Self-propelled hollow slip casting anchor rod with stress-measuring function and operating method

A grouting bolt, self-propelled technology, used in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of inconvenient processing of metal bolts, weak solid force, anchoring and grouting, etc. The effect of improving the working environment, simplifying the construction process, and solving rooted problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

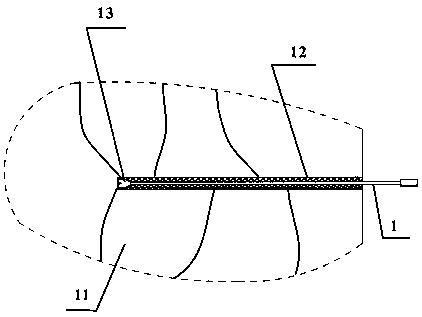

[0072] This embodiment has shown the anchor rod in the prior art, as figure 1 As shown, the rod body 1 is included, and the rod body is anchored in the pre-drilled borehole 12 (anchor hole). , and then inject the anchoring agent into the borehole 12, and after a period of time, the designed anchoring strength is reached, the anchoring effect is realized, and the anchoring effect is achieved.

[0073] Because the structure of the underground soil and rock mass is very complex, there are not only a large number of soft rock layers, but also a large number of geological structures such as folds and faults in the strata. When drilling holes 12 are arranged on such surrounding rocks 11, there is often structural integrity. Poor, easy to form broken rock mass, the problem that the hole wall is easy to collapse when the drill pipe is withdrawn after the broken rock mass is drilled, especially when it is affected by the mining dynamic pressure, it is more difficult to set the bolt and...

Embodiment 2

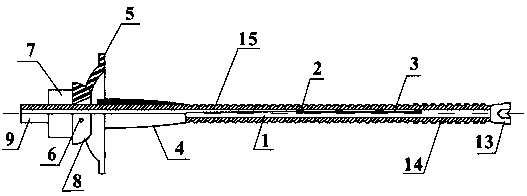

[0078] This embodiment provides a hollow grouting anchor rod which has a force measuring function and can be drilled by its own drill bit.

[0079] Self-advancing hollow grouting anchor with force measuring function, such as figure 2 , Figure 5 and Figure 6As shown, it includes a resin rod body 1 with a hollow structure. The front end of the rod body 1 is connected with a self-propelled drill bit 13, and the rear end is provided with a grouting port communicating with the inner cavity of the rod body 1. The rod body 1 is also provided with Stress measurement device 2 and anchoring structure, the anchoring structure is close to said self-propelled drill bit 13 .

[0080] By setting the self-propelled drill bit 13 at the front end of the anchor rod, the anchor rod can be used for anchoring while also having the function of a drill rod, thereby simplifying the construction process, canceling the construction process of returning the drill rod and inserting the anchor rod, an...

Embodiment 3

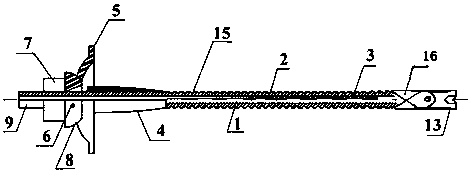

[0103] The anchor rod of this embodiment is used for anchoring in formations with geological structures such as folds and faults.

[0104] Self-advancing hollow grouting anchor with force measuring function, such as image 3 As shown, the anchor rod of this embodiment is basically the same as that of Embodiment 2, the difference is that the anchoring structure of this embodiment is a scissor expansion frame 16, which is arranged on the outer wall of the rod body 1 and located on the drill bit On one side of 13, the anchoring section is formed, and the anchoring structure is set as a scissor expansion frame 16. When the anchor rod is drilled in place, the scissor expansion frame 16 is opened by the rotation of the rod body or the structure of the scissor expansion frame 16 itself, so that the The scissor expansion frame 16 is combined with the inner wall of the anchor hole to anchor the anchor section of the anchor rod and complete the grouting anchor rod pre-tightening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com