Device and method for determining the status of a spindle of a machine tool

A technology of spindle and state, applied in the direction of drive device, computer control, general control system, etc., can solve the problem of the actual load of the spindle increasing the risk of failure, and achieve the effect of improving processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

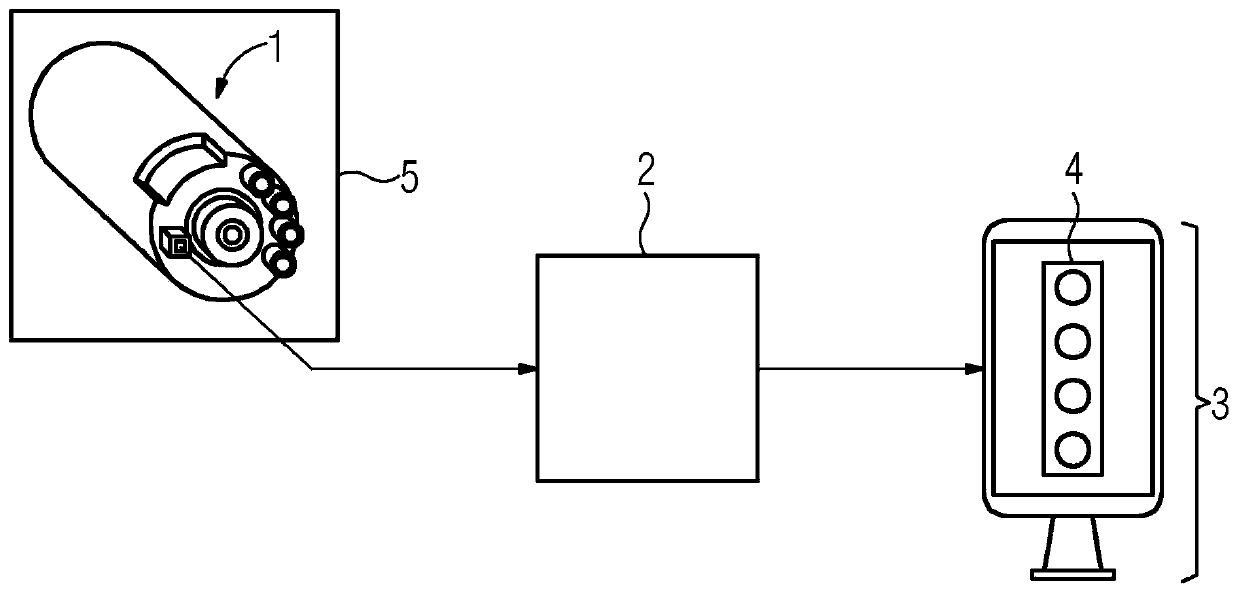

[0047] figure 1 The configuration of the system is shown, which includes the spindle 1 of the machine tool 5 , the device 2 and the visualization component 3 . The sensor data of the spindle 1 are detected by the acquisition means of the device 2 and analyzed in the processing unit of the device 2 by means of artificial intelligence. The processing means determines the spindle state from the analysis. The output means of the device 2 transmit the determined spindle state to the visualization means 3 . The visualization component 3 is embodied as a display. The signal light 4 on the visualization member 3 realizes four types of display: "permanent permission", "medium-term permission", "short-term permission" and "not allowed".

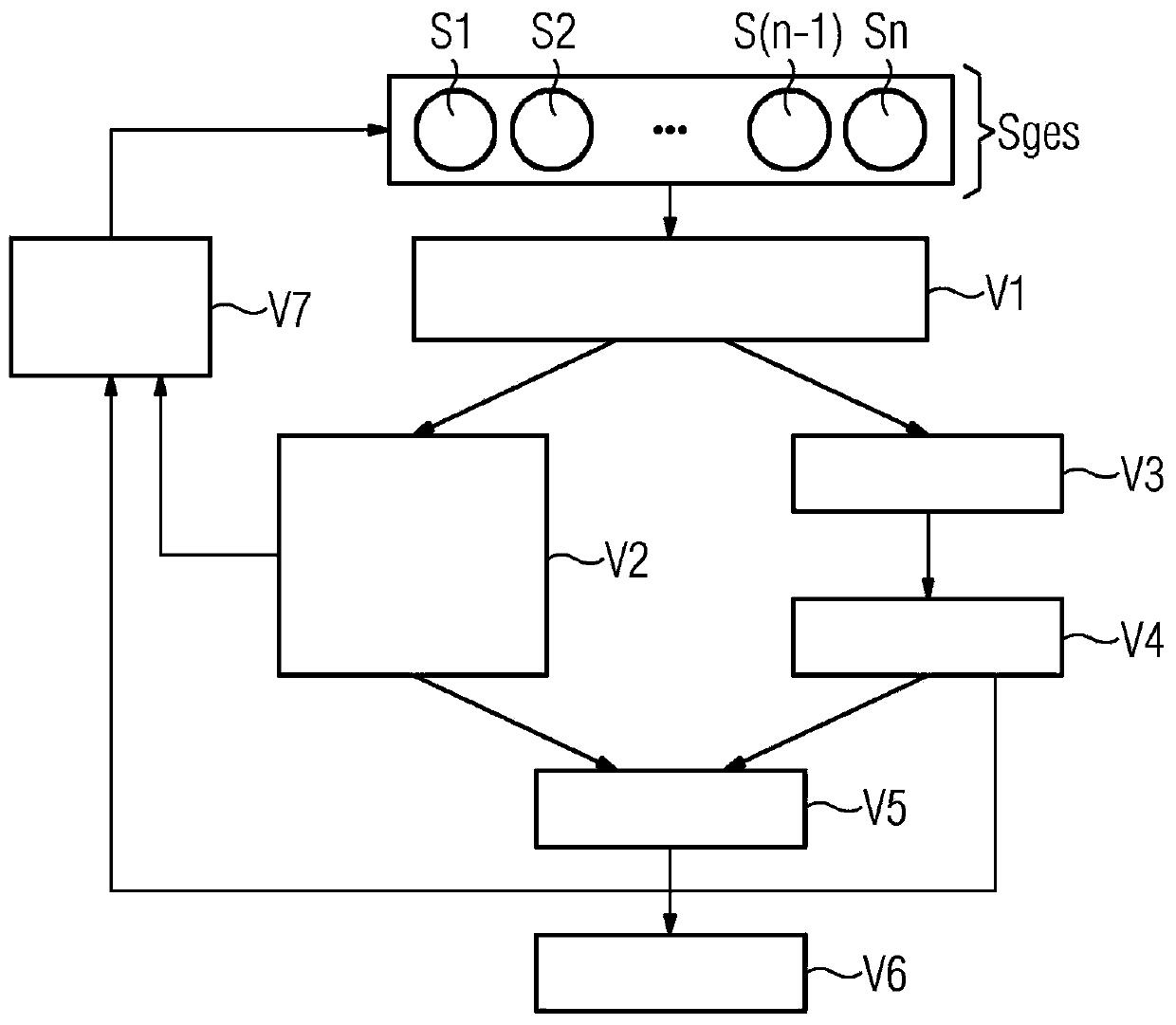

[0048] figure 2 The flow of the method is shown. First, the signal Sges is detected by the sensor. Here, for example, the spindle temperature S1 , the spindle torque S2 , the spindle force S(n−1) and the spindle speed Sn can be detected. Howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com