Coal mine tunnel broken surrounding rock layering grouting technology and method

A technology for crushing surrounding rocks and coal mine roadways, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problem that the shallow and deep grouting drilling cannot be unified, the deep grouting is poor, and the shallow and deep grouting materials cannot be the same. and other problems, to achieve the effect of good grouting effect and low grouting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

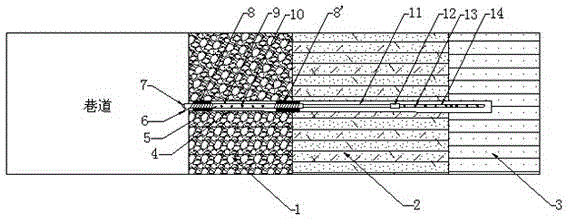

[0024] A coal mine roadway broken surrounding rock layered grouting process and method, such as figure 1 As shown, proceed as follows:

[0025] The first step is grouting drilling for vertical or oblique roadway surrounding rock construction. The hole diameter of the 2m part of the hole is at least φ42mm, and the hole diameter of the rest is required to be ≥φ28mm. The hole depth is generally more than 2000mm according to the needs of grouting reinforcement;

[0026] The second step is to wind the cotton yarn at the front and rear ends of the sealing device, the winding length is 200-300mm, and the thickness is slightly larger than the hole diameter, and the deep grouting pipe (deep grouting diversion pipe, deep grouting flower pipe) is connected, and inserted into the hole;

[0027] The third step is to connect the outer layer grout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com