Wood and bamboo-unfolded thick veneer collection laminated material and preparation method thereof

A technology of laminated lumber and veneer, which is applied in the direction of wood layered products, wooden veneer joints, veneer presses, etc., to achieve the effects of enhanced physical properties, good secondary processability, and strong longitudinal mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

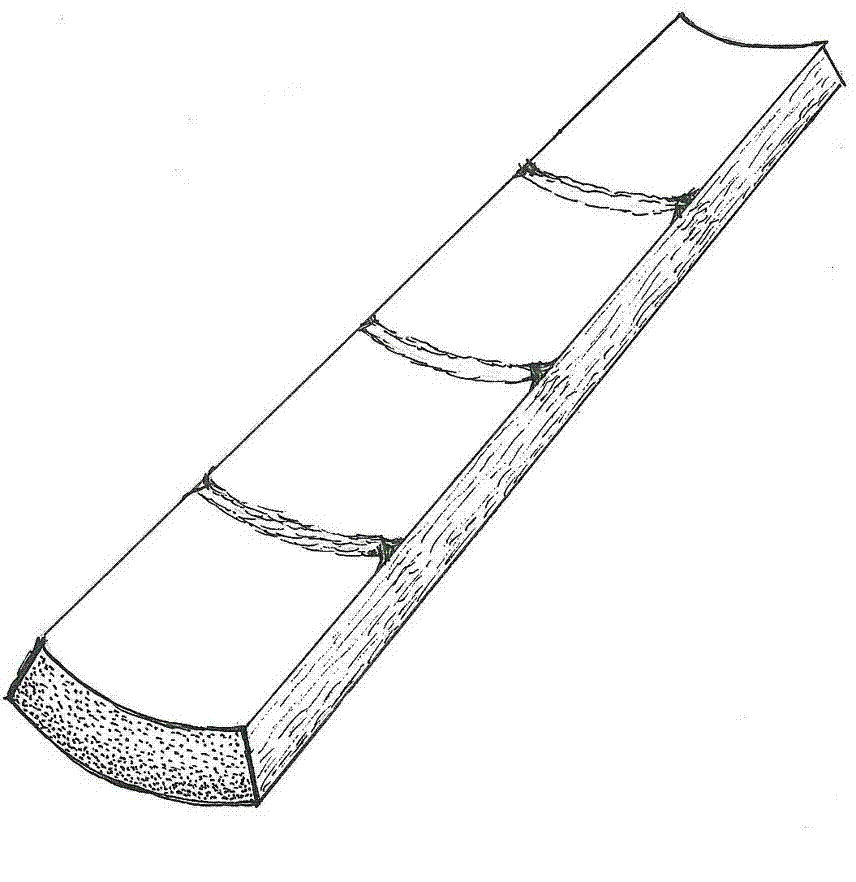

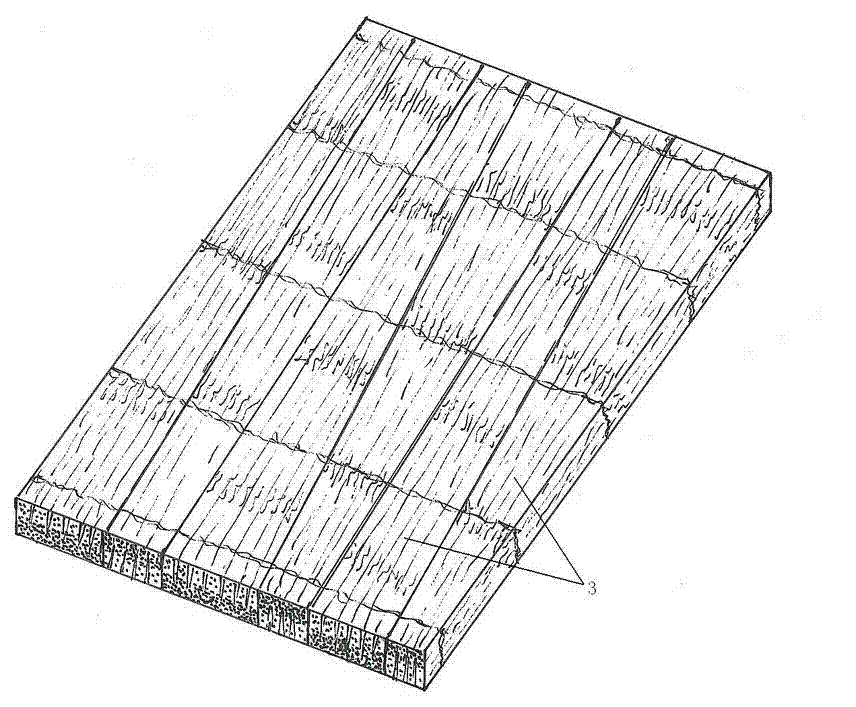

[0036] see Figure 4 , Figure 5 with Image 6 The wood and bamboo thick veneer aggregation laminated timber of the present embodiment is stacked alternately by at least three layers of odd-numbered wood laminate veneers 1 and bamboo thick veneer 2, and bonded by an adhesive Repression becomes an integration. Figure 4 It is shown that two layers of wood laminated veneer 1 and one layer of bamboo expanded thick veneer 2 are alternately superimposed on three layers of veneer. Figure 5 It is shown that three layers of wood laminated veneer 1 and two layers of bamboo thick veneer 2 are alternately superimposed on five layers of veneers. Image 6 It is shown that four layers of wood laminated veneer 1 and three layers of bamboo thick veneer 2 are alternately stacked to form a total of seven layers of veneer. It can be seen from the figure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com