Method for manufacturing back contact type crystalline silicon solar cell component

A technology for solar cells and a manufacturing method, which is applied to electrical components, semiconductor devices, circuits, etc., can solve the problems of complicated operations, non-conductive circuits, exposed solder tapes on the front of components, etc., and achieves simple and convenient operation, beautifying appearance, reducing The effect of breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

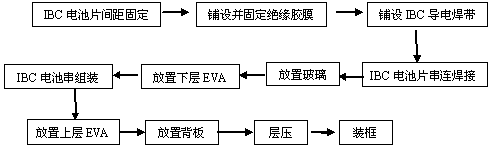

[0029] A method for manufacturing a back-contact crystalline silicon solar cell module described in this embodiment includes the following steps:

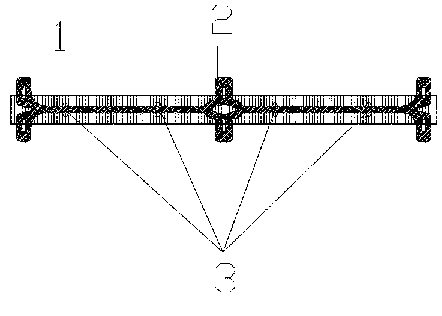

[0030] (1) Pre-bonding the conductive soldering strip 2 and the insulating film 1;

[0031] (2) Fix the back-contact crystalline silicon solar cells at a certain distance through the template, and arrange the polarity of the cells in the same direction, and place the conductive ribbon 2 pre-bonded with the insulating film 1 in the center of the two cells The edge of the sheet is aligned with the positive and negative electrodes 4 and 5 of the battery sheet for welding, and welded into a battery string;

[0032] (3) Place the glass, place the lower layer of EVA, assemble the battery string, place the upper layer of EVA, place the backplane, laminate and frame.

[0033] The steps of pre-bonding the conductive soldering strip 2 and the insulating adhesive film 1 in step (1) are as follows:

[0034] (1) Clean the surface of the condu...

Embodiment 2

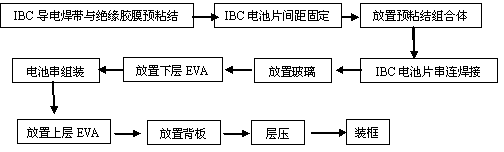

[0042] A method for manufacturing a back-contact crystalline silicon solar cell module described in this embodiment includes the following steps:

[0043] (1), such as image 3 , pre-bonding the conductive soldering strip 2 with the insulating adhesive film 1;

[0044] (2), such as Figure 4 , the back-contact crystalline silicon solar cells are fixed at a certain distance through the template, the polarity of the cells is arranged in the same direction, and the conductive soldering tape 2 pre-bonded with the insulating film 1 is placed in the center on the edge of the two cells Align the positive and negative electrodes 4 and 5 of the battery sheet for welding to form a battery string;

[0045] (3) Place the glass, place the lower layer of EVA, assemble the battery string, place the upper layer of EVA, place the backplane, laminate and frame according to the routine.

[0046] The steps of pre-bonding the conductive soldering strip 2 and the insulating adhesive film 1 in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com