Layered support method for rectangular coal roadway based on deep soft composite roof

A composite roof and weak technology, which is applied in the direction of earthwork drilling, mining equipment, bolt installation, etc., can solve the problems of insufficient grouting volume, inability to grouting support, etc., achieve timely grouting timing, save grouting cost, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

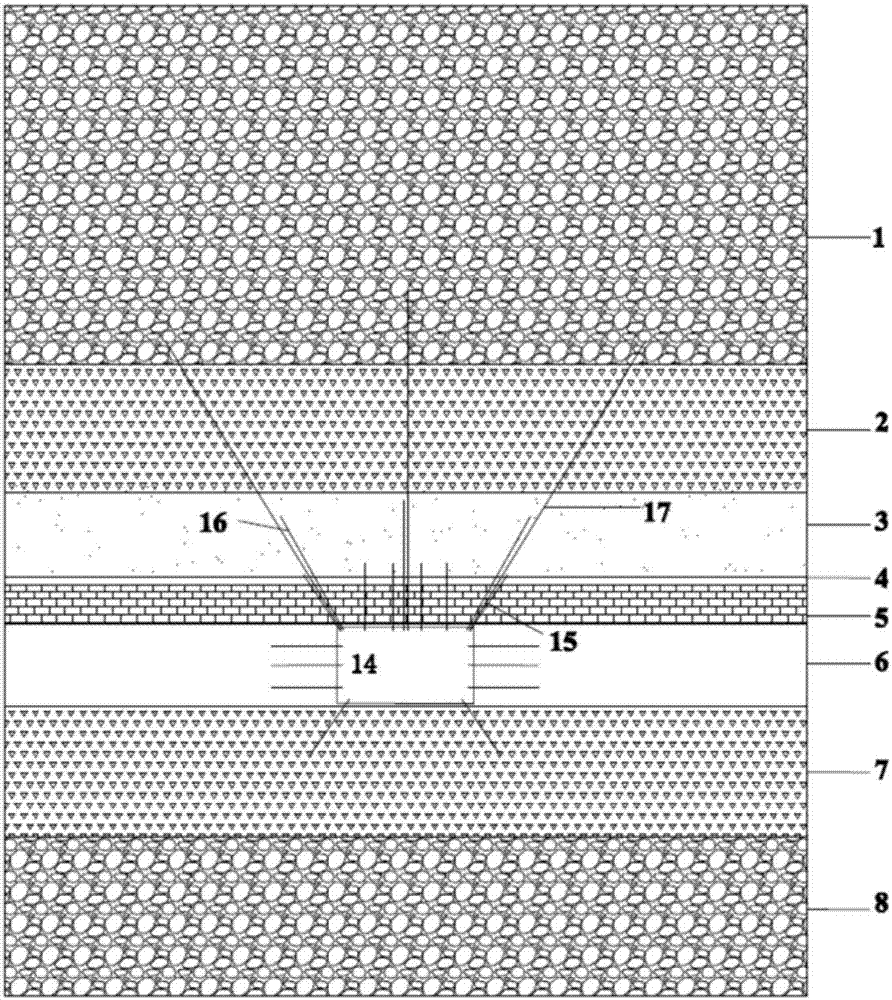

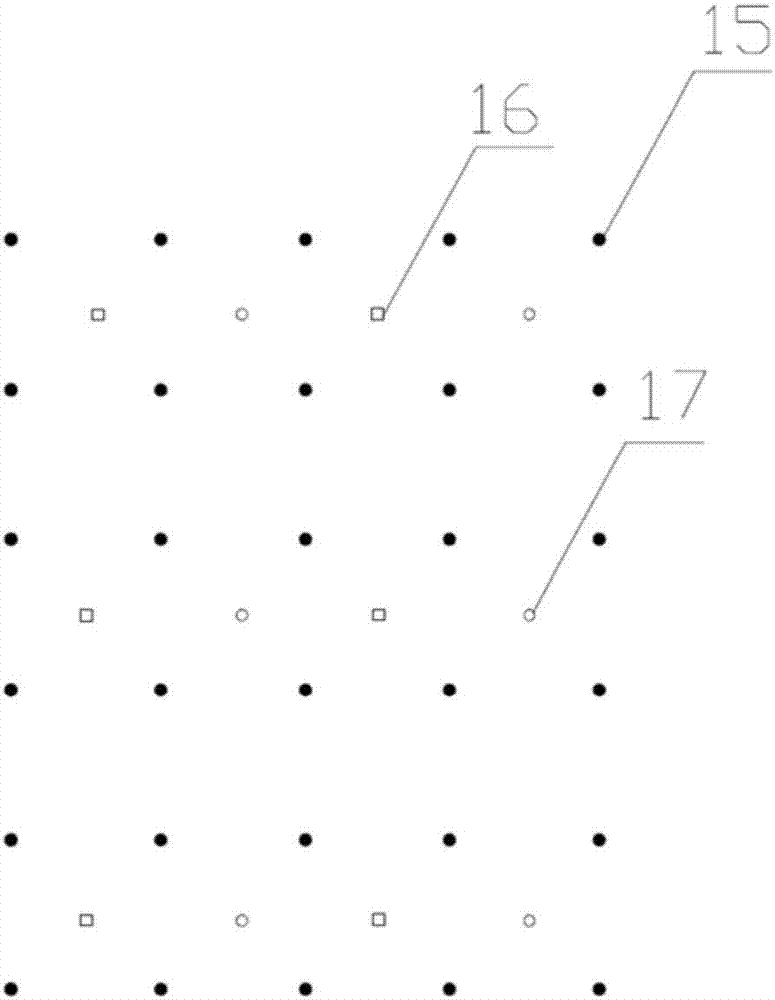

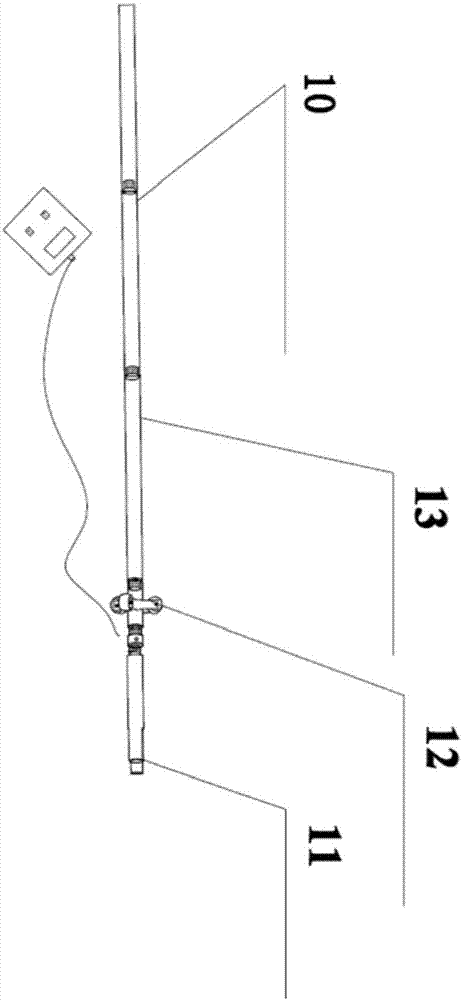

[0029] A layered support method for a rectangular coal roadway based on a deep weak composite roof of the present invention is obtained according to the mine drilling columnar diagram, the geological overview of the composite roof before the working face without recovery, the positions of soft and hard rock formations; when working After face mining, the location and range of crack development on the roof of the roadway are detected with a borehole peeper; then, the composite roof is supported layer by layer by using short grouted anchors and long grouted anchors with anchor cables.

[0030] A layered support metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com