Testing system and testing method of outburst-preventing bedrock buckling failure model of karst tunnel

A model test and anti-outburst technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of large model volume, labor and time, low test efficiency, etc. performance, improve test efficiency, save economy and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

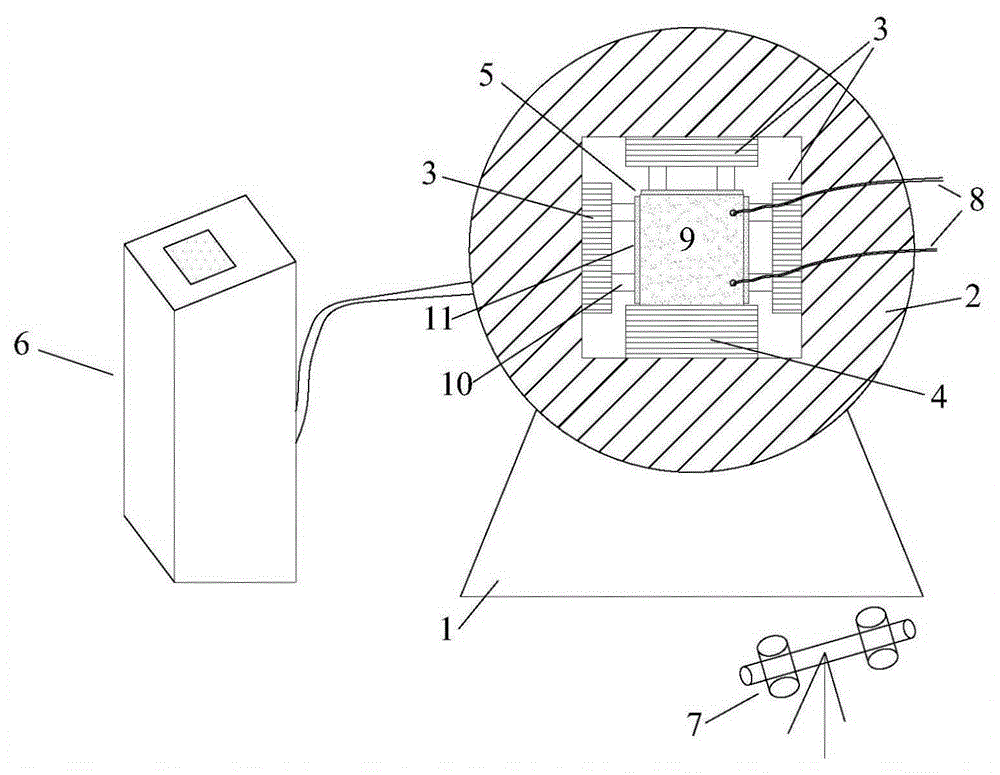

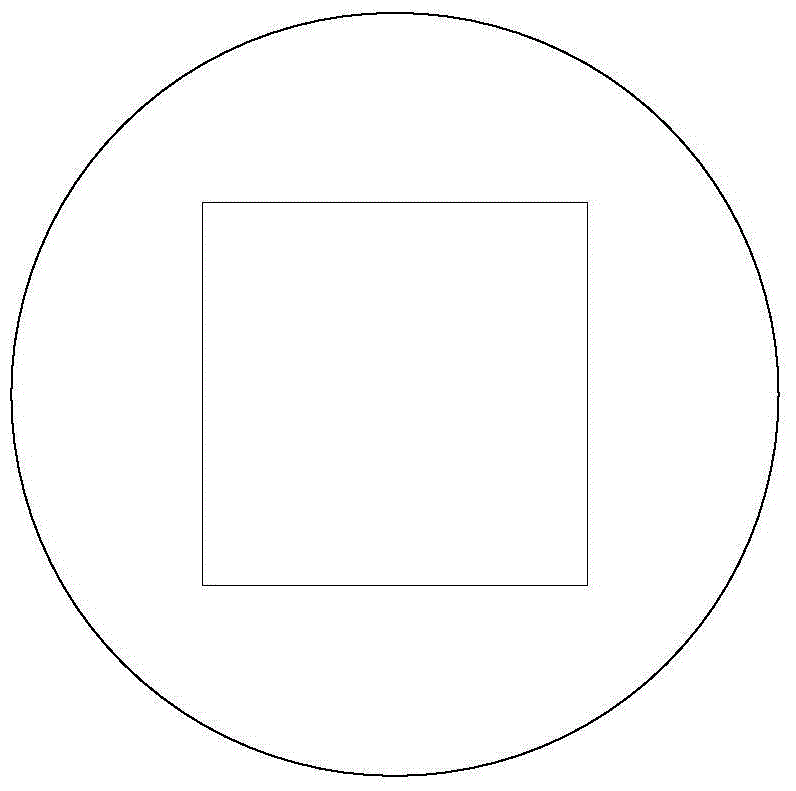

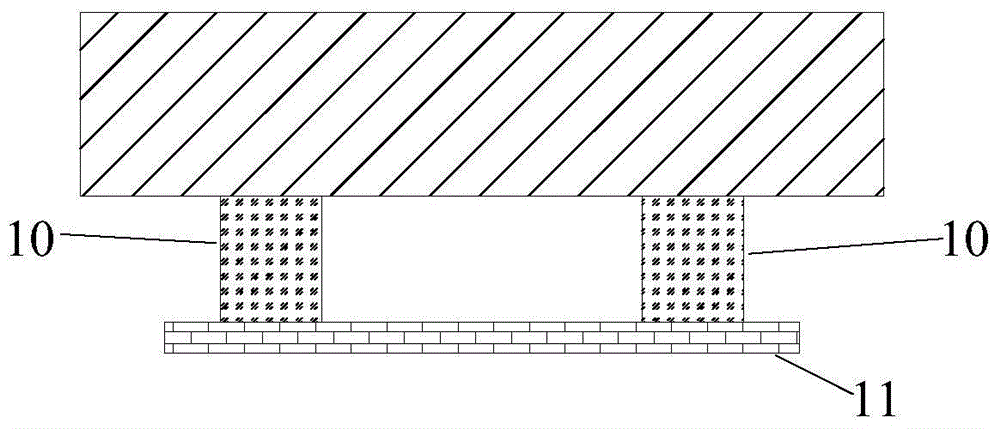

[0035] Embodiment 1: as figure 1 The schematic diagram of the karst tunnel anti-outburst rock plate instability failure model test system is shown, including the base 1, the circular bearing frame 2, the separate combined uniform loading device 3, the bearing platform 4, the electro-hydraulic servo control actuator 5, the electric Liquid servo control box 6, three-dimensional digital camera device 7 and three-dimensional acoustic emission device 8, and test model 9 in addition. Such as figure 2 The schematic diagram of the circular bearing frame is shown. The overall structure of the outer circle and inner square of the bearing frame makes the stress distribution in the test device more uniform during the model loading process, and has better bearing capacity. Such as image 3 The schematic diagram of the separated and combined uniform loading device is shown. The separated and combined loading device 3 is composed of two to three jacks 10 and a loading plate 11. The loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com