Method for measuring shale brittleness index based on rock stress-strain curves and ultrasonic longitudinal wave speed

A longitudinal wave velocity and ultrasonic technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, and the strength of materials using stable tension/pressure testing, etc., which can solve the problem of ignoring reservoir conditions, brittleness, and brittleness without considering reservoir conditions. effects, etc., to achieve the effect of improving accuracy and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

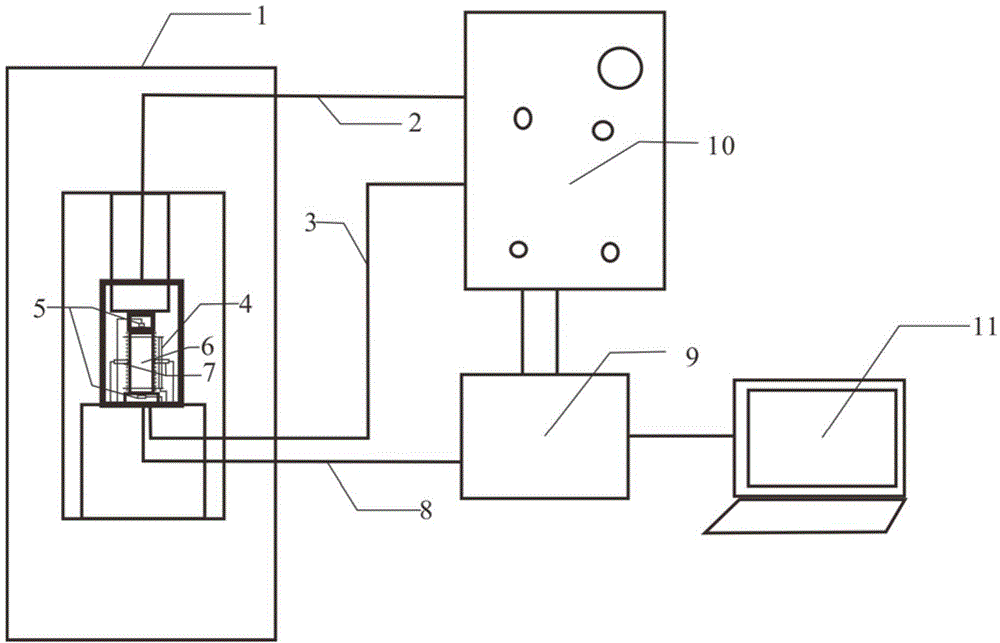

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] The brittleness index calculation method of the present invention is a calculation method under triaxial conditions, specifically: before the experiment, use the logging interpretation results or the shale in-situ stress test to obtain the in-situ stress value of the shale, and the triaxial compression test The confining pressure in the process is equal to the value of the minimum horizontal principal stress, which determines the brittleness index of the shale specimen under the actual reservoir stress condition.

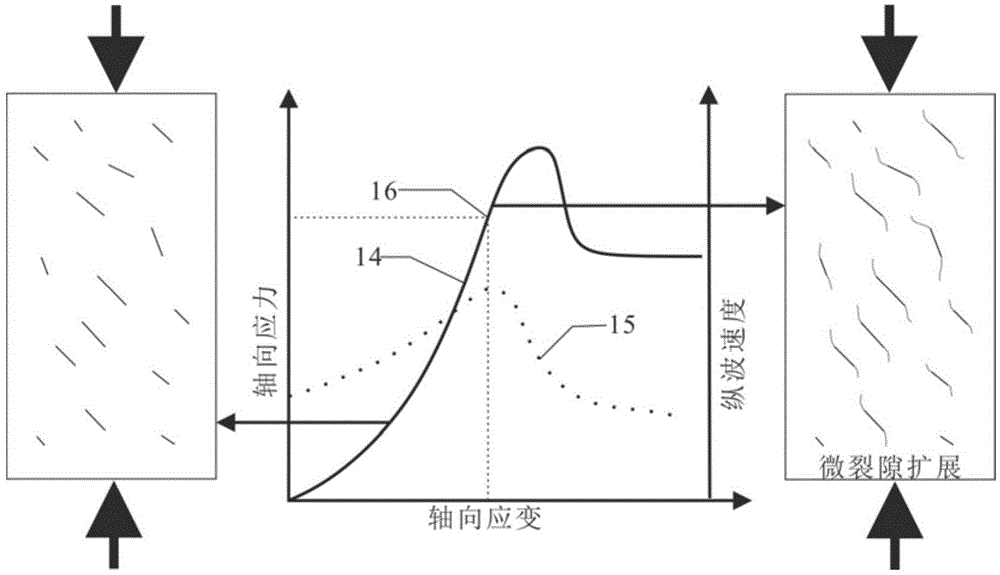

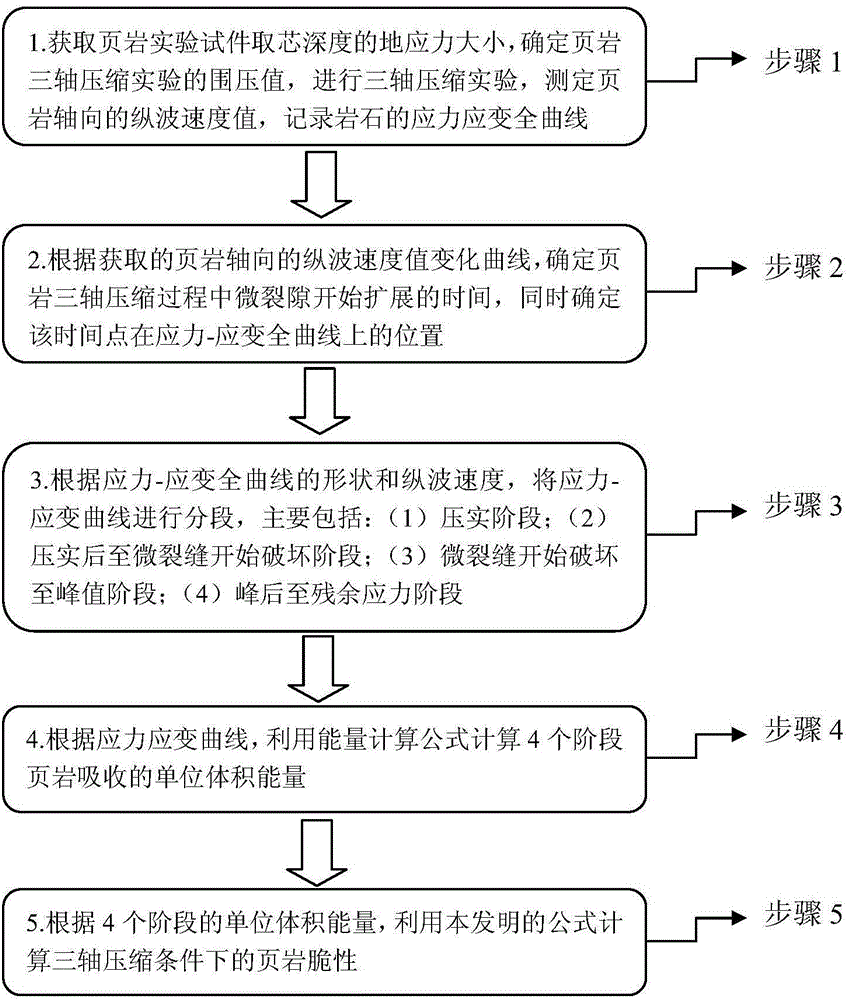

[0029] The implementation process of the present invention is as image 3 Shown:

[0030] (1) Determine the in-situ stress of the core section t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com