Patents

Literature

303results about How to "Suitable for industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

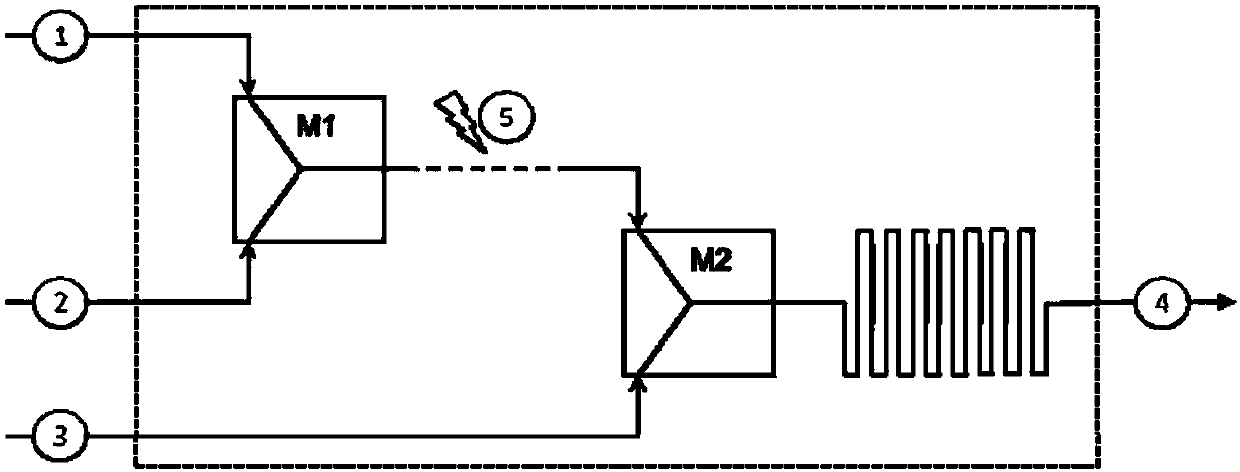

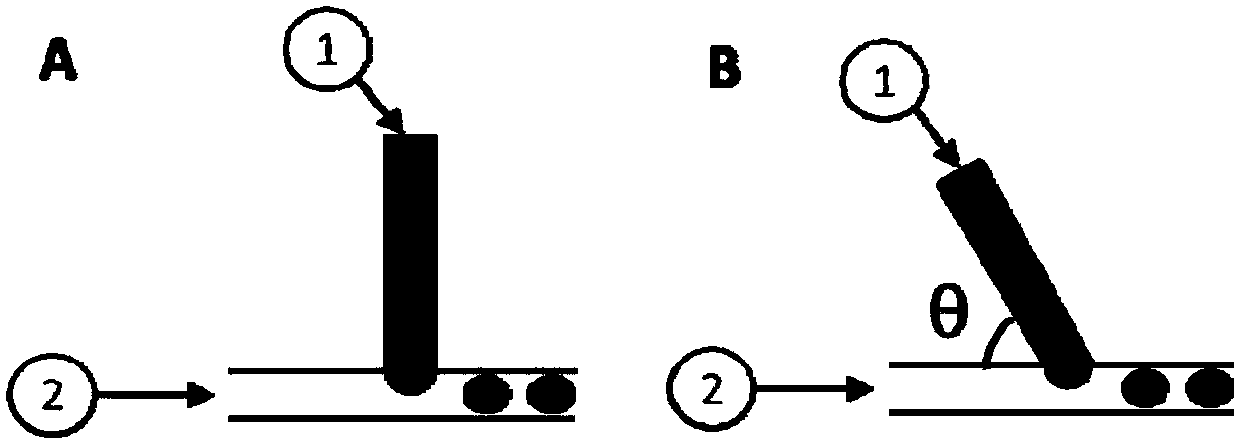

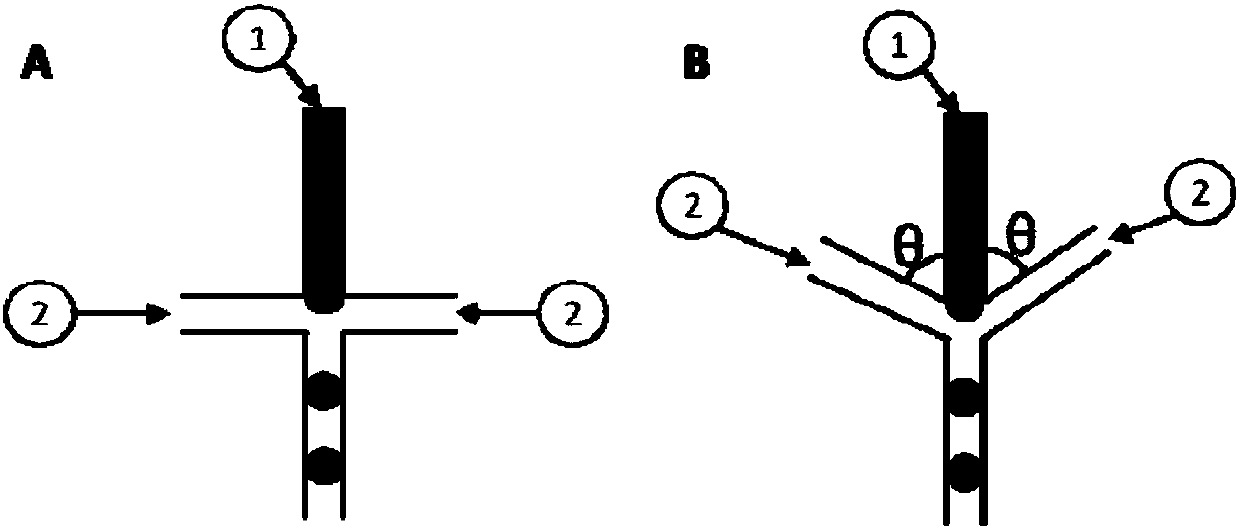

Microfluidic technology for one-step continuous preparation of calcium alginate microgel

ActiveCN107930542AFast shippingMaintain biological activityLaboratory glasswaresGel preparationOil phaseWater in oil emulsion

The invention relates to a microflow droplet technology-based method for one-step continuous preparation of multi-chamber calcium alginate microgel for immobilization of bioactive substances. The method realizes high-throughput continuous production of a microgel material. The method comprises forming a parallel and stable flow field through different hydrogel prepolymer solutions in a microfluidic channel, pouring the hydrogel prepolymer solutions for forming different chambers of the microgel into a microfluidic chip to form water phase solutions of multiple phase parallel fluids, mixing thewater phase solutions and an immiscible fluid (oil phase) through a T-shaped channel or a fluid focusing design to obtain water-in-oil emulsion drops and then alginic acid in the drops is linked immediately so that multi-chamber microgel is prepared, and cleaning the emulsion drops on the microfluidic chip so that the microgel is fast conveyed into a water phase. The method realizes one-step preparation of the calcium alginate microgel immobilized with bioactive substances and is suitable for industrial application.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

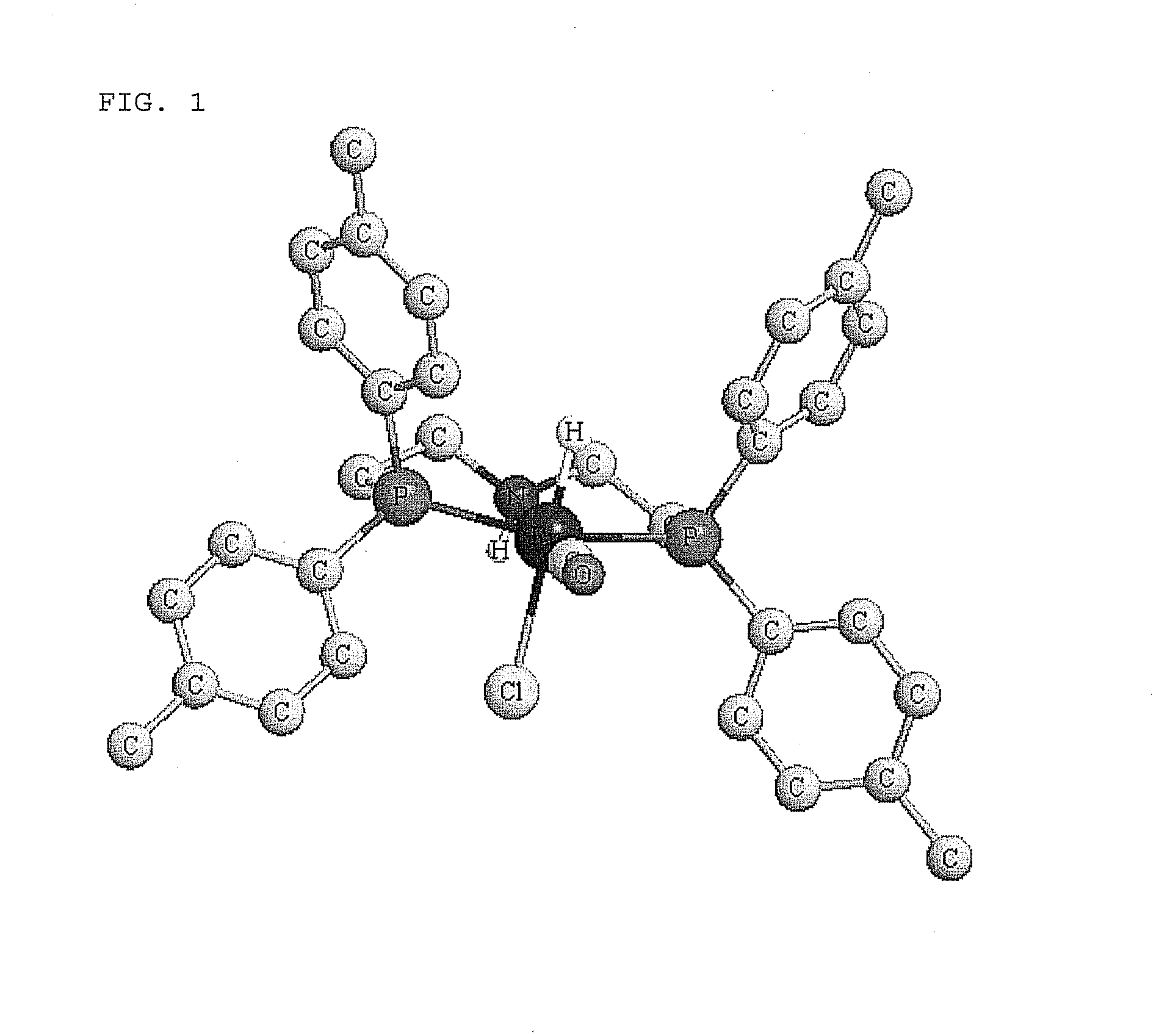

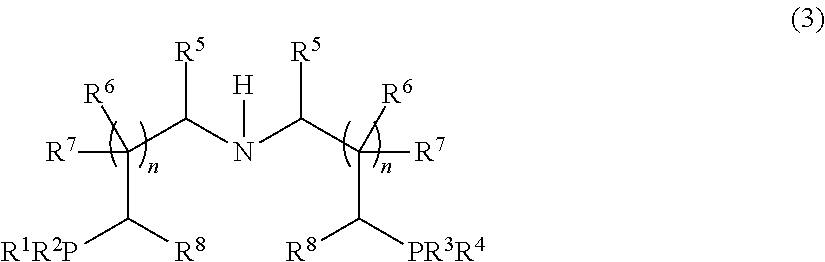

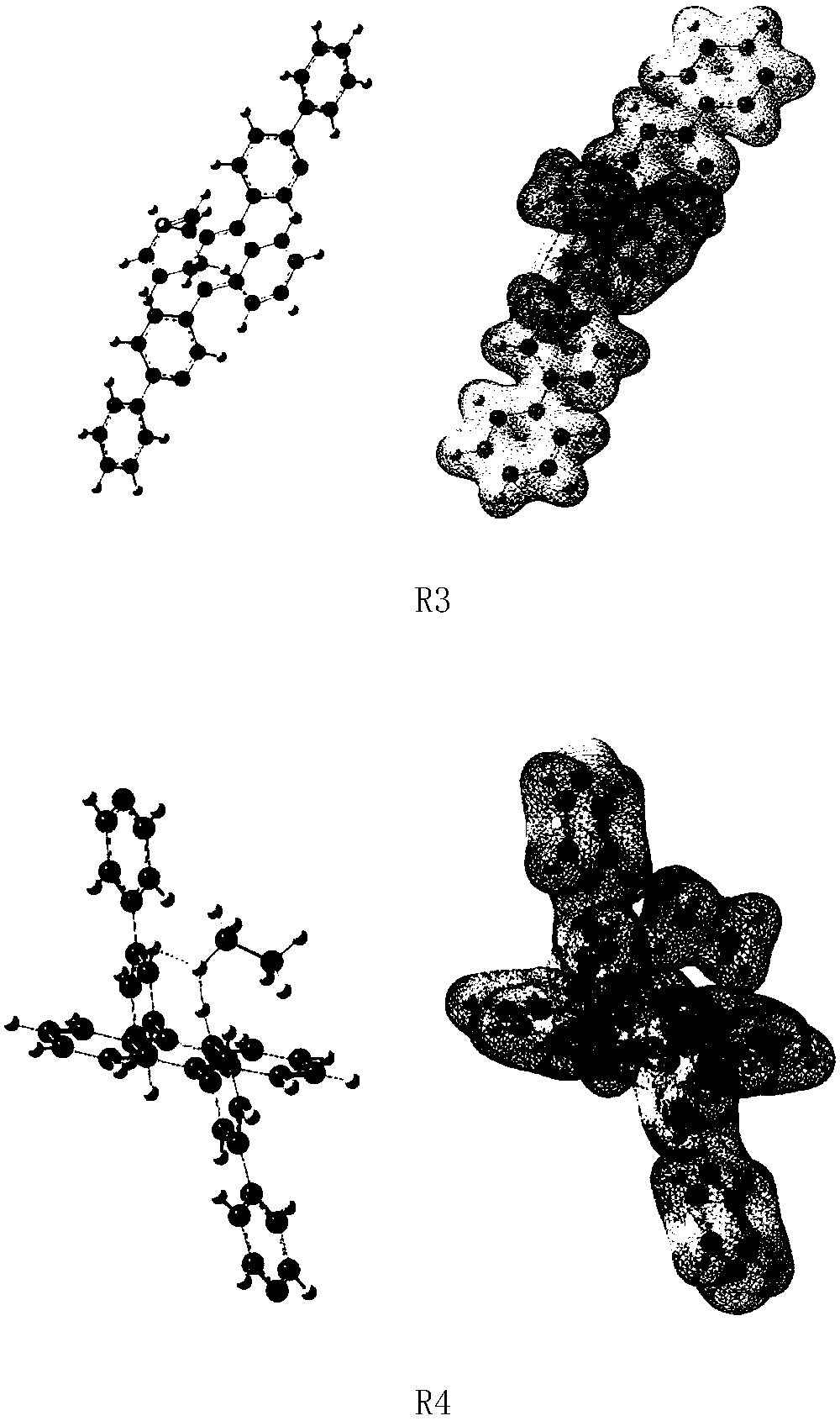

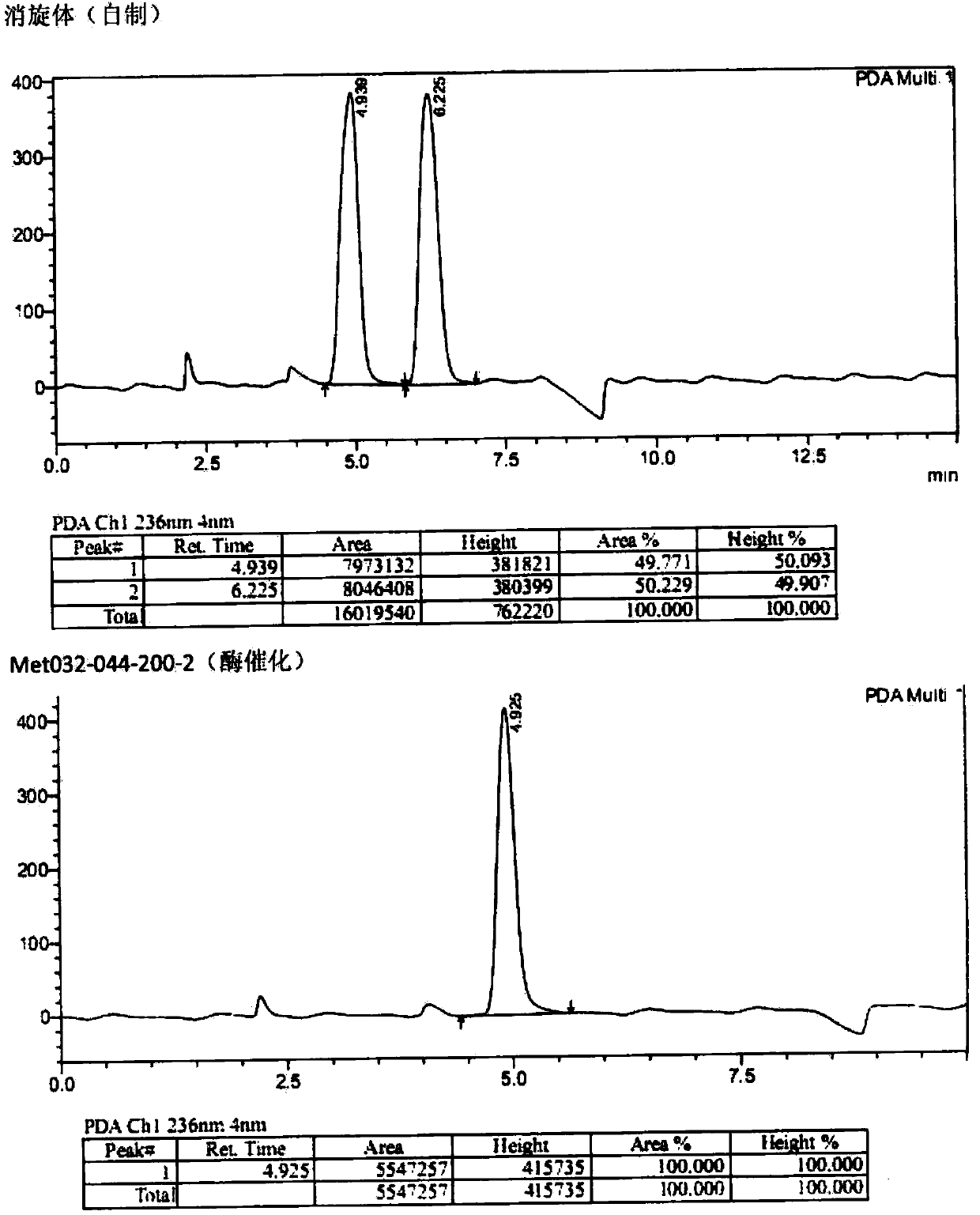

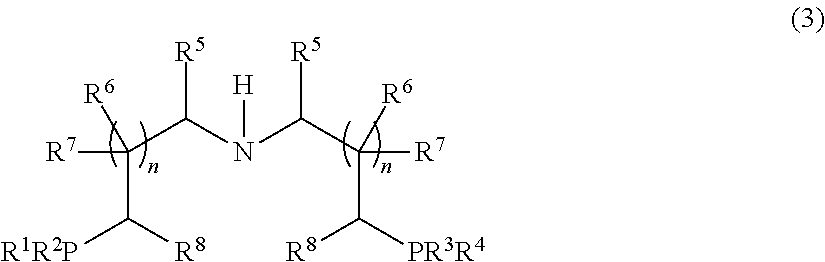

Novel ruthenium carbonyl complex having tridentate ligand, its production method and use

ActiveUS20110237814A1Improve stabilityEasy to operateRuthenium organic compoundsSilicon organic compoundsAlcoholRuthenium

The present invention relates to a ruthenium carbonyl complex that is represented by the following Formula (1):RuXY(CO)(L) (1)(in the Formula (1), X and Y, which may be the same or different from each other, represent an anionic ligand and L represents a tridentate aminodiphosphine ligand which has two phosphino groups and a —NH— group), its production method, and a method for production of alcohols by hydrogenation-reduction of ketones, esters, and lactones using the complex as a catalyst.The ruthenium carbonyl complex of the invention has a high catalytic activity and it can be easily prepared and handled.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Titanium niobic zincic acid bismuth sodium system leadless piezo-electric ceramic and preparation method thereof

InactiveCN101200369AImprove performanceHigh densityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPiezo electric

The invention discloses a triple system (Na,Bi)TiO3-NiO3-ZiO3-based lead-free piezoelectric ceramic material and preparation method, the B digital ion in the (Na0.5Bi0.5)TiO3 of the ABO3 type perovstike structure is replaced partially by composite ion (Zn(one-third)Nb(two-third))4+ and the A digital ion (Na0.5Bi0.5)2+ is replaced by Ba2+ to form lead-free piezoelectric ceramic that can be denoted with the formula ((Na0.5Bi0.5)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b) and ((Na0.5Bi0.5)(1-y)Ba(y)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b), wherein M(a)O(b) is one or more oxide. The piezoelectric ceramic adopts two-step synthetic method and is obtained by sintering. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 150pC per N, Kt can reach above 0.50, and Kp can be below 0.20. The lead-free piezoelectric has strong anisotropy, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

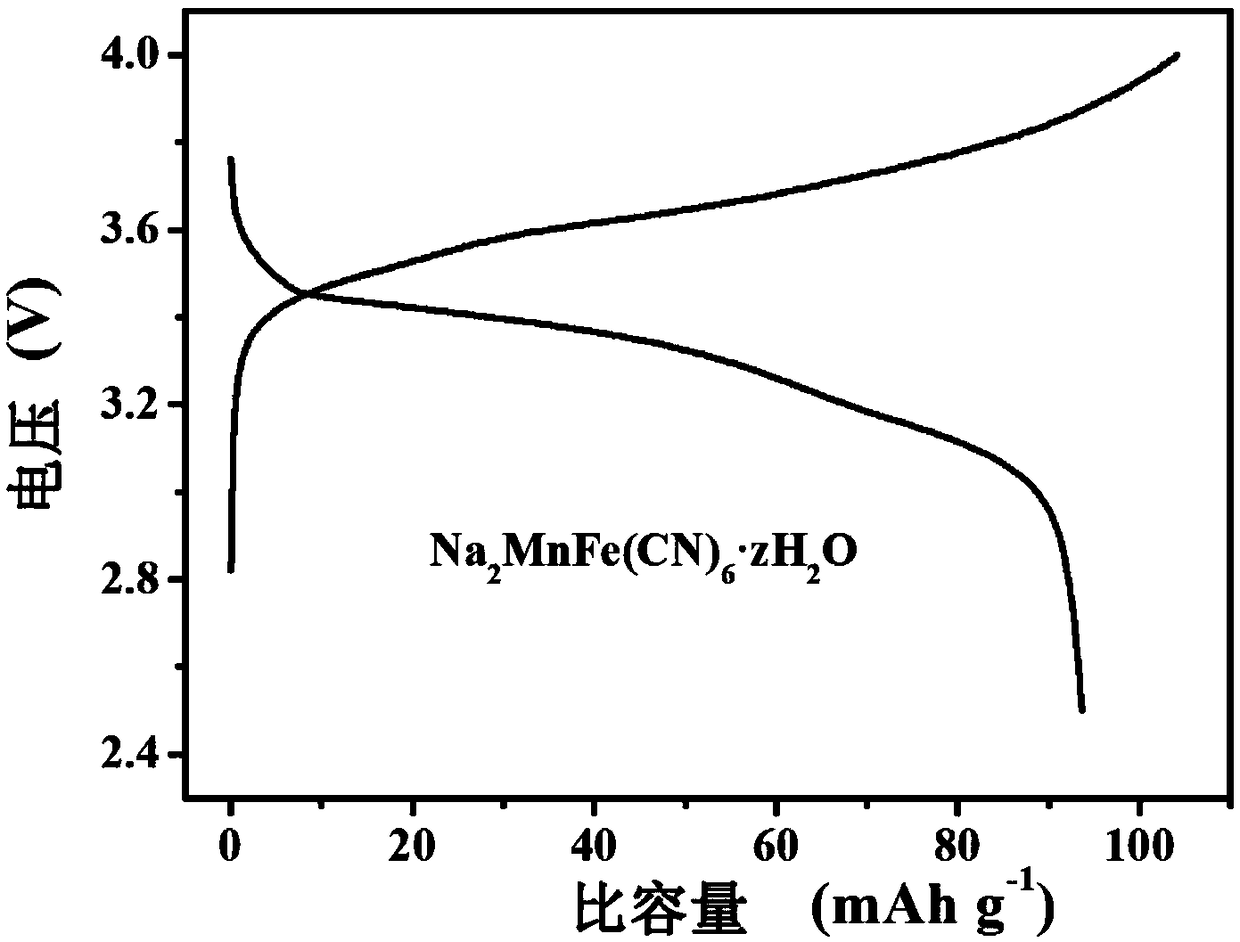

Sodium-ion battery anode material as well as preparation method and application thereof

ActiveCN108258239ALess structural defectsCrystallization intactSecondary cellsPositive electrodesIonCharge and discharge

The invention provides a sodium-ion battery anode material as well as a preparation method and application thereof. The anode material comprises doped prussian blue, wherein the prussian blue comprises a sodium element; the anode material is free of water. The preparation method of the anode material provided by the invention comprises the following steps: (1) mixing a solution A and a solution Bso as to obtain a suspension, wherein the solution A is a mixed solution of sodium ferrocyanide and sodium chloride; the solution B is a mixed solution of a doping source and a complexing agent; (2) performing solid-liquid separation on the suspension of the step (1), and collecting and drying a solid, thereby obtaining the anode material. The sodium-ion battery anode material provided by the invention has a univoltage platform, is excellent in charge and discharge property, is free of water and thus is particularly applicable to anodes of solid sodium ion batteries. The preparation method ofthe anode material provided by the invention is simple in process, low in cost and applicable to industrial application.

Owner:济宁中科恩吉科创新产业园管理有限公司

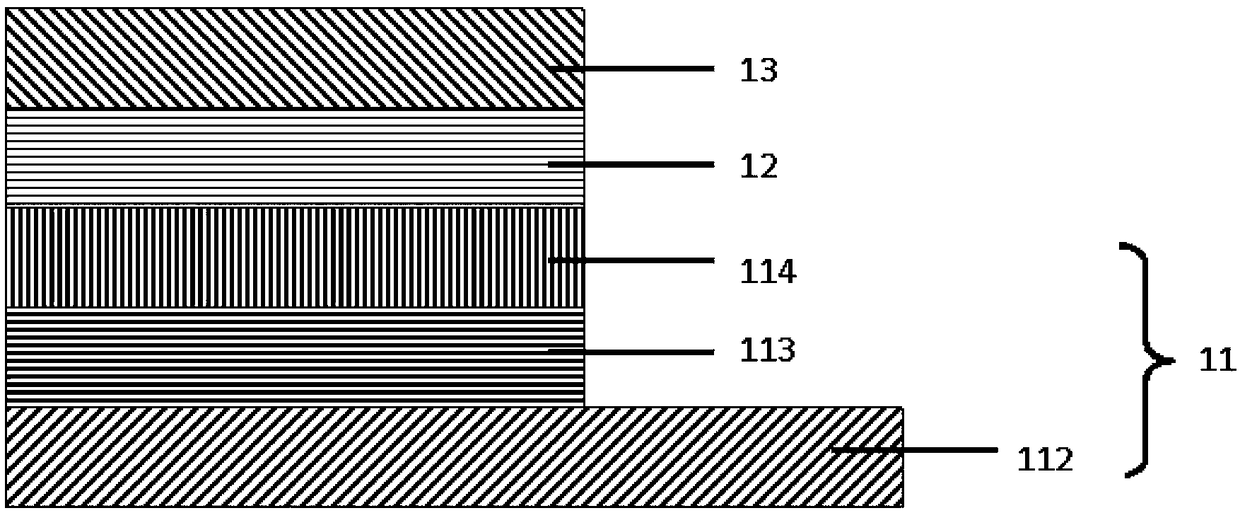

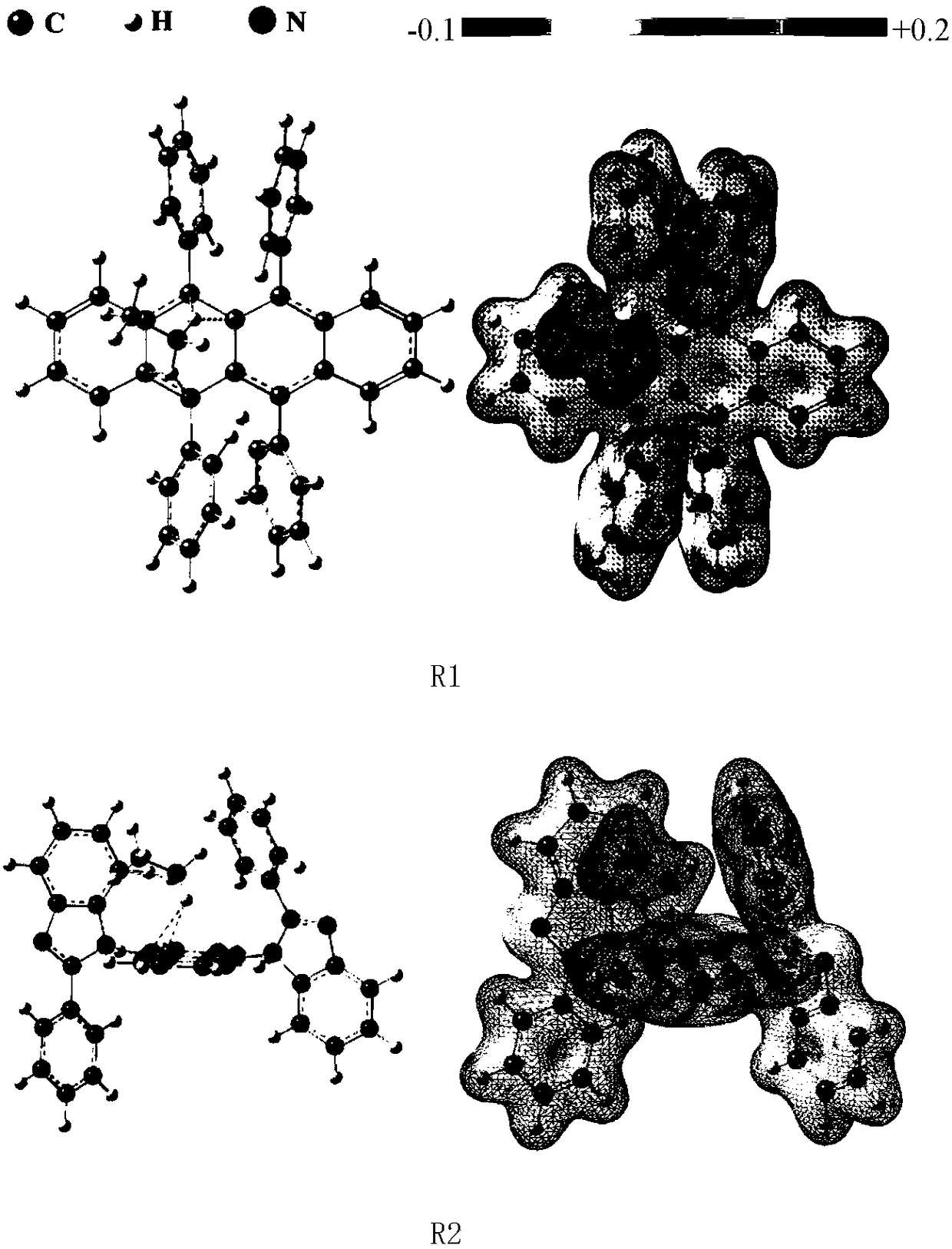

Perovskite film and preparation method thereof and application of perovskite film in photoelectric devices

ActiveCN108493343AImprove efficiencyGood repeatabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsLight-emitting diode

The invention relates to a stable perovskite film and a preparation method thereof and an application of the perovskite film in photoelectric devices. According to the perovskite film, an anti-solventcontaining small organic molecules of a conjugated pi system is dropwise added in a one-step spin-coating preparation process, and a mixed layer of the small organic molecules and perovskite is formed after annealing. Through supermolecular cation-pi interaction between the small organic molecules of the conjugated pi system and cations in the perovskite, the defect of the perovskite film can begreatly reduced and the stability is significantly improved. Furthermore, the invention further provides the corresponding photoelectric devices, such as a perovskite cell, a light-emitting diode anda photoelectric detector, prepared by using the preparation method of the perovskite film. Compared with a standard device to which the small organic molecules of the conjugated pi system are not added, the obtained photoelectric devices have the advantages that the performance and the stability are improved.

Owner:TSINGHUA UNIV

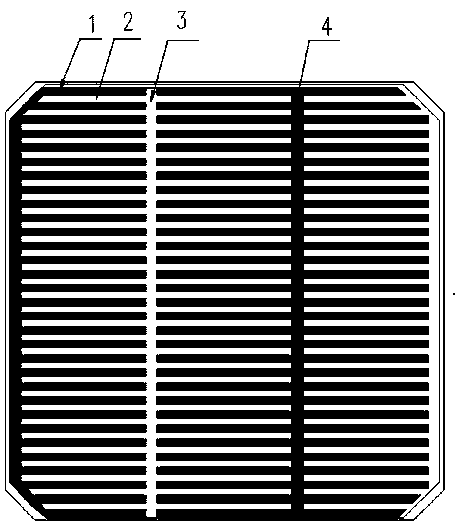

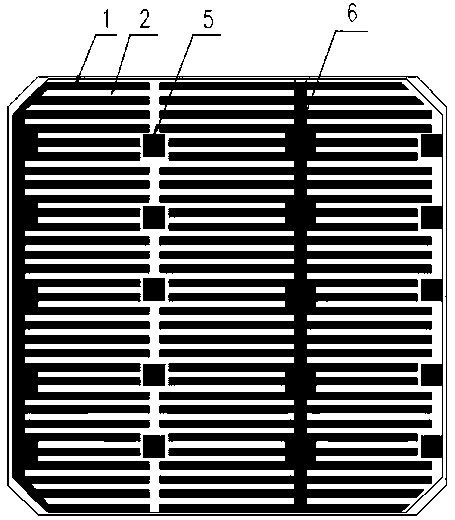

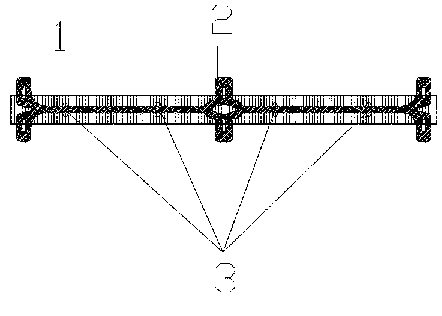

Electrode structure of interlaced back contact (IBC) solar cell

ActiveCN103426940AReduce lossesImprove photoelectric conversion efficiencySemiconductor devicesContact electrodePhotoelectric conversion efficiency

The present invention relates to an electrode structure of an IBC solar cell. The electrode structure of the IBC solar cell is characterized in that inter-digital interlaced positive / negative grid line electrodes are arranged on the backside of the solar cell, the positive / negative grid line electrodes are insulated in a laser etching or insulation paste manner, and all the positive / negative grid line electrodes on the backside are gathered on the strip-like or block-like positive / negative contact electrodes respectively; the positive / negative contact electrodes are connected via conductive solder strips, and the conductive solder strips and the block-like positive / negative grid line electrodes are isolated and insulated via the insulation paste film. The positive / negative contact electrodes of the two solar cells can be in a straight line by rotating the adjacent solar cells 180 degrees and then placing the adjacent solar cells, and the IBC solar cells can be soldered and connected via the routine linear conductive solder strips, so that the electrode structure of the IBC solar cell is simple, convenient, safe, reliable, beautiful and practical and is suitable for the industrialization application, the photoelectric conversion efficiency of the large-size cells is improved, and the development from the IBC cell to the cell of 6 inches or a larger size is realized.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

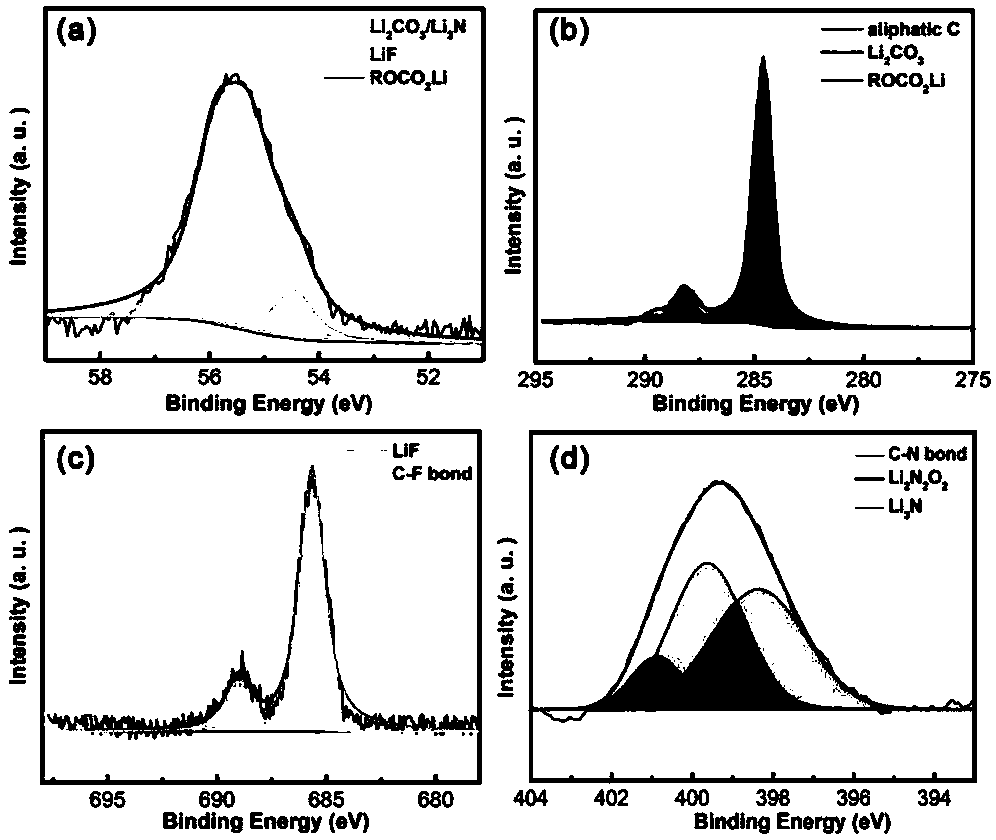

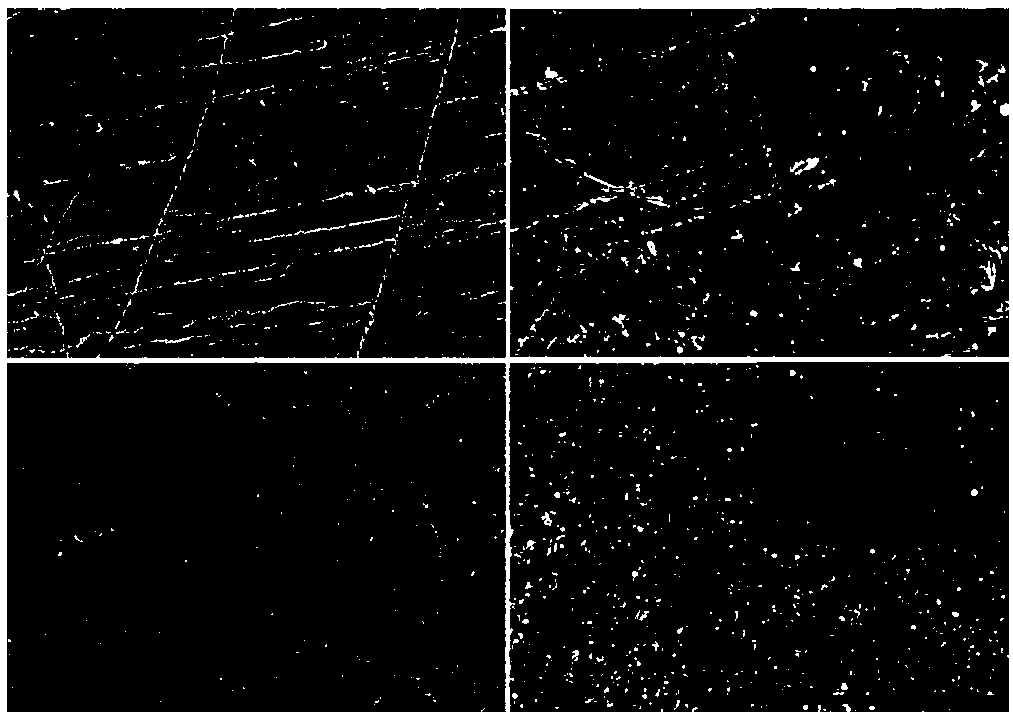

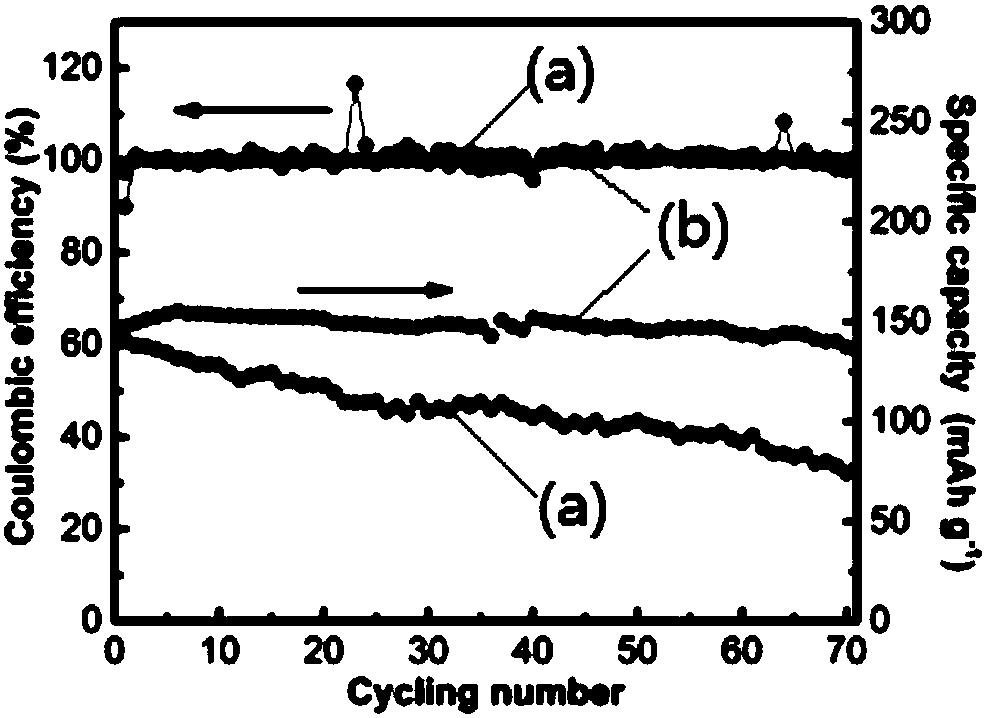

Preparation method of lithium cathode of solid-state battery

ActiveCN108461715ASimple methodEase of industrial productionCell electrodesSecondary cellsSolid state electrolyteOrganic solvent

The invention relates to a preparation method of a lithium cathode of a solid-state battery. The preparation method comprises the following steps of (1) mixing lithium salt, an organic solvent, and anelectrolyte additive to prepare an electrolyte, wherein the molar concentration of the lithium salt in the organic solvent is 1mol / L, and the mass concentration of the electrolyte additive is 1.0%; putting the metal lithium into the electrolyte to perform electrochemical pre-circulation, and forming a protective film at the surface of a cathode of the metal lithium; (2) cleaning the cathode of the metal lithium with the electrolyte solvent after circulating in step (1) in a glove box, and volatilizing the solvent, so as to obtain the lithium cathode. Compared with the prior art, the preparation method has the advantages that the preparation method is simple, the operation is easy, and the regulating and controlling are easy; the solid-state battery assembled by the lithium cathode can well avoid the poor reaction between the lithium cathode and the solid-state electrolyte interface, and can obtain excellent cycling property, lower impedance, and good electrochemical property.

Owner:SHANDONG UNIV

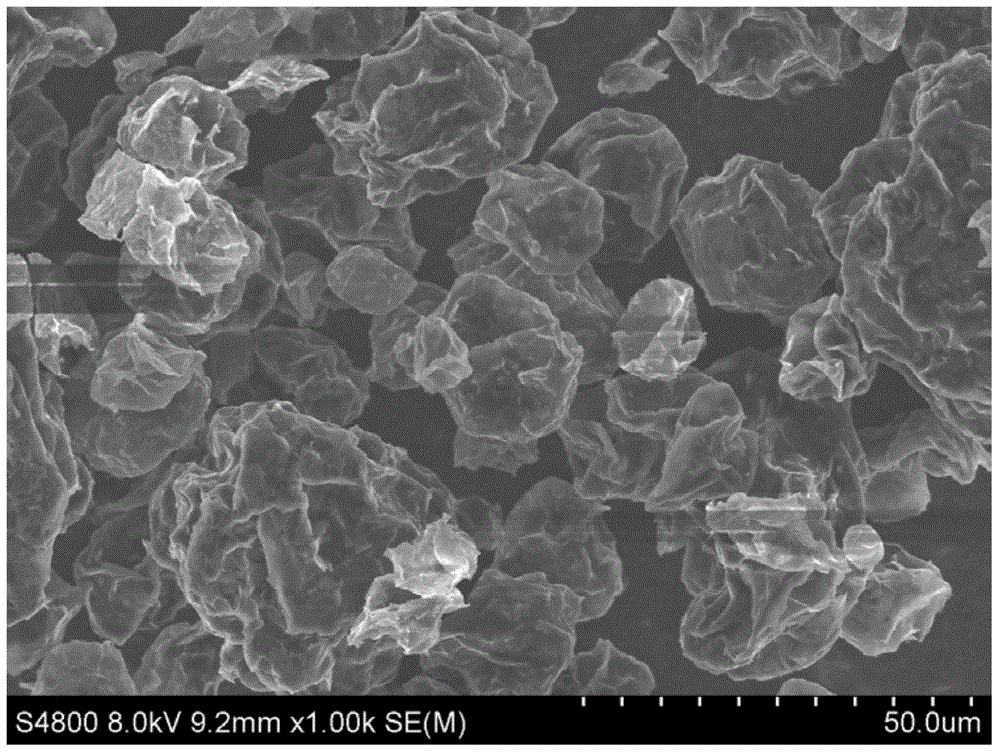

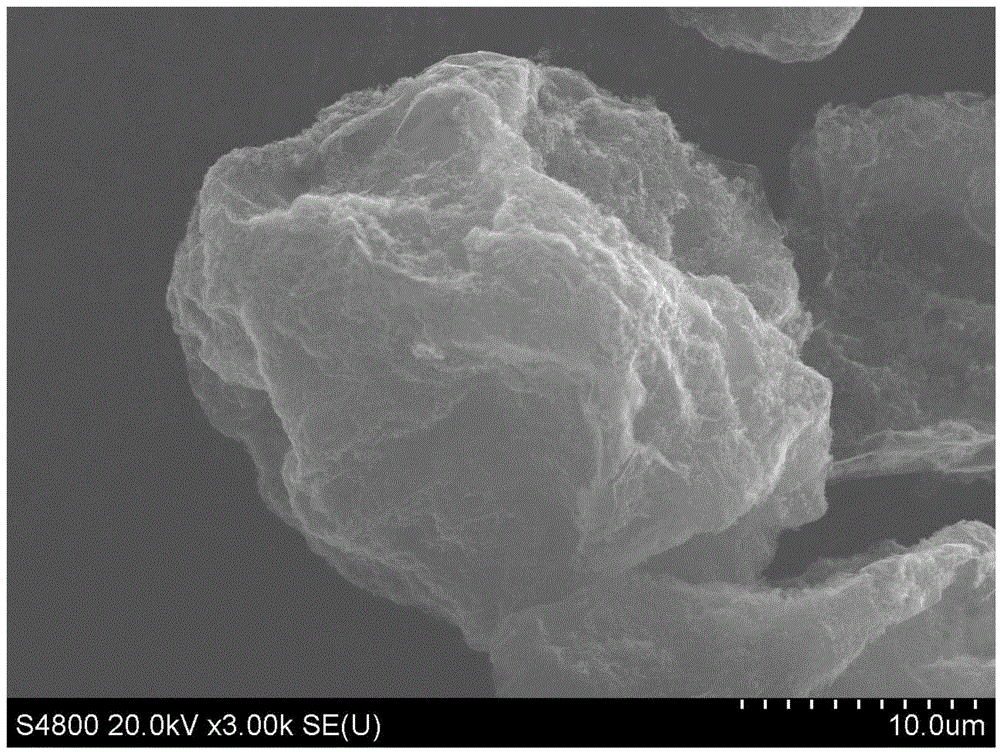

Graphene material powder and preparation method

ActiveCN105084345AImprove visual densitySolve industrial application problemsApparent densityMetallurgy

The invention provides a graphene material powder adaptive to industrialized application. The graphene material powder is formed by combining a grahpene material and a high molecule, the surface of the graphene material is uniformly coated with the high molecule, and thus a barrier is formed by the high molecule between adjacent graphene material, and the apparent density is 0.02 g / cm<3> or more. When being suffered external pressure, the provided graphene material powder does not overlap, and can easily recover to the original state and is convenient for transportation and storage; and also the graphene material powder possesses extremely good compatibility with other systems, and thus the application field of the graphene material powder in downstream products is greatly expanded. The industry application problem of the graphene material powder is successfully solved. The invention also provides a preparation method for the graphene material powder.

Owner:NINGBO MORSH TECH +1

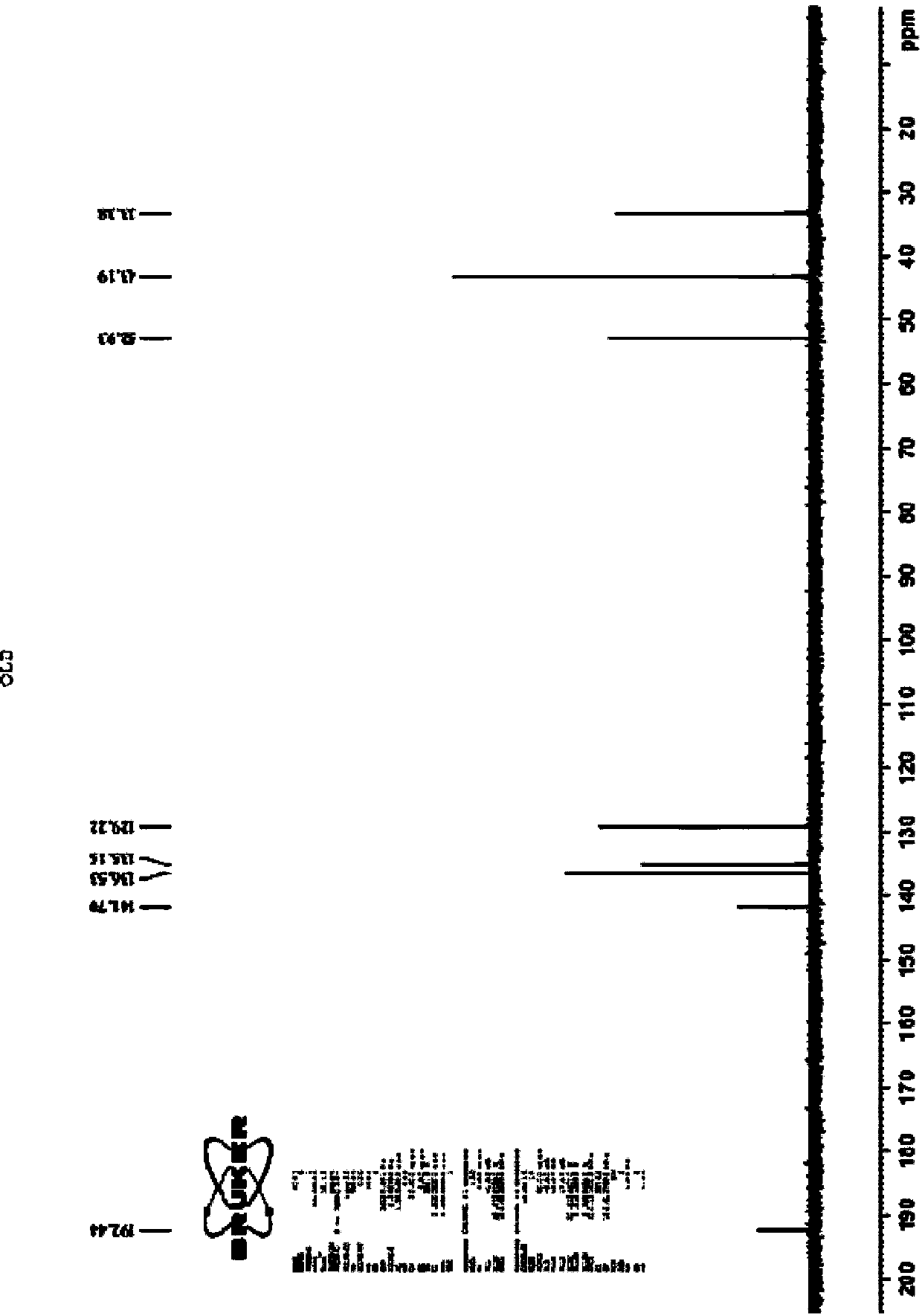

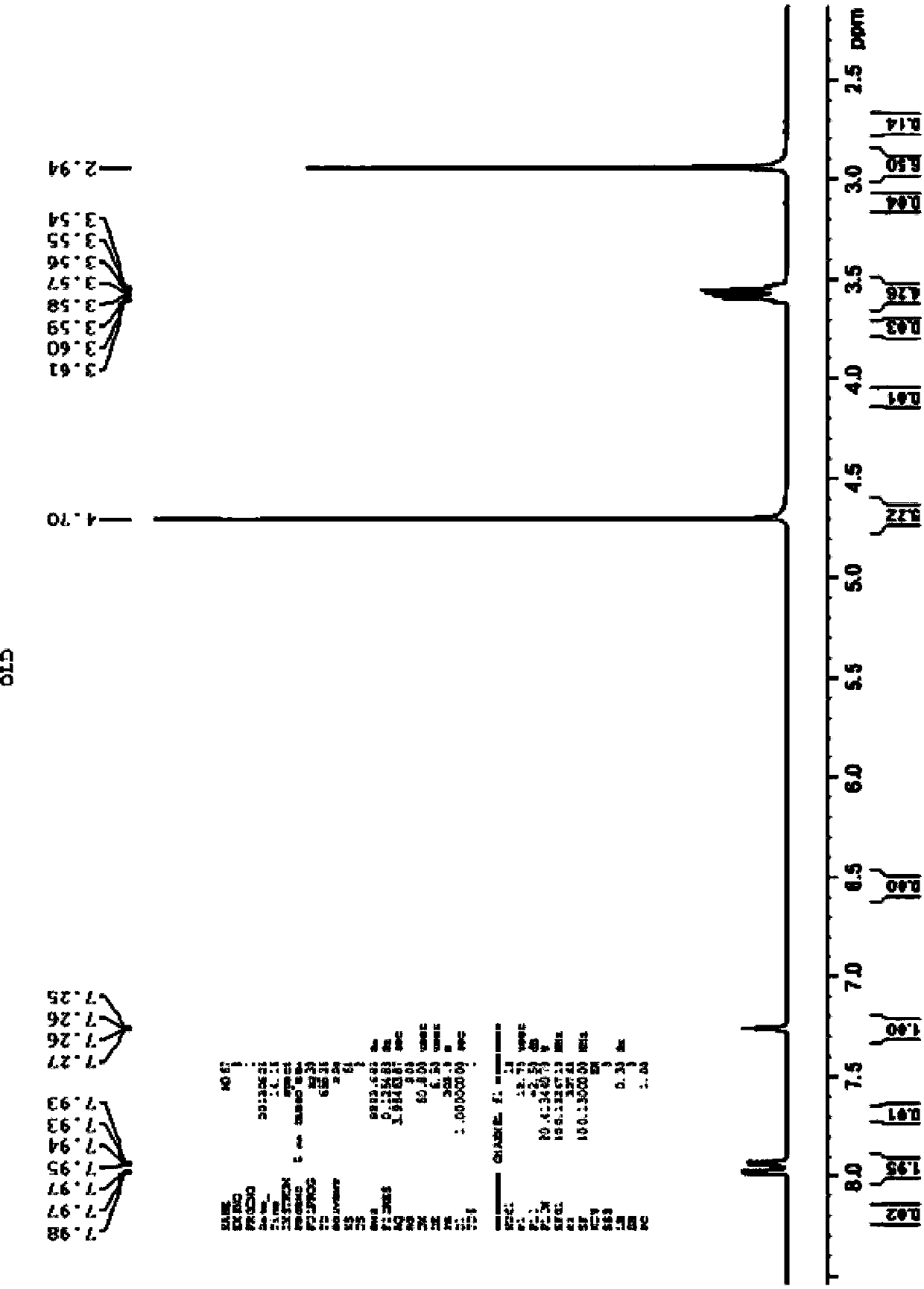

Biological preparation method of (S)-3-(dimethylamino)-1-(thiophene-2-radical)-1-propyl alcohol

The invention relates to a biological preparation method of (S)-3-(dimethylamino)-1-(thiophene-2-radical)-1-propyl alcohol. According to the method, (S)-3-(dimethylamino)-1-(thiophene-2-radical)-1-acetone or salt thereof is taken as a substrate, and the substrate is subjected to asymmetric reduction reaction in the presence of biocatalyst, cofactor and hydrogen donor to produce (S)-3-(dimethylamino)-1-(thiophene-2-radical)-1-propyl alcohol, wherein the biocatalyst is a combination of ketoreductase (KRED) and glucose dehydrogenase, the ydrogen donor is glucose, and the asymmetric reduction reaction is conducted at pH 6.8-7.0 and 25 DEG C-35 DEG C. Compared with the biological method in the prior art, the biological preparation method has higher processing stability, and is simpler, more efficient and safer. During the reaction, the generation of highly toxic organic solvents such as acetone can be avoided, the application principle of green chemistry is met, and the industrialized application is facilitated.

Owner:ENZYMEWORKS

Ruthenium carbonyl complex having tridentate ligand, its production method and use

ActiveUS8471048B2Easy to prepareImprove stabilityRuthenium organic compoundsSilicon organic compoundsAlcoholRuthenium

The present invention relates to a ruthenium carbonyl complex that is represented by the following Formula (1):RuXY(CO)(L) (1)(in the Formula (1), X and Y, which may be the same or different from each other, represent an anionic ligand and L represents a tridentate aminodiphosphine ligand which has two phosphino groups and a —NH— group), its production method, and a method for production of alcohols by hydrogenation-reduction of ketones, esters, and lactones using the complex as a catalyst.The ruthenium carbonyl complex of the invention has a high catalytic activity and it can be easily prepared and handled.

Owner:TAKASAGO INTERNATIONAL CORPORATION

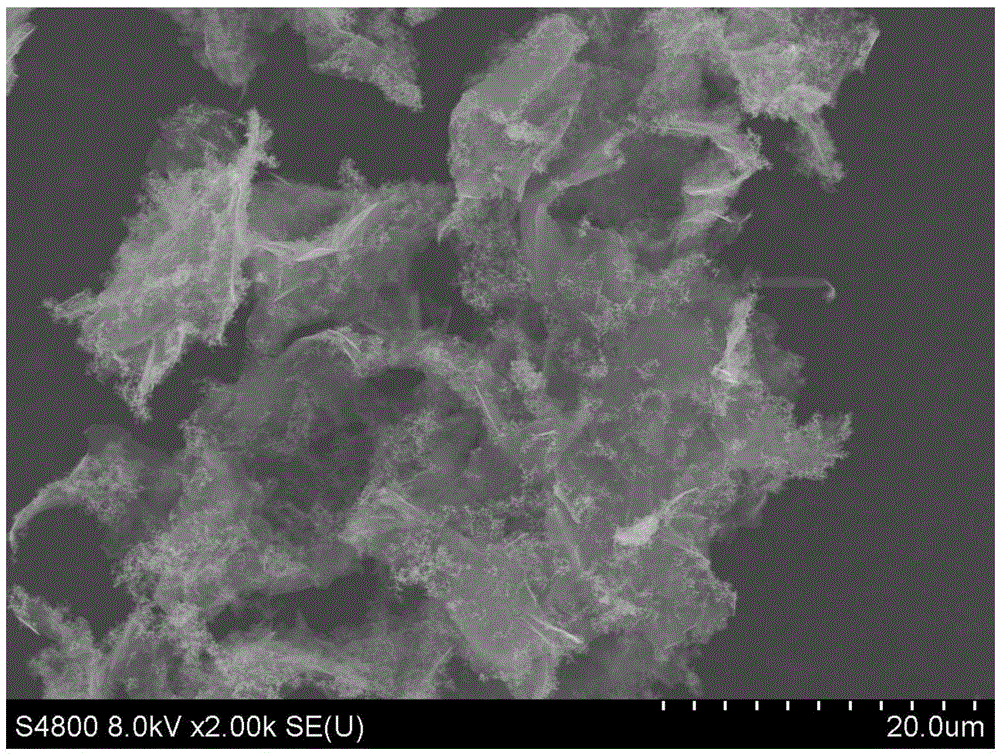

Graphene compound conductive powder and preparation method thereof

ActiveCN105523552ASolve industrial application problemsIncreased dispersionGrapheneDispersitySolvent

The invention provides graphene compound conductive powder obtained through hydrogen bond self-assembly of a graphene material and a conductive carbon material. A polypyridine compound is adsorbed on the surface of the graphene material, a carboxyl compound is adsorbed on the surface of the conductive carbon material, and the conductive carbon material contains no graphene. In the graphene compound conductive powder, the surface of the graphene material is uniformly covered with the conductive carbon material, so the adjacent graphene materials are separated by the conductive carbon material, and the dispersity of the graphene compound conductive powder in a solvent is effectively enhanced. The invention further provides a preparation method of the graphene compound conductive powder.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

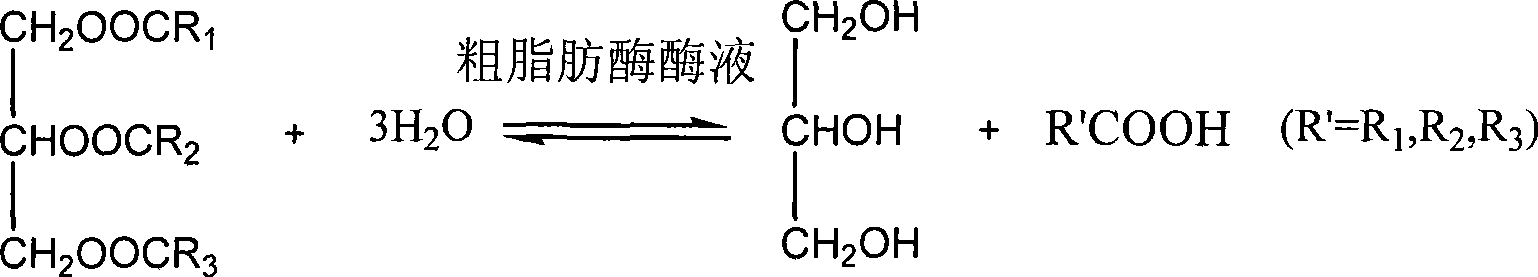

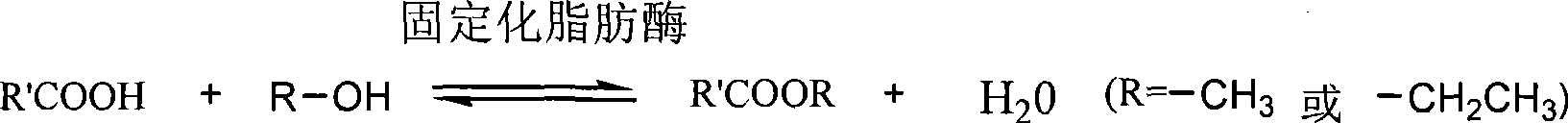

Method for synthesizing biodiesel by two-step catalysis of lipid via Yarrowia lipolytica lipase, and biodiesel obtained thereby

The present invention provides a crude lipase enzyme solution of Yarrowia lipolytica microzyme CGMCC No.2707 and a method for synthesizing biological diesel oil by catalyzing the hydrolization and esterification reaction of waste animal and vegetable fat by the immobilized lipase of the crude lipase enzyme solution. A method for preparing the lipase crude enzyme solution and the immobilized enzyme is also provided. The method uses hydrolization and esterification reactions of the oil and fat use lipase as catalysts, but does not use strong acid and strong base. The method has the advantages of mild reaction condition and small pollution. Organic solvent is not used during the entire production process of the fatty acid methyl ester / ethyl ester. The reaction is safe and the efficiency is high.

Owner:领先生物农业股份有限公司

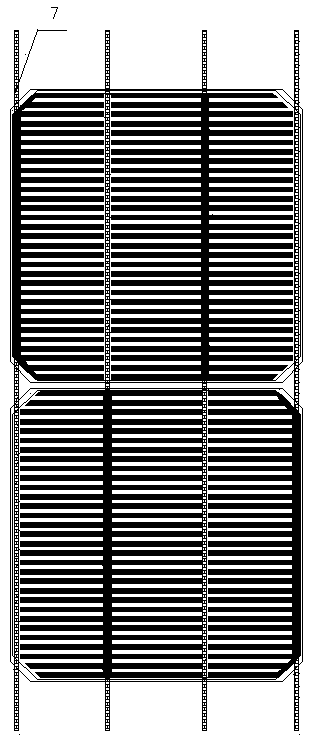

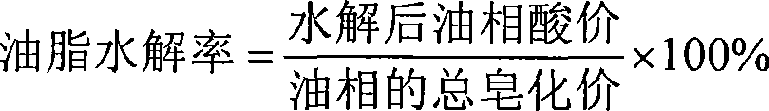

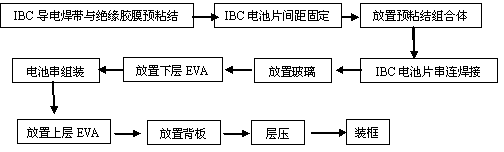

Method for manufacturing back contact type crystalline silicon solar cell component

InactiveCN103456843ASolve welding displacementSolve complexityFinal product manufacturePhotovoltaic energy generationEngineeringContact type

The invention relates to the technical field of manufacturing of a solar cell component, in particular to a method for manufacturing a back contact type crystalline silicon solar cell component. The method sequentially comprises the following steps of pre-bonding of a conductive solder strip and an insulation glue film, distance fixing of back contact type crystalline silicon solar cells, placing of a pre-bonding combination body, series welding of the solar cells, placing of glass, placing of lower layer EVA, assembling of a solar cell string, placing of upper layer EVA, placing of a back plate, laminating and framing. The method for manufacturing the back contact type crystalline silicon solar cell component solves the problems of welding shifting and complex and cumbersome working processes of the back contact type crystalline silicon solar cells, operation is simple and convenient, the method is suitable for industrial application, the production quality and the production efficiency of the back contact type crystalline silicon solar cell component can be effectively improved, the insulation glue film which has bonding performance after being heated is used, the thickness of the glue film is moderate, the breaking rate of the back contact type crystalline silicon solar cells in the welding process can be reduced, the welding strength is enhanced, the effect of beautifying the appearance is well achieved, safety and reliability are achieved, and attractiveness and practicability are achieved.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

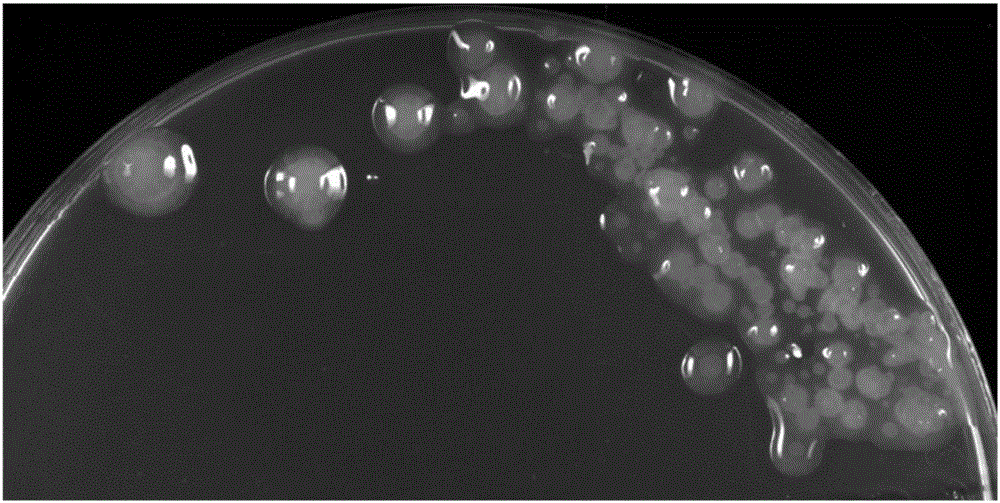

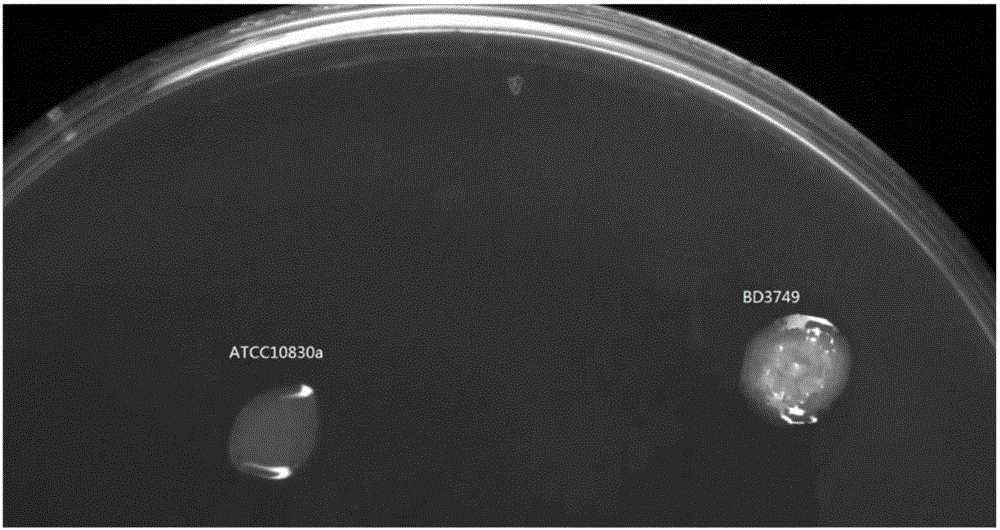

Leuconostoc mesenteroides as well as preparation method and application thereof

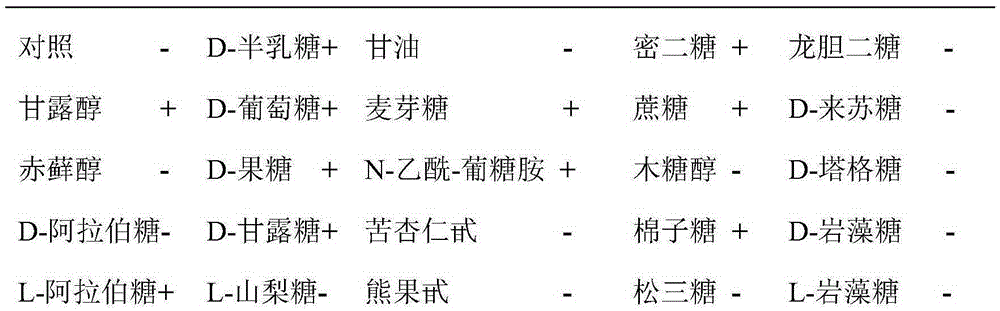

InactiveCN105349477AAffect qualityAffect shelf lifeMilk preparationBacteriaLeuconostoc mesenteroidesMicroorganism

The invention discloses Leuconostoc mesenteroides as well as a preparation method and an application of the Leuconostoc mesenteroides in polysaccharide production. The Leuconostoc mesenteroides is collected in CGMCC (China General Microbiological Culture Collection Center), the collection number is CGMCC No. 10064, and the culture name is BD3749. The Leuconostoc mesenteroides can be used for large-scale preparation of insoluble polysaccharides, so that whey separation can be controlled better, the Leuconostoc mesenteroides can be applied to fermentation of dairy products, and influence on the quality and shelf life of the dairy products due to severe damage to texture of the products because of whey separation during storage of the dairy products can be avoided. A strain culture method is simple and easy to operate, large quantity of insoluble polysaccharides is prepared from the Leuconostoc mesenteroides, and the Leuconostoc mesenteroides is suitable for industrialized application and has broad market.

Owner:BRIGHT DAIRY & FOOD

Technical method for extracting dietary fiber from pear residue

ActiveCN104187456AAvoid emissionsHigh extraction rateFood precipitationFood dryingBiotechnologyAntioxidant capacity

The invention discloses a technical method for extracting dietary fiber from pear residue; the pear residue is a waste material produced in the production of pear juice, contains a large number of sclereid, is poor in palatability when direct used as a feed, is a waste of resources and seriously pollutes the environment when use as a waste material; by use of the pear residue for dietary fiber production, the pear industry additional value can be increased, and energy can be saved and emission can be reduced. The technical method comprises the following steps: 1, pear residue pretreatment, 2, ultrasonic assisted enzymolysis, 3, precipitation with ethanol, and 4, drying to obtain pear residue dietary fiber including pear residue soluble dietary fiber and pear residue insoluble dietary fiber; the extraction rate of the pear residue soluble dietary fiber is 13%-15%, at the 20-80 DEG C, the solubility stability of the pear residue soluble dietary fiber is 85% above, the pear residue soluble dietary fiber is strong in antioxidant ability; the pear residue insoluble dietary fiber has good water holding capacity and swelling capacity, and is high-quality dietary fiber. The technical method has the advantages of simple process, short enzymolysis time and low cost, and is suitable for industrial application.

Owner:HEFEI UNIV OF TECH

Method for preparing scutellarin

ActiveCN105218606AEfficient chemical synthesis preparationFew synthetic stepsSugar derivativesSugar derivatives preparationMeth-Acylation

The invention discloses a method for preparing scutellarin. The method comprises the following steps: taking phenol as a starting material, preparing a chalcone intermediate compound 6 through bromination, methoxy substitution, friedel-crafts acylation and the like, performing oxidative cyclisation on the chalcone intermediate compound 6 to obtain a key flavone intermediate 4',6-dihydroxy-5,7-dimethoxy flavone-compound 7, and preparing high-purity scutellarin through benzoylation, selective demethylation, glycosylation and hydrolysis reaction of the key intermediate. According to the method, the adopted raw material reagents are all low in price and easy to obtain, the synthesis steps are less, the operation is simple and convenient, production control is easy, the product yield and purity are high, and the method is suitable for scutellarin production.

Owner:KUNMING UNIV OF SCI & TECH

Process for surface diffusion treatment of silicon chip of solar cell

InactiveCN101587920AReduce surface recombinationAchieve removalFinal product manufactureSemiconductor devicesProcess equipmentNormal diffusion

The invention relates to the technical field of solar cell manufacturing, in particular to a process for the surface diffusion treatment of a silicon chip of a solar cell. The process comprises the following steps: firstly, before diffusion source deposition, introducing gases containing chlorine and oxygen into a diffusion furnace to perform chlorine doped oxidization treatment on the silicon chip surface to form a layer of silicon dioxide layer containing chlorine on the surface of the silicon chip; and secondly, performing diffusion source deposition. The chlorine doped oxidization treatment performed before a normal diffusion process can effectively reduce the surface recombination of the silicon chip and realize an excellent surface state, so the performance of finished cells is improved. The novel process avoids increasing novel processing equipment and manpower, influence on productivity and environmental pollution, and is extremely suitable for the industrial application.

Owner:TRINA SOLAR CO LTD

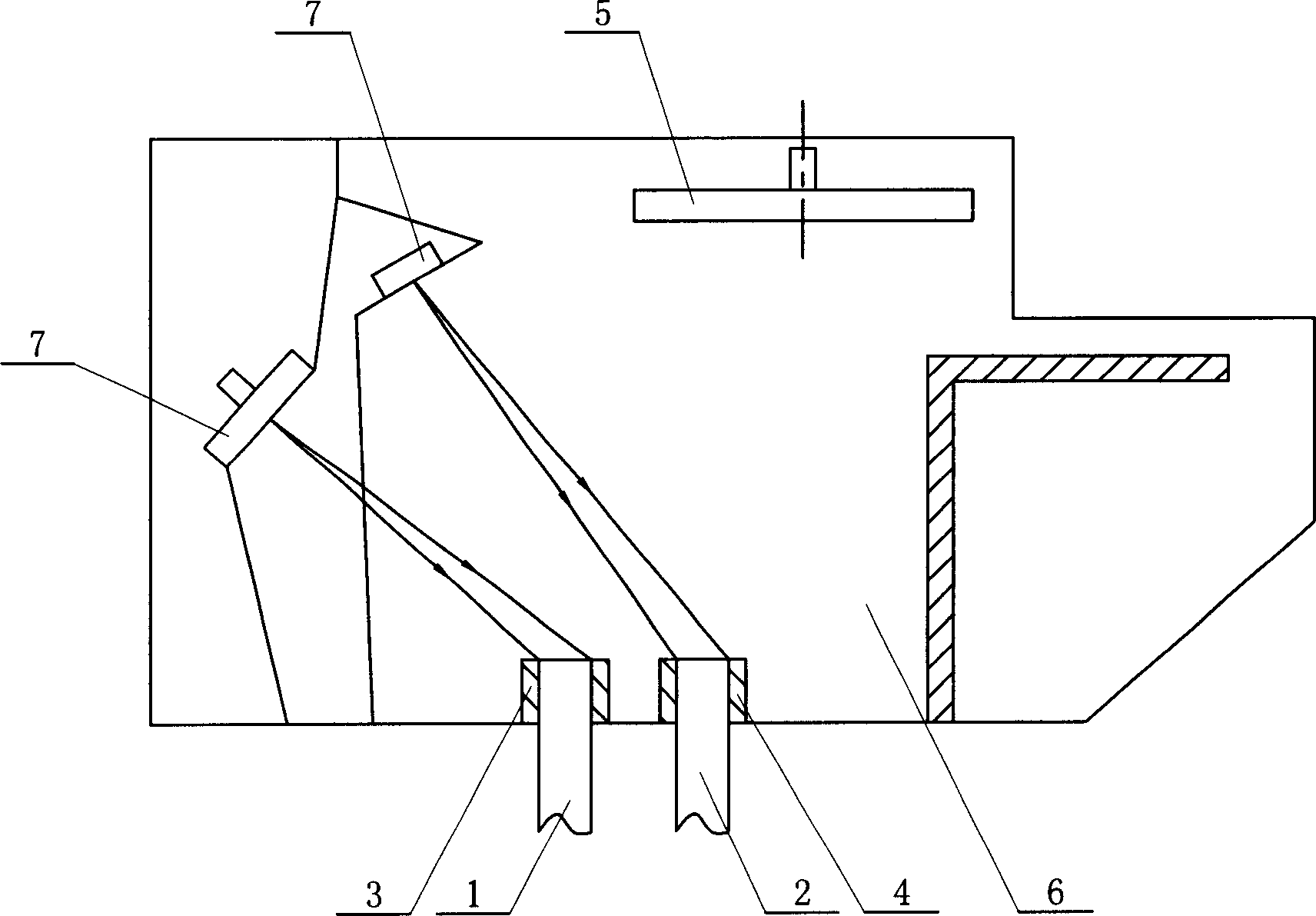

Electronic tablet counting machine allowing tablets to be subpackaged in multiple bottles simultaneously

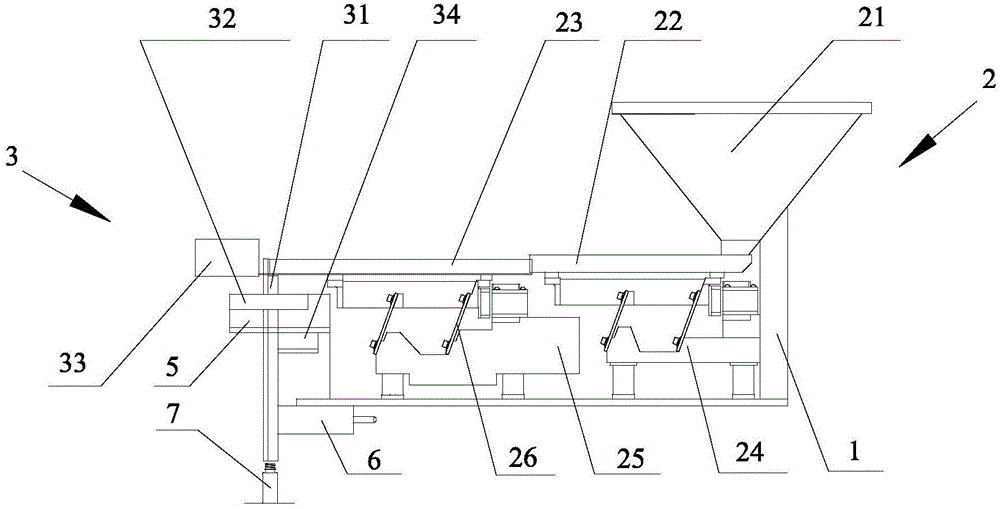

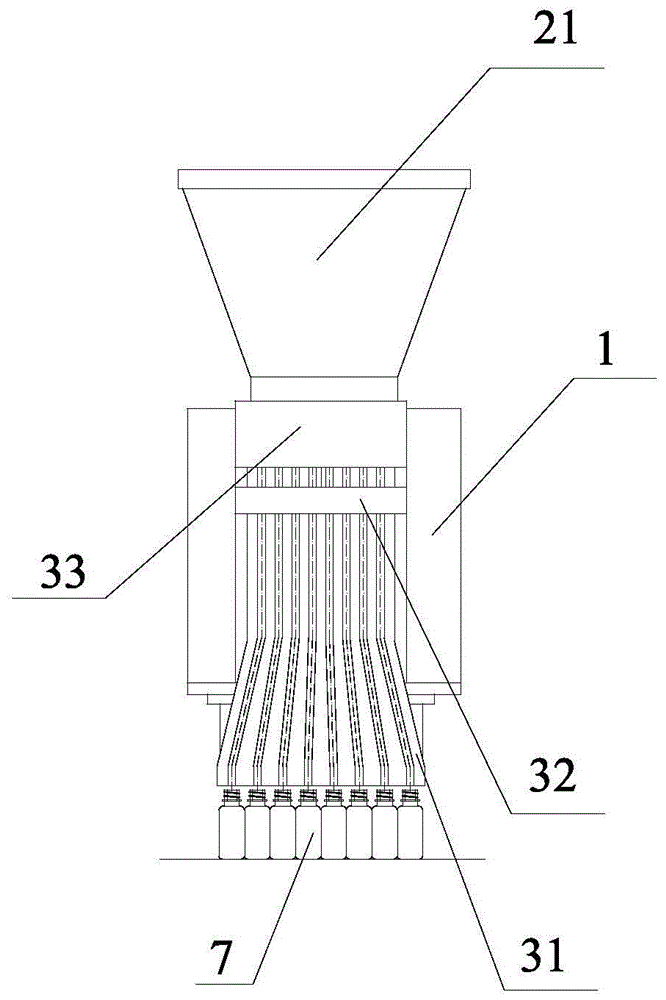

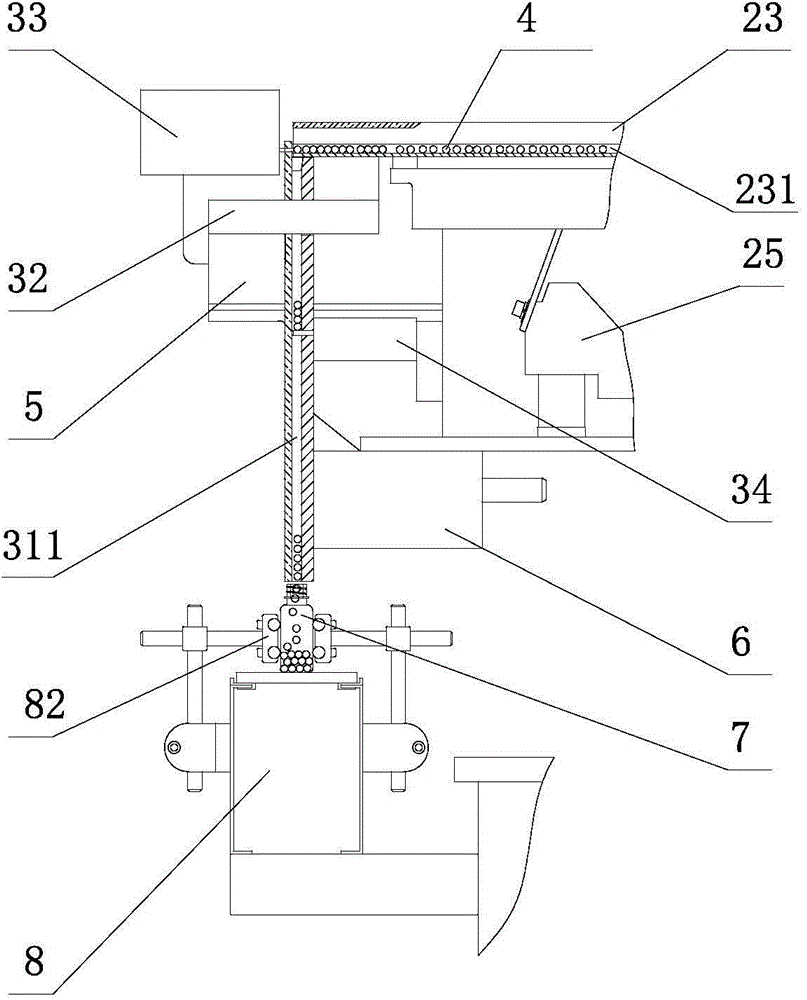

InactiveCN104527999AStable deliverySimple structurePackaging automatic controlSolid materialEngineeringBottle

The invention discloses an electronic tablet counting machine allowing tablets to be subpackaged in multiple bottles simultaneously. The machine comprises a feeding mechanism, a counting and subpackaging mechanism, a bottle conveying mechanism and a control device, wherein the feeding mechanism and the counting and subpackaging mechanism are arranged on the machine base. The counting and subpackaging mechanism is fixed to a supporting plate at the feeding end of the feeding mechanism, the bottle conveying mechanism is arranged below the counting and subpackaging mechanism, the feeding mechanism, the counting and subpackaging mechanism and the bottle conveying mechanism are electrically connected with the control device, the feeding mechanism comprises a plurality of horizontally vibrating conveying tablet channels, the counting and subpackaging mechanism comprises a plurality of vertical discharging pipes matched with the conveying tablet channels, upper end inlets of the vertical discharging pipes are aligned to the conveying tablet channels, and lower end outlets of the vertical discharging pipes are aligned to openings of the tablet bottles. The electronic tablet counting machine is simple in structure and can subpakage the tablets into the tablet bottles, tablet conveying is quick and stable, counting and subpackaging are quick and accurate, production efficiency of medicine subpakaging can be greatly improved, and the machine has good industrialized application value.

Owner:南通恒力包装科技股份有限公司

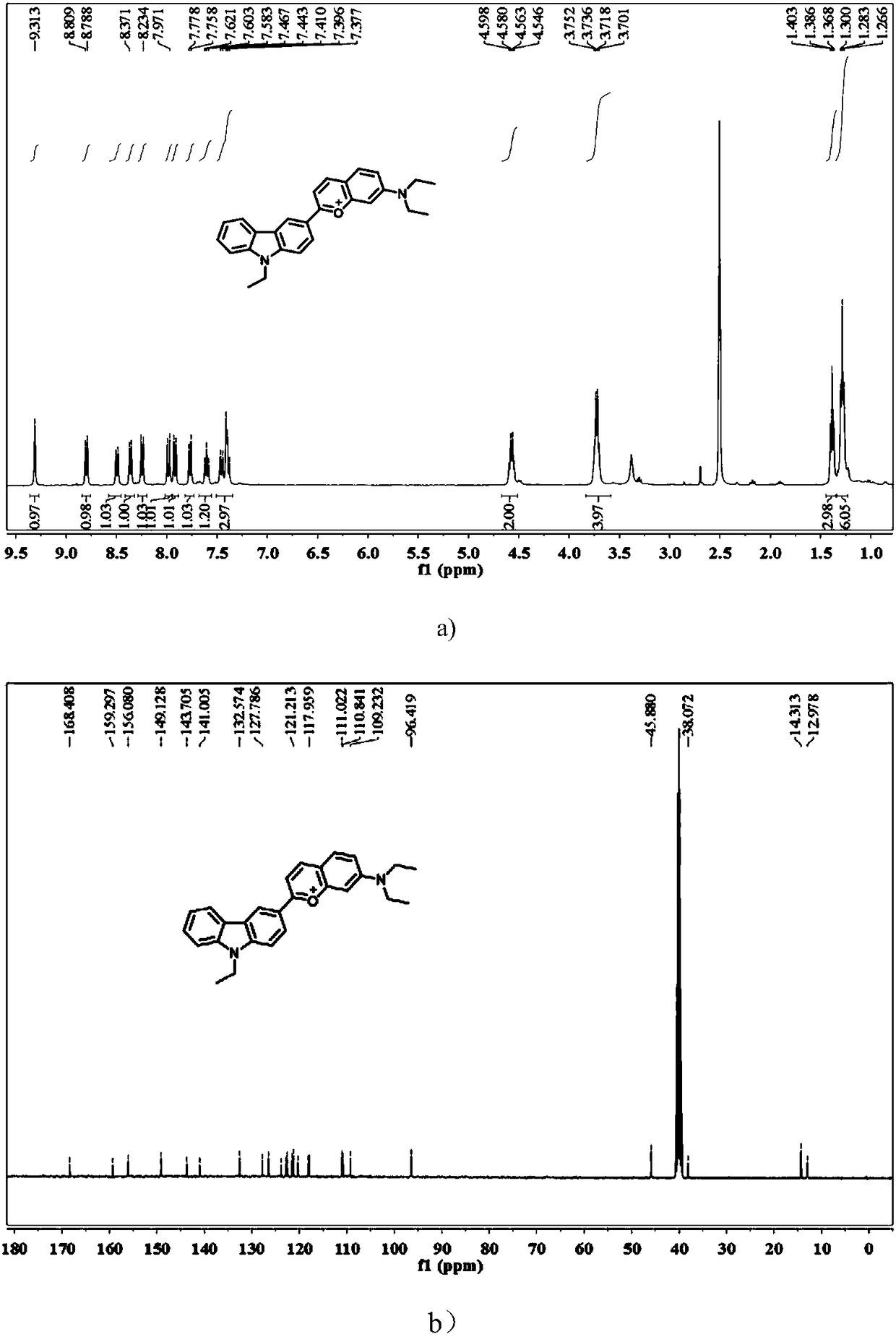

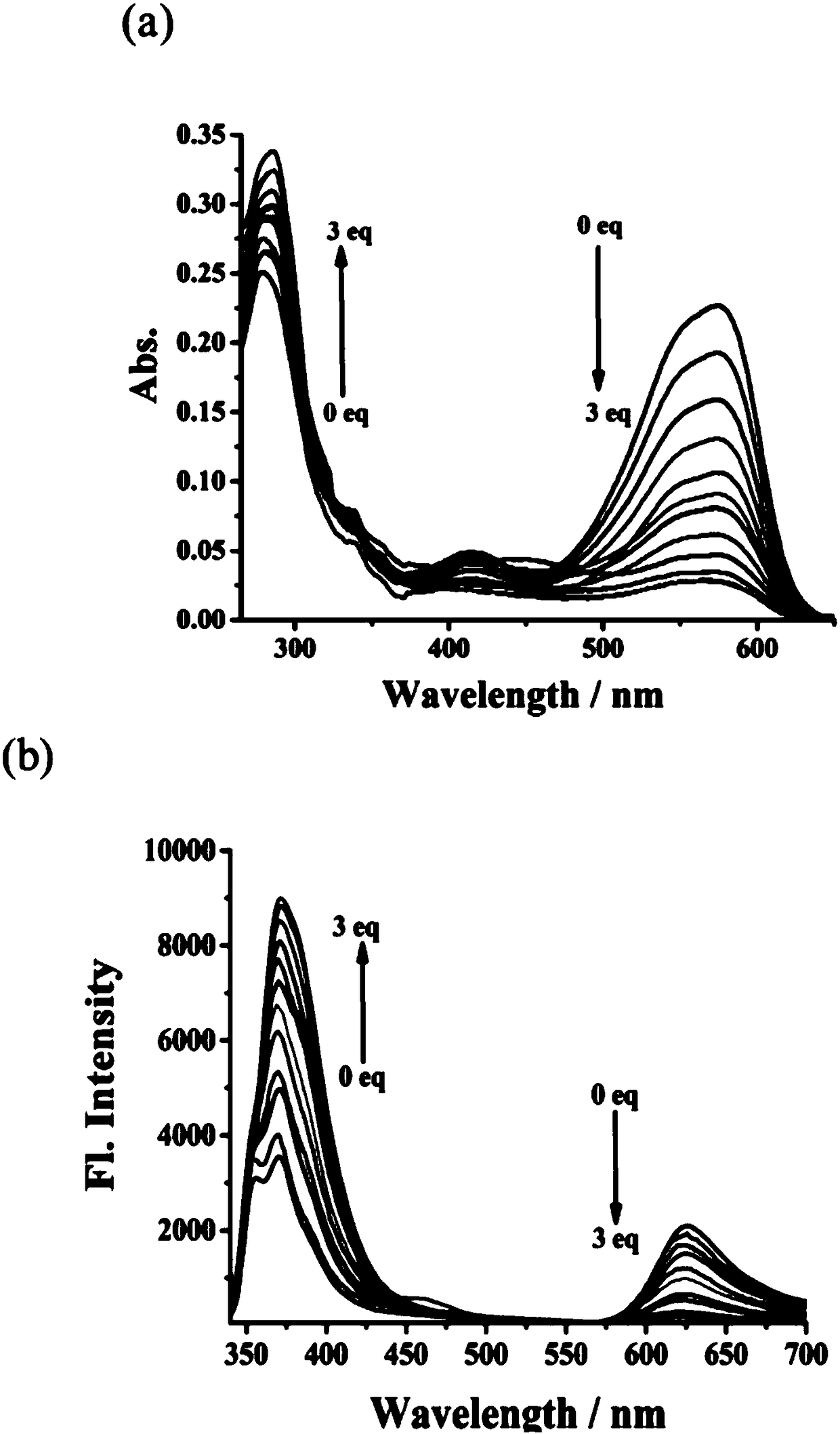

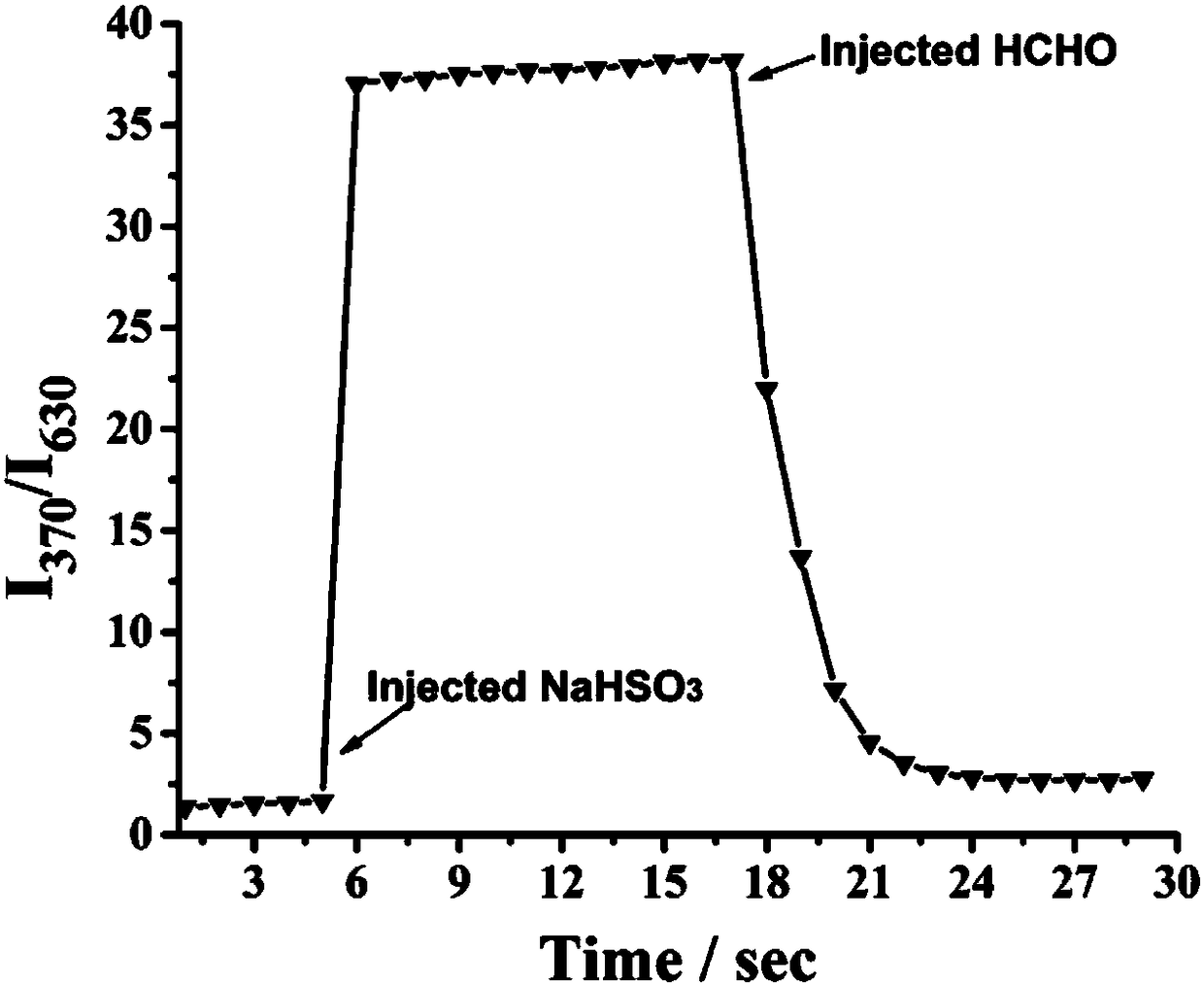

Fluorescent probe of reversible sulfur dioxide/sulphurous acid (hydrogen) salt

InactiveCN108117544AThe synthesis steps are simpleRaw materials are easy to getOrganic chemistryFluorescence/phosphorescenceHydrogenOxonium ion

The invention provides a fluorescent probe of reversible sulfur dioxide / sulphurous acid (hydrogen) salt, with the chemical name of 7-diethylin-2-(9-ethyl-9H-carbazole-3) benzo iso-pyran oxonium ion. The fluorescent probe can detect sulfur dioxide / sulphurous acid (hydrogen) salt in a solution, cells, tissues or a living body, wherein the living body includes fish, mice, rat, guinea pig and rabbit;and reversibility is realized by formaldehyde. The fluorescent probe is simple in synthesis steps, easily available in material, high in yield and suitable for industrial application.

Owner:UNIV OF JINAN

Graphene material powder and preparation method

The invention provides a graphene material powder suitable for industrial application, the graphene material powder is prepared by compounding a graphene material and an imbibition expanding material, the surface of the graphene material is covered with the imbibition expanding material, so that adjacent graphene materials can be obstructed by the imbibition expanding material. When the graphene material powder is dispersed in a solvent, the imbibition expanding material between graphene material sheet layers rapidly absorbs a liquid for expansion to strut the graphene material sheet layers. At the same time, the graphene material powder has good compatibility with other systems, the application field of the graphene material powder in the downstream products is greatly expanded, and the problem of industrial application of the graphene material powder is successfully resolved. The invention also provides a preparation method of the graphene material powder.

Owner:NINGBO MORSH TECH +1

Method for extracting and separating anthocyanidin and polysaccharide from blueberry pomace

The invention relates to a method for extracting and separating anthocyanidin and polysaccharide from blueberry pomace. According to the method, blueberry pomace is used as raw material, enzyme-water solution is used as extraction solvent, and negative pressure cavitation strengthening extraction technology and macroporous resin enrichment and separation technology are applied to obtain anthocyanidin and polysaccharide from the blueberry pomace. Content of anthocyanidin in the obtained product is 26%-40%, and content of polysaccharide is 2.6%-13.8%. The method has the advantages that by-products of blueberries are utilized comprehensively, equipment is simple, economization and environmental protection. Further, the method fits with current trend of development and is suitable for industrialization.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

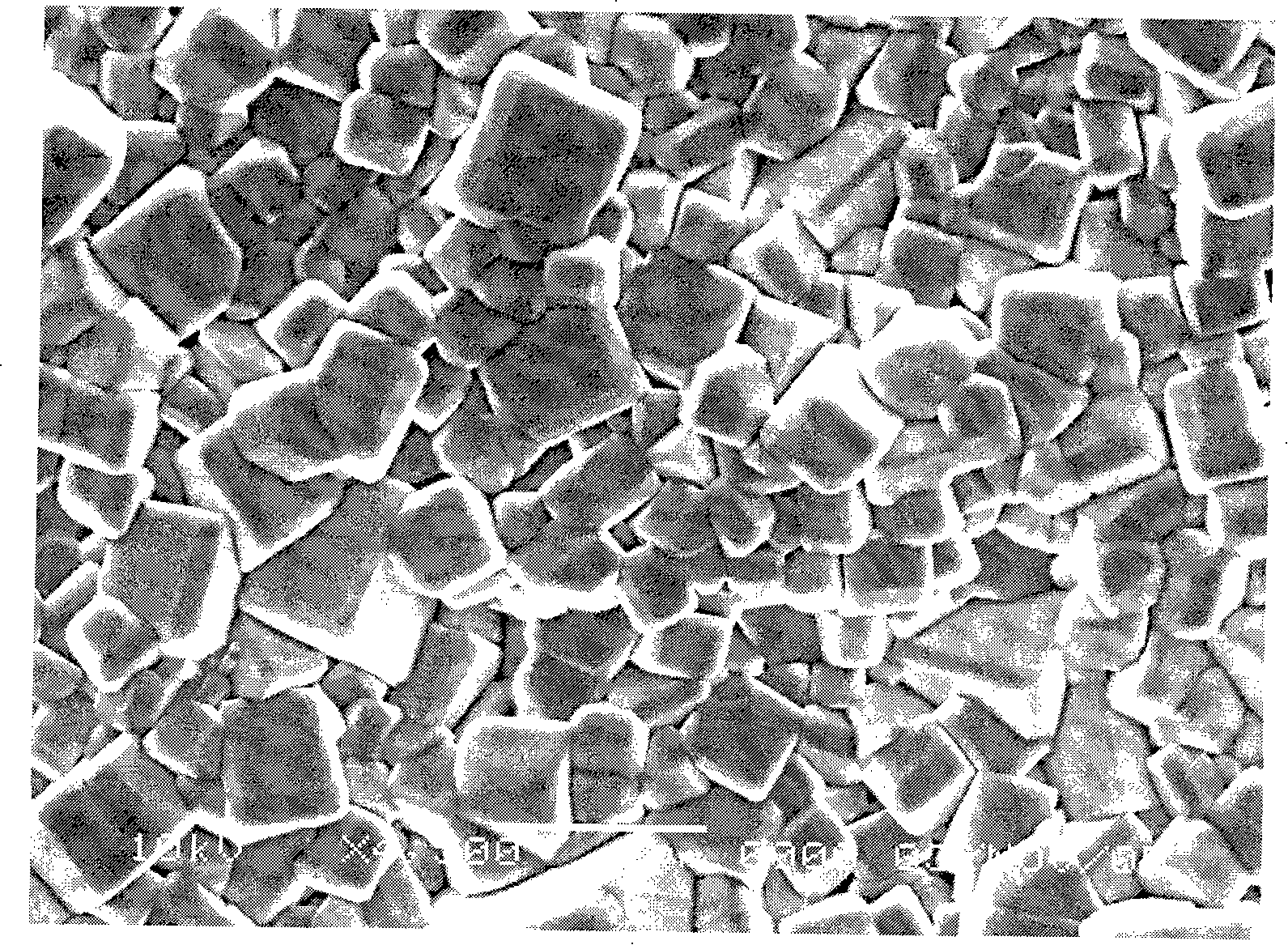

A manufacturing method of a high-strength small-size mill ball

ActiveCN104607102AHigh strengthSuitable for industrial applicationOther chemical processesGranulation in rotating dishes/pansHigh intensityUltimate tensile strength

The invention discloses a novel process for manufacturing a high-strength small-size mill ball by using a large-scale ball rolling machine as a forming device and through granulation by using a mother nucleus and powder material grading optimization. Firstly, granulation is performed by adopting one or more of raw materials as the mother nucleus, the large-scale ball rolling machine is used, and the optimized grading raw materials are added according to a certain material water ratio, and forming is performed by rolling. Finally, parameters of the ball rolling machine are adjusted, surface levelling of a ball blank is achieved, and after sintering, the small-size mill ball having a high degree of sphericity, high strength and low abrasion is obtained.

Owner:江苏金石研磨有限公司

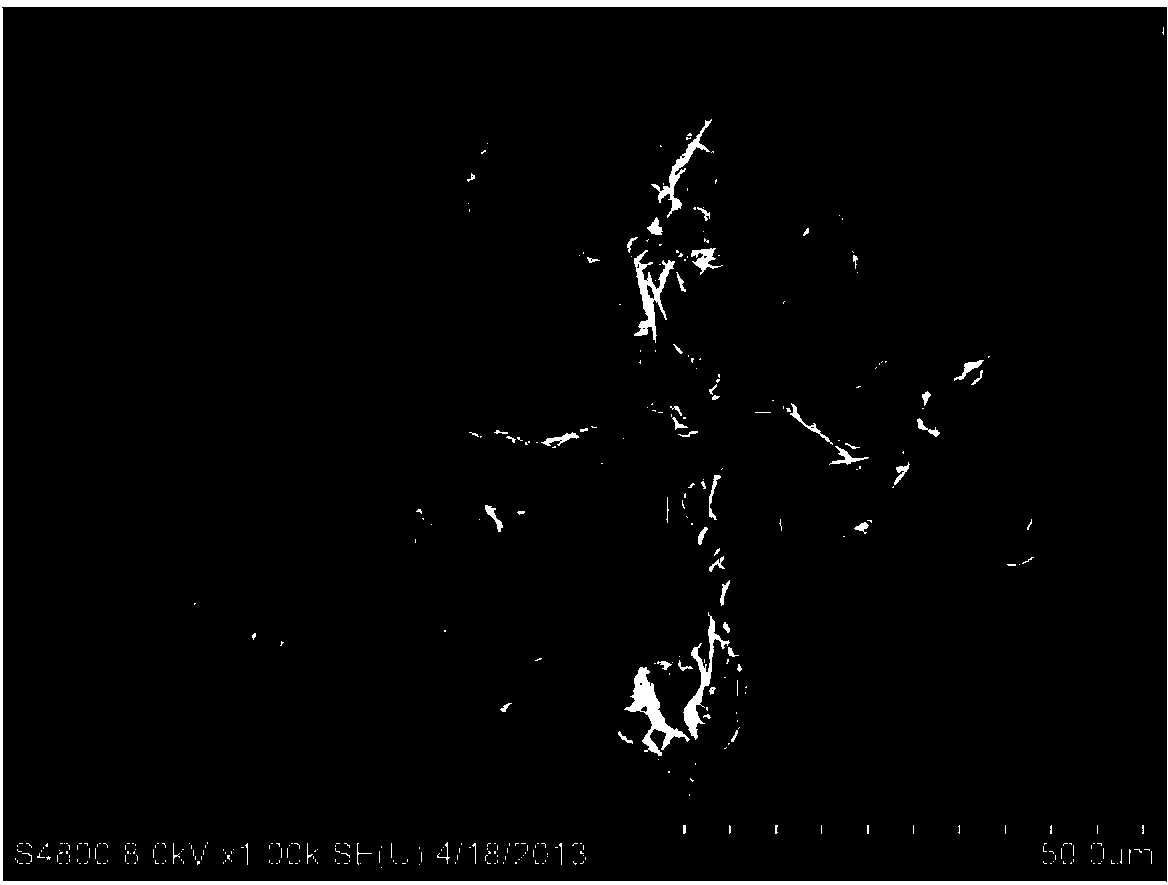

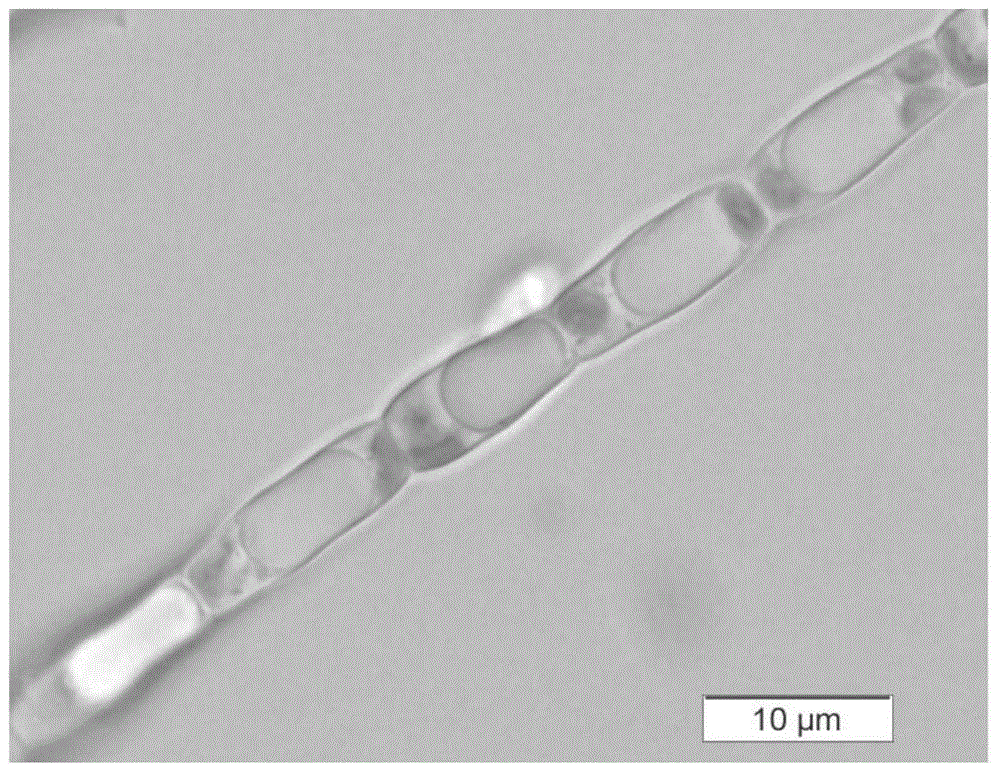

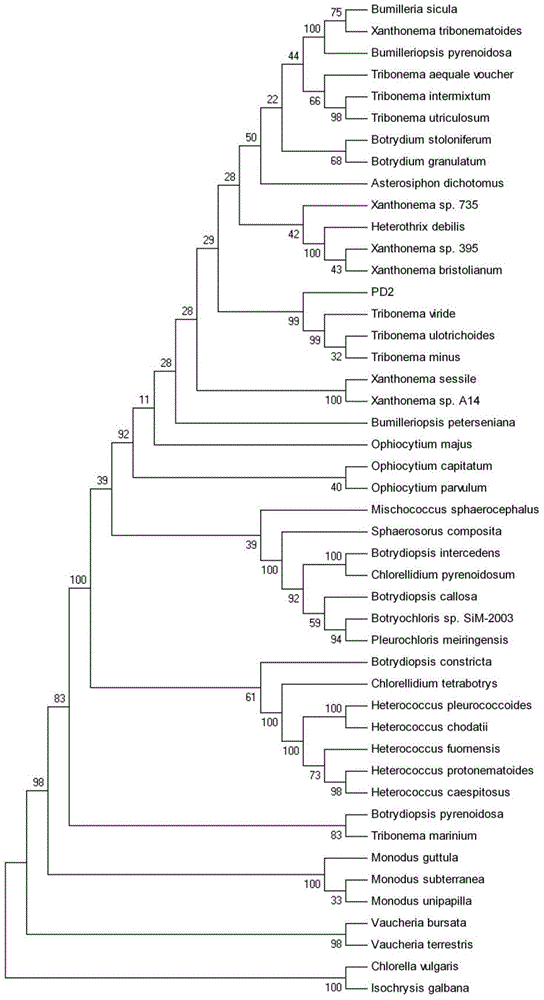

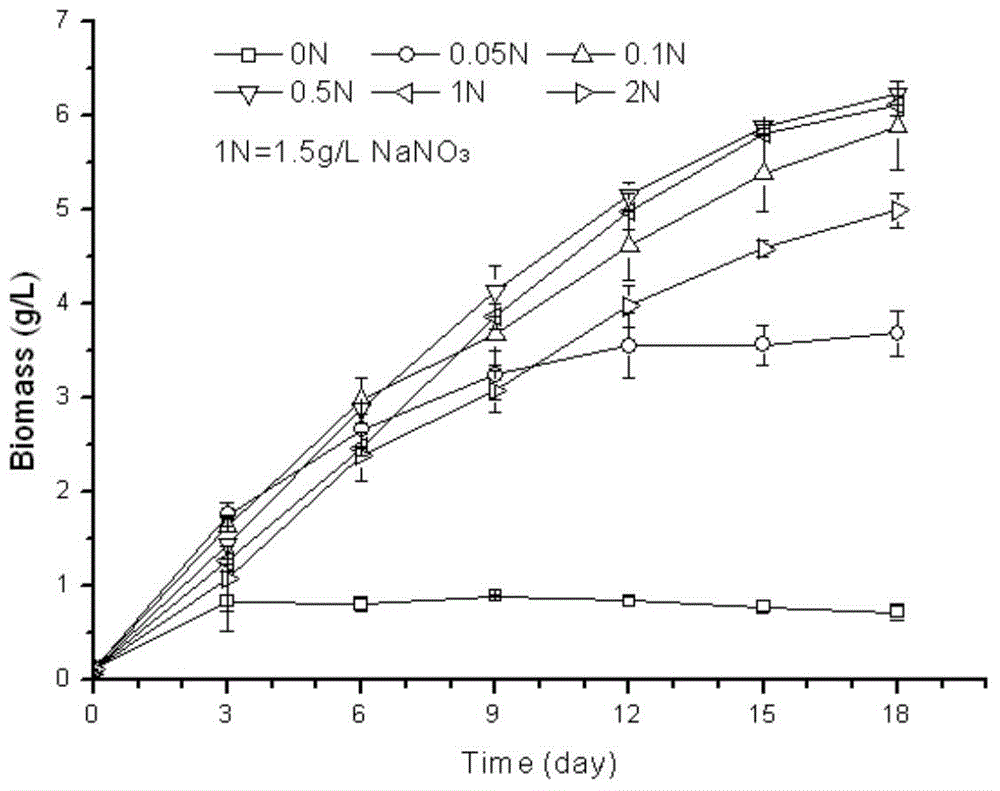

Novel-type tribonema and cultivation and application thereof

The invention discloses a Tribonema sp. PD2 strain with a preservation number of CGMCC No.10488, and application thereof in the production of biodiesel, palmitoleic acid, feed, food, skin care products, and therapeutic drugs for cardiovascular and cerebrovascular diseases, and in the carbon dioxide emission reduction, and waste gas treatment and / or wastewater treatment. The Tribonema sp. PD2 strain has the advantages of fast growth, high biomass and easiness in harvesting, and is suitable for industrial application. The oil content of the Tribonema sp. PD2 strain is as much as 60% or more of the dry biomass, wherein the content of C16-C18 is as much as 85% of the total fatty acids, the content of the palmitoleic acid (C16:1omega7) is no less than 45% of the total fatty acids, and the content of the total unsaturated fatty acids is as much as 65% of the total fatty acids. Therefore the Tribonema sp. PD2 strain is especially suitable for the production of biodiesel and the development of health care products and foods.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

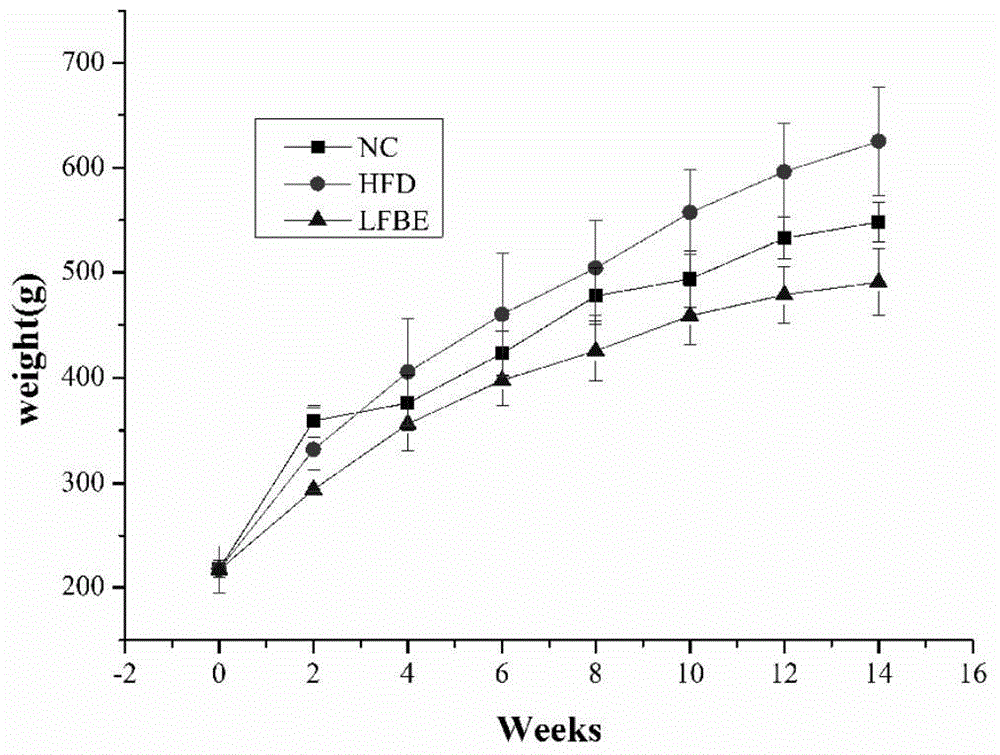

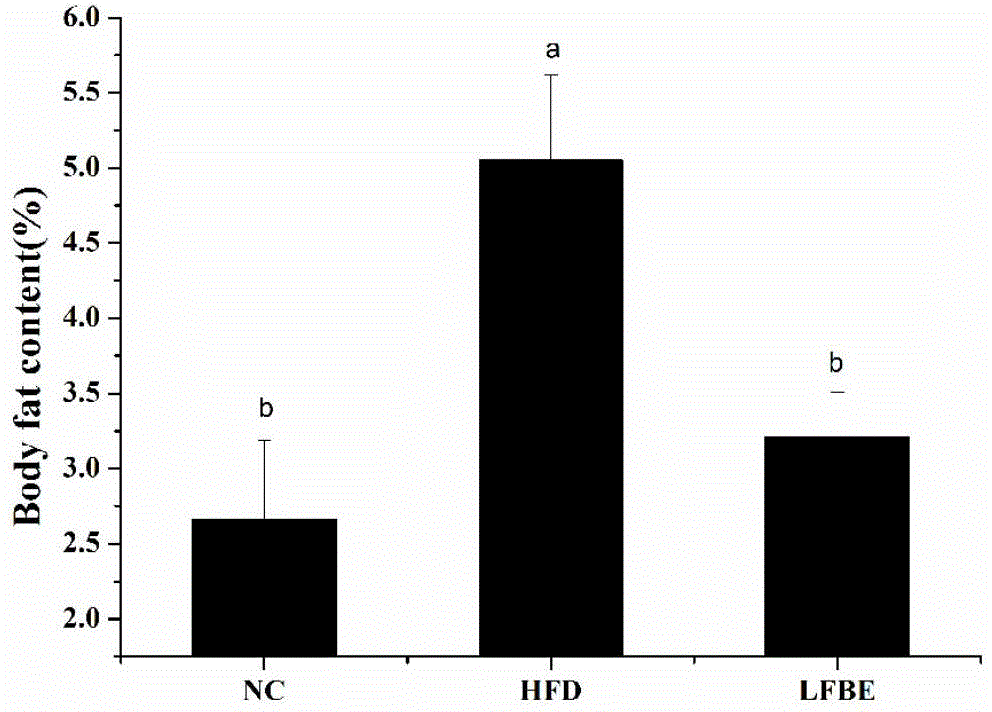

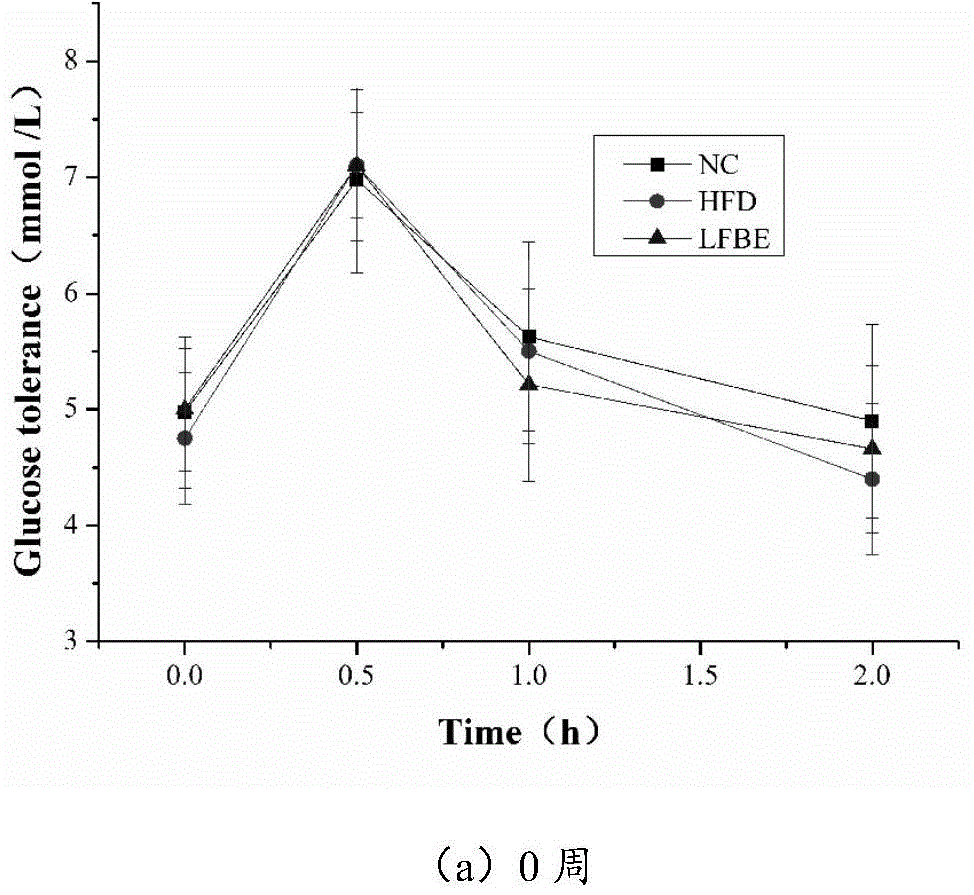

Lactobacillus-fermented barley extract as well as preparation method and application thereof

InactiveCN104621566AHigh protein contentIncreased beta-glucan contentFood preparationFood materialPolyphenol

The invention provides lactobacillus-fermented barley extract as well as a preparation method and an application thereof, and belongs to the field of the biological technology of foods. According to the invention, through fermentation of barley with lactobacillus, biotransformation of nutrient substances is realized, and the lactobacillus-fermented barley extract is prepared. The lactobacillus-fermented barley extract can be used as a food or a food material for suppressing obesity and improving the insulin-resistance function. The lactobacillus-fermented barley extract disclosed by the invention has protein content, beta-glucan content and polyphenol content which are obviously higher than those of unfermented barley extract, and has the effects of maintaining the body weight and reducing body-fat generation.

Owner:JIANGSU UNIV

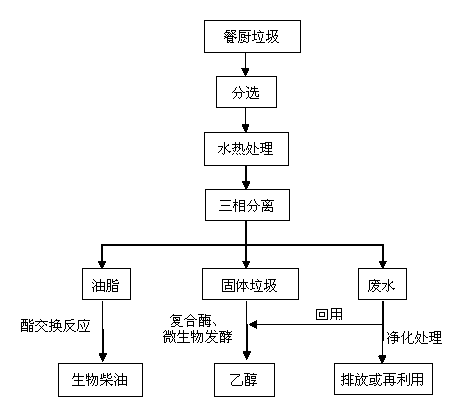

Method for improving alcohol output of kitchen waste by hydrothermal pretreatment

ActiveCN103695526AIncrease productionSimple configurationEnergy inputMicroorganism based processesChemistryHeat processing

The invention discloses a method for improving alcohol output of kitchen waste by hydrothermal pretreatment, wherein kitchen waste is used as raw material for producing energy, so that biomass recycling is realized while waste material is fully used. The method comprises the following steps: performing sorting, hydrothermal treatment and three-phase separation on the kitchen waste, and then, adding complex enzyme and mixed flora into the separated solid waste to perform fermentation so as to generate alcohol; reusing the wastewater obtained by three-phase separation for a fermentation tank, purifying and discharging or reusing the kitchen wastewater which is not reused; preparing biodiesel from the oil obtained by three-phase separation through ester exchange reaction. In the method for improving alcohol output of kitchen waste by hydrothermal pretreatment, by virtue of the hydrothermal treatment technology, the kitchen waste is hydrolyzed more completely, and by simultaneous feeding of the complex enzyme and mixed flora, high-efficiency production of alcohol from fermented kitchen waste can be realized. Strains selected for the method are simple and easy to obtain, the disposition method is simple, the fermentation technology is simple and convenient, and the fermentation effect is excellent, so that the method for improving alcohol output of kitchen waste by hydrothermal pretreatment is especially suitable for industrialized application.

Owner:SOUTH CHINA AGRI UNIV

Preparation method of ultrathin, large-size, high-silicon silicon steel sheet by electron beam physical vapor deposition

InactiveCN1804109AUniform compositionIncrease deposition rateVacuum evaporation coatingSputtering coatingSilicon siliconMetallurgy

The preparation method for ultrathin lager-size high-silicon electron-beam PVD silicon steel sheet comprises: in vacuum, bombarding with electron beam as heat source to melt the silicon steel sheet material into vapor state; then, depositing the sheet on substrate to obtain the high-silicon silicon sheet plate; finally, uncovering the plate. This invention overcomes the defect in prior art, controls evaporating speed of different material to adjust the product intergradient and thickness, has high efficiency, and special fit to industrialization.

Owner:HARBIN INST OF TECH

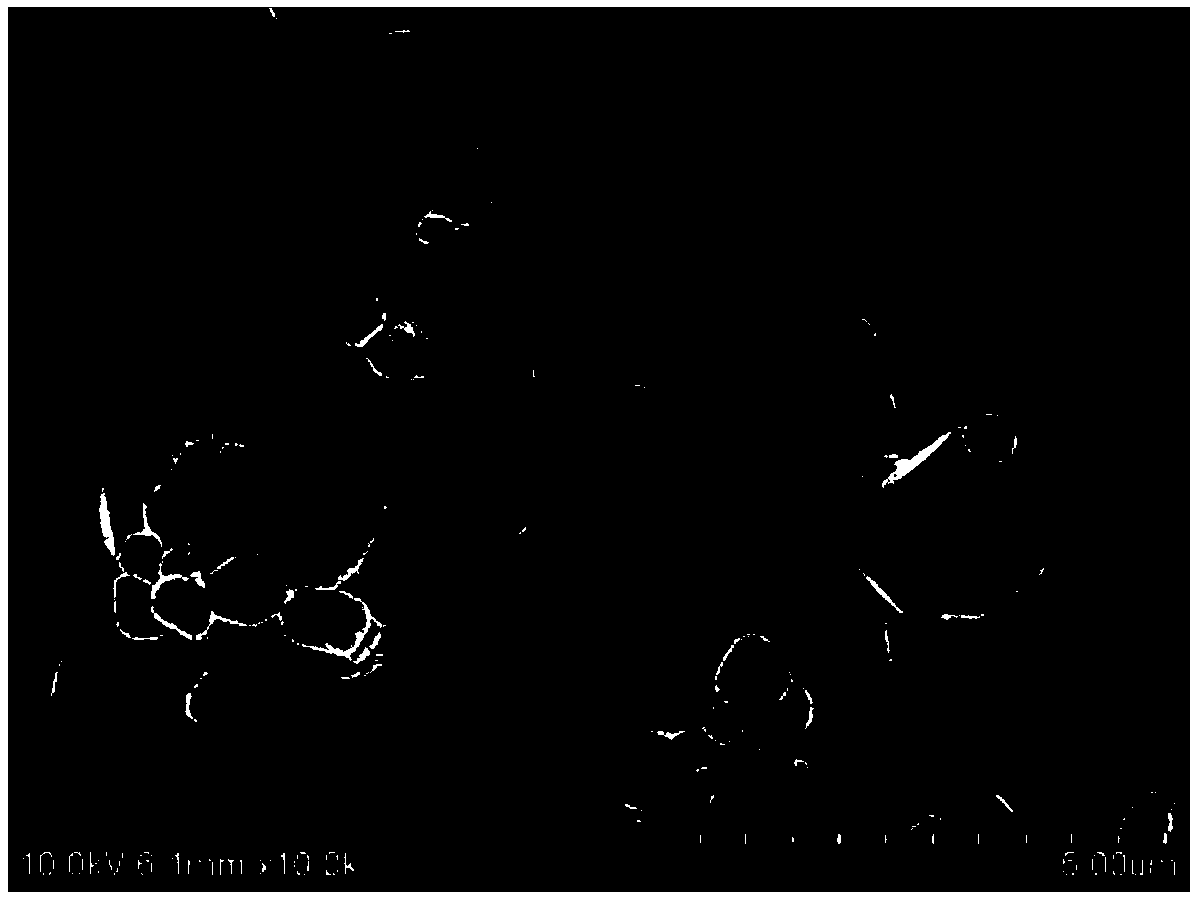

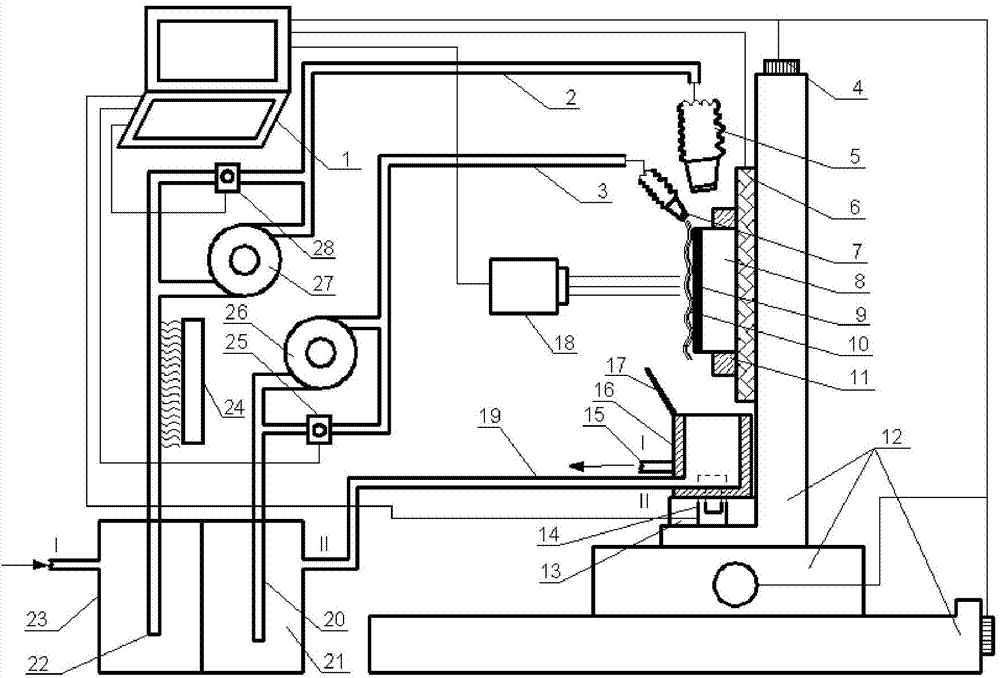

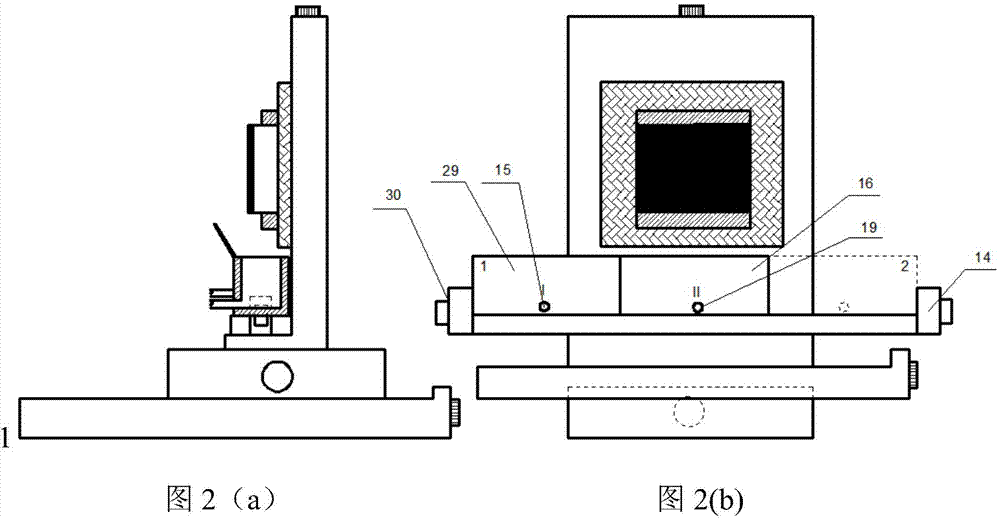

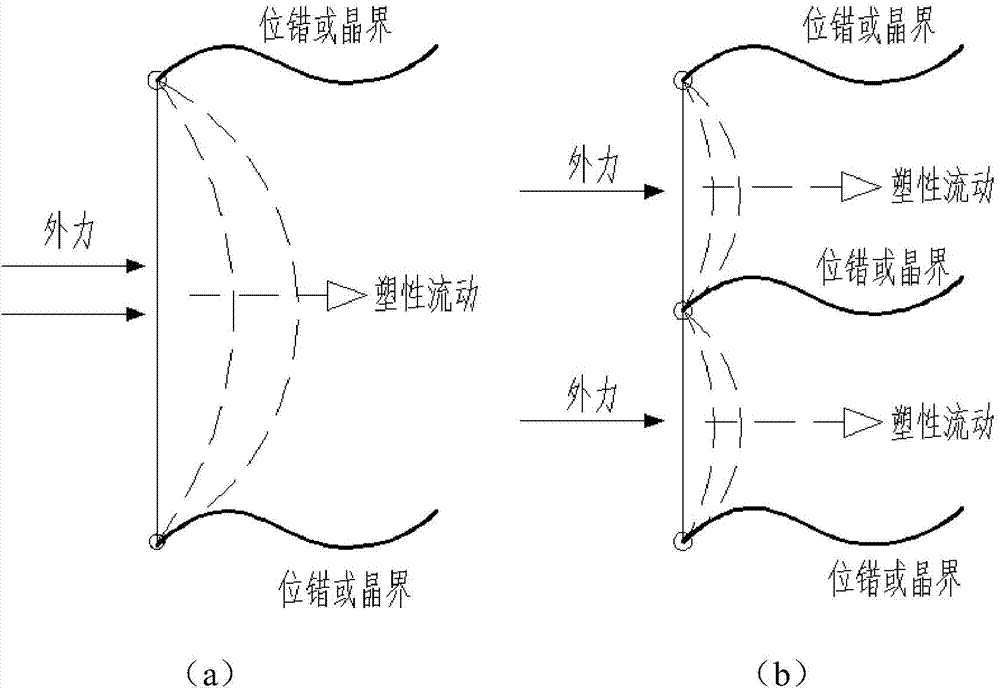

Method and device capable of remarkably improving shock resistance of aviation aluminium alloy material

The invention discloses a method and a device capable of remarkably improving the shock resistance of an aviation aluminium alloy material. The device comprises a laser device, a clamp, a heating platform, a moving platform, a refrigeration loop, a restraint system and a computer system. The method disclosed by the invention comprises the following steps of: obtaining high-density dislocation and dislocation tangle on the surface of the material on the basis of dynamic strain aging and by virtue of warm laser shot blasting, and generating an obvious grain refinement organization simultaneously; and after the shot blasting is finished, sharply cooling a workpiece in aqueous solution at 5-8 DEG C, reducing dislocation annihilation and a grain growth process, and finally obtaining a microstructure with coexisting high-density dislocation and ultra-fine grains at a room temperature, thus increasing the damping of the material and improving the shock resistance of the material. The method and the device disclosed by the invention are capable of greatly improving the shock resistance of the material, simple in process and low in cost.

Owner:JIANGSU UNIV

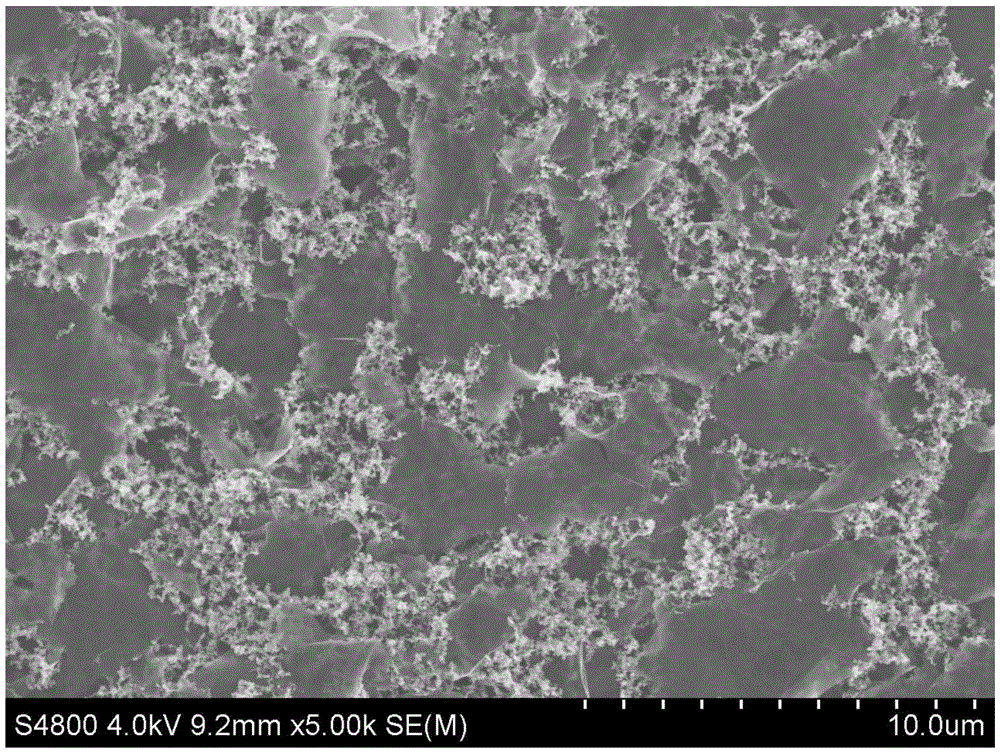

Graphene-titanium black composite conductive agent and preparation method thereof

ActiveCN107393622AGood dispersionIncrease profitOxide conductorsCarbon-silicon compound conductorsPolyolGraphite

The invention relates to a graphene-titanium black composite conductive agent. The graphene-titanium black composite conductive agent comprises a graphene material and a modified titanium black material, wherein the modified titanium black material is obtained by modifying titanium black material through polymer alcohol or polyhydric alcohols; the surface of the modified titanium black material is provided with hydroxyl groups; and the graphene material is tightly combined with the modified titanium black material through the hydroxyl groups in the surface of the modified titanium black material. The invention also provides a preparation method of the graphene-titanium black composite conductive agent.

Owner:NINGBO MORSH TECH

Preparation method of instant silverfish protein powder

InactiveCN106234752AIncrease added valueIncrease contentProtein composition from fishCentrifugationAdditional values

The invention relates to a preparation method of instant silverfish protein powder. Silverfishes are taken as a raw material, and processes of raw material pretreatment, smashing, enzymolysis, enzyme deactivation, centrifugation, fishy smell elimination, concentration and spray drying are carried out, so that the instant silverfish protein powder is prepared, wherein silverfish protein hydrolysis degree reaches 49.10%, silverfish protein recovery rate reaches 98.00%, the product is milky white in colour and luster and convenient to carry, has no fishlike smell, is long in storage period, easily soluble and easily dispersed and is a functional fish protein powder product, and health food is provided for human while additional value of silverfishes is improved. Technology is relatively simple, and enzymolysis time is short, so that the preparation method of the instant silverfish protein powder is applicable to industrial application. The preparation method of the instant silverfish protein powder has positive influence on further developing the silverfishes and expanding types of highly processed products of the silverfishes.

Owner:CHAOHU UNIV

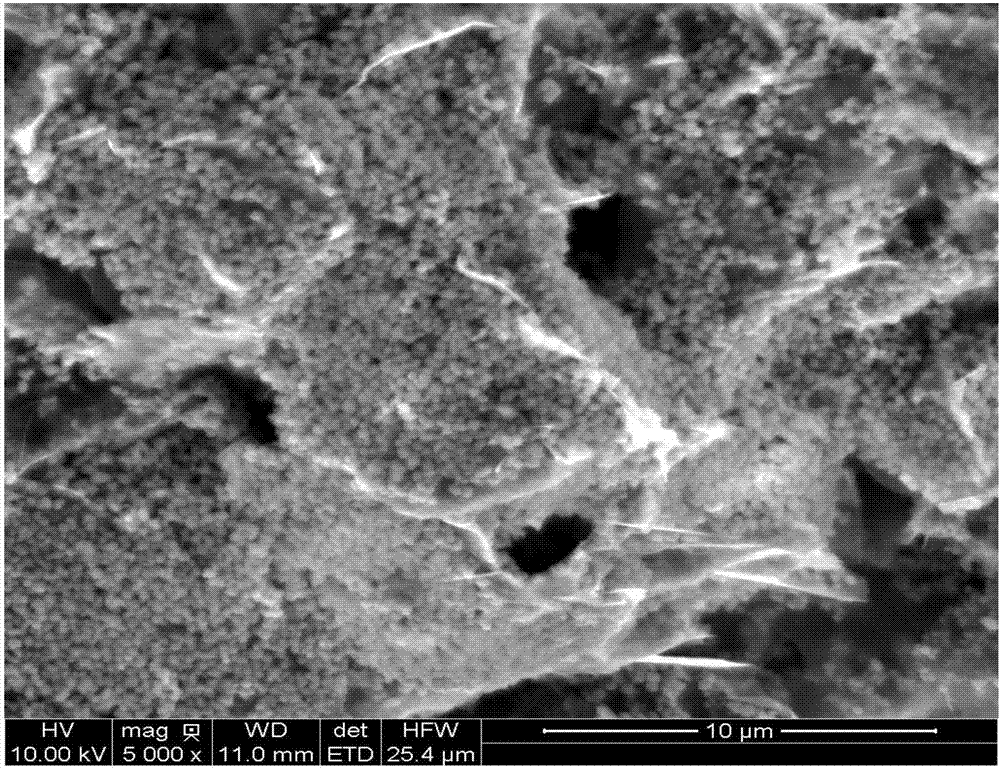

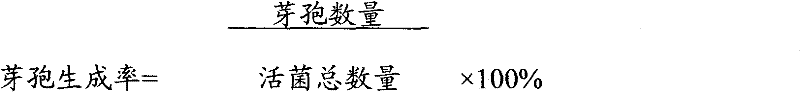

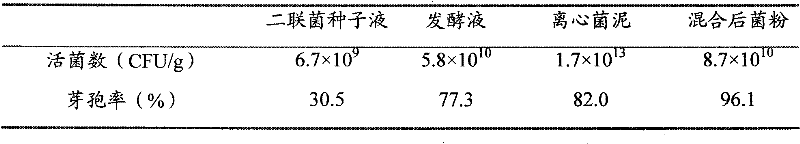

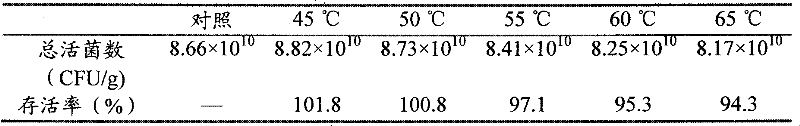

Composite microbial additive for feed and preparation method of composite microbial additive

InactiveCN102524534AHeat resistantExtended shelf lifeBacteriaMicroorganism based processesDiseaseCooking & baking

The invention discloses a composite microbial additive for feed, in particular to a microbial feed additive containing two kinds of bacilli and a preparation method of the microbial feed additive, and belongs to the technical field of microbial feed additives. According to the microbial feed additive, bacillus subtilis and bacillus licheniformis are mixed according to a certain proportion for fermentation culture, and after bacterium mud obtained through fermentation liquid centrifugation is treated, the low-temperature baking is carried out to obtain powder agents. The microbial feed additive prepared by the method has the advantages that the viable bacterium content is high, the heat resistance and the animal intestine and stomach environment resistance are realized, the storage period of the product is long, the effects of balancing the animal intestinal tract flora and improving the immunity and the disease resistance can be realized after the microbial feed additive is added into animal feed, the weight gain is promoted, the feed conversion rate is improved, the material-weight ratio is reduced, and the microbial feed additive has various effects of treatment, prevention, health care and immunity enhancement.

Owner:HARBIN YINGRUISI FEED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com