Microfluidic technology for one-step continuous preparation of calcium alginate microgel

A microfluidic technology, calcium alginate technology, is applied in the field of preparing microgels embedded with living cells or bioactive molecular drugs, which can solve the problems of cytotoxicity, decreased survival rate, and lack of injectability. Achieve good biocompatibility and maintain biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

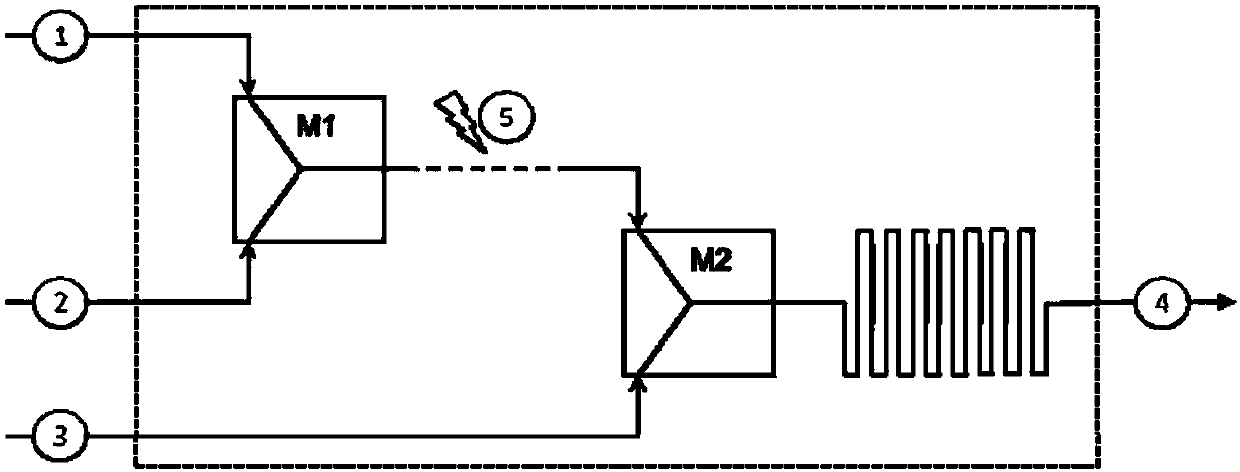

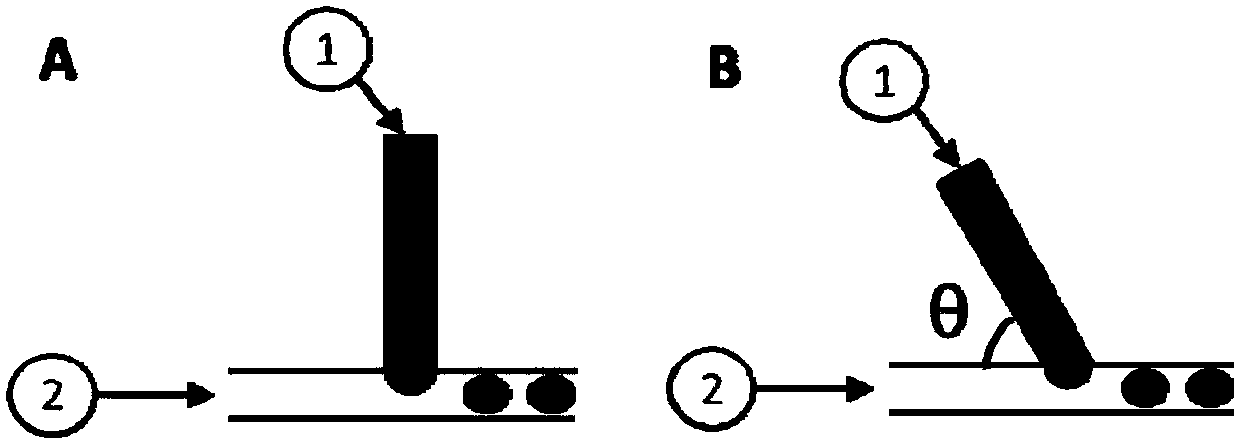

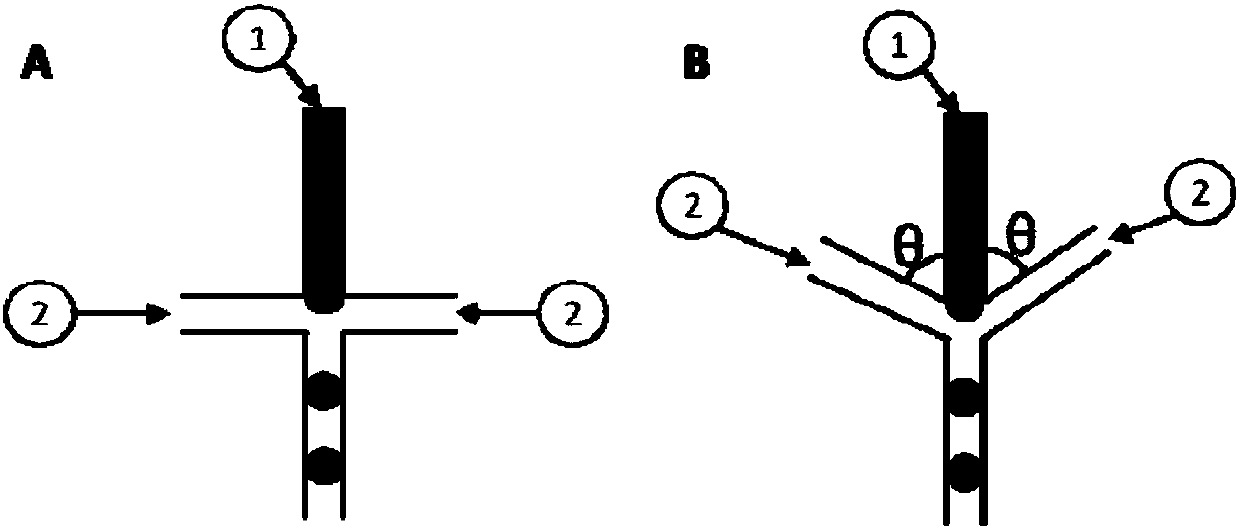

[0081] Such as figure 1 As shown, a microfluidic device includes ① first input channel, ② second input channel, ③ third input channel, ④ output channel, ⑤ hydrogel prepolymer cross-linking channel, M1 is water and oil In the blending region, the unblended two-phase pass has a "T"-shaped structure (such as figure 2 shown) or a fluid-focusing structure (such as image 3 shown) microfluidic channel. M2 is the microfluidic channel where the upstream prepared emulsion is blended with the second heavy oil phase. The surface of the inner wall of the microchannel is treated with hydrophobicity.

[0082] Dissolve sodium alginate and fluorescein-labeled dextran (molecular weight: 10kDa) in deionized water to prepare an aqueous solution with a sodium alginate content of 1w / v% and a fluorescein-labeled dextran content of 0.01w / v% , and then add an aqueous chelate solution with a final concentration of 100 mM calcium ion-nitrilotriacetic acid (Ca-NTA); use the aqueous solution configu...

Embodiment 2

[0095] Example 2 for size control

[0096] Dissolve sodium alginate in deionized water to obtain an aqueous solution with a sodium alginate content of 2w / v%, and dissolve calcium-nitrilotriacetic acid (Ca-NTA) in deionized water to obtain an aqueous solution with a concentration of 100 mM; two of the above two solutions An aqueous solution was obtained by blending configuration, wherein the final solution concentration of sodium alginate was 1w / v%, and the concentration of Ca-NTA was 80mM, and this aqueous solution was used as the internal phase aqueous solution of the water-in-oil emulsion. The mixed solution obtained by blending the fluorinated surfactant of perfluorobutyl-methyl ether, perfluoroether-polyvinyl alcohol-perfluoroether (Krytox-PEG-Krytox) block copolymer, and acetic acid with its As the first heavy oil phase of water-in-oil emulsion system. The surfactant concentration in the above oil phase is 1v / v%, and the concentration of acetic acid is 0.1v / v%. Finally,...

Embodiment 3

[0098] Embodiment 3 live cell embedding

[0099] Cell culture: with NIH3T3 ( CRL-1658 TM ) fibroblast culture as an example, the proliferation medium is composed of DMEM containing 10% fetal bovine serum (FBS, Gibco). Culture conditions are 37 °C, 95% relative humidity and 5% CO 2 . Cell culture medium was changed every three days. Before use, cells were detached in phosphate-buffered saline (PBS) using trypsin / EDTA solution (0.25% trypsin / 0.02% EDTA) for 5 minutes and suspended in medium for use.

[0100] Sodium alginate labeled with green fluorescence was dissolved in cell culture medium DMEM solution, and a 2w / v% sodium alginate aqueous solution was prepared. The cell suspension, sodium alginate aqueous solution and calcium-ethylenediaminetetraacetic acid (Ca-EDTA) chelate aqueous solution are blended to obtain a sodium alginate concentration of 1w / v% in the mixed solution, and a final concentration of Ca-EDTA of 100mM , a cell concentration of 10 6pieces / ml. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com