Preparation method of ultrathin, large-size, high-silicon silicon steel sheet by electron beam physical vapor deposition

A technology of physical vapor deposition and silicon steel sheets, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as incapable of industrial production, achieve high work efficiency, reasonable design, and easy control of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Embodiment 1: The method of this embodiment is as follows: in a vacuum environment, use an electron beam as a heat source to bombard the raw material of the high-silicon silicon steel sheet, so that the raw material of the high-silicon silicon steel sheet is melted into a vapor state, and then the high silicon steel sheet in the vapor state is The silicon steel sheet raw material is deposited on the substrate to obtain a high-silicon silicon steel sheet, and the high-silicon silicon steel sheet can be peeled off from the substrate. The raw material of the high-silicon silicon steel sheet is the high-silicon ferroalloy raw material, which can be obtained by vacuum smelting with silicon steel sheet scrap (or pure iron) and pure silicon.

[0007] The specific steps of this embodiment are as follows: 1. Prepare a high-silicon ferroalloy ingot as a raw material for a high-silicon silicon steel sheet: pure iron and pure silicon (pure silicon and silicon steel sheet scraps can ...

specific Embodiment approach 2

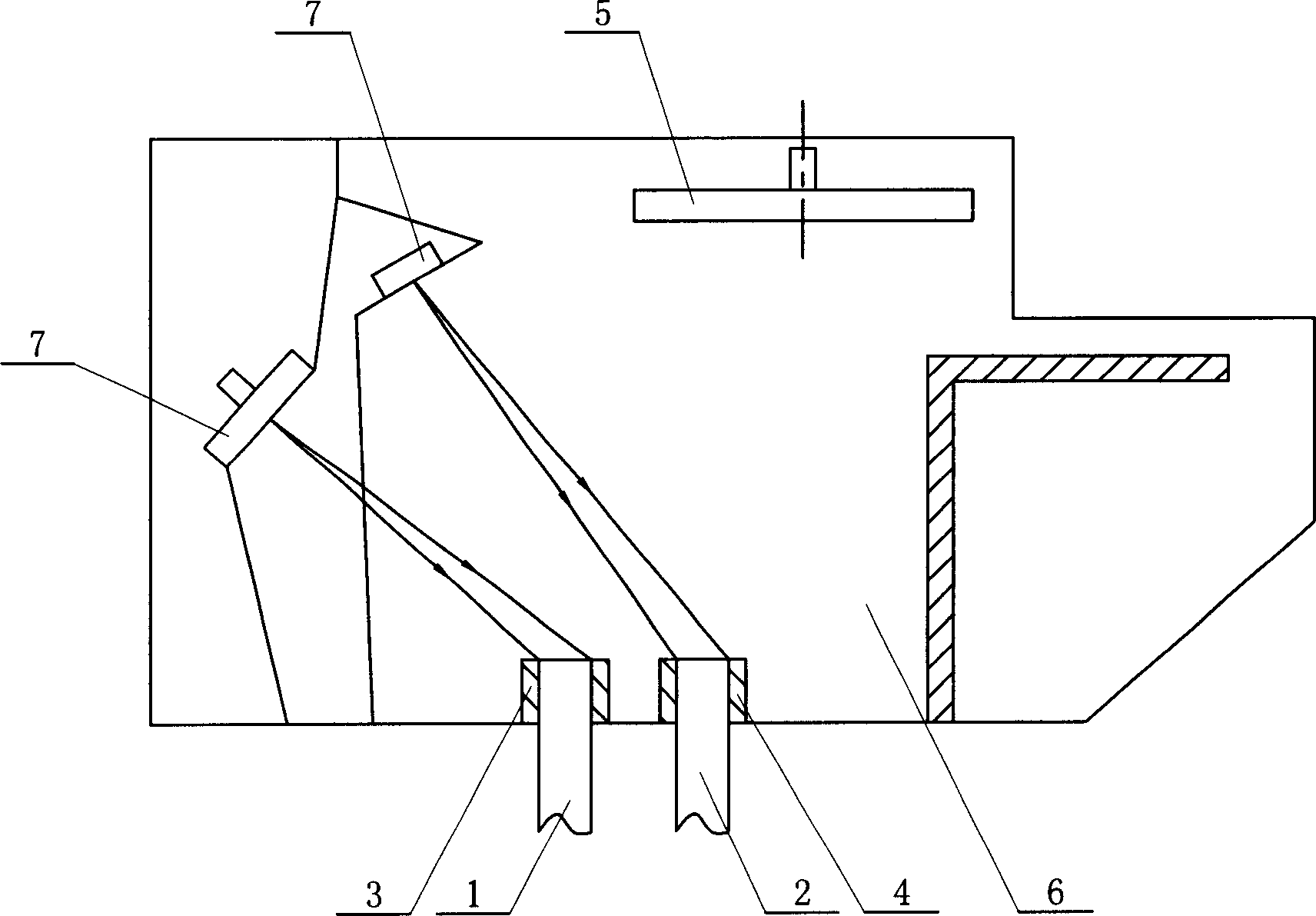

[0008] Specific embodiment two: the following combination figure 1 The present embodiment will be specifically described. The steps of this embodiment are as follows: 1. Put the pure iron ingot 1 and the pure silicon material 2 into the No. 1 crucible 3 and the No. 2 crucible 4 respectively, and place a layer of CaF on the surface of the pure iron ingot 1 2 2. Install the substrate 5, adjust the distance between the substrate 5 and the upper surface of the pure iron ingot 1 between 300-500mm, scrub the lower surface of the substrate 5 with acetone, seal the vacuum chamber 6, and pump the vacuum chamber 6 Vacuum, generally pumped to a vacuum of about 10 -4 Pa; 3. Make the substrate 5 rotate around its own center line in its own plane, set the rotational speed to 5-30rpm, and heat the substrate 5 to 500-800°C at the same time; 4. Use the electron beam generated by the electron gun 7 to evaporate first CaF 2 powder to form a layer of 5-10 μm CaF on the lower surface of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com