Microcosmic crack, acoustics and mechanics synchronous detection system for rock

A technology of simultaneous detection and crack detection, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., can solve problems that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

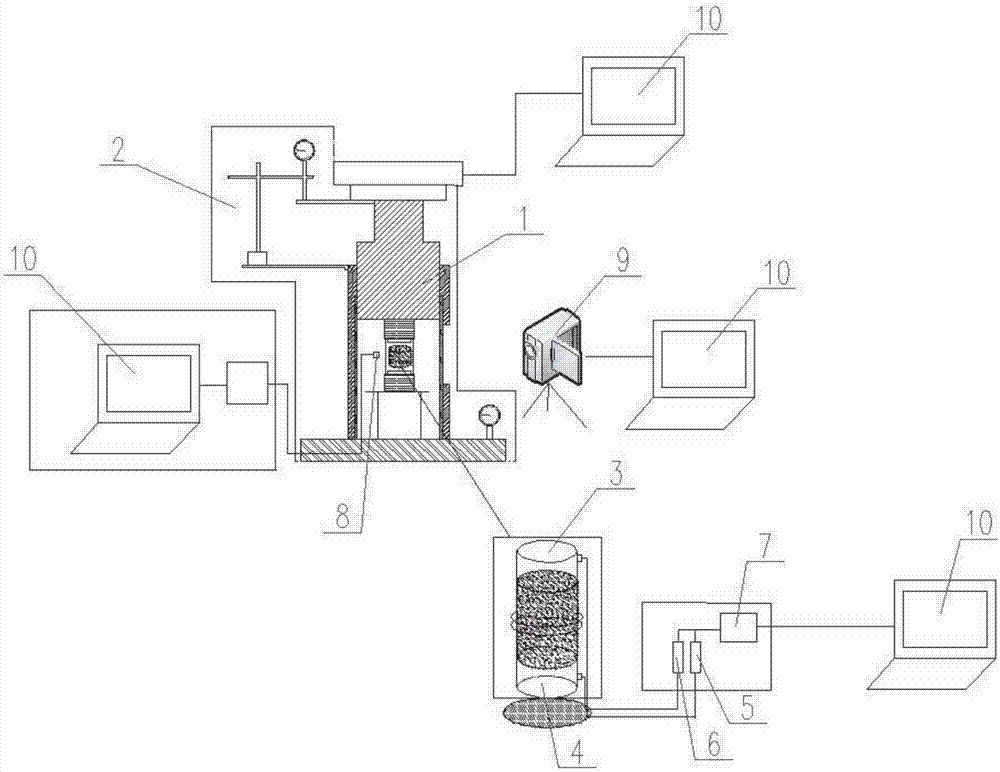

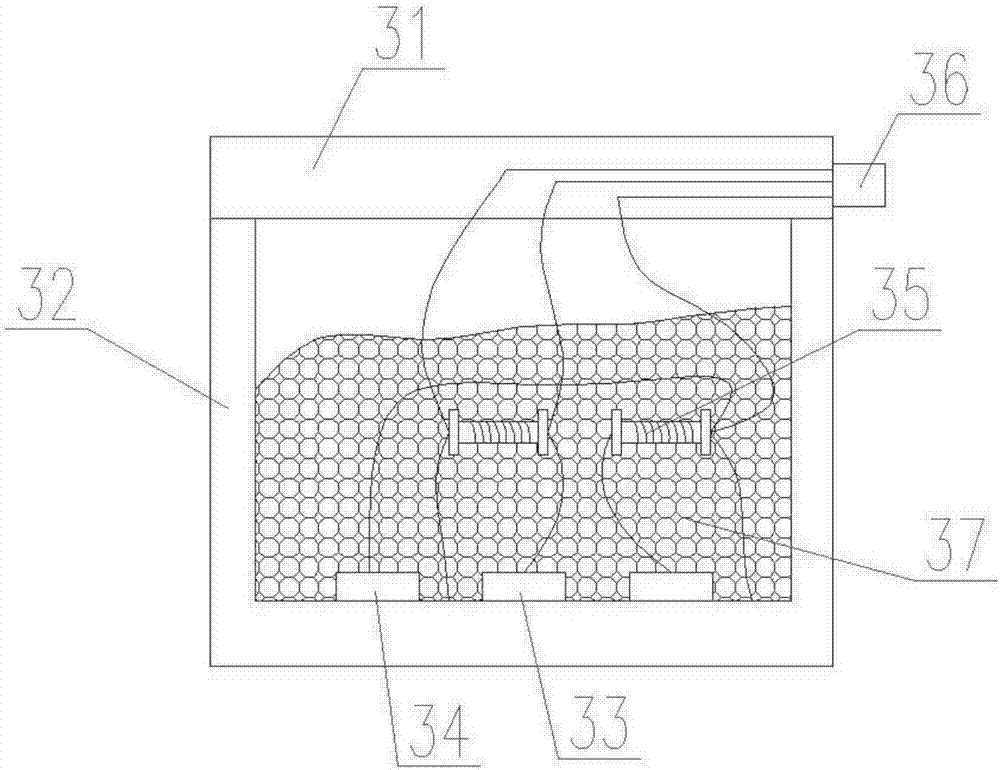

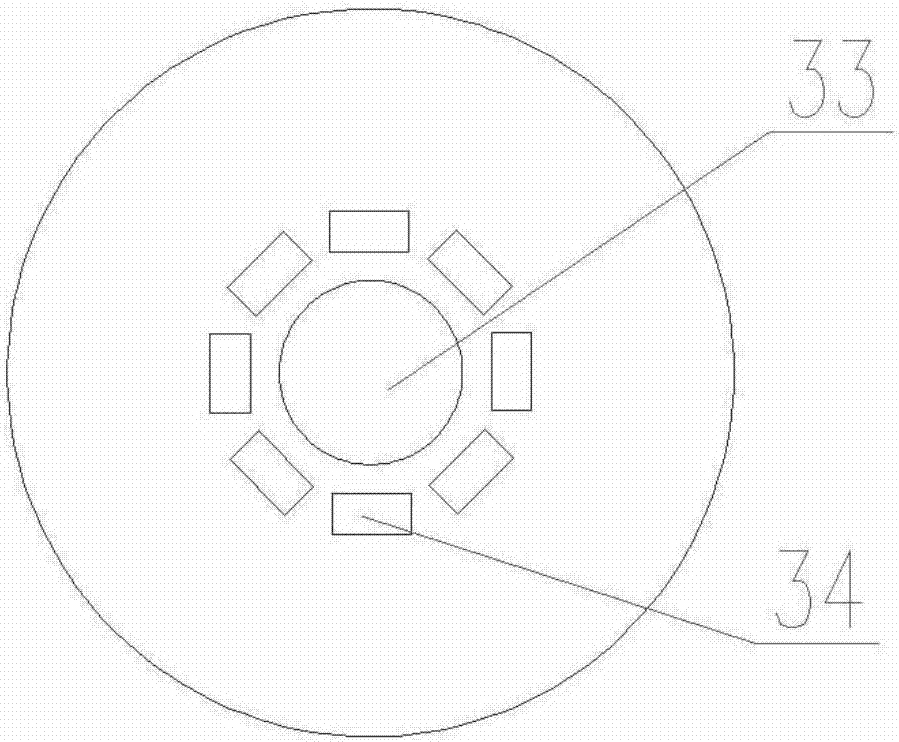

[0036] as attached figure 1 As shown, a rock mesoscopic crack and acoustic mechanics synchronous detection system includes a testing machine 1, a mechanical system 2, an ultrasonic system, an infrasound system, a crack monitoring system and a PC system 10, wherein the mechanical system 2, the ultrasonic system, the secondary Both the acoustic system and the crack monitoring system are connected to the PC system 10, and the rock to be monitored is installed on the testing machine 1.

[0037] The mechanical system 2 is used to obtain data such as stress and strain generated by the rock on the testing machine 1 during the failure process, and transmit the generated data to the PC system 10, which stores and processes the data.

[0038] The ultrasonic system includes an ultrasonic probe, a connection tool and an oscilloscope 7. In order to te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com