Method for preparing anode/electrolyte double-layer structure of solid oxide fuel cell by single grouting

A solid oxide, solid electrolyte technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of complex preparation process of SOFC, and achieve the effect of simple process, shortened production cycle, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

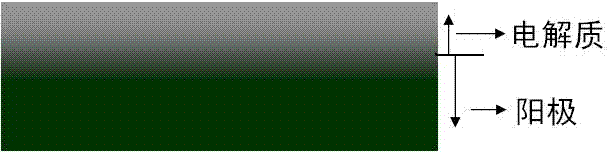

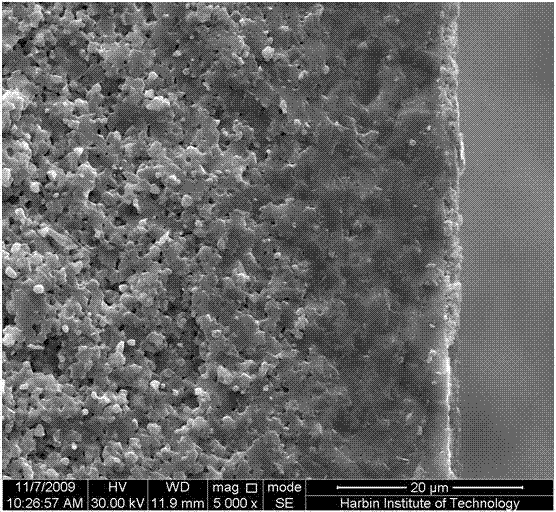

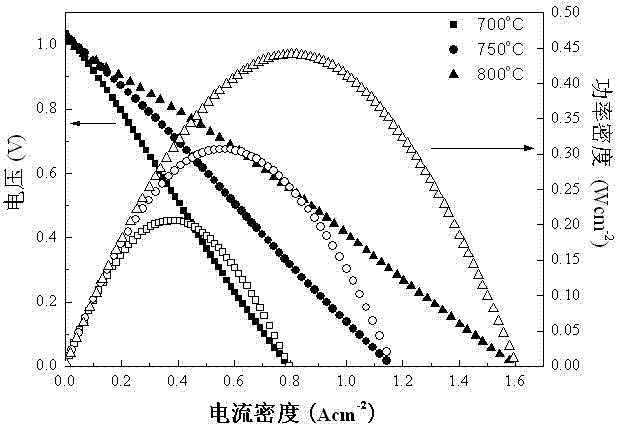

[0016] Specific Embodiment 1: The method for preparing a solid oxide fuel cell anode / electrolyte double-layer structure by single grouting in this embodiment is realized through the following steps: 1. Preparation of slurry: mix NiO powder and solid electrolyte powder according to the mass ratio Mix at a ratio of (0.2~5):1, then add gum arabic and water, and then ball mill for 0.25~24h to obtain a slurry, wherein the mass of gum arabic is 1%~20% of the total mass of NiO powder and solid electrolyte powder , the quality of water is 0.3~5 times of the total mass of NiO powder and solid electrolyte powder, the particle size of NiO powder is 1~50 microns, and the particle size of solid electrolyte powder is 50~800nm; 2. The anode / electrolyte double layer structure Preparation: Pour the slurry obtained in step 1 into a flat-bottomed mold with only plaster at the bottom, let it stand for 5-15 hours to obtain a green body, and then place the green body at a temperature of 1000-1500 ° ...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the NiO powder is pre-fired at a temperature of 600-1100°C for 2-5 hours before mixing the NiO powder with the solid electrolyte powder in Step 1. Other steps and parameters are the same as those in Embodiment 1.

[0020] In this embodiment, the NiO powder is pre-fired to adjust the particle size of the NiO powder. Part of the NiO powder particles are agglomerated, and the particle size of the agglomerated particles becomes larger, so that the difference in sedimentation speed between it and the solid electrolyte powder becomes larger, which is more conducive to obtaining the composition The solid oxide fuel cell anode / electrolyte double-layer structure with more obvious double-layer structure and better performance can be obtained by high-temperature sintering of the green body with obvious distribution characteristics and good layering.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 2 in that the NiO powder is pre-calcined at a temperature of 800-1000° C. for 3-5 hours. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com