Sodium-ion battery anode material as well as preparation method and application thereof

A cathode material and sodium element technology, which is applied in the field of cathode materials for sodium ion batteries and their preparation, can solve problems such as the application of difficult solid-state sodium ion batteries, and achieve the effects of complete crystallization and fewer structural defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a kind of preparation method of cathode material, and its specific method is:

[0063] (1) Under stirring conditions at 25°C and a speed of 500rpm, both solution A and solution B are added dropwise to water at a rate of 0.5mL / min, and the suspension is obtained after the addition is complete; the solution A is decahydrate Sodium ferrocyanide and sodium chloride are dissolved in water to form a mixed solution, and the solution B is a mixed solution formed by dissolving cobalt chloride and complexing agent sodium citrate in water;

[0064] (2) centrifuging the suspension described in step (1), taking the solid, and drying the obtained solid in a vacuum drying oven at 100° C. and a vacuum of 10 mTorr for 48 hours to obtain the positive electrode material;

[0065] Wherein, in the suspension described in step (1), the mass concentration of sodium chloride is 1wt%, and in solution A, the concentration of sodium ferrocyanide is 0.02mol / L; in solution ...

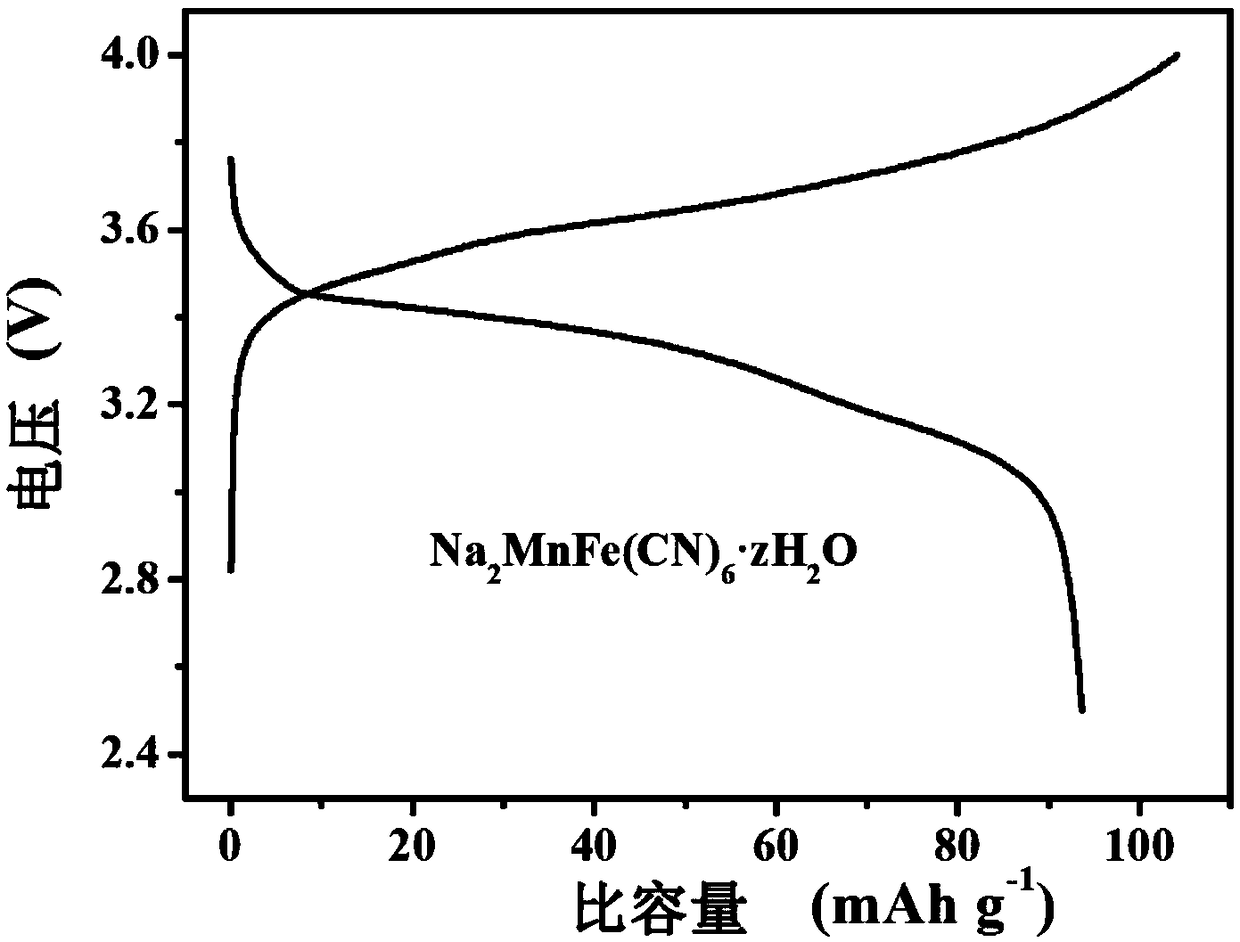

Embodiment 2

[0070] This embodiment provides a kind of preparation method of cathode material, and its specific method is:

[0071] (1) Under the stirring conditions of 50°C and a speed rate of 300rpm, both solution A and solution B were added dropwise to water at a rate of 0.1mL / min. After the addition was complete, the obtained suspension was placed in a hydrothermal kettle The hydrothermal reaction was carried out at 175°C for 20 hours to obtain a suspension after the hydrothermal reaction; the solution A was sodium ferrocyanide decahydrate and sodium chloride dissolved in water to form a mixed solution, and the solution B was manganese chloride and Complexing agent EDTA is dissolved in the mixed solution that forms in water;

[0072] (2) Centrifuge the suspension after the hydrothermal reaction described in step (1), take the solid, and dry the obtained solid in a vacuum drying oven at 110°C and a vacuum of 12.5mTorr for 36h to obtain the described Cathode material;

[0073] Wherein,...

Embodiment 3

[0082] This embodiment provides a kind of preparation method of cathode material, and its specific method is:

[0083] (1) Under the condition of stirring at 70°C and a rate of 1000rpm, both solution A and solution B were added dropwise to water at a rate of 1.0mL / min. After the addition was complete, the obtained suspension was placed in a hydrothermal kettle Hydrothermal reaction at 200°C for 15 hours to obtain a suspension after the hydrothermal reaction; the solution A is sodium ferrocyanide decahydrate and sodium chloride dissolved in water to form a mixed solution, and the solution B is nickel sulfate and complex A mixed solution formed by dissolving acetic acid in water;

[0084] (2) Centrifuge the suspension after the hydrothermal reaction described in step (1), take the solid, and dry the obtained solid in a vacuum oven at 120° C. and a vacuum of 15 mTorr for 24 hours to obtain the positive electrode Material;

[0085] Wherein, in the suspension described in step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com