Method for judging rock burst proneness of rock material

A rock material, oriented technology, applied in the direction of applying stable tension/compression to test material strength, etc., can solve problems such as overestimation and failure to consider rock plastic strain energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The conventional uniaxial compression test of rock and a loading and unloading experiment were carried out on the INSTRON-1346 electro-hydraulic servo material testing machine to judge the rock.

[0027] The specific process is as follows:

[0028] The diameter D of the cylindrical sample is taken as 48-51mm, and the length (thickness) L of the sample is taken as 96-102mm, that is, 2.0 times of the diameter, such as figure 1 shown. The test shall be carried out according to the following steps:

[0029] (1) Firstly, a conventional uniaxial compression test is carried out, and the sample is loaded at a displacement loading rate of 0.065 mm / min until failure, and the uniaxial compressive strength σ of the rock sample is obtained c , σ c It can be read directly according to the data obtained by the testing machine.

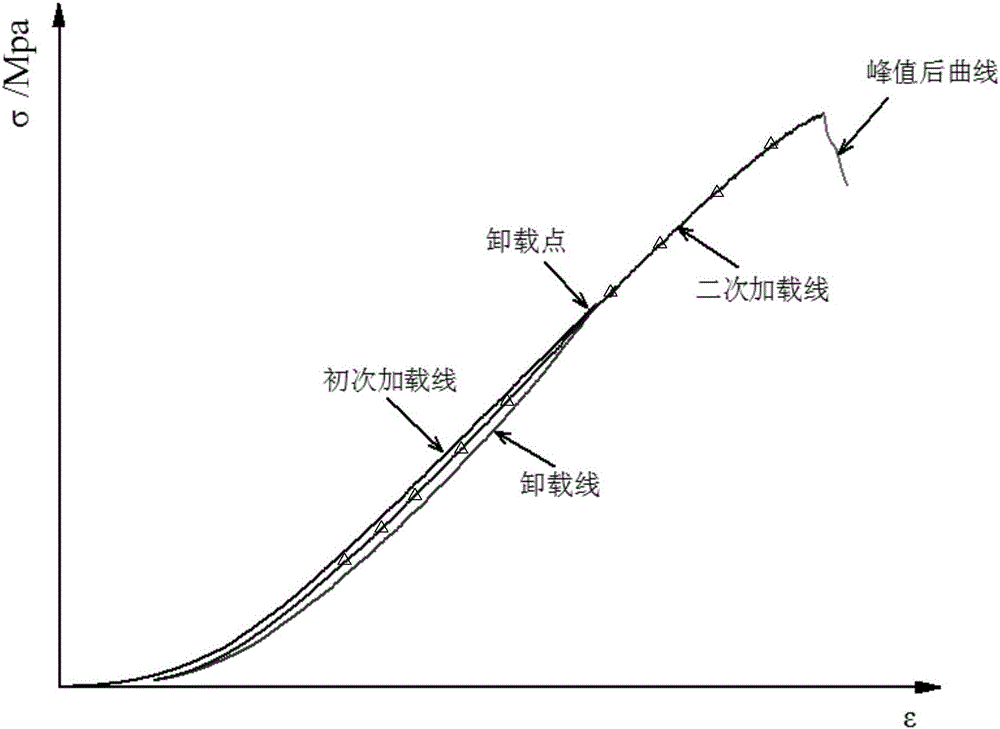

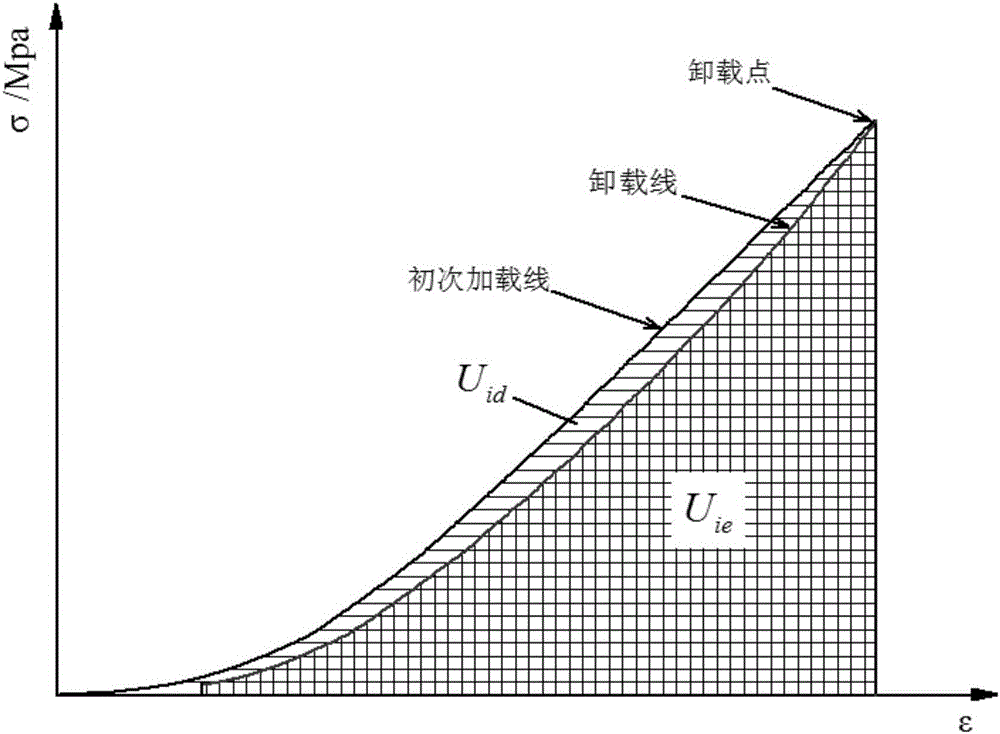

[0030] (2) Another 5 samples were loaded to 0.7σ at the same loading rate c , 0.75σ c , 0.8σ c , 0.85σ c , 0.9σ c , and then unloaded at 0.065mm / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com