Method for synthesizing biodiesel by two-step catalysis of lipid via Yarrowia lipolytica lipase, and biodiesel obtained thereby

A biodiesel and yeast technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of increasing the risk of industrialized production, increasing the intensity of equipment investment, and affecting production efficiency, and achieving increased industrialization feasibility. performance, improved production efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

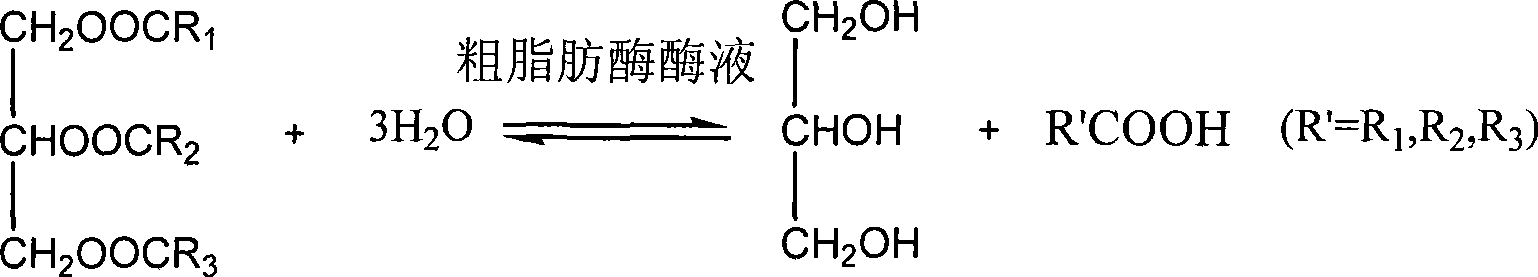

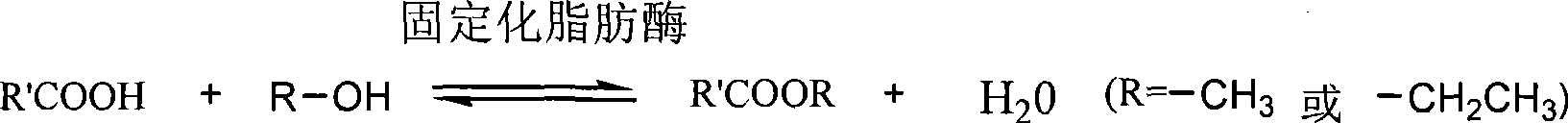

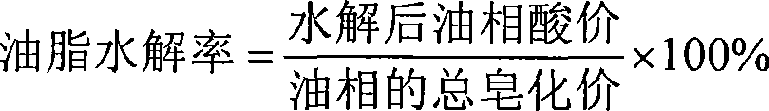

Method used

Image

Examples

Embodiment 1

[0060] Preparation of crude lipase enzyme solution: Yarrowia lipplytica CGMCCNO.2707 was cultured on the slope of eggplant bottle for 12 hours and then inoculated in a fermenter for cultivation. After 90 hours of cultivation, the hydrolase activity was measured to reach 8500u / ml Lower the tank, collect the fermentation broth after the lower tank, use the model SSP450 centrifuge produced by Zhangjiagang Xinhua Chemical Machinery Co., Ltd. to centrifuge at 1900 rpm, and take out the solids and bacterial cells in the fermentation broth to obtain the crude Lipase enzyme solution.

[0061] Preparation of immobilized lipase: based on the total weight of lipase fermentation broth, first mix 2‰ polyvinyl alcohol, 1‰ Tween 80, 2‰ PVP and 1‰ MgSO 4 The immobilized auxiliary agent is added to the lipase fermentation broth and mixed evenly. Mix silk (about 1:1.5, the ratio of the weight of the carrier to the crude lipase enzyme solution) with the crude lipase enzyme solution, so that the amou...

Embodiment 2

[0065] The same as in Example 1, except that 20g of commercially available soybean oil was added to a 100ml ground-mouthed conical flask with a stopper, and then 12ml (enzyme activity 480U / ml) of Candida rugosa 14830 lipase fermentation broth was added. The reaction is carried out by rpm incubation and shaking. The method for preparing fatty acids in Example 1 is used to obtain the crude fatty acids used for the esterification reaction.

[0066] Take 1.39g of the above fatty acid, add 291ul of ethanol, add 0.14g of the immobilized lipase in Example 1, and react with shaking at 30°C and 190 rpm for 8 hours. The final fatty acid ethyl ester conversion rate is measured by the acid value analysis method. Up to 81%.

Embodiment 3

[0068] The same as in Example 1, except that 20g of soybean acidified oil purchased from Qinhuangdao Jinhai Cereals, Oils and Foodstuffs Co., Ltd. was added into a 100ml ground-mouthed conical flask, and then 0.4ml (enzyme activity 5000U / ml) lipolytic Yarrow was added. Yeast strain CGMCC NO.2707 crude lipase enzyme solution, and then adopt the method of preparing fatty acid in Example 1 at 40°C, and react with 130 rpm incubation and shaking to obtain crude fatty acid used for esterification reaction.

[0069] Take 1.40g of the fatty acid described in Example 1, add 202ul of methanol, add 0.14g of the immobilized enzyme described in Example 1, and shake the reaction at 30°C and 190 rpm for 8 hours, using the detection method in Example 1. The final fatty acid methyl ester conversion rate reached 82%.

[0070] The obtained certain amount of fatty acid methyl esters are subjected to vacuum distillation under a vacuum degree of 95KPa, and the fractions at 190-210°C are collected as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com