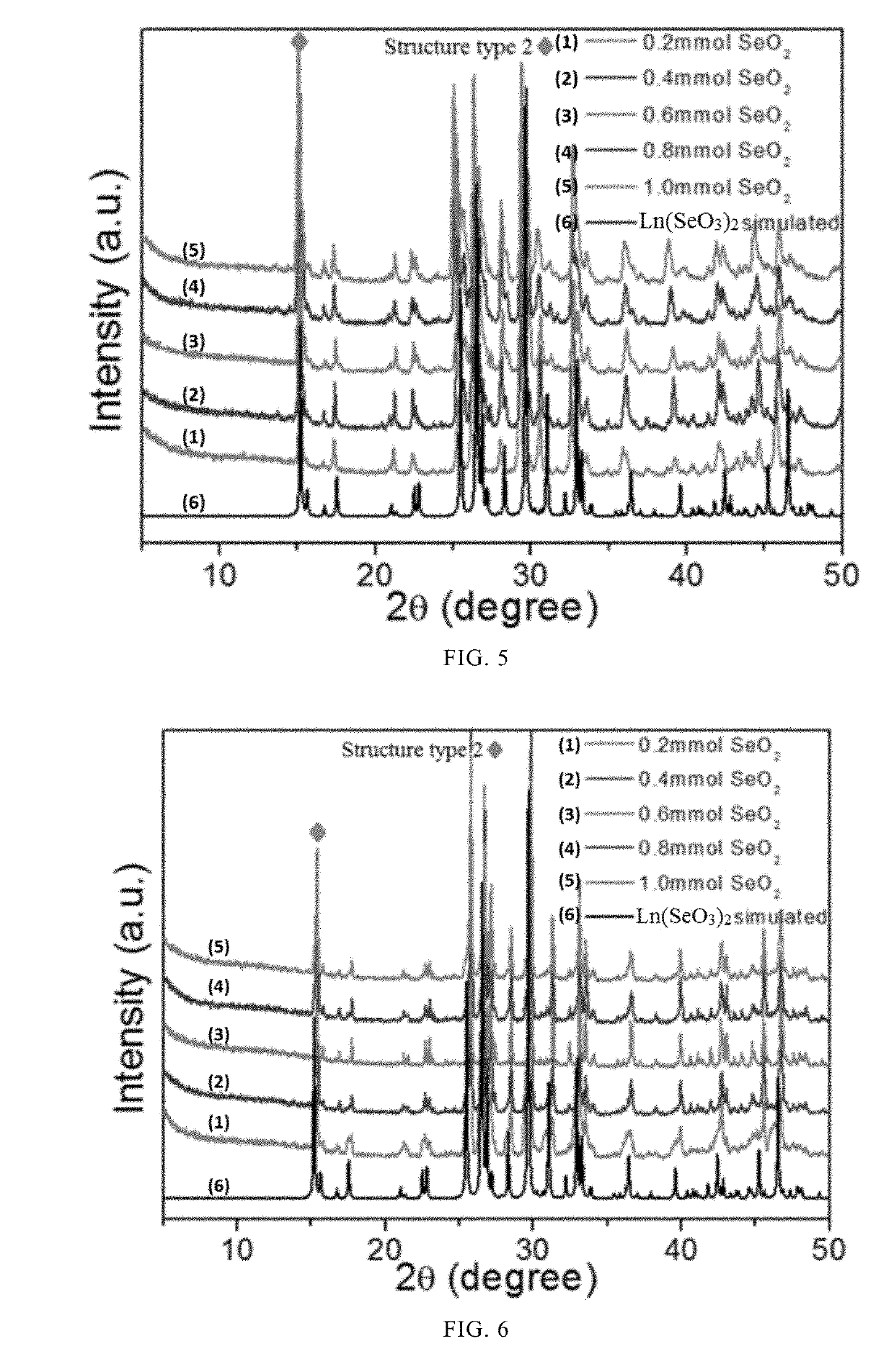

ActiveUS10711324B2Inexpensive, environmentally-friendlyImprove efficiencyPolycrystalline material growthFrom normal temperature solutionsLanthanideSelenium Oxide

Owner:SUZHOU UNIV

Method and application for preparing sodium selenite from selenium dioxide containing bismuth and copper

ActiveCN106219500APromote absorptionEfficient use ofAccessory food factorsSelenium/tellurium oxyacid saltsVulcanizationNon-ferrous extractive metallurgy

The invention discloses a method and application for preparing sodium selenite from selenium dioxide containing bismuth and copper, and belongs to the technical field of recycling and reuse of non-ferrous metal metallurgy byproducts. According to the method, crude selenium dioxide generated from a recycled precious metal system is treated with processes of hydrolysis bismuth removal and vulcanization copper removal, then sodium selenite can be generated, chlorine and sulfur added in the bismuth removal and copper removal process are essential mineral elements in animal bodies and can join in substance metabolism inside the animal bodies, and if sodium selenite is used as a feed additive, the absorption effect of animal feed can be improved; bismuth and copper as impurities in crude sodium selenite can be effectively utilized. The method is short in process procedure, the whole process is a sealed circulation system, the environment is not polluted, and requirements of clean production can be met.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for leaching selenium from cadmium selenide waste

ActiveCN106744725BImprove leaching rateHigh recovery rateCadmium compoundsSelenium/tellurium oxyacid saltsCadmium selenideHigh pressure

The invention relates to a method for leaching selenium from cadmium selenide waste. The method adopts two-section oxygen pressure alkaline leaching; the cadmium selenide waste is subjected to first-section oxygen pressure alkaline leaching, and the leaching residue of the first-section oxygen pressure alkaline leaching is used as the raw material of second-section oxygen pressure alkaline leaching; the leaching liquid of the second-section oxygen pressure alkaline leaching returns to a leaching agent of the first-section oxygen pressure alkaline leaching; and the first-section oxygen pressure alkaline leaching and second-section oxygen pressure alkaline leaching are both performed in a high-pressure reaction kettle, and oxygen is introduced to both as an oxidizing agent. In the method provided by the invention, selenium in the cadmium selenide waste exists in the leachate totally in a form of sodium selenite, thereby being safe and environment-friendly; and the selenium recovery rate is high, and the cost is low.

Owner:FIRST RARE MATERIALS CO LTD

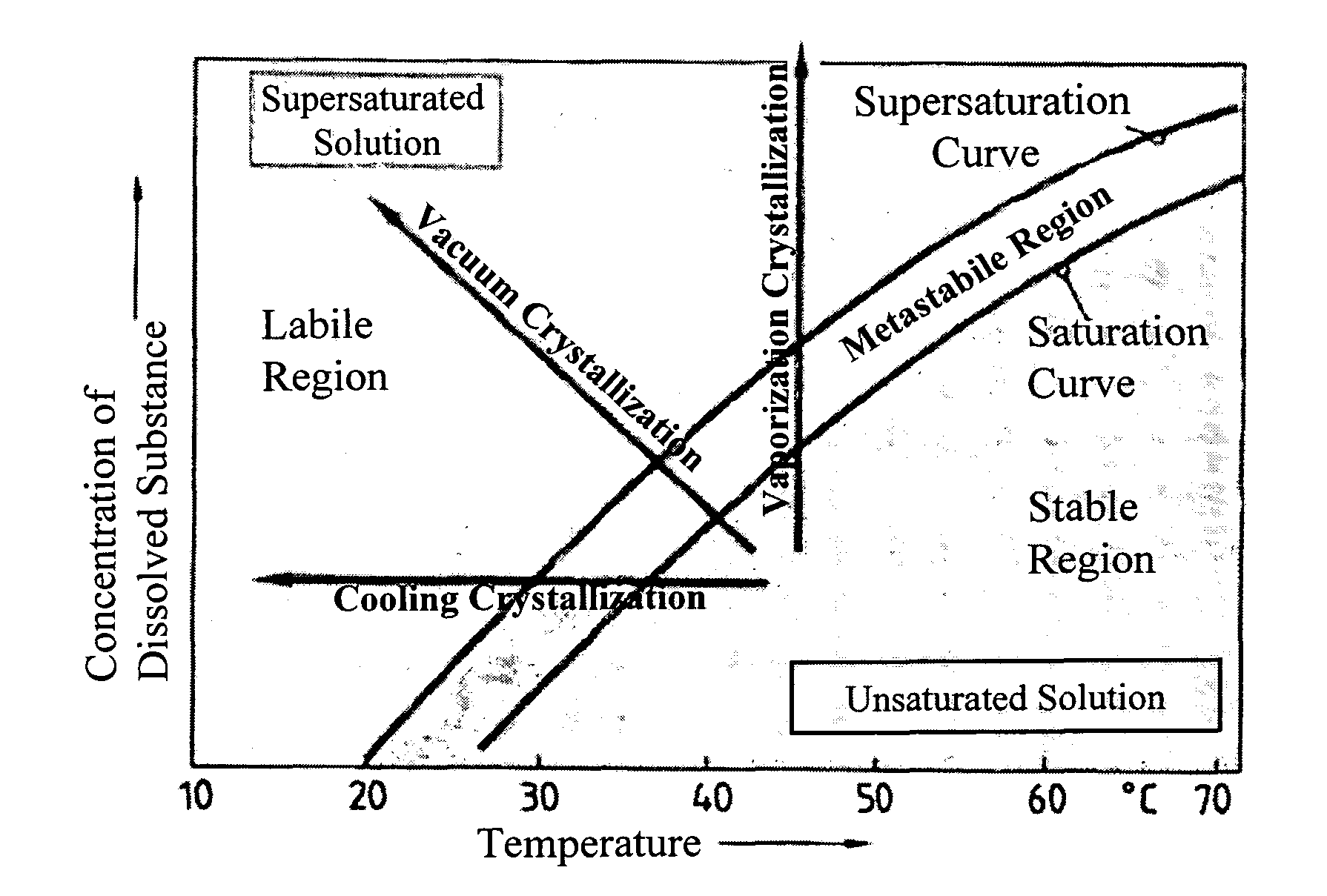

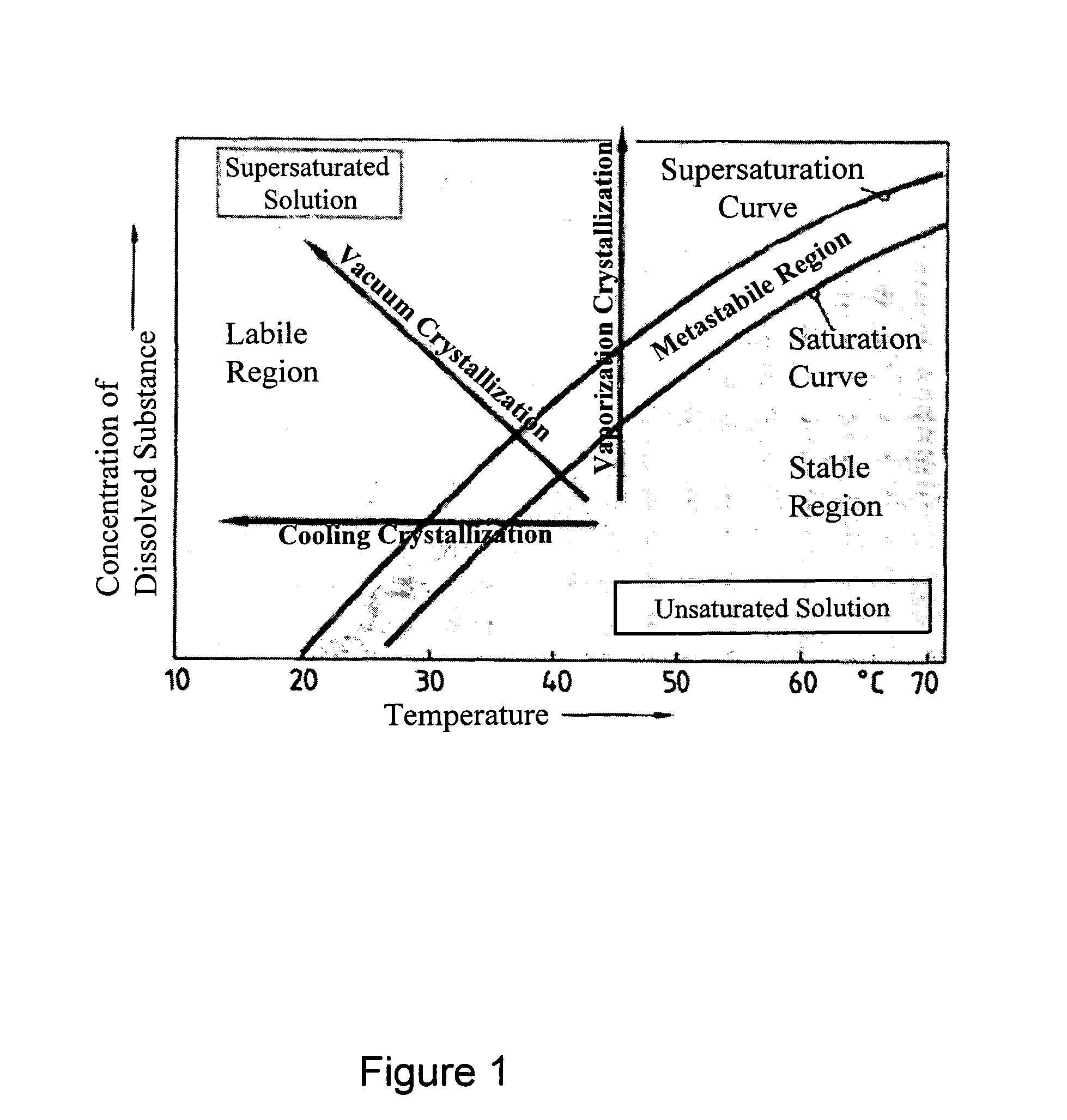

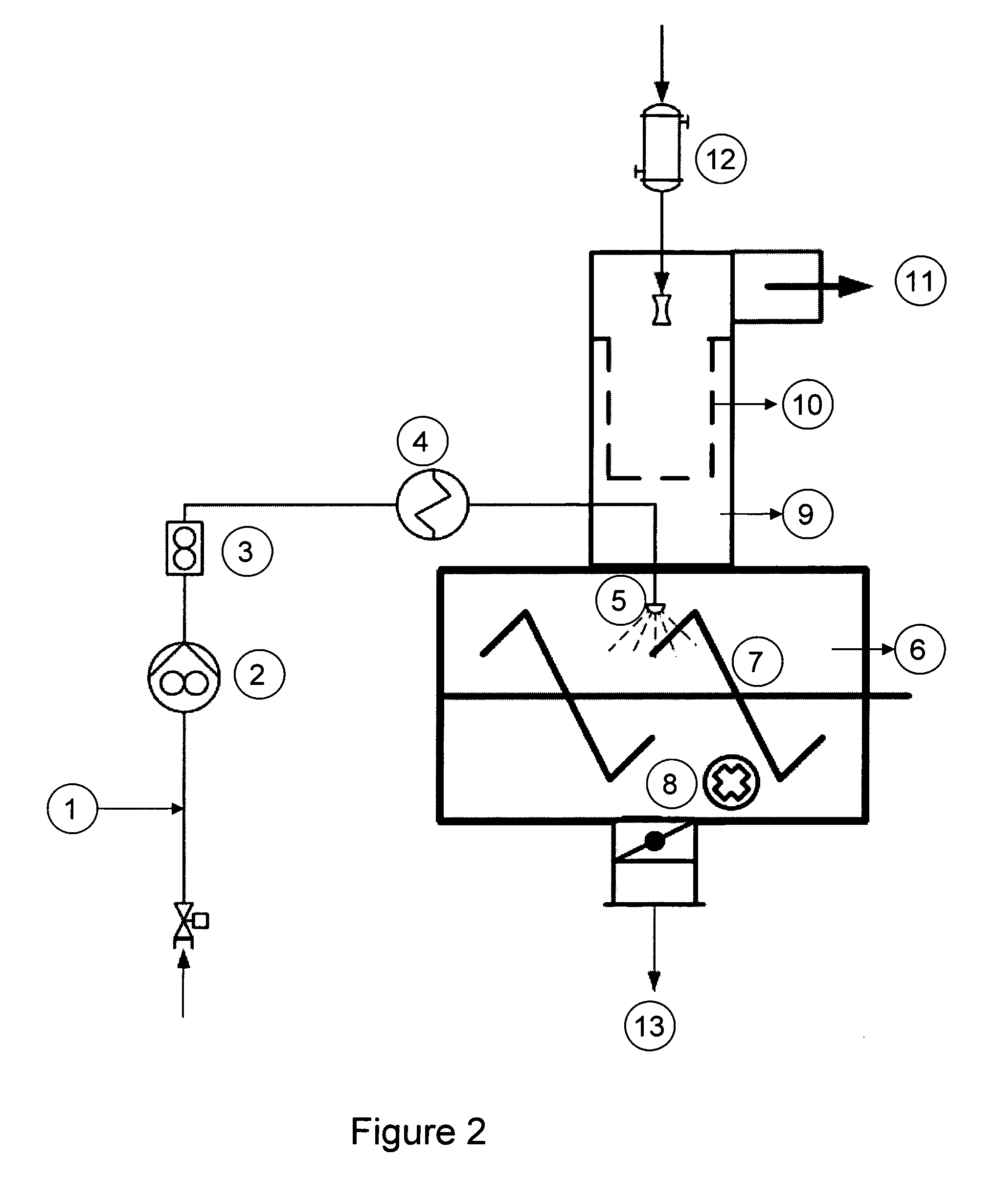

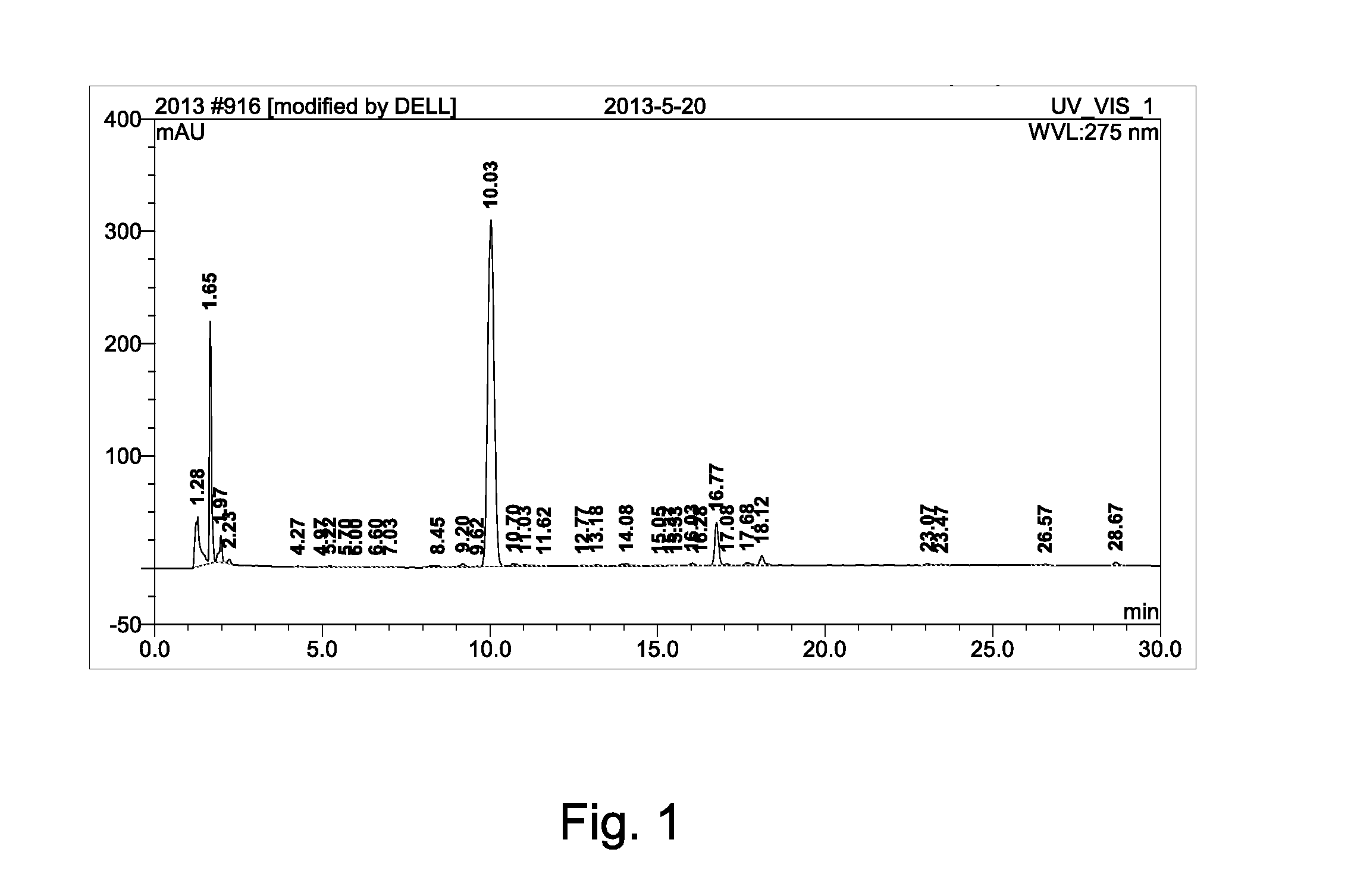

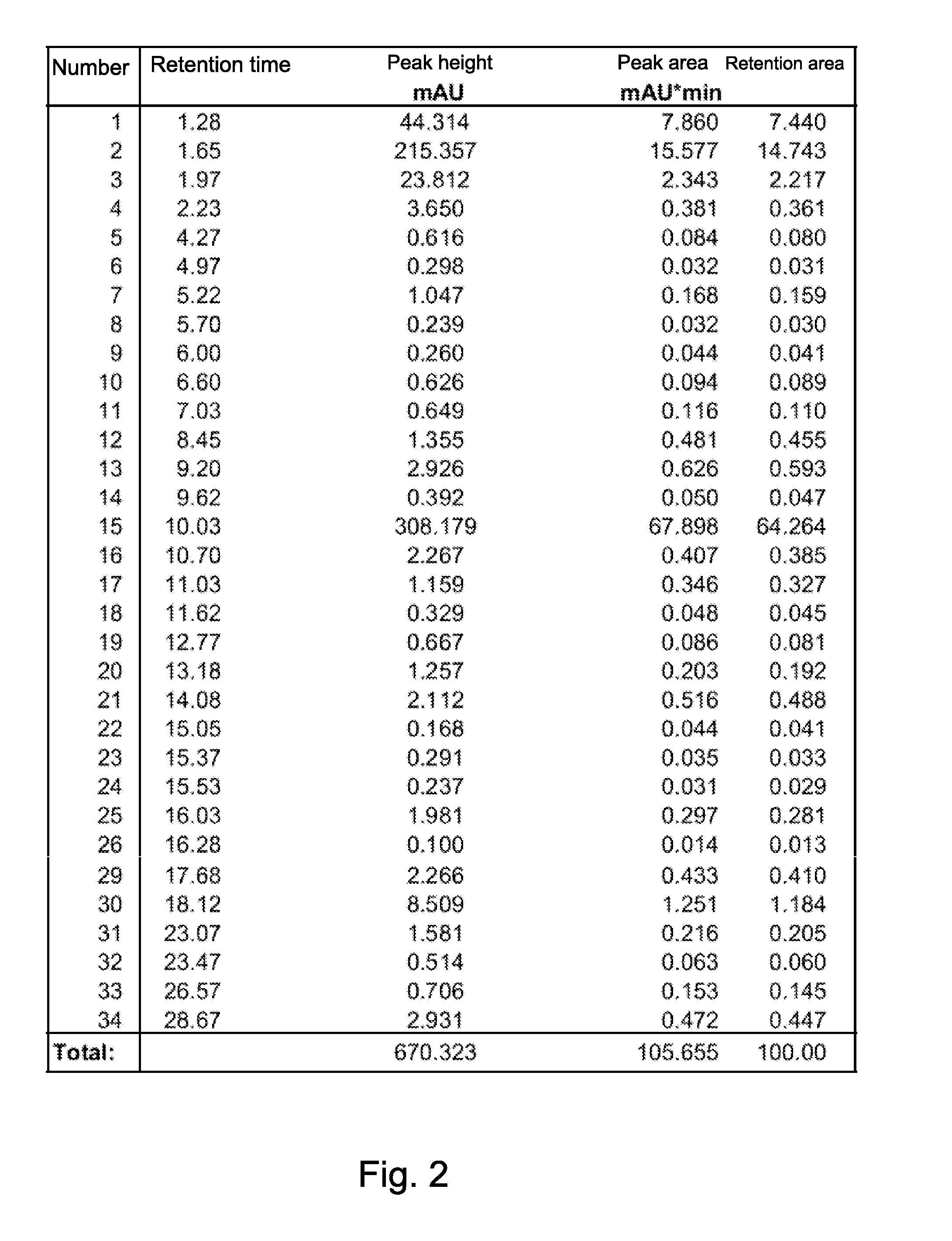

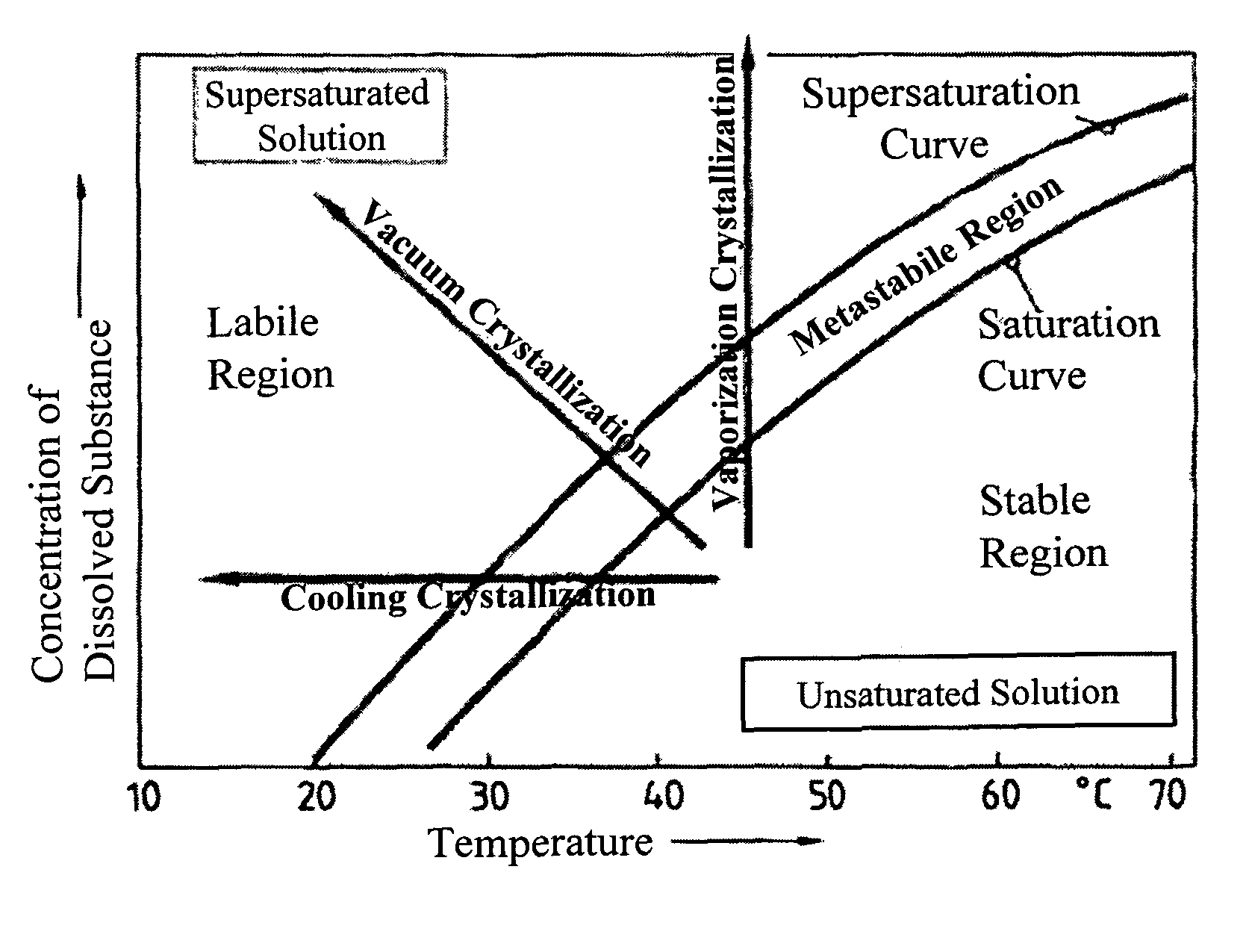

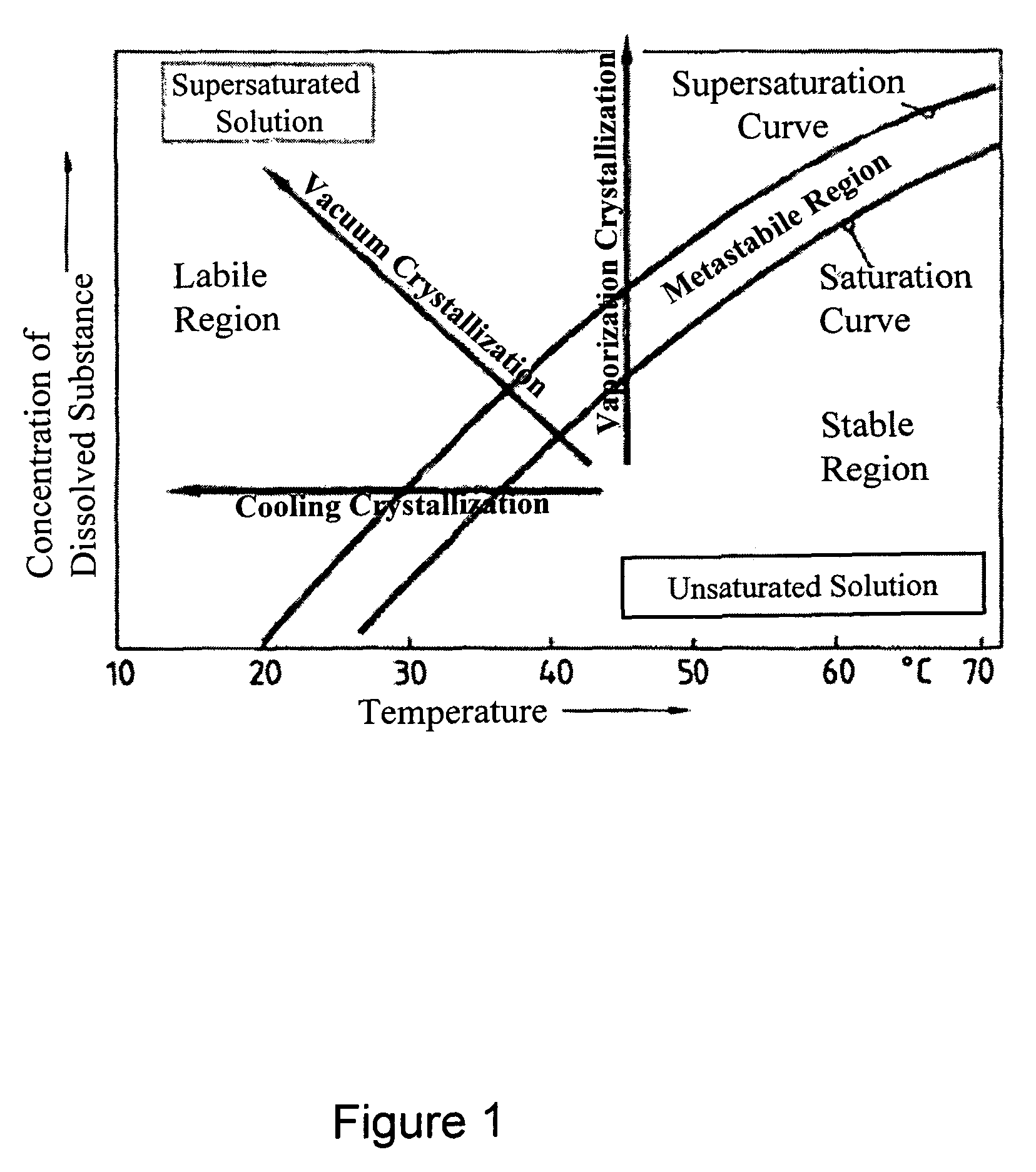

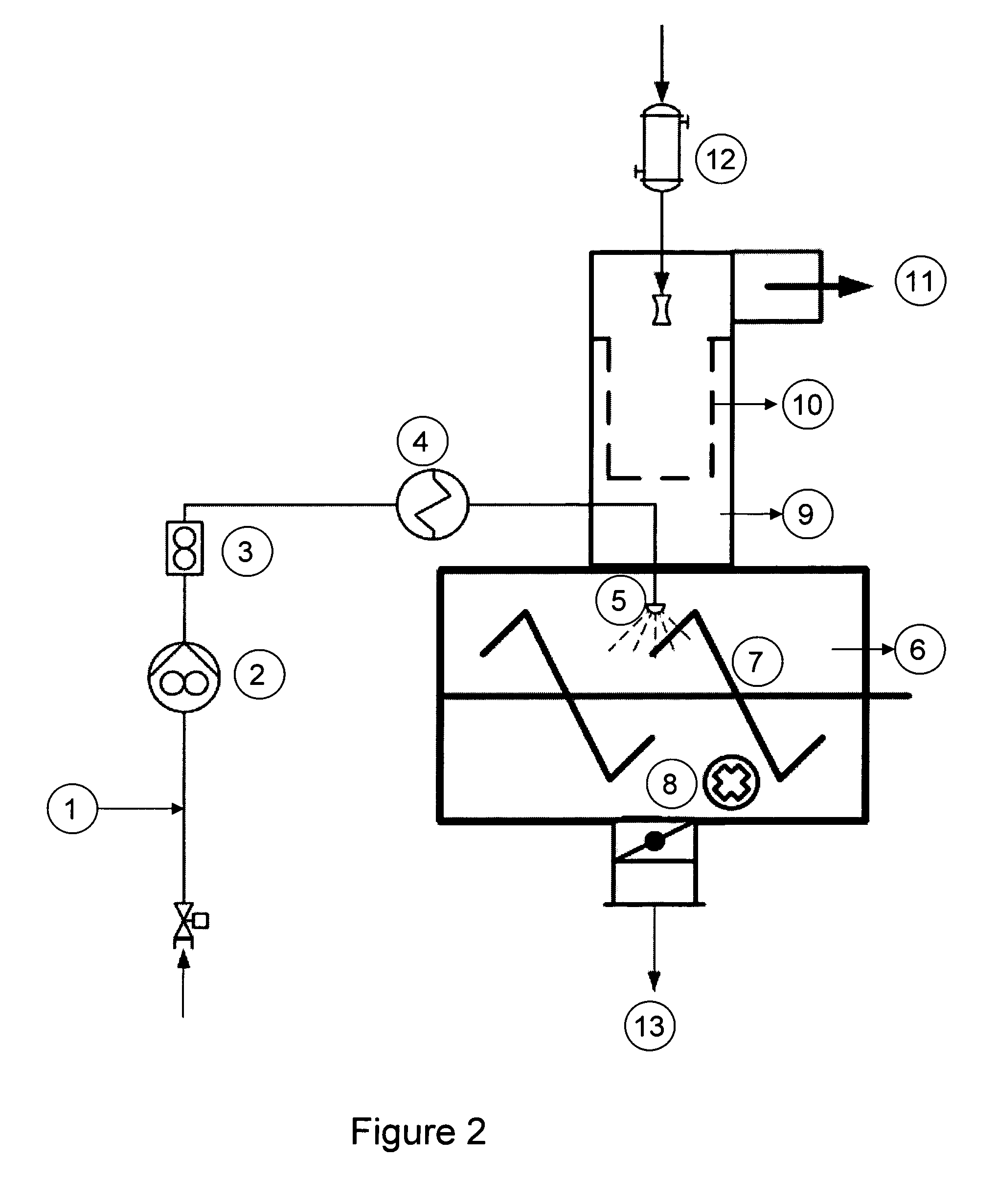

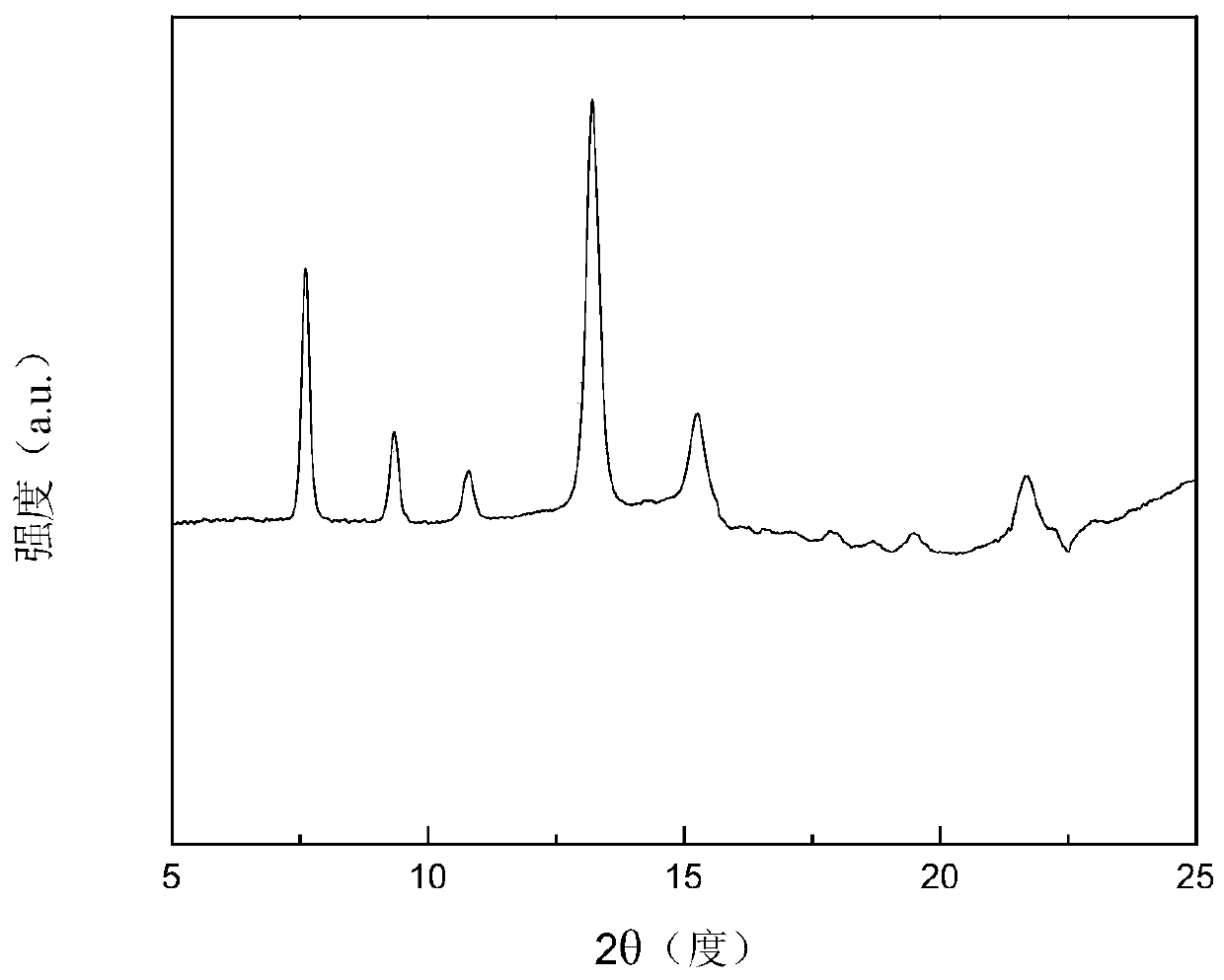

Method of producing pharmacologically pure crystals

ActiveUS20130149232A1Powder deliveryPhosphorus sulfur/selenium/tellurium compoundsPharmaceutical drugCrystalline materials

Owner:BIOSYN ARZEIMITTEL GMBH

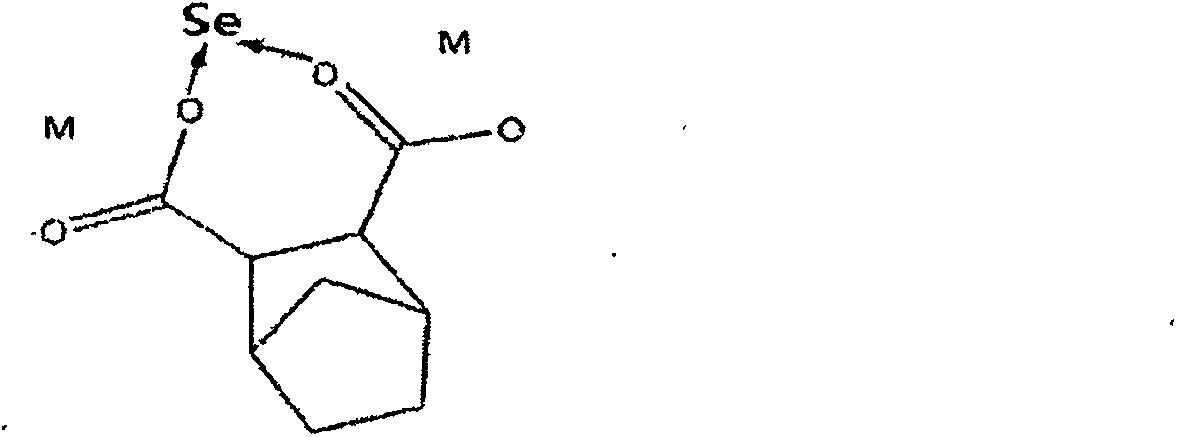

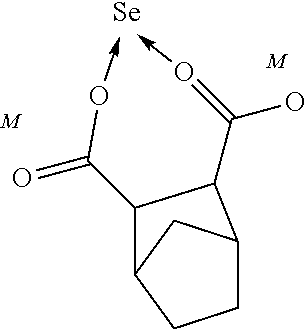

Complex targeting hepatitis B virus

ActiveUS20150353536A1Improve immunityGood effectBiocideOrganic chemistrySide effectChronic hepatitis

A compound medicine for treating acute and chronic hepatitis B, includes a polyphenolic selenium compound having a functional group of alkali metal ion and selenium coordination complex, which has functions of directly killing HBV and destroying replication template of HBV. Auxiliary formulas thereof include high-purity oxymatrine and glycyrrhizin sulfate. The oxymatrine has an effect of anti-HBV, and is capable of treating acute and chronic hepatitis B, regulating immune system and increasing leukocyte. Serving as a main hepatocyte membrane protective agent, the glycyrrhizin sulfate has not only an effect of anti-inflammation, but also it is capable of regulating immune system and protecting hepatocyte. The compound medicine has no toxicity or side effect.

Owner:SHANGHAI AI QI ECOLOGICAL TECH

a mg based 3 teo 6 Violet inorganic pigment of structure and its preparation method and application

ActiveCN112758900BKeep the same colorThe preparation method is simple and environmentally friendlySelenium/tellurium oxyacid saltsPhysical chemistryManganese

The invention discloses a Mg-based 3 TeO 6 The purple inorganic pigment of structure and its preparation method and application, the molecular formula of described purple inorganic pigment is Mg 3‑2x mn x Li x TeO 6 , wherein 0.02≤x≤0.15; the preparation method of the purple inorganic pigment comprises the following steps: proportioning a compound containing magnesium, a compound containing tellurium, a compound containing manganese, Li 2 CO 3 After mixing and grinding, it is calcined at 750-900°C, and the purple inorganic pigment is obtained after cooling. The purple inorganic pigment of the invention is resistant to acid, alkali and high temperature, the preparation method is environment-friendly, and the raw materials are cheap and non-toxic, and can be used in the chemical production of paints, coatings, paintings, plastics and rubber.

Owner:SUN YAT SEN UNIV

Method of producing pharmacologically pure crystals

ActiveUS8636973B2Powder deliverySulfur/selenium/tellurium inorganic active ingredientsPure crystalCrystallization

Owner:BIOSYN ARZEIMITTEL GMBH

High-pressure preparation method of quadrature-phase copper tellurium oxide

InactiveCN111498815AHigh purityImprove qualityUltra-high pressure processesSelenium/tellurium oxyacid saltsPhysical chemistryCrystal structure

The invention discloses a high-pressure preparation method of a quadrature-phase copper tellurium oxide, and belongs to the technical field of magnetic material preparation. The molecular formula of the copper tellurium oxide is Cu3TeO6, and the copper tellurium oxide has a monoclinic crystal structure. According to the preparation method, cubic-phase copper tellurium oxide formed by sintering copper oxide powder and tellurium dioxide powder is used as a precursor, synthesis is carried out on a high-pressure device, and the synthesis pressure is 17 GPa or above. The method disclosed by the invention is carried out in an anhydrous and modifier-free environment, so that unnecessary impurities can be avoided, and the purity of the obtained quadrature-phase copper tellurium oxide is high.

Owner:JILIN UNIV

Method for Extracting Mercury from Heavy Acid Mud

ActiveCN106893865BEfficient separationAvoid pollutionProcess efficiency improvementSelenium/tellurium oxyacid saltsSludgePotassium chlorate

The invention particularly relates to a method for extracting mercury from heavy-metal-related acid mud, belonging to the technical field of resources and environment. The method comprises the following steps that step 1, the heavy-metal-related acid mud and hydrochloric acid are added into water and are heated; then potassium chlorate is added; reaction is performed at certain temperature to obtain a mixed liquid containing mercuric chloride; step 2, alkali is added in for neutralization to control pH, so that a mixed solution containing mercuric oxide sediment and Na2SeO3 is obtained; solid-liquid separation is performed, and a selenium-containing solution enters a selenium separation system for recycling selenium; step 3, the mercury oxide sediment obtained through separation in the step 2 is dried and is rectified by adopting a continuous vacuum rectification method; and generated mercury steam is condensed and recycled to obtained refined mercury. According to the method, a wet technique is adopted for processing, so that high-efficient separation of mercury and selenium is realized; then the high-purity mercury product is manufactured through continuous vacuum rectification; and smoke pollution caused by direct roasting of the acid mud is avoided.

Owner:湖南省环境保护科学研究院 +1

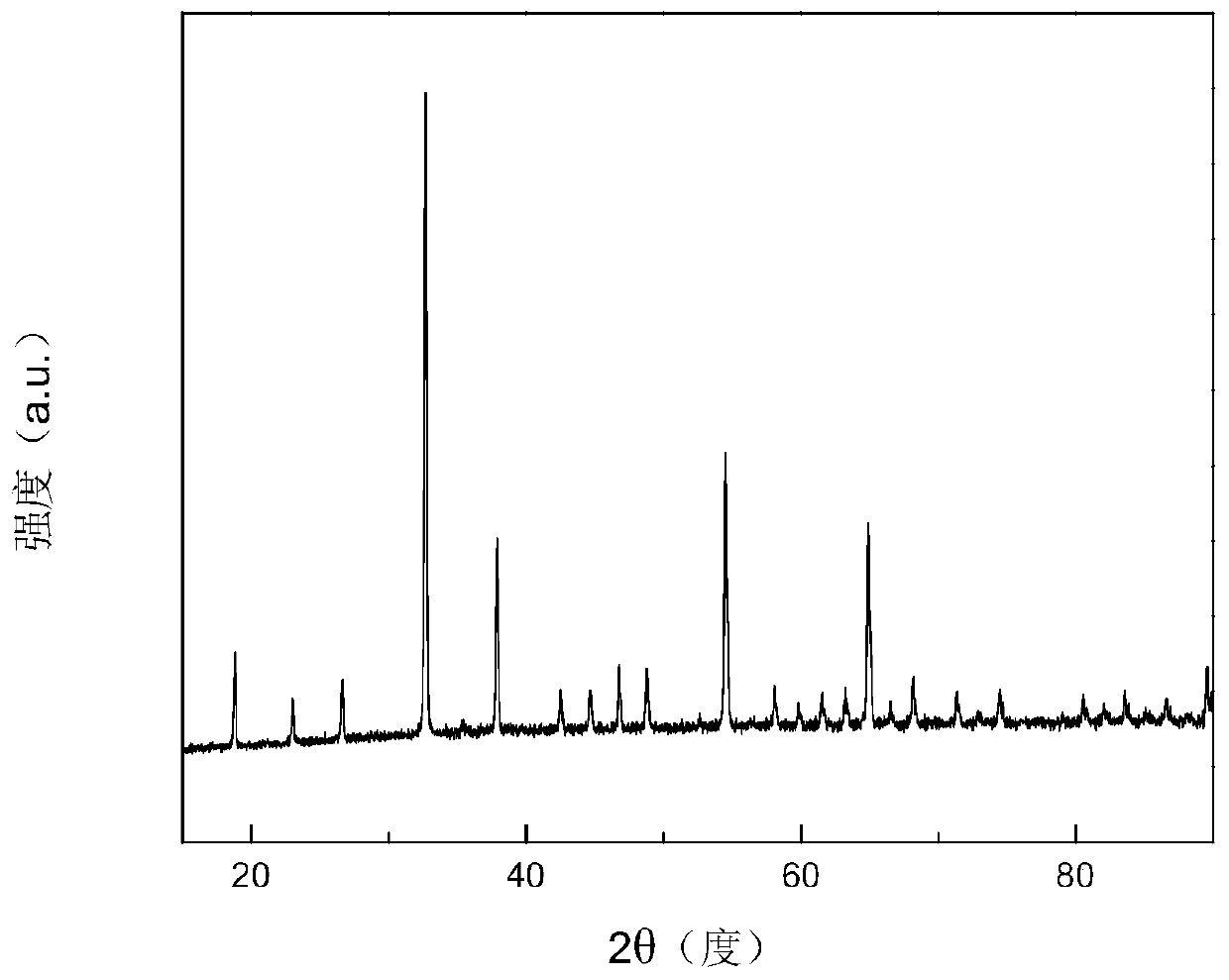

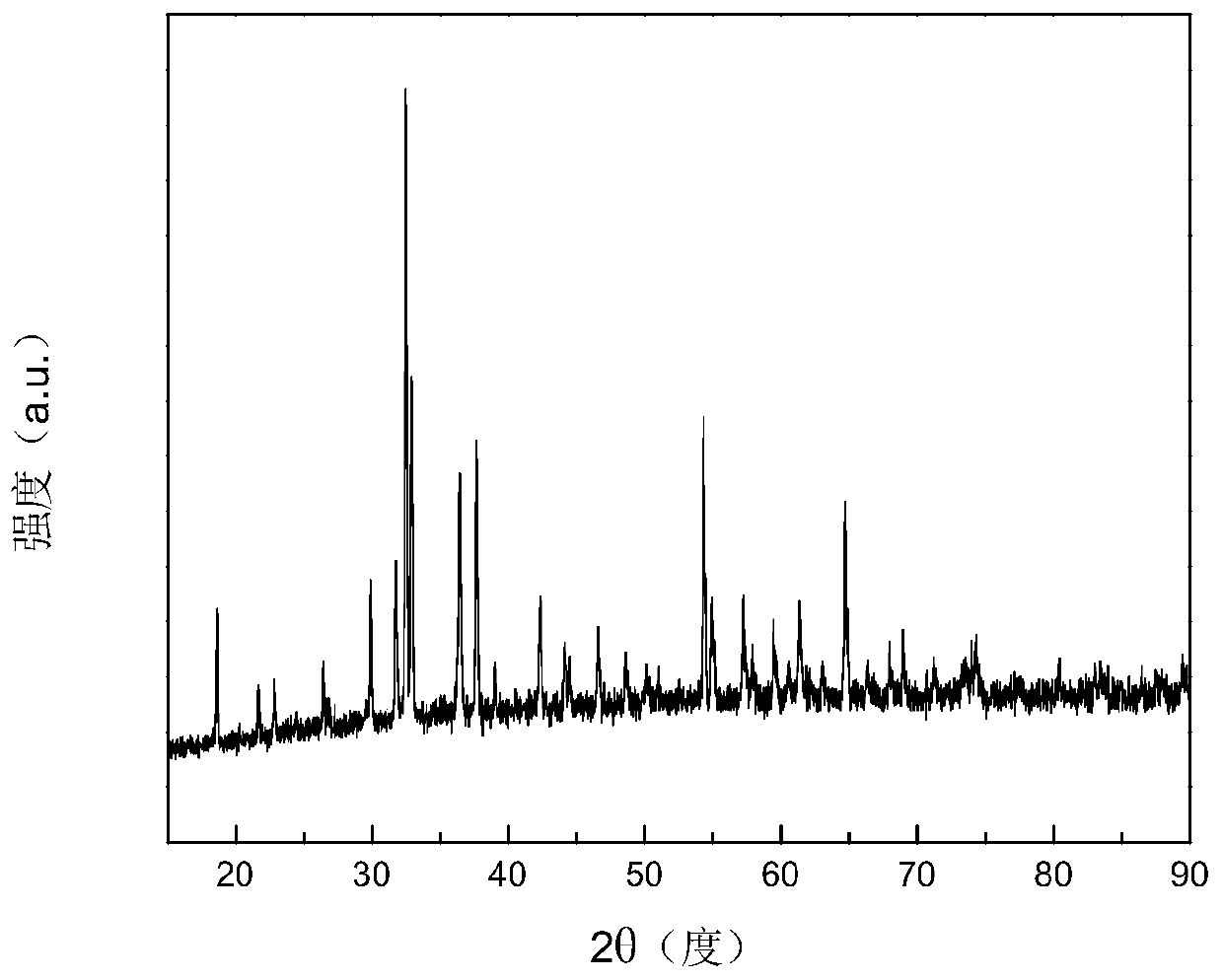

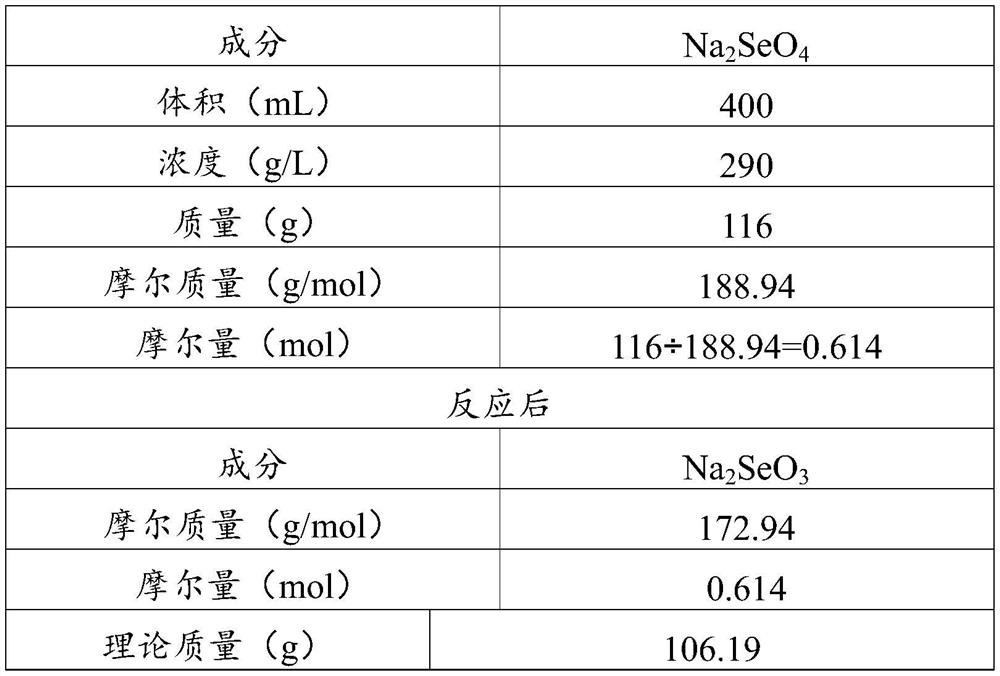

Method for reducing hexavalent selenium into tetravalent selenium

PendingCN113735070AEfficient recyclingThe recovery method is simpleSelenium/tellurium oxyacid saltsSodium sulfitesSulfite salt

The invention provides a method for reducing hexavalent selenium into tetravalent selenium, and relates to the technical field of chemical recovery. The method for reducing hexavalent selenium into tetravalent selenium comprises the following steps: dissolving a hexavalent selenium compound in water to form a hexavalent selenium solution, and heating the hexavalent selenium solution to 70-90 DEG C; and adding hydrochloric acid into the hexavalent selenium solution, performing stirring and reaction until the potential value of the solution is 900-960mv, and stopping the reaction. According to the method, the solution system reaches the reduction potential of selenium by utilizing the reducibility of hydrochloric acid, so that hexavalent selenium which is difficult to be reduced into elementary substance by a conventional reducing agent (such as sodium sulfite) is reduced into tetravalent selenium which is easy to be reduced into elementary substance, and the selenium can be effectively recovered into elementary substance.

Owner:广东先导稀贵金属材料有限公司

Method for removing radioactive element thorium in rare earth mineral

ActiveUS20190144968A1Improve efficiencyHighly inexpensivePolycrystalline material growthFrom normal temperature solutionsLiquid wasteLanthanide

The present invention relates to a method for removing radioactive element thorium in a rare earth mineral, comprising: mixing the rare earth mineral with selenium dioxide in water, reacting radioactive element thorium with selenium dioxide by hydrothermal method, cooling to form a crystal, and separating the crystal to remove the radioactive element thorium. In the invention, tetravalent element thorium is selectively bound to inorganic ligand selenium dioxide in a hydrothermal environment to form a crystal, thereby achieving removal of radioactive element thorium. The method has high crystallization rate and high decontamination efficiency, and removes thorium from trivalent lanthanide element by crystallization solidification under a uniform reaction condition. Compared to a conventional industrial method for thorium separation, the method has low energy consumption and high separation ratio, enables one-step solidification separation, and effectively avoids the disadvantages of redundant separation operations and a large amount of organic and radioactive liquid wastes.

Owner:SUZHOU UNIV

Fabrication method for ibiiiavia-group amorphous compound and ibiiiavia-group amorphous precursor for thin-film solar cells

Owner:IND TECH RES INST

Complex targeting hepatitis B virus

ActiveUS9353105B2Improve immunityGood effectOrganic chemistryOrganic compound preparationSide effectChronic hepatitis

A compound medicine for treating acute and chronic hepatitis B, includes a polyphenolic selenium compound having a functional group of alkali metal ion and selenium coordination complex, which has functions of directly killing HBV and destroying replication template of HBV. Auxiliary formulas thereof include high-purity oxymatrine and glycyrrhizin sulfate. The oxymatrine has an effect of anti-HBV, and is capable of treating acute and chronic hepatitis B, regulating immune system and increasing leukocyte. Serving as a main hepatocyte membrane protective agent, the glycyrrhizin sulfate has not only an effect of anti-inflammation, but also it is capable of regulating immune system and protecting hepatocyte. The compound medicine has no toxicity or side effect.

Owner:SHANGHAI AI QI ECOLOGICAL TECH

Method for controlling content of tellurium dioxide and content of tellurite in tellurite product

ActiveCN105480956AControl of tellurite trihydrate contentAvoid decompositionSelenium/tellurium oxyacid saltsMetalMole ratio

The invention discloses a method for controlling the content of tellurium dioxide, the content of anhydrous tellurite and the content of trihydrate tellurite in a tellurite product. The method comprises the following steps that firstly, alkali metal hydroxide and tellurium dioxide are reacted in an aqueous solution with the mole ratio of 2.00:(1.00-1.15) to obtain a tellurite solution; secondly, alkali metal hydroxide is added in the tellurite solution, wherein the adding amount of alkali metal hydroxide accounts for X of alkali metal hydroxide in the first step by weight, different numerical value ranges are selected from X to control the content of tellurium dioxide, the content of anhydrous tellurite and the content of trihydrate tellurite in the tellurite product, and X is larger than zero and smaller than or equal to 8.00%. By means of the method, high-purity potassium tellurite can be prepared, and high-purity needle-like trihydrate potassium tellurite can also be prepared in an industrialized mode.

Owner:广东先导稀贵金属材料有限公司

The method and application of preparing sodium selenite by selenium dioxide containing bismuth and copper

ActiveCN106219500BPromote absorptionEfficient use ofAccessory food factorsSelenium/tellurium oxyacid saltsVulcanizationNon-ferrous extractive metallurgy

The invention discloses a method and application for preparing sodium selenite from selenium dioxide containing bismuth and copper, and belongs to the technical field of recycling and reuse of non-ferrous metal metallurgy byproducts. According to the method, crude selenium dioxide generated from a recycled precious metal system is treated with processes of hydrolysis bismuth removal and vulcanization copper removal, then sodium selenite can be generated, chlorine and sulfur added in the bismuth removal and copper removal process are essential mineral elements in animal bodies and can join in substance metabolism inside the animal bodies, and if sodium selenite is used as a feed additive, the absorption effect of animal feed can be improved; bismuth and copper as impurities in crude sodium selenite can be effectively utilized. The method is short in process procedure, the whole process is a sealed circulation system, the environment is not polluted, and requirements of clean production can be met.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime

ActiveCN111575483BSuitable for industrial applicationAvoiding the problem of hard-to-leach telluriumProcess efficiency improvementSelenium/tellurium oxyacid saltsTelluric acidSlag

The invention discloses a method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime, and relates to the technical field of rare and precious metal metallurgy. Sodium reacts to obtain selenium-tellurium-containing arsenic leaching solution and alkali leaching residue; the leaching solution reacts with lime water to obtain selenium-tellurium-containing solution and calcium arsenate residue; alkali leaching residue reacts with sulfuric acid to obtain copper sulfate and acid leaching residue; Reaction to obtain telluric acid and selenium-containing solution; react acid leaching residue with nitric acid to obtain silver nitrate solution and lead gold residue; react silver nitrate and hydrochloric acid to obtain silver chloride and nitric acid; react lead gold residue with sodium carbonate solution to obtain carbonized residue and sodium sulfate solution; react the carbonized slag with nitric acid to obtain lead nitrate solution and gold-containing enrichment; react lead nitrate solution with sulfuric acid to obtain lead sulfate and nitric acid solution. The purpose of the invention is to solve the problems of high cost, single recovered metal and poor comprehensive recovery effect in the existing method for recovering metal from copper anode slime.

Owner:KUNMING BOREN PRECIOUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com