Preparation method of lithium cathode of solid-state battery

A solid-state battery and lithium negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not being able to fully satisfy high ionic conductivity, single protective layer composition and structure, and limit the rate performance of solid-state batteries, and achieve suitable Suitable for industrial application, good mechanical properties, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. A method for preparing a solid-state battery lithium negative electrode, comprising the following steps:

[0045] (1) First prepare LiTFSI with a concentration of 1mol / L and dissolve it in DOL / DME / FEC (volume ratio 9:9:2), then add LiNO with a mass concentration of 1.0% 3 the electrolyte;

[0046] (2) Put the metal lithium negative electrode into the electrolyte of step (1), assemble Li / Li symmetrical battery, carry out electrochemical pre-cycle after the battery stands still for 12h, the parameter of electrochemical pre-cycle is: current density is 0.5mA / cm 2 ; The limit voltage range is -1 ~ 1V; the number of cycles is 1 circle.

[0047] (3) Disassemble the battery cycled in step (2) in the glove box, take out the metal lithium negative electrode, wash it carefully with an electrolyte solvent, and then place it in the glove box until the solvent evaporates completely.

[0048] 2. An all-solid-state battery, comprising the metal lithium negative electrode prepar...

Embodiment 2

[0060] 1. A method for preparing a lithium negative electrode of a solid-state battery, Example 1.

[0061] 2. An all-solid-state battery, which is the same as in Example 1, except that the solid-state electrolyte is a LAGP-PEO composite solid-state electrolyte film.

[0062] 3. Compared with the all-solid-state battery, it is the same as that in Example 1, except that the solid-state electrolyte is a LAGP-PEO composite solid-state electrolyte film.

[0063] Performance Testing:

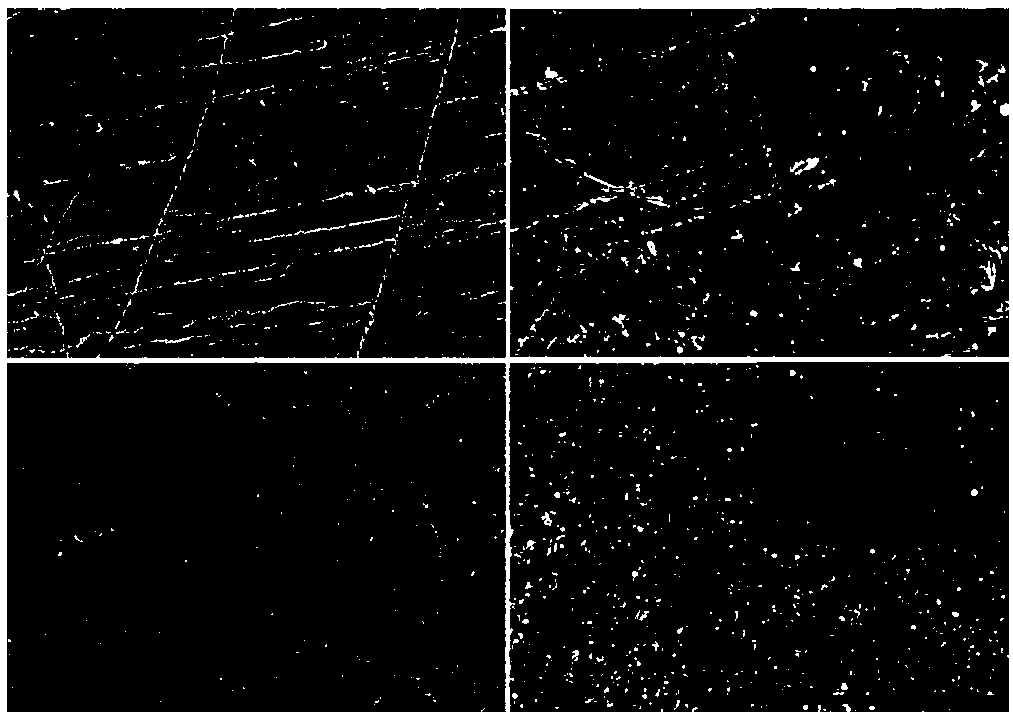

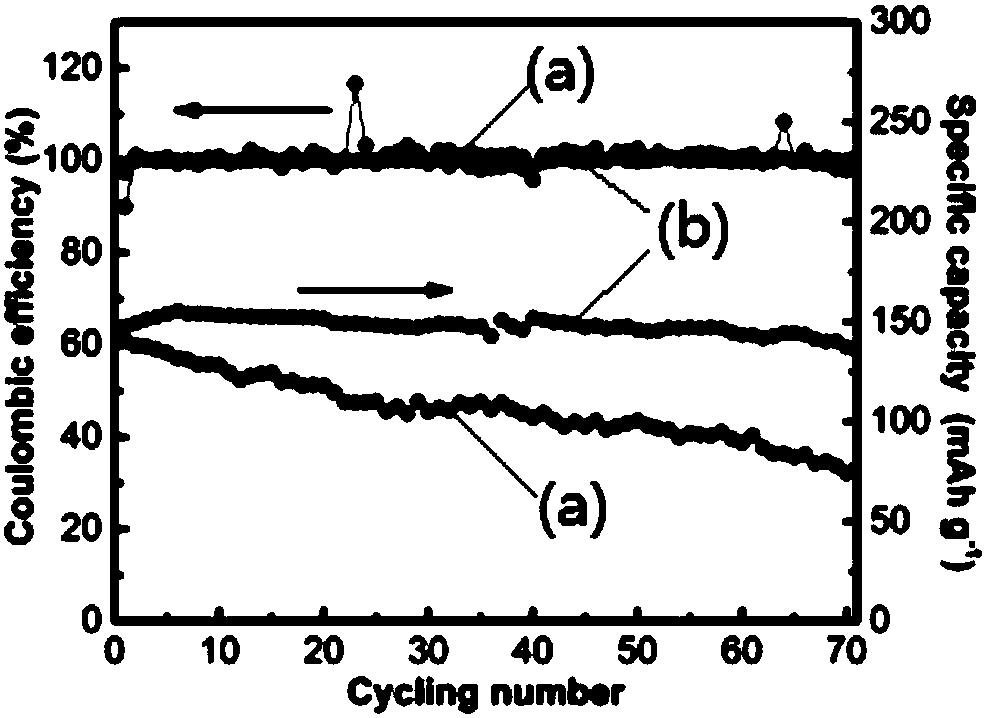

[0064] (1) The metal lithium negative electrode prepared in this example was charged at 0.1mA cm -2 The assembled Li-LAGP / PEO-LFP after electrochemical pre-cycling at current density was cycled for 160 cycles at 0.1C, and the surface morphology was observed under SEM. The results are as follows Figure 5 shown; from Figure 5 It can be seen in: Figure 5 (a) is the morphology of the untreated lithium negative electrode after cycling. It can be seen that the surface of the electrode is very uneven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com