Titanium niobic zincic acid bismuth sodium system leadless piezo-electric ceramic and preparation method thereof

A titanium-niobium-bismuth-zincate-sodium-based, lead-free piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems that the preparation method has not been reported, and achieve a Practicality, process stability, strong anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

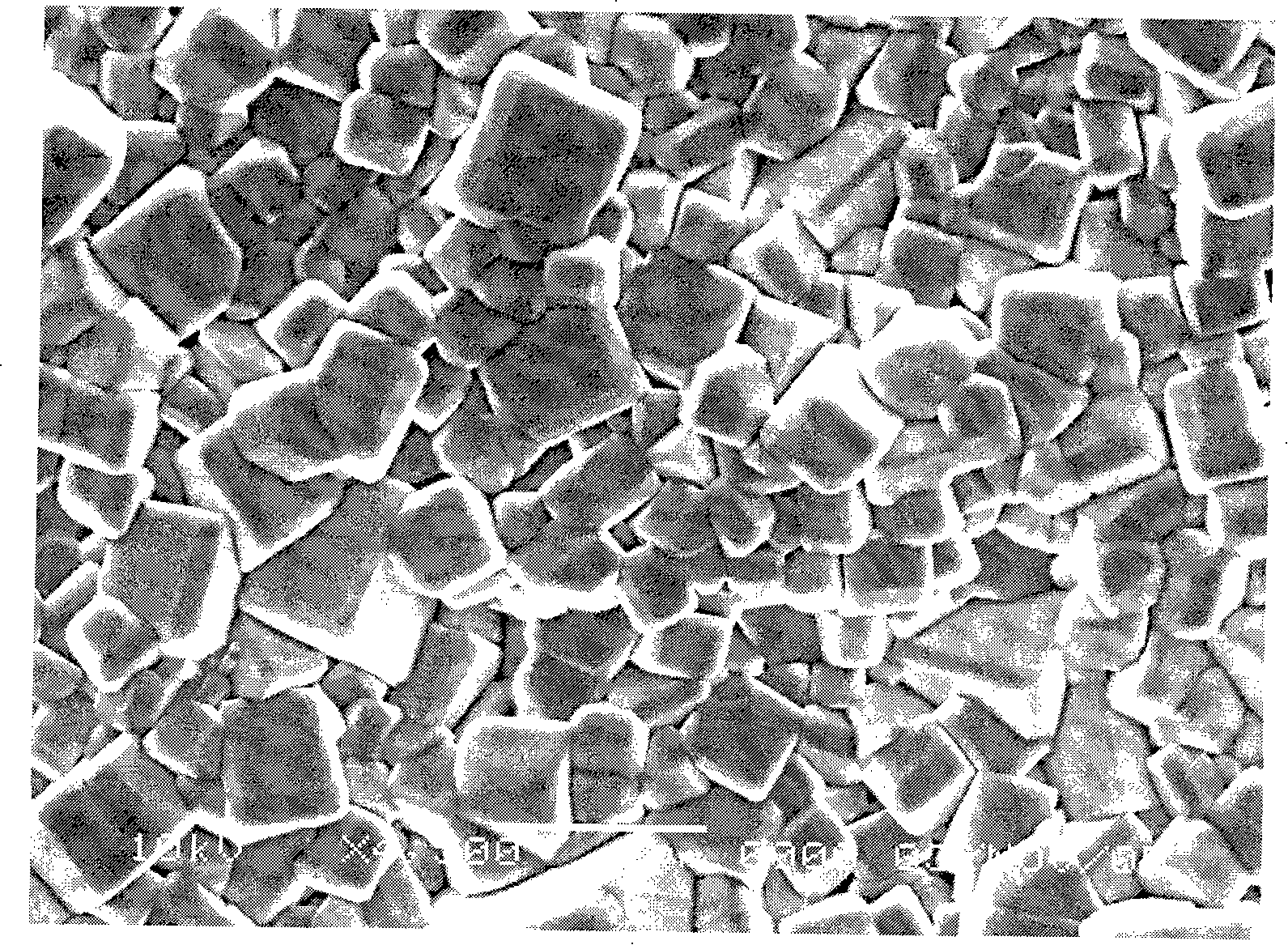

Image

Examples

Embodiment 1

[0023] With ZnO and Nb 2 o 5 As raw material, according to the chemical formula ZnNb 2 o 6 Perform batching, wet grinding with absolute ethanol as the medium, and synthesize ZnNb at 950-1100°C after drying 2 o 6 , ZnNb was obtained after grinding and sieving 2 o 6 Powder; ZnNb 2 o 6 、 Bi 2 o 3 、Na 2 CO 3 and TiO 2 As a raw material, according to the chemical formula (Na 1 / 2 Bi 1 / 2 ) Ti 1-x (Zn 1 / 3 Nb 2 / 3 ) x o 3 , x=0.01 (mole fraction), carry out batching, wet grinding with absolute ethanol as the medium, synthesize ceramic material at 950°C after drying; add binder to the porcelain material, and sinter at 1170°C for 3 hours; the ceramic material after sintering The sheet is ground to 1.00±0.02mm with sandpaper, covered with silver on both sides, and polarized in 80°C silicone oil after firing the silver. The polarization electric field is 4kv / mm, and the polarization time is 10min;

[0024] performance:

[0025] d 33 (pC / N)K t K p ε r t...

Embodiment 2

[0028] The preparation method is the same as in Example 1, but the synthesis temperature in the second step is 900°C, the sintering temperature is 1150°C, and the composition expression: (Na 1 / 2 Bi 1 / 2 ) Ti 0.98 (Zn 1 / 3 Nb 2 / 3 ) 0.02 o 3

[0029] performance:

[0030] d 33 (pC / N)K t K p ε r tanδ(%) ρ(g / m 3 )

[0031] 101 0.46 0.14 625 2.93 5.64

Embodiment 3

[0033] The preparation method is the same as in Example 1, but the second step is synthesized with ZnNb 2 o 6 、 Bi 2 o 3 、Na 2 CO 3 、BaCO 3 and TiO 2 As the raw material, the synthesis temperature of the second step is 1000°C, the sintering temperature is 1200°C, the polarization temperature is 60°C, the polarization electric field is 6kv / mm, and the polarization time is 15min;

[0034] Composition expression: (Na 1 / 2 Bi 1 / 2 ) 0.97 Ba 0.03 Ti 0.99 (Zn 1 / 3 Nb 2 / 3 ) 0.01 o 3

[0035] performance:

[0036] d 33 (pC / N) K t K p ε r tanδ(%) ρ(g / m 3 )

[0037] 128 0.45 0.15 598 3.15 5.73

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com