5xxx series Al-Mg alloy grain boundary corrosive liquid and corrosion method

A technology of grain boundary corrosion and etching solution, applied in the field of metallographic corrosion of aluminum alloys, can solve the problems of difficulty in increasing grain boundaries of 5xxx series Al-Mg alloys, increase in time cost and economic cost, unfavorable grain morphology and alloy properties, etc. To achieve the effect of saving time cost and economic cost, clearly visible grain boundaries, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

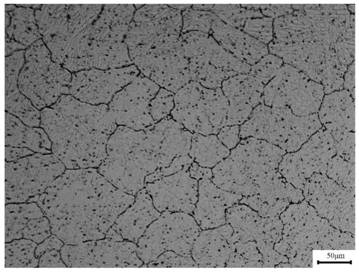

Embodiment 1

[0033] The grain boundary corrosion method of 5xxx series aluminum alloy comprises the following steps:

[0034] (1) Configure corrosion solution, its formula consists of the following components: 110mL , 15 mL , 0.5 mL HF, 0.5 HCl, 2 g ;in The concentrations of the three acids , HF and HCl are 68%, 40% and 38% respectively.

[0035] Quantitatively weighed , and then add water, HF, , HCl;

[0036] (2) Inlay aluminum alloy samples, hot-mount the 5xxx series aluminum alloy samples in a mounting machine using phenolic resin powder, and the mounting temperature and time are 130°C and 8 min, respectively;

[0037] (3) Grinding. After the inlaid sample is cooled, grind the inlaid sample with sandpaper from low mesh to high mesh; use 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, and 1500 mesh in sequence , 2000 mesh, 3000 mesh, 5000 mesh, and 7000 mesh sandpaper are polished under running water;

[0038] (4) Polishing, polishing the polished sample; f...

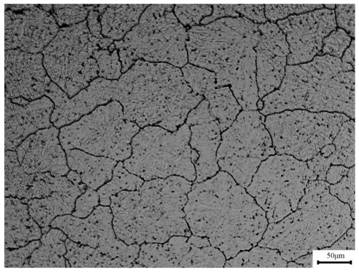

Embodiment 2

[0045] 5xxx series aluminum alloy grain boundary corrosion method, is characterized in that, comprises the following steps:

[0046] (1) Prepare the corrosion solution, its formula consists of the following components: 95 mL , 18mL , 2 mL HF , 1.8 mL HCl , 3.5 g ;in The concentrations of the three acids , HF and HCl are 66.%, 40%, and 37% respectively. Quantitatively weighed , and then add water, HF, , HCl;

[0047] (2) Inlay aluminum alloy samples, hot-mount the 5xxx series aluminum alloy samples in a mounting machine using phenolic resin powder, and the mounting temperature and time are 130°C and 8 min, respectively;

[0048] (3) Grinding. After the inlaid sample is cooled, grind the inlaid sample with sandpaper from low mesh to high mesh; use 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, and 1500 mesh in sequence , 2000 mesh, 3000 mesh, 5000 mesh, and 7000 mesh sandpaper are polished under running water;

[0049](4) Polishing, polishing the ...

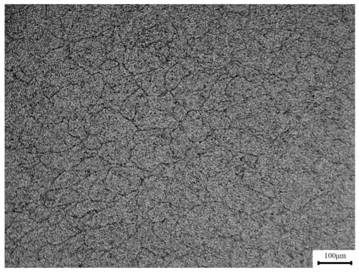

Embodiment 3

[0056] 5xxx series aluminum alloy grain boundary corrosion method, is characterized in that, comprises the following steps:

[0057] (1) Prepare the corrosion solution, its formula consists of the following components: 80 mL , 20 mL , 3.5 mL HF, 3 mL HCl, 5 g ;in The concentrations of the three acids , HF and HCl are 65%, 40% and 36% respectively.

[0058] Quantitatively weighed , and then add water, HF, , HCl;

[0059] (2) Inlay aluminum alloy samples, hot-mount the 5xxx series aluminum alloy samples in a mounting machine using phenolic resin powder, and the mounting temperature and time are 130°C and 8 min, respectively;

[0060] (3) Grinding. After the inlaid sample is cooled, grind the inlaid sample with sandpaper from low mesh to high mesh; use 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, and 1500 mesh in sequence , 2000 mesh, 3000 mesh, 5000 mesh, and 7000 mesh sandpaper are polished under running water;

[0061] (4) Polishing, polishing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com