Patents

Literature

121 results about "Rock failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock failure definition. Stress strain relationships in rocks examined the elastic behavior of rocks, which was largely reversible. Here we deal with permanent deformation. By rock failure, we mean the formation of faults and fracture planes, crushing, and relative motion of individual mineral grains and cements.

Quantitative forecasting method of tectonic fissure occurrence

InactiveCN104200039AEasy to openHigh porositySpecial data processing applicationsPredictive methodsMechanical property

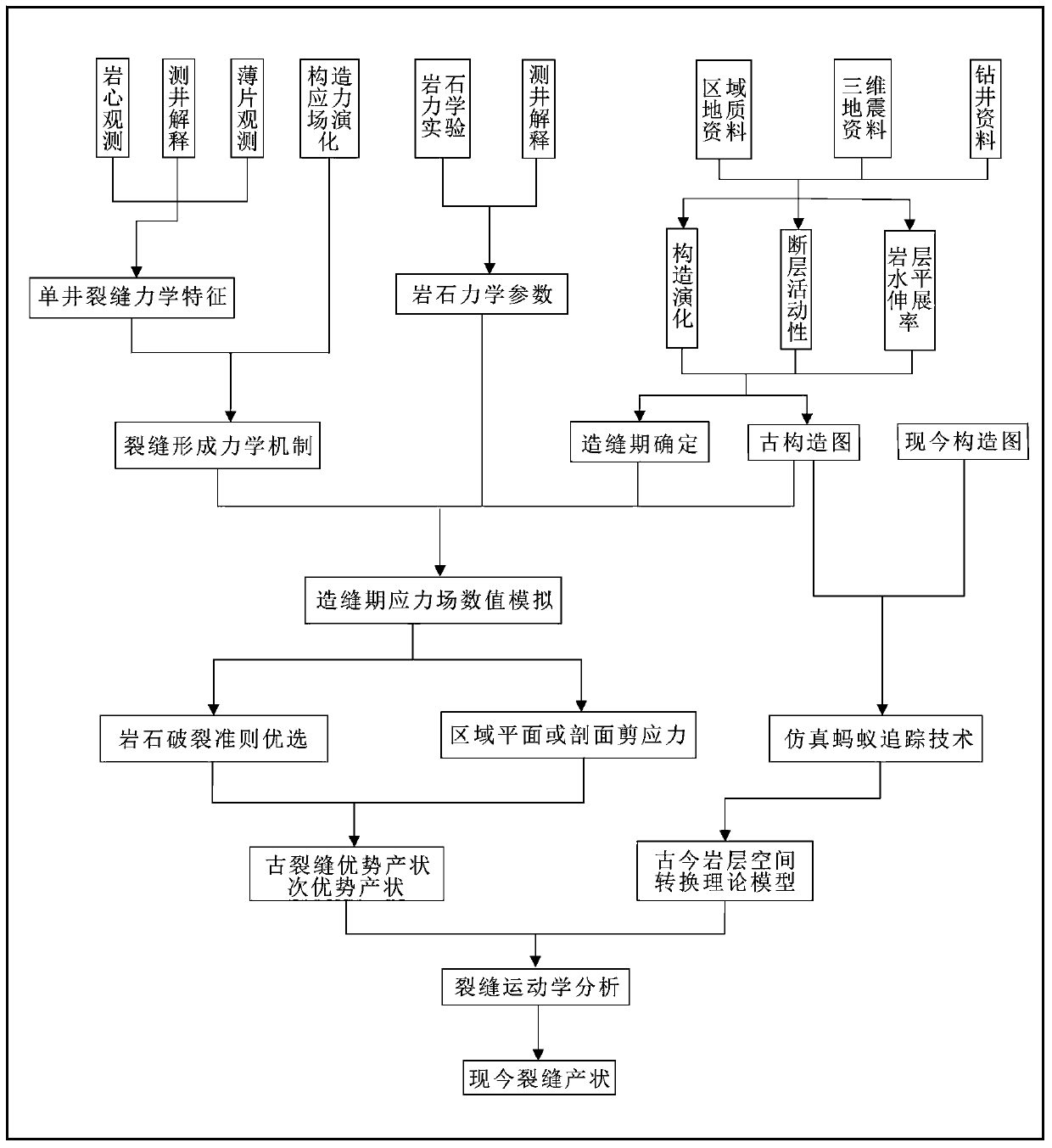

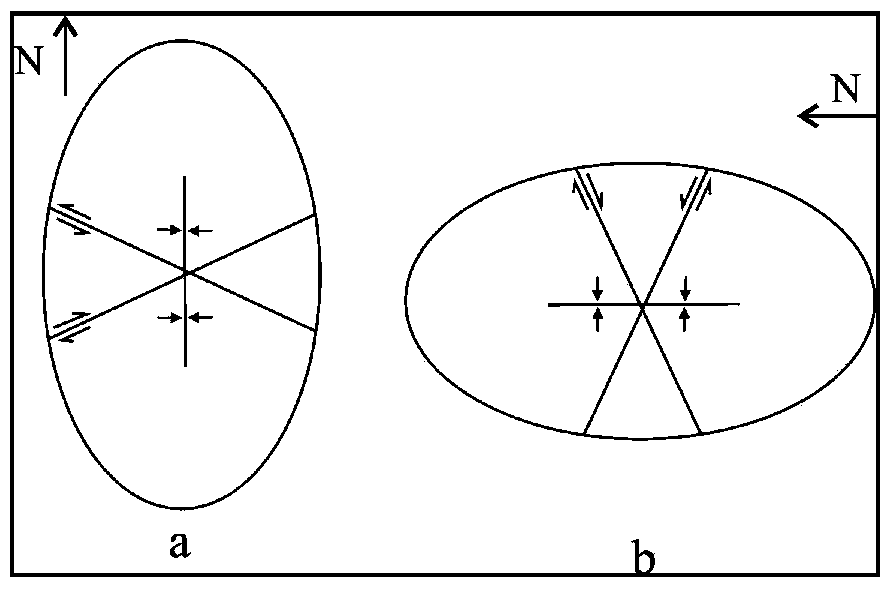

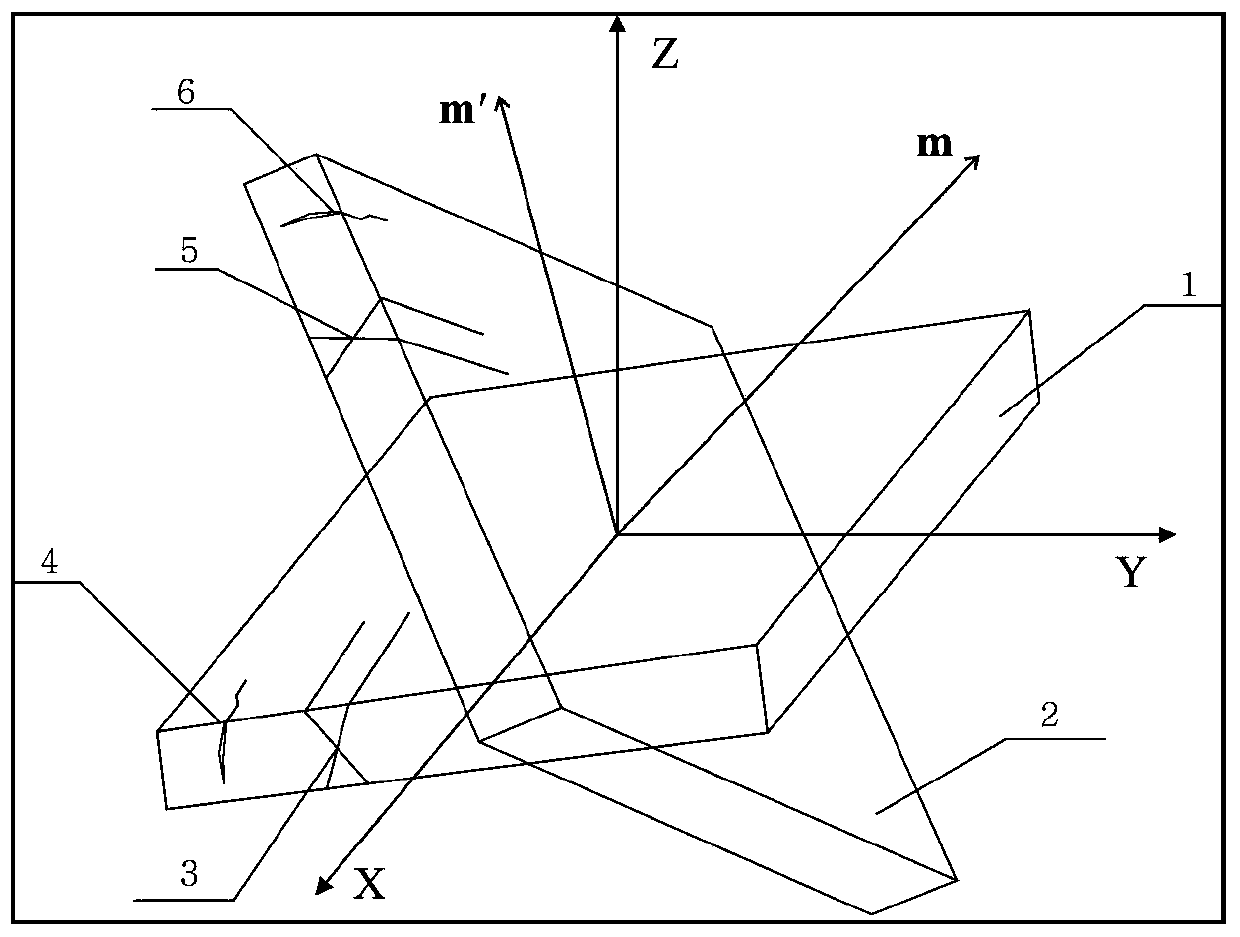

The invention relates to the field of oil-gas field exploration and development, particularly to a quantitative forecasting method of tectonic fissure occurrence. The quantitative forecasting method includes firstly determining a fissure mechanical property and rock mechanics parameters in a research area and restoring a paleotectonic map; secondly performing a numerical simulation of a paleostress field; thirdly selecting an appropriate rock failure principle according to the simulated paleostress field and the fissure mechanical property, and forecasting the best occurrence and the second-best occurrence of paleofissures on the basis of plane shearing strength distribution or profile shearing strength distribution of the stress field in the research area; coupling spatial positions of the paleorock stratum and the current rock stratum based on the simulated ant tracing technique, and then establishing a spatial switching theoretical model of the paleorock stratum and the current rock stratum; performing the quantitative analysis of fissure kinematics characteristics, and forecasting the occurrence of the current fissures according to that of the paleofissures.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Calculating method for size of fracturing and broken region of horizontal well for shale

ActiveCN105019877AAccurate quantitative evaluationSolve problems that cannot be widely promoted and appliedFluid removalCalculation methodsPoromechanics

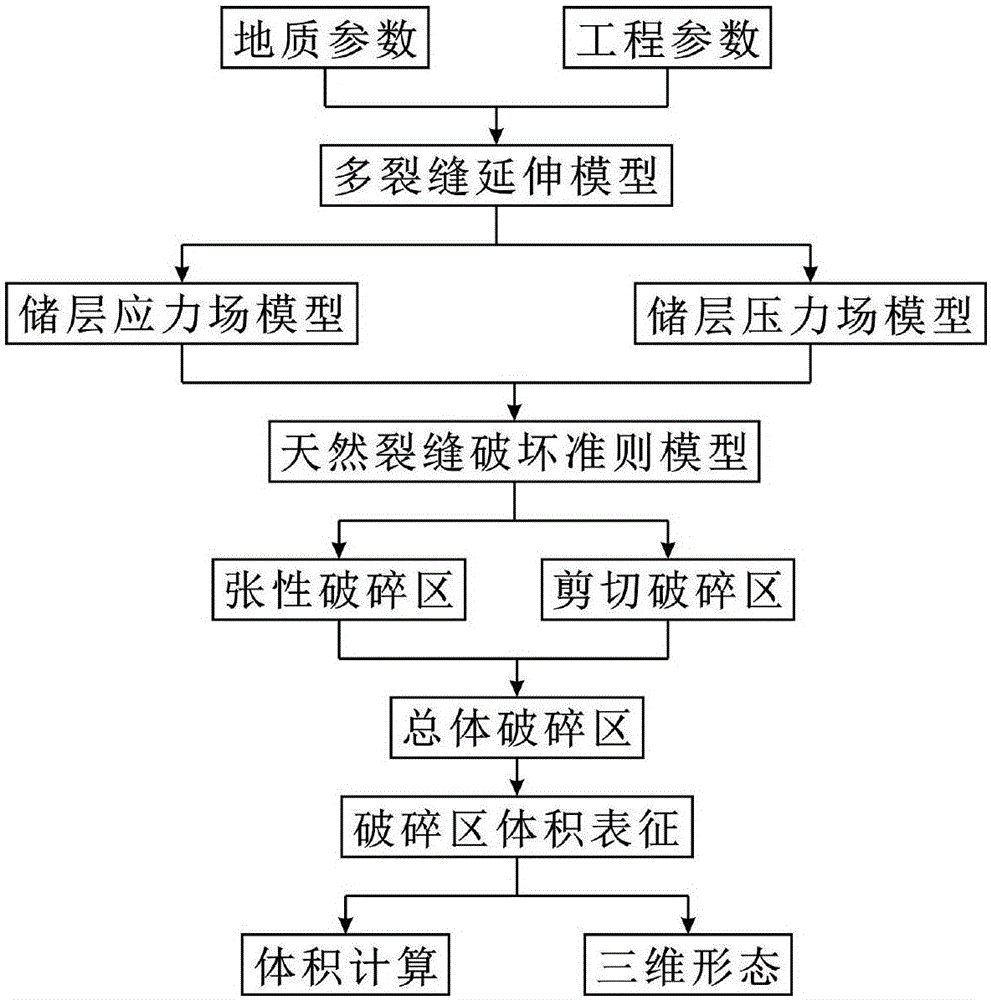

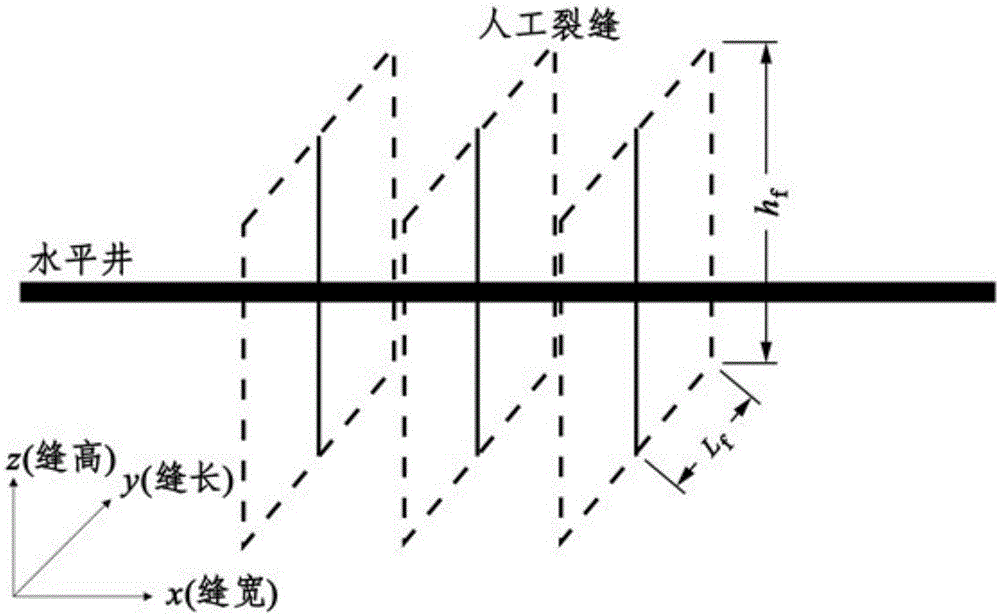

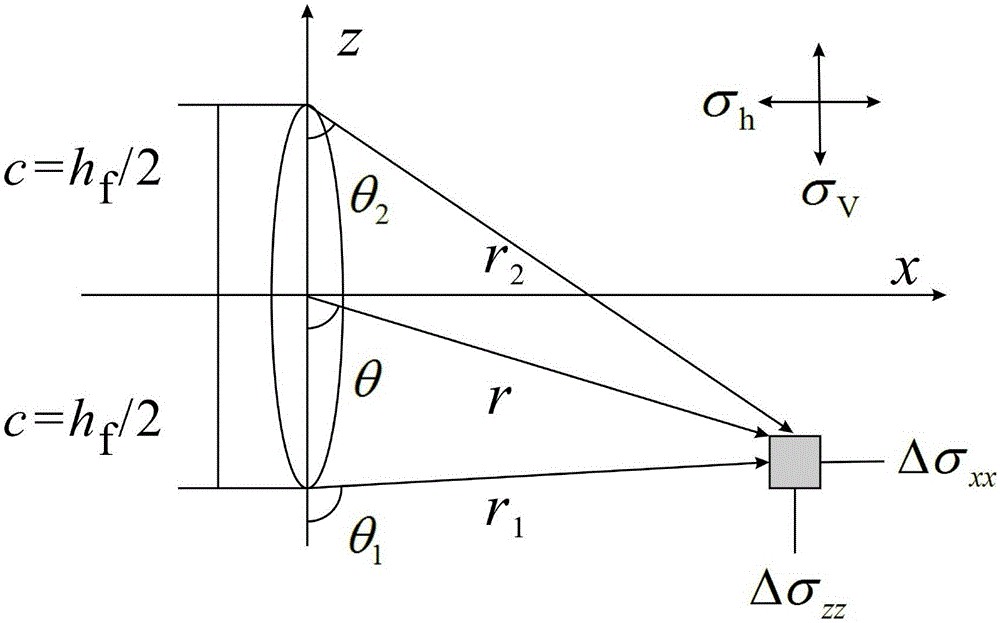

The invention discloses a calculating method for the size of a fracturing and broken region of a horizontal well for shale. The calculating method comprises following steps of: A, utilizing the theory of crack propagation available to establish a hydraulic fracture extension model during a shale fracturing process; B, utilizing the theory of rock mechanics available to establish a model for stress field variation during a shale fracturing process; C, utilizing the theory of seepage mechanics available to establish a model for pressure field variation during a shale fracturing process; D, utilizing the rock breaking theory available to establish a rule model for natural fractures; E, combining the above four steps to calculate and represent the size of the fracturing and broken region by means of a calculation flow. The calculating method for the size of the fracturing and broken region of the horizontal well for shale has following beneficial effects: time and money spent on calculating the size of the broken region during fracture of the horizontal well for shale are saved so that the valuation of the size of the fracturing and broken region can be extensively prompted and applied.

Owner:SOUTHWEST PETROLEUM UNIV

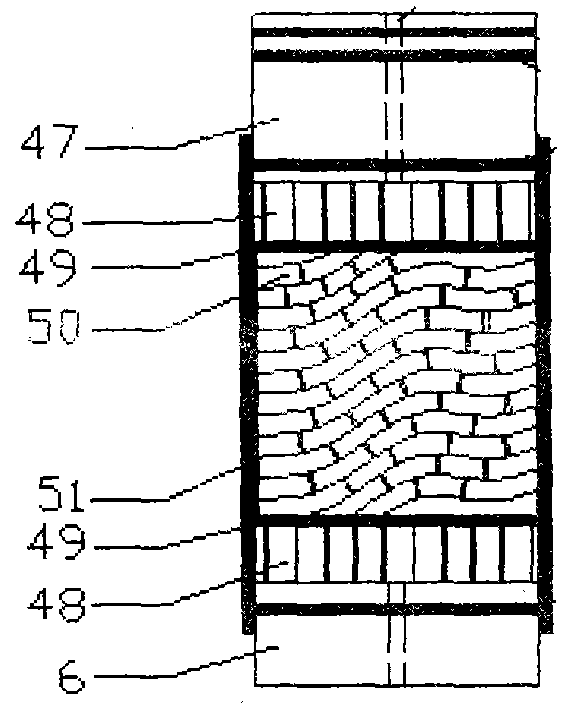

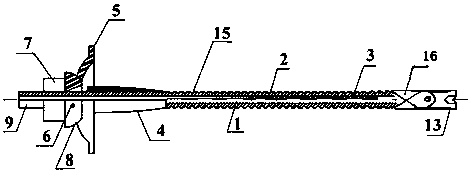

Pressure rock failure and instability process and dynamic permeability test apparatus and method thereof

ActiveCN104977234AEasy to replaceUniform confining pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisCouplingInstability

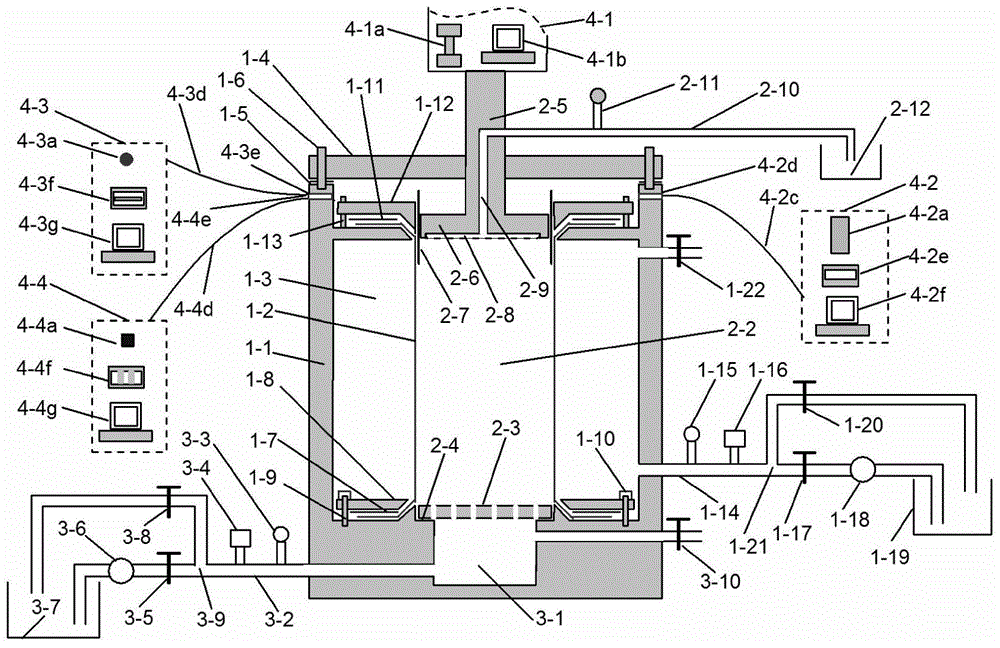

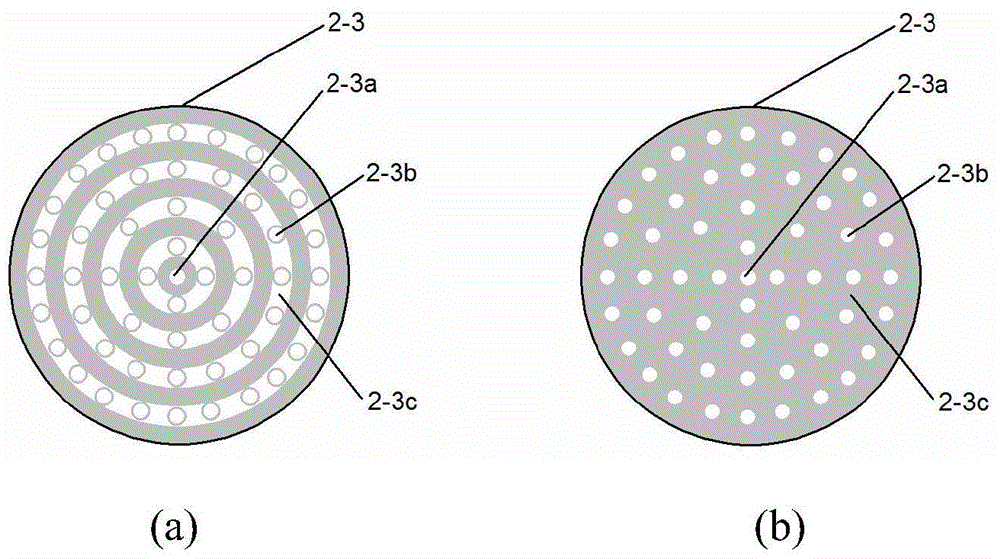

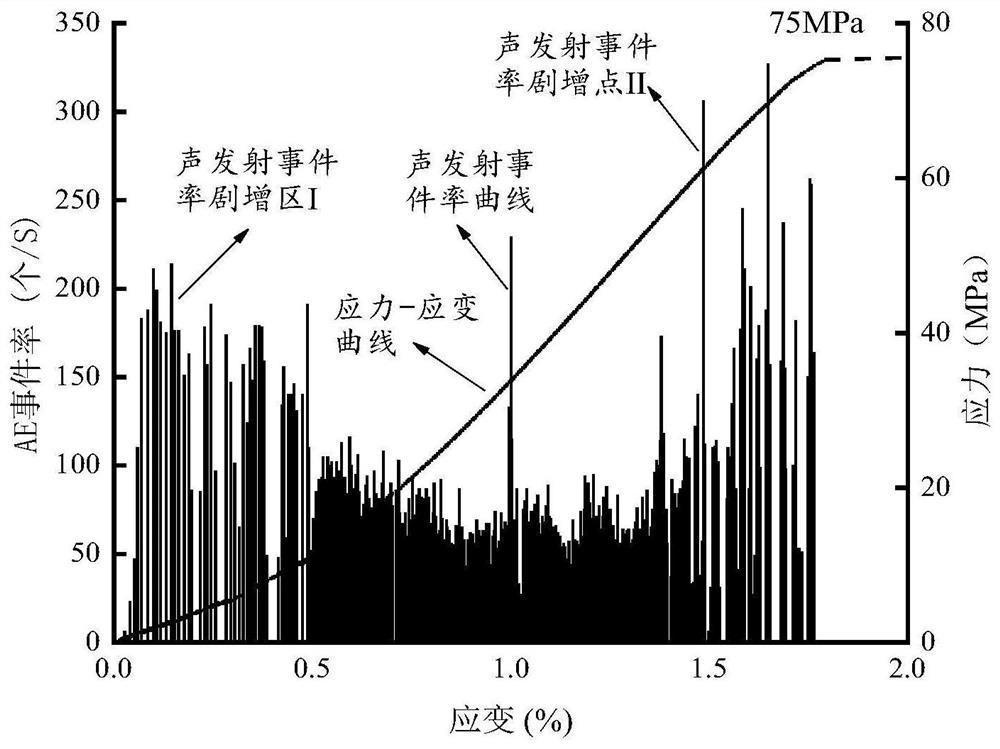

The invention relates to a pressure rock failure and instability process and dynamic permeability test apparatus and a method thereof. A stress strain signal, a sound emission signal and an apparent resistivity signal in the pressure rock failure and instability process are acquired and processed by using a large pressure rock permeability test device to obtain the stress strain relationship, the quantity and positions of sound emission events and the rock apparent resistivity change rule induced by pressure water permeability increase in large pressure rock failure and instability process in order to obtain the dynamic evolution role of crack expansion, perforation and instability in the rock failure process under hydraulic-mechanical coupling action and the corresponding dynamic permeability. The hydraulic-mechanical coupling failure mechanism and the pressure permeability of rocks, and the deformation and strength characteristics, the crack expansion, perforation and failure characteristics and the permeability evolution rule of pressure water in the crack expansion-perforation-failure process of the rocks under the hydraulic-mechanical coupling action are researched in the invention. The apparatus and the method have important engineering values in realization of safe mining under water pressure on pressure water.

Owner:ANHUI UNIV OF SCI & TECH

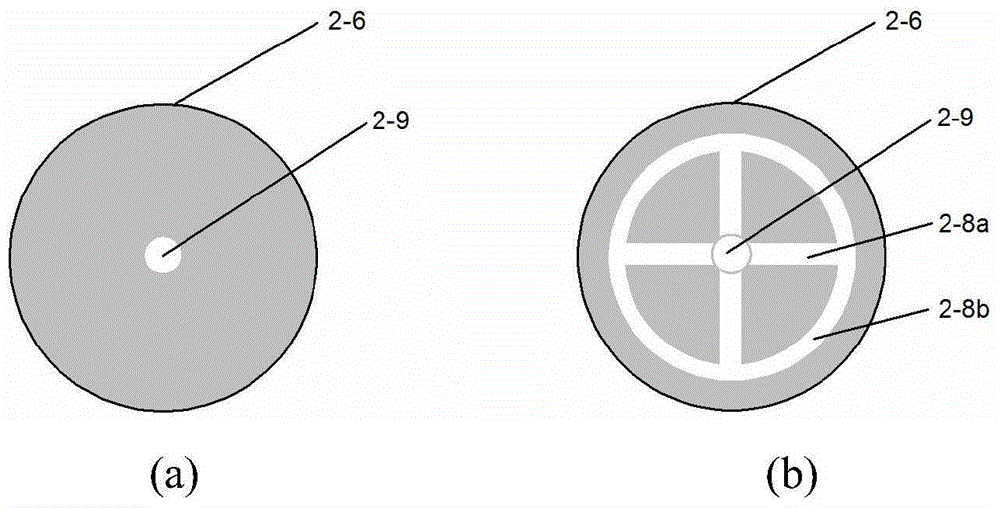

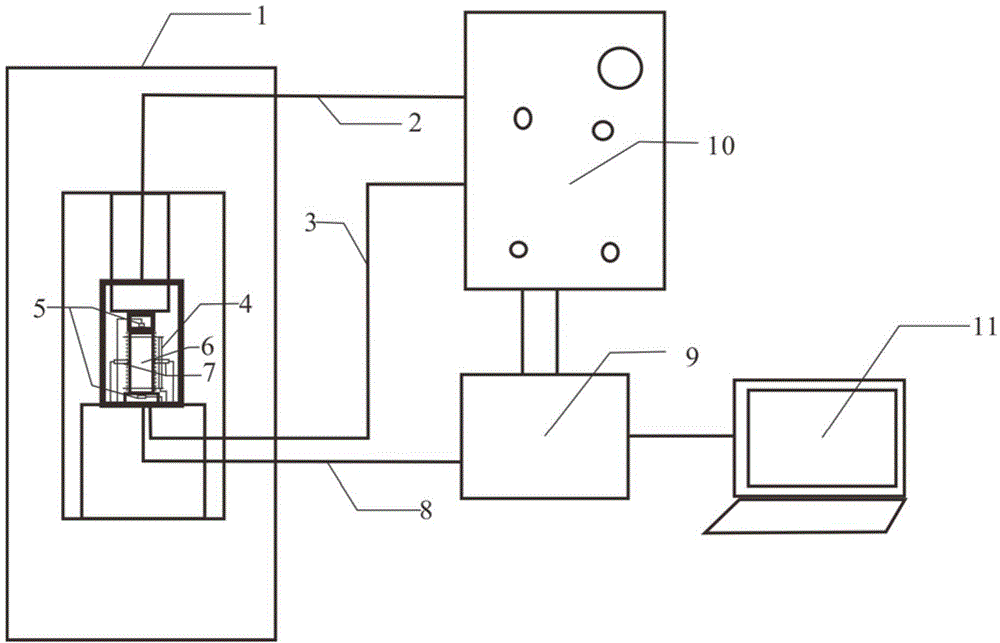

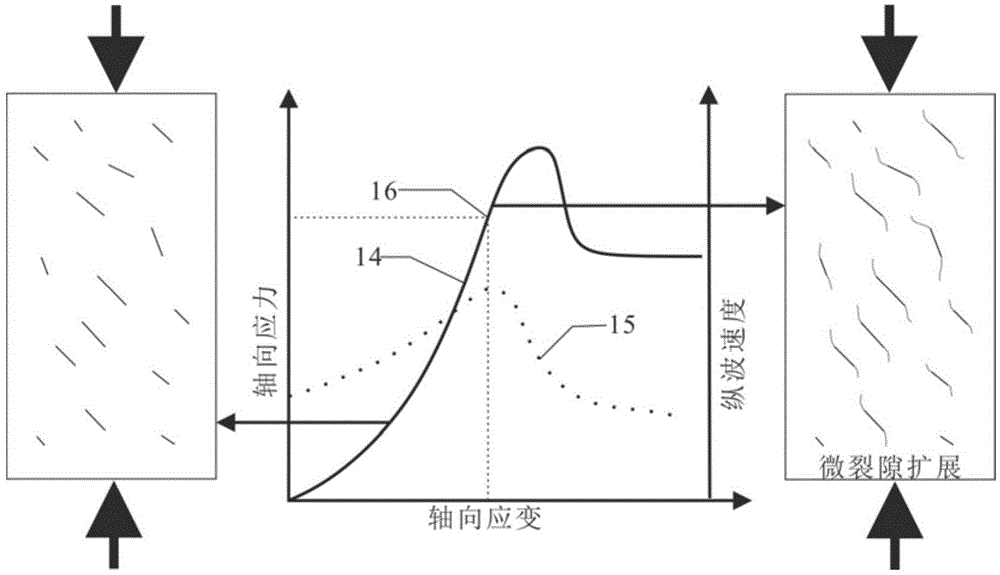

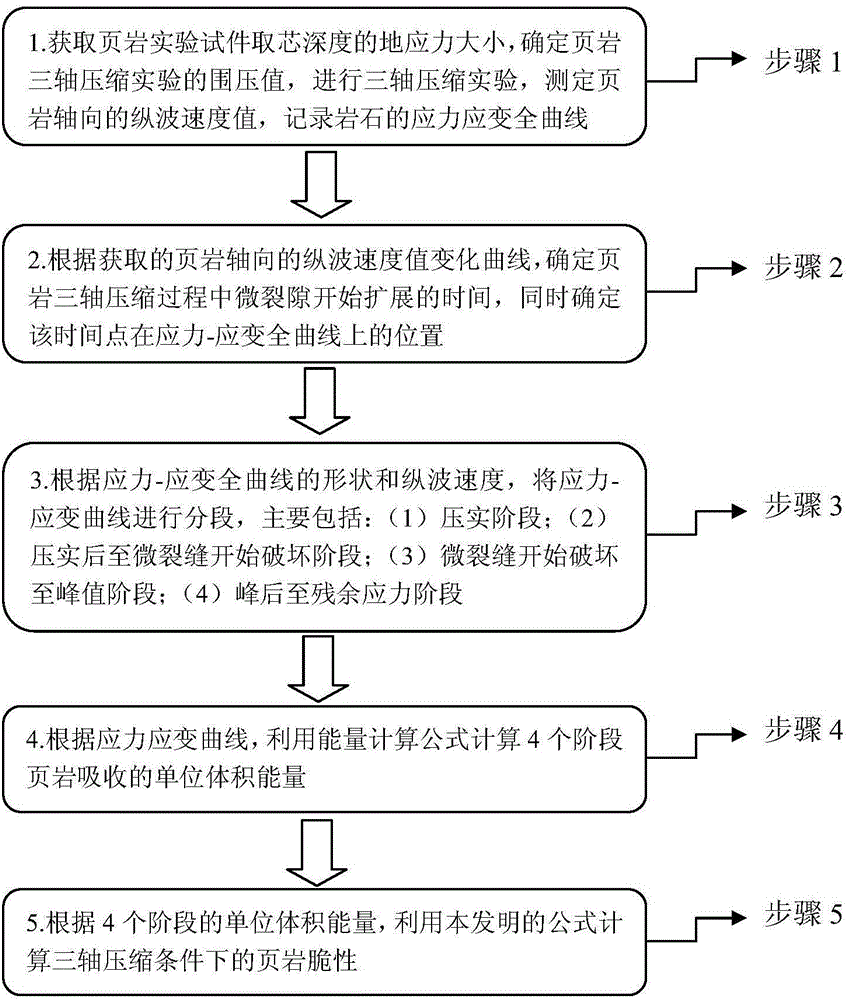

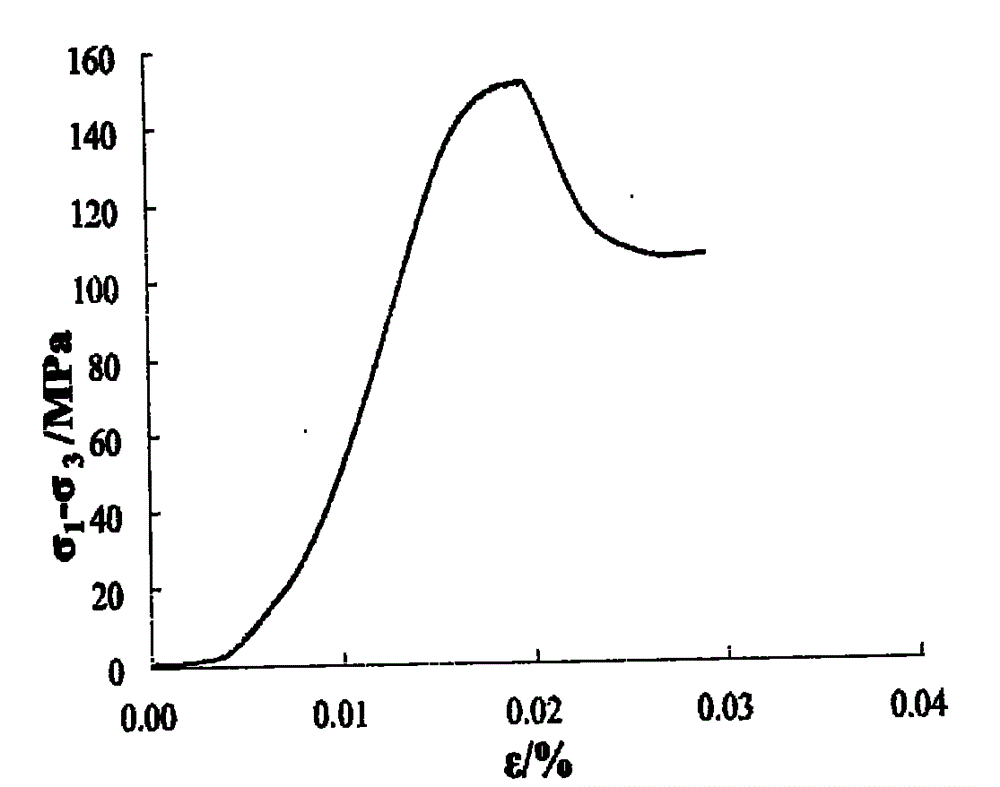

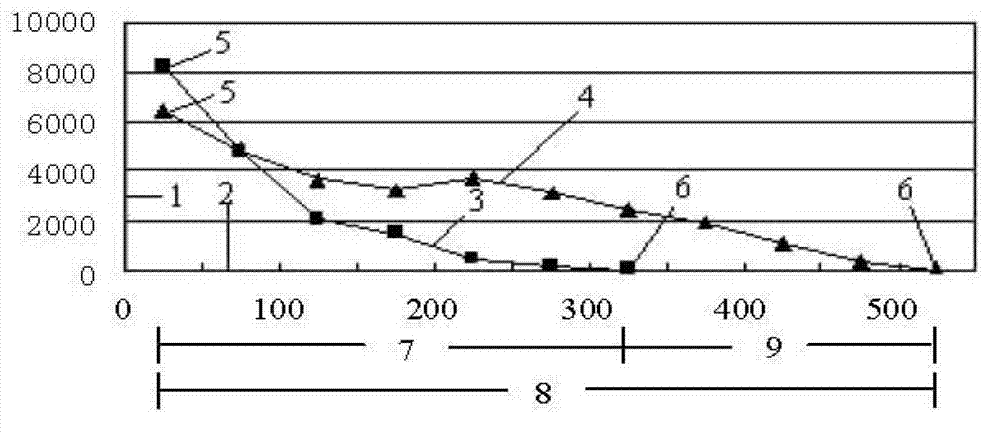

Method for measuring shale brittleness index based on rock stress-strain curves and ultrasonic longitudinal wave speed

ActiveCN104865124AImprove accuracyImprove rationalityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesLongitudinal waveStress–strain curve

The invention provides a method for measuring a shale brittleness index based on triaxial compression complete stress-strain curves and ultrasonic longitudinal wave speed. The method comprises the following steps: obtaining a triaxial compression complete stress-strain curve and the ultrasonic longitudinal wave speed of each time point in an experimental process by adopting dynamic and static combined triaxial compression experiment; determining a time point when a shale microcrack starts to be damaged by utilizing a change curve of the longitudinal wave speed; according to the change of the longitudinal wave speed and the shape of the complete stress-strain curve, dividing the complete stress-strain curve into four stages, namely, a stage of microcrack closure, a stage from compaction to starting of microcrack damage, a stage from microcrack extension to damage instability and a stage after rock damage instability; by utilizing the complete stress-strain curve, calculating the unit volume energy absorbed by a shale test piece in the corresponding stage; calculating the shale brittleness index by utilizing the ratio of the unit volume energy absorbed in the elastic stage to the absorbed total unit volume energy. The method is a comprehensive calculation method considering mechanical properties of shale in each stage and improves the accuracy and reasonability of rock brittleness evaluation.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

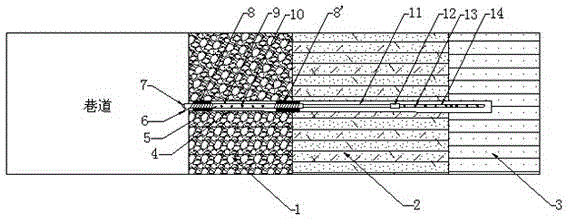

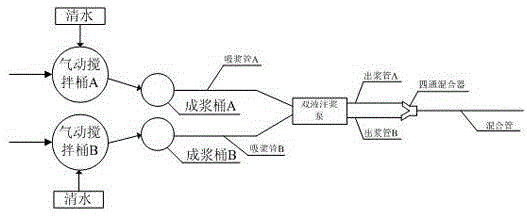

Coal mine tunnel broken surrounding rock layering grouting technology and method

InactiveCN104594914AReduce grouting costsGood grouting effectUnderground chambersTunnel liningViscosityCoal

The invention discloses a coal mine tunnel broken surrounding rock layering grouting technology and method. Novel double-fluid inorganic grouting materials are adopted, and the method is matched with a novel grouting hole sealing device to achieve drilling layering grouting. The method comprises the steps that grouting drilling is constructed at first, the dual-layer grouting hole sealing device is adopted for hole sealing, then, grouting materials with the low water cement ratio, high viscosity and high condensation speed are adopted to be used in cooperation with the low-pressure and low-flow grouting technology, an outer layer grouting pipe is utilized for conducting grouting on a surrounding rock shallow layer broken zone to form an effective grouting stopping layer, then, the water cement ratio of the grouting materials is improved gradually, the material permeability characteristics are improved, the material curing time is prolonged, the grouting pressure is gradually improved, and an inner layer grouting pipe is utilized for completing surrounding rock deep layer grouting. The method adapts to surrounding rock failure and permeability characteristic zoned characteristics, the grout leakage problem is effectively solved, and layering grouting in the same drilled hole is achieved.

Owner:HENAN POLYTECHNIC UNIV +1

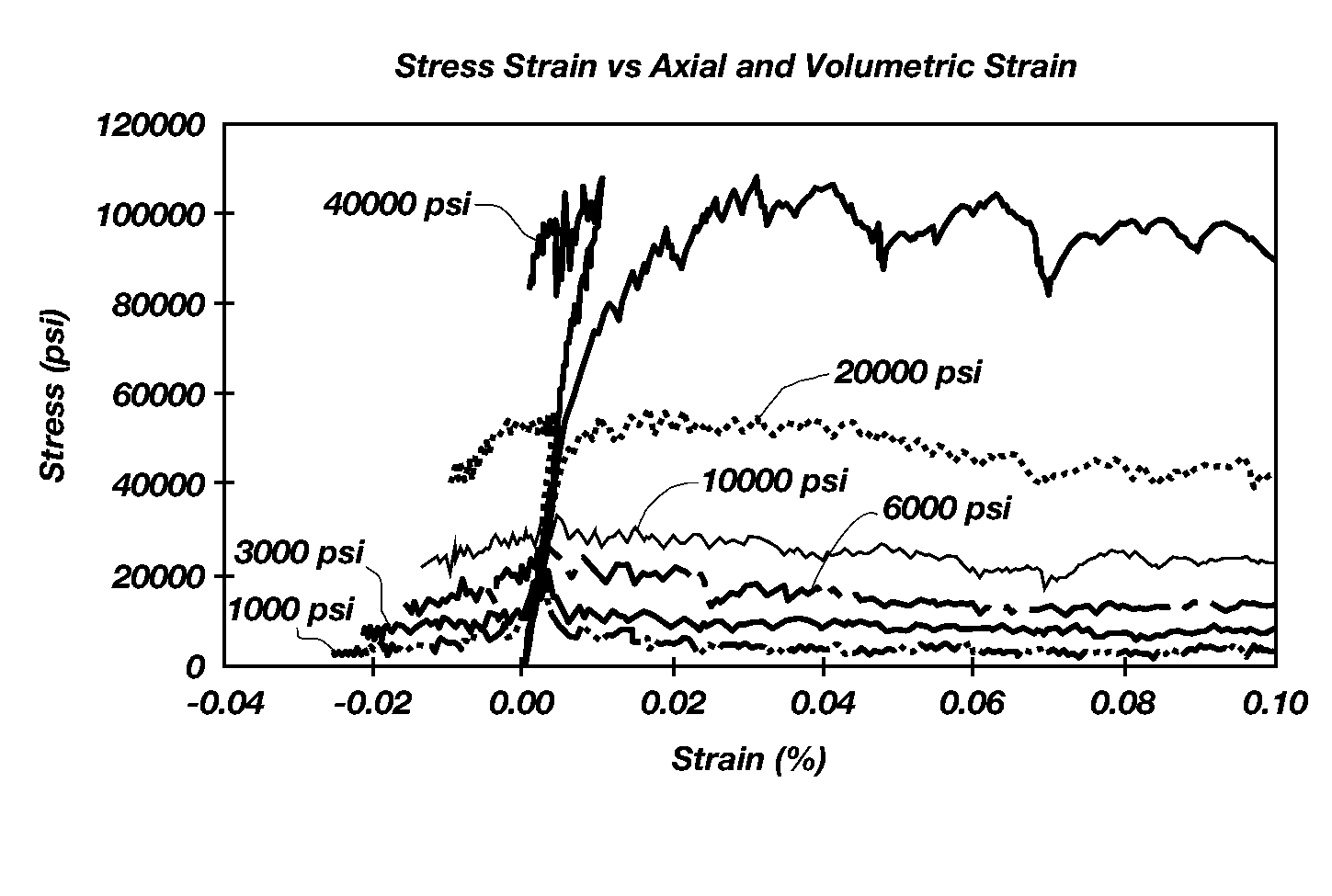

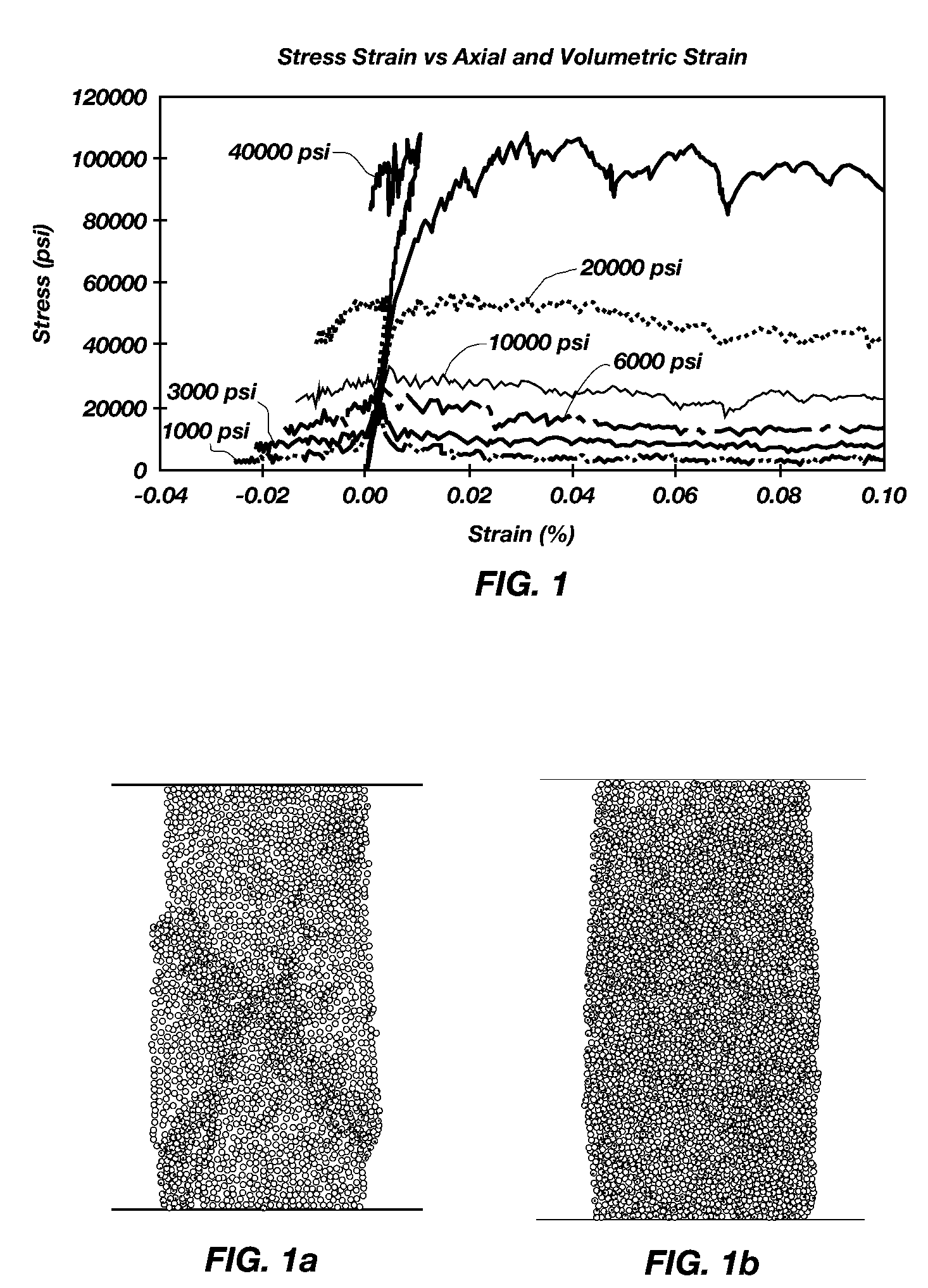

Discrete element modeling of rock destruction under high pressure conditions

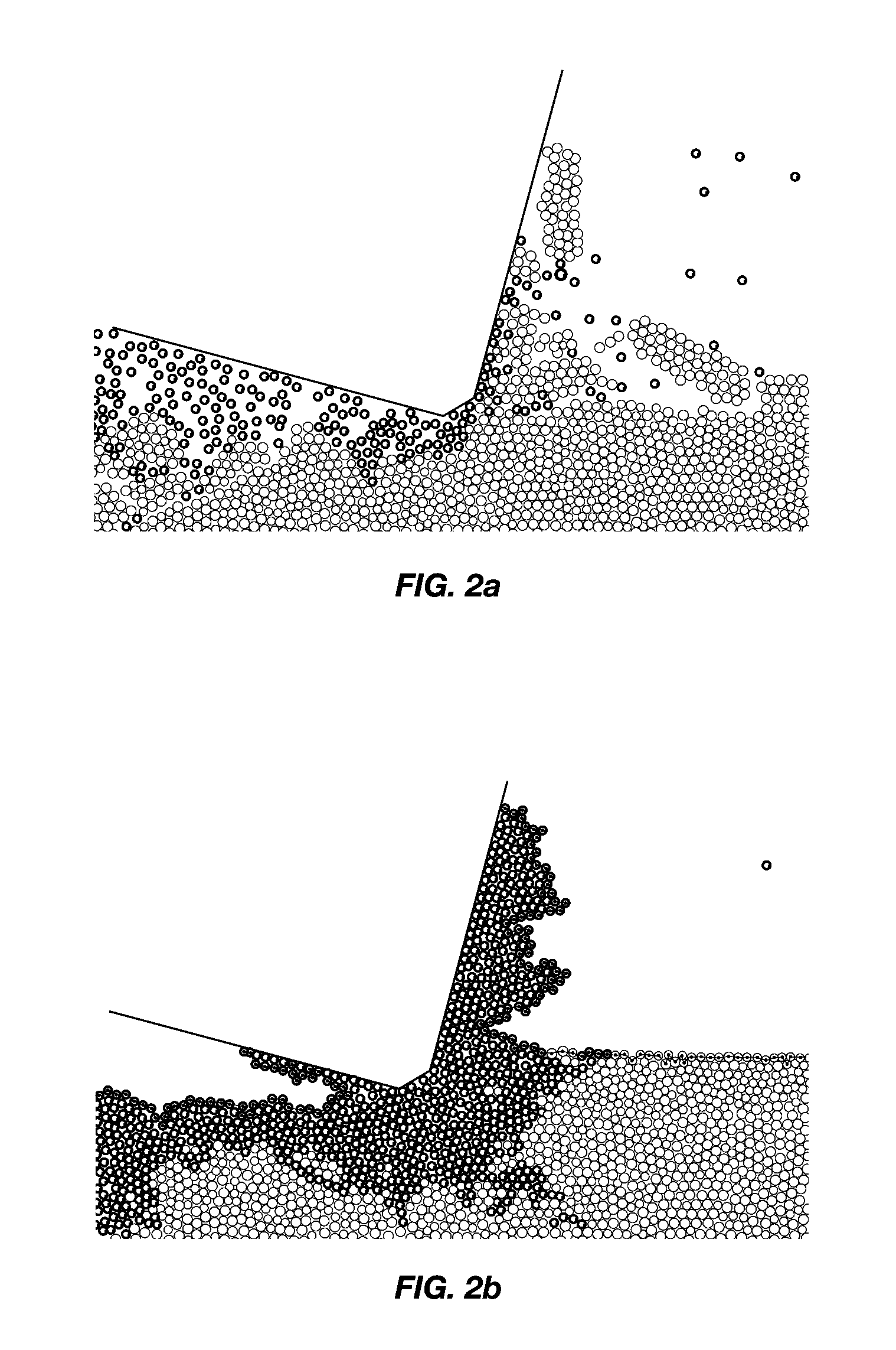

ActiveUS20090132218A1Way accurateSimple designDrill bitsConstructionsDiscrete element simulationWell drilling

Discrete Element Modeling (DEM) of rock subject to high confining pressures, such as in a subterranean drilling environment, may be used to predict performance of cutting structures used in drill bits and other drilling tools, as well as of the tools themselves. DEM may also be used to create “virtual” rock exhibiting specific drillability characteristics with or without specific reference to any actual rock, for purposes of assessing cutting efficiency of various cutting structure configurations and orientations, as well as of drilling tools incorporating same.

Owner:BAKER HUGHES INC

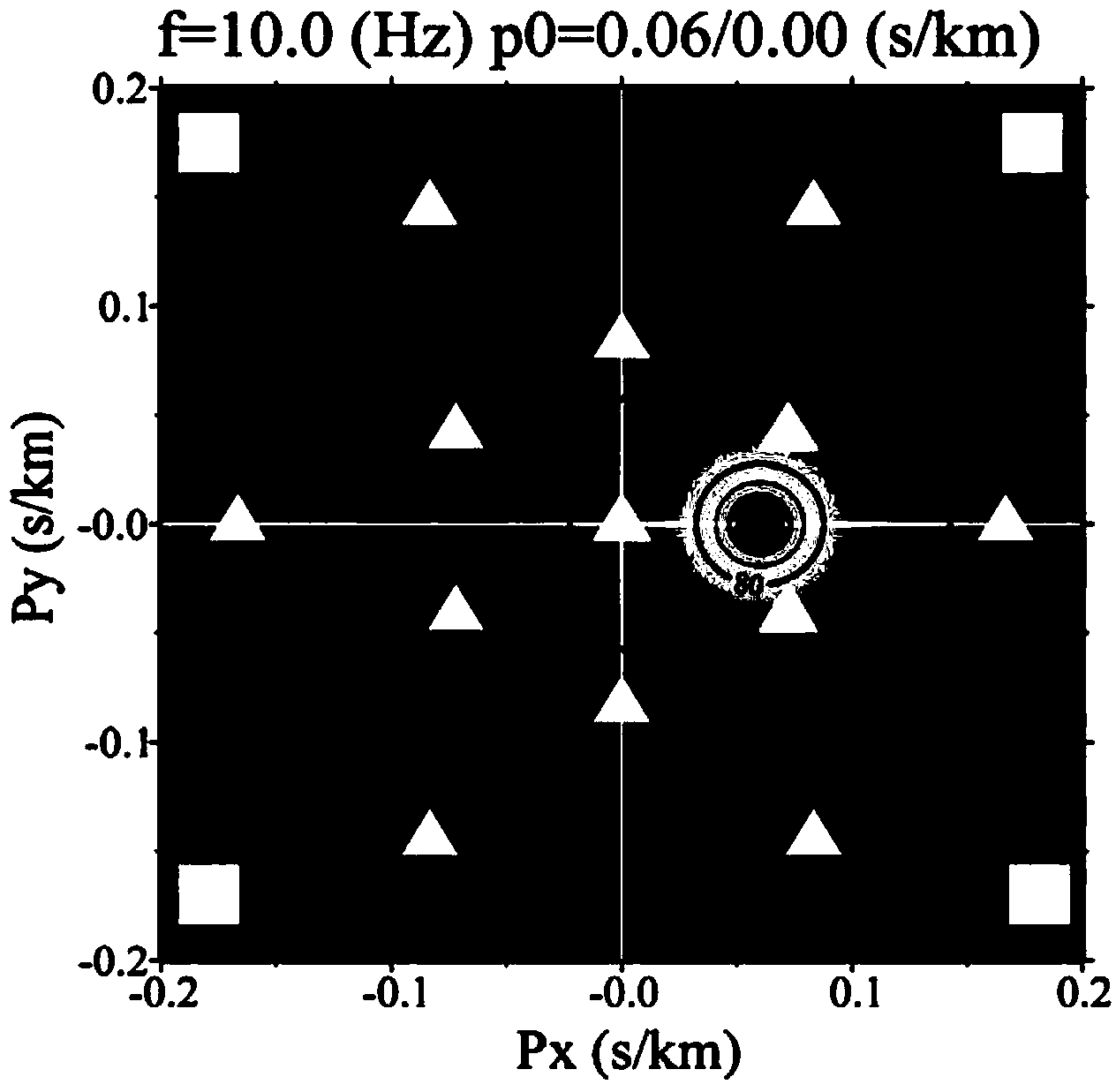

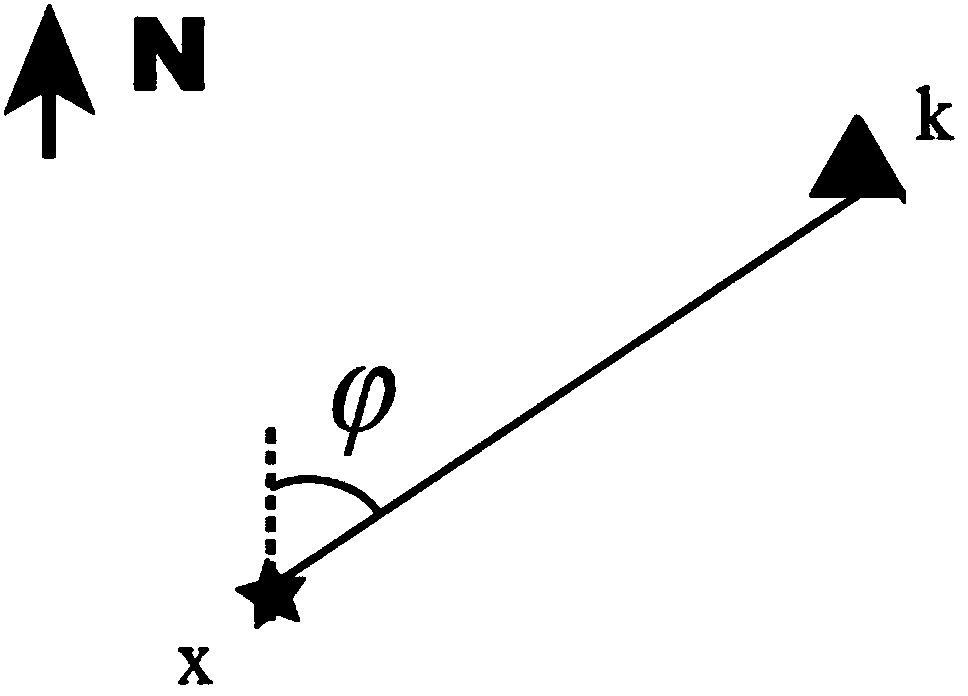

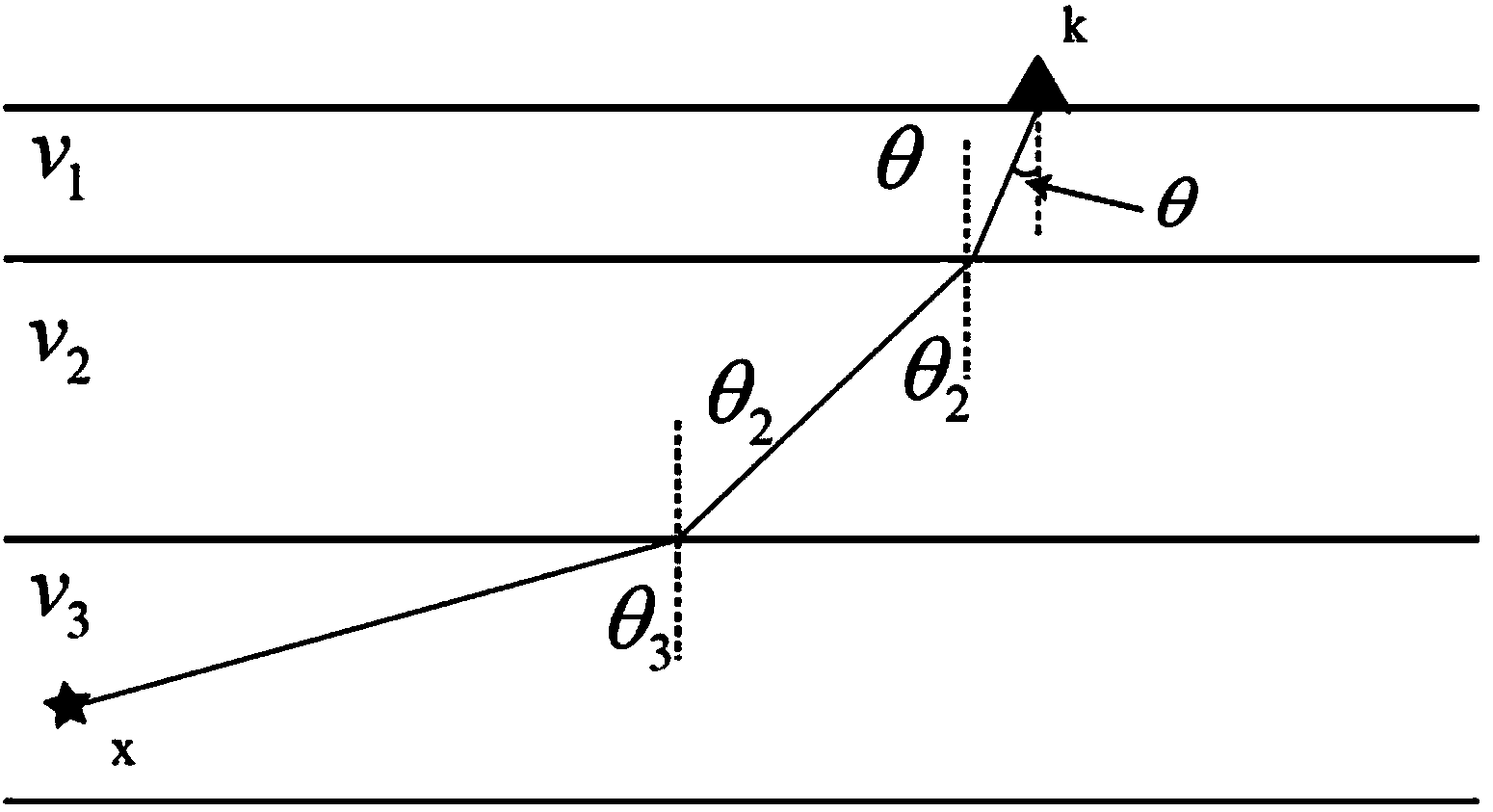

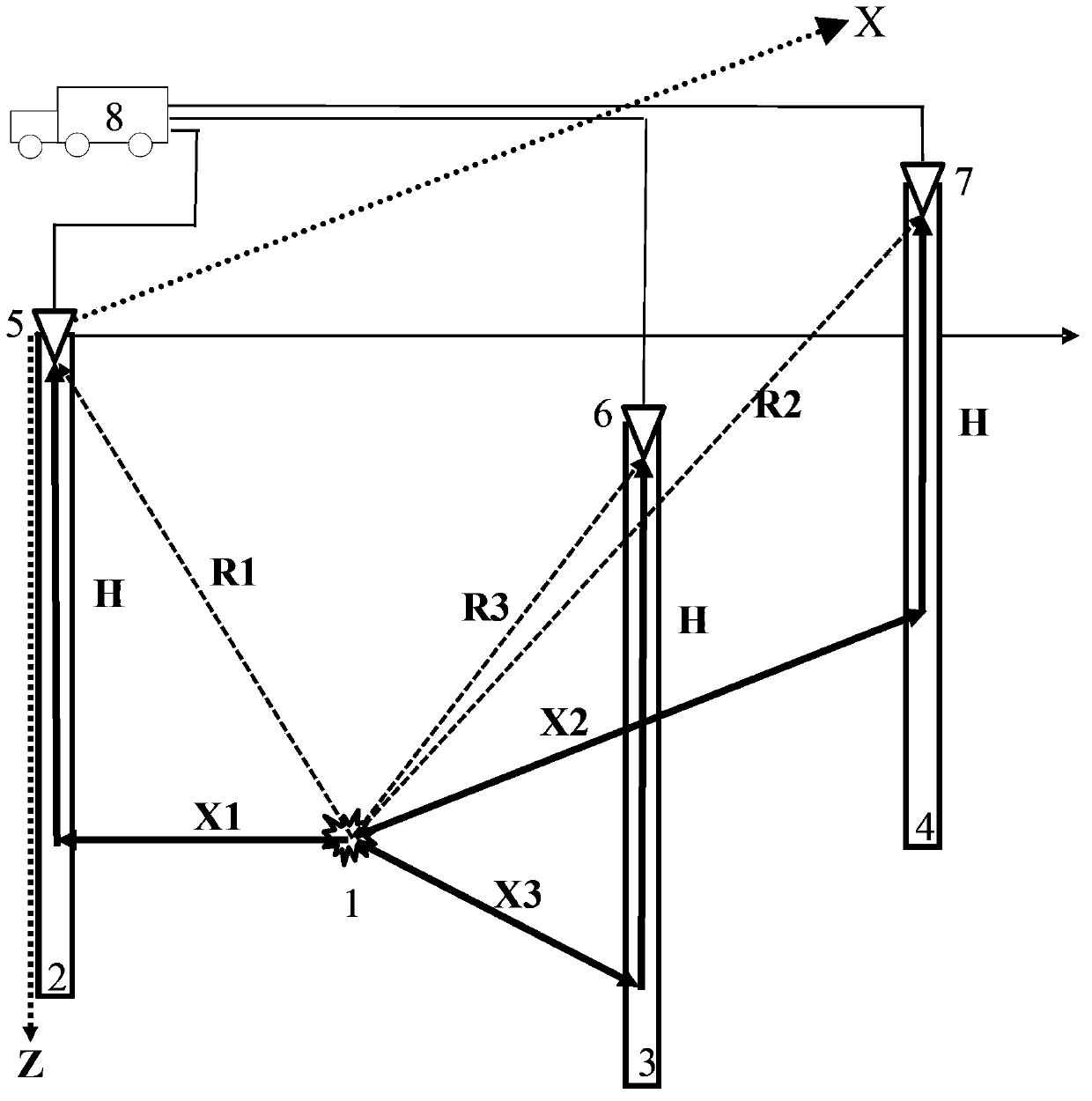

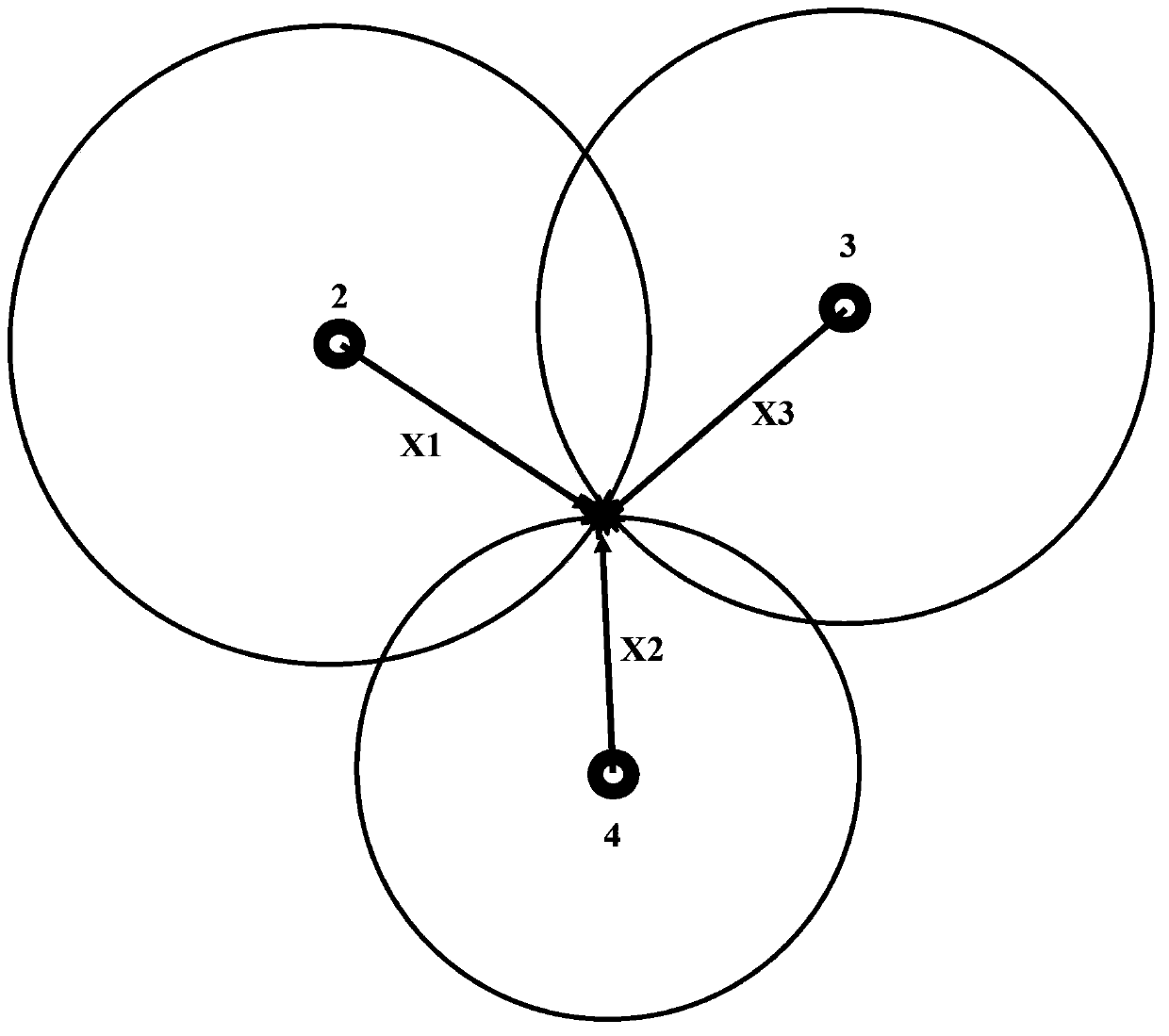

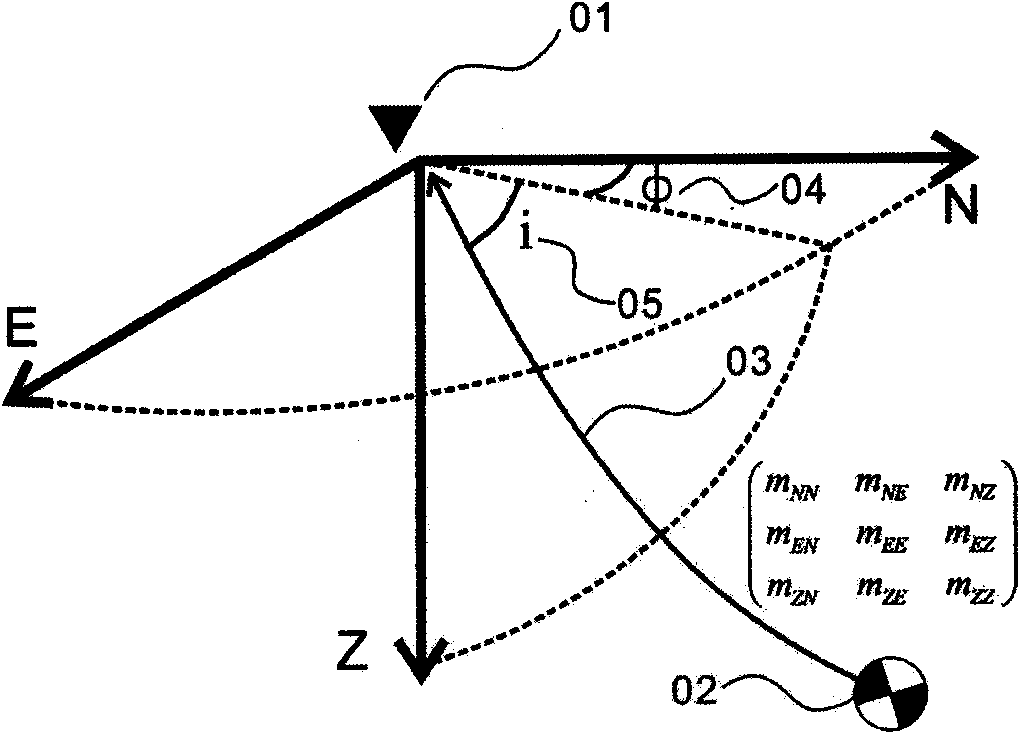

Microseism monitoring and positioning method based on full-waveform vector offset superposition

ActiveCN104280775AHigh positioning accuracyMonitoring the effect of fracturingSeismic signal processingGeophoneFull waveform

The invention discloses a microseism monitoring and positioning method based on full-waveform vector offset superposition. The purpose of monitoring and positioning microseisms is achieved by the data recorded by an earth surface three-component geophone through the method of vector superposition of the three components of P waves, SH waves and SV waves. The microseism monitoring and positioning method is suitable for detecting microseism signals, particularly, under the conditions that microseism energy is very weak caused by rock failure in the fracture improvement process and a traditional method loses efficacy, the effect of microseism detecting can be greatly improved, the defect that only microseisms with large energy can be detected in a traditional method is overcome, more microseisms with weaker signals can be detected, and the effect of fracture improvement can be more comprehensively monitored. According to the method, a good effect is achieved on monitoring of earth surface microseisms, very weak microseism signals can be detected, combined positioning of the P waves and the S waves can be conducted, and therefore the positioning precision is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

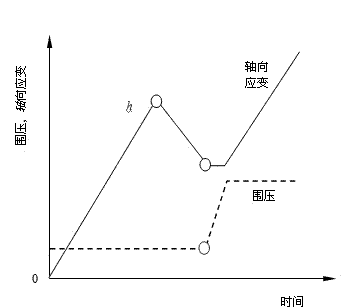

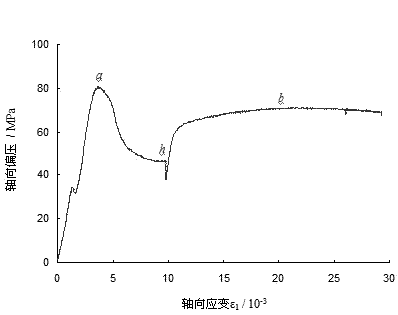

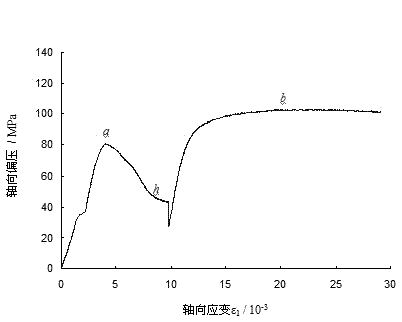

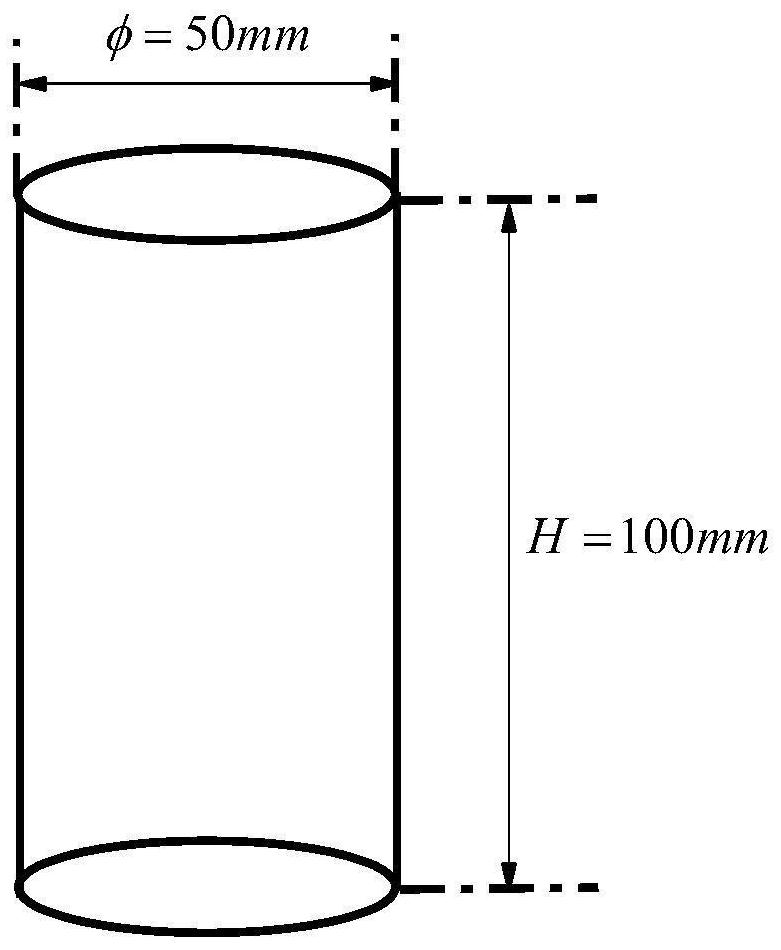

Path loading method used in determination of rock triaxial strength after failure

InactiveCN102221504AUnderstanding Mechanical BehaviorLoad method is simplePreparing sample for investigationMaterial strength using tensile/compressive forcesHydrostatic pressurePeak value

The invention discloses a path loading method used in the determination of rock triaxial strength after rock failure. The method comprises the following steps that: first, samples of engineering rock mass requiring testing are collected; the collected samples are prepared into cylindrical samples; upper and lower rigid loading terminals of the samples closely contact a pressure head of a testing machine; hydrostatic pressure is applied to the cylindrical sample, such that an initial confining pressure to the sample is loaded to a designed value; with the initial confining pressure maintained, axial load is then applied to the cylindrical sample, and the pressure to the sample is loaded to a control point after a peak value intensity, such that a rock failure sample is formed; hydrostatic pressure is then applied to the rock failure sample, such that final confining pressure to the sample is loaded to a higher value; with the final confining pressure maintained, axial load is then applied to the rock failure sample, such that a yielding failure is occurred to the rock sample. With the testing method, mechanical characteristics of rock re-failure after failure can be researched, triaxial strength characteristics of rocks after failures can be acquired, and corresponding technical measures can be provided for the problems in failed surrounding rock reinforcing in the field of deep underground engineering.

Owner:CHINA UNIV OF MINING & TECH

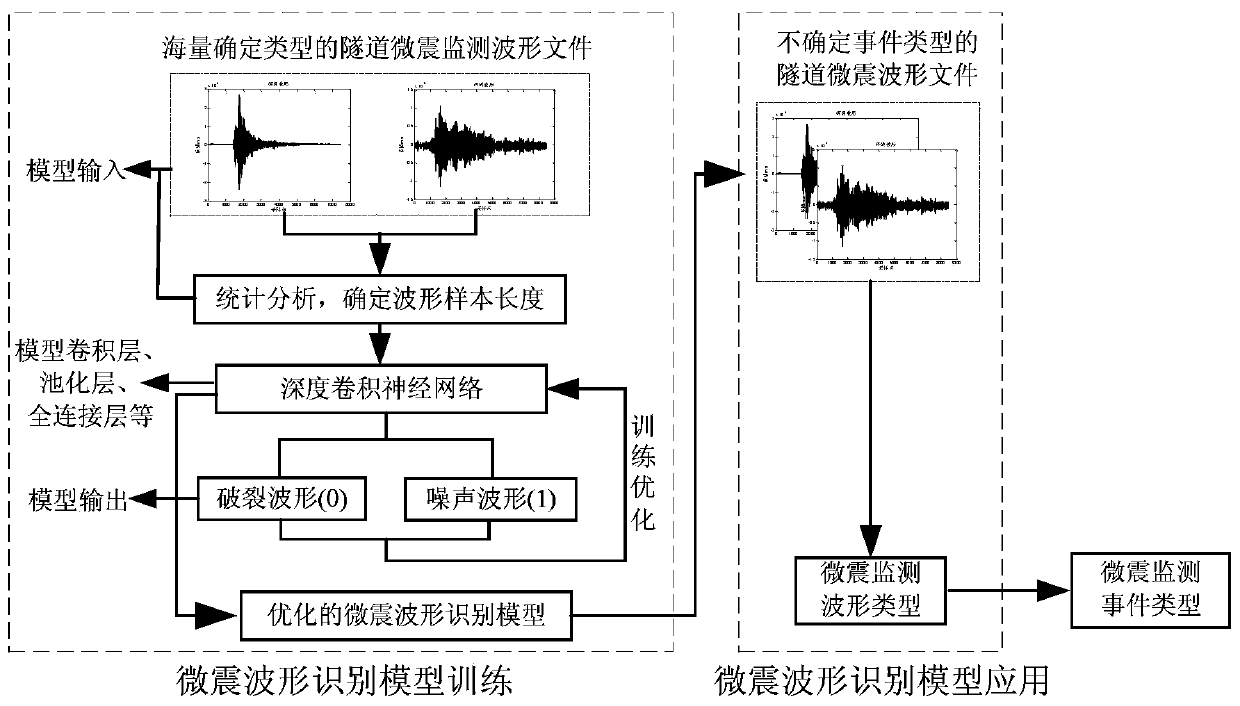

Automatic identification method of rock failure events in tunnel micro-seismic monitoring

InactiveCN110058294AImprove efficiencyImprove accuracyEarthquake measurementSeismic signal processingFeature extractionAutomatic Identification System

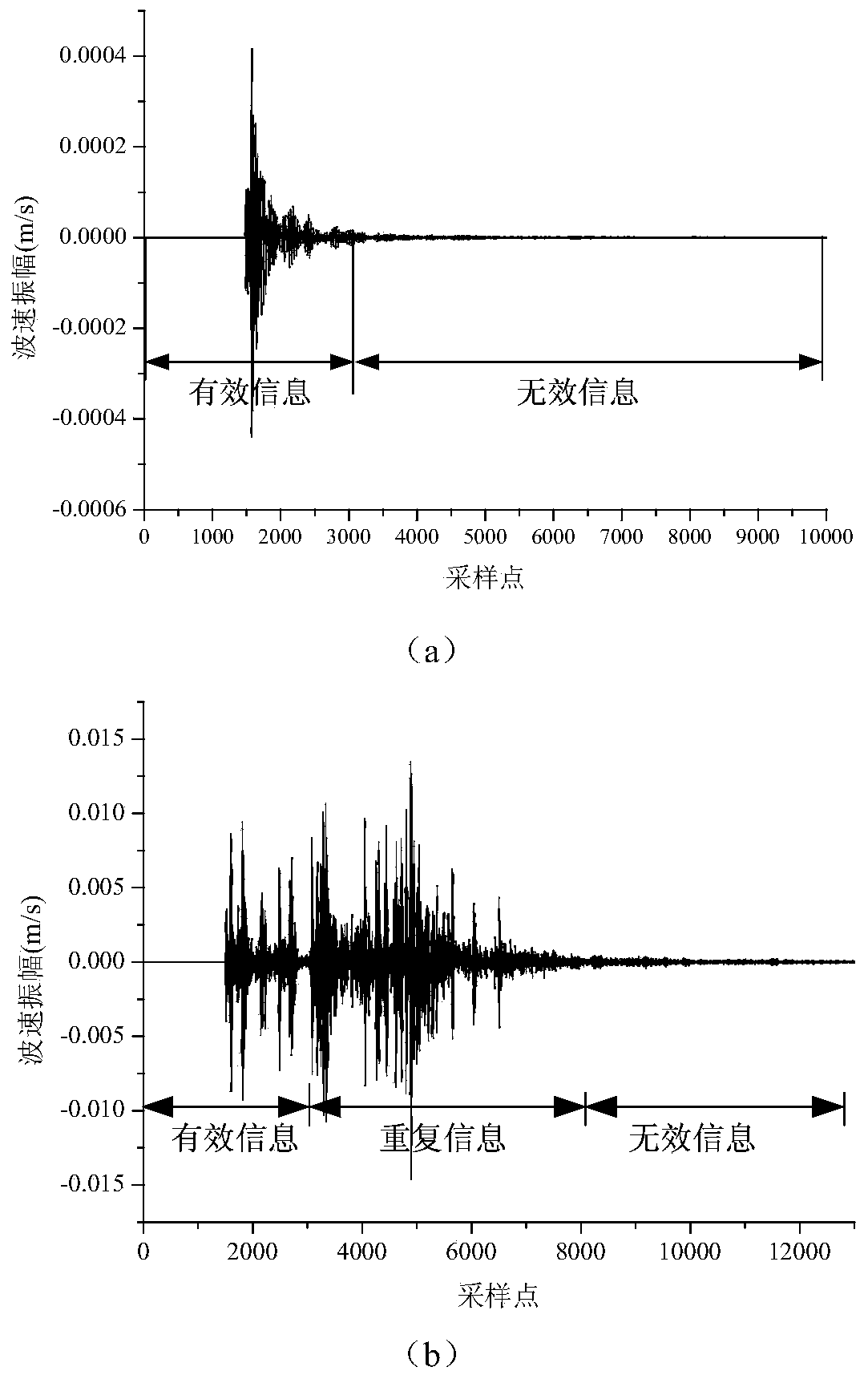

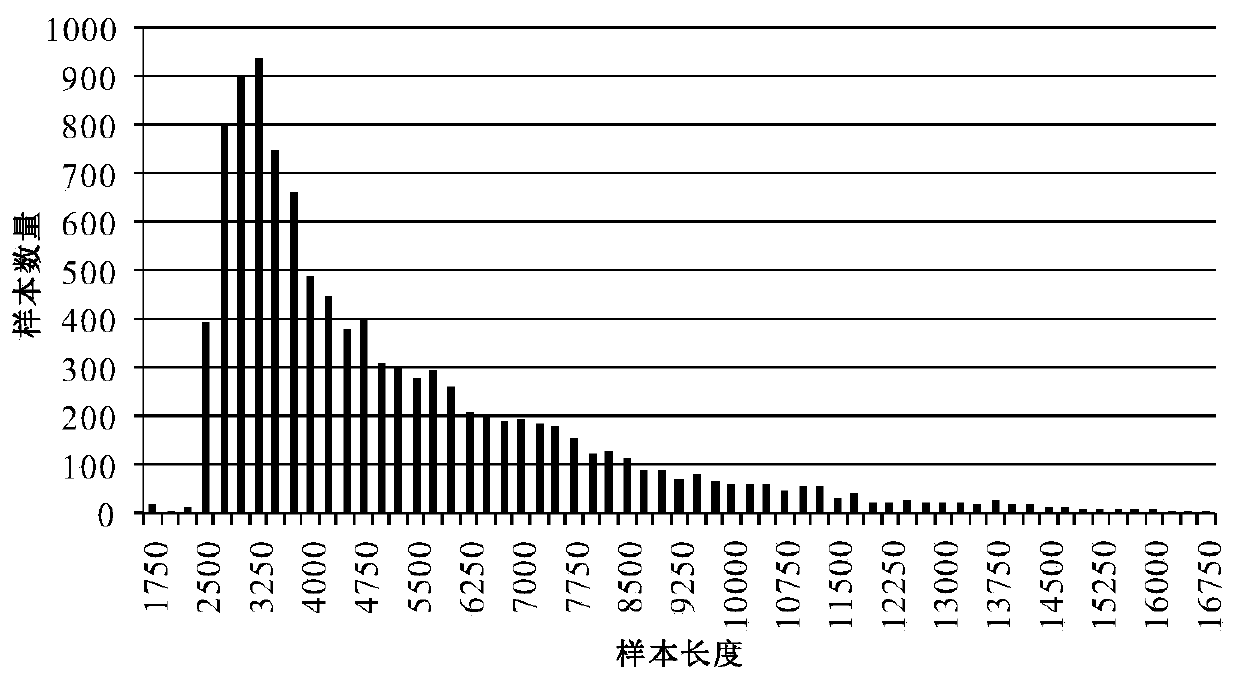

The invention provides an automatic identification method of rock failure events in tunnel micro-seismic monitoring, and relates to the technical field of tunnel micro-seismic monitoring. The method includes the steps that first, a large number of tunnel micro-seismic monitoring waveforms with known types are used for establishing a waveform sample database, then effective information of the waveforms in the waveform sample database is analyzed statistically, and the length of a waveform sample for deep learning is determined; an identification model of the tunnel micro-seismic monitoring waveforms based on a deep convolutional neural network is established; the large number of to-be-identified micro-seismic waveforms are input into the waveform identification model, and waveform type identification results of the to-be-identified micro-seismic waveforms are output; and finally, the types of the micro-seismic events are determined according to the waveform type identification results.According to the automatic identification method of the rock failure events in tunnel micro-seismic monitoring, an original waveform of micro-seismic monitoring is directly identified, waveform feature extraction is not needed, the influence of improper eigenvalue selection on the signal identification accuracy is avoided, identification from the types of the micro-seismic monitoring waveforms tothe types of the micro-seismic events is realized, and the identification results can be directly used for rock burst micro-seismic early warning.

Owner:NORTHEASTERN UNIV

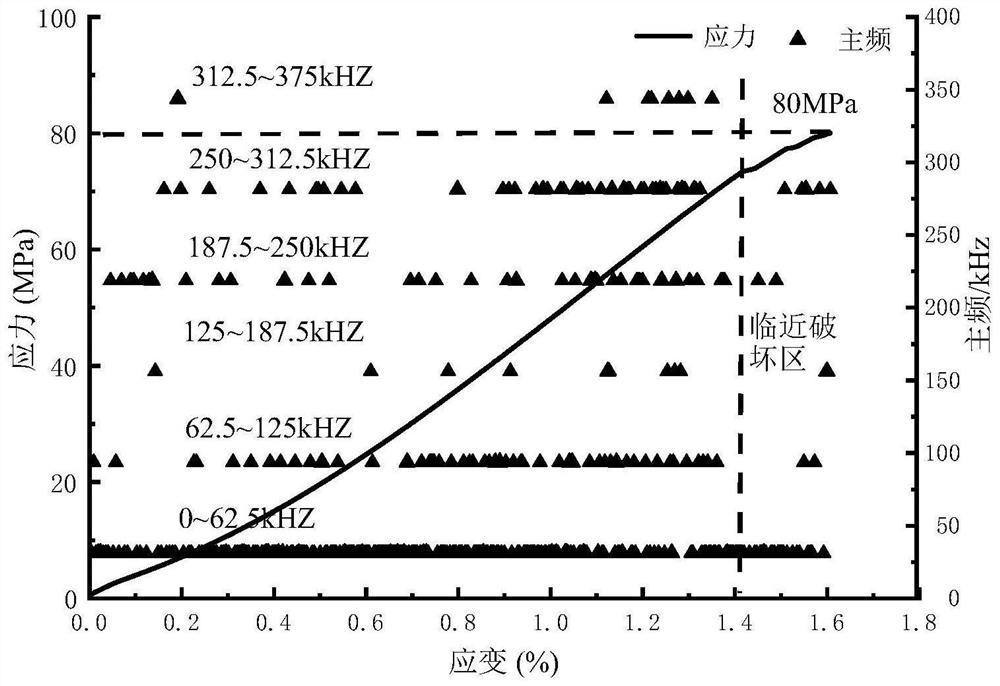

Method and device for acoustic discrimination of multistage yield points by rock triaxial single sample method

InactiveCN103868993AStability judgmentJudgment rangeAnalysing solids using sonic/ultrasonic/infrasonic wavesSingle sampleAcoustic emission

The invention discloses a method and a device for acoustic discrimination of multistage yield points by a rock triaxial single sample method. The upper end and the lower end in a triaxial chamber are respectively provided with an upper rigid pressure head and a lower rigid pressure head; the device is characterized in that an acoustic emission (AE) probe and an acoustic wave probe coupling testing device are respectively and fixedly arranged in the upper rigid pressure head and the lower rigid pressure head in a sealing way, and are used for bearing the high-pressure oil in the triaxial chamber; an AE acquisition system and an acoustic meter are connected; in the rock axial loading process, AE test and acoustic wave velocity test are completed at the same time in the whole process of rock microcrack dynamic propagation until yield failure, and the like; the experiment information data such as AE and acoustic wave can be output by the AE acquisition system and the acoustic meter in the rock failure process; the yield points can be judged jointly according to the propagation of microcrack in rock matrix, the AE characteristic change law near the yield points and the acoustic wave velocity change characteristics; the level of axial pressure loading is controlled to be stopped by a computer, and the next level of axial pressure loading of confining pressure is carried out; the multistage yield points of a rock single sample test piece are sequentially discriminated and tested.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

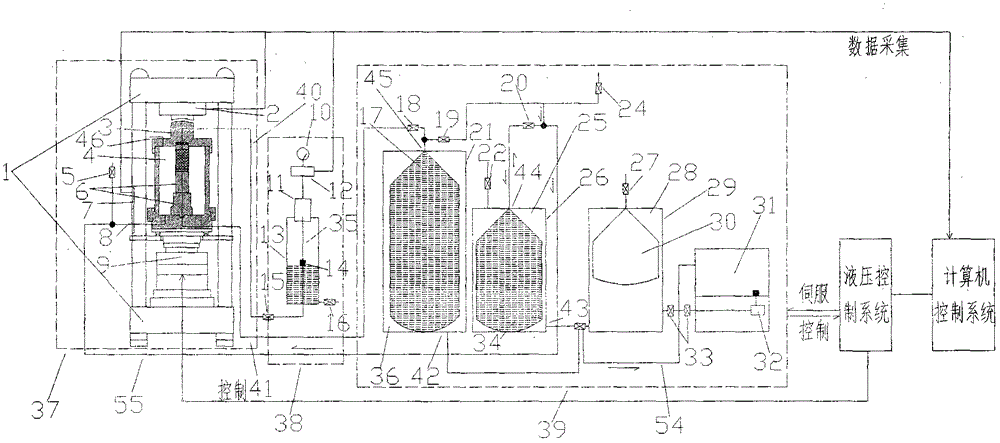

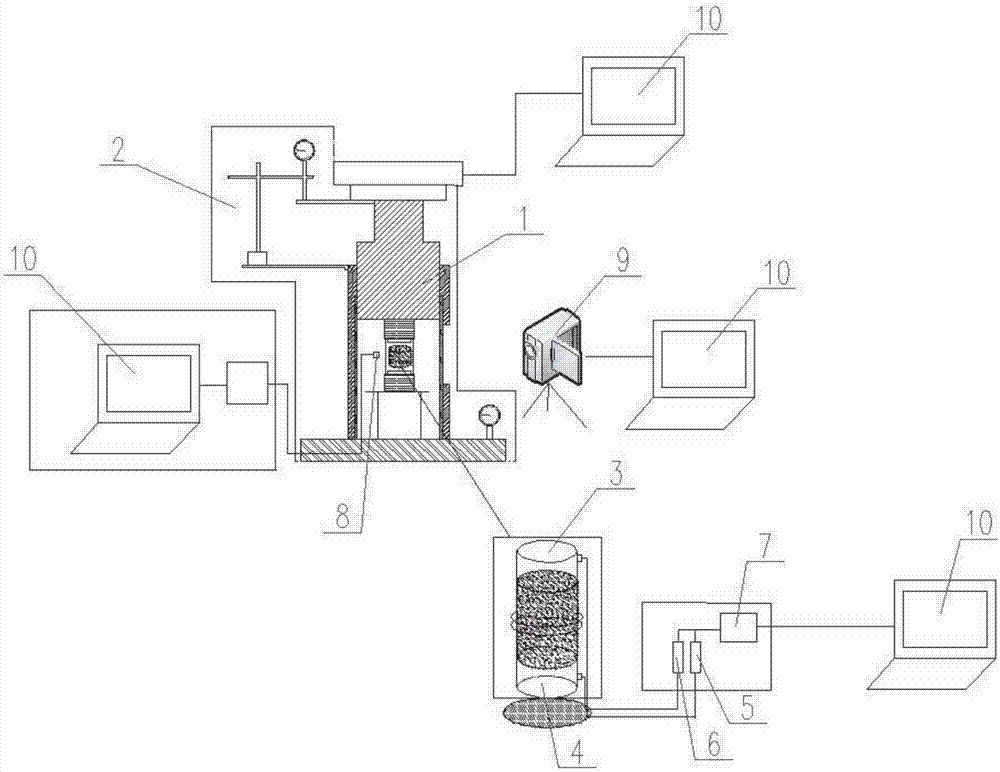

Test system for rock breaking mode at high ground stress and osmotic pressure

ActiveCN104483202AMaterial strength using tensile/compressive forcesData acquisitionExperimental control

The invention discloses a test system for a rock breaking mode at high ground stress and osmotic pressure. The test system comprises a test device for the rock breaking mode at the high ground stress and osmotic pressure and utilizes a test technique, wherein the test device is an organic combination of main equipment including an experimental sample mounting system, a high ground stress applying system, an high osmotic pressure applying system, an experimental control system, a measurement and data collection system and the like. According to the test system, the rock breaking mode and a rock breaking evolvement rule at the high ground stress and osmotic pressure can be tested.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

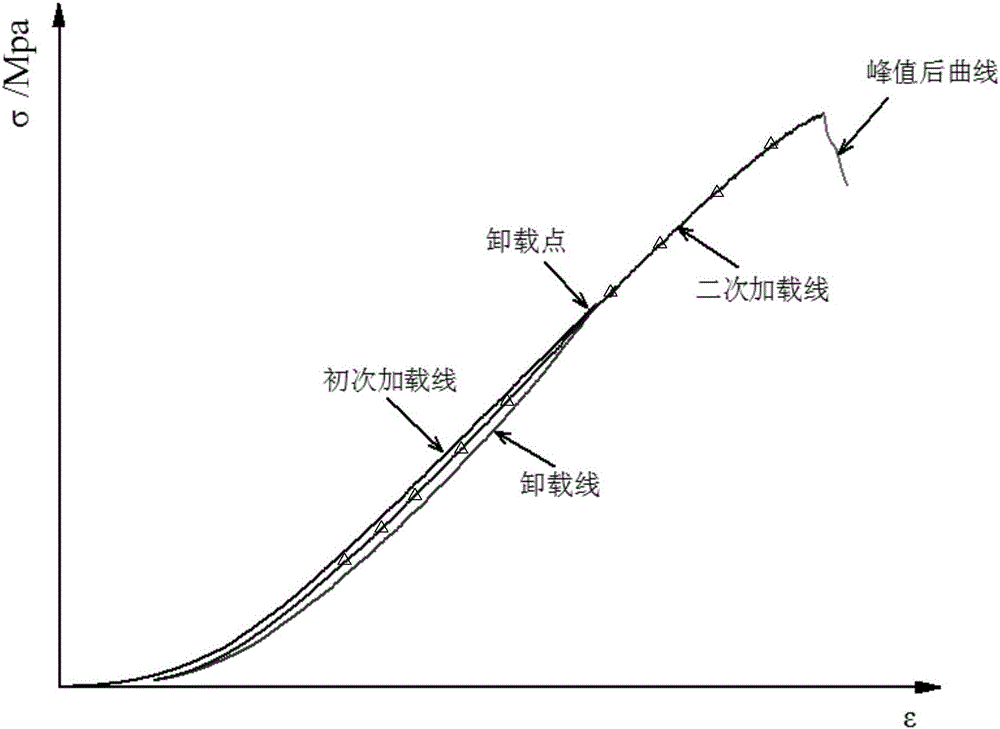

Method for judging rock burst proneness of rock material

ActiveCN105738204ARealize quantitative calculationMaterial strength using tensile/compressive forcesStrain energyStress–strain curve

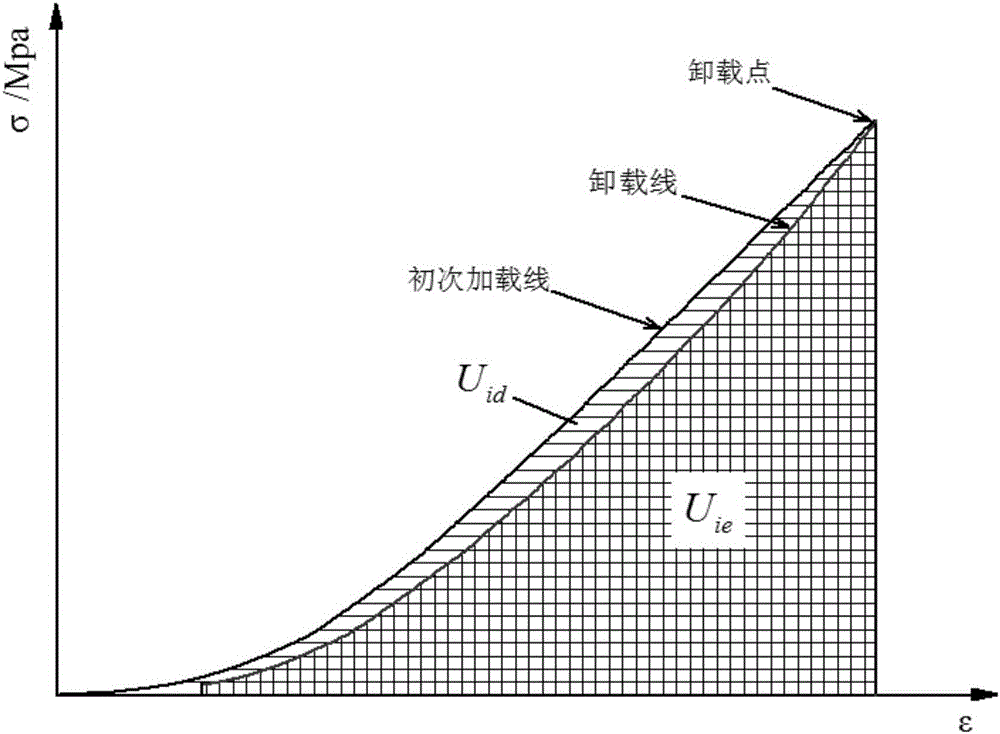

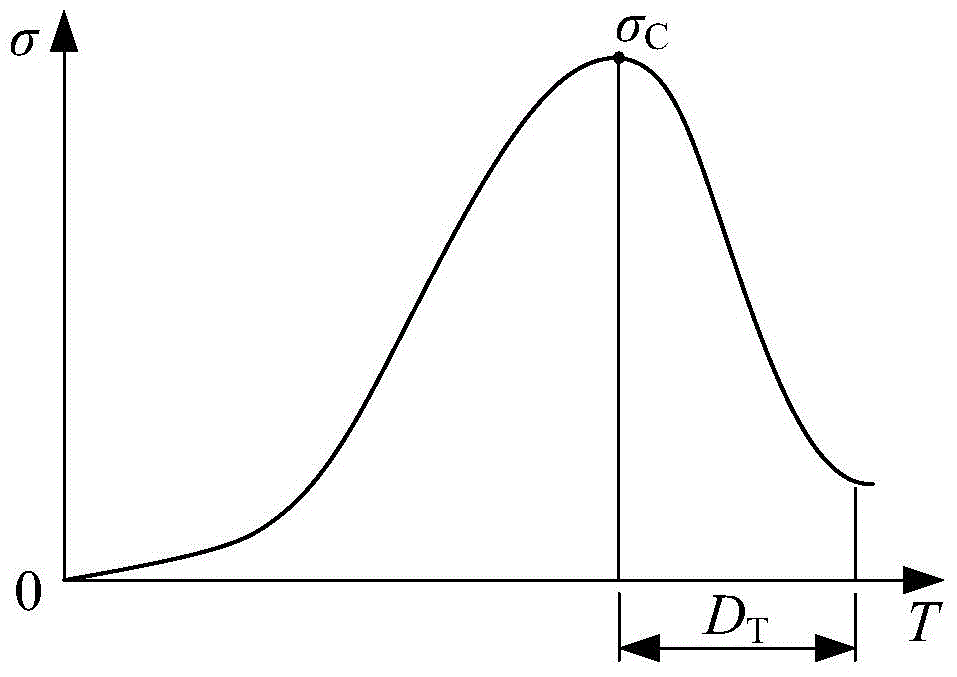

The invention discloses a method for judging the rock burst proneness of a rock material. According to the method, the dissipated energy required by burst of rock is calculated according to a stress-strain curve after the rock reaches the peak intensity; due to a one-off loading and unloading experiment on a rock test sample, a real series value (Ki) and a ratio (lambda(i)) of the elastic strain energy to the total input energy before the rock reaches the peak value are in linear relation, so that the ratio (lambda(i)) of the elastic strain energy to the total input energy when the rock reaches the peak intensity, and the total input energy U1 at the peak intensity of the rock can be calculated according to the stress-strain curve, so as to obtain the elastic deformation energy at the peak intensity of the rock. Therefore, the problem that the elastic strain energy stored therein cannot be calculated as the rock under the peak intensity cannot be unloaded in time is solved; the calculated elastic strain energy is compared with the post-peak dissipated energy to judge whether the rock material has the rockburst proneness. The invention provides a brand-new judgment method for determining the rockburst proneness of the rock material.

Owner:CENT SOUTH UNIV

Test and evaluation method for deep hard roof coal seam bump proneness

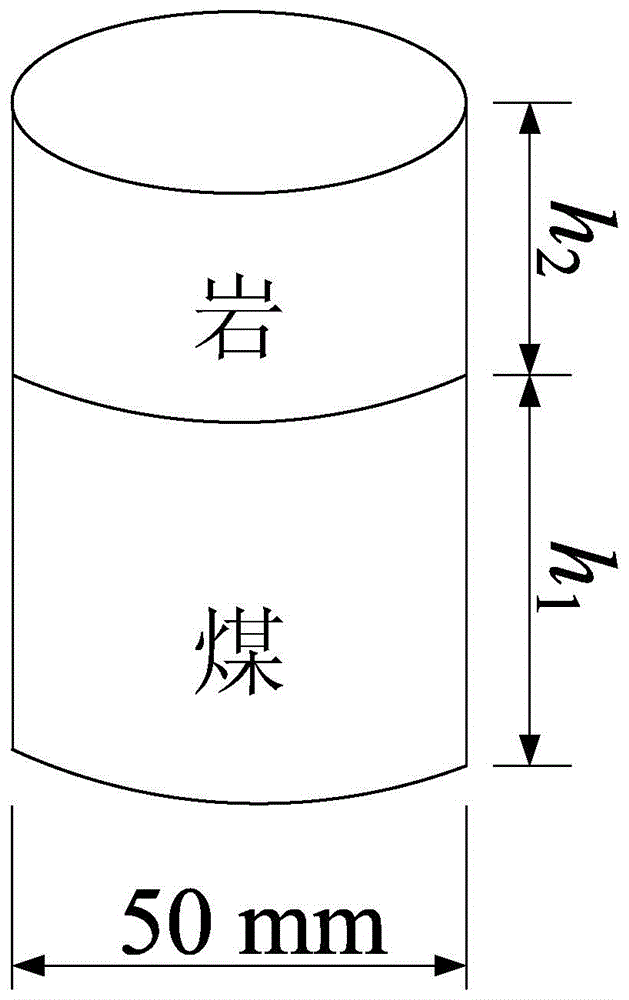

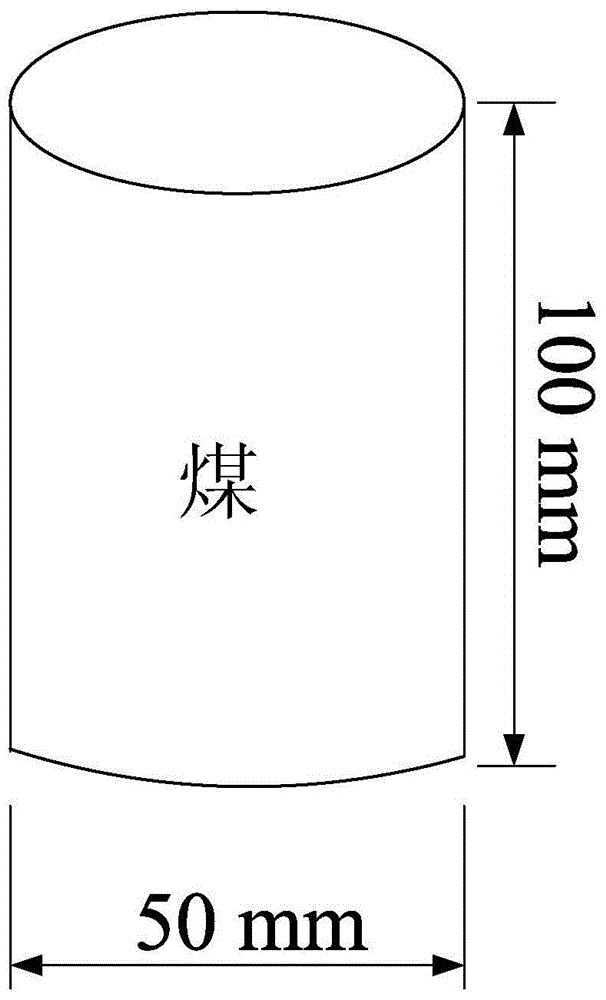

ActiveCN105021457AImprove accuracyThe evaluation result is accurateMaterial strength using tensile/compressive forcesEngineeringEvaluation finding

The invention discloses a test and evaluation method for deep hard roof coal seam bump proneness. The method comprises the steps of: preparing standard pure coal test pieces, standard pure rock test pieces and standard coal-rock combination test pieces; calculating the residual energy release rate of the standard coal-rock combination test pieces; and evaluating the proneness of the standard coal-rock combination test pieces. The standard coal-rock combination test pieces of corresponding proportions are made according to the actual thickness of on-site hard roofs and coal bodies, and by means of a quantization process, the influence of the coal rock combination effect and the combination size effect to bump proneness is fully reflected, and the accuracy of the evaluation result is significantly enhanced. Also, the method provided by the invention takes the coal-rock combination residual energy release rate to evaluate the coal seam bump proneness, gives full consideration to the time effect of the residual energy and destruction process during coal-rock failure, overcomes the one-sidedness existing in simple use of energy index and failure time index, and solves the problem of erroneous judgment and misjudgment to bump proneness from the source.

Owner:SHANDONG UNIV OF SCI & TECH

Rock damage prediction method based on acoustic emission source dominant frequency uniqueness

ActiveCN111879858AMaterial analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionFrequency characteristic

The invention provides a rock damage prediction method based on acoustic emission source dominant frequency uniqueness. The rock damage prediction method comprises the steps of preparation of a standard rock test piece, acoustic emission source positioning, acoustic emission source type identification, calculation of acoustic emission dominant frequencies corresponding to different types of sources and rock damage prediction. According to the method, the defects of wide acoustic emission main frequency band and non-obvious acoustic emission main frequency characteristics of an existing rock damage prediction method based on acoustic emission main frequency characteristics are overcome. The method is suitable for predicting rock damage in Brazilian splitting tests, shearing tests and creeptests under uniaxial and triaxial compression conditions.

Owner:JIANGXI UNIV OF SCI & TECH

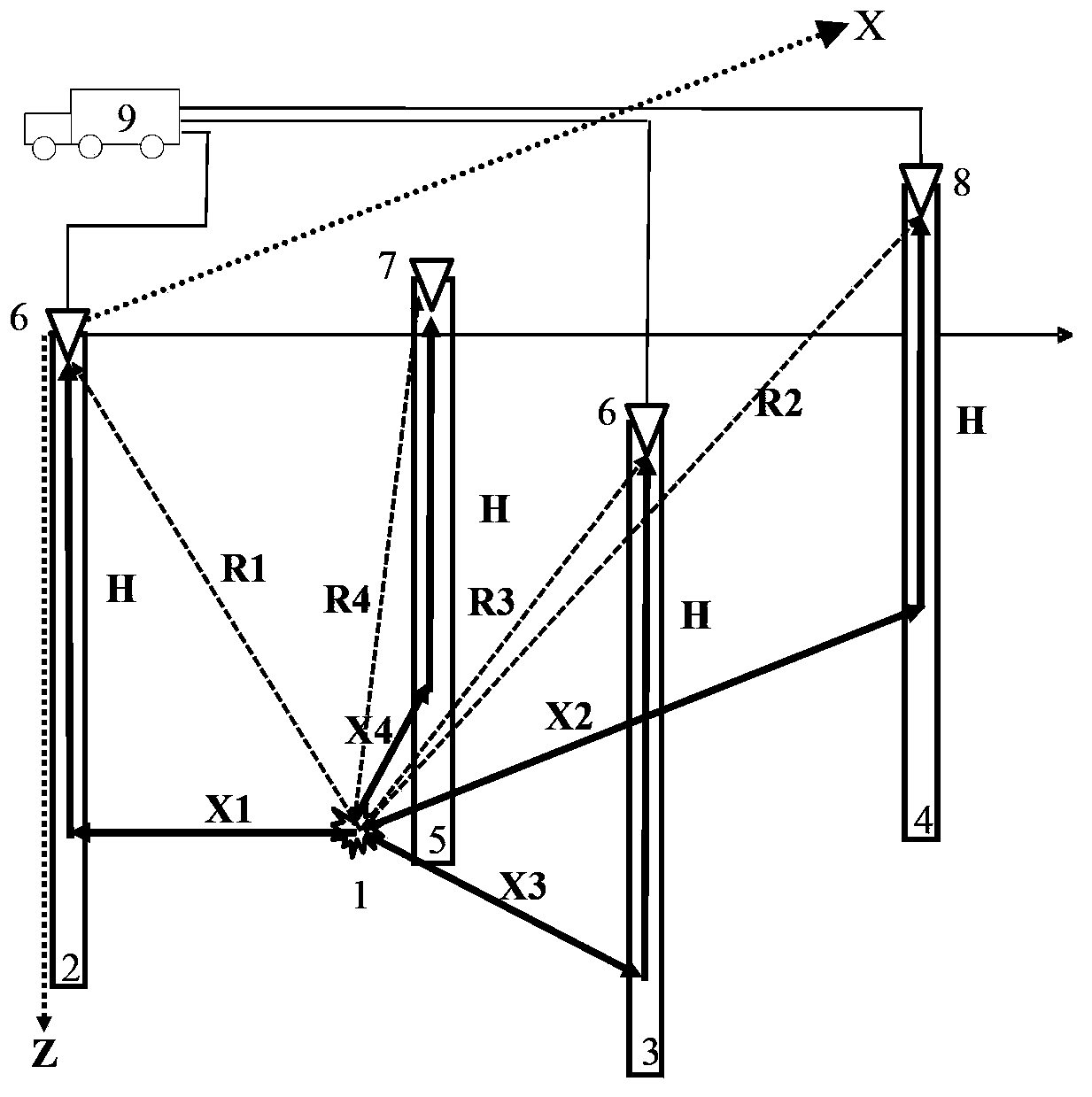

Method for performing hydraulic-fracturing microseismic monitoring by utilizing uphole geophones

ActiveCN104215934APrecise positioningEasy constructionPosition fixationSeismic signal receiversGeophoneHydraulic action

The invention relates to a method for performing hydraulic-fracturing microseismic monitoring by utilizing uphole geophones and applying geophysical prospecting. The geophones are mounted on hydraulic-fracturing uphole casings, micro-seismic signals generated by underground rock under the high-pressure hydraulic action during fracturing are recorded, and micro-seismic signal waves are transmitted to the casings along the horizontal direction to be converted into sound waves which are transmitted along the steel casings to be recorded by the uphole geophones. By the method, geometric position coordinates of underground rock failure points can be determined rapidly and accurately on a fracturing construction site, and the method and device simple in construction can be applied to dynamic imaging and rapid post-fracturing assessment of hydraulically created fractures of low permeability reservoirs and shale reservoirs of oil fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

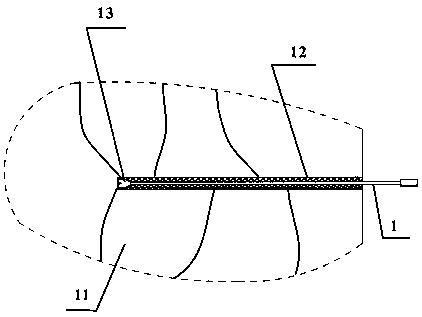

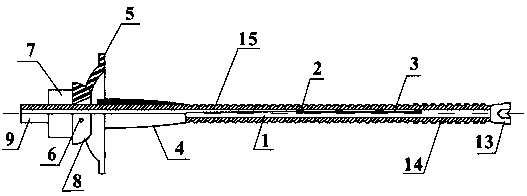

Self-propelled hollow slip casting anchor rod with stress-measuring function and operating method

InactiveCN107905827ASimplify the construction processImprove construction efficiencyAnchoring boltsStress measuresStress conditions

The invention relates to the technical field of tunnel and underground construction anchoring equipment, in particular to a self-propelled hollow slip casting anchor rod with a stress-measuring function and an operating method. The self-propelled hollow slip casting anchor rod with the stress-measuring function includes a rod body with a hollow structure, a self-propelled drill is connected at thefront end of the rod body, and the back end of the rod body is provided with a slip casting opening which communicates with an inner cavity of the rod body; and the rod body is further provided witha stress-measuring device and an anchoring structure which is close to the self-propelled drill. According to the self-propelled hollow slip casting anchor rod with the stress-measuring function, thestress-measuring device is arranged to combine the processes of drilling, anchoring and slip casting into the same construction process, and the anchoring can be achieved in short time; and stress conditions of all sections of the anchoring rod in the supporting process can be monitored, so that the supporting mechanism of action and the stress conditions of the anchoring rod under the various kinds of surrounding rock conditions can be known, and critical evidences and references are supplied to the research of design parameters for the anchoring rod, improvement of the construction techniqueand the surrounding rock failure mechanism.

Owner:SOUTHWEST PETROLEUM UNIV

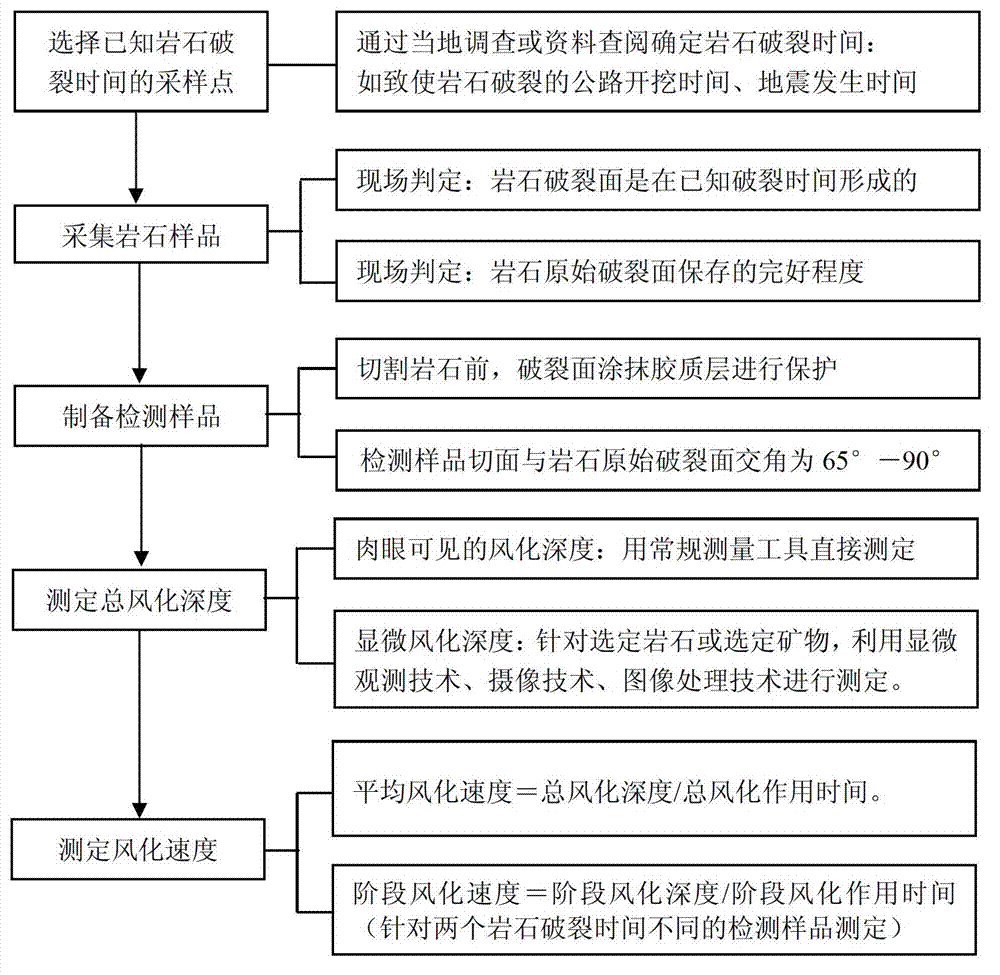

Rock weathering speed measurement method

ActiveCN102967548ASolve the technical problem that the weathering time is difficult to simulateRealize quantitative measurementWeather/light/corrosion resistanceStart timeImaging processing

The invention provides a rock weathering speed measurement method. The rock weathering speed measurement method comprises the steps of firstly discovering microscopic weathering characteristics in the initial rock weathering stage, namely the natural phenomenon that microcracks formed in fracture planes after rock failure continuously extend in rocks, and definitely defining the starting and stopping points and the starting and stopping time of the rock weathering. As for microscopic weathering characteristics, the rock weathering speed measurement method can carry out quantitative measurement on the width of the microcracks (namely, the rock weathering depth) by adopting a microscopic observation technology, a camera shooting technology and an image processing technology, and solves the technological problem that the microscopic weathering characteristics are invisible to the naked eyes. The rock weathering speed measurement method can record the rock cracking time by utilizing human activity events or geological events, determine the starting time of the weathering, and solve the technical problem that the weathering simulation time is hard to prolong to more than ten years. The rock weathering speed measurement method has the advantages of easiness in operation and accuracy in measurement results.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

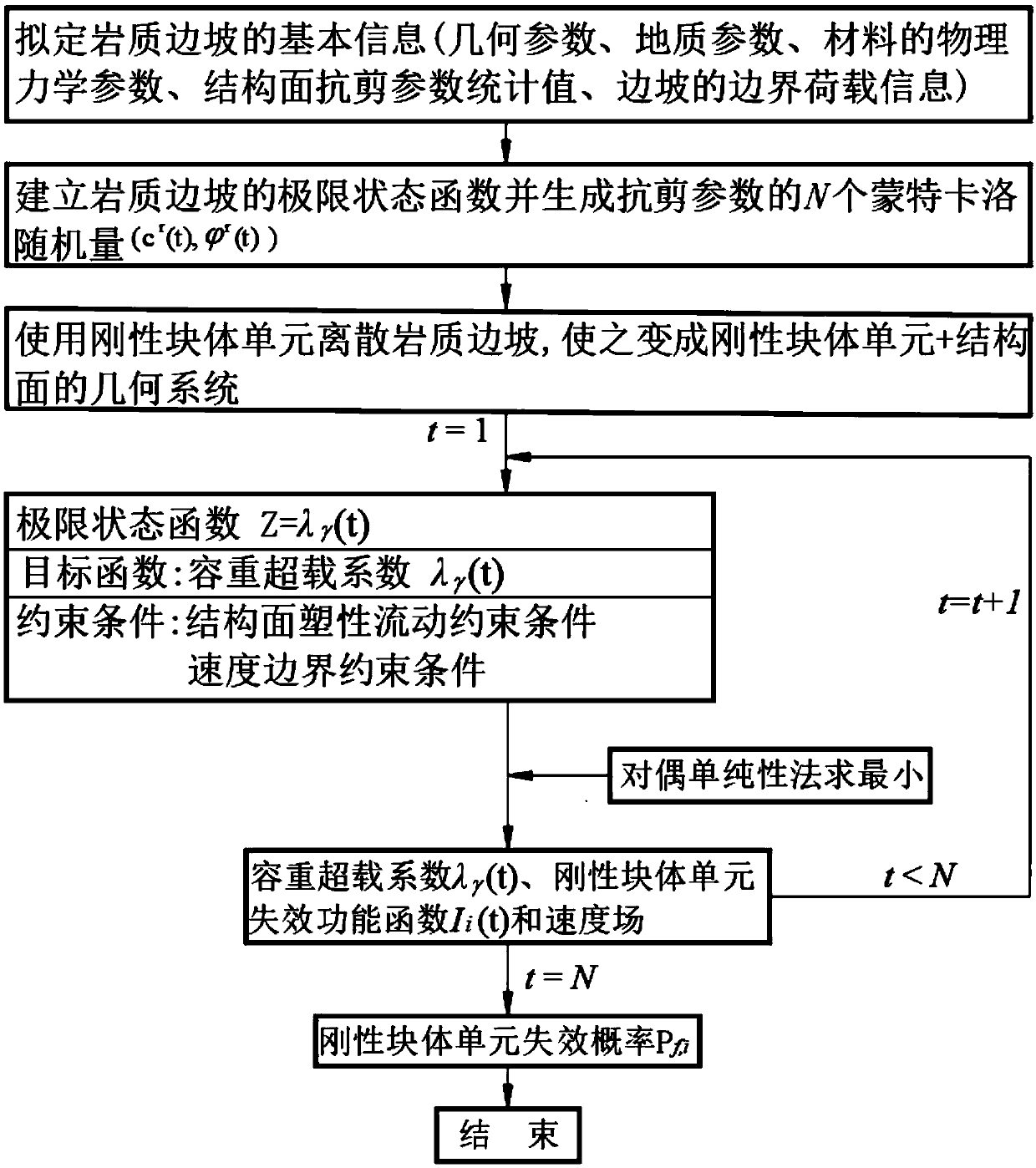

Method for calculating rock failure probability in rock slope

ActiveCN108763697AFailure Probability StatisticsClimate change adaptationDesign optimisation/simulationResearch ObjectPlastic limit analysis

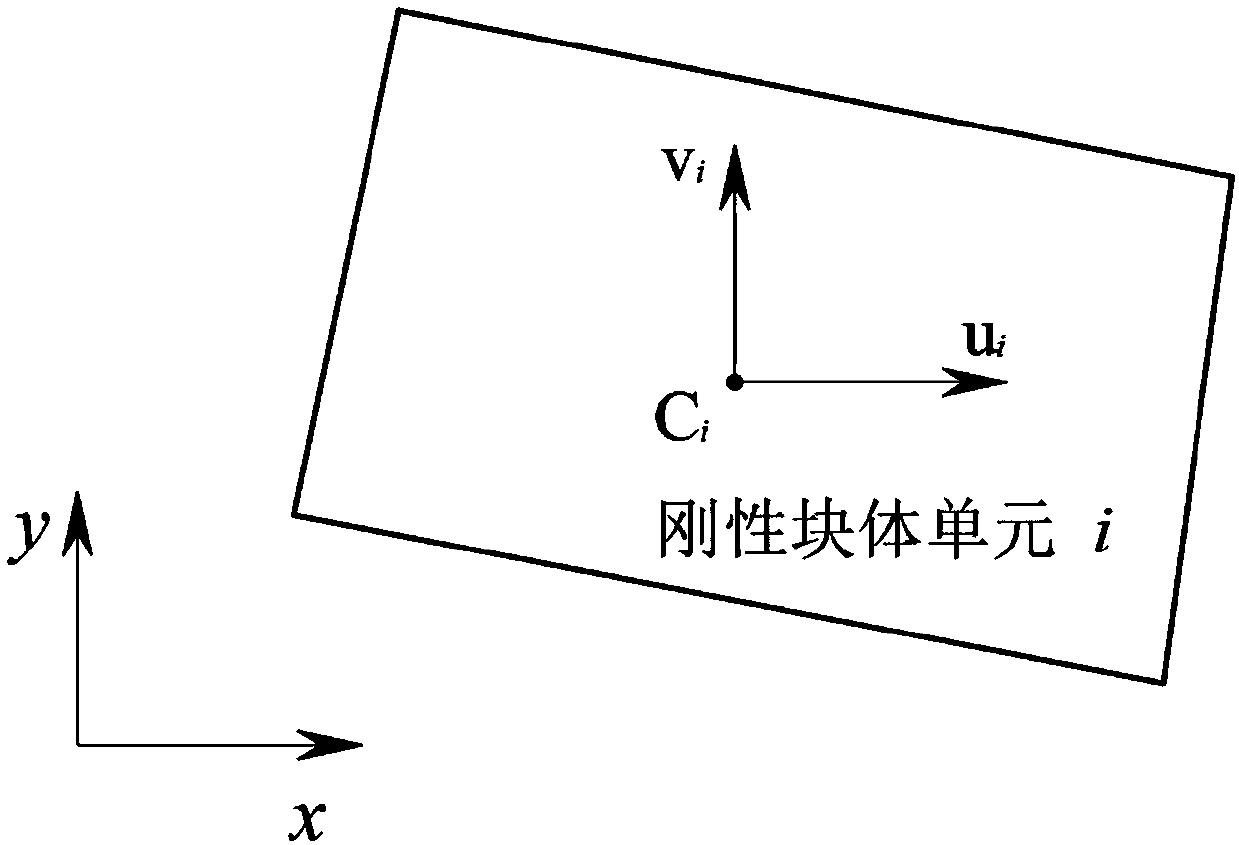

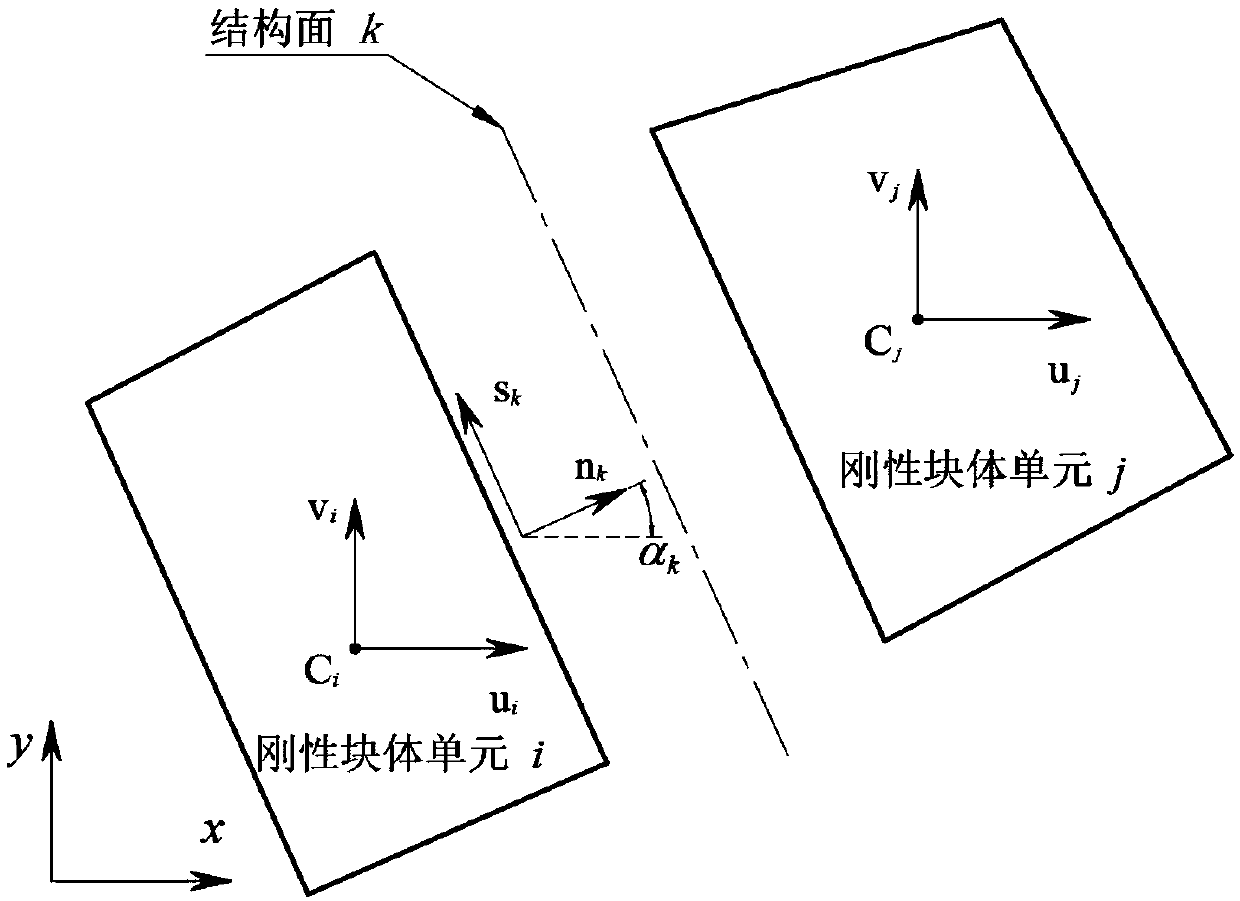

The present invention discloses a method for calculating the rock failure probability in a rock slope. The method comprises: step 1, formulating a calculation parameter of a rock slope; step 2, establishing a limit state function of the rock slope; step 3, discretizing the rock slope by using rigid block elements; step 4, establishing an upper bound linear programming model for solving the rock failure probability; and step 5, solving the upper bound linear programming model by using a Monte Carlo method, and calculating the rock failure probability. According to the method disclosed by the present invention, a two-dimensional rock slope is taken as a research object, the upper bound theorem of plastic limit analysis, and the rigid block element discrete technology, the linear programmingmethod and the Monte Carlo method are combined to establish a mathematical programming model of the upper bound method for calculating the rock failure probability; and the model can be effectively used to calculate the rock failure probability and obtain the failure probability and the corresponding failure mode of all rock blocks in the rock slope.

Owner:KUNMING UNIV OF SCI & TECH

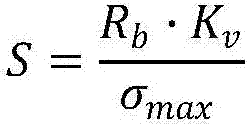

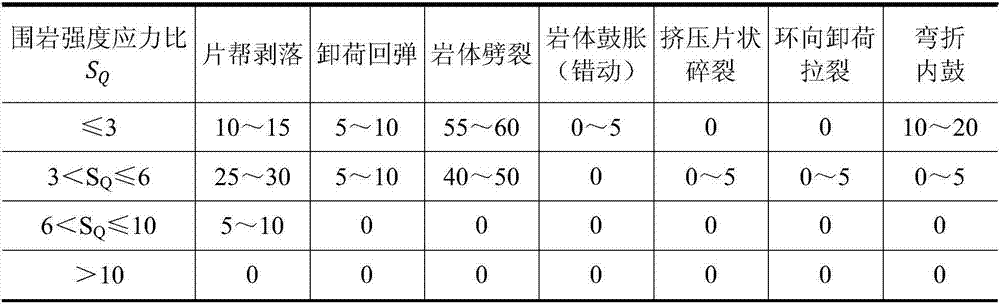

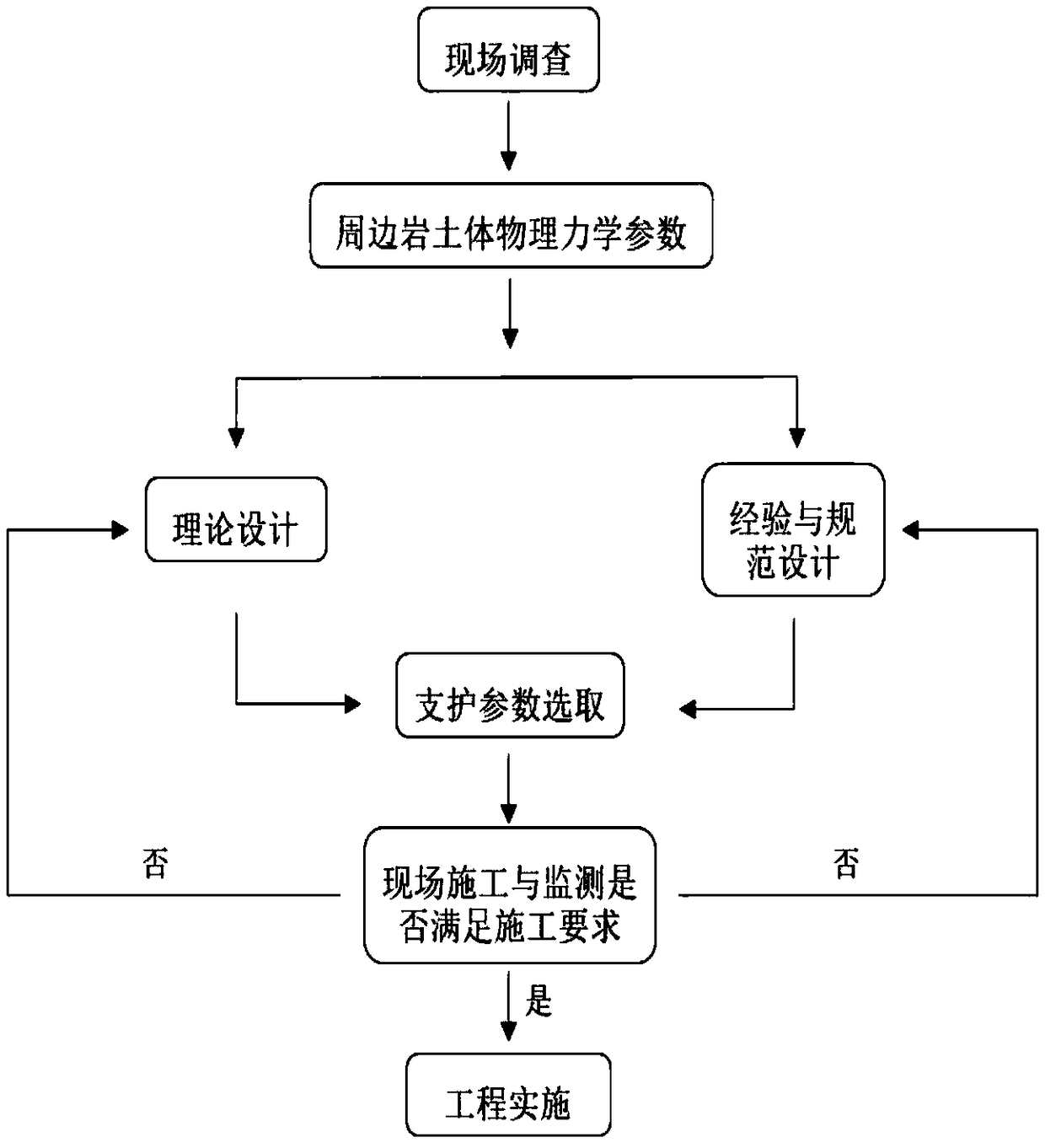

Method for predicting stratified rock mass underground cavern surrounding rock failure type in high ground stress region

The invention discloses a method for predicting the stratified rock mass underground cavern surrounding rock failure type in a high ground stress region, and relates to the field of rock-soil and water conservancy and hydropower engineering. The technical scheme adopted by the invention comprises the steps of A, performing geological survey, and carrying out engineering geological rock division by combining engineering significance and scale; B, selecting representative rocks, and performing a saturated uniaxial compression strength test on the selected rocks respectively, carrying out generalization on each engineering geological rock group according to the representative rocks, calculating the content of each representative rock in each engineering geological rock group, and then calculating the comprehensive compression strength Rbz of each engineering geological rock group by taking the content as a weight; C, conducting a three-dimensional space stress test, and acquiring the maximum principal stress [sigma]max; D, respectively calculating a strength-stress ratio SQ of each part of the cavern surrounding rock; and E, judging the failure type and occurrence probability of each part of the cavern surrounding rock. The method disclosed by the invention has important engineering significance for guiding a large underground cavern excavating and supporting method, parameter selection, supporting strength and engineering economic comparison and selection and the like.

Owner:POWERCHINA CHENGDU ENG

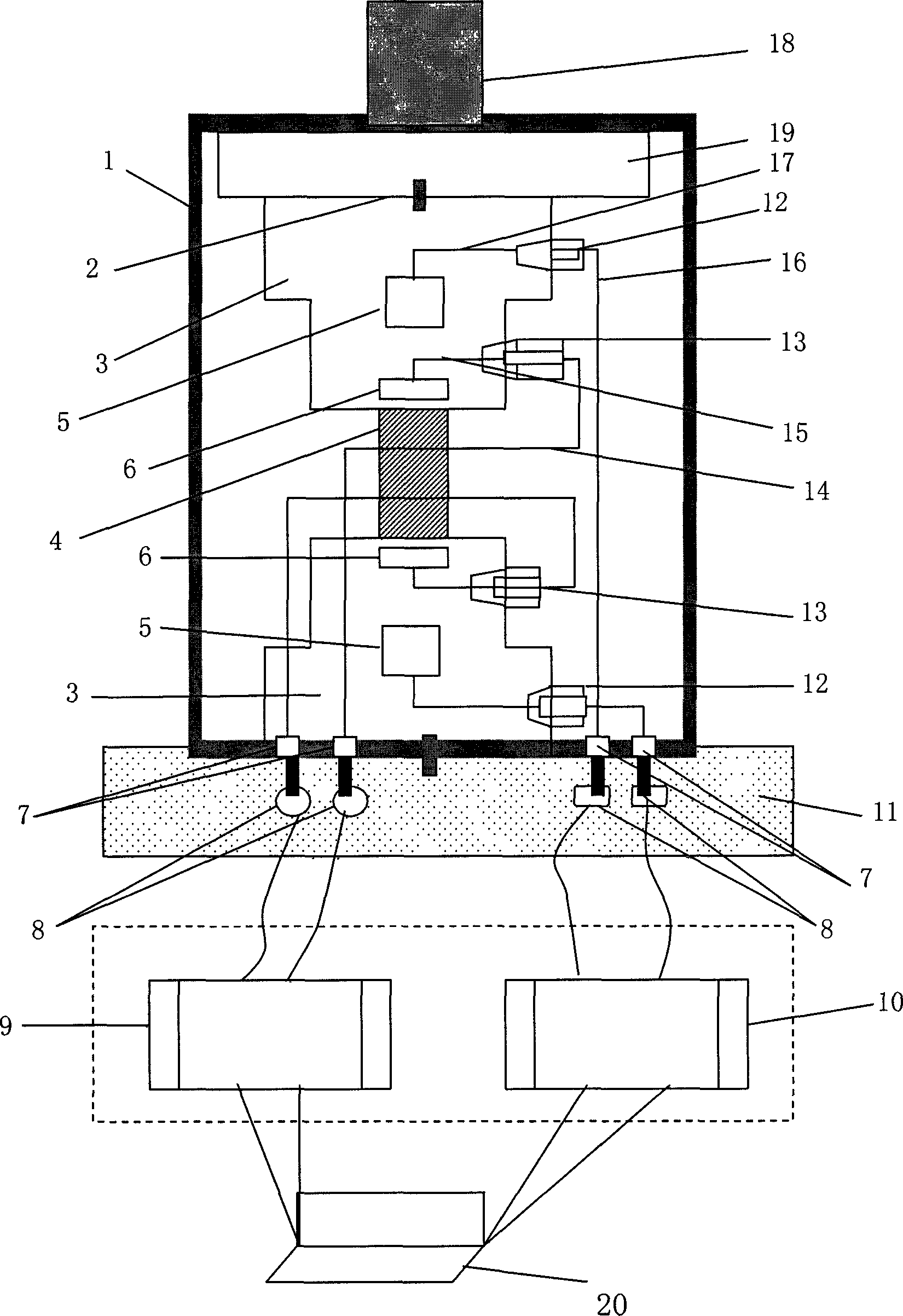

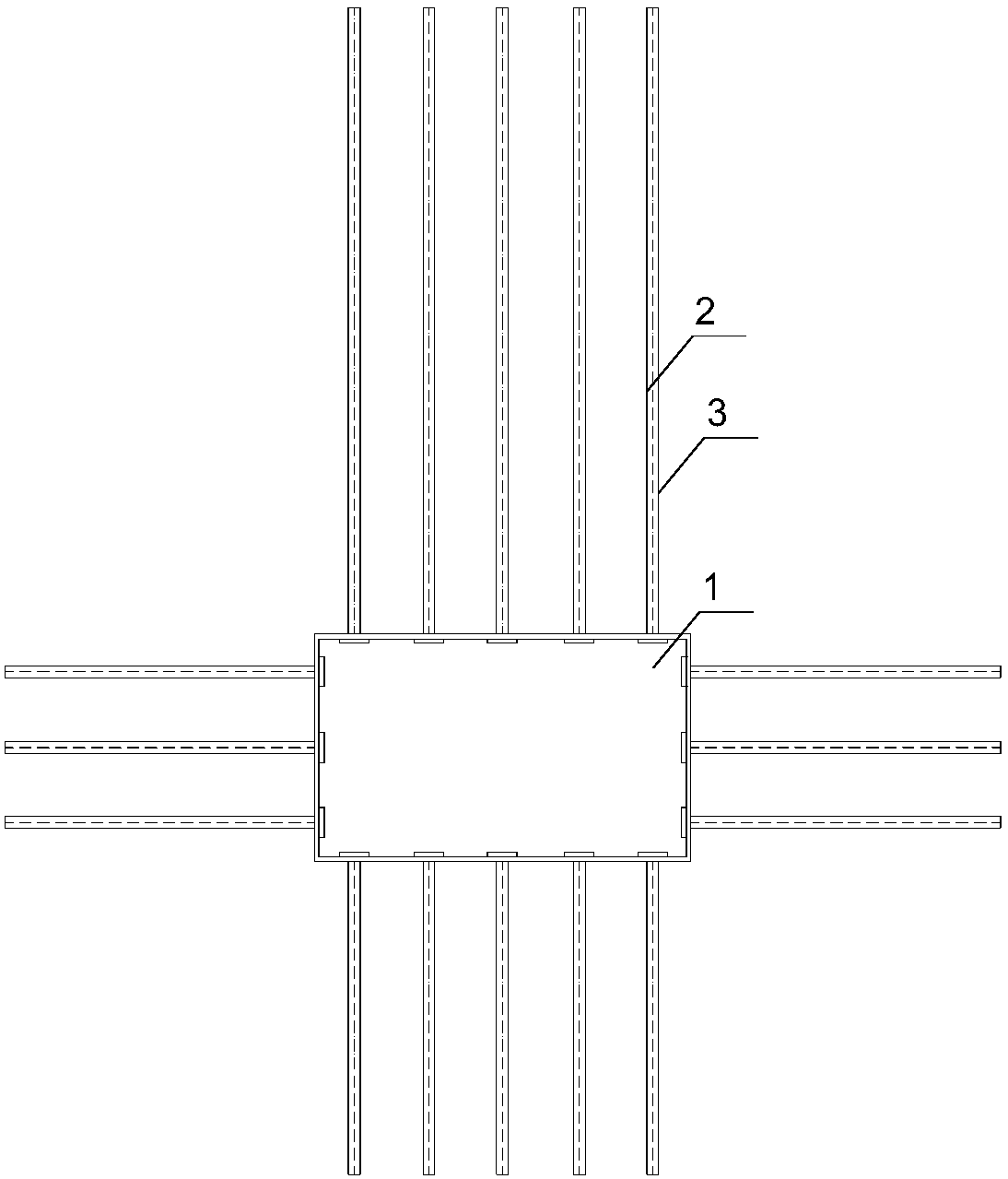

Microcosmic crack, acoustics and mechanics synchronous detection system for rock

InactiveCN107192601ARich elastic wave informationEarly warning instabilityMaterial strength using tensile/compressive forcesInstabilityMachining system

The invention relates to a microcosmic crack, acoustics and mechanics synchronous detection system for a rock. The microcosmic crack, acoustics and mechanics synchronous detection system comprises a testing machine, and further comprises a mechanical system, an ultrasonic system, an infrasound system, a crack detection system and a PC machine system, wherein the mechanical system transmits stress and strain data, which are generated in a rock destroying process on the testing machine, to the PC machine system; the ultrasonic system transmits an ultrasonic signal, which is generated in the rock destroying process, into the PC machine system; the infrasound system acquires infrasound data generated in the rock destroying process and transmits the infrasound data to the PC machine system; the crack detection system transmits a crack evolution process of a rock observation surface into the PC machine system. The microcosmic crack, acoustics and mechanics synchronous detection system for the rock can synchronously detect the mechanics, microcosmic cracks and ultrasonic wave and infrasound activity rules in the rock destroying process, so as to commonly describe the deforming and destroying mechanism of the rock and pre-warn the overall instability of the rock (mass).

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

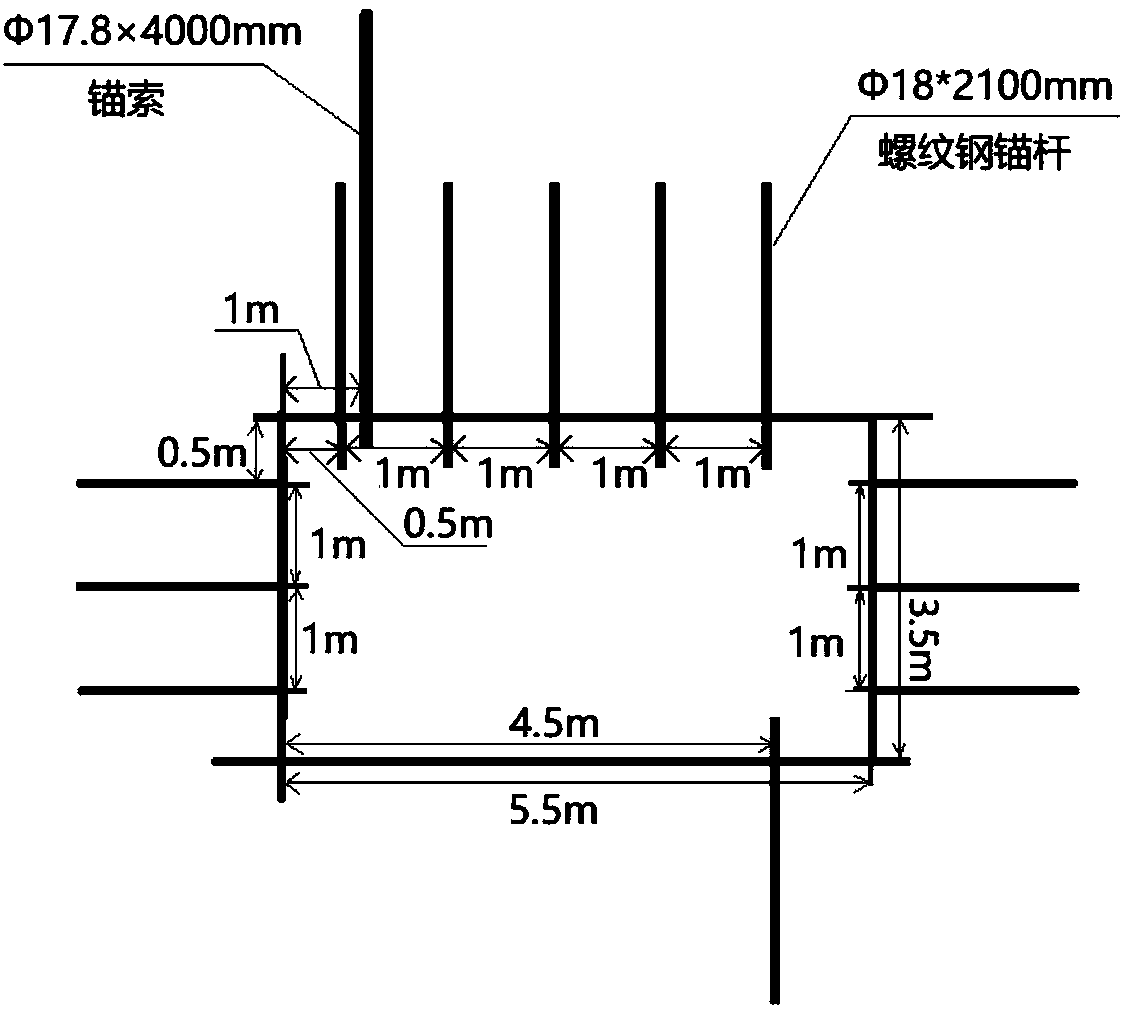

Bolt cable support method for monitoring of roadway surrounding rock failure

InactiveCN108060942AAccurately grasp the damage situationRapid Quantitative DesignMining devicesData processing applicationsEngineeringRock failure

The invention discloses a bolt cable support method for monitoring of roadway surrounding rock failure. The bolt cable support method comprises the steps that a plurality of roadway drilled holes areformed in a roadway, and a displacement sensor is arranged in each roadway drilled hole; displacement data are collected through the displacement sensors, and the damage degree of the roadway is judged through combining of the displacement data and the arranging positions of the displacement sensors; and bolt cable support is conducted on the roadway according to the roadway damage degree obtainedin the step (2). According to the bolt cable support method for monitoring of the roadway surrounding rock failure, a precise monitoring method based on deformation of roadway surrounding rock is utilized, the deformation amount of the plastic failure surrounding rock of the roadway surrounding rock can be determined, and information is more accurate and timely. The bolt cable support method canrealize intelligent design of roadway support parameters, and application of workers on a site is greatly facilitated.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

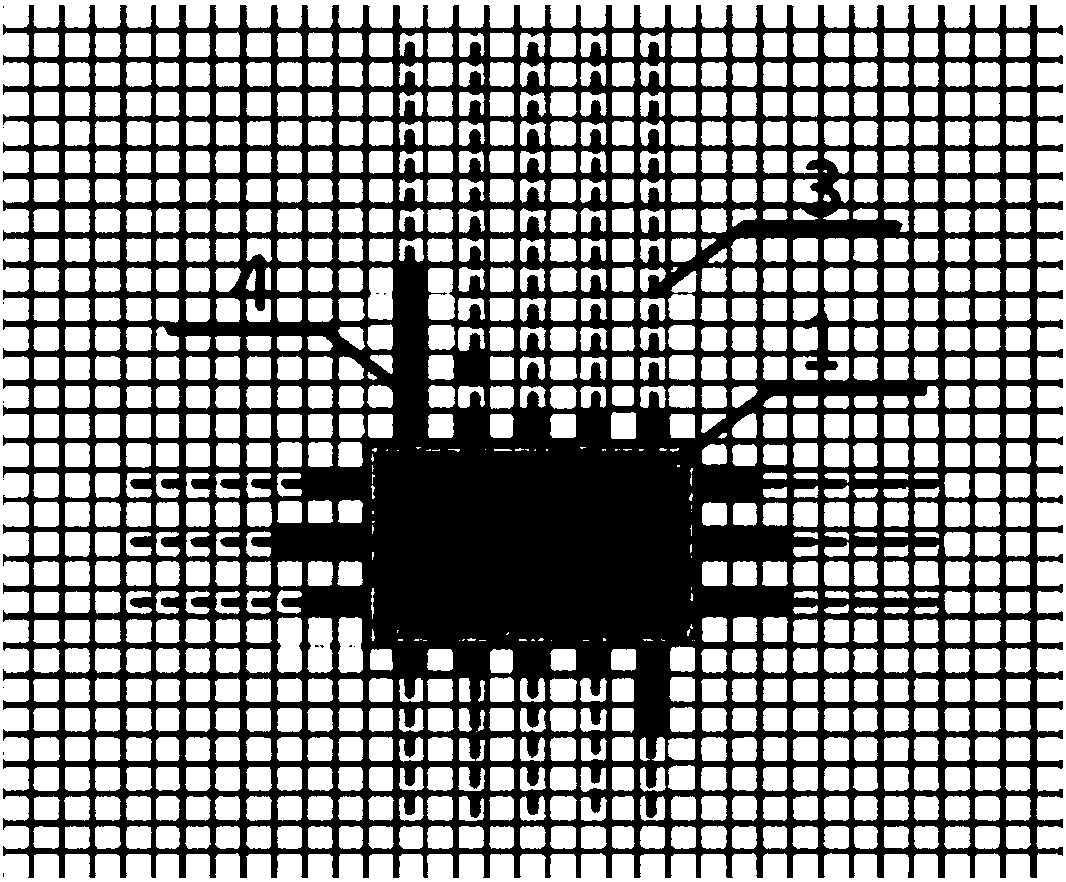

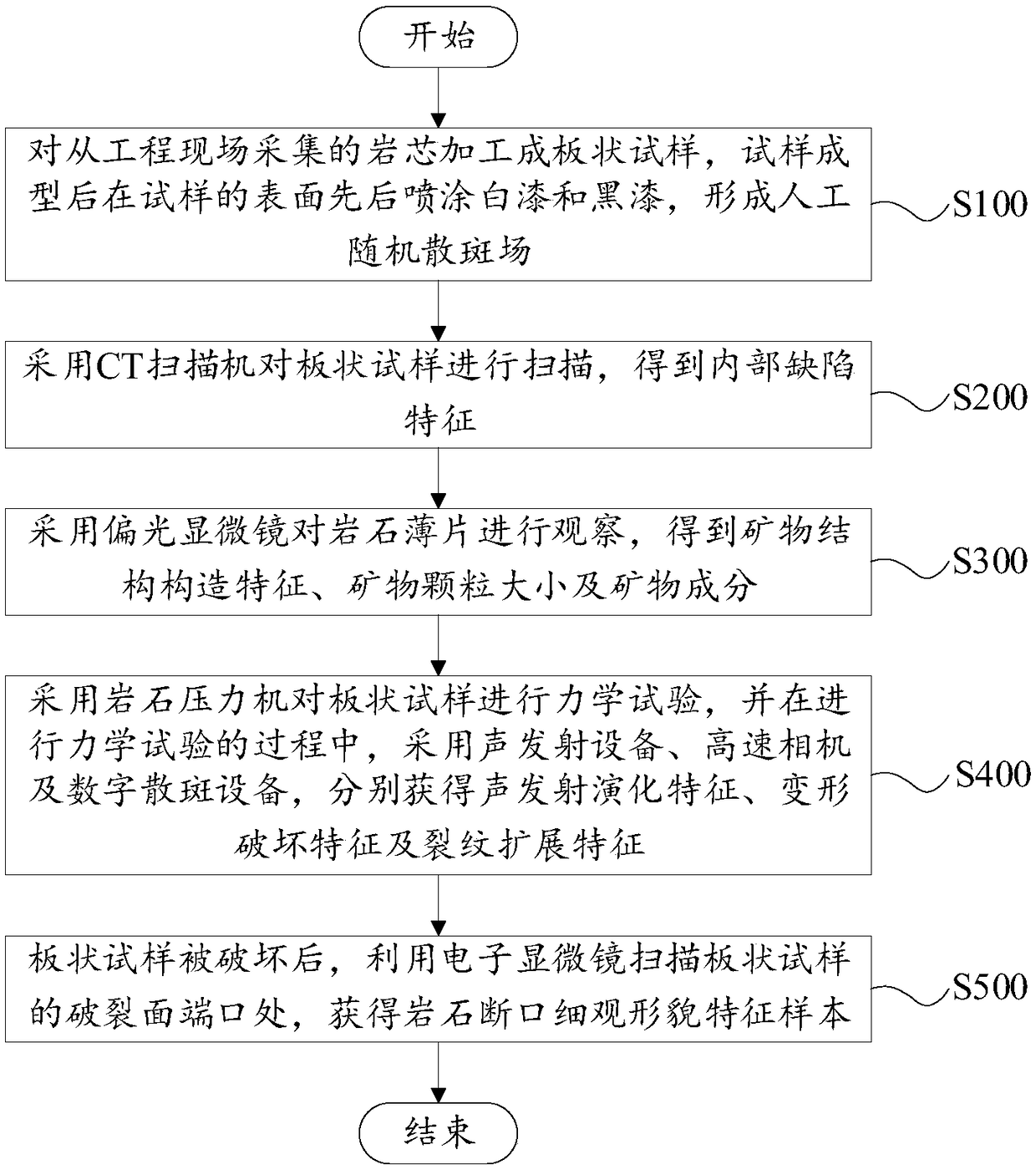

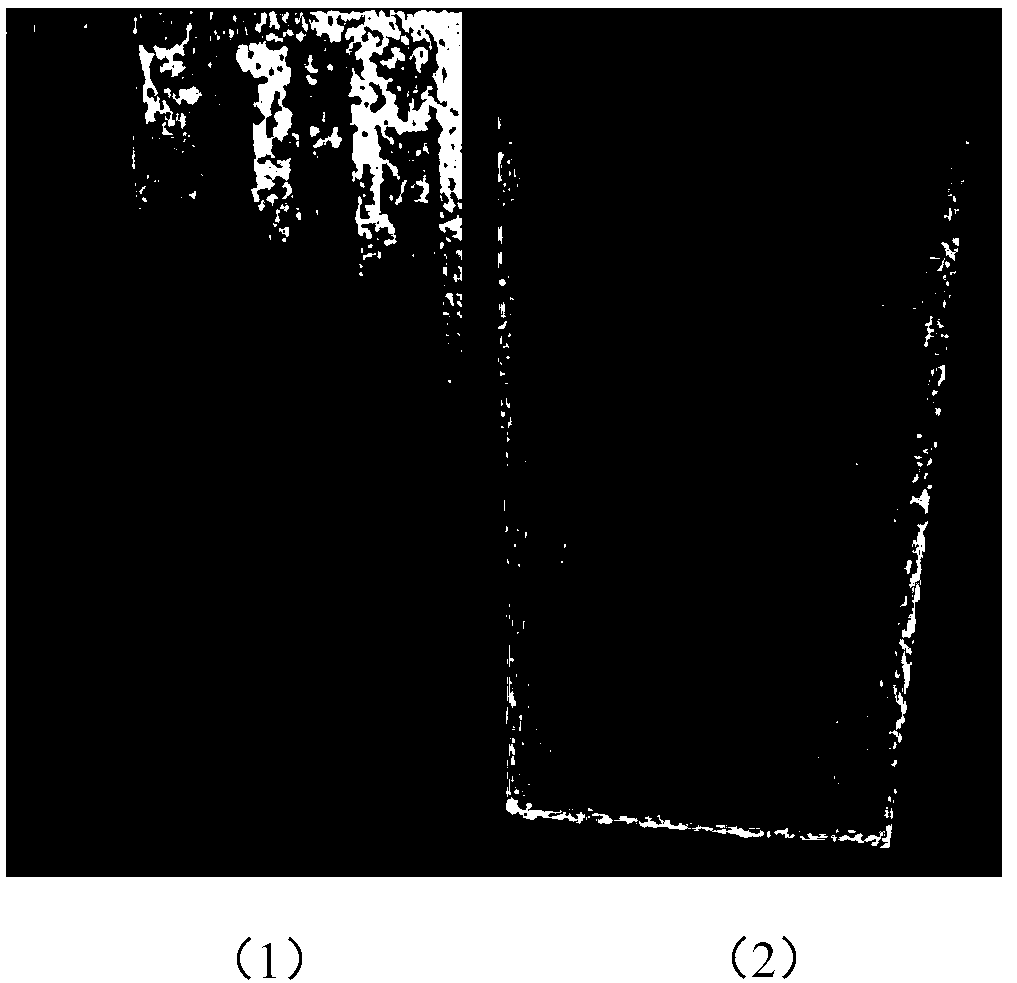

Test method for rock fracture evolution and rupture characteristics

InactiveCN108693040AGood synergyMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesRock coreAcoustic emission

The embodiment of the invention provides a test method for rock fracture evolution and rupture characteristics, and relates to the technical field of rock mechanics engineering. The method includes the steps: processing a rock core collected from engineering sites into a plate-shaped sample, spraying a white paint and a black paint on the surface of the sample after the sample is formed successively, and forming an artificial random speckle field; scanning the plate-shaped sample by a CT scanning machine, to obtain internal defect characteristics; carrying out mechanical test on the plate-shaped sample by a rock press, in the process of the mechanical test, adopting an acoustic emission device, a high-speed camera and a digital speckle device, and obtaining acoustic emission evolution characteristics, deformation and rupture characteristics and crack propagation characteristics respectively; and after the plate-shaped sample is destroyed, scanning a rupture surface end port of the plate-shaped sample by an electron microscope, to obtain a rock fracture micro-morphological characteristic sample. The test method for rock fracture evolution and rupture characteristics provided by theembodiment of the invention can enhance the synergy of exploring rock fracture characteristics and rupture mechanism.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

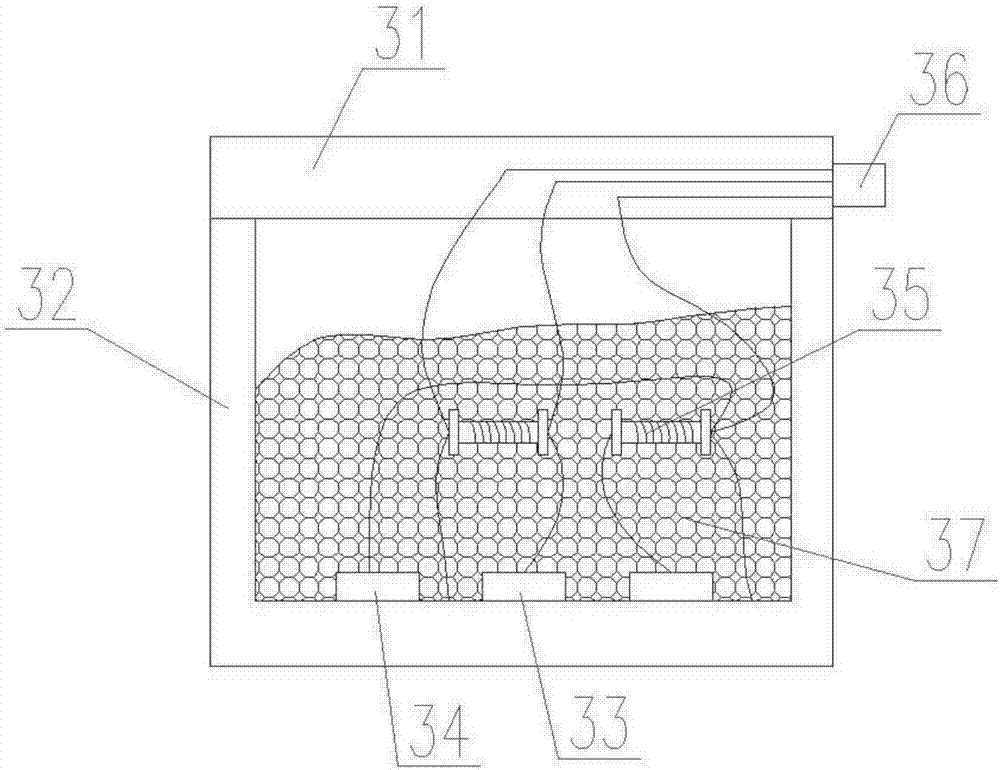

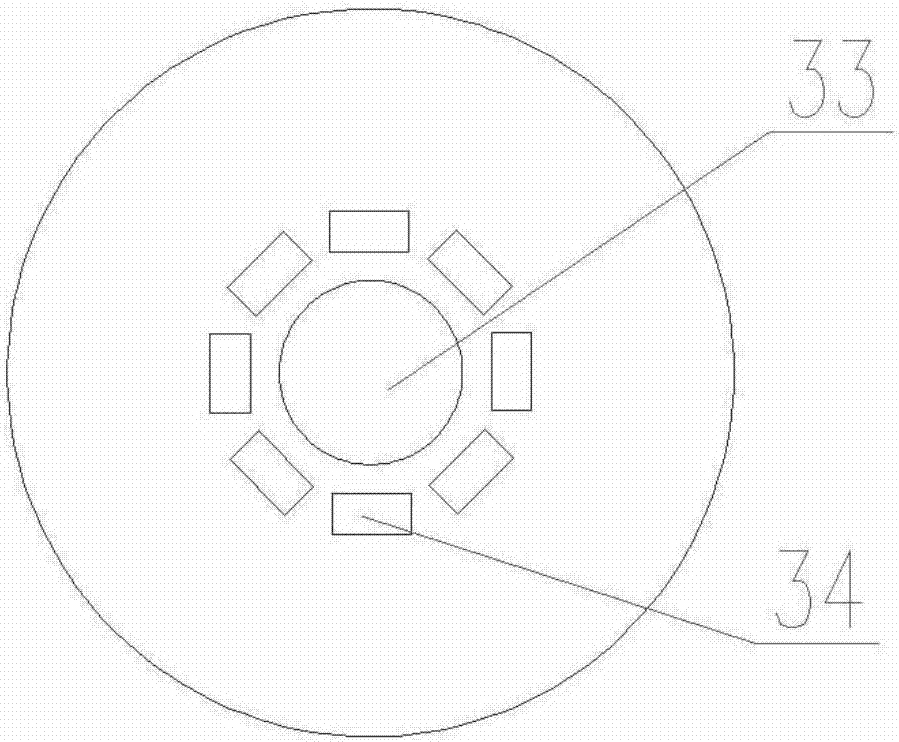

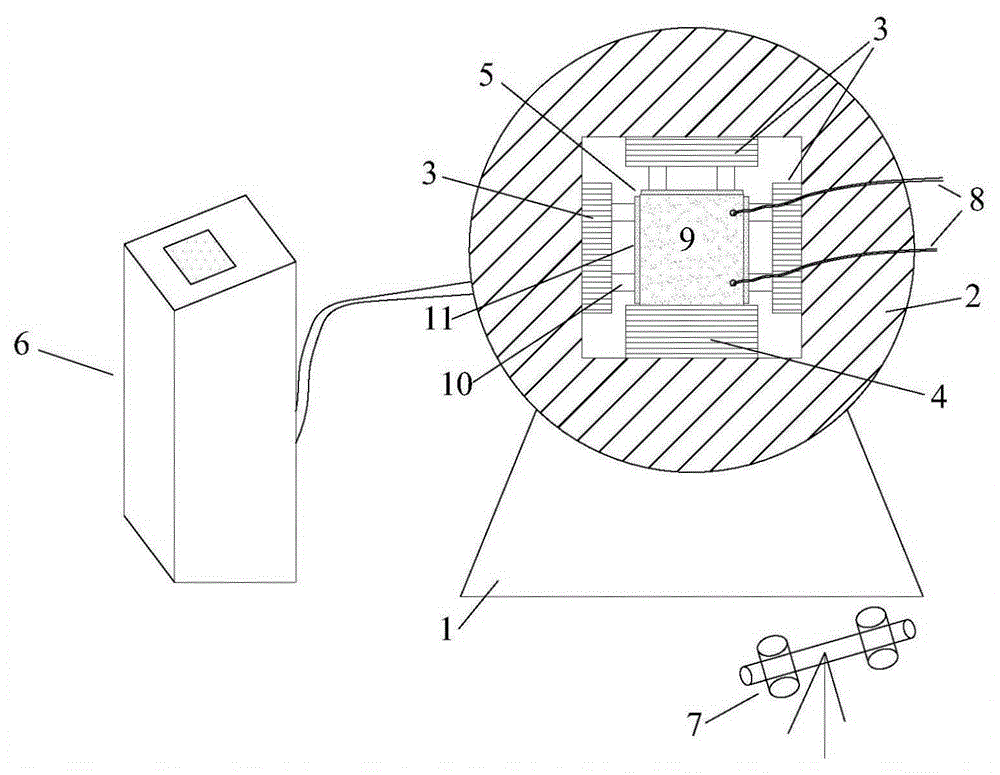

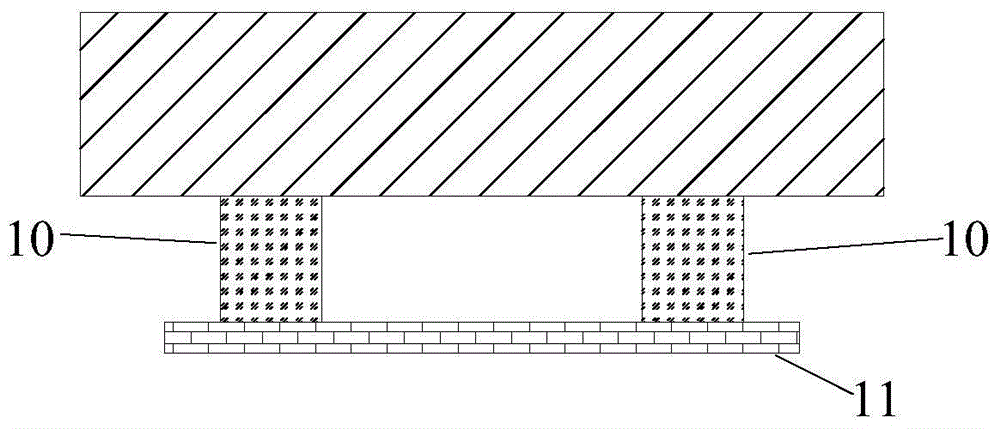

Testing system and testing method of outburst-preventing bedrock buckling failure model of karst tunnel

InactiveCN105136582ASave economic costSave time and costMaterial strength using tensile/compressive forcesRock failureKarst tunnel

The invention discloses a testing system and a testing method of an outburst-preventing bedrock buckling failure model of a karst tunnel, which belong to the testing system and the testing method of a surrounding rock failure model under a hydraulic coupling action. The testing system of the outburst-preventing bedrock buckling failure model of the karst tunnel comprises a base, a round bearing frame, separated combination type uniformly-distributed loading devices, a bearing platform, an electro-hydraulic servo control actuator, an electro-hydraulic servo control box, a three-dimensional digital camera and three-dimensional sound emission devices; the separated combination type uniformly-distributed loading devices are utilized for loading a testing model in the horizontal direction and the vertical direction; the electro-hydraulic servo control actuator is utilized for simulating water pressure of the rear side of a bedrock; the three-dimensional digital camera and the three-dimensional sound emission devices are utilized for monitoring and locating three-dimensional deformation and three-dimensional sound emission information of the testing model during a testing process. According to the testing system and the testing method of the outburst-preventing bedrock buckling failure model of the karst tunnel, disclosed by the invention, an engineering environment of an outburst-preventing bedrock is accurately simulated, the testing efficiency is increased, the testing time and the economic cost are reduced, and the accuracy of a testing result is increased.

Owner:CHINA UNIV OF MINING & TECH

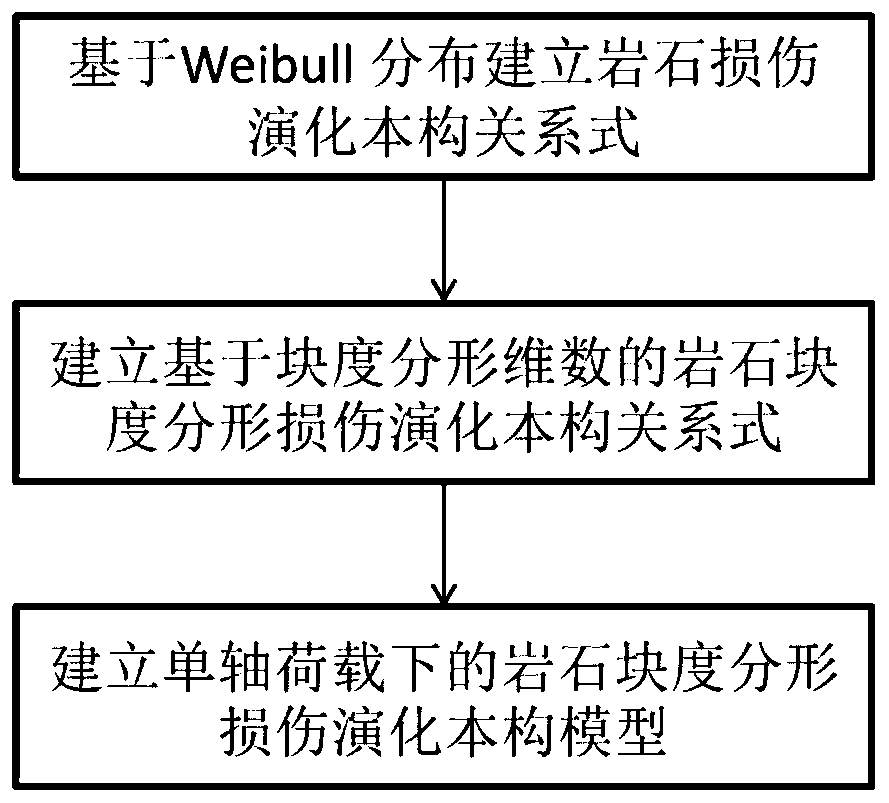

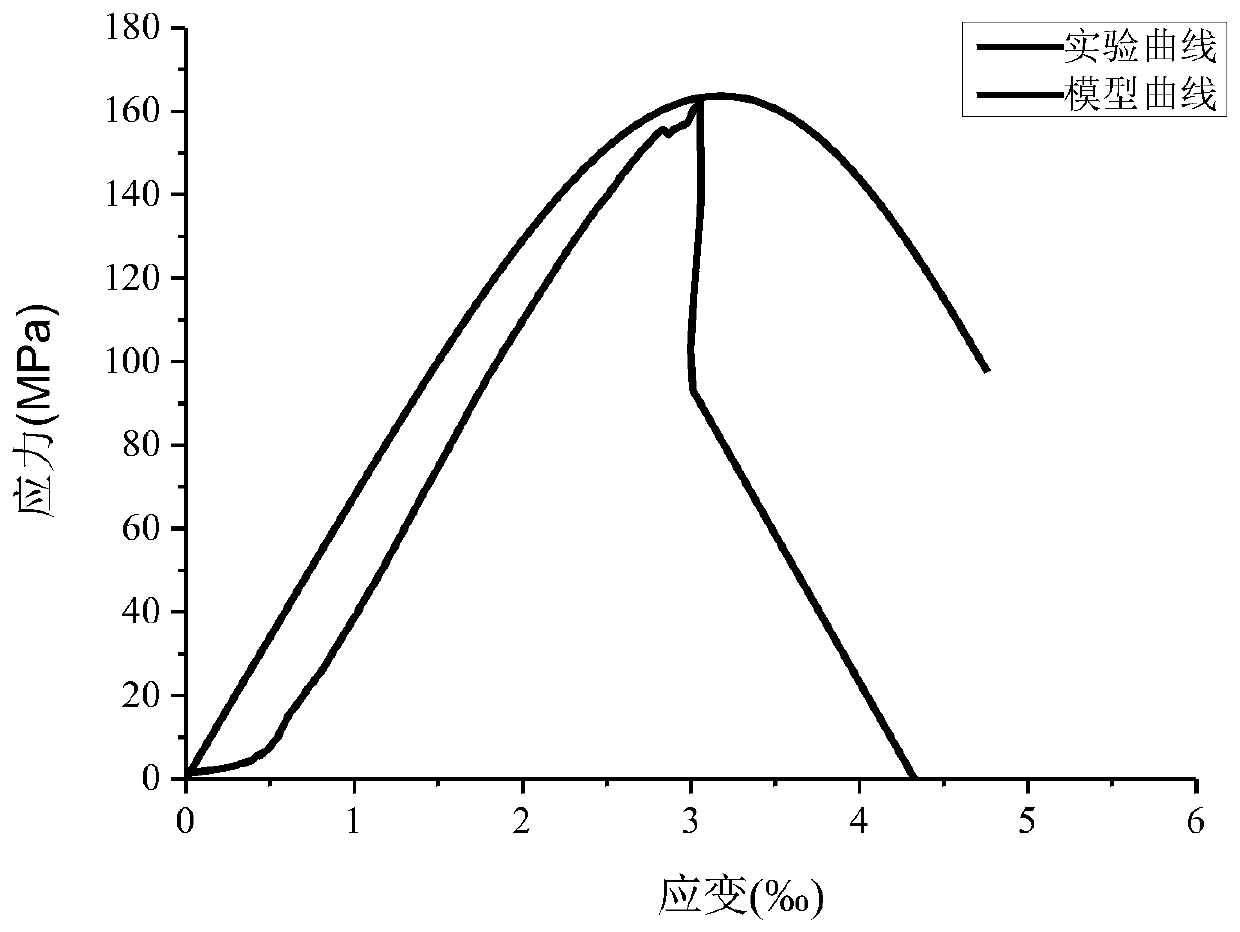

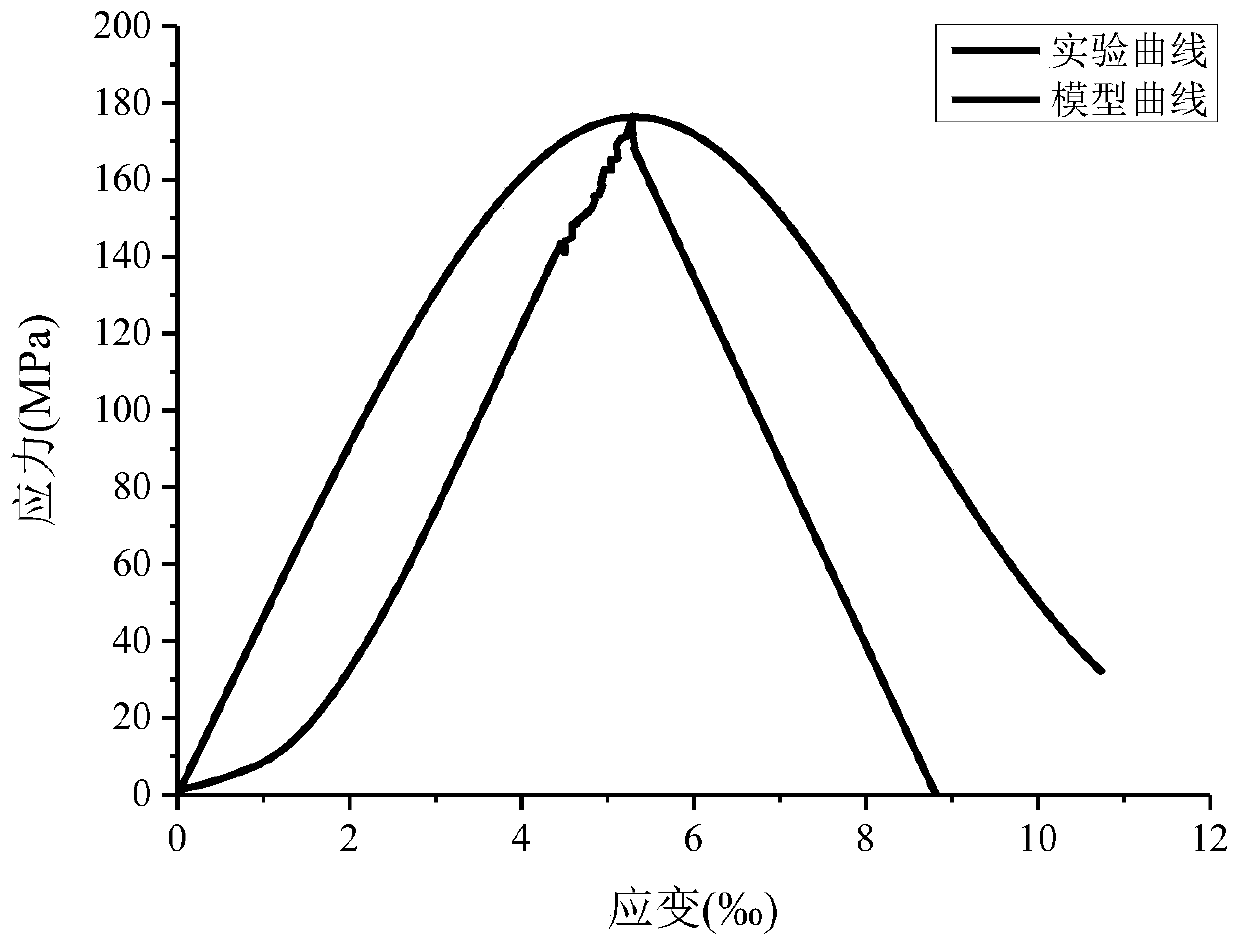

Method for establishing rock lumpiness fractal damage evolution constitutive model under uniaxial load

PendingCN110705113AThe method steps are simpleEasy to implementForecastingDesign optimisation/simulationRock failureEngineering

The invention discloses a method for establishing a rock lumpiness fractal damage evolution constitutive model under a uniaxial load. The method comprises the following steps of: 1, establishing a rock damage evolution constitutive relational expression based on Weibull distribution; 2, establishing a rock lumpiness fractal damage evolution constitutive relational expression based on the lumpinessfractal dimension; and 3, establishing a rock lumpiness fractal damage evolution constitutive model under the uniaxial load. The method provided by the invention has simple steps, high implementationconvenience, a new constitutive equation for describing the rock damage process is established; according to the method, the model for representing the damage evolution condition in the rock by adopting the rock lumpiness fractal dimension is established, so that systematization and deepening of research on the rock damage law by applying the fractal theory are facilitated, the reality can be truly reflected, the practicability is high, and the popularization and application values are high.

Owner:JIANGXI UNIV OF SCI & TECH

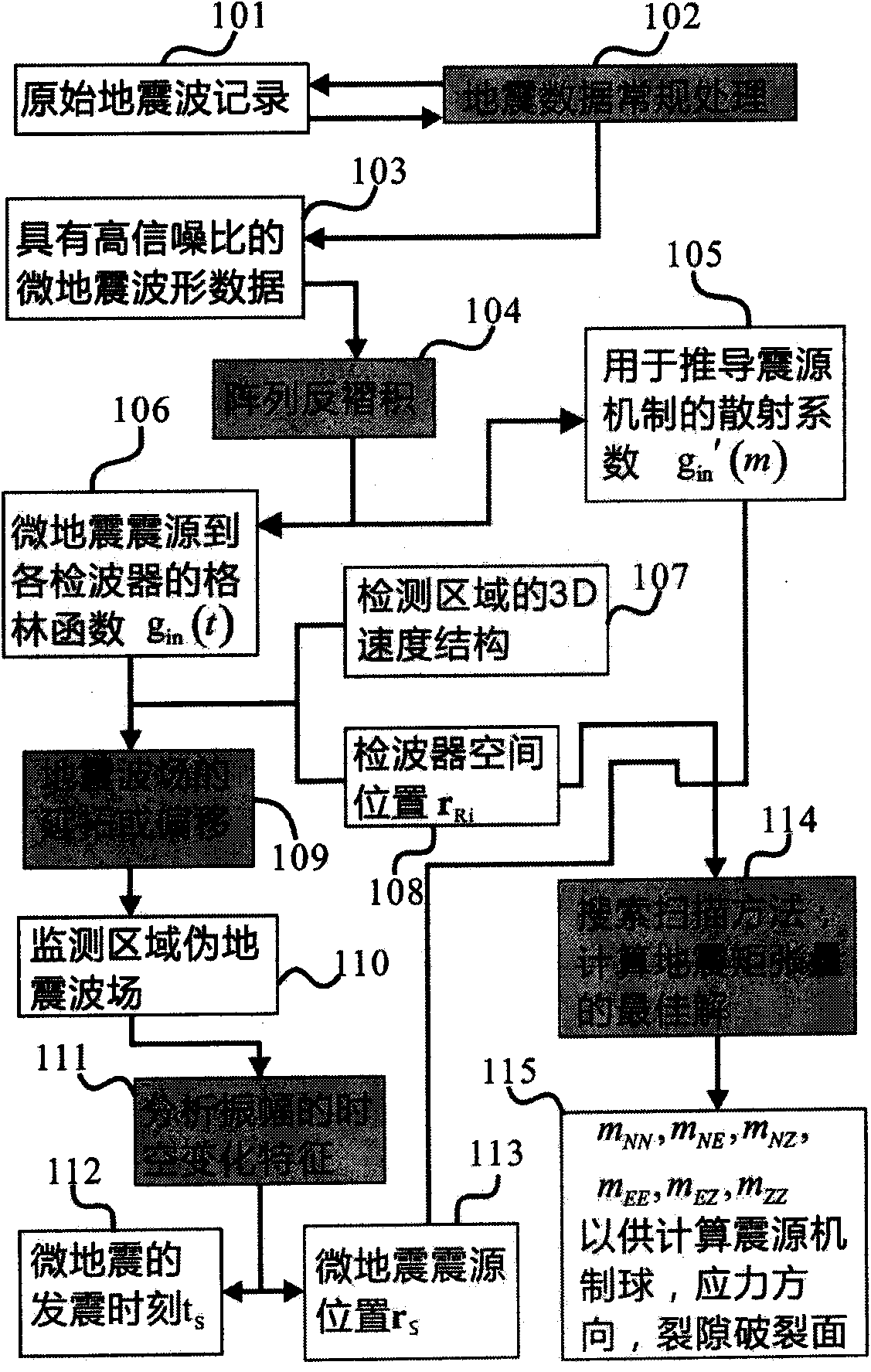

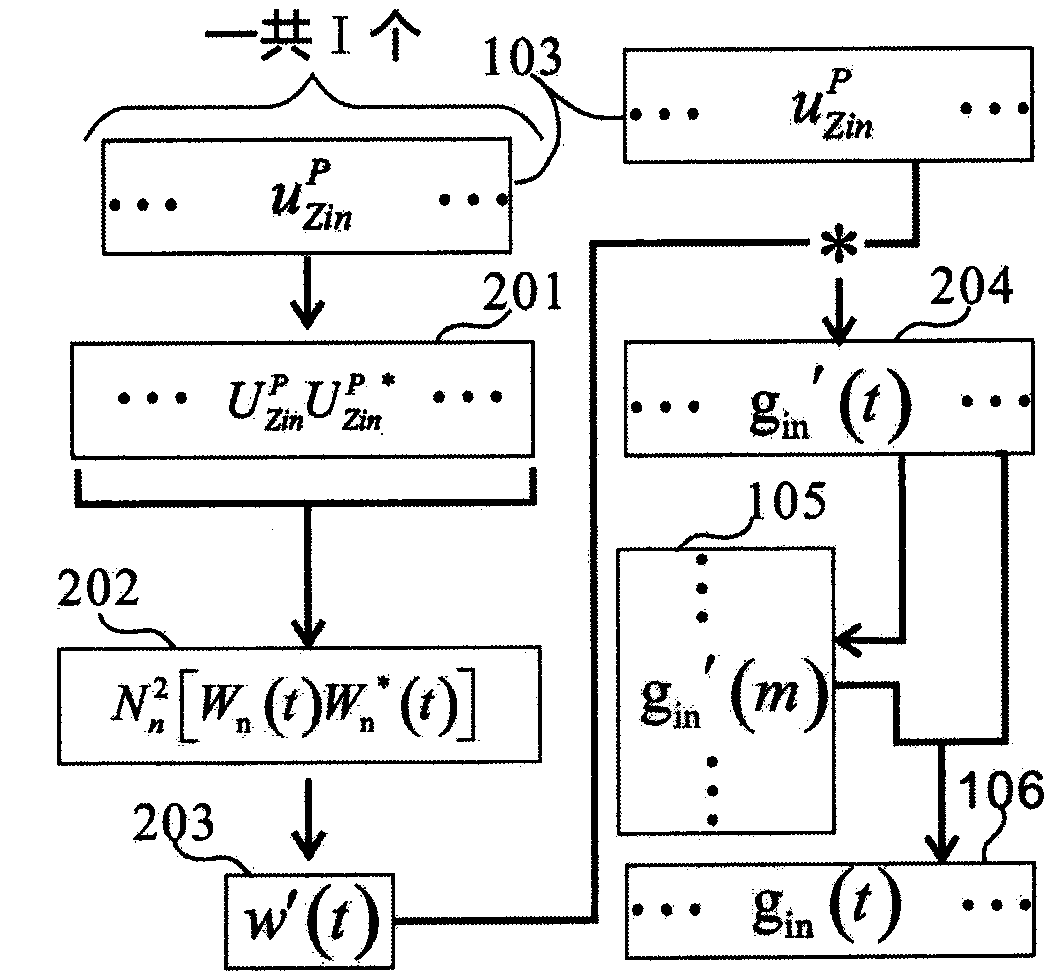

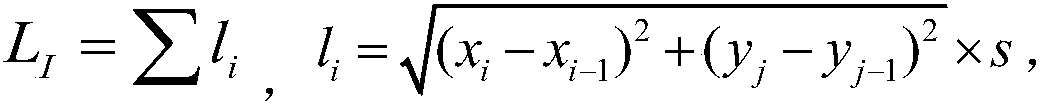

Hydraulic fracturing monitoring method based on array deconvolution treatment

The invention is applied to development of underground resources such as shale gas, tight sandstone gas and terrestrial heat, and provides a method for monitoring rock failures caused by hydraulic fracturing. The method comprises the steps that a scattering coefficient related to a micro earthquake focal mechanism and a Green function from a focus to all wave detectors are obtained through array deconvolution treatment; the obtained Green function is subjected to continuation or offset, so that an underground monitoring area pseudo wave field in an earthquake-triggering period is obtained; the spatial position of the micro earthquake focus is picked up according to the change of maximum energy of the wave field; the moment tension of the focal mechanism is searched for according to the position of the focus and the scattering coefficient related to the focal mechanism and can be used for analysis of the focal mechanism. By means of the method, the position and the focal mechanism of a micro earthquake caused by fracturing can be obtained.

Owner:NANJING UNIV

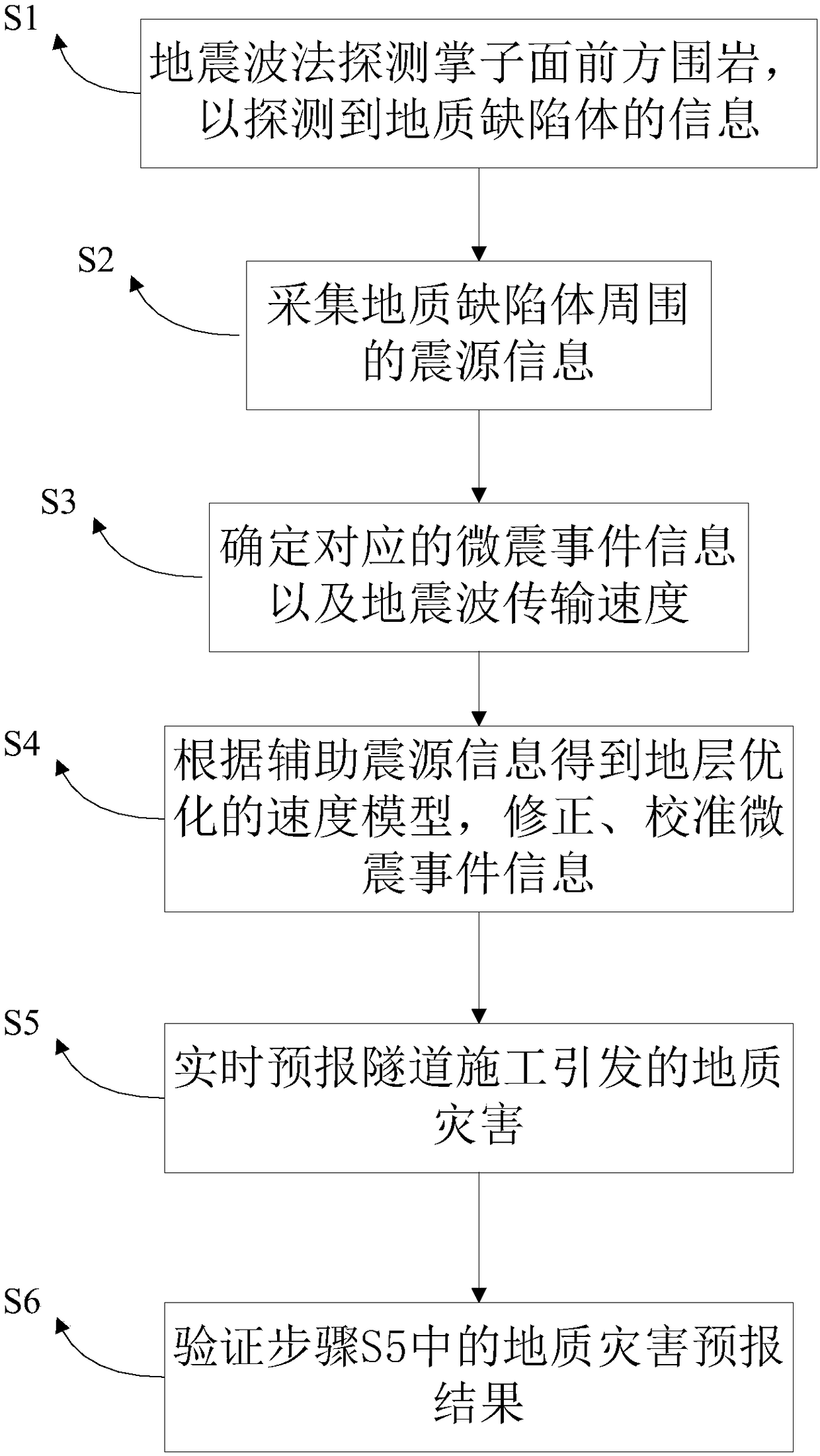

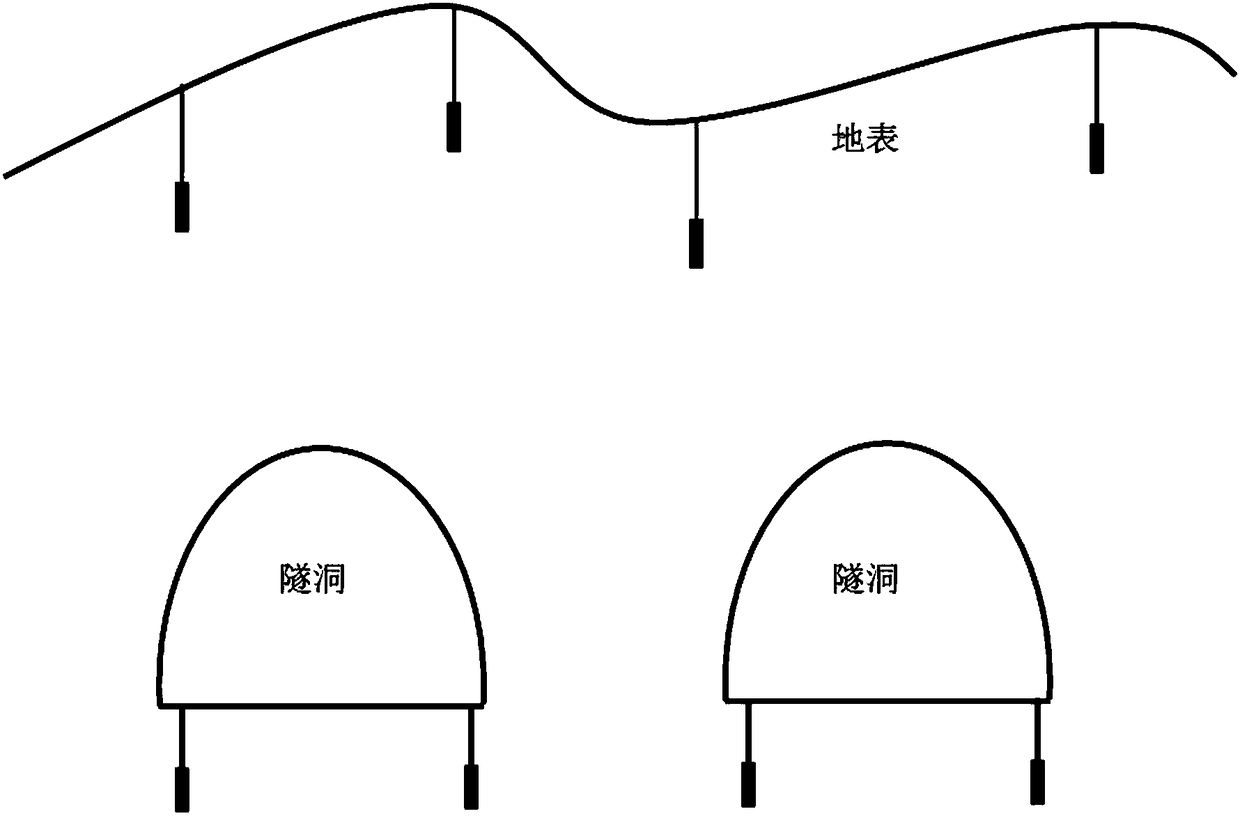

Tunnel construction geological disaster forecasting method

ActiveCN108415066ADamage real-time monitoringPinpoint the exact location of the ruptureEarthquake measurementSeismic signal processingBusiness forecastingSeismic wave

The present invention discloses a tunnel construction geological disaster forecasting method. The method comprises the steps of: S1, prior to tunnel excavation, detecting information of a geological flaw body of a tunnel surrounding rock at front of a tunnel face; S2, in the process of tunnel excavation, collecting rock failure focus information around the geological flaw body and auxiliary focusinformation in a hole; S3, according to the rock failure focus information, determining corresponding micro-seism event information and a seismic wave transmission speed corresponding to the micro-seism event information; S4, according to a speed model of stratum optimization, correcting and calibrating the seismic wave transmission speed in the step S3 so as to correct and calibrate the micro-seism event information; and S5, forecasting geological disasters caused by tunnel construction in real time. Through combination of the seismic wave method and the micro-seismic monitoring technology, the tunnel construction geological disaster forecasting method considers the seismic waves caused by construction factors to perform correction and calibration of the rock failure micro-seism event, forecast the geological disasters which are likely to happen in the construction process such as collapsing, roof collaspe and the like.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY +1

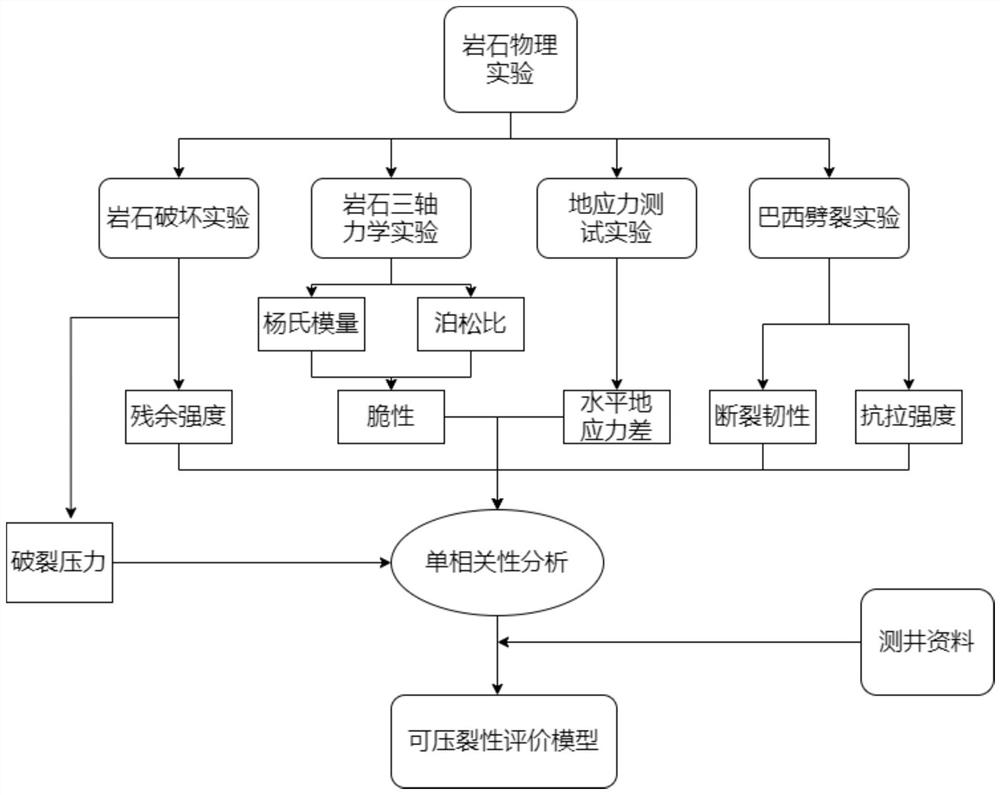

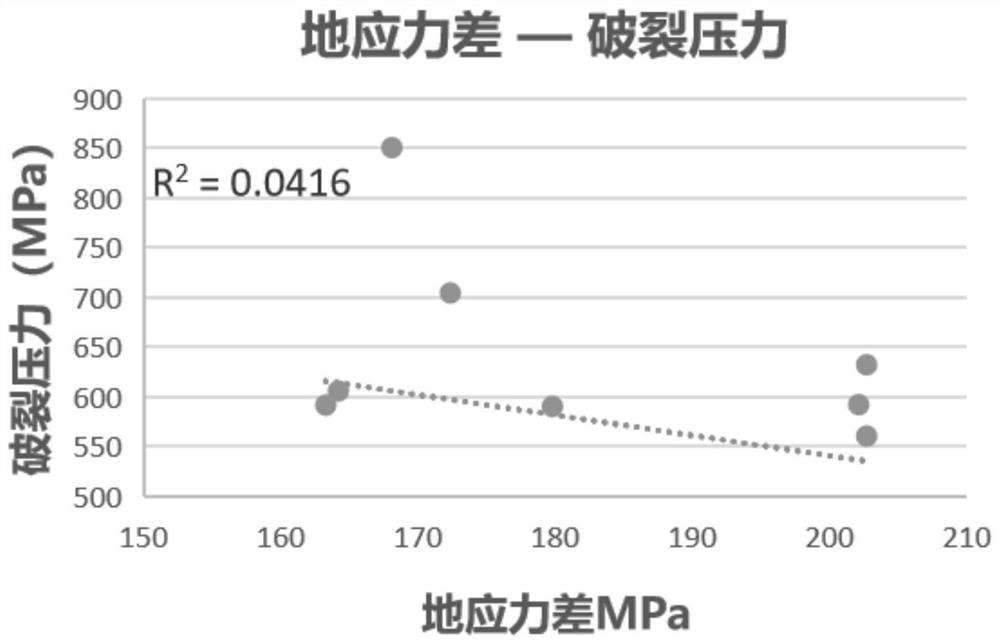

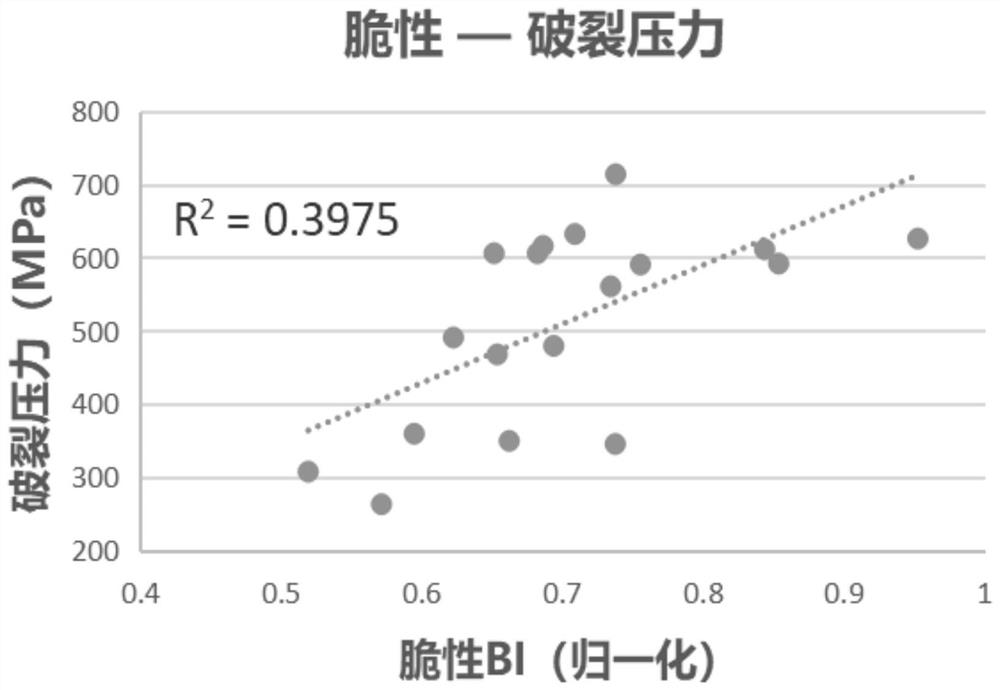

Method for evaluating fracturing property of complex reservoir

ActiveCN112307601ASolve the problem of poor accuracy of fracturing evaluationSolve the problem of poor evaluation accuracyFluid removalDesign optimisation/simulationRock coreWell logging

The invention discloses a method for evaluating fracturing property of a complex reservoir, and particularly relates to the field of oil and gas exploration and development of complex reservoirs. Themethod comprises the following steps: selecting a plurality of rock core samples in a complex reservoir, sequentially carrying out a crustal stress test experiment, a rock triaxial mechanical experiment and a rock damage experiment on one part of the rock core samples, determining the horizontal crustal stress difference, brittleness and residual stress of the rock core samples, carrying out a Brazilian split test on the other part of the rock core samples, determining the fracture toughness and tensile strength of the rock core samples, determining the fitting degree between parameters and the fracture pressure of the rock samples based on regression analysis, calculating weighting coefficients of the parameters, calculating a crack correction factor by utilizing logging data, establishing a complex reservoir fracturing evaluation model by integrating measurement parameters of the rock samples and the crack correction factor, and evaluating the fracturing property of the complex reservoir. According to the method, the accuracy of evaluation of the fracturing property of the complex reservoir is improved, and efficient development of complex oil and gas resources is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

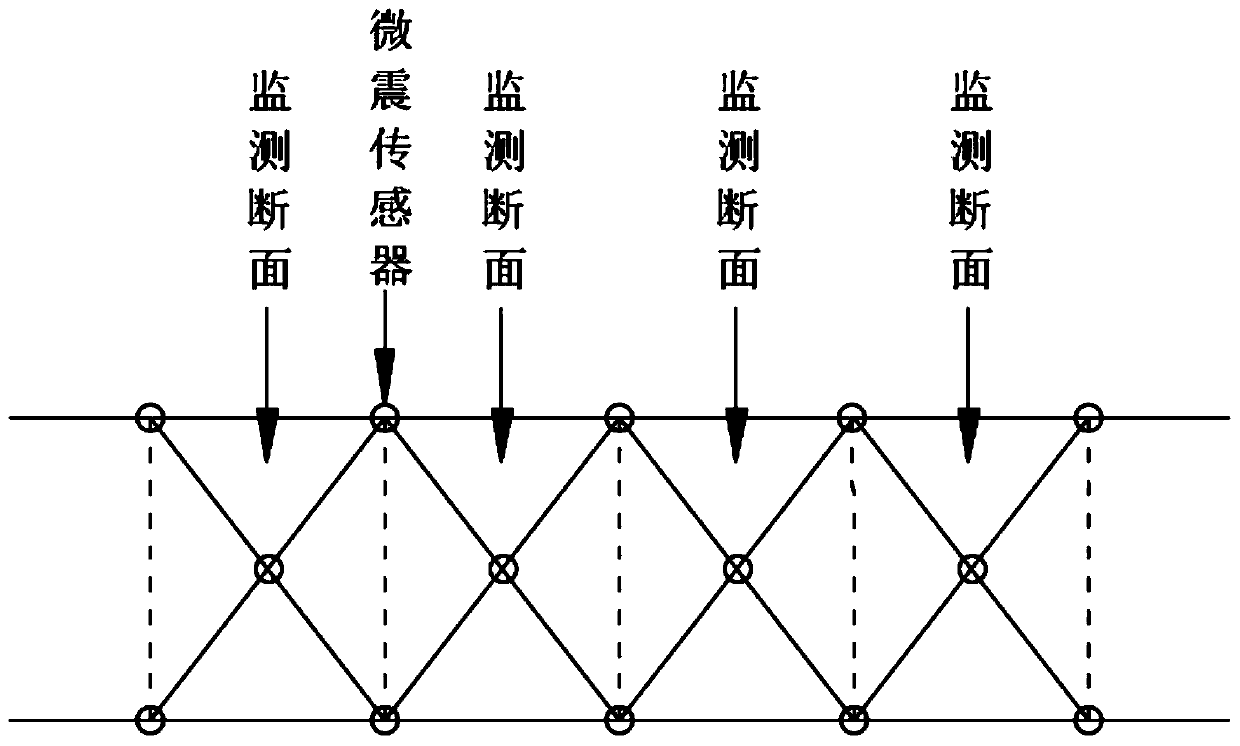

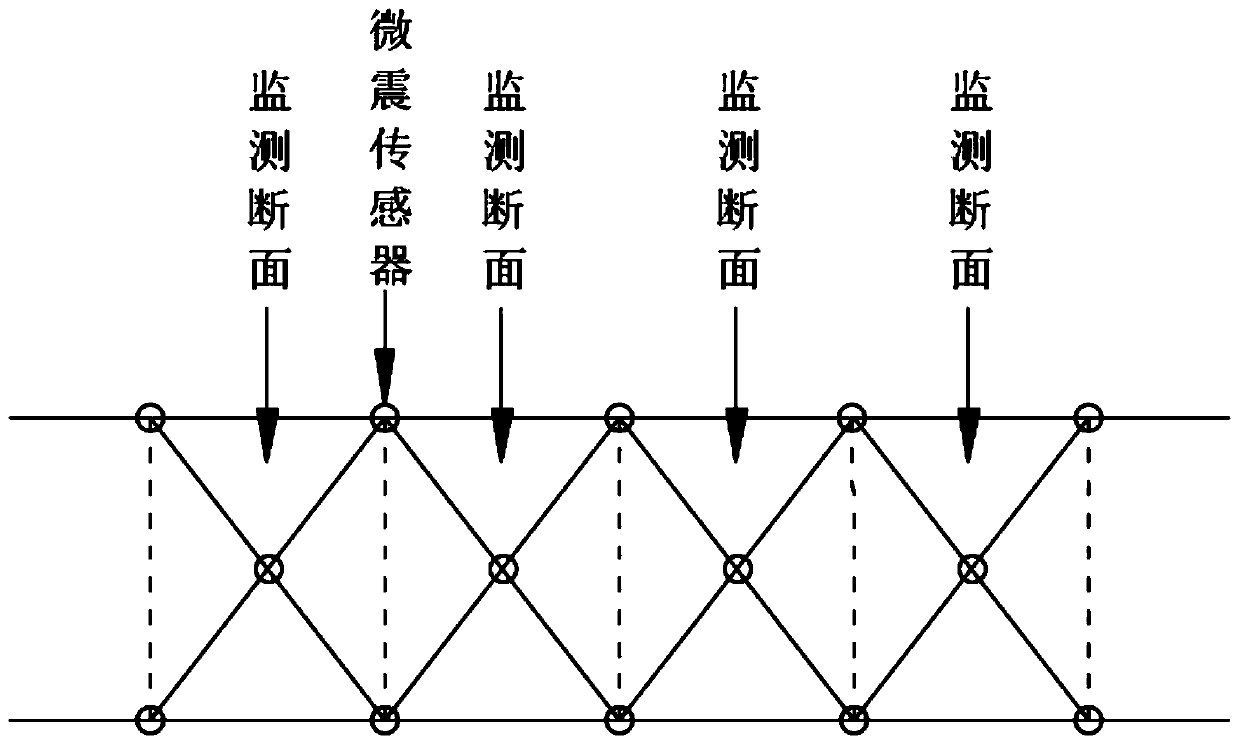

Rock burst prediction method for TBM tunneling tunnel

PendingCN111125872AEasy to filterQuick filterGeometric CADDesign optimisation/simulationData acquisitionRock sample

The invention discloses a rockburst prediction method for a TBM tunneling tunnel. The rockburst prediction method comprises the steps of establishing a related multi-dimensional normal cloud model, carrying out test simulation, establishing a test model, carrying out AI data analysis and carrying out dynamic data acquisition. According to the method, a multi-dimensional normal cloud model is established according to tunnel engineering characteristics and rock burst inducing factors, so that effective parameter information can be conveniently and quickly screened; by researching surrounding rock failure characteristics and influence factors of different types of rockburst, a powerful test means is provided for selecting a reasonable construction method and a support system in a constructionstage; a risk grade evaluation model is established, so that rock sample parameters and corresponding collected data are directly input in the actual tunnel construction process, a risk grade evaluation result is obtained, rockburst information of a corresponding rock sample can be comprehensively obtained, and countermeasures are taken in advance once; micro-seismic sensors are distributed on aplurality of monitoring sections in an X shape, a vibration signal monitoring network is established, and vibration information in each radial direction and each axial direction in the sections can becomprehensively acquired.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Method for predicting and evaluating mud shale hydrofracturing crack net expansion rule

InactiveCN108563901ADesign optimisation/simulationSpecial data processing applicationsStatistical analysisHydraulic fracturing

The invention provides a method for predicting and evaluating a mud shale hydrofracturing crack net expansion rule, and solves the problems that a crack net system formed after hydraulic power fracturing of mud shale is complex, quantitative representation for cracks is difficult, and no definite representation exist in the actual fracturing design. The research method comprises the steps that firstly, hydrofracturing is carried on analog engineering, then a modal crack net is extracted, then modal crack net digitalization is carried out, lastly, statistical analysis and research of a digitalcrack net are carried out, the crack net area, crack length, width, fractal dimension and other parameters are analyzed concretely, counting and representing are carried out on the crack net to obtainthe damage degree of shale, the complex degree and extension form of the crack net are represented, the comprehension of the shale damage degree and crack net extension form can obtain the crack netexpansion rule and evaluate a hydrofracturing effect, wherein the more seriously the rock is destroyed, the more complex the crack net is generated, and the better the shale hydrofracturing effect is.

Owner:ZHONGYUAN ENGINEERING COLLEGE

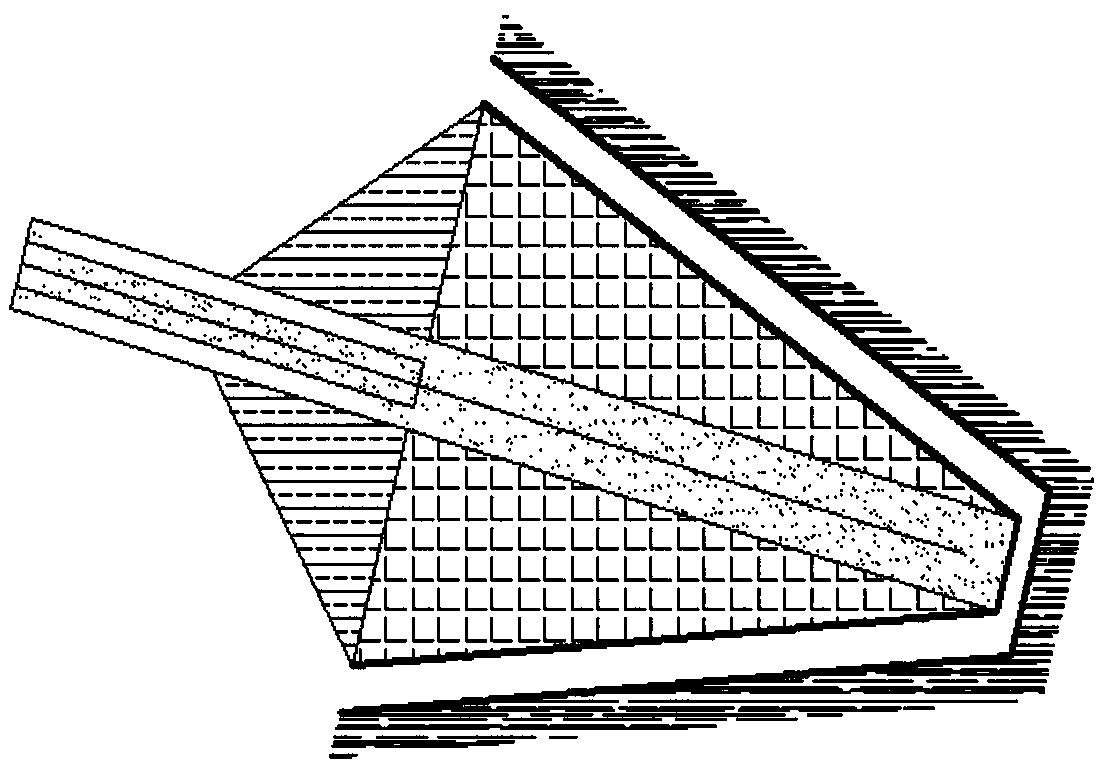

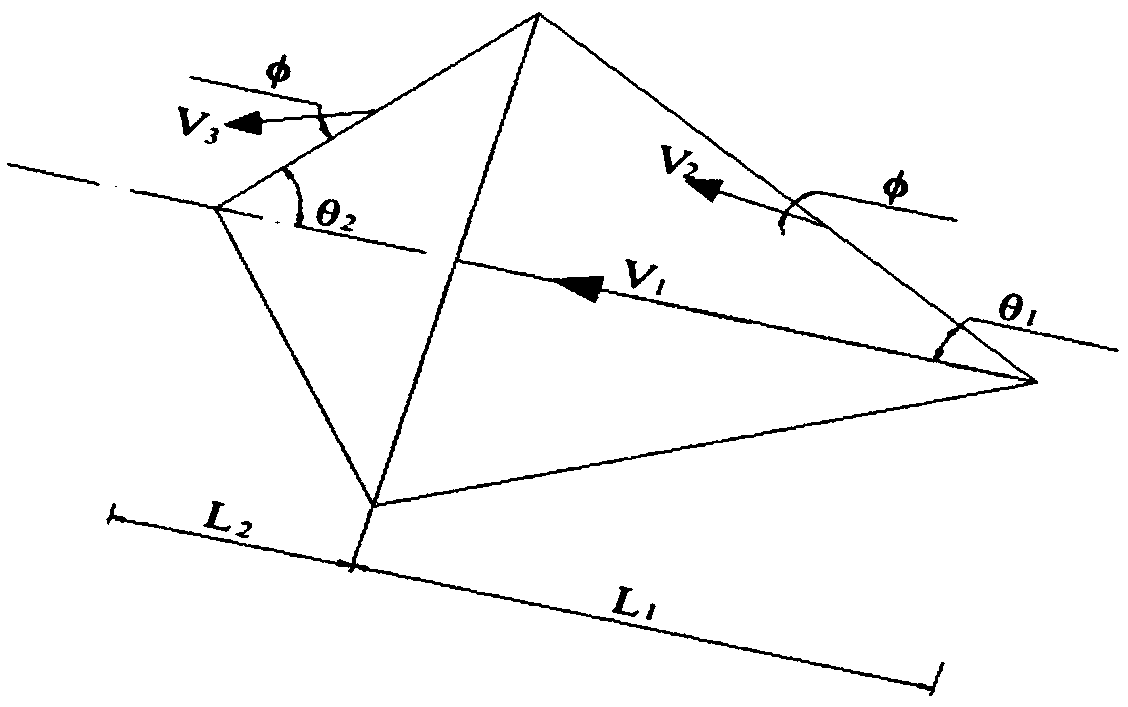

A method for calculating the effective anchorage length of a non-prestressed anchor cable of a rock slope

ActiveCN108984957AClimate change adaptationDesign optimisation/simulationMechanical modelsLoad distribution

The invention discloses a method for calculating the effective anchoring length of a non-prestressed anchor cable of a rock slope. Firstly, a rock mass failure body model around a non-prestressed anchor cable grouting body is established. The velocity field around the grouted rock mass is established, and the energy loss and external force power in the slip plane are deduced. According to the reciprocal theorem of internal and external work, the calculation formula of the maximum pulling force that the anchor cable can bear is deduced. The stress distribution of rock failure surface element isestablished, and the maximum drawing force formula of anchor cable is deduced according to the equilibrium condition of the force. Combined with the formula of maximum drawing force deduced above, the formula of effective anchorage length of anchor cable is deduced. This method can be applied to complex and changeable rock geological conditions with uncertain engineering conditions. Based on theplastic mechanics limit analysis method, the mechanical model is established, and the load distribution law of rock mass around the anchor rod is obtained. The effective anchorage length of the anchorrod is deduced through the solution of the ultimate pullout force of the system anchor rod and the design is carried out.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com