Method for controlling content of tellurium dioxide and content of tellurite in tellurite product

A tellurite and tellurium dioxide technology, applied in the field of chemical chemistry, can solve the problems of affecting product purity, unable to realize industrial production, and low purity of potassium tellurite products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

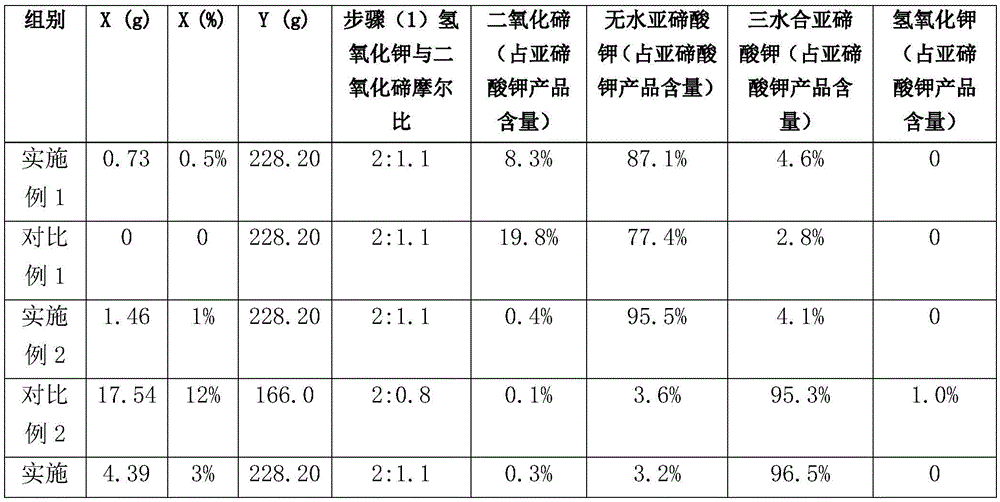

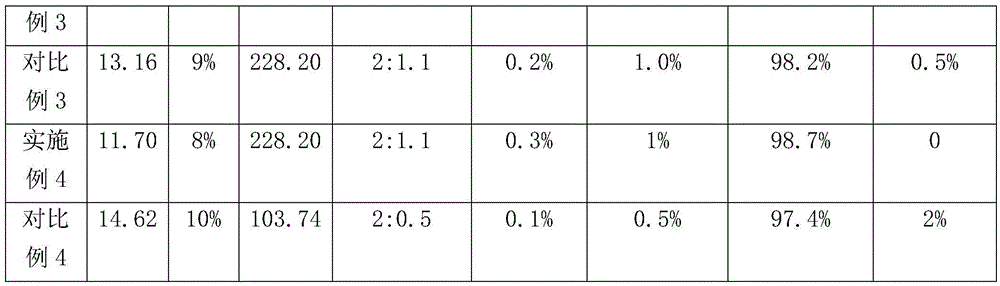

[0042] The tellurite product prepared in Example 2 is compared with the tellurite product prepared in Comparative Example 2, because it also adds suitable potassium hydroxide to the filtrate after the tellurite solution is prepared, and When preparing tellurite solution, the ratio of alkali metal hydroxide to tellurium dioxide is appropriate, the amount of tellurium dioxide produced in the prepared tellurite product is reduced, and the content of anhydrous potassium tellurite is greatly increased , the content of potassium tellurite trihydrate was significantly reduced.

Embodiment 3

[0043] The tellurite product prepared in Example 3 is compared with the tellurite product prepared in Comparative Example 3, because it also adds suitable potassium hydroxide to the filtrate after preparing the tellurite solution. The amount of tellurium dioxide produced in the prepared tellurite product is greatly reduced, the content of potassium tellurite trihydrate is greatly increased, and needle-shaped crystals are obtained, and the content of anhydrous potassium tellurite is obviously reduce.

Embodiment 4

[0044] The tellurite product prepared in Example 4 is compared with the tellurite product prepared in Comparative Example 4, because it also adds suitable potassium hydroxide to the filtrate after the tellurite solution is prepared, and When preparing the tellurite solution, the ratio of alkali metal hydroxide to tellurium dioxide is appropriate, and the amount of tellurium dioxide produced in the prepared tellurite product is greatly reduced, and the anhydrous potassium tellurite The content is greatly increased, and the content of potassium tellurite trihydrate is also increased, and acicular crystals are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com