Patents

Literature

36results about How to "Strong anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

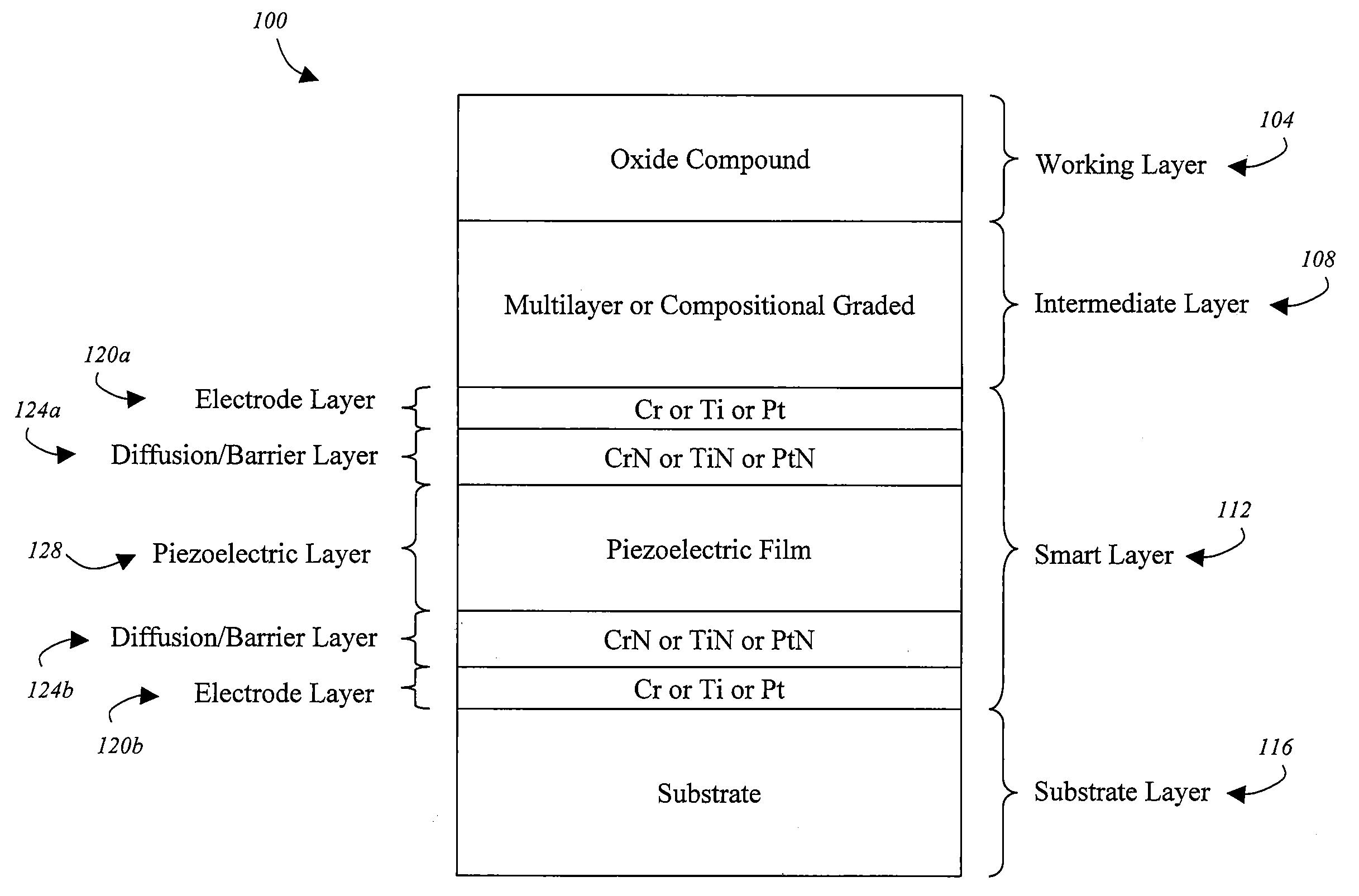

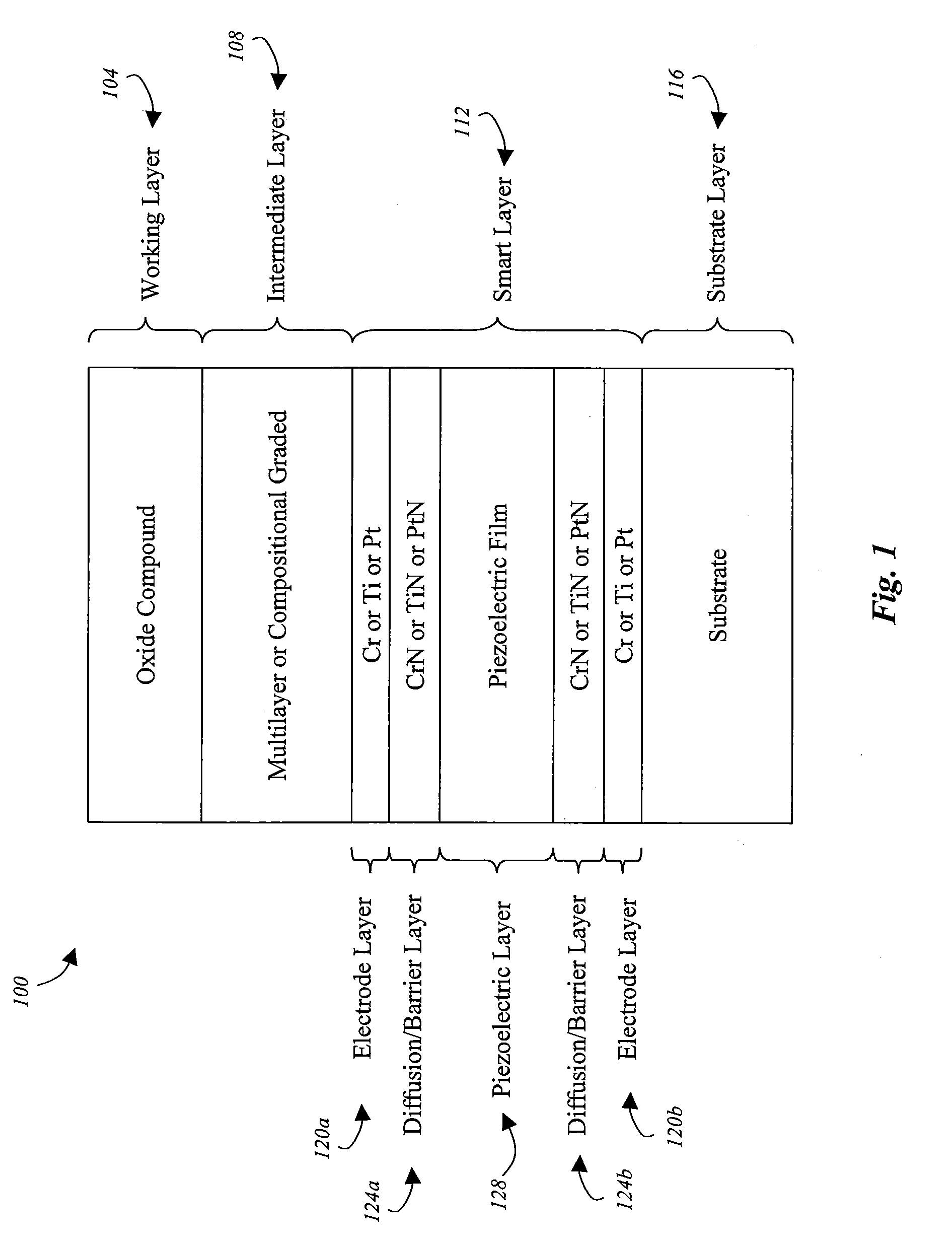

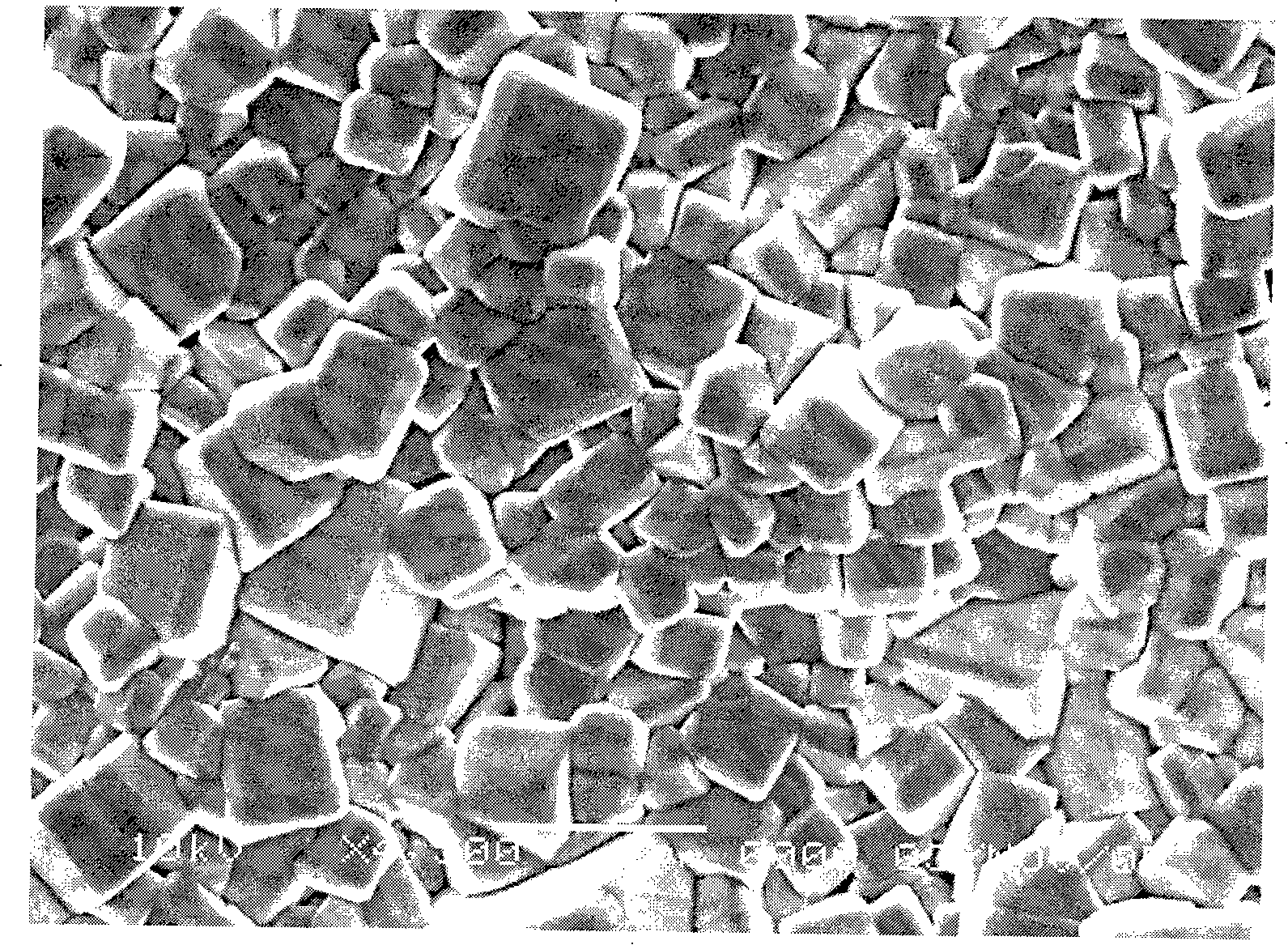

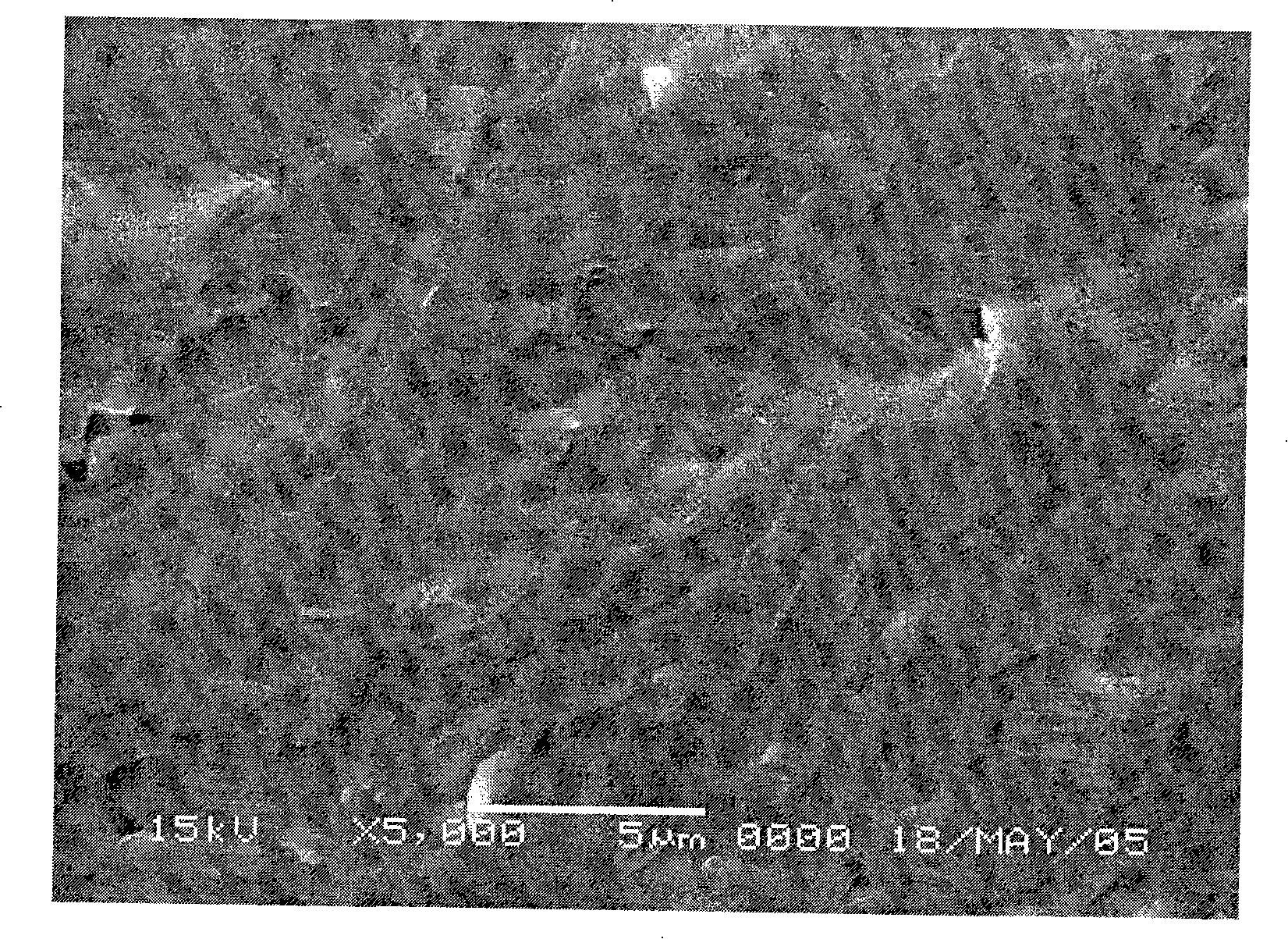

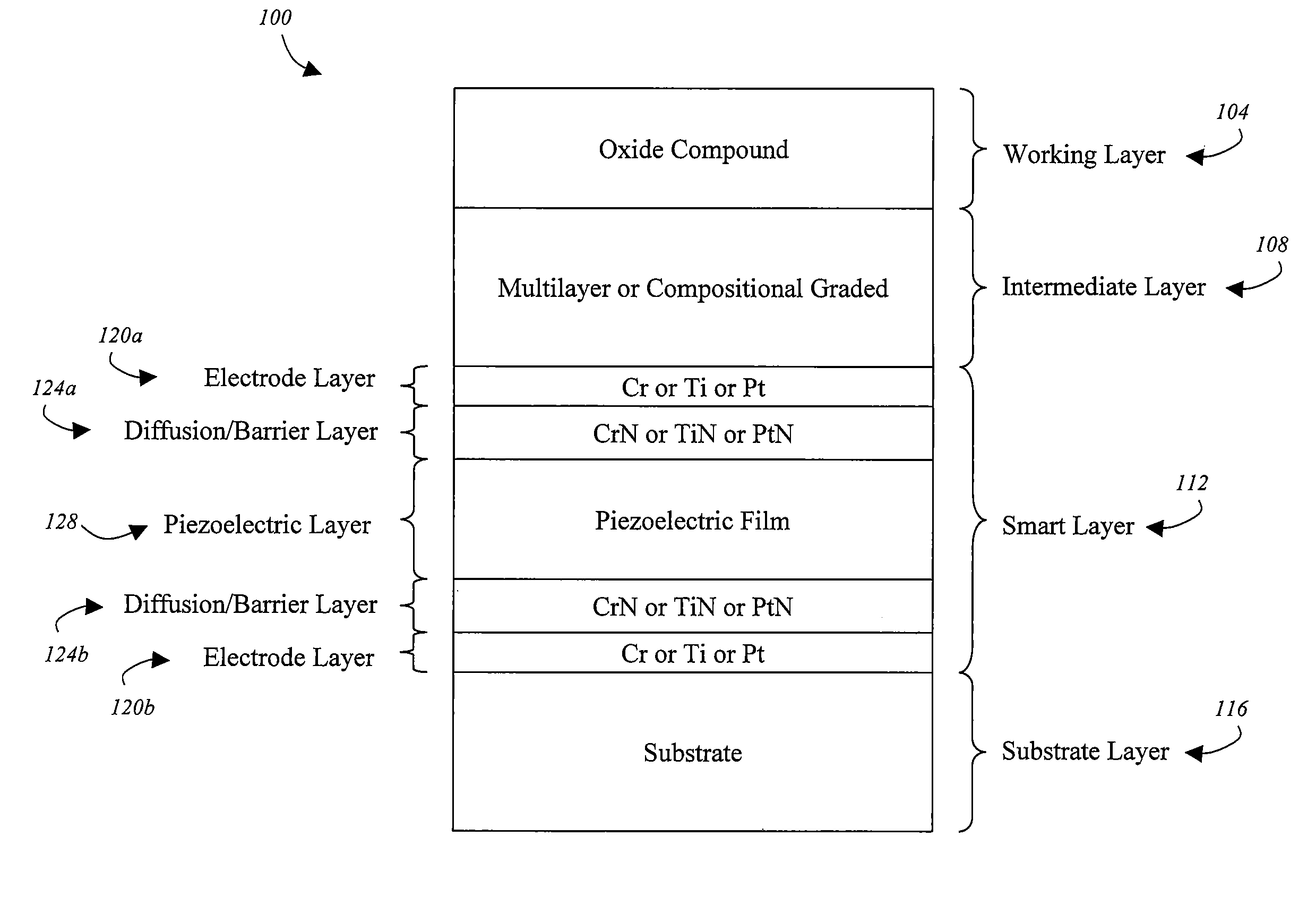

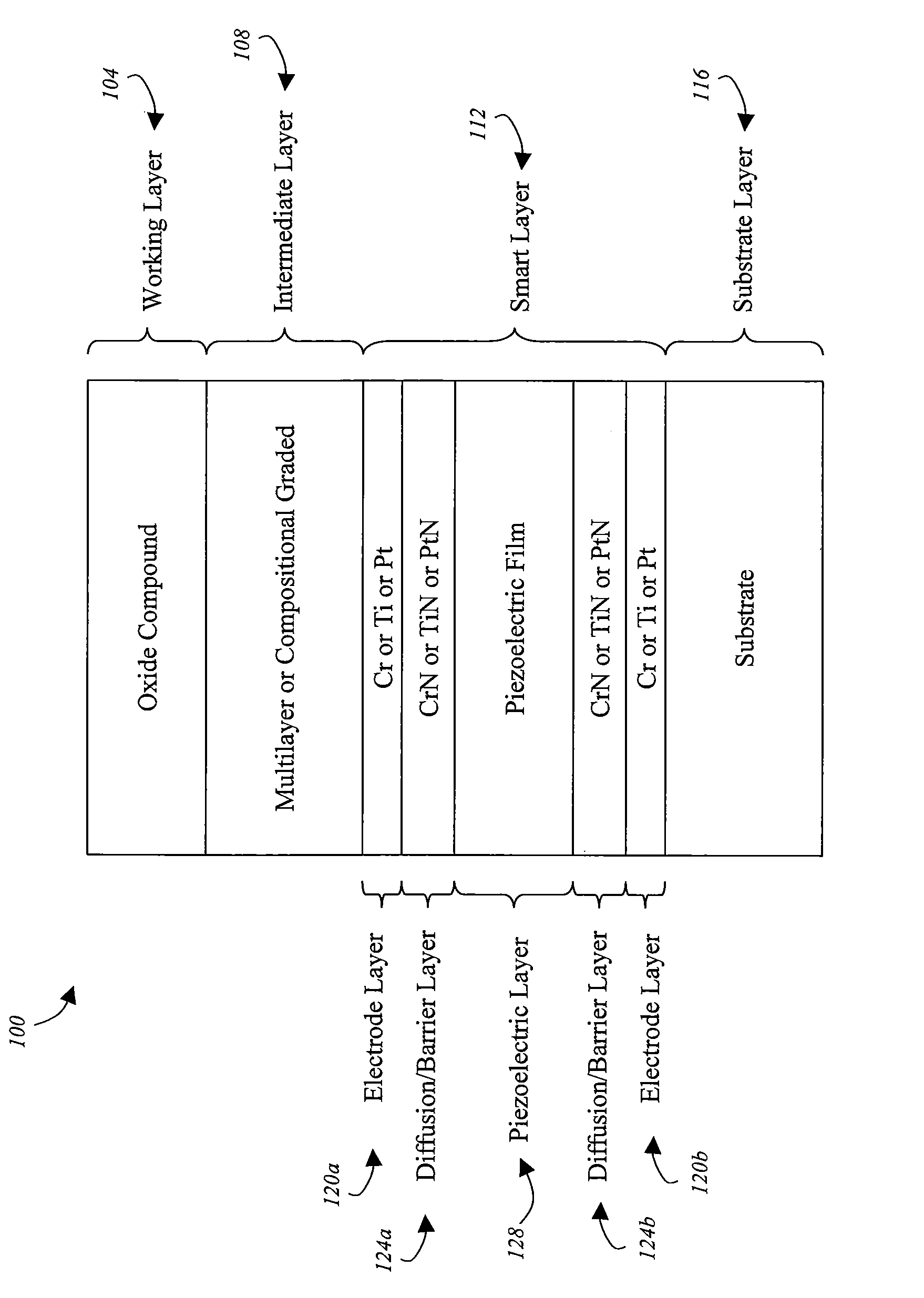

Piezoelectric sensor based smart-die structure for predicting the onset of failure during die casting operations

InactiveUS20080250863A1Strong anisotropyPiezoelectric propertyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDie castingCatastrophic failure

An in-situ apparatus is provided for monitoring the state of stress / strain and cracking in a die surface. The apparatus may also be used to facilitate the prudent removal of the die from the surface so that it may be repaired before catastrophic failure occurs. Accordingly, the yield of a process used to generate die cast structures may be greatly increased.

Owner:COLORADO SCHOOL OF MINES

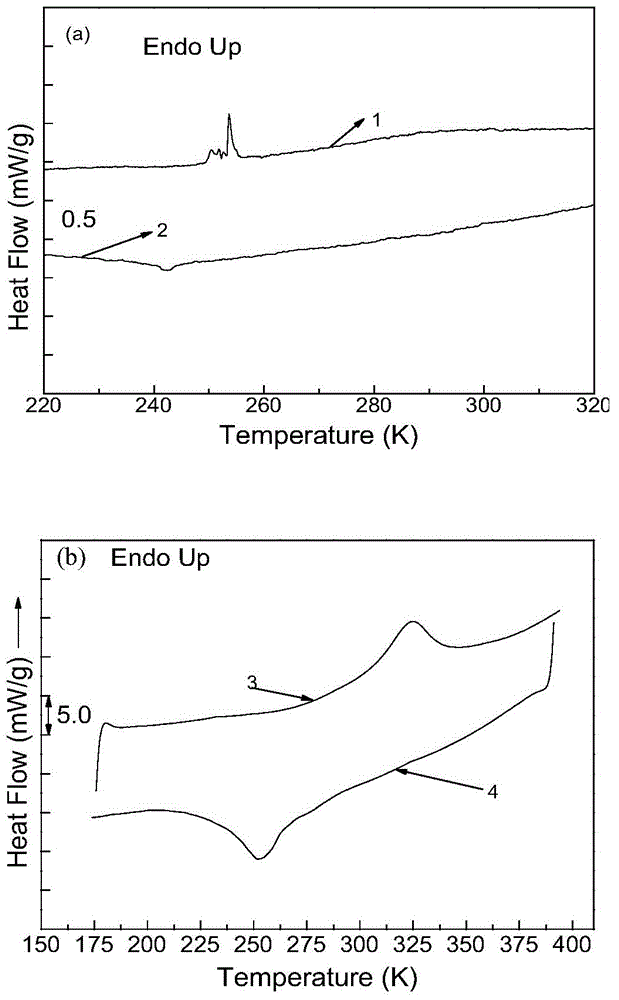

Titanium niobic zincic acid bismuth sodium system leadless piezo-electric ceramic and preparation method thereof

InactiveCN101200369AImprove performanceHigh densityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPiezo electric

The invention discloses a triple system (Na,Bi)TiO3-NiO3-ZiO3-based lead-free piezoelectric ceramic material and preparation method, the B digital ion in the (Na0.5Bi0.5)TiO3 of the ABO3 type perovstike structure is replaced partially by composite ion (Zn(one-third)Nb(two-third))4+ and the A digital ion (Na0.5Bi0.5)2+ is replaced by Ba2+ to form lead-free piezoelectric ceramic that can be denoted with the formula ((Na0.5Bi0.5)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b) and ((Na0.5Bi0.5)(1-y)Ba(y)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b), wherein M(a)O(b) is one or more oxide. The piezoelectric ceramic adopts two-step synthetic method and is obtained by sintering. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 150pC per N, Kt can reach above 0.50, and Kp can be below 0.20. The lead-free piezoelectric has strong anisotropy, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

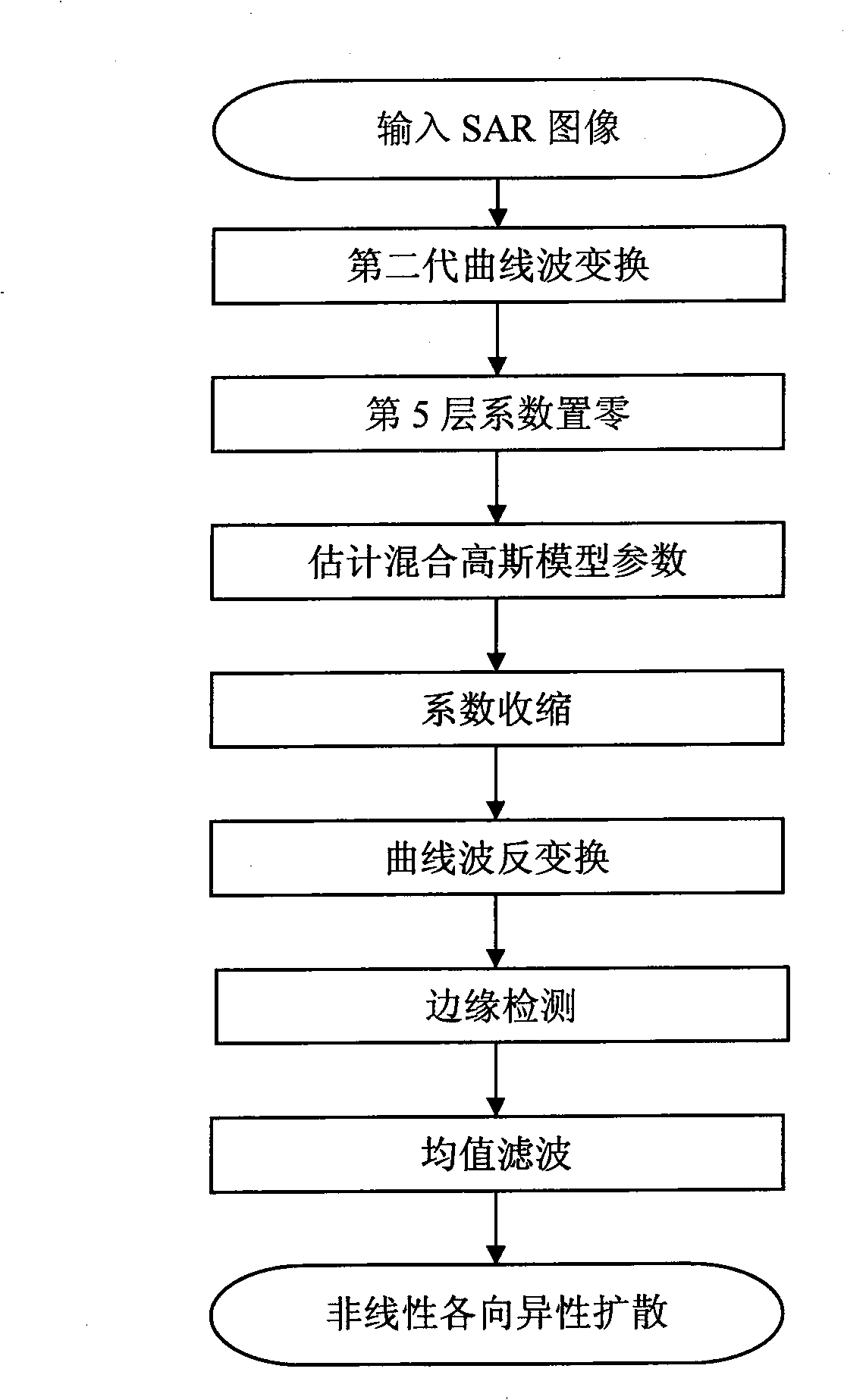

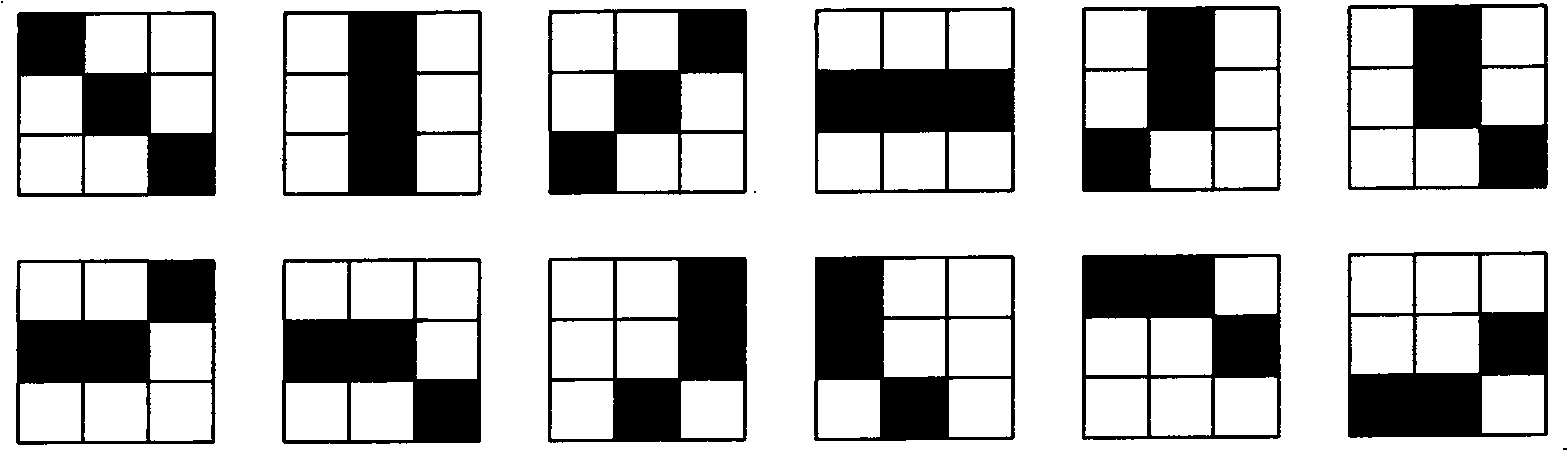

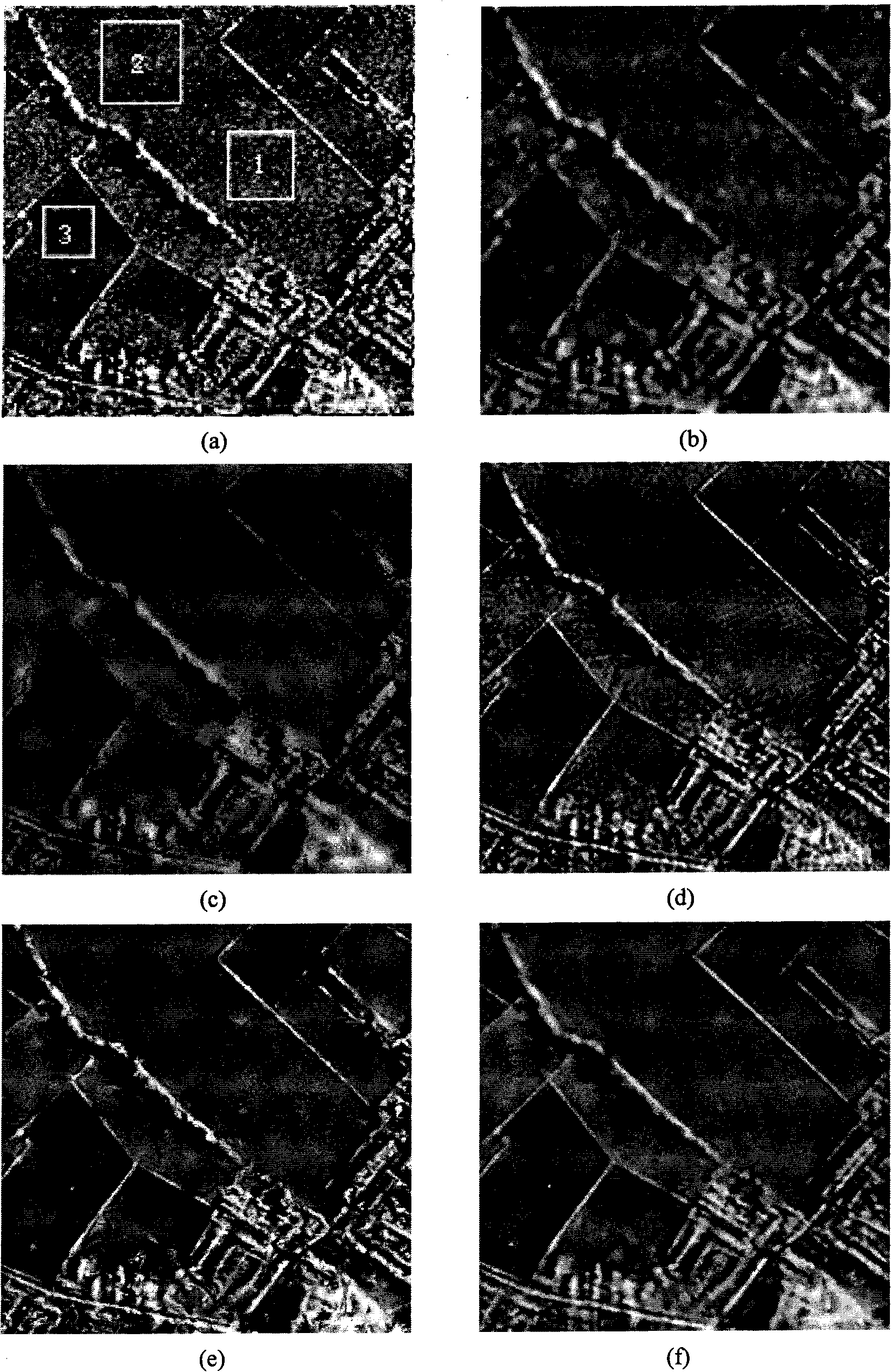

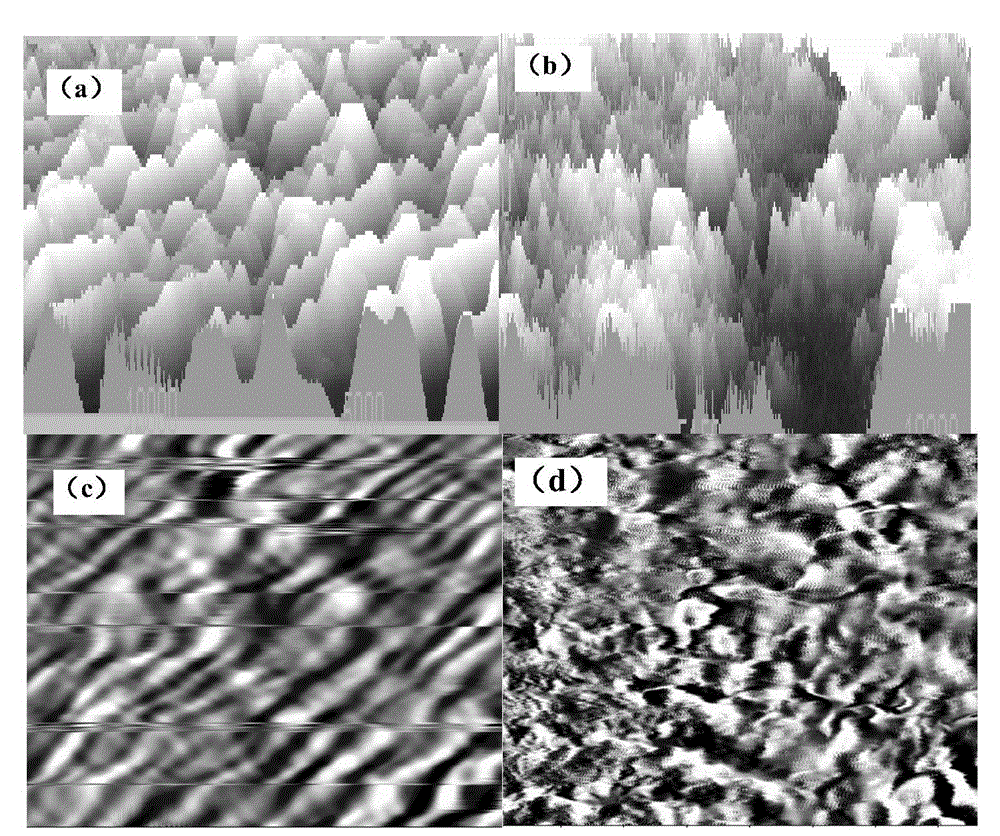

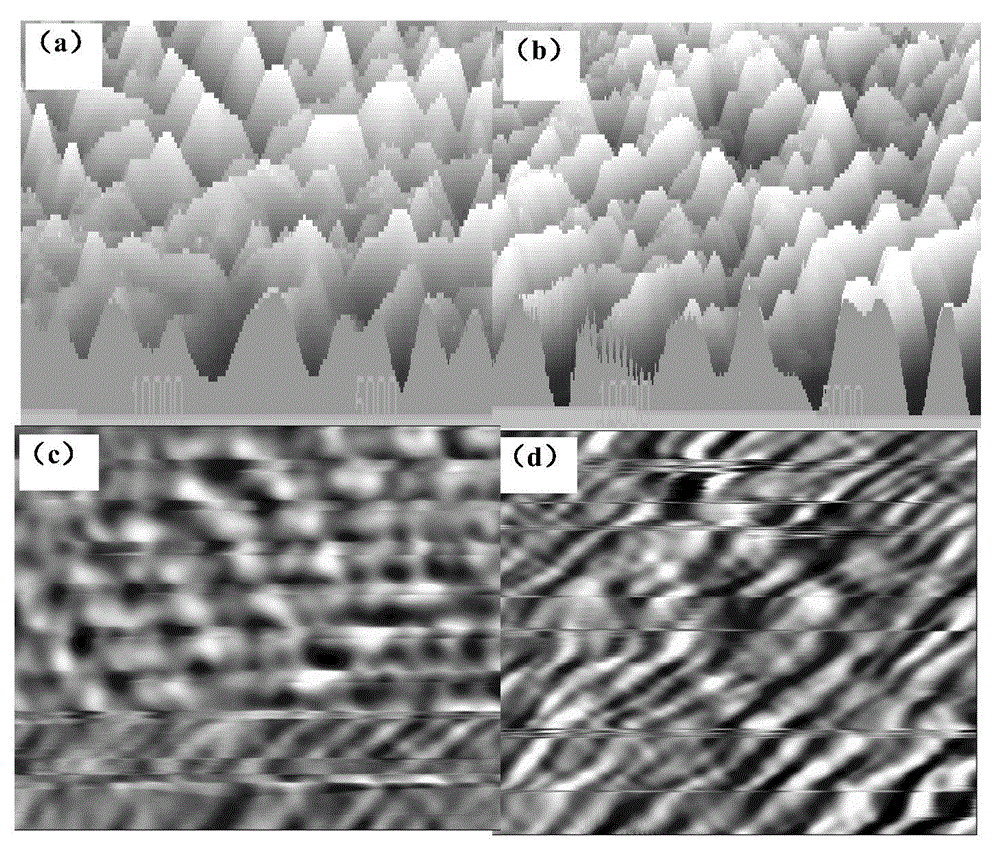

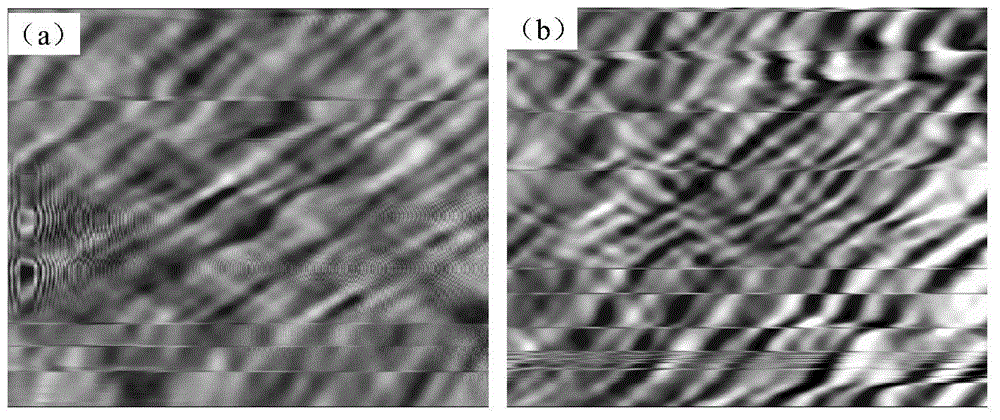

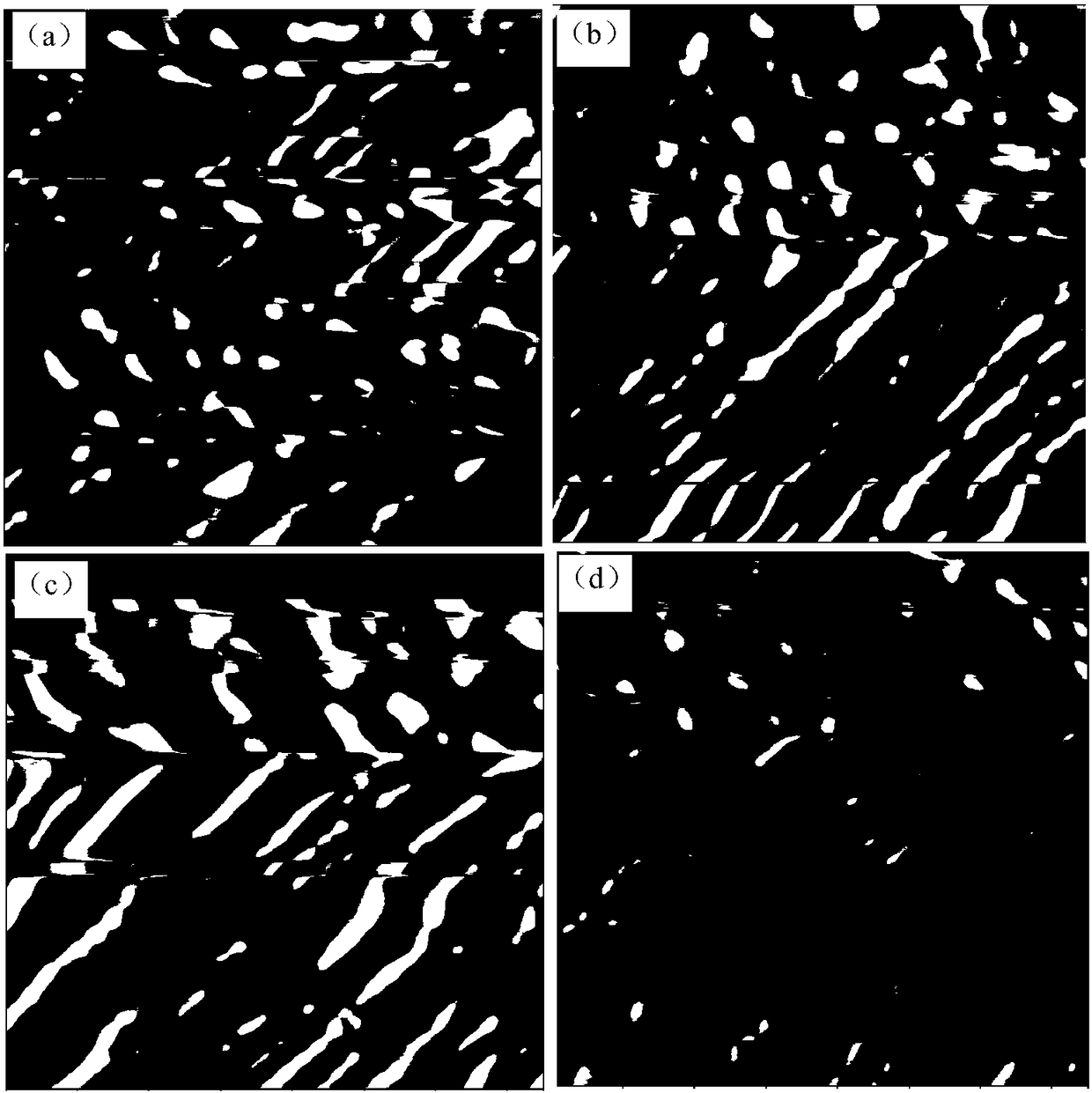

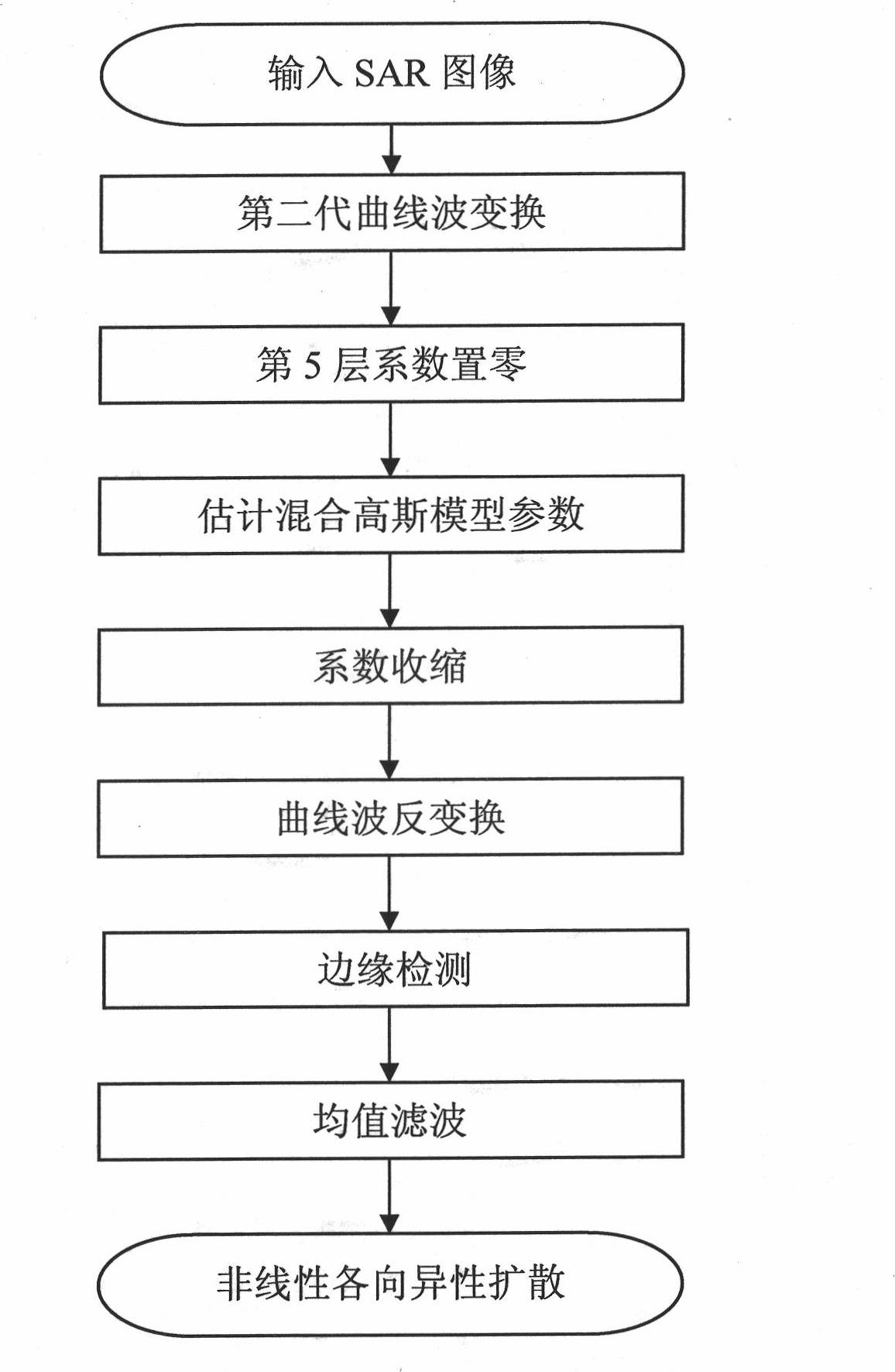

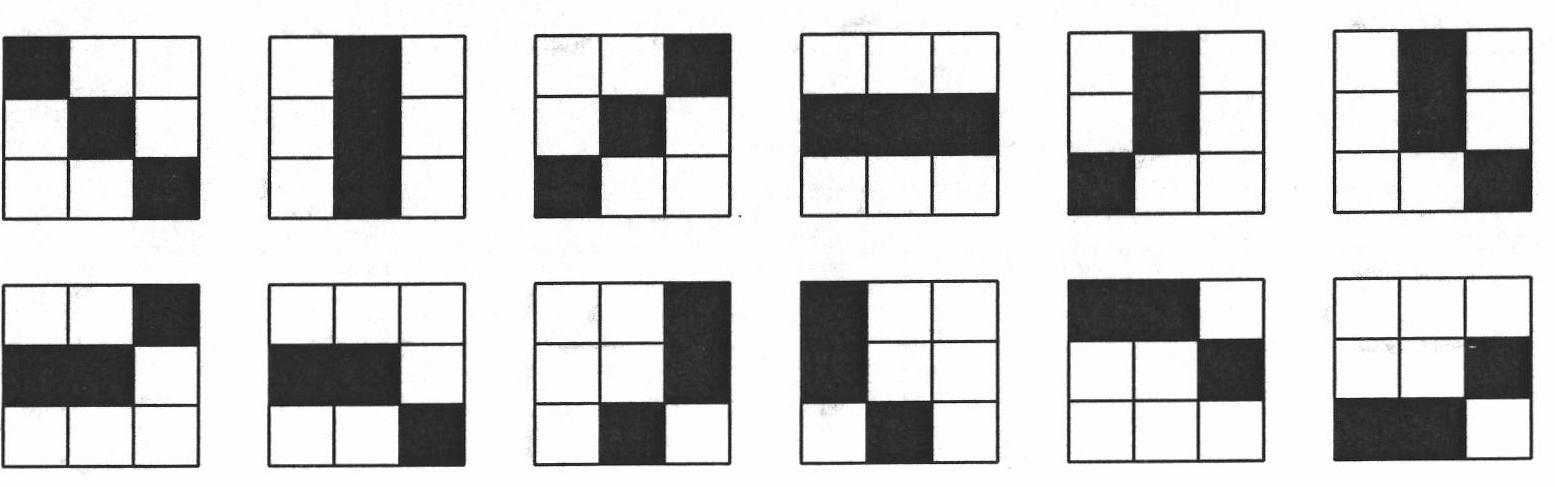

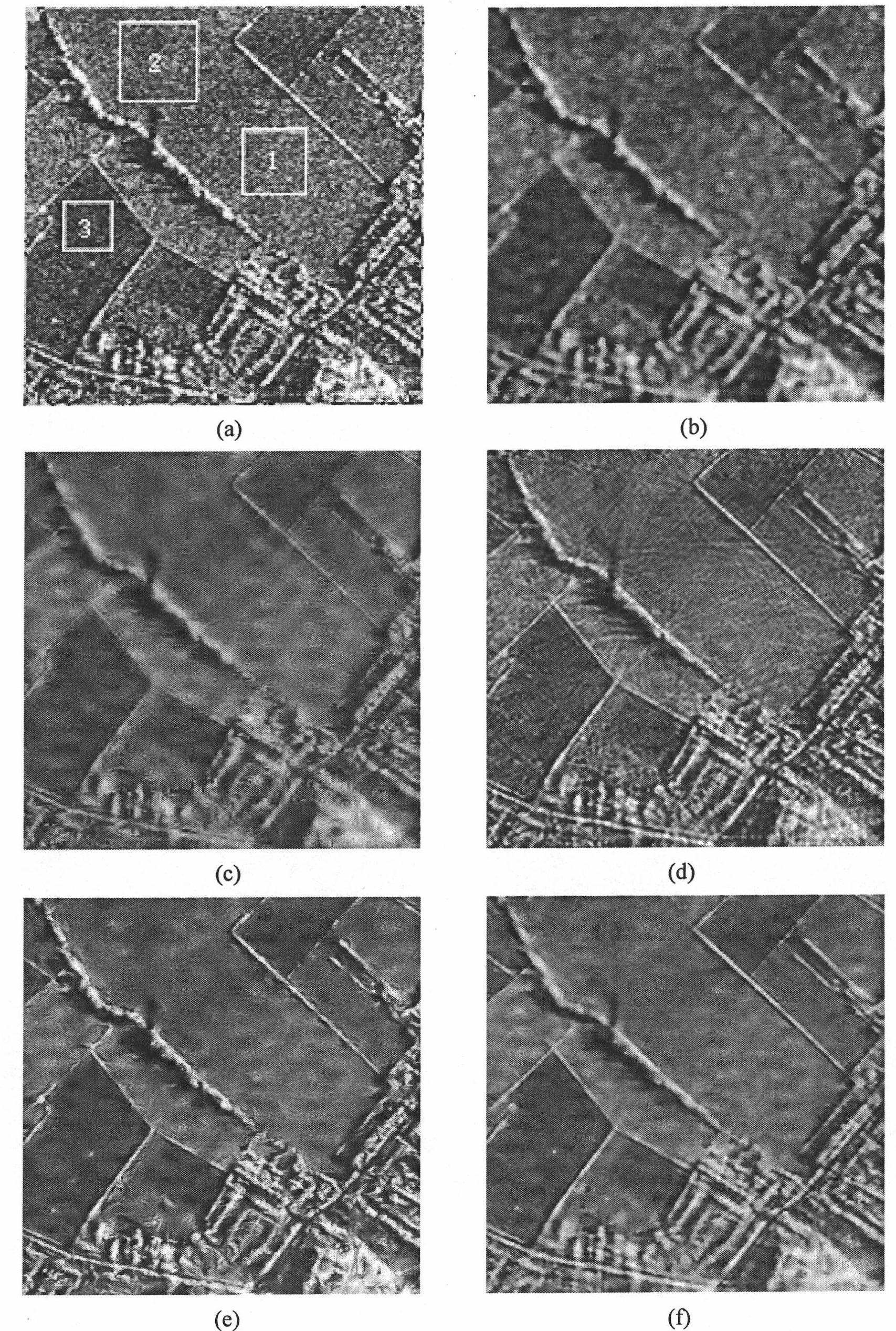

SAR image speckle suppression method based on second generation curvilinear wave transformation

ActiveCN101540042AGuaranteed edgeDirectionalImage enhancementWave based measurement systemsAverage filterPoint target

The invention discloses an SAR image speckle suppression method based on second generation curvilinear wave transformation, which mainly overcomes the defect of scratch effect and point target loss brought by a curvilinear wave to the SAR image speckle suppression. The SAR image speckle suppression method comprises the following steps: performing the second generation curvilinear wave transformation to a selected test image and partitioning the selected test image into 5 layers of subbands; keeping coefficients of the first layer unchangeable and zero-setting coefficients of the fifth layer; respectively evaluating parameter vectors of hybrid Gaussian models from the second layer to the fourth layer by an EM method; marking the coefficients from the second layer to the fourth layer; reconstructing the image, detecting the edge of the reconstructed image, and performing the average filtering to the uniform area of the reconstructed image to obtain the filtered image; and performing the nonlinear anisotropy dispersion iteration to a difference image obtained by the original image and the filtered image to obtain a speckle suppressed image. The invention has the advantages of keeping clean edge of the image, removing the scratch effect and remaining the point target characteristic information of the image, and can be used for preprocessing scene analysis and image understanding in the SAR image.

Owner:XIDIAN UNIV

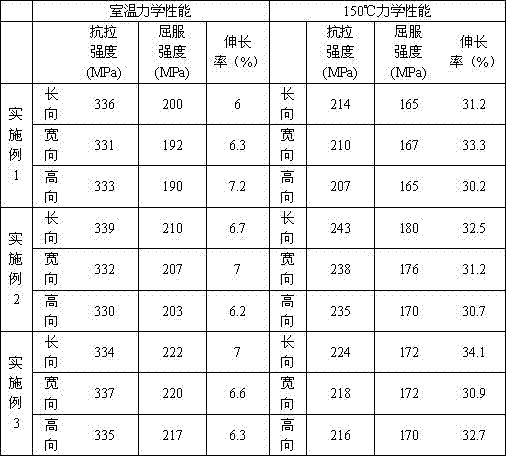

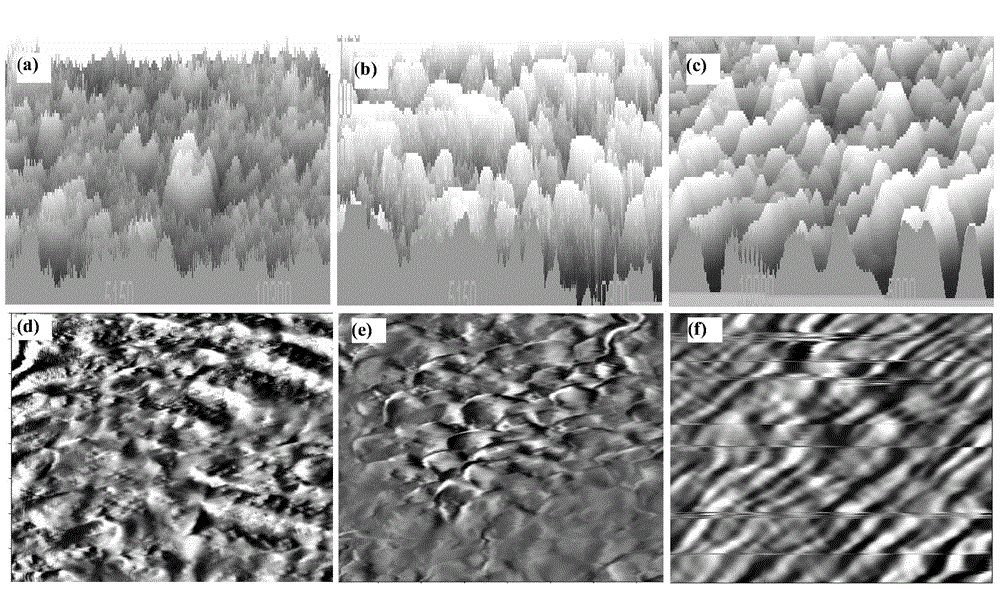

Forging process for eliminating anisotropism of large-sized AQ80M magnesium alloy bearing member

The invention relates to a forging process for eliminating anisotropism of a large-sized AQ80M magnesium alloy bearing member and belongs to the technical field of magnesium alloy material machining. The process specifically includes the steps that an ingot blank is prepared; extrusion blooming is performed with the low extrusion ratio, specifically, extrusion is performed on an extruding machine with the extrusion ratio being 3-4 and the extrusion speed being 0.3-2.8 mm / s; cooperating with intermediate annealing, multiple passes of direction-changing heading are performed on a hydraulic press so that the blank can be forged into a large-sized magnesium alloy bearing member; and the magnesium alloy bearing member is subjected to aging treatment. By means of the forging process, preparation of magnesium alloy bearing members with the size being larger than 470*390*170 mm<3> can be achieved; after aging treatment is finished, the yield strength difference among the length direction, the width direction and the height direction is smaller than or equal to 10 MPa at both the room temperature and the temperature of 150 DEG C; and the problem of anisotropism of large-sized magnesium alloy parts is solved.

Owner:湖南镁宇科技有限公司

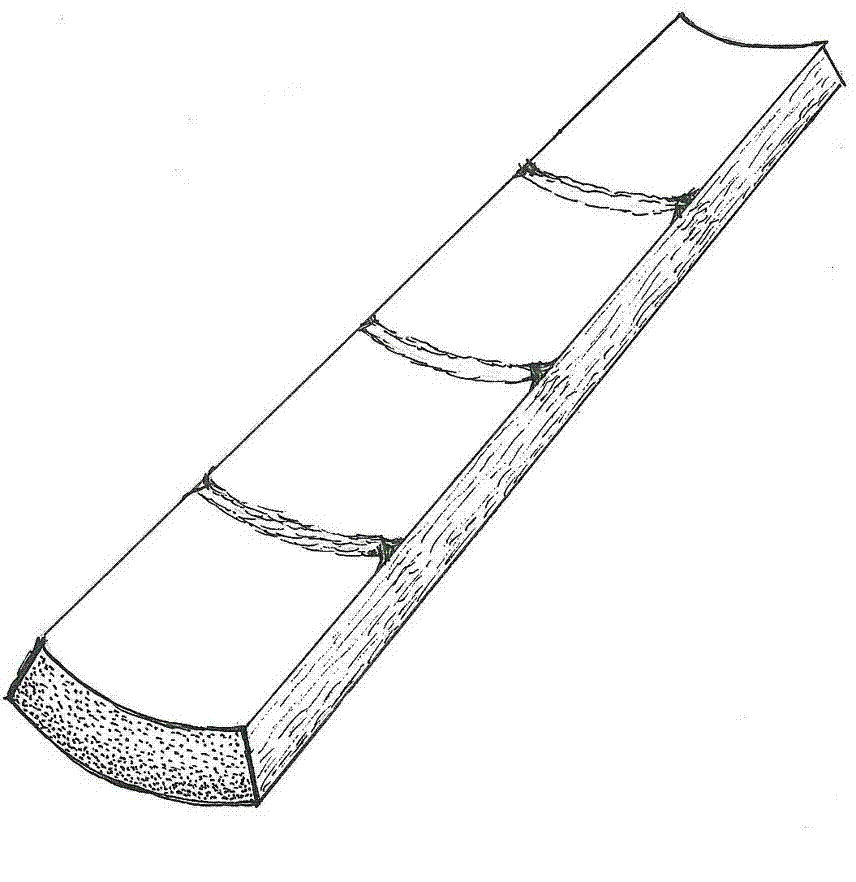

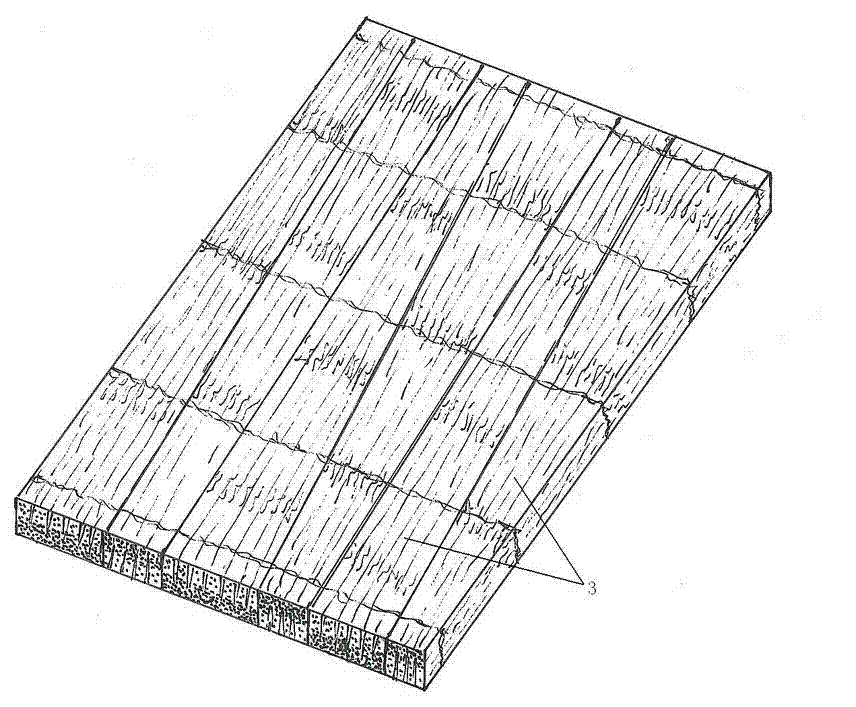

Wood and bamboo-unfolded thick veneer collection laminated material and preparation method thereof

InactiveCN102765111AIncrease profitIncrease the scope of applicationPlywood pressesVeneer pressesSurface layerMechanical property

The invention discloses a wood and bamboo-unfolded thick veneer collection laminated material with fast-growing woods and mao bamboos as raw materials and a preparation method of the wood and bamboo-unfolded thick veneer collection laminated material. The wood and bamboo unfolded thick veneer collection laminated material comprises at least three layers of odd wood laminated veneers and bamboo unfolded thick veneers, wherein the wood laminated veneers and the bamboo unfolded thick veneers are alternately and hierarchically stacked and are bonded and pressed into an integrated body through adhesive agents; the wood laminated veneers are distributed on both a surface layer and a bottom layer of the integrated body; and all the veneer layers are longitudinally arranged or horizontally and longitudinally arranged. The bamboo-unfolded thick veneers are formed in a way that every two of ladder-shaped unfolded bamboo plate unit bodies formed by unfolding original arc-shaped bamboo blocks correspond to each other in a turned way and are longitudinally laminated. According to the wood and bamboo-unfolded thick veneer collection laminated material provided by the invention, the production process is simplified, the production cost is reduced, the raw material consumption of unit product is controlled, the benefits of woods and bamboos are fully exerted, the mechanical property of wood and bamboo compound materials is improved, and the application range is widened.

Owner:刘佐财 +1

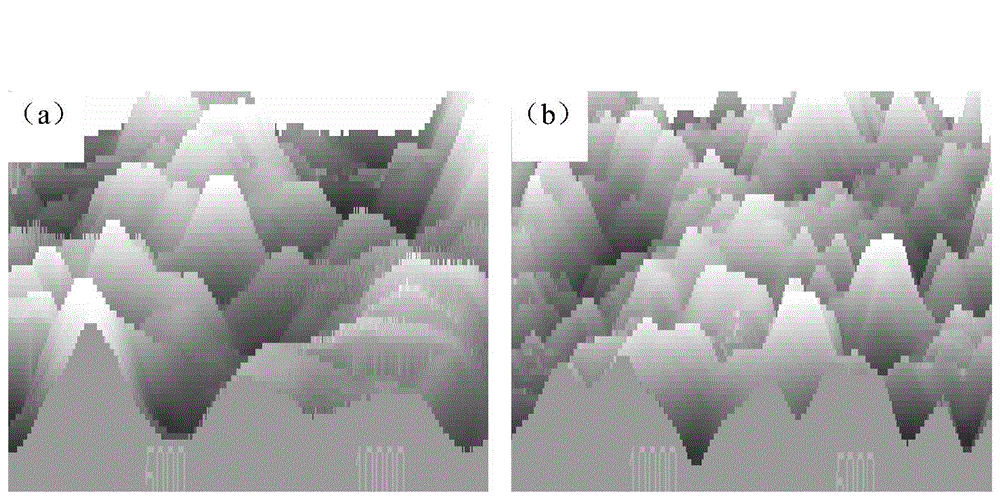

Method for preparing Ni52Mn24Ga24 alloy film through laser pulse sputtering deposition

InactiveCN104947052AAccurate ingredientsReduce roughnessVacuum evaporation coatingSputtering coatingElectric arc furnaceAlloy thin film

The invention relates to a method for preparing a Ni52Mn24Ga24 alloy film through laser pulse sputtering deposition. The method comprises the following steps: respectively placing metal simple substances Ni, Mn and Ga in a vacuum nonconsumable electrode electric arc furnace for smelting according to the mole ratio of 52:24:24; vacuumizing the interior of the electric arc furnace to 5*10<-3> Pa, and introducing inert gas for protection so as to obtain a round target material; placing a treated glass substrate and the target material in a vacuum system, and vacuumizing to 1*10<-4> Pa, wherein the temperature of the glass substrate is 550-600 DEG C and the distance between the glass substrate and the target material is 3-5 cm; emitting laser through a laser, wherein the frequency is 3-6 Hz, and the sputtering time is 40-170 minutes; finally, annealing for 0.5-3 h at 800-850 DEG C so as to prepare the Ni52Mn24Ga24 alloy film. The prepared Ni52Mn24Ga24 alloy film is more accurate in component, low in roughness, smoother in surface, high in anisotropy, good in toughness, high in strength, simple in preparation process, and easy for industrial production and has an important practical value for micro intelligence and high integration.

Owner:DALIAN UNIV

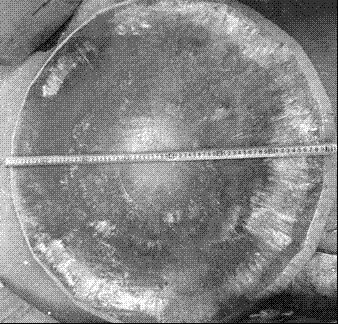

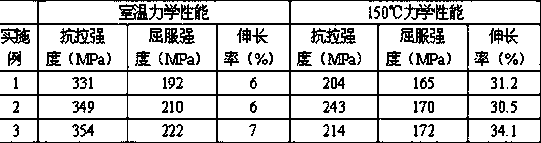

Swaging integrated forming process for large-diameter AQ80M magnesium alloy cake material

ActiveCN106890865AGuaranteed forming effectGuaranteed mechanical propertiesExtrusion control devicesPre deformationRoom temperature

The invention relates to a swaging integrated forming process for a large-diameter AQ80M magnesium alloy cake material, and belongs to the technical field of processing of a magnesium alloy material. The process comprises the following specific steps: preparing an AQ80M magnesium alloy ingot blank by semi-continuous casting; heating an extrusion die and an extrusion barrel; carrying out extrusion pre-deformation at low extrusion ratio; straightening and cutting the blank; carrying out multi-directional forging forming; and carrying out aging treatment. By the swaging integrated forming process for the large-diameter AQ80M magnesium alloy cake material, the large-diameter magnesium alloy cake material of which the diameter is phi 690 mm to phi 700 mm, the thickness is 100-110 mm, the tensile strength is greater than or equal to 330 MPa, the yield strength is greater than or equal to 190 MPa and the ductility is greater than or equal to 6% at room temperature, and the tensile strength is greater than or equal to 200 MPa, the yield strength is greater than or equal to 160 MPa and the ductility is greater than or equal to 30% at the temperature of 150 DEG C. The prepared large-size magnesium alloy cake material completely meets requirements of a large magnesium alloy part.

Owner:湖南镁宇科技有限公司

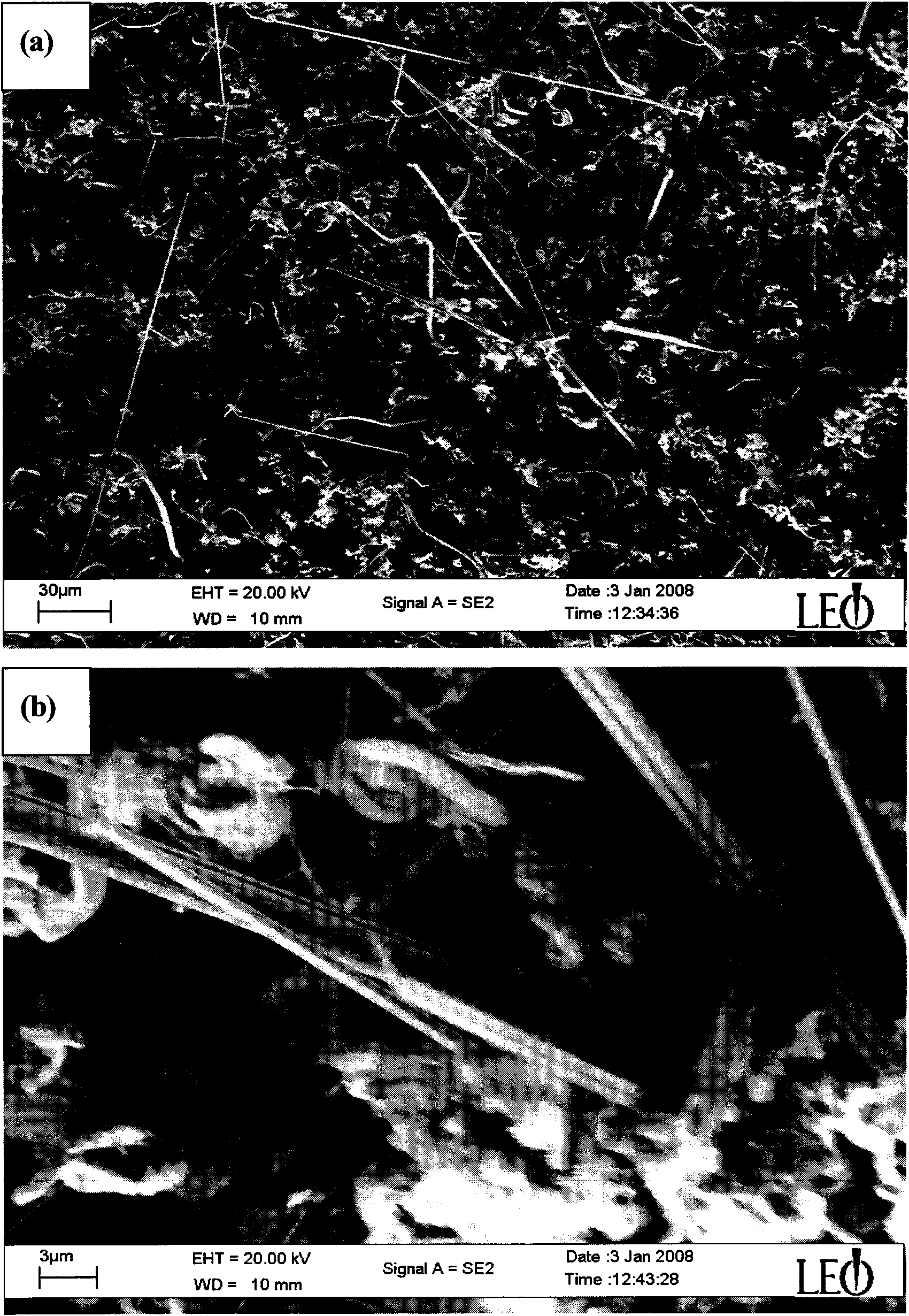

Method for preparing Sn crystal whiskers

InactiveCN101935872AStrong anisotropySave energyPolycrystalline material growthFrom solid stateChemical reactionDecomposition

The invention relates to the field of new materials, in particular to a novel metal crystal whisker material and a method for preparing metal tin (Sn) crystal whiskers, which solve the problems of high requirements on crystal whisker production equipment, complex crystal whisker preparation process, high price of the crystal whisker and the like. The method comprises the following steps of: smelting tin (Sn) and rear earth elements (neodymium (Nd), cerium (Ce) and lanthanum (La)) into an Sn-RE compound; smashing the Sn-RE compound into powder which is taken as a parent material for growing the Sn crystal whiskers; and after the Sn-RE compound powder is stored under the atmospheric conditions at the room temperature for a certain time, triggering the Sn crystal whiskers to spontaneously grow on the parent material by chemical reaction of automatic decomposition of the Sn-RE compound under the atmospheric conditions to obtain the Sn crystal whisker material. In the method, the growth process of the crystal whiskers is controlled by mainly controlling the growth time, namely the whisker growth condition can be suitable for natural environments of different places, and corresponding production equipment and temperature and moisture control conditions are not needed, so the production cost of the crystal whiskers can be effectively controlled.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

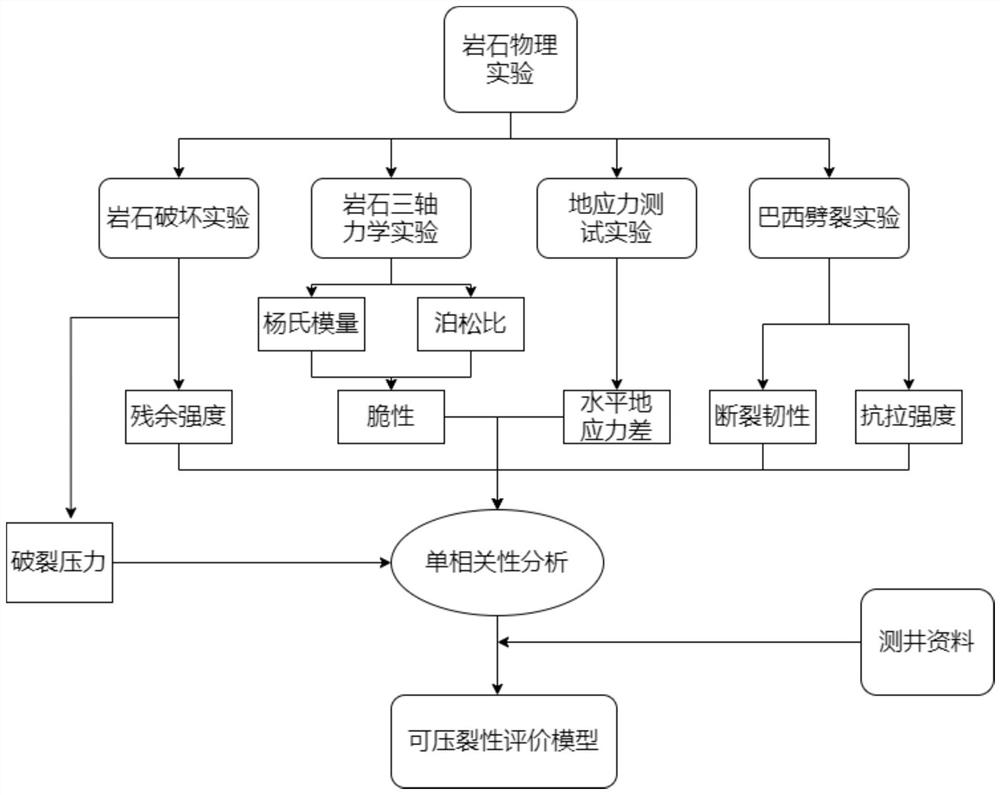

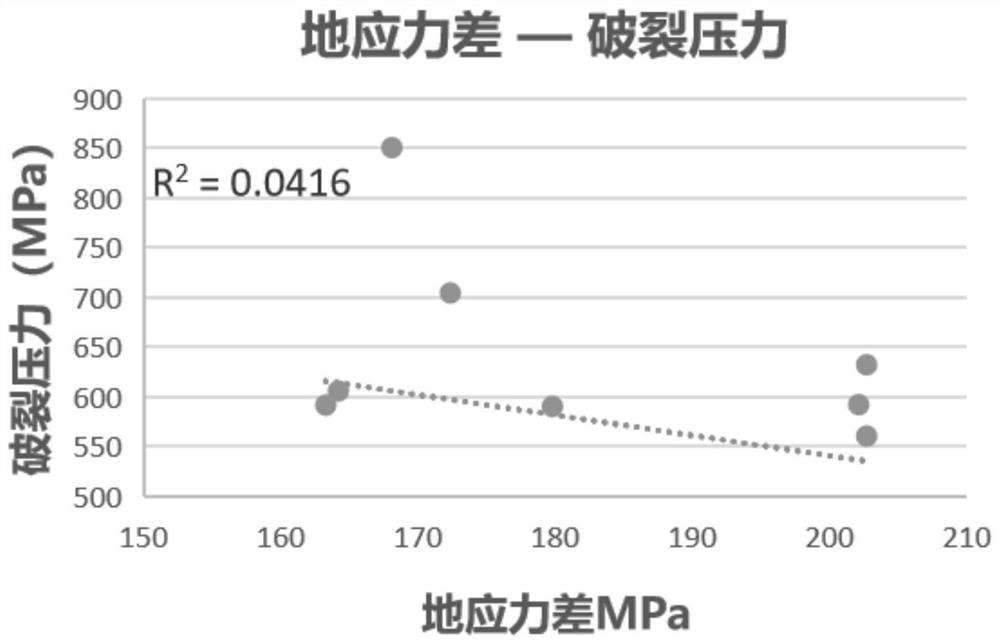

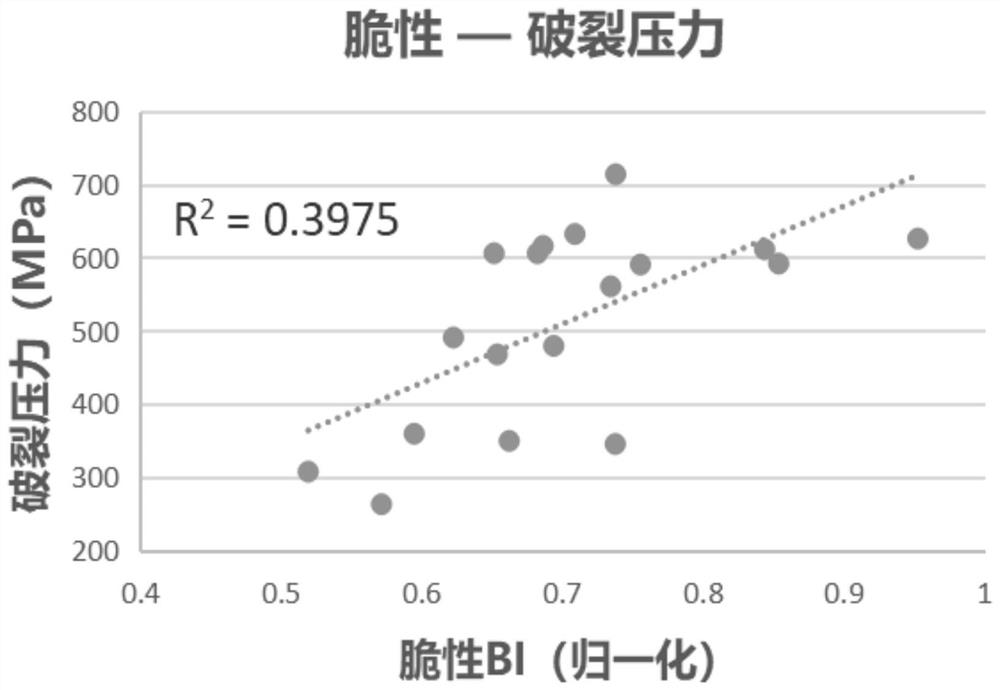

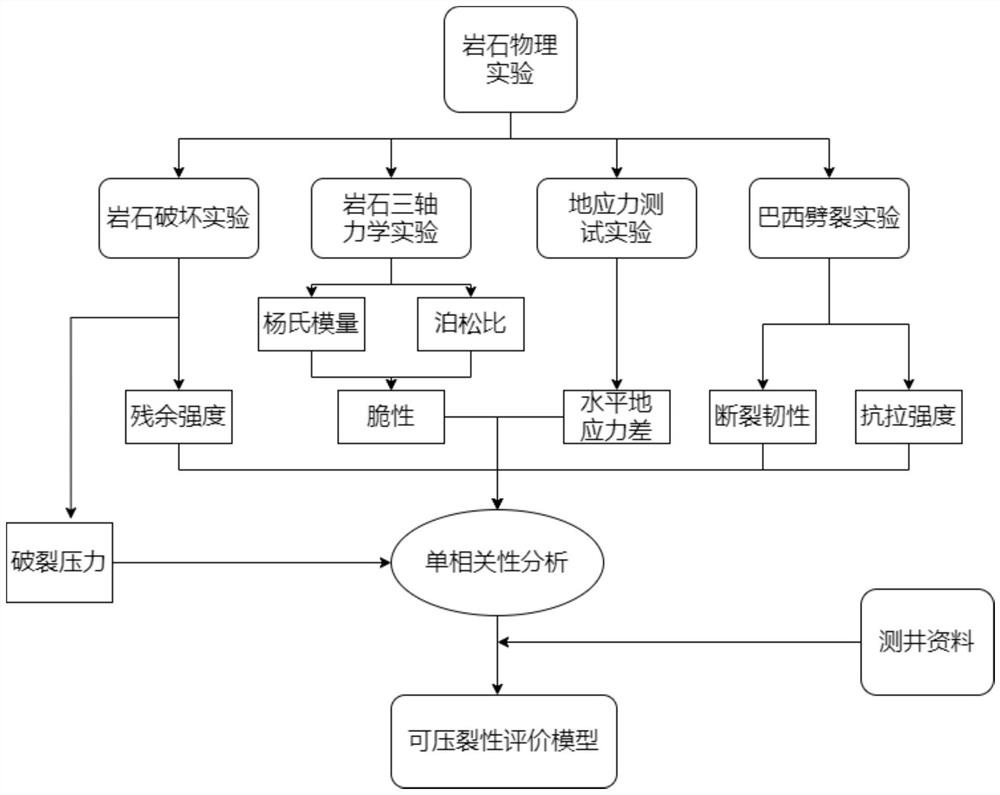

Method for evaluating fracturing property of complex reservoir

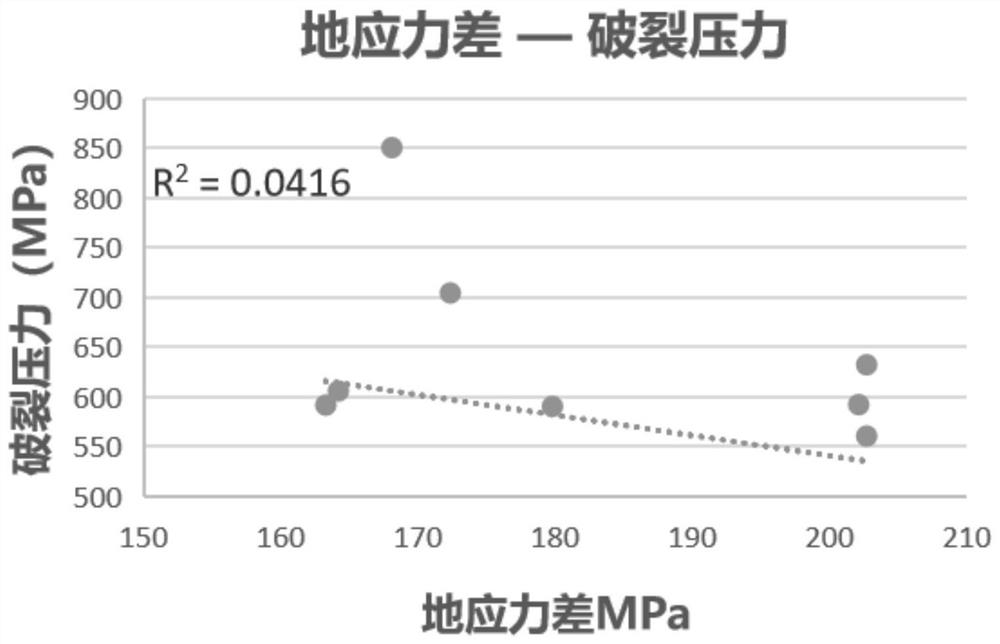

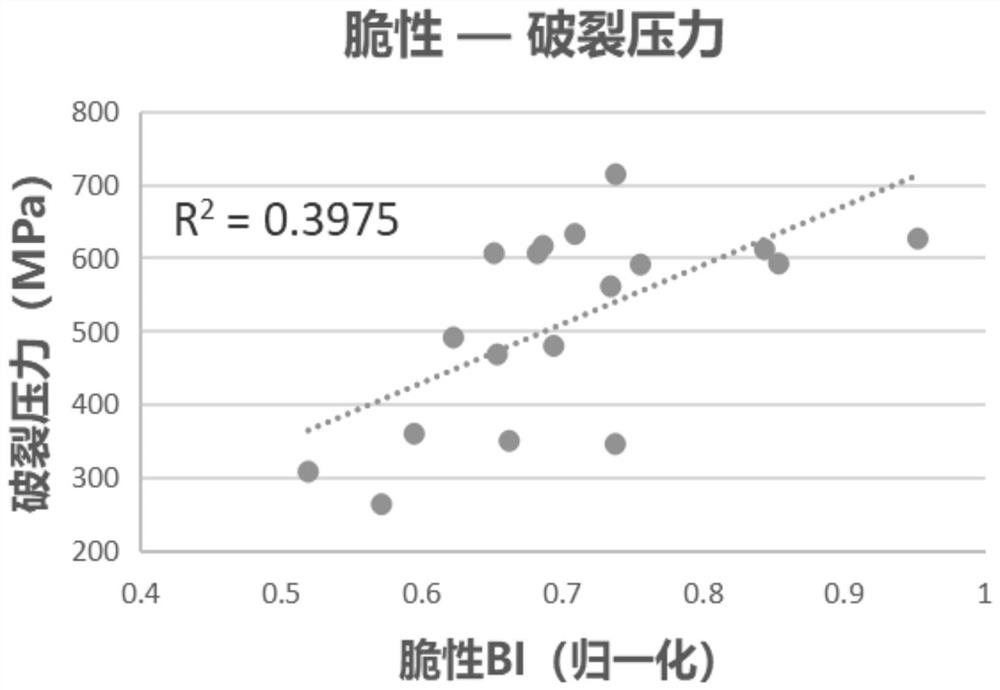

ActiveCN112307601ASolve the problem of poor accuracy of fracturing evaluationSolve the problem of poor evaluation accuracyFluid removalDesign optimisation/simulationRock coreWell logging

The invention discloses a method for evaluating fracturing property of a complex reservoir, and particularly relates to the field of oil and gas exploration and development of complex reservoirs. Themethod comprises the following steps: selecting a plurality of rock core samples in a complex reservoir, sequentially carrying out a crustal stress test experiment, a rock triaxial mechanical experiment and a rock damage experiment on one part of the rock core samples, determining the horizontal crustal stress difference, brittleness and residual stress of the rock core samples, carrying out a Brazilian split test on the other part of the rock core samples, determining the fracture toughness and tensile strength of the rock core samples, determining the fitting degree between parameters and the fracture pressure of the rock samples based on regression analysis, calculating weighting coefficients of the parameters, calculating a crack correction factor by utilizing logging data, establishing a complex reservoir fracturing evaluation model by integrating measurement parameters of the rock samples and the crack correction factor, and evaluating the fracturing property of the complex reservoir. According to the method, the accuracy of evaluation of the fracturing property of the complex reservoir is improved, and efficient development of complex oil and gas resources is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Flake high frequency soft magnetic micro powder fracturing along C crystal face, preparation method therefor and application thereof

InactiveCN104835610AStrong anisotropyMagnetic/electric field screeningInorganic material magnetismMass ratioRare earth

The invention relates to flake high frequency soft magnetic micro powder fracturing along C crystal face, a preparation method therefor and application thereof, belonging to the field of magnetic materials. The flake high frequency soft magnetic micro powder is characterized in that the micro powder is flake micro powder of an intermetallic compound RCo17, the C crystal face of the micro powder grain is parallel to the face of the flake, the thickness of the flake is of submicron size, the width thereof is of micron size, and the micro powder grain is of a rhombohedral structure and has strong negative magnetocrystalline anisotropy. The preparation method comprises the following steps of under argon shield, smelting rare earth metals and cobalt which are matched in proportion into a cast ingot, and performing full homogenization phasing treatment; and putting the cast ingot into an agate tank and ball milling for 0-3 hours, finally, transferring the material into a steel tank, ball milling for 2-6 hours in a mixed medium of normal heptane and dimethyl silicone oil, so as to enable the grain to directionally fracture along the C face into flake micro powder, wherein in ball milling, the mass ratio of medium to material is (20-40):1. The C face of the material of the invention and the face of the micron flake are parallel, so that in preparation of an oriented compound material, both rotation orientation in a magnetic field and rolling orientation through external stressing are available, and the magnetic conductivity of the compound material can be improved.

Owner:LANZHOU UNIVERSITY

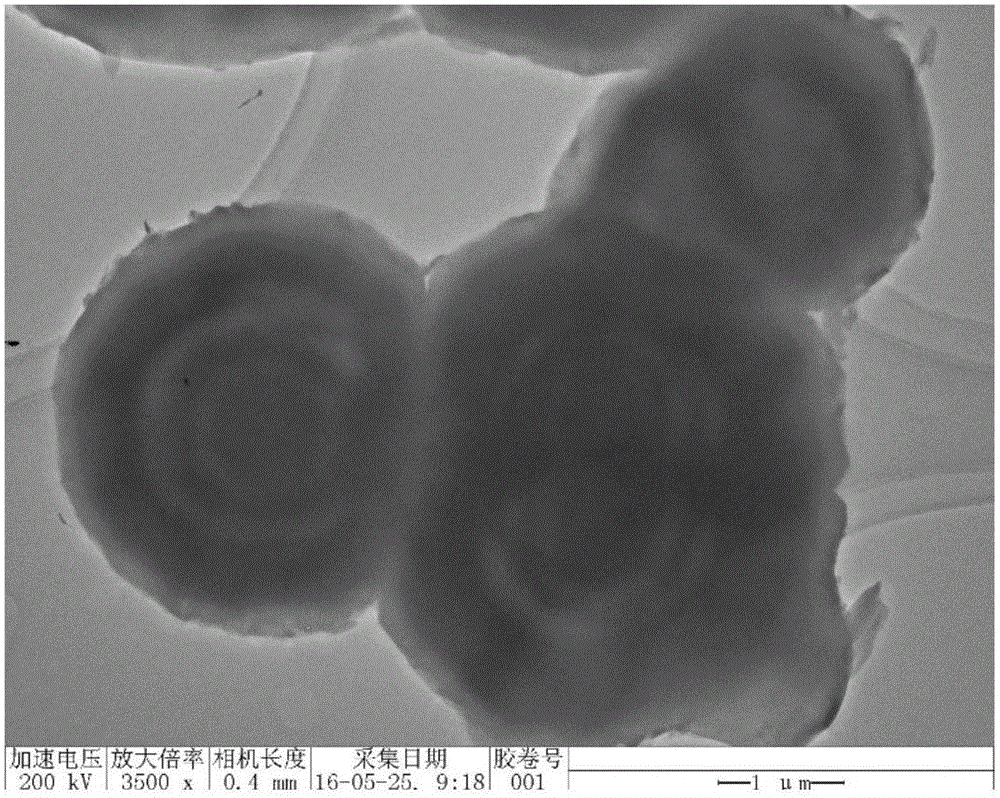

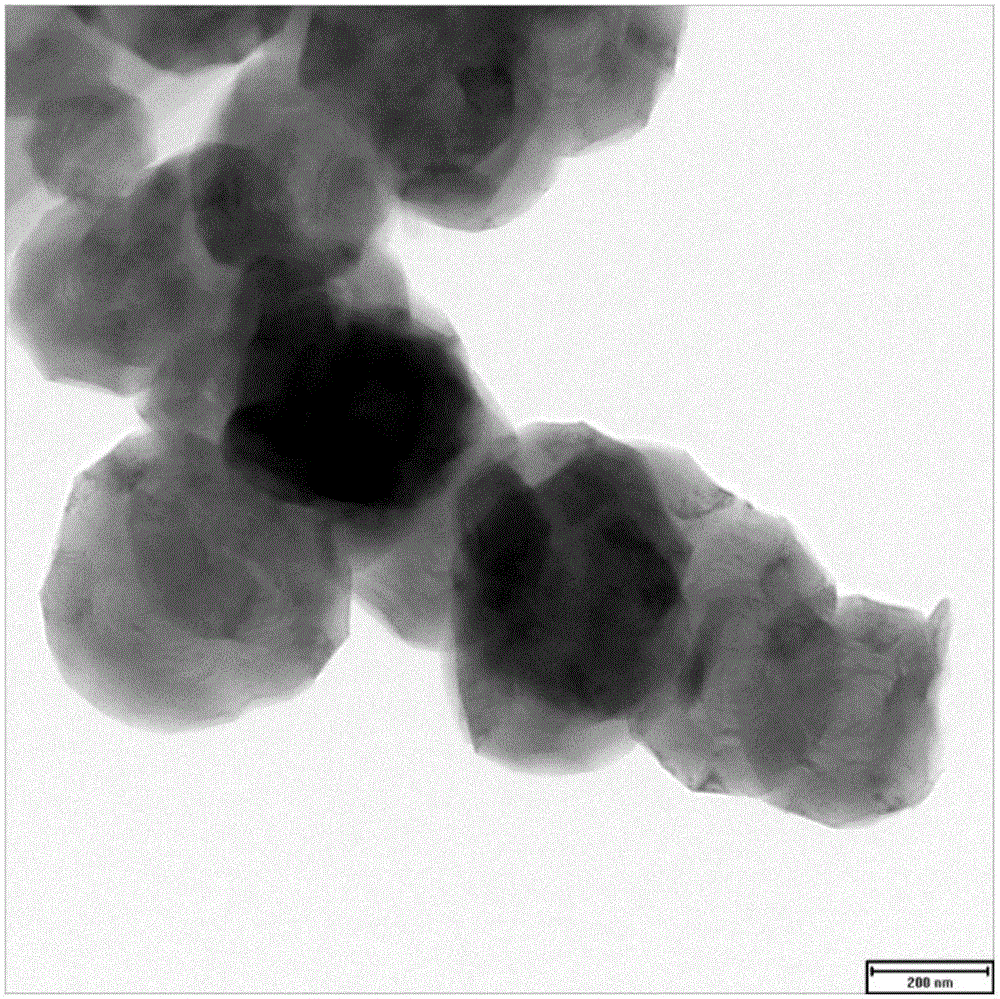

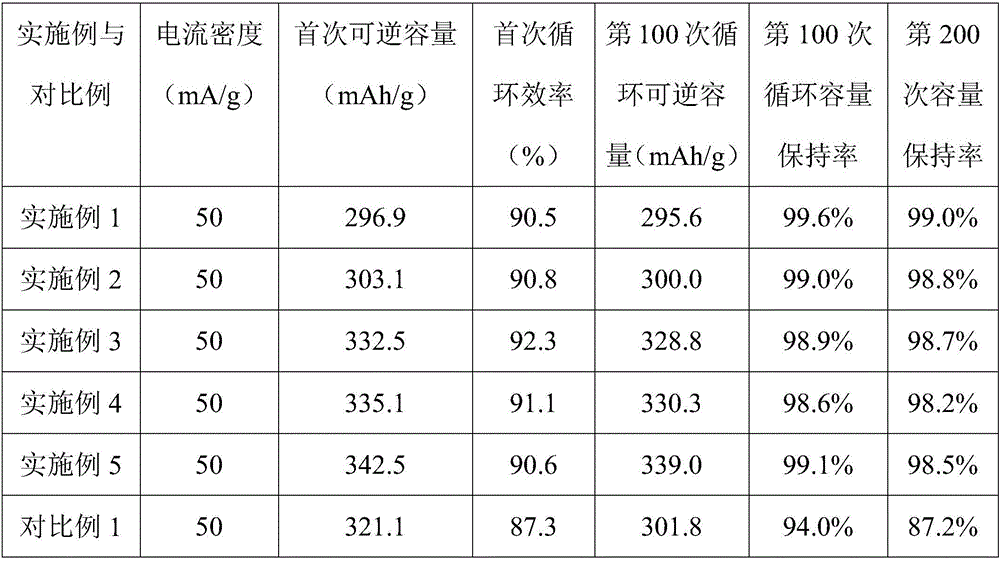

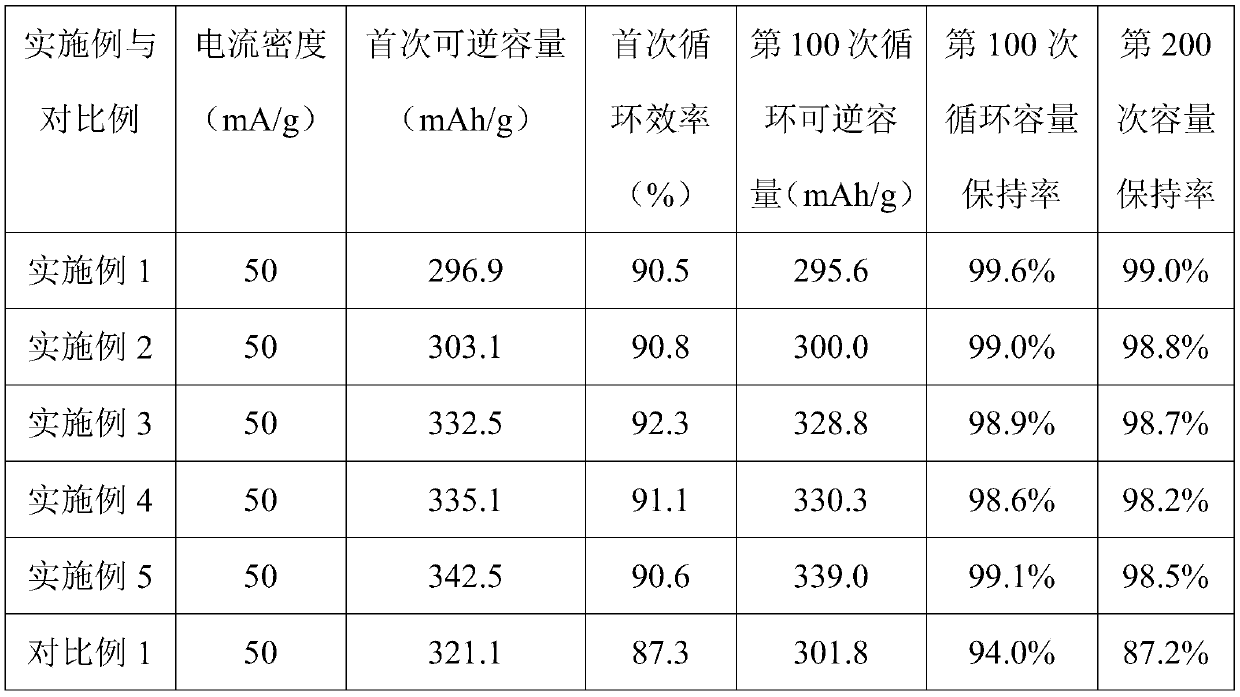

Carbon negative electrode material of lithium-ion battery with long cycle life and preparation method of carbon negative electrode material

ActiveCN106252597AWide selection of raw materialsIncrease profitCell electrodesHigh rateResin coating

The invention relates to a carbon negative electrode material of a lithium-ion battery with long cycle life and a preparation method of the carbon negative electrode material. The material has a multi-layer carbon shell structure, and carbon shells are in spherical-like concentric arrangement and have a spherical shape and the diameters are 0.5-30 microns. The carbon material is prepared through low-temperature thermal treatment and high-temperature thermal treatment on a precursor which is prepared by chemical vapor pyrolysis or through carbon particles by a resin coating method. The carbon material has charge and discharge behaviors similar to a graphite negative electrode material, overlong cycling stability, more excellent charge and discharge capacity and high rate capability when used as the negative electrode material of the lithium-ion battery.

Owner:BEIJING UNIV OF CHEM TECH

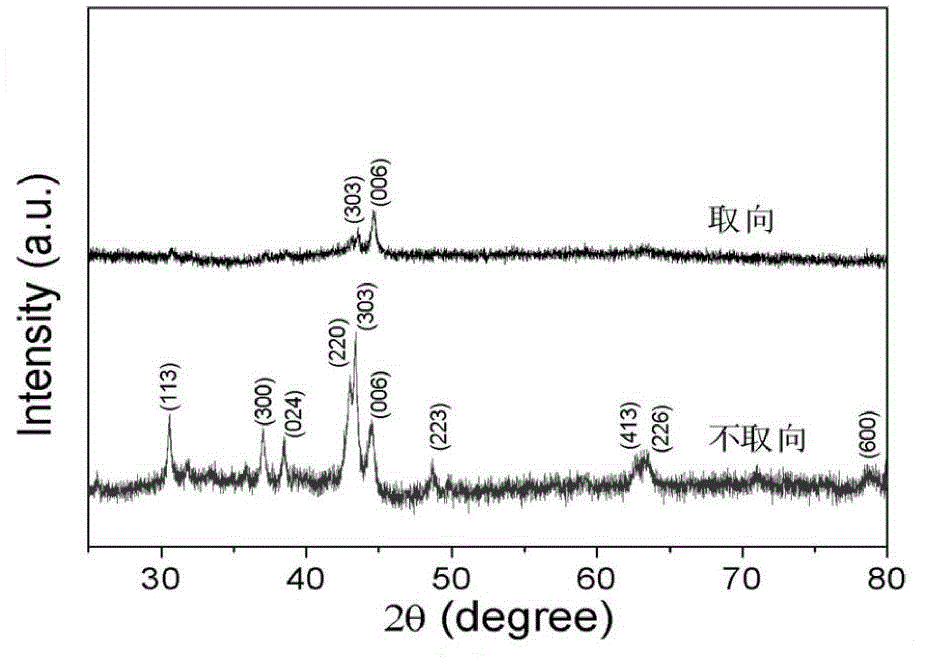

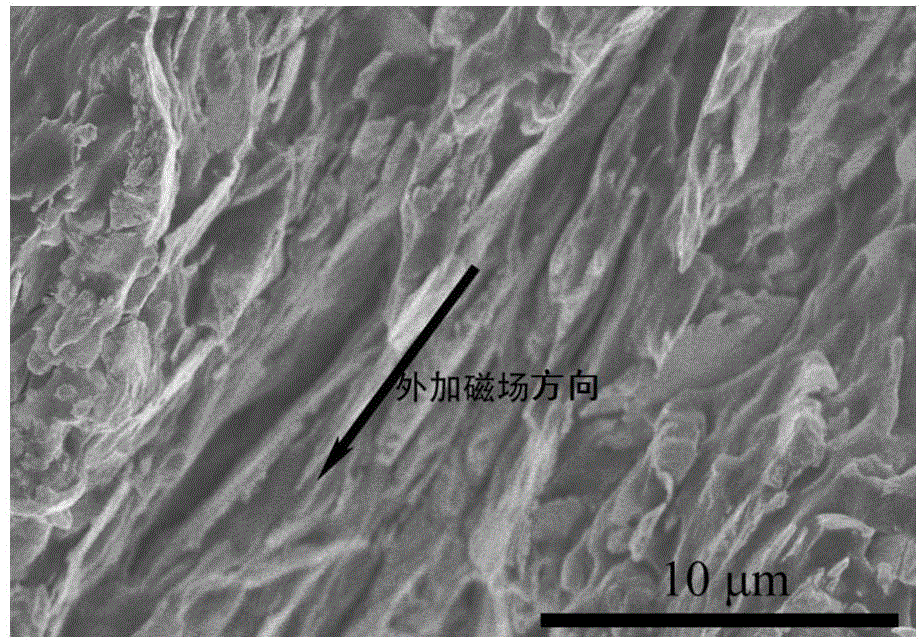

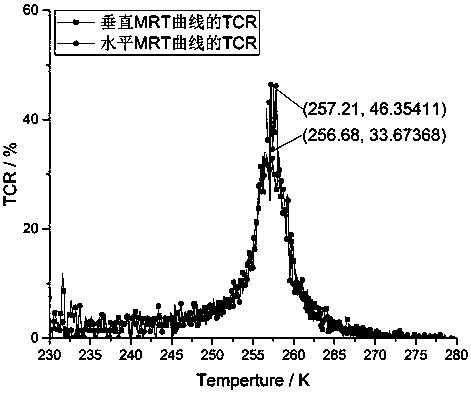

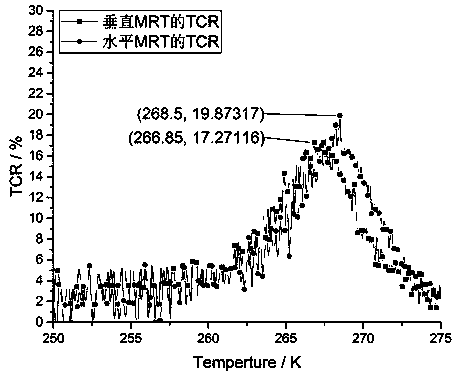

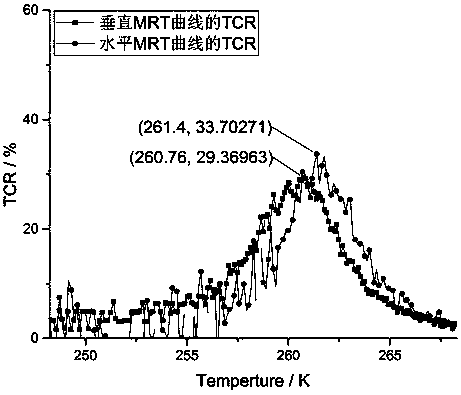

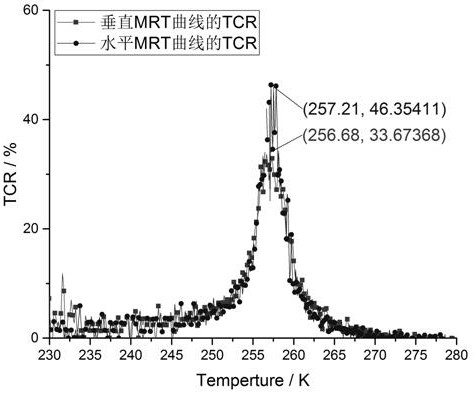

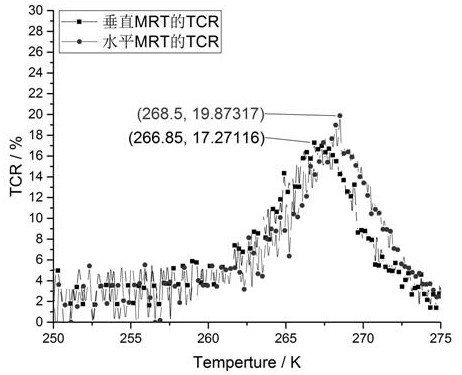

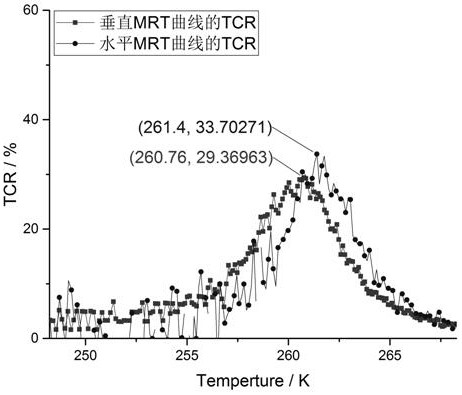

Preparation method of anisotropic lanthanum calcium manganese oxygen-based ceramic target

The invention discloses a preparation method of an anisotropic lanthanum calcium manganese oxygen-based ceramic target, and belongs to the technical field of ceramic preparation. The method concretelycomprises the following steps of a soil process, a gel process, a glue drying process, a primary crushing process, a primary roasting process, a silver doping process, a powder static pressure process, a secondary roasting process, a secondary crushing process, a pre-molding pressing process, a final mold static pressing process and a tertiary roasting process. The method provided by the invention has the advantages that the Ag doping effect can be improved through liquid phase mixing and seepage sintering; the doping loss is greatly reduced, so that the practical doping proportion is similarto the calculation quantity; the anisotropy of the ceramic target is further enhanced; the non-oxidization sintering process is combined, so that a La1-xCaxMnO3 substrate and an Ag element are not oxidized before the doping completion; the doping effect is further improved. The isostatic cool pressing process is combined; multidirectional stress is generated in the seepage and pressing process; the target optimum growth is facilitated; meanwhile, the defect tissues are greatly eliminated; the ceramic target has strong anisotropy.

Owner:KUNMING UNIV OF SCI & TECH

Manufacturing method for Ni50Mn34In12Co4 alloy film of high smoothness

ActiveCN105018888AAccurate ingredientsReduce roughnessVacuum evaporation coatingSputtering coatingElectric arc furnaceShielding gas

The invention relates to a manufacturing method for a Ni50Mn34In12Co4 alloy film of high smoothness. The method includes the following steps that metal elements of Ni, Mn, In and Co are prepared according to the mol fractional ratio of 50:34:12:4 and placed in a vacuum nonconsumable electrode electric-arc furnace to be smelted; the electric-arc furnace is vacuumized to be of 5*10-3 Pa, and is filled with shielding gas to obtain a round target; a processed substrate and the target are placed in a vacuum system, the vacuum system is vacuumized to be of 1.0*10-4 Pa, and the distance between the substrate and the target is 3-5 cm; a laser device emits laser, the control frequency is 3-4 Hz, sputtering is conducted for 1-3 h, and a film of the required thickness is obtained; and the film is subjected to annealing for 0.5-3 h at the temperature of 800-900 DEG C, and then Ni50Mn34In12Co4 ferromagnetism shape memory alloy film of the high smoothness is obtained. The Ni50Mn34In12Co4 alloy film prepared according to the method has more accurate ingredients, lower roughness and good anisotropism. The alloy film is good in toughness, high in strength and easy to prepare and produce industrially, and is of great practical value on micro intelligence and high integration.

Owner:DALIAN UNIV

Piezoelectric sensor based smart-die structure for predicting the onset of failure during die casting operations

InactiveUS8833174B2Strong anisotropyPiezoelectric propertyForce measurementUsing electrical meansDie castingCatastrophic failure

An in-situ apparatus is provided for monitoring the state of stress / strain and cracking in a die surface. The apparatus may also be used to facilitate the prudent removal of the die from the surface so that it may be repaired before catastrophic failure occurs. Accordingly, the yield of a process used to generate die cast structures may be greatly increased.

Owner:COLORADO SCHOOL OF MINES

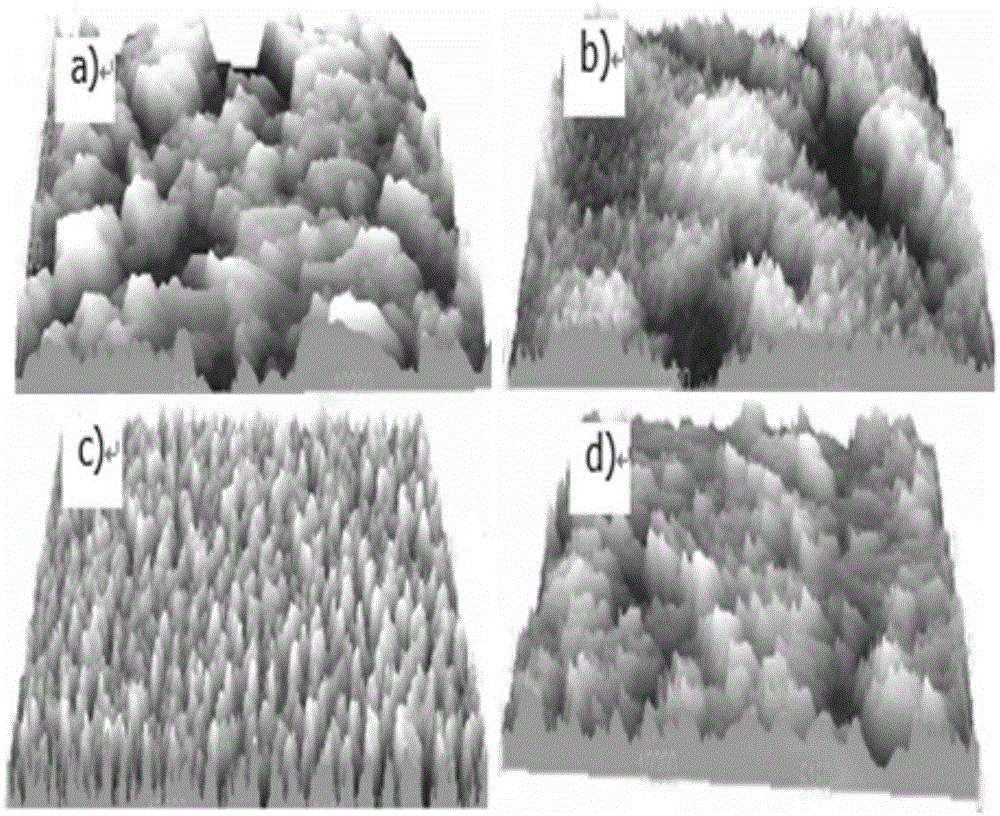

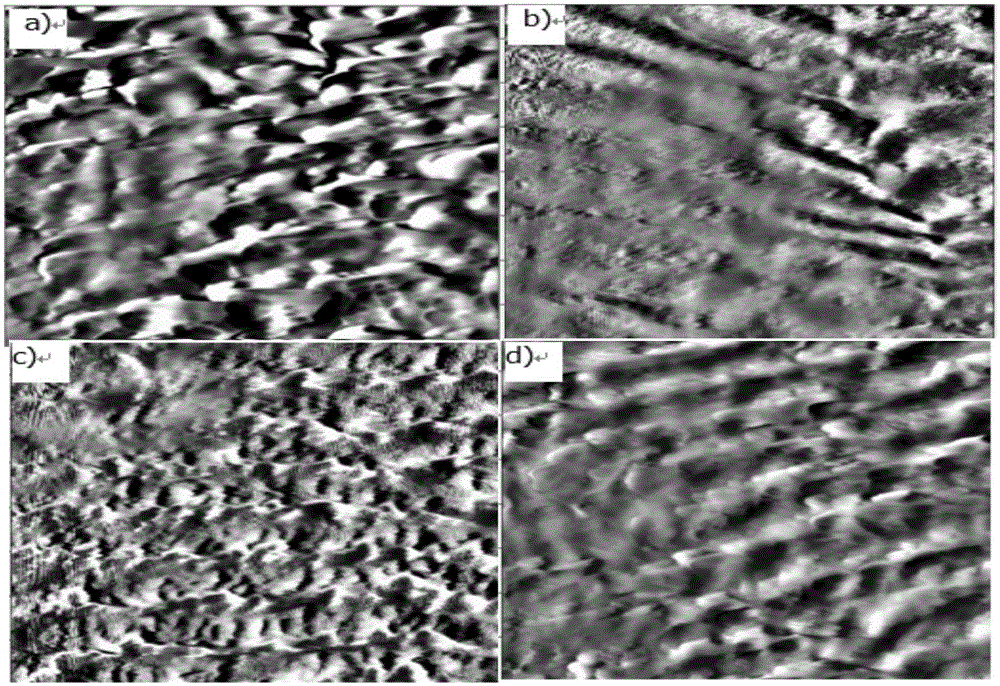

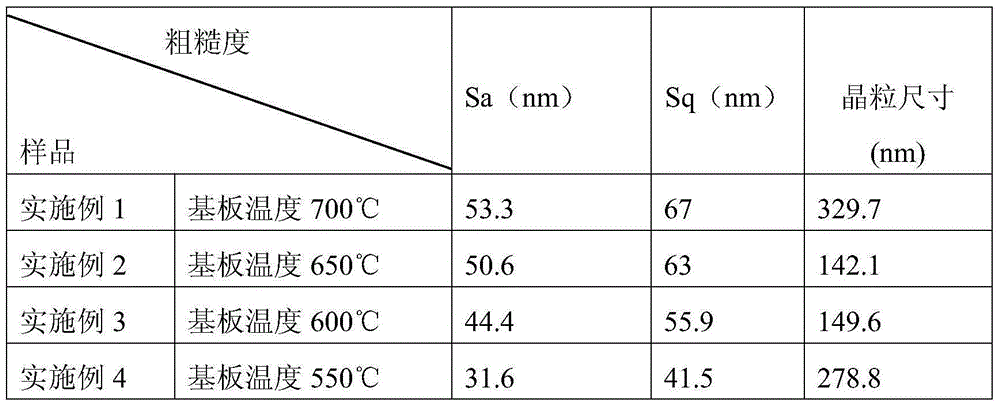

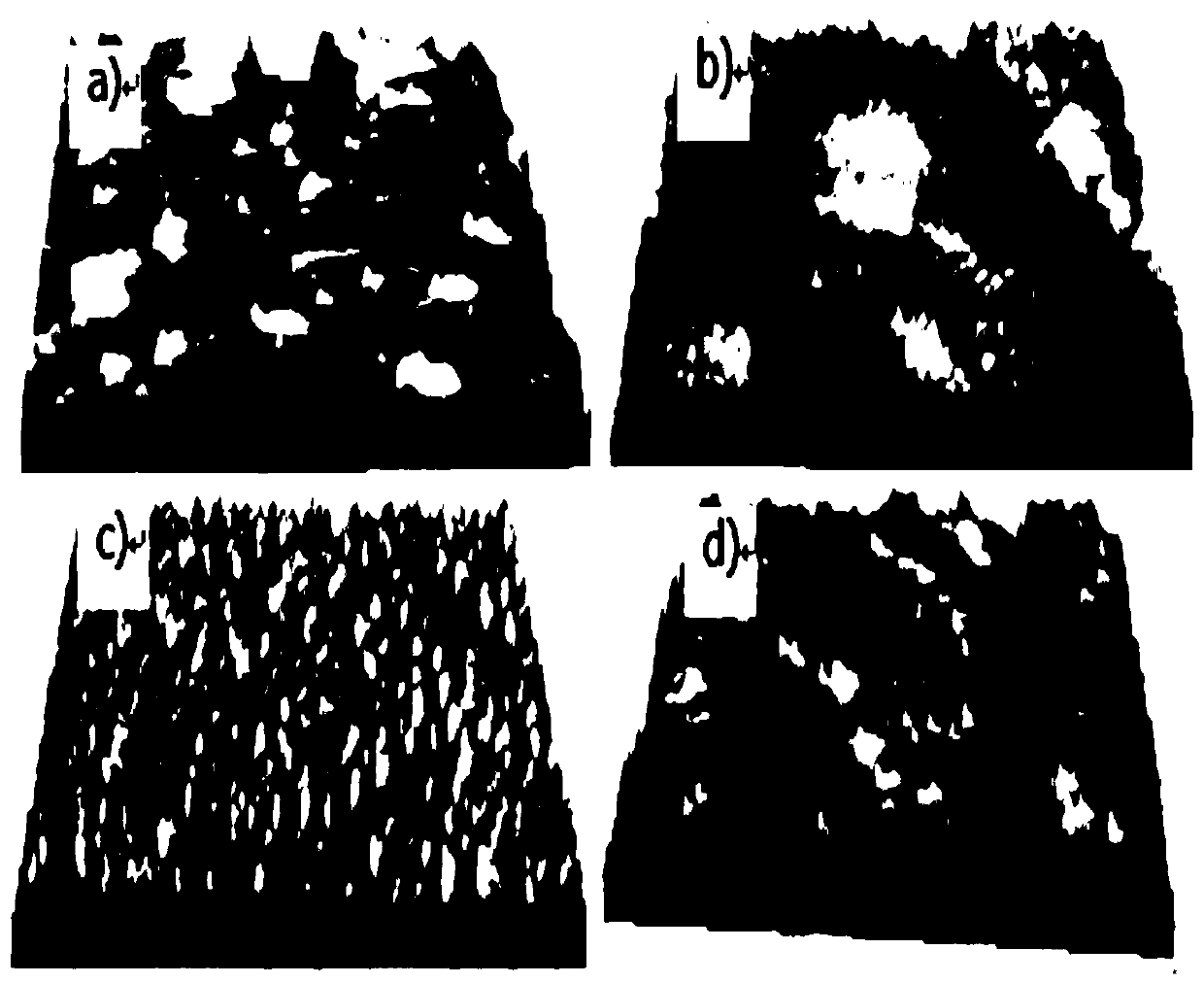

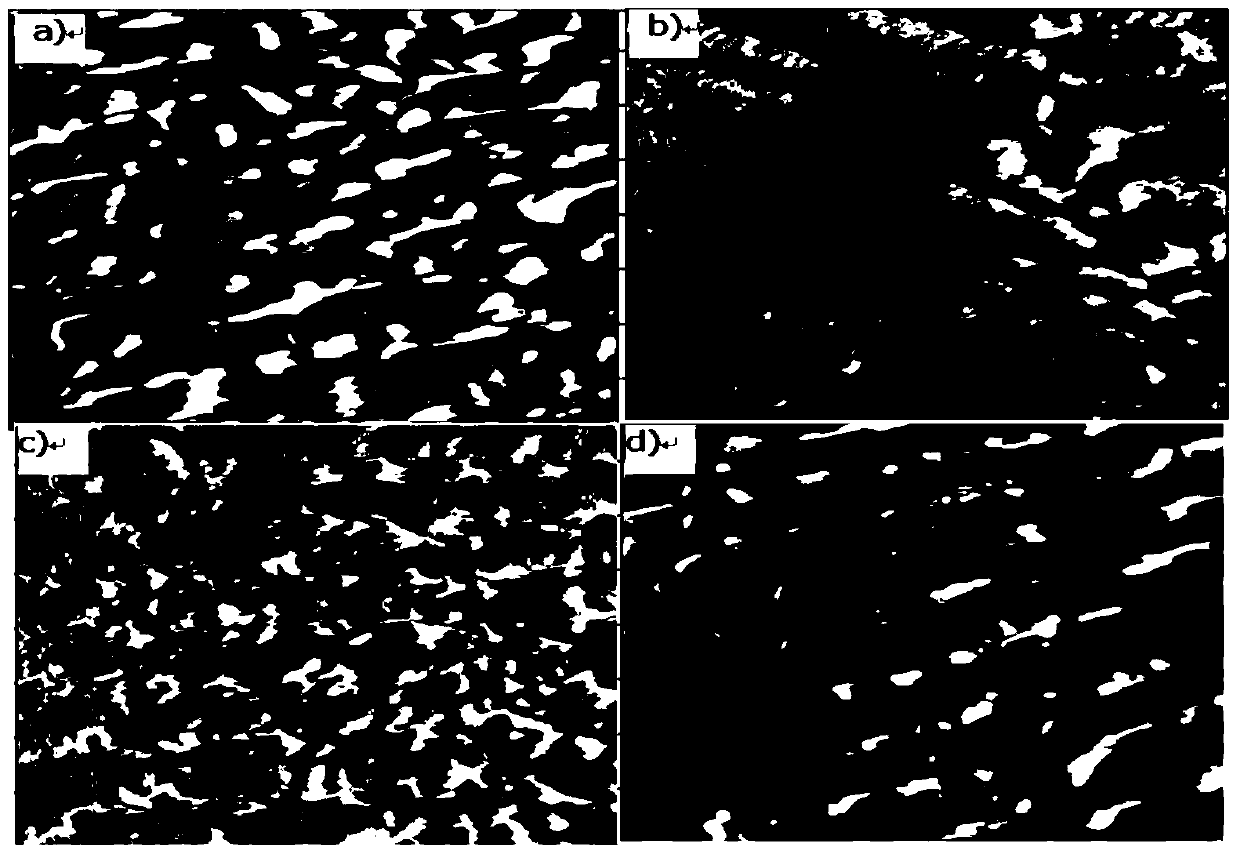

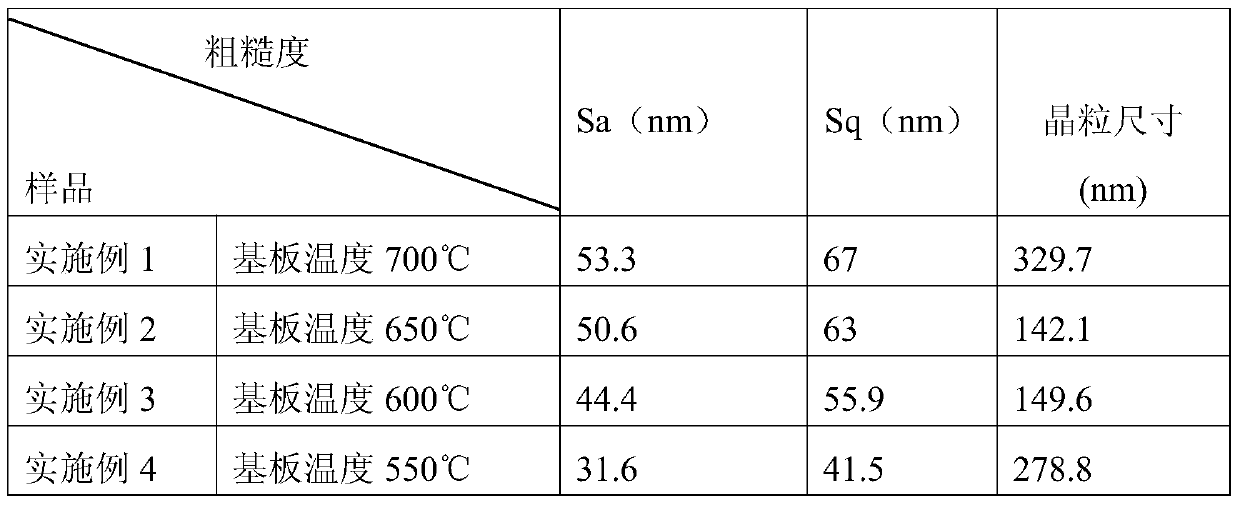

Preparation method of high-manganese alloy film Mn53Ni23Ga24

InactiveCN104947053AAccurate ingredientsFlat surfaceVacuum evaporation coatingSputtering coatingShielding gasManganese

The invention provides a preparation method of a high-manganese alloy film Mn53Ni23Ga24. The preparation method comprises the following steps: taking metal simple substances, namely Mn, Ni and Ga as target raw materials with the mole fraction ratio of Mn to Ni to Ga being 53:23:24, placing the target raw materials in a non-consumable vacuum arc furnace for smelting, vacuumizing to 5*10<-3>Pa, and then introducing shielding gas, so as to obtain a round target material; placing a pre-processed base plate and the target material in a vacuum system, and vacuumizing to 1.0*10<-4>Pa, wherein the temperature of the base plate is 500-700 DEG C, and the interval between the base plate and the target material is 3-5 cm; emitting lasers by a laser device, controlling the frequency to be 3-4 Hz, and sputtering for 1-3 hours, so as to prepare a film with required thickness; finally, annealing the film at the temperature of 800-900 DEG C, so as to obtain the high-manganese alloy film Mn53Ni23Ga24. According to the Mn53Ni23Ga24 alloy film prepared by the preparation method, the components are more precise, the roughness is low, the surface is smoother, the anisotropism is good, the martensite phase transformation temperature of the film is equivalent to that of block materials, required raw materials are low in price and rich in reserves, and the prepared alloy film is excellent in tenacity, high in strength, simple in technology, and easy for industrial production.

Owner:DALIAN UNIV

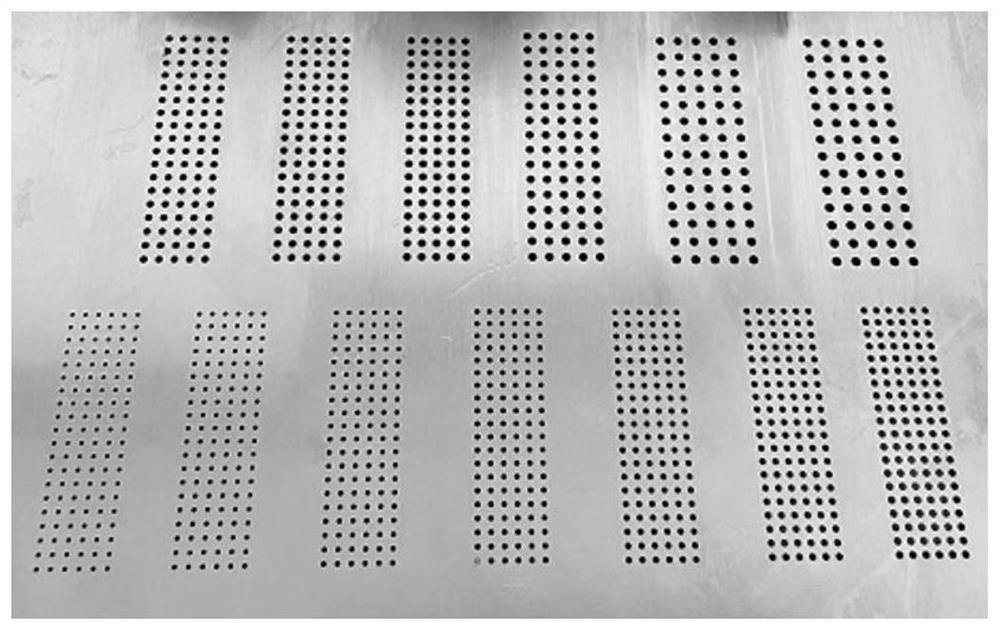

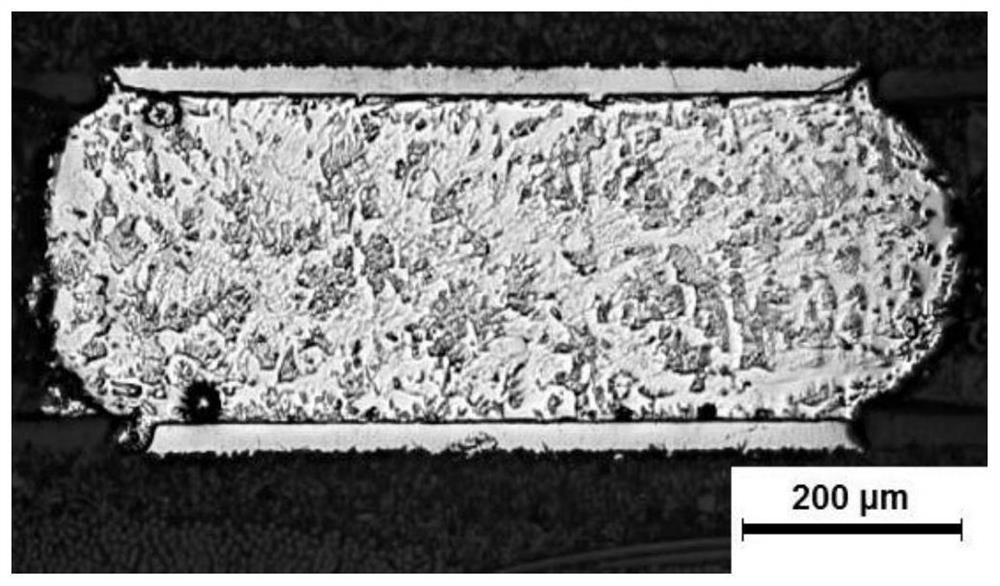

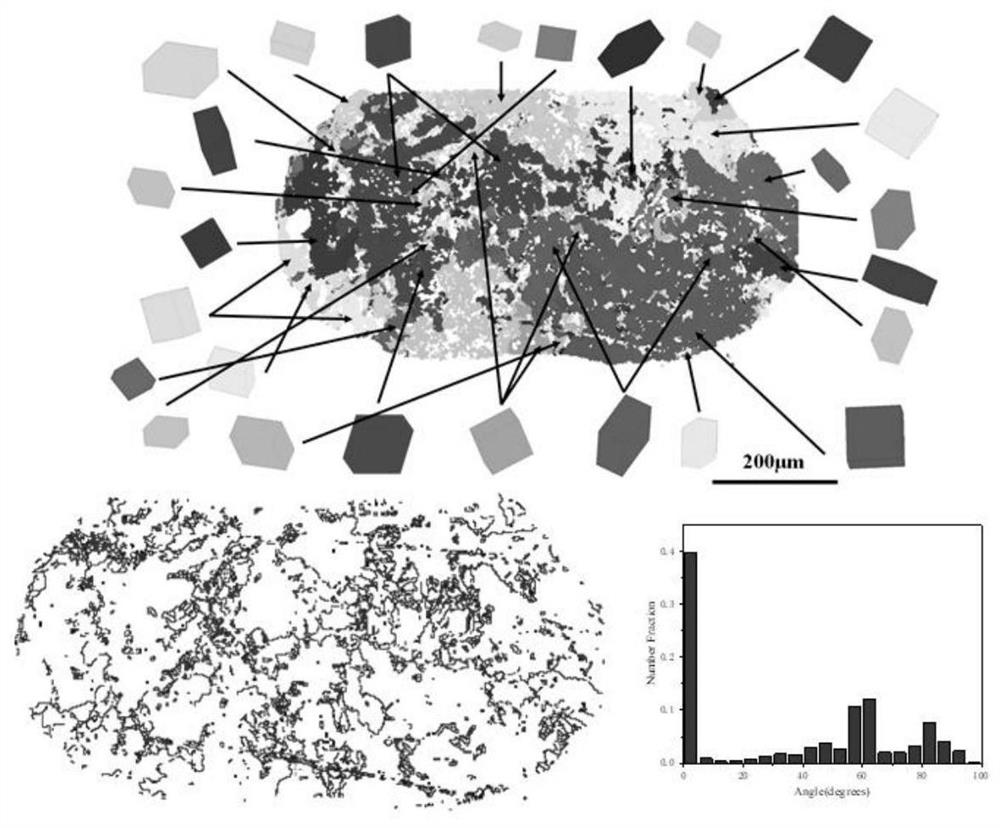

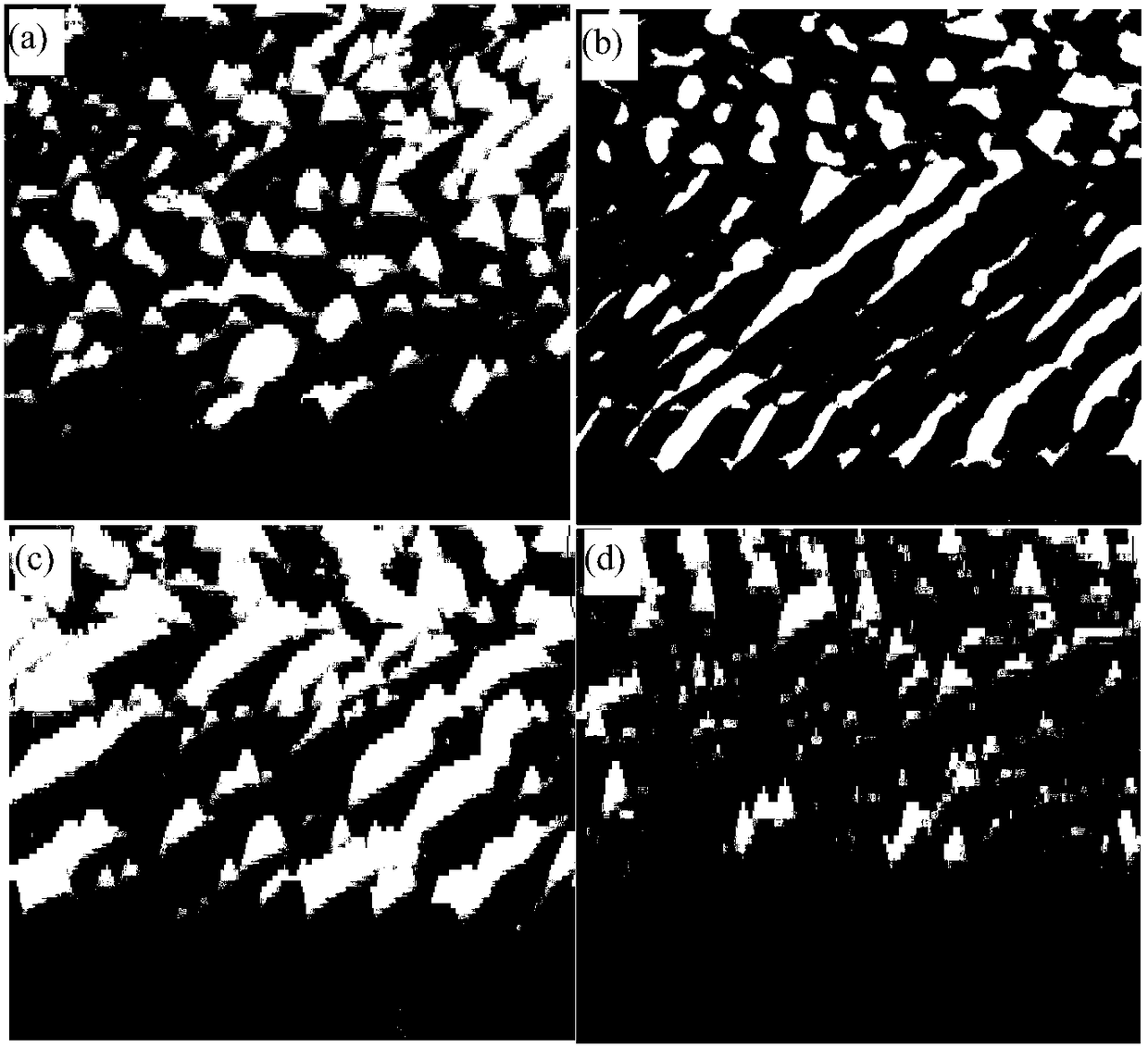

Method for forming polycrystalline structure welding spot by prefabricating IMC bonding pad

ActiveCN114211067AControllable solder joint sizeIncreased anisotropyHeating appliancesWelding/cutting media/materialsMaterials preparationFiller metal

The invention discloses a method for forming a polycrystalline structure welding spot by prefabricating an IMC bonding pad, and belongs to the technical field of material preparation and connection, the polycrystalline structure welding spot is formed by prefabricating the IMC bonding pad, and the method comprises the key steps that a welding ball is remelted and cooled on the prefabricated IMC bonding pad; the condition that the reliability and the service life of a Sn-based brazing filler metal welding spot are reduced due to anisotropy of Sn can be improved, and the welding spot is determined to be a polycrystalline structure welding spot through the EBSD technology. Therefore, the polycrystalline structure welding spots can effectively reduce the condition of unfavorable Sn grain orientation; the process is simple, the cost is low, and polycrystalline welding spots with controllable welding spot sizes and different grain orientations are manufactured.

Owner:BEIJING UNIV OF TECH

Method for preparing ni-mn-co-in alloy film by laser pulse sputtering deposition

ActiveCN105296925BAccurate ingredientsStrong anisotropyVacuum evaporation coatingSputtering coatingSelf consumptionShielding gas

Owner:DALIAN UNIV

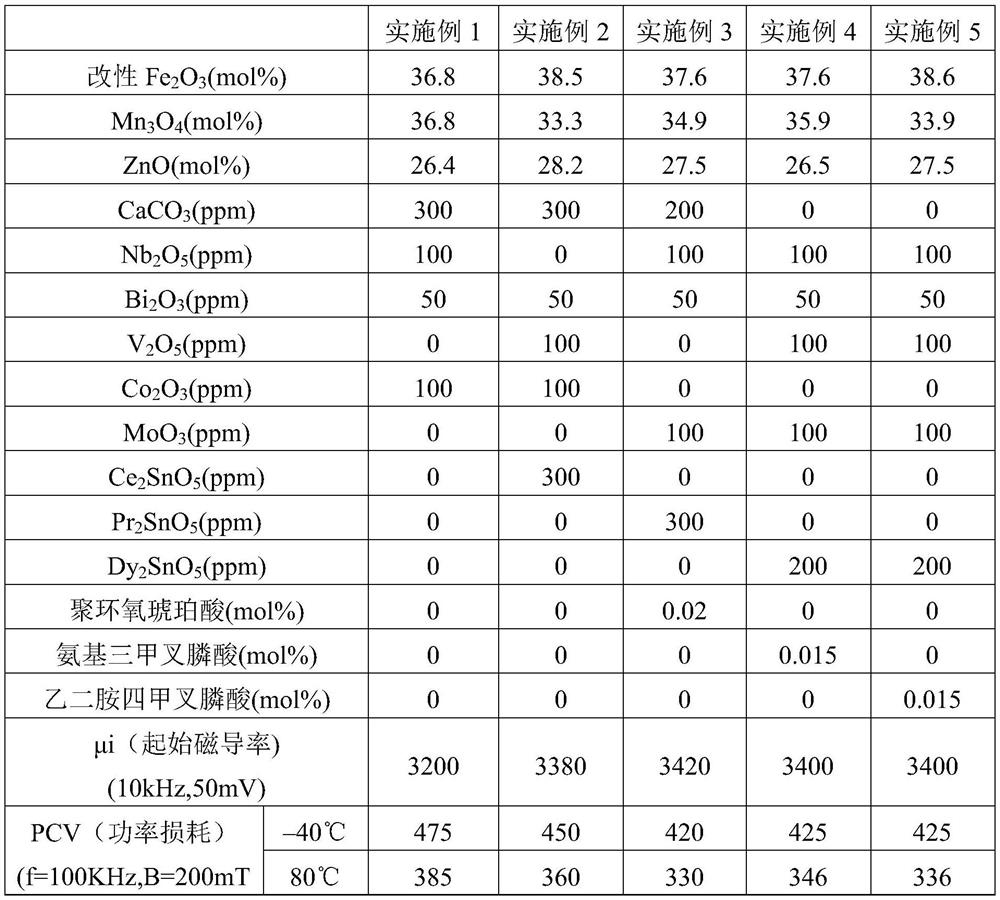

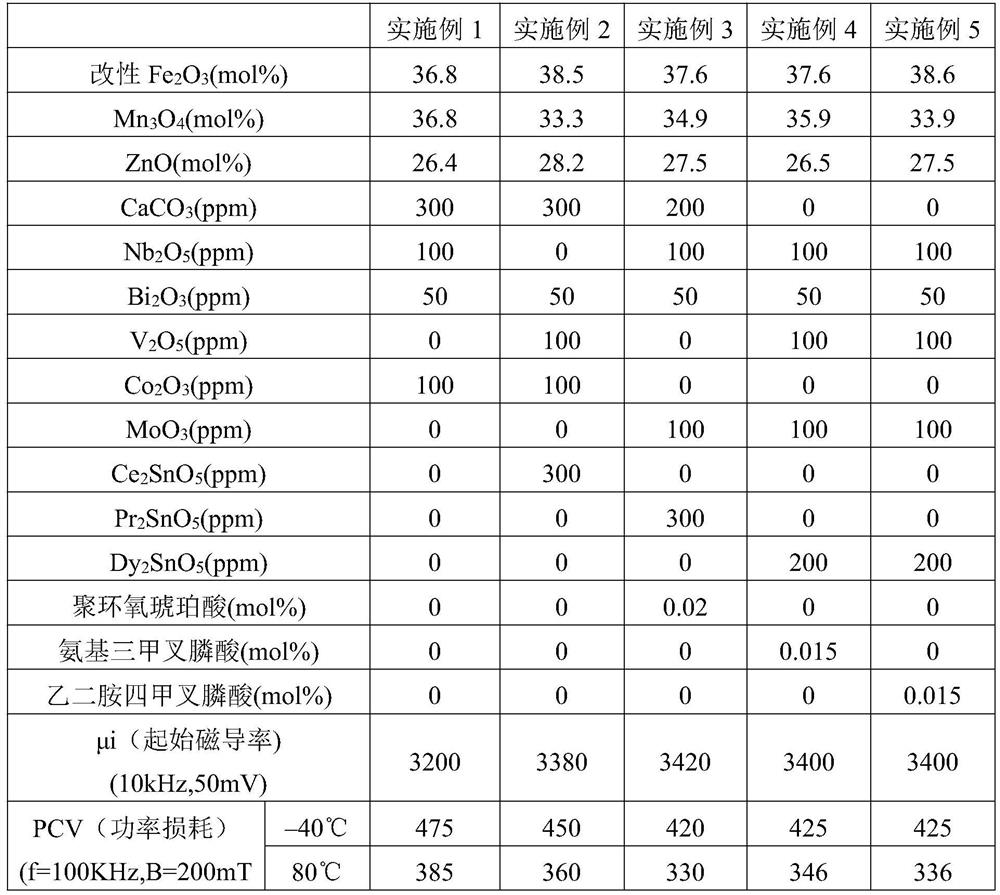

Low-loss soft magnetic ferrite material for 5G and preparation method thereof

ActiveCN113200741AReduce voidsNo deformationInorganic material magnetismInductances/transformers/magnets manufactureDielectric lossSoft magnet

The invention belongs to the technical field of ferrite synthesis, and relates to a low-loss soft magnetic ferrite material for 5G and a preparation method thereof. The material comprises 36.8 mol%-38.5 mol% of modified Fe2O3, 26.4 mol%-28.2 mol% of ZnO and the balance of Mn3O4. The soft magnetic ferrite material further comprises additives which comprise at least four of CaCO3, Nb2O5, Bi2O3, V2O5, Co2O3 and MoO3. The soft magnetic ferrite material further comprises a distortion resisting agent. According to the invention, Fe2O3 is modified by wrapping SiC fibers in Fe2O3, the modified raw material can be doped from all directions in the crystal after material transportation and mixing, the doping effect is more obvious, meanwhile, a barrier layer formed by the distortion resisting agent on the surface of the crystal can reduce gaps and also can prevent crystal lattices from deforming, the distortion resisting agent can be volatilized in the subsequent sintering process, so that the ferrite can keep relatively high magnetic conductivity while relatively low dielectric loss is ensured.

Owner:湖北微硕新材料有限公司 +1

A kind of preparation method of anisotropic lanthanum calcium manganese oxide ceramic target

The invention discloses a preparation method of an anisotropic lanthanum calcium manganese oxygen-based ceramic target, and belongs to the technical field of ceramic preparation. The method concretelycomprises the following steps of a soil process, a gel process, a glue drying process, a primary crushing process, a primary roasting process, a silver doping process, a powder static pressure process, a secondary roasting process, a secondary crushing process, a pre-molding pressing process, a final mold static pressing process and a tertiary roasting process. The method provided by the invention has the advantages that the Ag doping effect can be improved through liquid phase mixing and seepage sintering; the doping loss is greatly reduced, so that the practical doping proportion is similarto the calculation quantity; the anisotropy of the ceramic target is further enhanced; the non-oxidization sintering process is combined, so that a La1-xCaxMnO3 substrate and an Ag element are not oxidized before the doping completion; the doping effect is further improved. The isostatic cool pressing process is combined; multidirectional stress is generated in the seepage and pressing process; the target optimum growth is facilitated; meanwhile, the defect tissues are greatly eliminated; the ceramic target has strong anisotropy.

Owner:KUNMING UNIV OF SCI & TECH

A Method for Fractability Evaluation of Complex Reservoirs

ActiveCN112307601BSolve the problem of poor accuracy of fracturing evaluationSolve the problem of poor evaluation accuracyFluid removalDesign optimisation/simulationRock coreRock sample

The invention discloses a method for evaluating the fractureability of complex reservoirs, and specifically relates to the field of oil and gas exploration and development of complex reservoirs. The present invention selects a plurality of rock core samples in complex reservoirs, and sequentially conducts in-situ stress test experiments, rock triaxial mechanics experiments and rock failure experiments on a part of the rock core samples to determine the horizontal in-situ stress difference, brittleness, and residual stress of the rock core samples, The fracture toughness and tensile strength of the core samples were determined by performing the Brazilian splitting experiment on another part of the core samples, and the fitting degree between each parameter and the fracture pressure of the rock samples was determined based on regression analysis, and the weighting coefficients of each parameter were calculated. The data is used to calculate the fracture correction factor, and the measured parameters of rock samples and fracture correction factors are integrated to establish a complex reservoir fracturability evaluation model to evaluate the fracturability of complex reservoirs. The invention improves the accuracy of fracturing evaluation of complex reservoirs, and is beneficial to the efficient development of complex oil and gas resources.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Extrusion and forging integrated forming process of large diameter aq80m magnesium alloy cake

ActiveCN106890865BGrain refinementIncreased risk of crackingExtrusion control devicesPre deformationRoom temperature

The invention relates to a swaging integrated forming process for a large-diameter AQ80M magnesium alloy cake material, and belongs to the technical field of processing of a magnesium alloy material. The process comprises the following specific steps: preparing an AQ80M magnesium alloy ingot blank by semi-continuous casting; heating an extrusion die and an extrusion barrel; carrying out extrusion pre-deformation at low extrusion ratio; straightening and cutting the blank; carrying out multi-directional forging forming; and carrying out aging treatment. By the swaging integrated forming process for the large-diameter AQ80M magnesium alloy cake material, the large-diameter magnesium alloy cake material of which the diameter is phi 690 mm to phi 700 mm, the thickness is 100-110 mm, the tensile strength is greater than or equal to 330 MPa, the yield strength is greater than or equal to 190 MPa and the ductility is greater than or equal to 6% at room temperature, and the tensile strength is greater than or equal to 200 MPa, the yield strength is greater than or equal to 160 MPa and the ductility is greater than or equal to 30% at the temperature of 150 DEG C. The prepared large-size magnesium alloy cake material completely meets requirements of a large magnesium alloy part.

Owner:湖南镁宇科技有限公司

A kind of preparation method of ni50mn34in12co4 alloy film with high flatness

ActiveCN105018888BAccurate ingredientsReduce roughnessVacuum evaporation coatingSputtering coatingElectric arc furnaceShielding gas

The invention relates to a preparation method of a Ni50Mn34In12Co4 alloy thin film with high flatness. It includes the following steps: respectively taking Ni, Mn, In, and Co metal elements according to the mole fraction ratio of 50:34:12:4 and placing them in a vacuum non-consumable electrode electric arc furnace for smelting; vacuuming the electric arc furnace to 5×10 ‑3Pa, fill with protective gas to obtain a circular target; place the processed substrate and target in a vacuum system, evacuate to 1.0×10‑4Pa, and the distance between the substrate and the target is 3-5cm; then use a laser The laser was emitted, the frequency was controlled at 3-4 Hz, and the film was sputtered for 1-3 hours to obtain a thin film with the required thickness; finally, after annealing at 800-900 °C for 0.5-3 h, a high-flatness Ni50Mn34In12Co4 ferromagnetic shape memory alloy film was prepared. The Ni50Mn34In12Co4 alloy thin film prepared by the invention has more accurate composition, lower roughness and strong anisotropy; the alloy thin film has good toughness, high strength, simple preparation process, easy industrial production, and has important practicality for micro-intelligence and high integration. value.

Owner:DALIAN UNIV

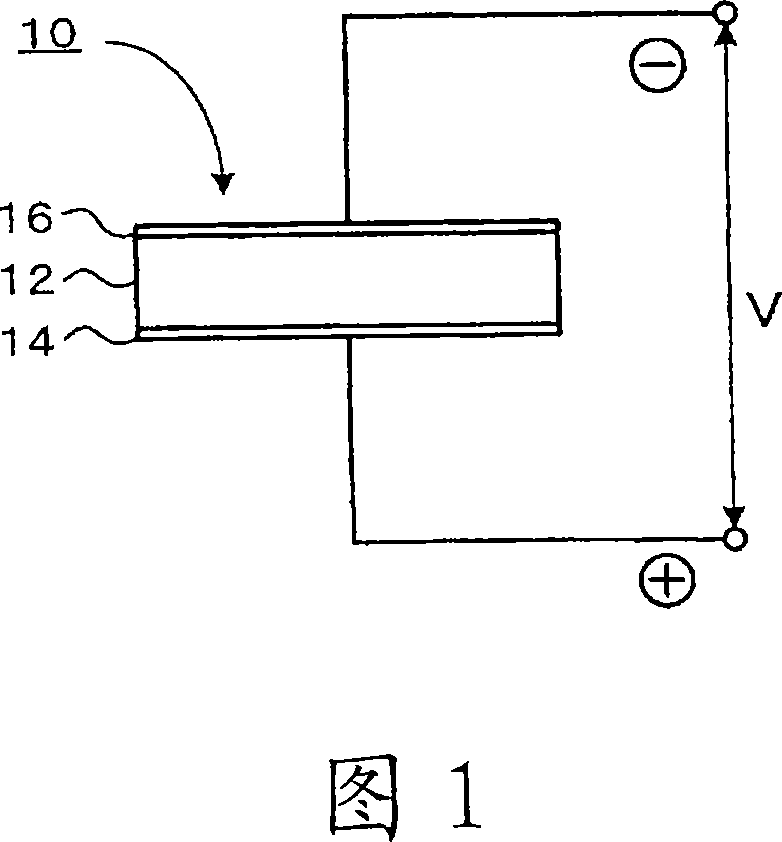

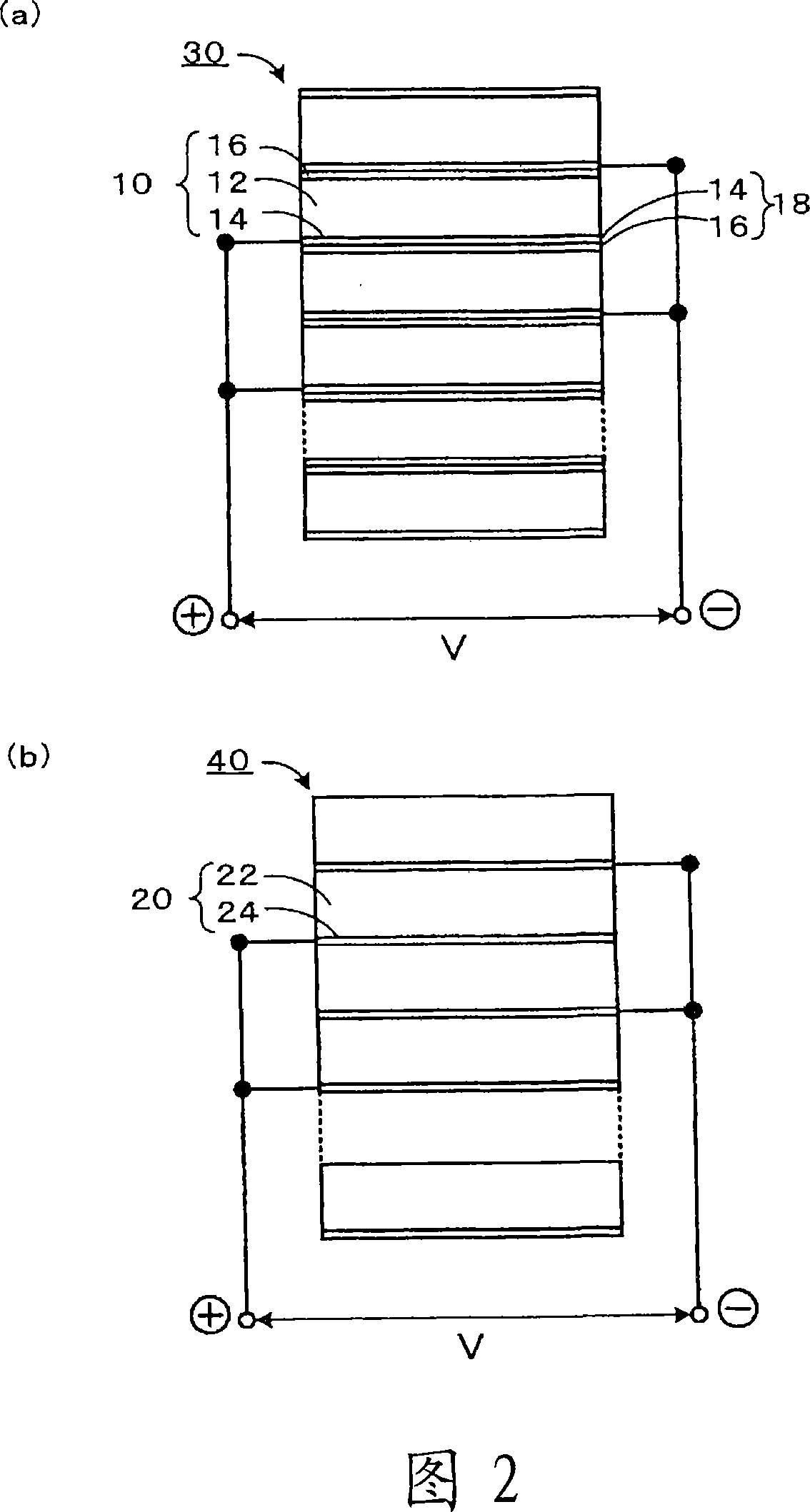

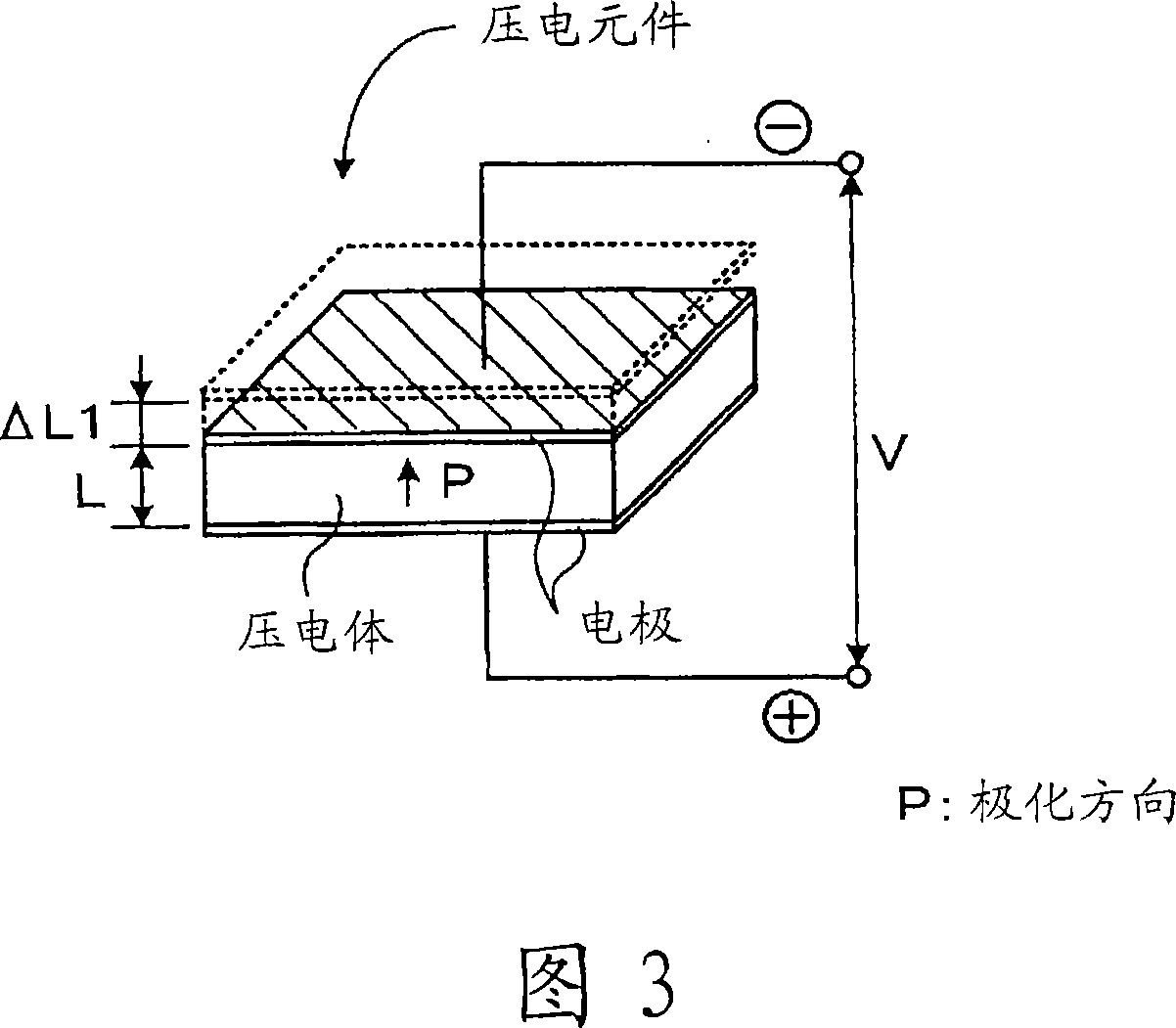

Piezoelectric element

InactiveCN101133502AImprove high temperature resistanceStable playPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesComposite materialElectrode

Owner:IBIDEN CO LTD +1

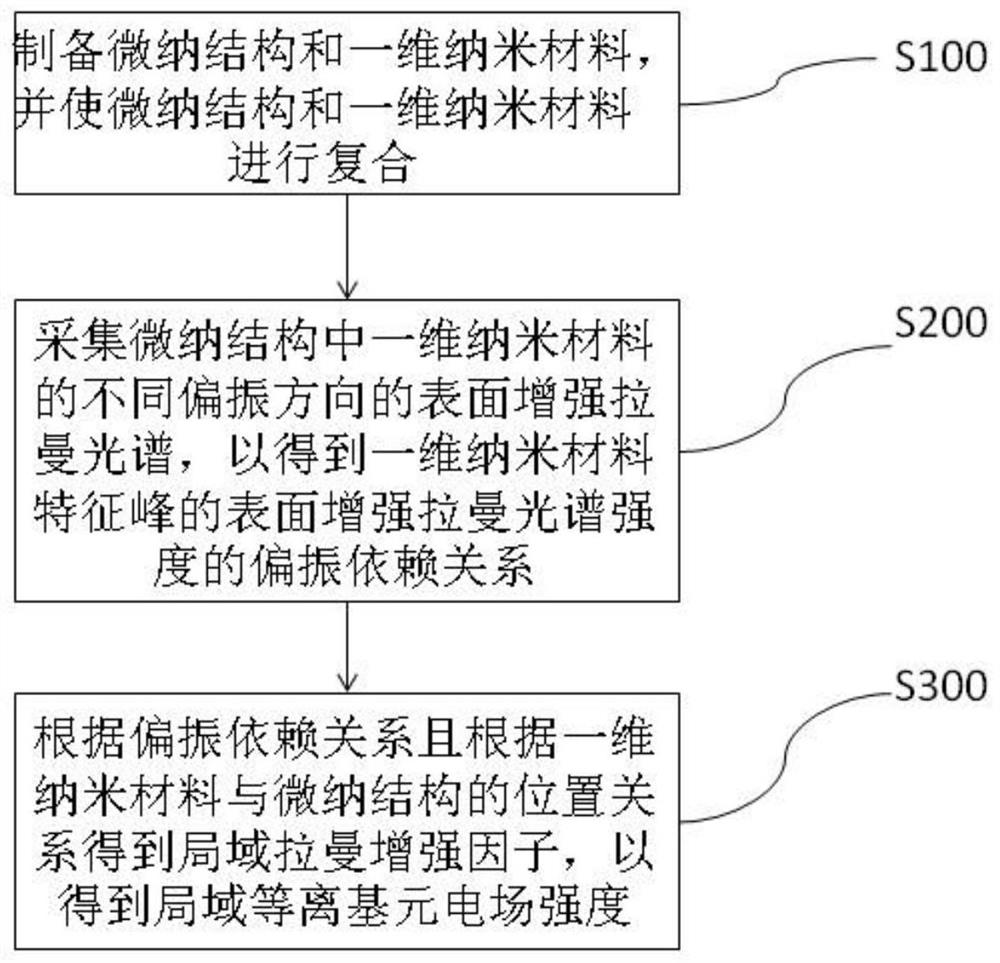

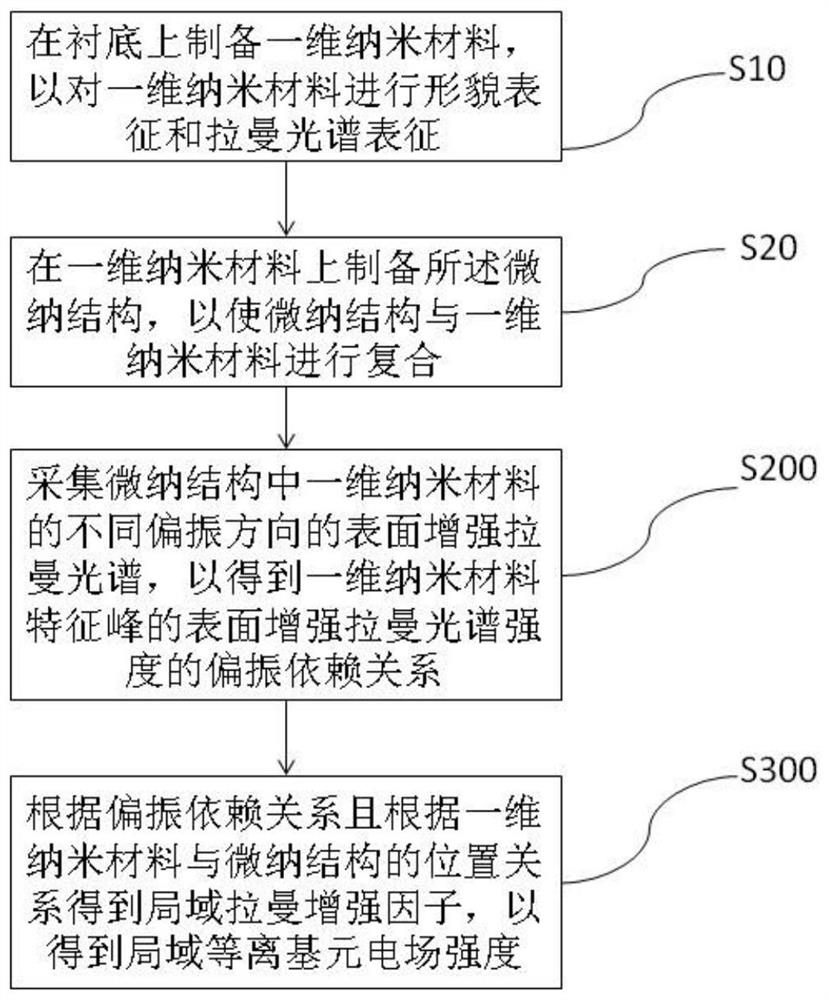

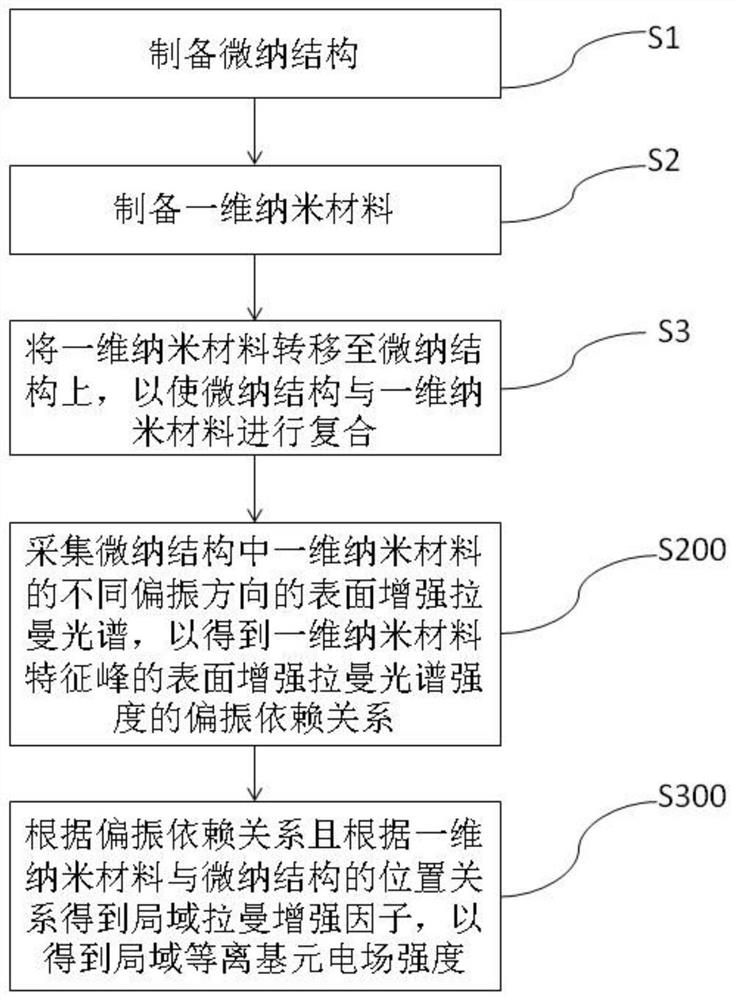

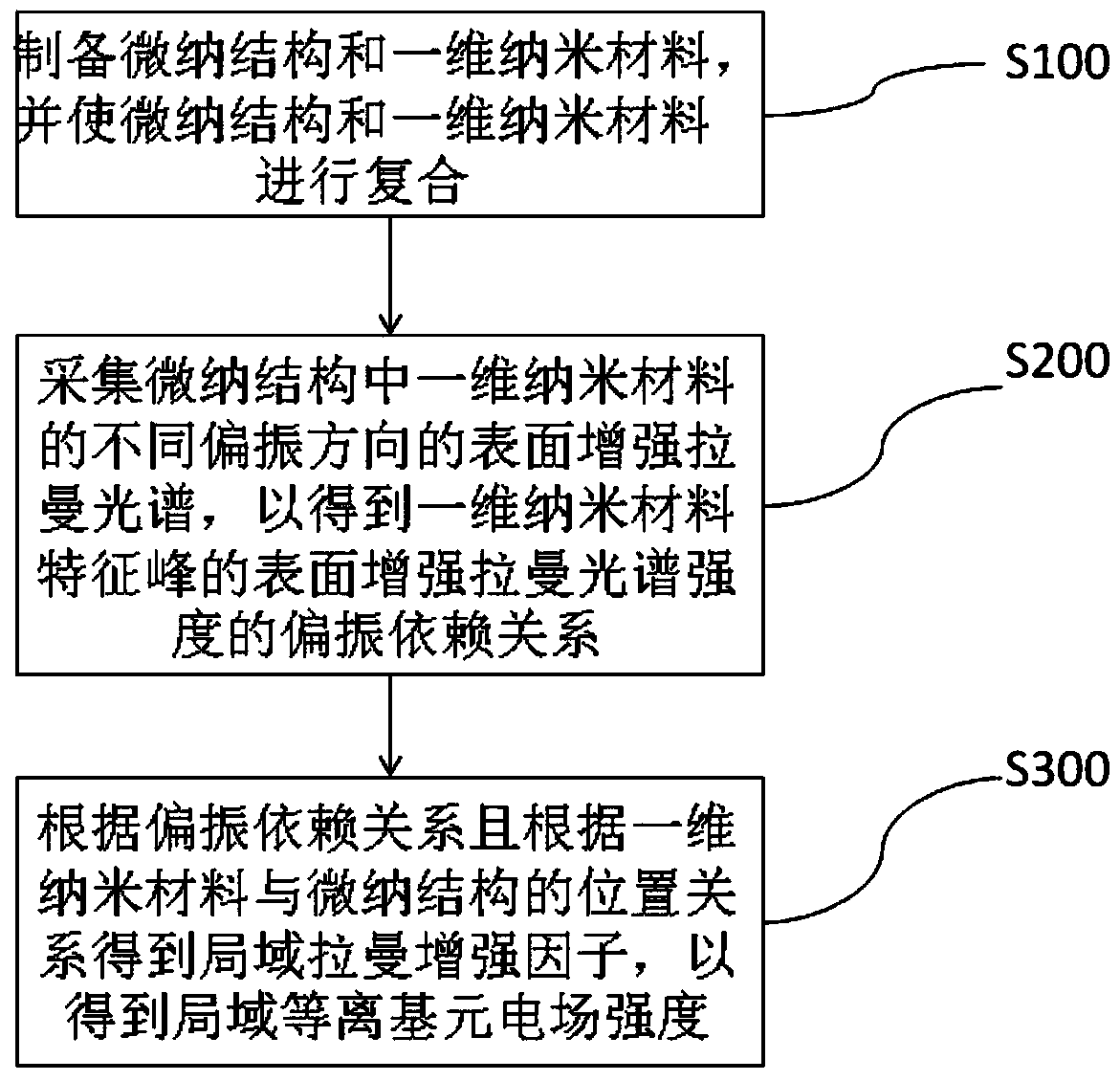

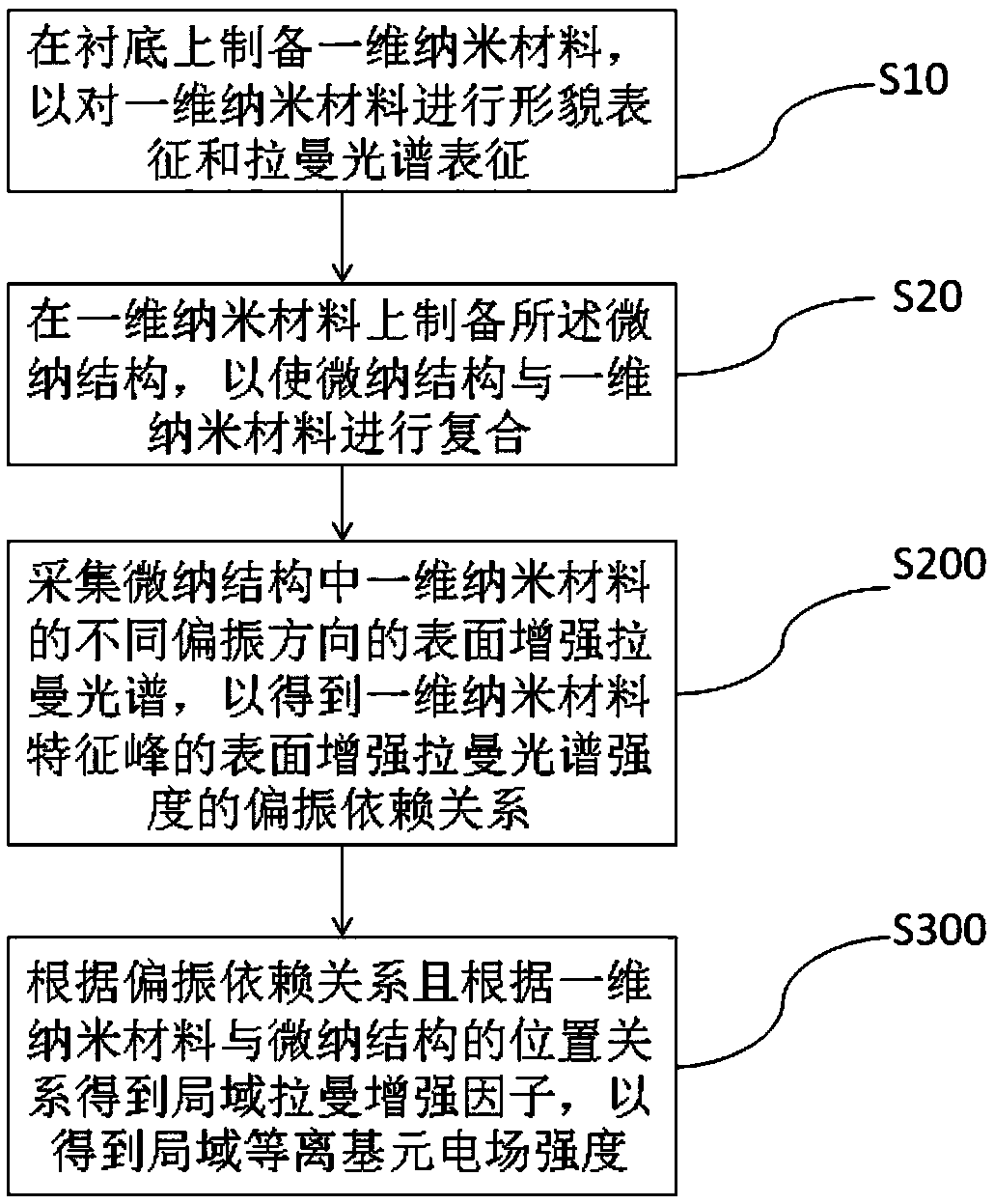

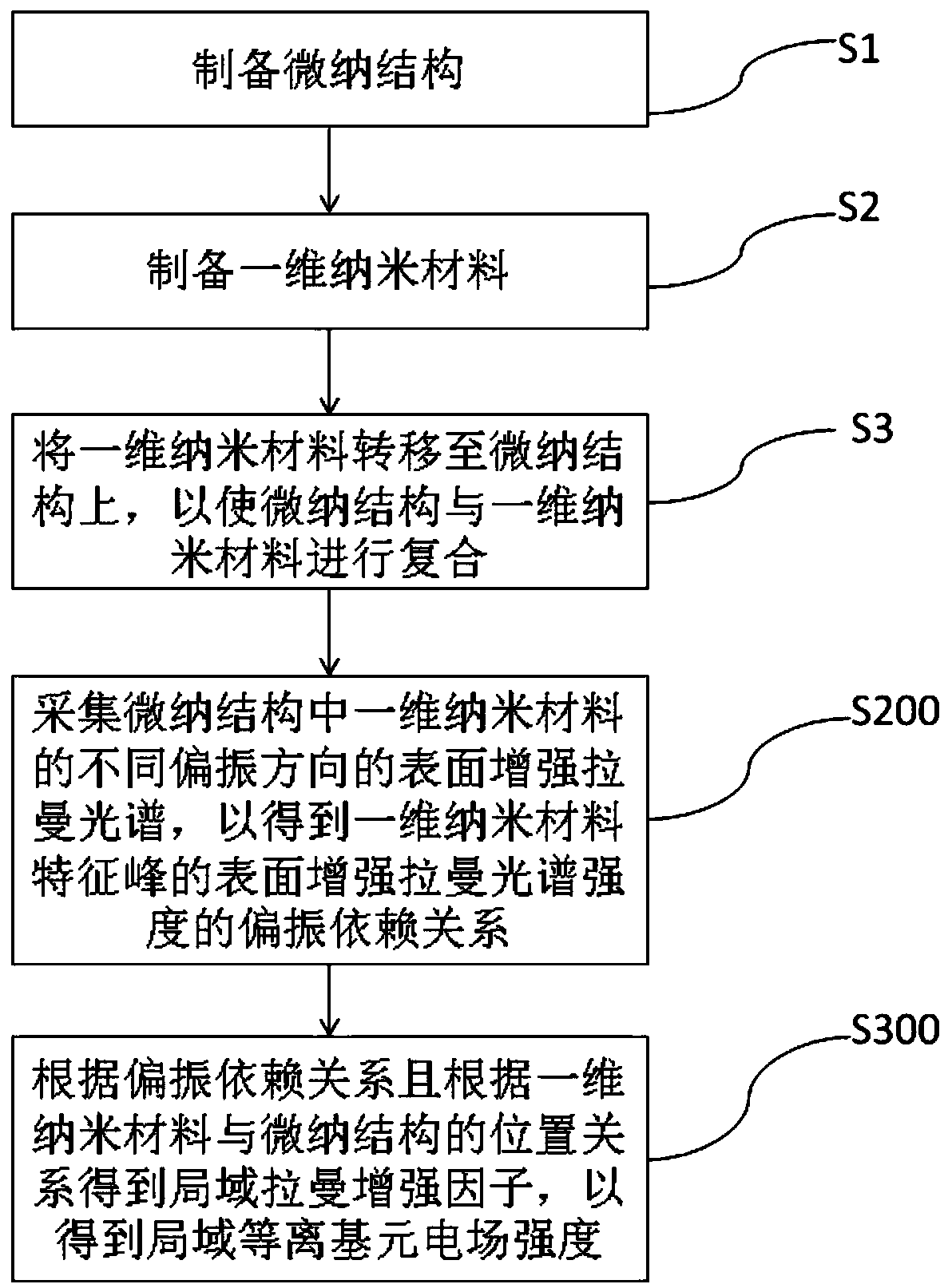

A detection method based on one-dimensional nanomaterials

ActiveCN108956577BHigh-resolutionHigh resolution detectionRaman scatteringElectrical field strengthSurface-enhanced Raman spectroscopy

The invention provides a one-dimensional nanomaterial-based detection method for detecting a local electric field of a plasmon in a micro-nano structure, and relates to the technical field of nano-optics. The detection method comprises the following steps: preparing the micro-nano structure and the one-dimensional nanomaterial, and compounding the micro-nanostructure with the one-dimensional nanomaterial; acquiring surface-enhanced Raman spectra of the one-dimensional nanomaterial in the micro-nanostructure in different polarization directions to obtain a polarization dependency of the surface-enhanced Raman spectrum intensity of a characteristic peak of the one-dimensional nanomaterial; and obtaining a local Raman enhancement factor according to the polarization dependency and a positional relationship between the one-dimensional nanomaterial and the micronano structure in order to obtain the local electric field intensity of the plasmon. The problem of low resolution of detection ofthe local electric field density in the prior art is solved in the invention.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

SAR image speckle suppression method based on second generation curvilinear wave transformation

ActiveCN101540042BGuaranteed edgeStrong anisotropyImage enhancementWave based measurement systemsAverage filterEuclidean vector

The invention discloses an SAR image speckle suppression method based on second generation curvilinear wave transformation, which mainly overcomes the defect of scratch effect and point target loss brought by a curvilinear wave to the SAR image speckle suppression. The SAR image speckle suppression method comprises the following steps: performing the second generation curvilinear wave transformation to a selected test image and partitioning the selected test image into 5 layers of subbands; keeping coefficients of the first layer unchangeable and zero-setting coefficients of the fifth layer; respectively evaluating parameter vectors of hybrid Gaussian models from the second layer to the fourth layer by an EM method; marking the coefficients from the second layer to the fourth layer; reconstructing the image, detecting the edge of the reconstructed image, and performing the average filtering to the uniform area of the reconstructed image to obtain the filtered image; and performing thenonlinear anisotropy dispersion iteration to a difference image obtained by the original image and the filtered image to obtain a speckle suppressed image. The invention has the advantages of keepingclean edge of the image, removing the scratch effect and remaining the point target characteristic information of the image, and can be used for preprocessing scene analysis and image understanding in the SAR image.

Owner:XIDIAN UNIV

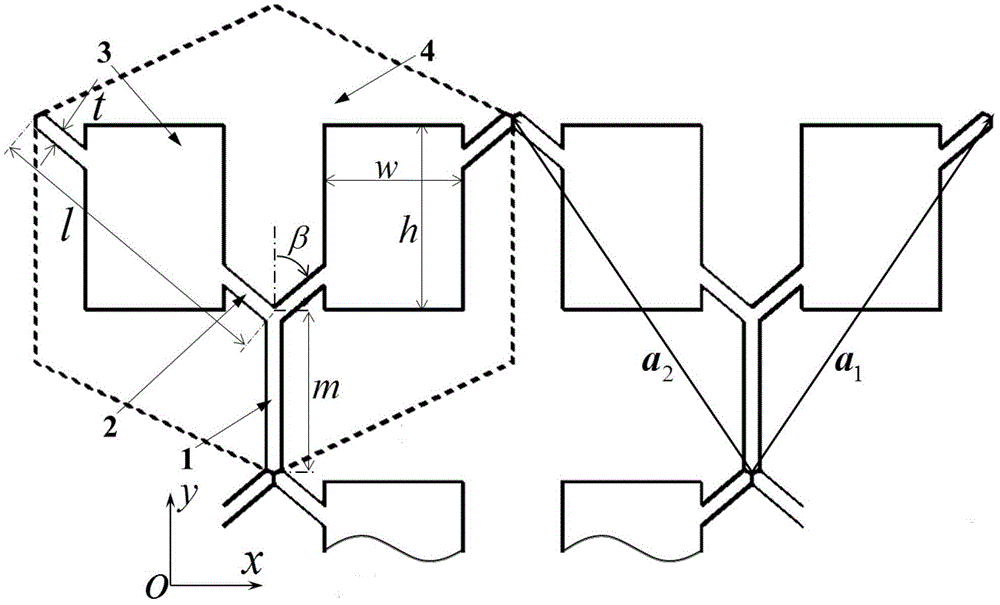

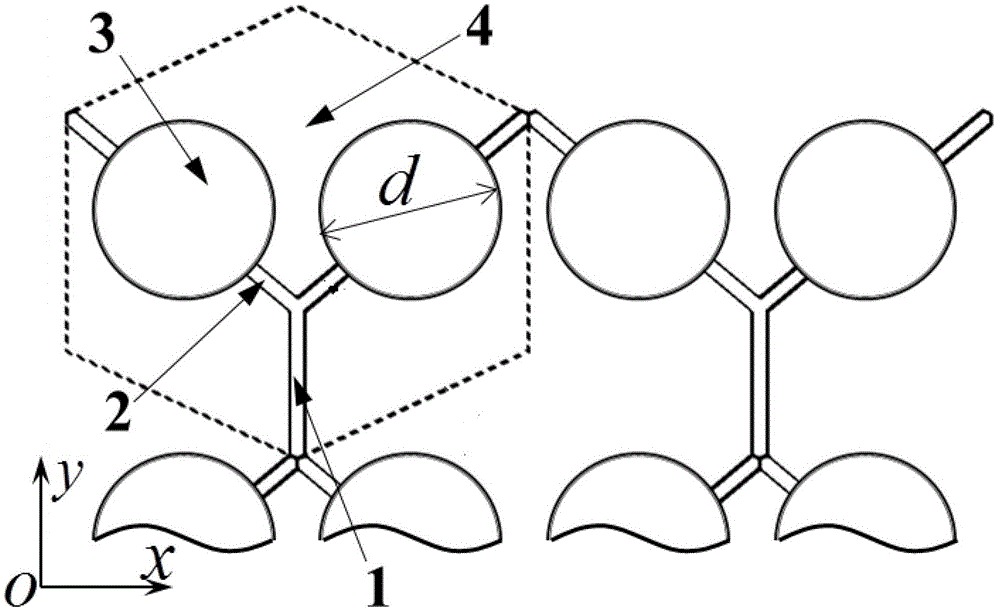

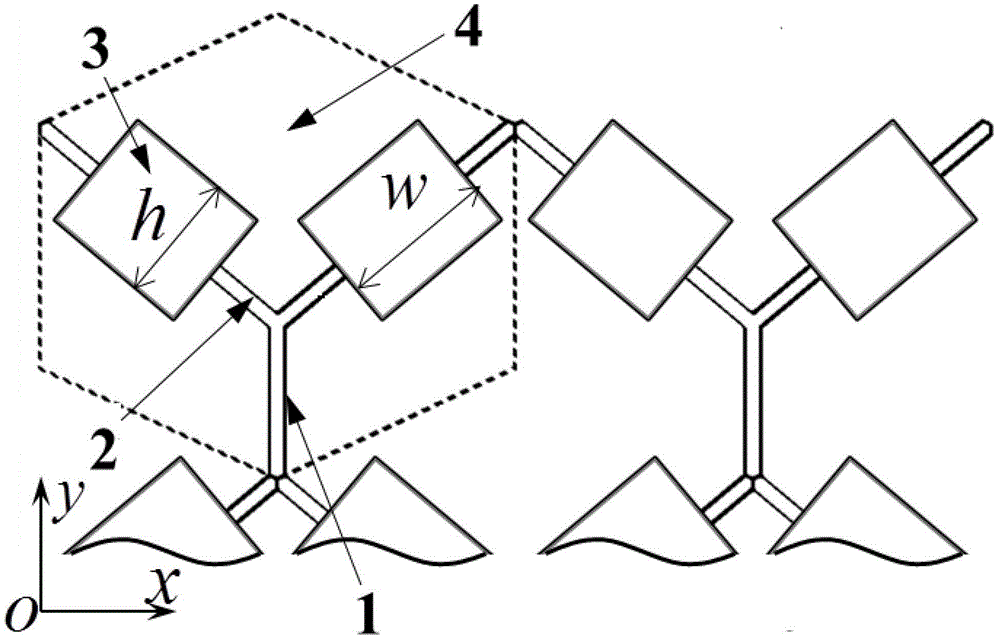

A metamaterial with five-mode material characteristics and its determination method

ActiveCN105116103BImprove acoustic propertiesReduce connection stiffnessSound producing devicesMaterial analysisQuantitative determinationRectangular coordinates

The invention relates to a metamaterial having the characteristics of a pentamode material, and a determination method thereof, and belongs to the field of sound wave regulation. The metamaterial has good characteristics of the pentamode material, is a honeycomb microstructure formed by unit cells, and each of the unit cells comprises a Y-shaped rod, balancing weights and a cavity; the rectangular coordinates of each of the unit cells is xoy and is a principal axis coordinate; each of the unit cells is a hexagon with parallel opposite sides with a same length, and one group of the opposite edges is vertical in direction; 6 vertexes of each of the unit cells from the smallest vertex of a y-axial coordinate along an anticlockwise direction are named as No.1-6 vertexes; the Y-shaped rod is formed through intersecting a vertical rod and bilaterally symmetrically distributed oblique rods in the unit cell, the intersection point of the three rods is No.0 vertex in the vertical symmetric axis of the unit cell, and the other ends of the vertical rods and the oblique rods are respectively positioned in the No.1, No.3 and No.5 vertexes; and the balancing weights are bilaterally symmetrically fixedly arranged on the oblique rods and are not in contact with the No.0 vertex. Whether the metamaterial has obvious pentamode characteristics or not is determined according to the unit cell configuration parameters pi and mu through the method, so the method fills the gap in quantitative determination methods of current pentamode material characteristics.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of 5g application low-loss soft ferrite material and preparation method thereof

ActiveCN113200741BReduce voidsNo deformationInorganic material magnetismInductances/transformers/magnets manufactureDielectric lossSoft magnet

Owner:湖北微硕新材料有限公司 +1

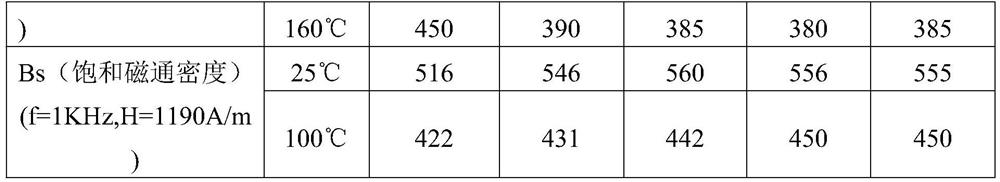

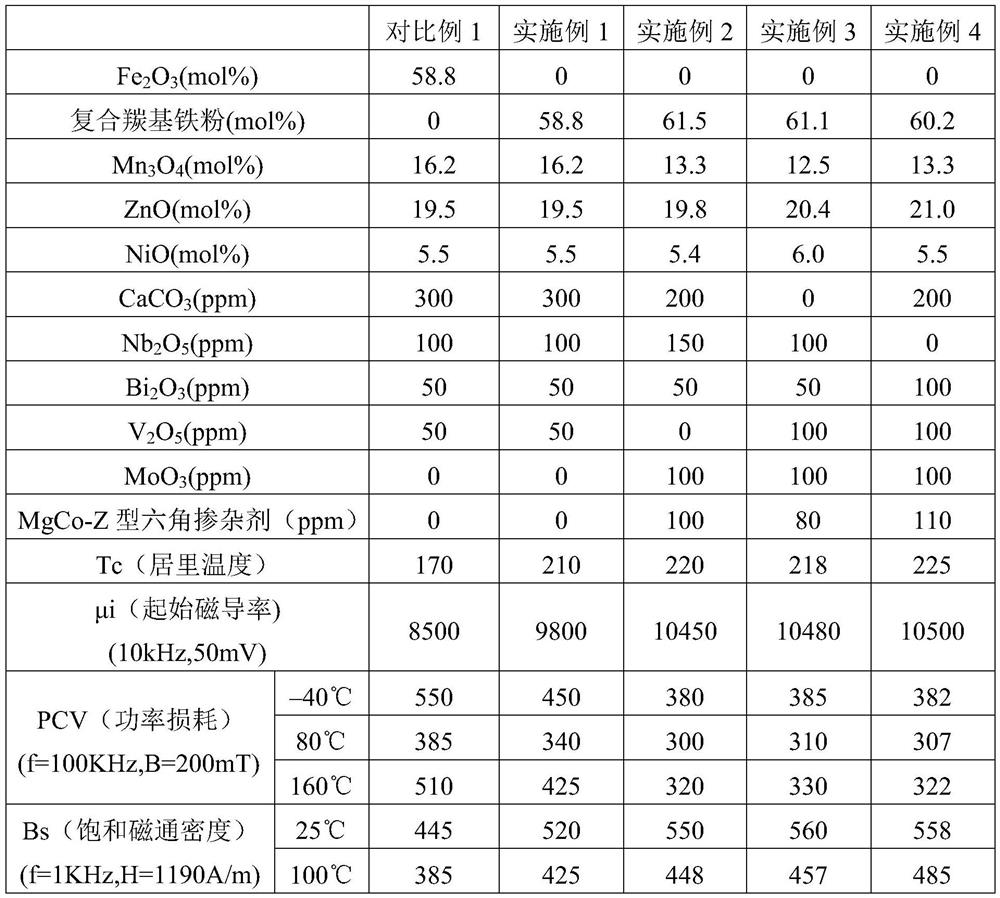

High-superposition and high-permeability ferrite material and preparation method thereof

The invention belongs to the technical field of ferrite preparation, and discloses a high-superposition and high-permeability ferrite material and a preparation method thereof. The high-superposition and high-permeability ferrite material comprises raw materials, auxiliary additives and an MgCo-Z type hexagonal dopant, the raw materials comprise a mixture of composite carbonyl iron powder, Mn3O4, ZnO and NiO, the content of the composite carbonyl iron powder is 58.8-61.5 mol%, the content of the ZnO is 19.5-21.0 mol%, the content of the NiO is 5.5-6.0 mol%, and the balance is Mn3O4; The auxiliary additives comprise at least four of CaCO3, Nb2O5, Bi2O3, V2O5 and MoO3, on the basis of a traditional ternary formula system, a small amount of NiO is added to form a quaternary formula system, the saturation magnetic flux density and the magnetic conductivity of the material can be improved, the ferrite formed under the synergistic effect of the additives guarantees high Curie temperature and high initial magnetic conductivity, power loss can be greatly reduced, and high saturation magnetic flux density and superposition capability can be maintained.

Owner:湖北微硕新材料有限公司 +1

One-dimensional nanomaterial-based detection method

ActiveCN108956577AHigh-resolutionHigh resolution detectionRaman scatteringMicro nanoElectrical field strength

The invention provides a one-dimensional nanomaterial-based detection method for detecting a local electric field of a plasmon in a micro-nano structure, and relates to the technical field of nano-optics. The detection method comprises the following steps: preparing the micro-nano structure and the one-dimensional nanomaterial, and compounding the micro-nanostructure with the one-dimensional nanomaterial; acquiring surface-enhanced Raman spectra of the one-dimensional nanomaterial in the micro-nanostructure in different polarization directions to obtain a polarization dependency of the surface-enhanced Raman spectrum intensity of a characteristic peak of the one-dimensional nanomaterial; and obtaining a local Raman enhancement factor according to the polarization dependency and a positional relationship between the one-dimensional nanomaterial and the micronano structure in order to obtain the local electric field intensity of the plasmon. The problem of low resolution of detection ofthe local electric field density in the prior art is solved in the invention.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A kind of long cycle life lithium ion battery carbon negative electrode material and preparation method thereof

ActiveCN106252597BWide selection of raw materialsIncrease profitCell electrodesHigh rateResin coating

The invention relates to a carbon negative electrode material of a lithium-ion battery with long cycle life and a preparation method of the carbon negative electrode material. The material has a multi-layer carbon shell structure, and carbon shells are in spherical-like concentric arrangement and have a spherical shape and the diameters are 0.5-30 microns. The carbon material is prepared through low-temperature thermal treatment and high-temperature thermal treatment on a precursor which is prepared by chemical vapor pyrolysis or through carbon particles by a resin coating method. The carbon material has charge and discharge behaviors similar to a graphite negative electrode material, overlong cycling stability, more excellent charge and discharge capacity and high rate capability when used as the negative electrode material of the lithium-ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com