A method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime

A copper anode slime and gold-enriching technology is applied in selenium/tellurium compounds, selenium/tellurium oxysalts, chemical instruments and methods, etc. It can solve the problems of low recovery rate, environmental pollution, and poor comprehensive recovery effect. Achieve the effects of reducing processing costs, increasing gold enrichment multiples, and significant emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

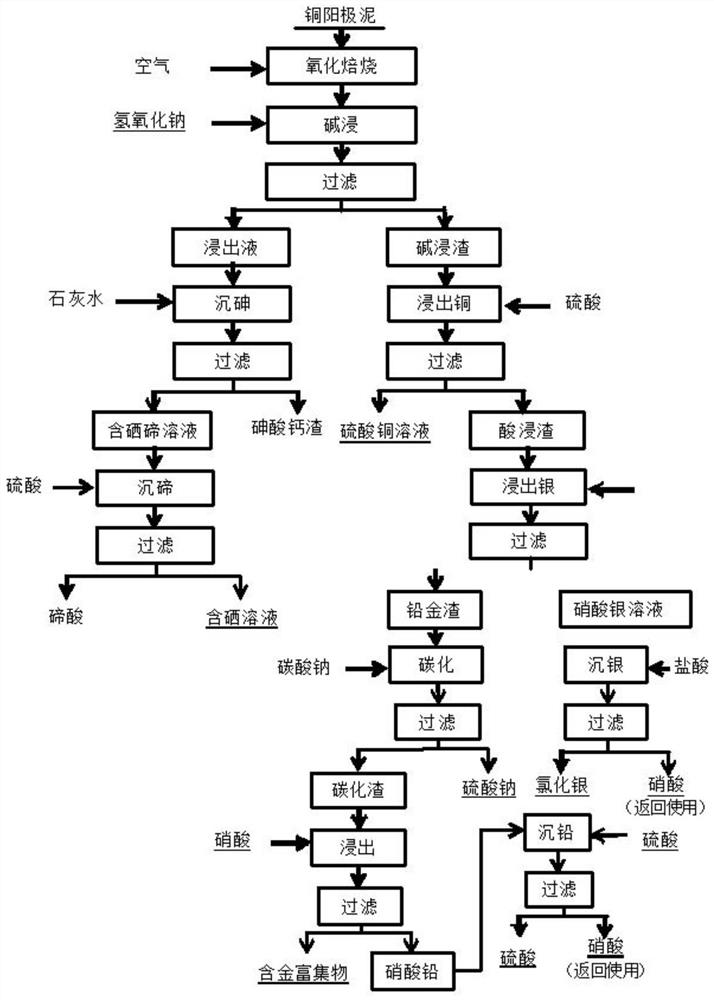

[0044] Embodiment 1-7 A kind of process flow chart of the method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime. figure 1 shown.

Embodiment 1

[0046] A method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime, the method comprising the following steps:

[0047] S1, first low-temperature oxidation roasting of copper anode slime obtains roasting product, and filtering obtains selenium-tellurium-arsenic leachate and alkali leaching residue after described roasting product and sodium hydroxide solution stirring reaction; The condition of described low-temperature oxidative roasting is: in air Roasting under conditions, the roasting temperature is 300 ℃, the thickness of the material layer is 10mm, and the roasting time is 4h; the concentration of the sodium hydroxide solution is 20%, and the liquid-solid ratio of the sodium hydroxide solution to the roasting product is 5:1 , the reaction temperature of the sodium hydroxide solution and the calcined product is 75°C.

[0048] S2, filter to obtain selenium-containing tellurium solution and calcium arsenate slag ...

Embodiment 2

[0055] A method for separating selenium, tellurium, arsenic, copper, lead, silver and enrichment of gold from copper anode slime, the method comprising the following steps:

[0056] S1, first low-temperature oxidation roasting of copper anode slime obtains roasting product, and filtering obtains selenium-tellurium-arsenic leachate and alkali leaching residue after described roasting product and sodium hydroxide solution stirring reaction; The condition of described low-temperature oxidative roasting is: in air Roasting under conditions, the roasting temperature is 250 ° C, the thickness of the material layer is 10mm, and the roasting time is 3h; the concentration of the sodium hydroxide solution is 15%, and the liquid-solid ratio of the sodium hydroxide solution to the roasting product is 4:1 , the reaction temperature of the sodium hydroxide solution and the calcined product is 80 °C.

[0057] S2, filter to obtain selenium-containing tellurium solution and calcium arsenate sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com