Patents

Literature

89 results about "Discrete element simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

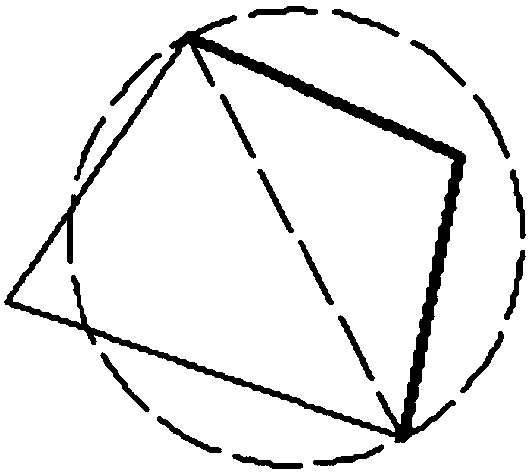

Contact judgment method of spherical particles and triangular meshes in discrete element simulation

InactiveCN103235854ASolve the problem of contact judgmentAvoid the problem of separately establishing the contact judgment algorithmSpecial data processing applicationsDiscrete element simulationGraphics

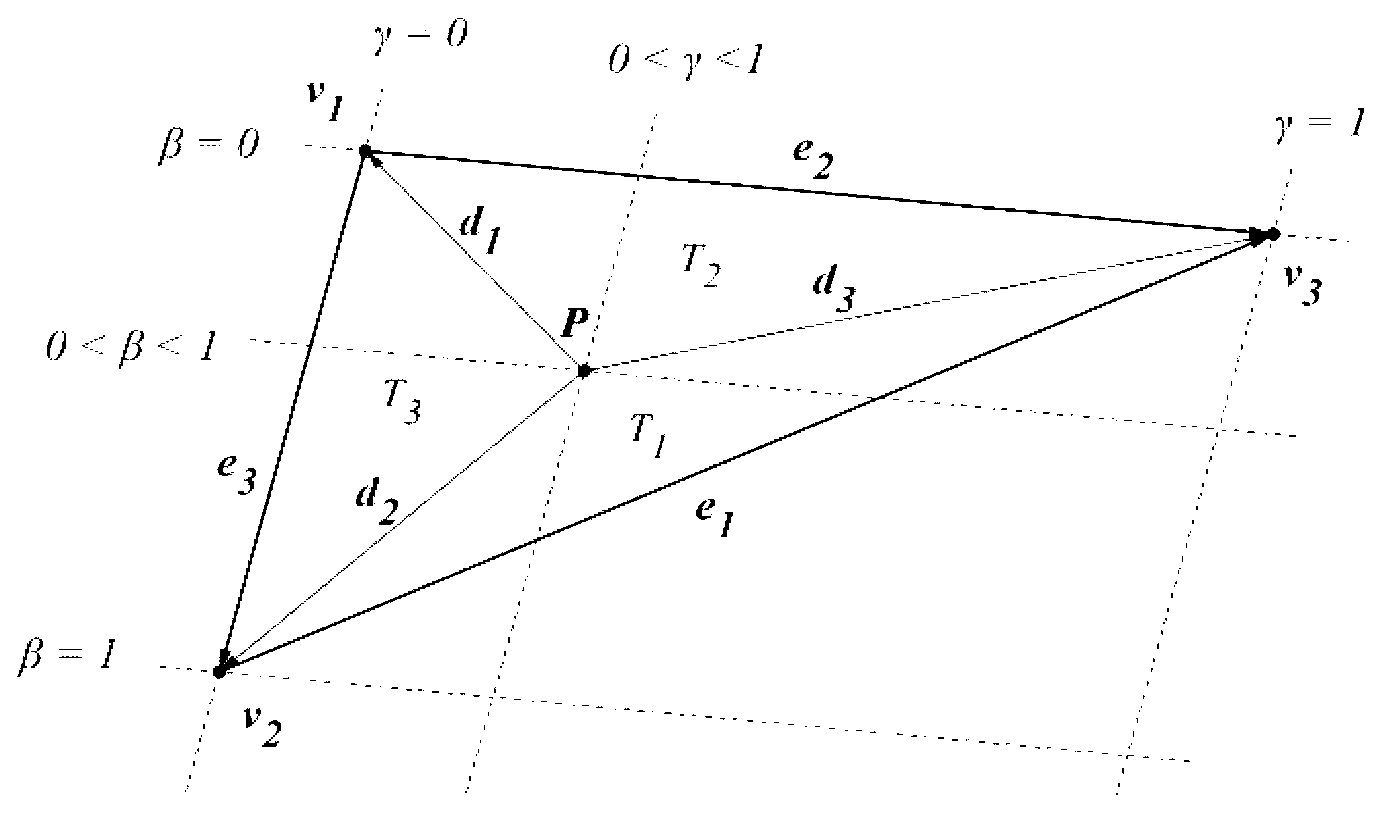

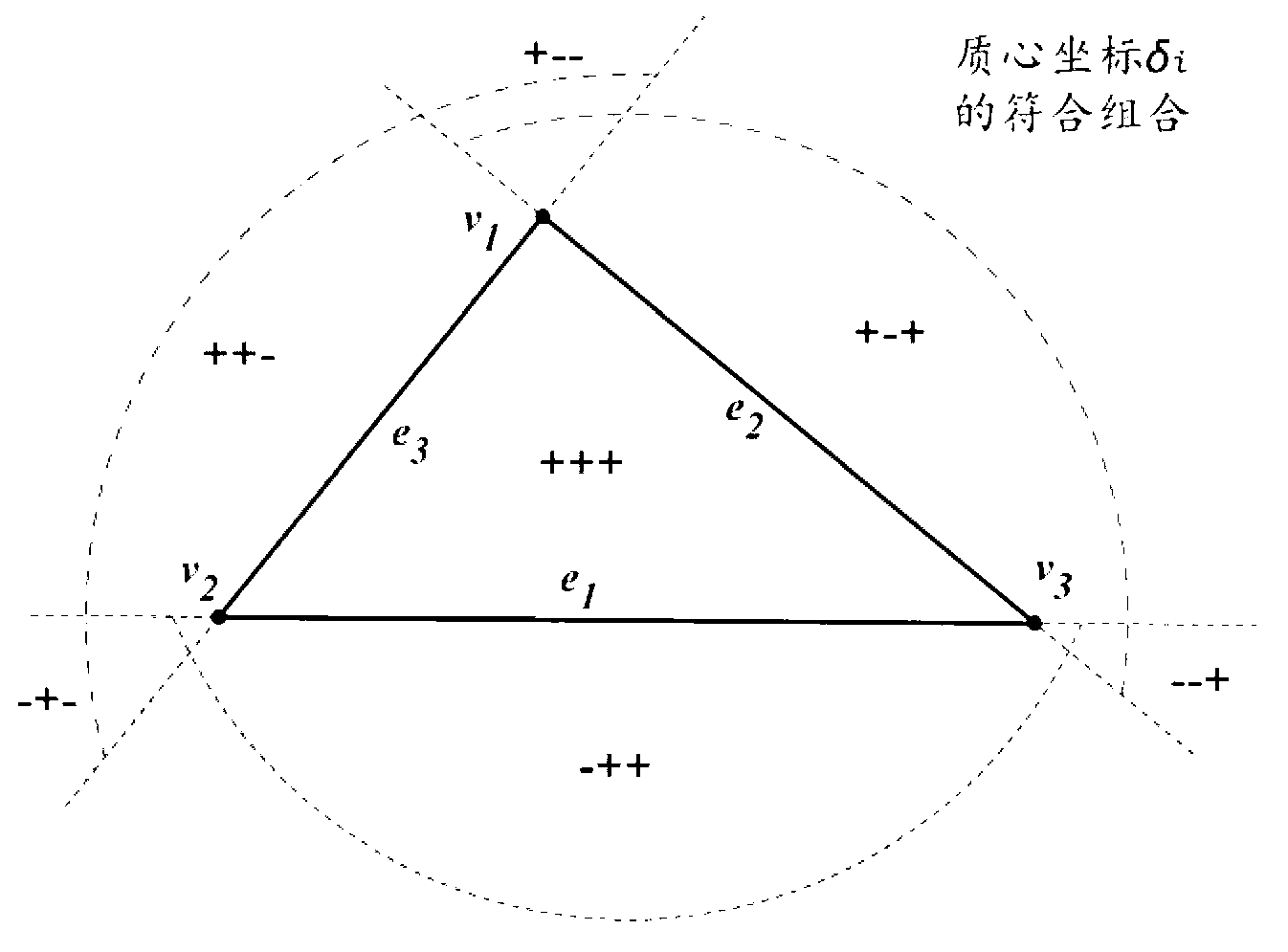

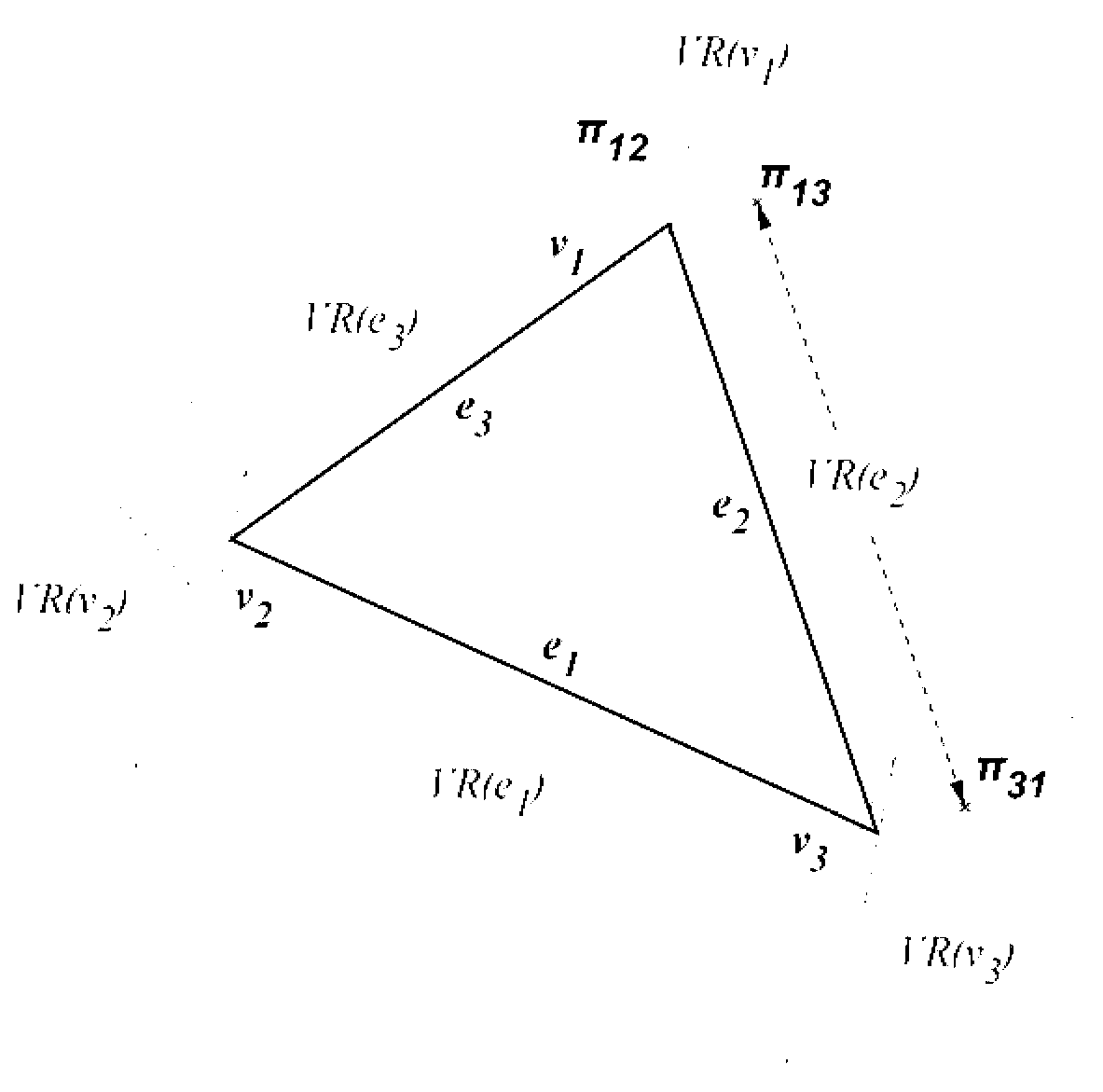

The invention relates to a contact judgment method of spherical particles and triangular meshes in discrete element simulation. The contact judgment method of the spherical particles and the triangular meshes in the discrete element simulation comprises steps of searching neighbor meshes of a target particle to confirm a boundary triangle unit which performs intersecting detection with the target particle; confirming primary contacting information between the target particle and the boundary triangle unit in combination with a symbolic assembly of triangular Voronoi space and center-of-mass coordinates; and judging effectiveness of the primary contacting information, eliminating invalid contacting information and adding the effective contacting information into a contacting linked list to calculate the contact force of particles through a discrete element simulation program. The contact judgment method of the spherical particles and the triangular meshes in the discrete element simulation has the advantages of avoiding respectively building contact judgment algorithms for every kind of basic graphic elements; providing a method for directly positioning an area generating contact to save execution steps of the contact judgment; building judging criteria for eliminating the invalid contact information among multiple contact information; and finally effectively solving the contact judgment problem of the spherical particles and complex geometry boundaries in the discrete element simulation.

Owner:WUHAN UNIV

Seepage simulation method for constructing coal body based on finite element-discrete element CT (Computer Tomography)

ActiveCN106960070AFracture RealizationUniversally applicableDesign optimisation/simulationSpecial data processing applicationsPorous mediumMobile grid

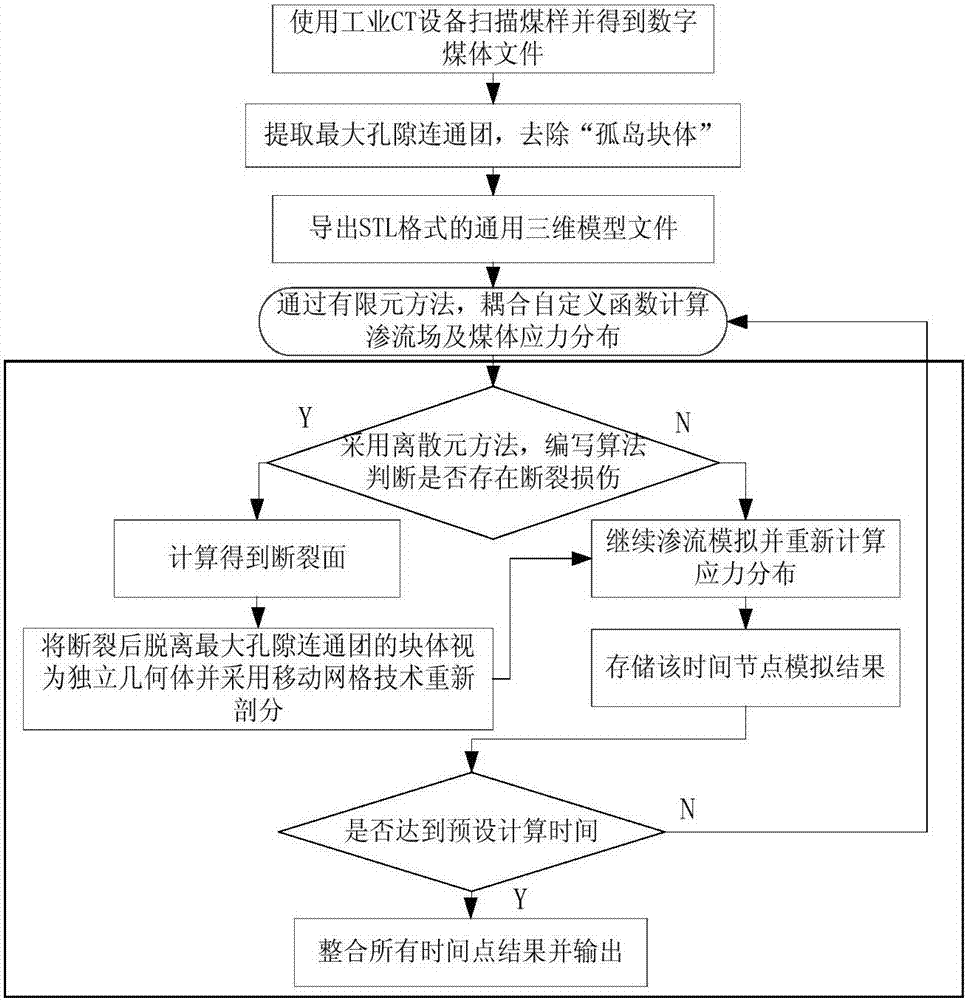

The invention discloses a seepage simulation method for constructing a coal body based on finite element-discrete element CT (Computer Tomography). The method comprises the following steps: performing industrial CT scanning to obtain a three-dimensional data body of the coal body, performing three-dimensional reconstruction, and removing an ''island block'' to obtain a general three-dimensional geometric model which can be called by simulation software; writing a coal body fracture discrimination algorithm by a discrete element simulation method, and determining whether the coal body is deformed, even fractured under the action of hydraulic pressure stress; meanwhile, realizing migration of coal body fragments formed after fracture in the coal body along with moisture flow based on an finite element simulation method by a mobile grid method; and performing numerical simulation of a moisture seepage pressure field, a seepage speed field and a coal body moisture increment at the same time in order to reveal deformation and fracture phenomena of the coal body and a migration rule of moisture in a water injection process of a porous medium coal bed to the maximum extent.

Owner:SHANDONG UNIV OF SCI & TECH

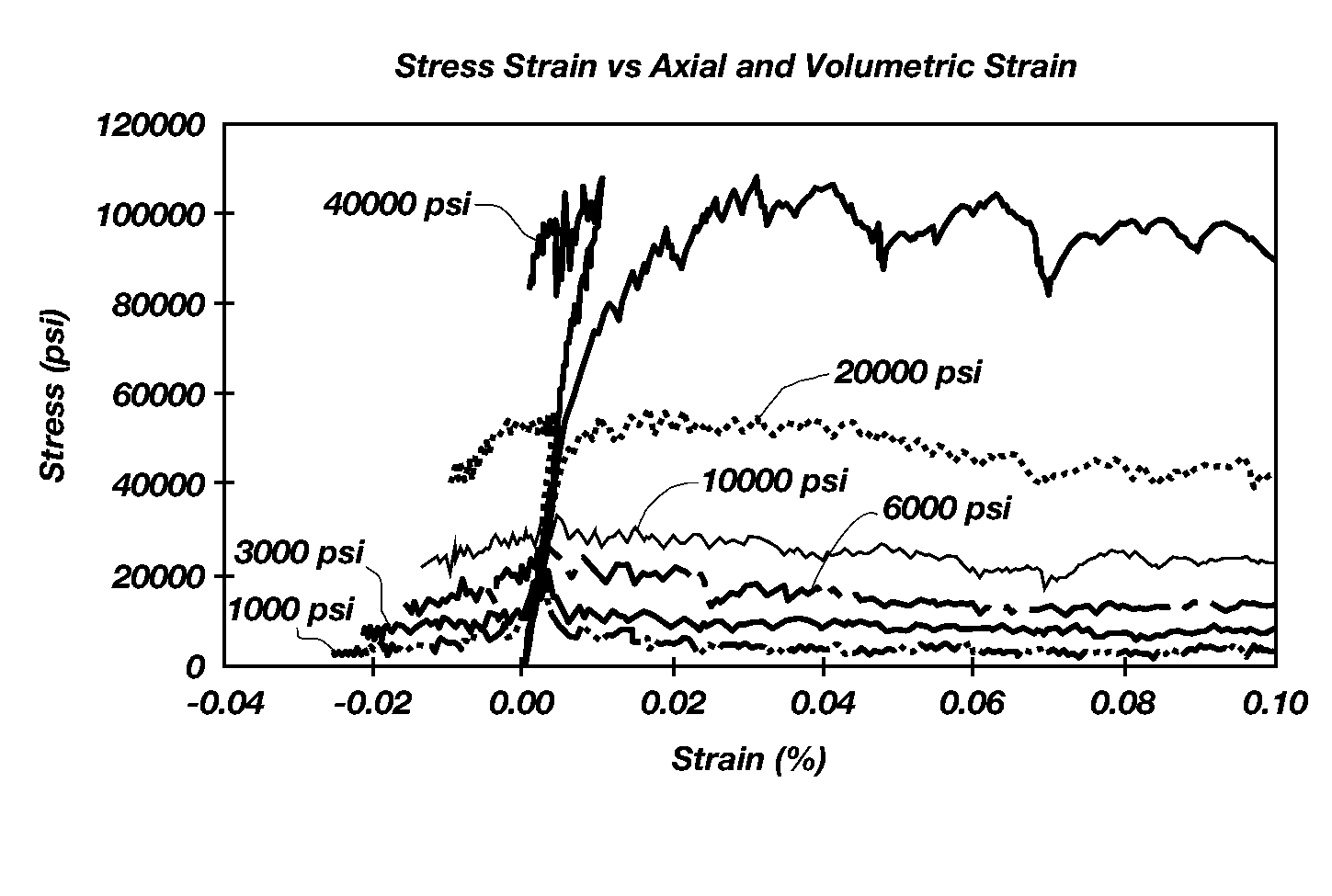

Discrete element modeling of rock destruction under high pressure conditions

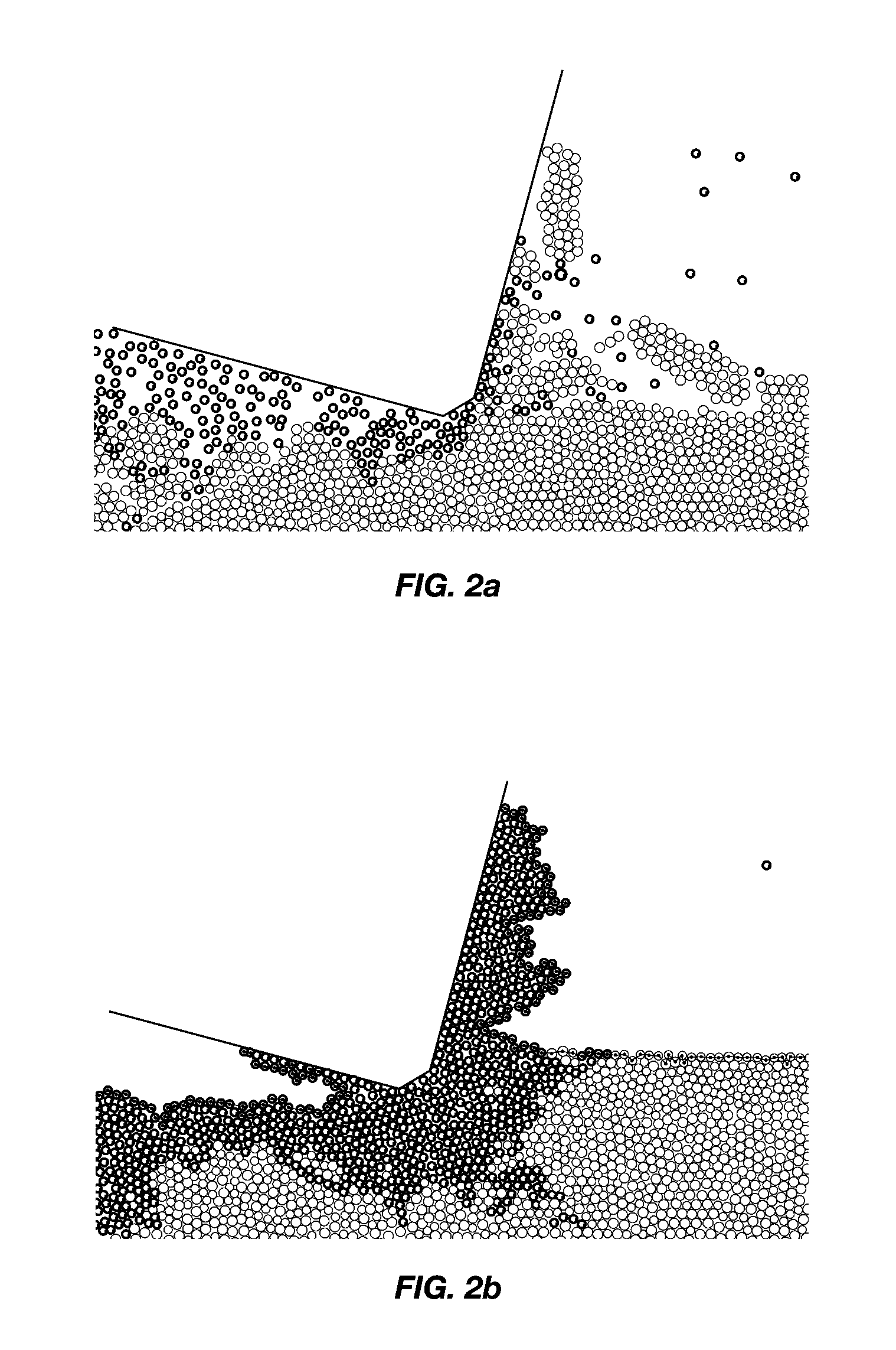

ActiveUS20090132218A1Way accurateSimple designDrill bitsConstructionsDiscrete element simulationWell drilling

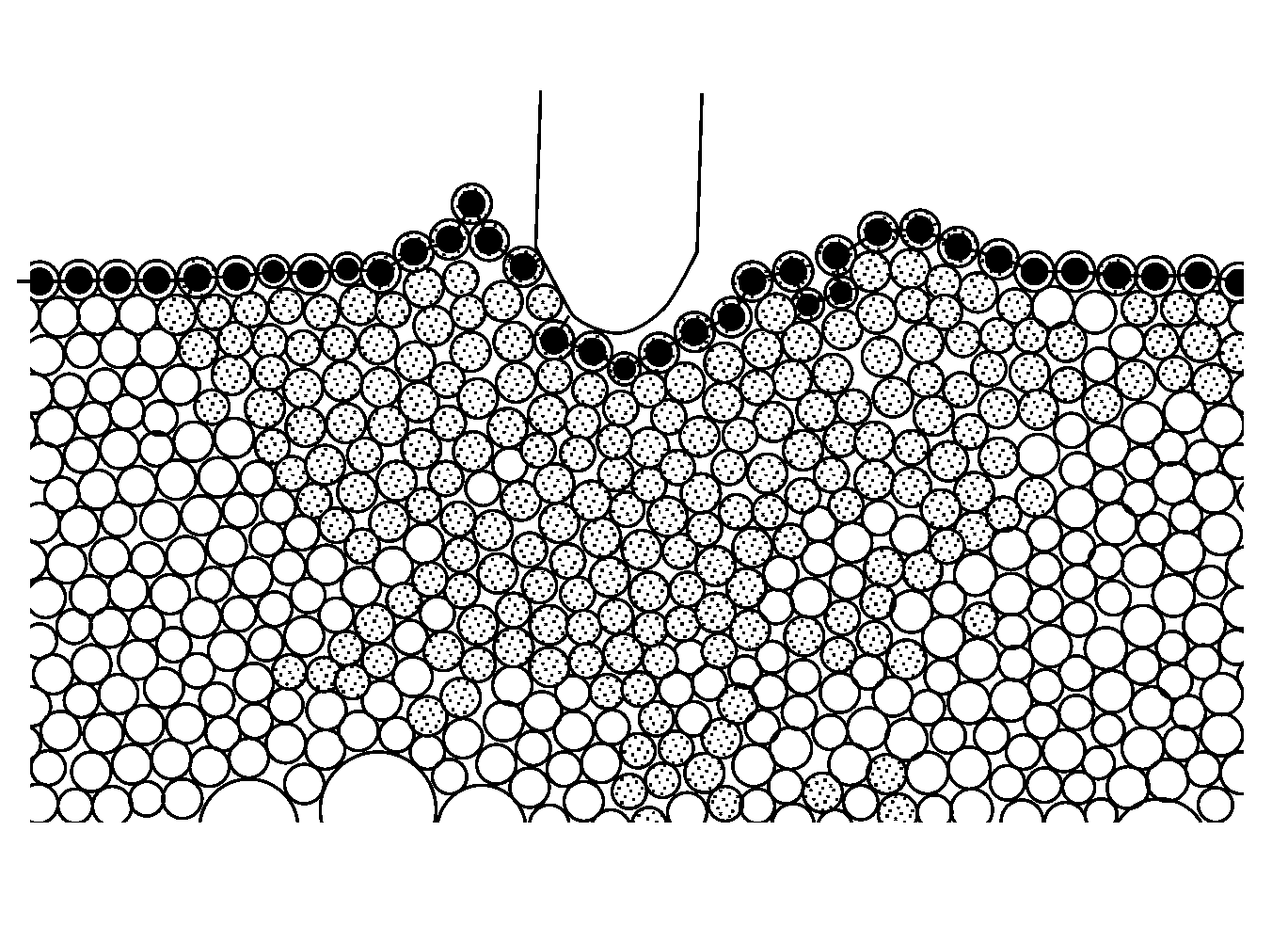

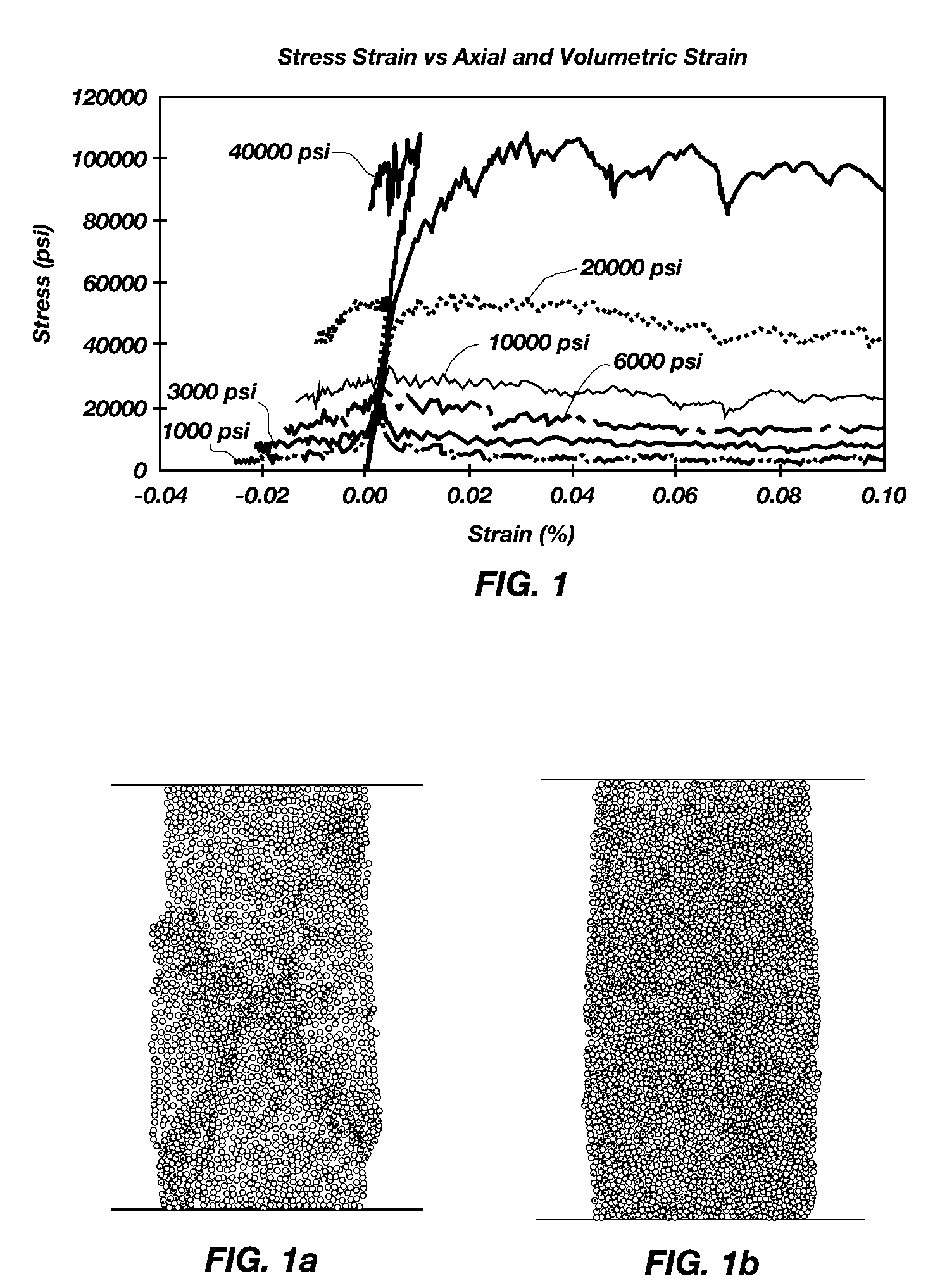

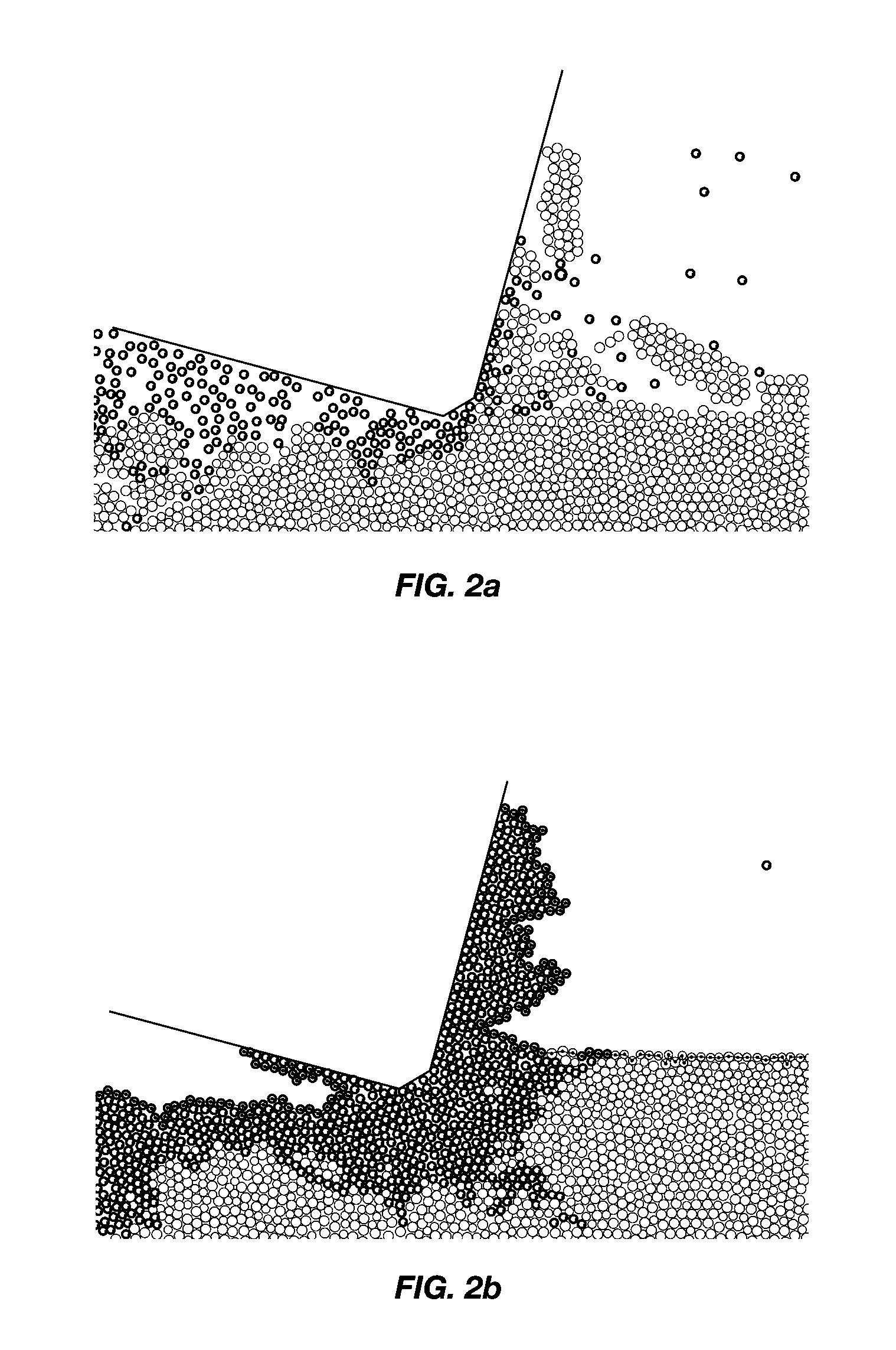

Discrete Element Modeling (DEM) of rock subject to high confining pressures, such as in a subterranean drilling environment, may be used to predict performance of cutting structures used in drill bits and other drilling tools, as well as of the tools themselves. DEM may also be used to create “virtual” rock exhibiting specific drillability characteristics with or without specific reference to any actual rock, for purposes of assessing cutting efficiency of various cutting structure configurations and orientations, as well as of drilling tools incorporating same.

Owner:BAKER HUGHES INC

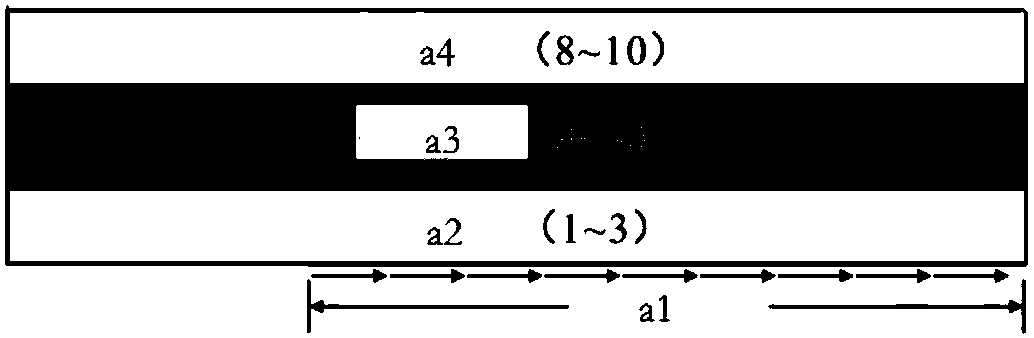

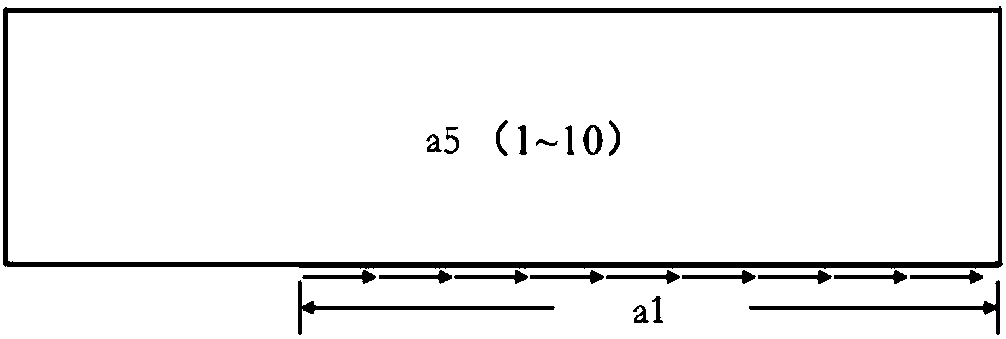

Temperature field analysis method of bituminous mixture test piece on the basis of discrete element simulation

InactiveCN104899351AAccurately establishedEmbody superioritySpecial data processing applicationsField analysisAggregate distribution

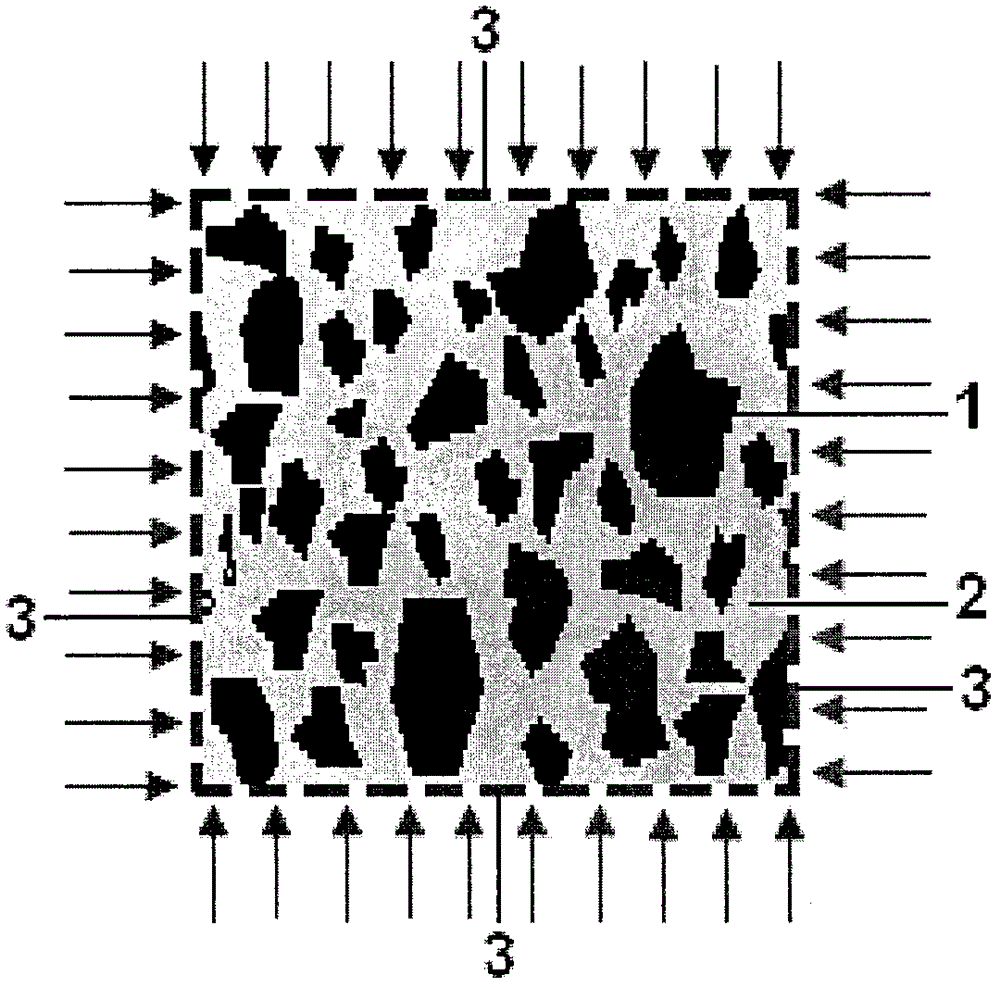

The invention discloses a temperature field analysis method of a bituminous mixture test piece on the basis of discrete element simulation, belongs to the technical field of bituminous mixture, and solves the problem that a finite element method can not accurately analyze the internal temperature field of the bituminous mixture test piece in a high-temperature environment. The temperature field analysis method comprises the following steps: firstly, forming the bituminous mixture test piece, collecting a digital image of irregular aggregate distribution, and converting the digital image into a digital test piece of a two-dimensional CAD (Computer-Aided Design) image format after the digital image is subjected to image processing; then, importing discrete element software, independently generating irregular aggregate and bituminous mortar according to the positions of aggregate blocks and the bituminous mortar, and constructing a two-dimensional test piece discrete element model; simulating a situation that the test piece is heated in the high-temperature environment, setting a boundary condition of the test piece model, the thermophysical property parameters of the aggregate and the bituminous mortar and the internal contact thermal resistance of a unit; and applying certain constant-high-temperature and room-temperature heat flow around the test piece model, recording the temperature change situations of each point in the test piece at different moments, drawing a comparison graph, and combining with a temperature field and a heat flow distribution cloud chart generated by the software to analyze the temperature field of the bituminous mixture test piece.

Owner:NANJING FORESTRY UNIV

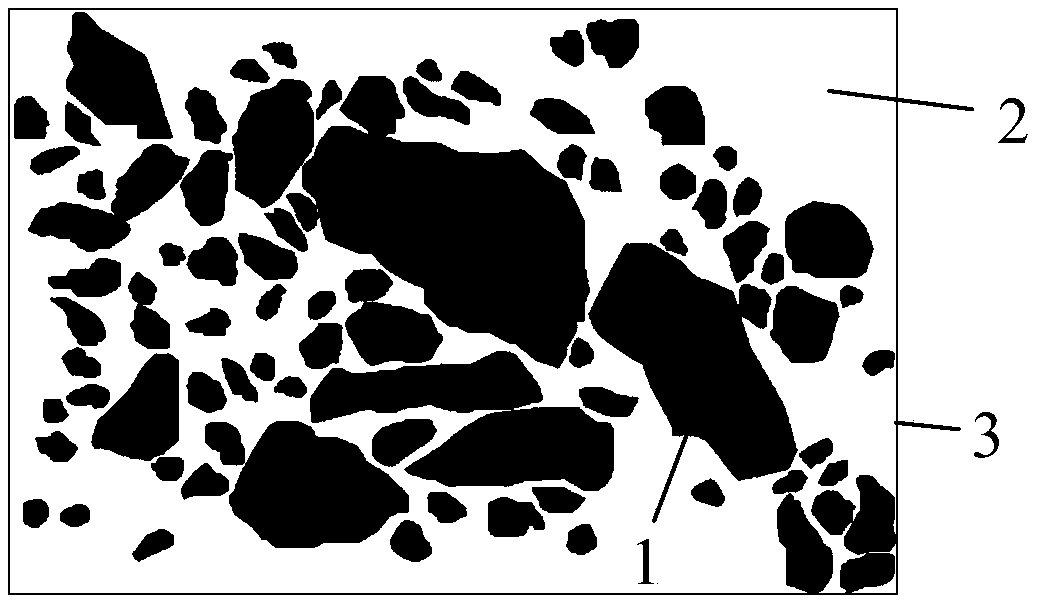

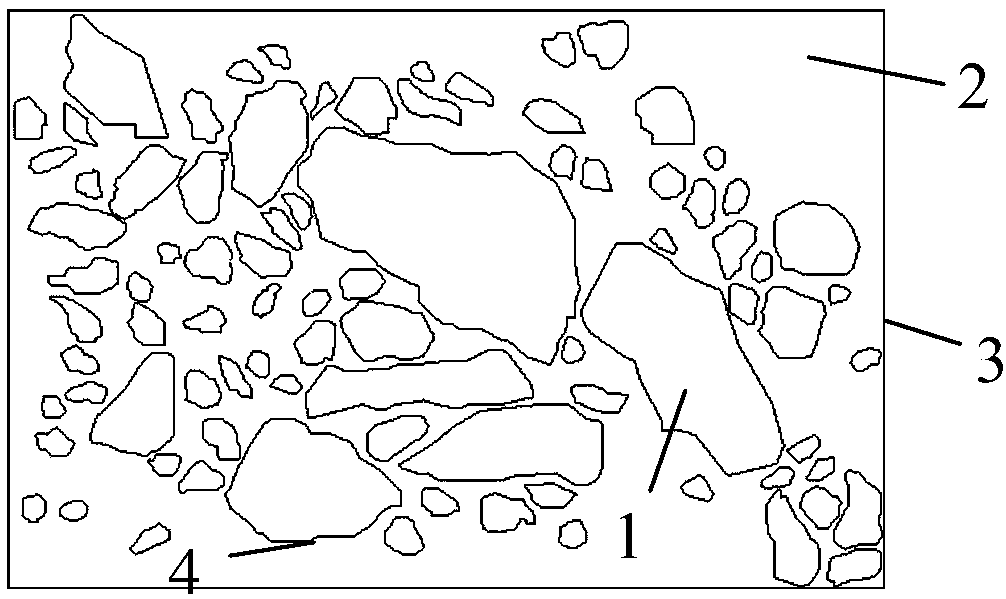

A particle flow numerical simulation method for reflecting the distribution of the real engineering soil-rock mixture

PendingCN109359416AAccurate extractionFast and low costScene recognitionDesign optimisation/simulationModel parametersNumerical models

The invention discloses a particle flow numerical simulation method for reflecting the distribution of the real engineering soil-rock mixture. The method comprises the following steps: taking photos to obtain the real image of the soil-rock mixture on the project site; using the processing technology to recognize rocks and extract their boundary coordinates; combined with particle sieving and image data, obtaiing the particle size distribution of soil-rock mixture; testing the strength and deformation of soil and rock and deformation parameters.; establishing a numerical model of particle flowin soil-rock mixture; calibrating parameters of particle flow numerical model and carrying numerical tests of mechanical properties of soil-rock mixture specimens. The method is convenient to implement and can be programmed to model intelligently, and can overcome the limitation of test size and meet the requirement of engineering. It is suitable for DEM simulation of binary media such as earth-rock mixture and concrete.

Owner:HEBEI UNIV OF TECH

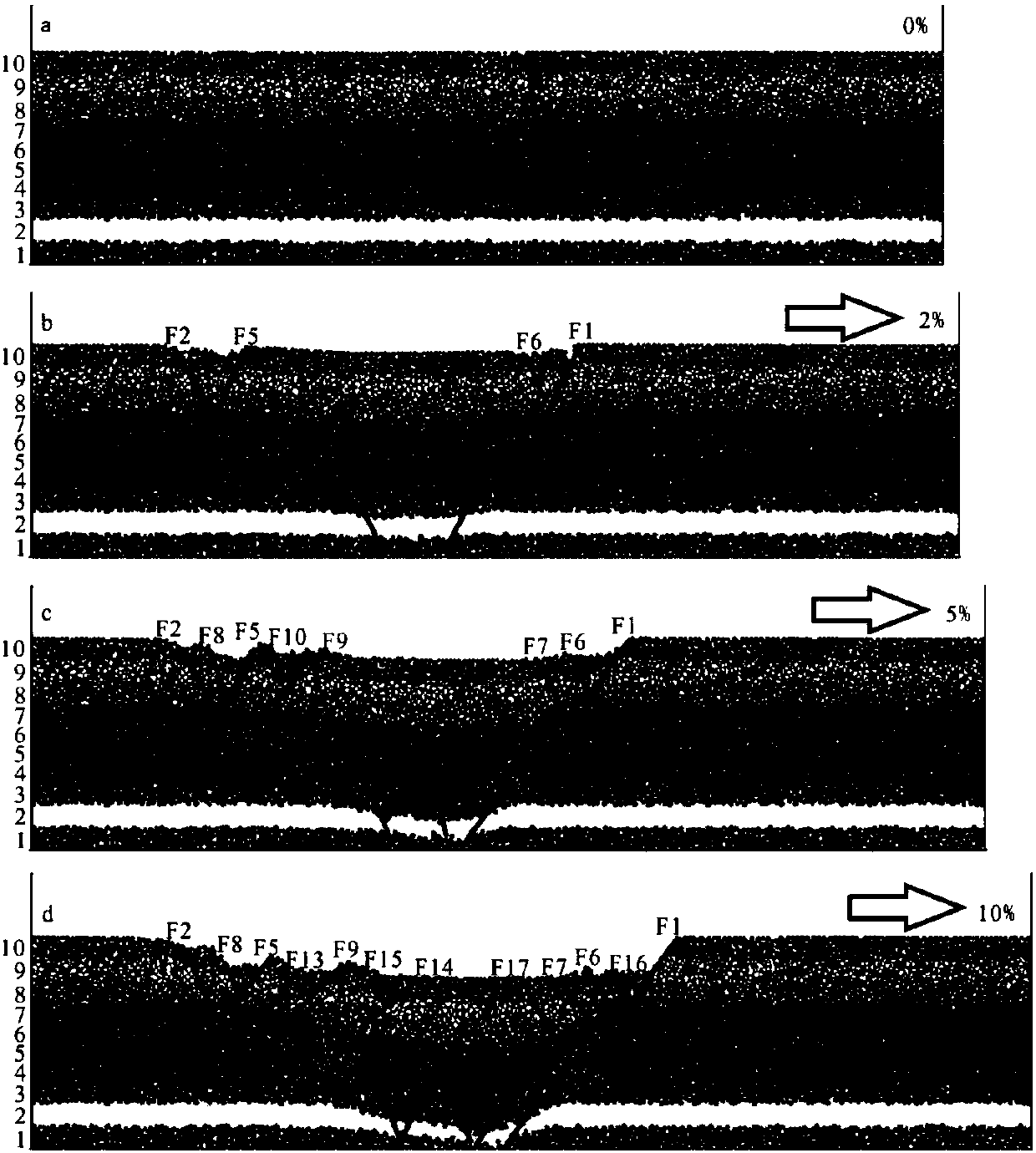

Hierarchical-extension discrete element simulation method

ActiveCN107808030AAccurately reflectHigh simulation accuracyDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationBasement

The invention provides a hierarchical-extension discrete element simulation method. The method comprises the steps that based on formation rock mechanical properties and basement fault positions of areal formation, a discrete element numerical simulation formation is constructed, wherein the discrete element numerical simulation formation comprises a simulation formation, and the simulation formulation has a hierarchical-extension superposed deformation structure of an intermediate ductile layer; and the simulation formulation accurately simulates the rock mechanical properties of the real formation through adjustment of filling material properties, construction and / or structures. Through the hierarchical-extension discrete element simulation method, the model construction mode is simple,the simulation mode is easy to realize, and the simulation result has good accuracy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

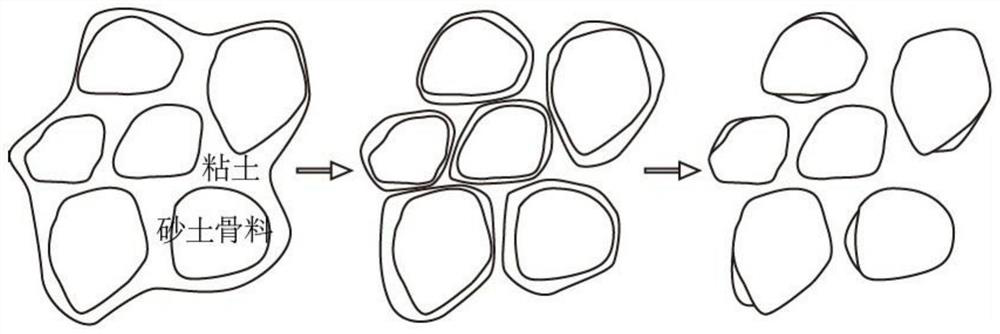

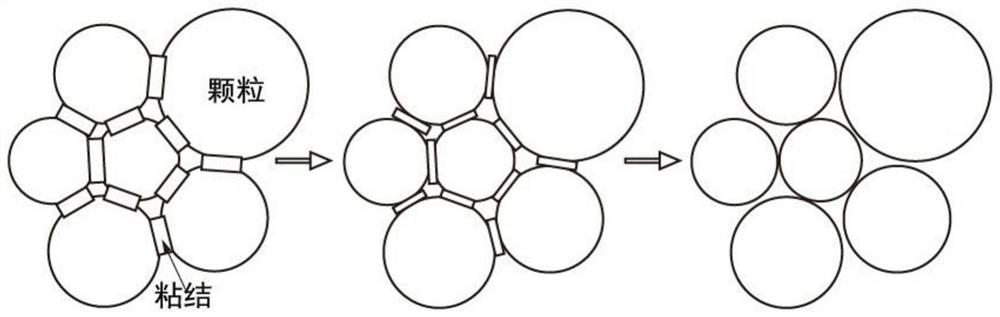

Discrete element numerical simulation method for viscous sandy soil hydraulic erosion damage

ActiveCN111709148AObserve and record movementSimple thinkingDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationSoil science

The invention discloses a discrete element numerical simulation method for viscous sandy soil hydraulic erosion damage. The method comprises the steps of:establishing an initial calculation space areaand a viscous sandy soil numerical model; initializing a numerical model and balancing stress; compiling a strength degradation criterion linear bonding contact model based on a time effect to simulate a clay phase between aggregate particles in the viscous sandy soil; selecting a contact model as a mesomechanics model of contact between aggregate particles, and valuing mesoscopic parameters of the contact model; calibrating the numerical model through a direct shear strength test; establishing a flow field to simulate the hydraulic erosion damage process of the viscous sandy soil; and obtaining a numerical simulation result of the hydraulic erosion damage test. According to the method, the viscous sand hydraulic erosion damage is simulated through the discrete elements, the thought is simplified, the viscous sand hydraulic erosion damage process can be truly simulated on the mesoscopic level under the conditions that the calculated amount is reduced as much as possible and the calculation efficiency is improved, the migration situation of soil particles is observed and recorded, and the result is accurate.

Owner:HEBEI UNIV OF TECH

Structure surface wear simulation method based on discrete element method

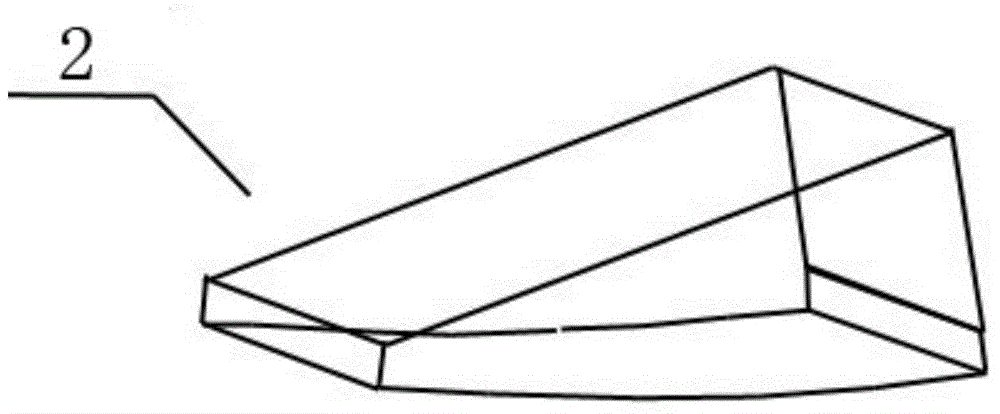

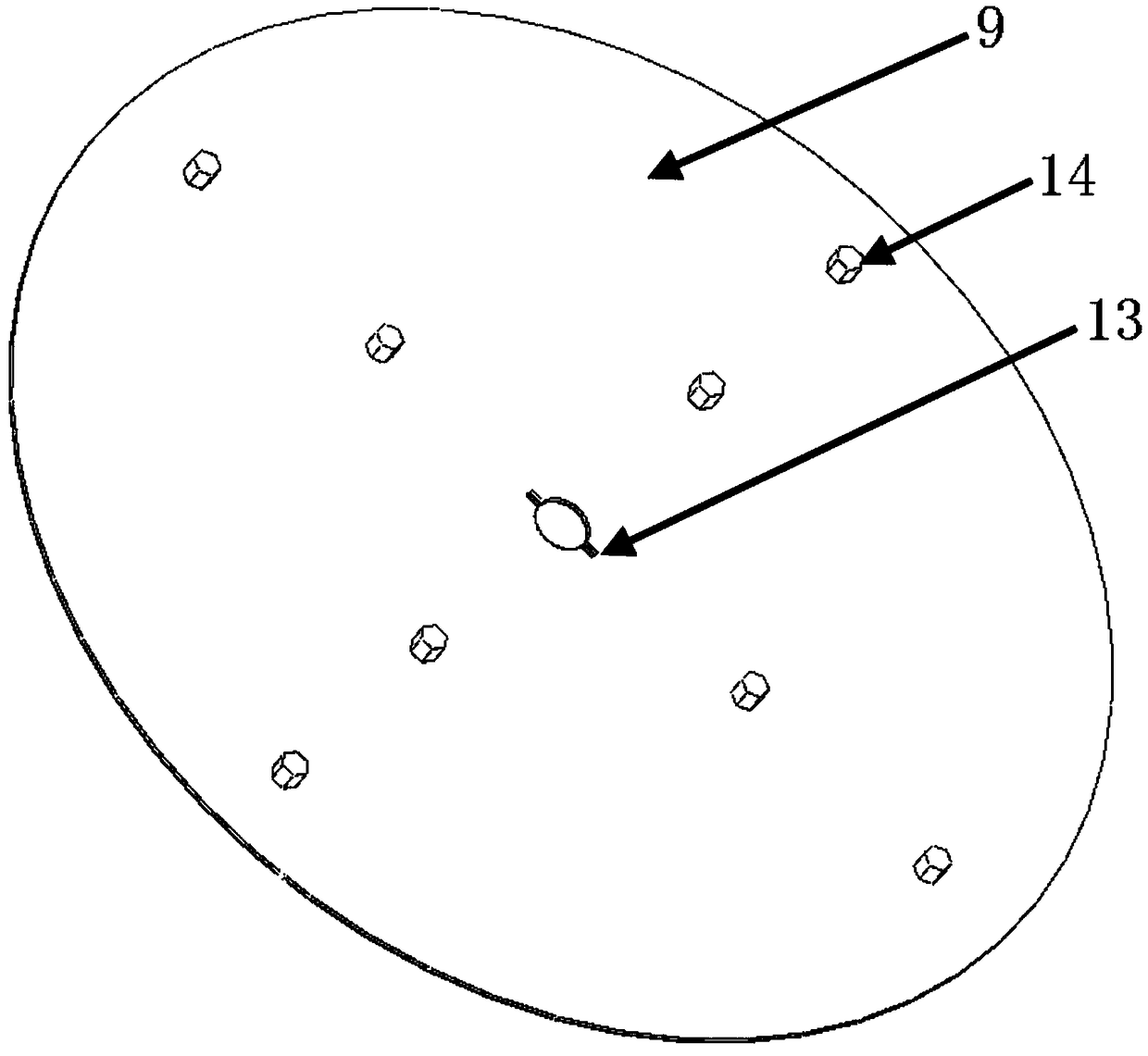

The invention provides a structure surface wear simulation method based on a discrete element method. The structure surface wear simulation method includes the following steps that S1, the structure surface shape is obtained, and a target surface is divided into a triangular mesh composed of a plurality of triangular units; S2, discrete element simulation is conducted on the triangular units, the scattered particle collision processes of the triangular units are simulated, and thus the collision energy data of all the triangular units are computed and recorded; S3, the sizes of the materials stripped out of the surfaces of all the triangular units are computed according to the collision energy data obtained in S2, and thus the height variable quantity of the centers of mass of all the triangular units is obtained according to the material sizes; S4, the target surface is fitted again according to the height variable quantity of the centers of mass of all the triangular units obtained in S3. The structure surface wear simulation method based on the discrete element method provides reference for structural design, functional design, service life design and the like of scattered material processing equipment.

Owner:SHANGHAI AEROSPACE SYST ENG INST

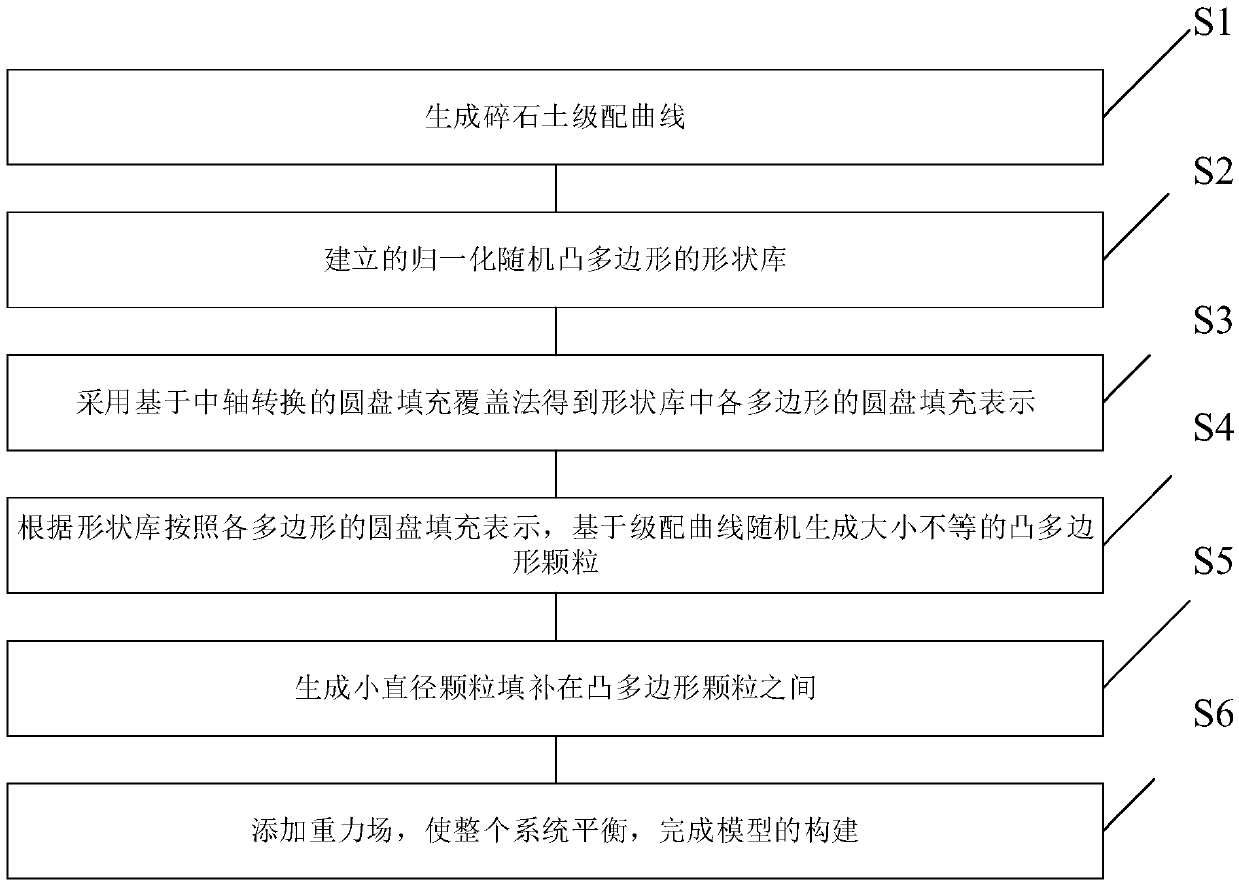

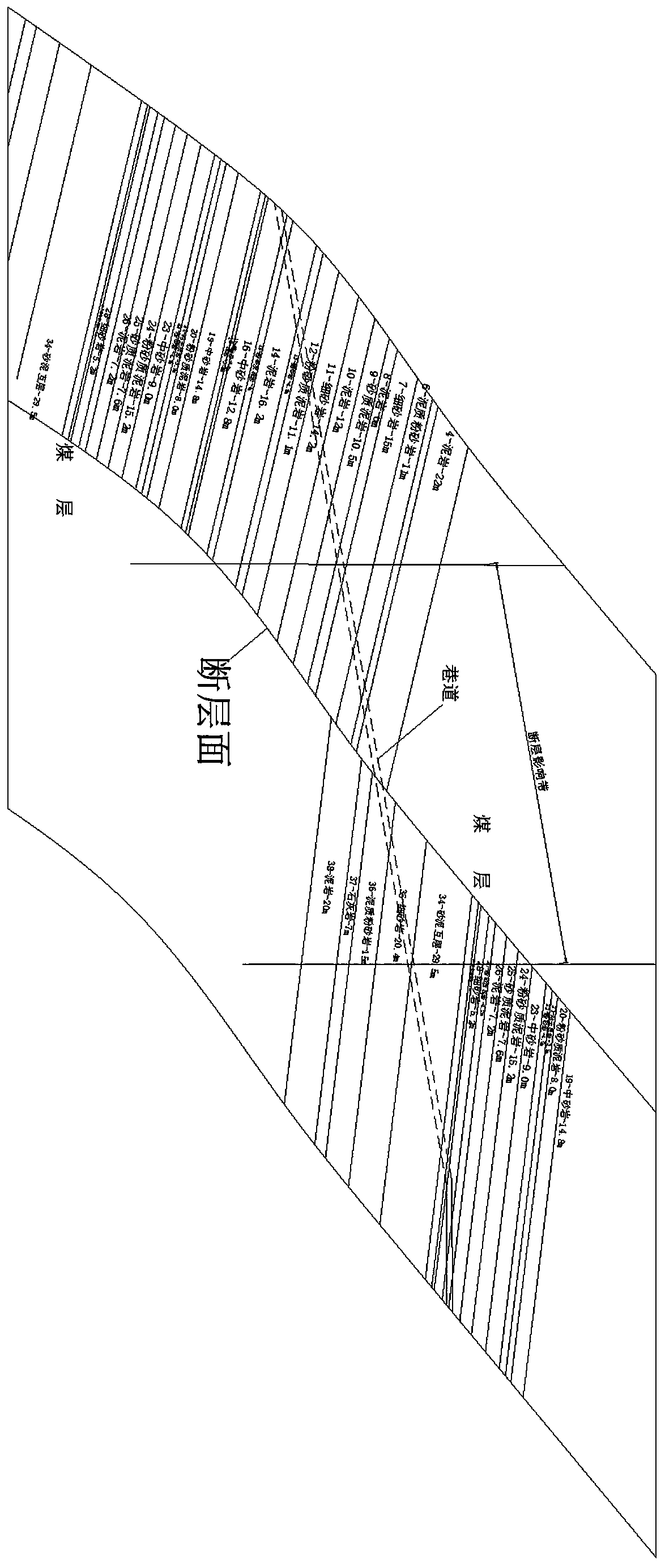

Gravelly soil layer discrete element simulation method considering particle shape randomness

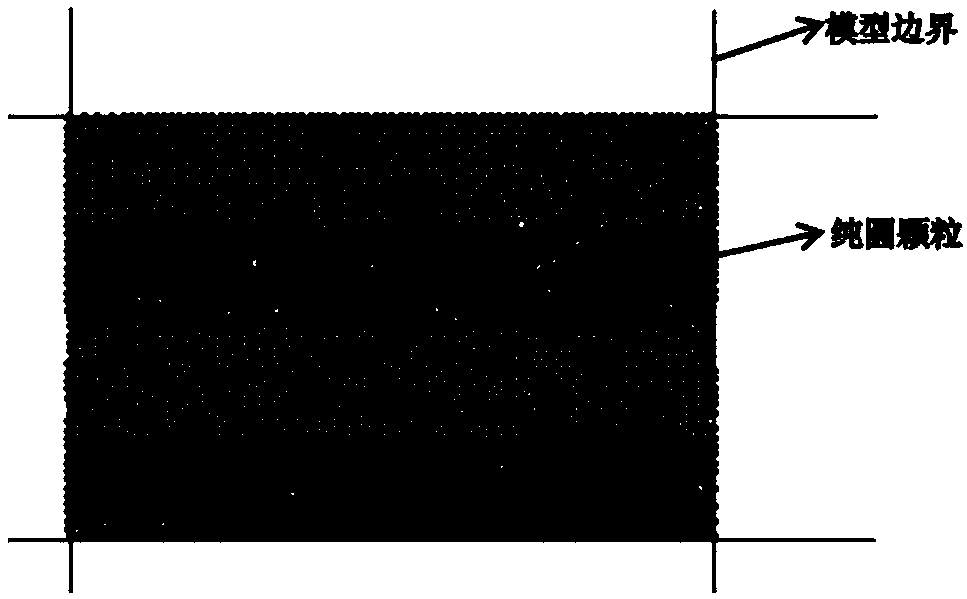

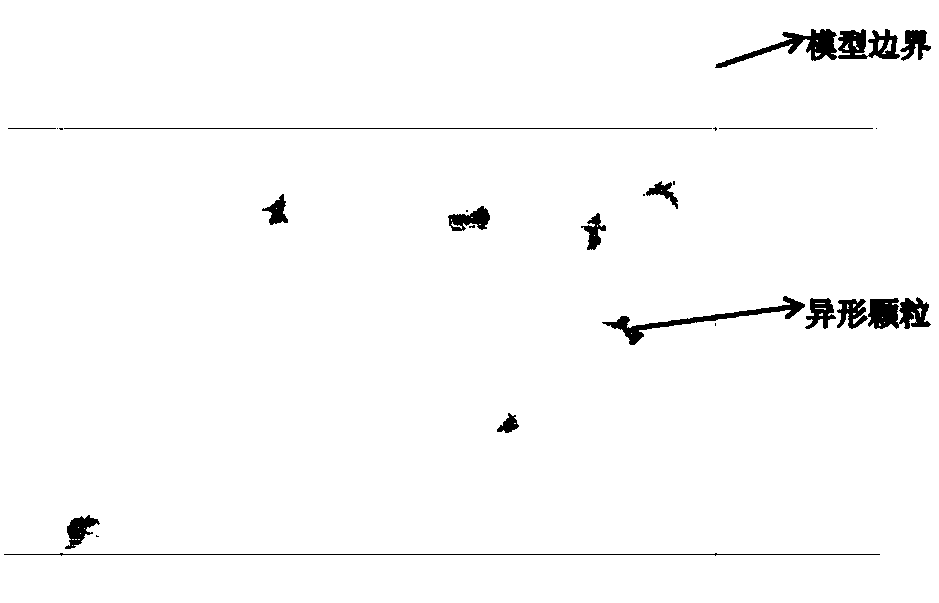

InactiveCN108052690AFacilitates automatic generationPromote normalizationGeometric CADDesign optimisation/simulationSoil aggregateDiscrete element simulation

The invention relates to a gravelly soil layer discrete element simulation method considering particle shape randomness. The method comprises the steps of S1: generating a gravelly soil grading curve;S2: establishing a shape library of normalized random convex polygons; S3: obtaining disk filling representations of the polygons in the shape library by adopting a medial axis transformation-based disk filling coverage method; S4: randomly generating convex polygon particles different in size based on the grading curve through the disk filling representations of the polygons according to the shape library; S5: generating small-diameter particles to fill the convex polygon particles; and S6: adding a gravity field for enabling a whole system to be balanced, and finishing the building of a model. Compared with the prior art, the method is used for simulating rock-soil aggregate strata, so that the engineering problems of constitutive relations of rock-soil aggregates, destruction forms, foundation pit excavation, slope stabilization, tunneling and the like can be conveniently researched.

Owner:TONGJI UNIV

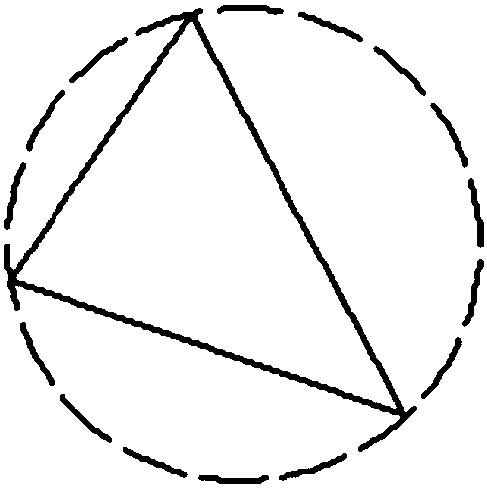

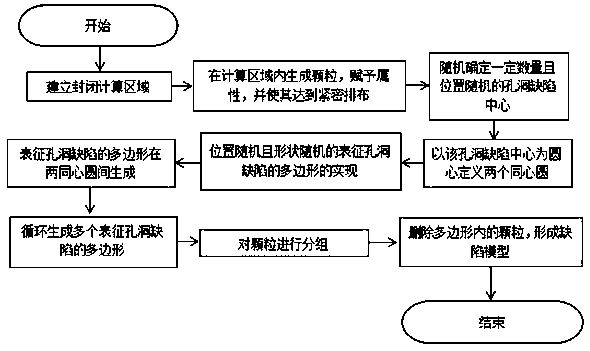

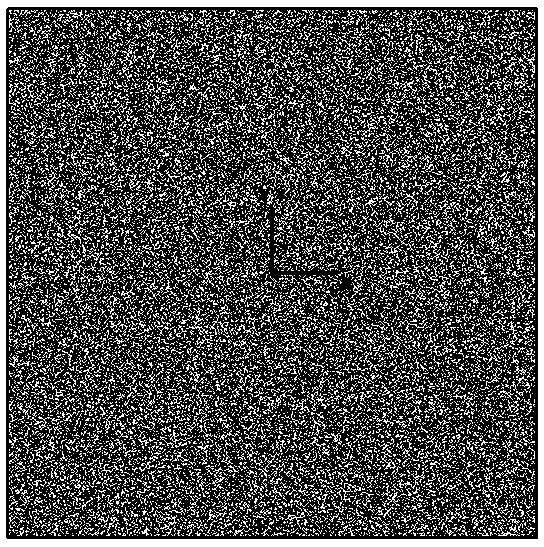

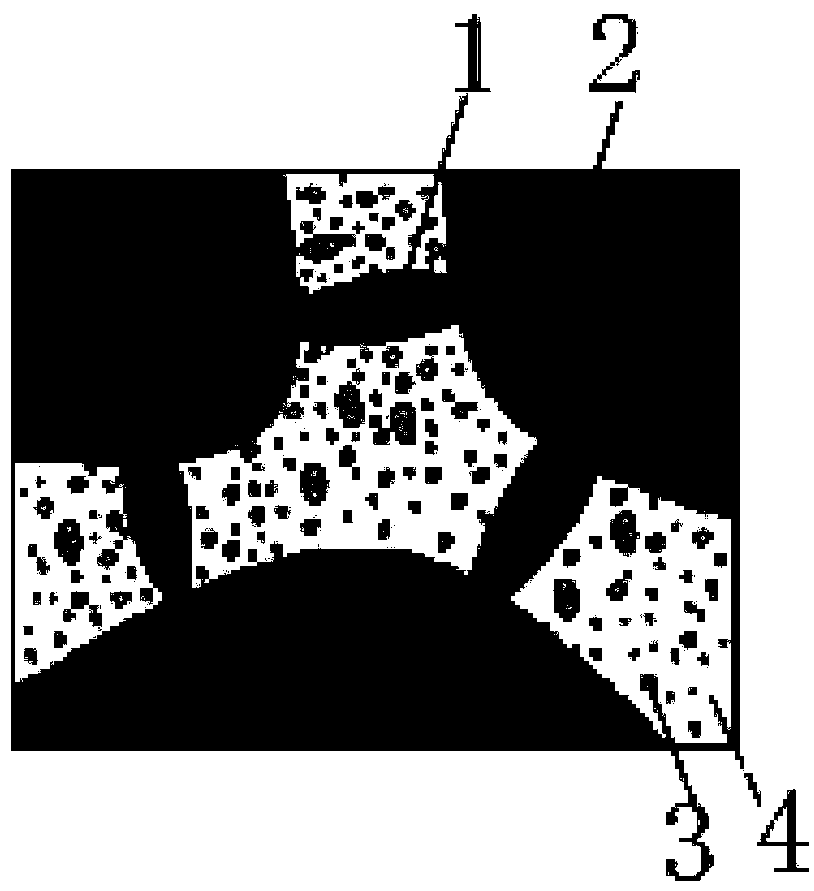

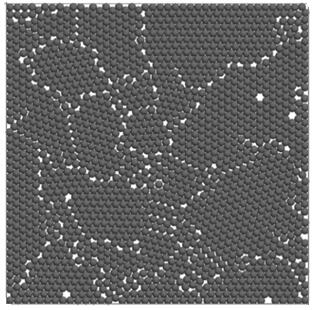

Brittle material discrete element modeling method considering shape of hole defect and distribution randomness thereof

ActiveCN108846186ADesign optimisation/simulationSpecial data processing applicationsMaterial defectDiscrete element simulation

The invention discloses a brittle material discrete element modeling method for considering a shape of a hole defect and the distribution randomness thereof, which is mainly used for the discrete element simulation research of brittle materials such as engineering ceramics. The method includes: creating a closed area, and adding a certain number of particles with uniformly or normally distributedradiuses into the closed area to achieve tight arrangement of the particles; selecting an appropriate contact model to give the particles a certain strength of connection keys; determining a certain number of randomly located hole defect centers through a position random function, and constructing each hole defect polygon with shape randomness; and finally deleting a closed area wall, and deletingthe particles in the polygon to form a hole defect. The method is easy to program, is simple to debug, conforms to the existence state of the actual brittle material defects, can make the simulationexperiment result more accurate, more in line with the actual situation, and can improve the effectiveness of the simulation experiment.

Owner:XIANGTAN UNIV

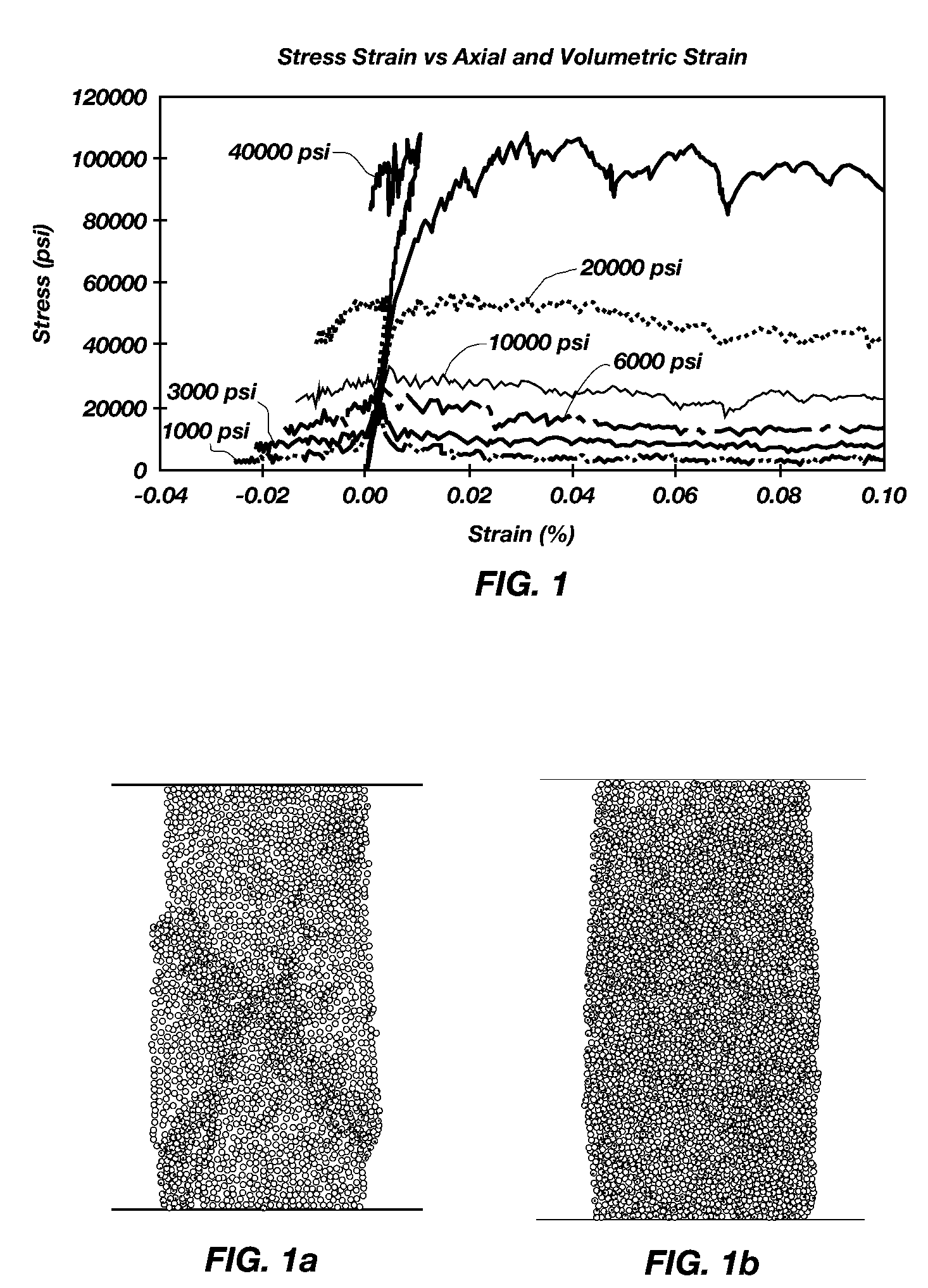

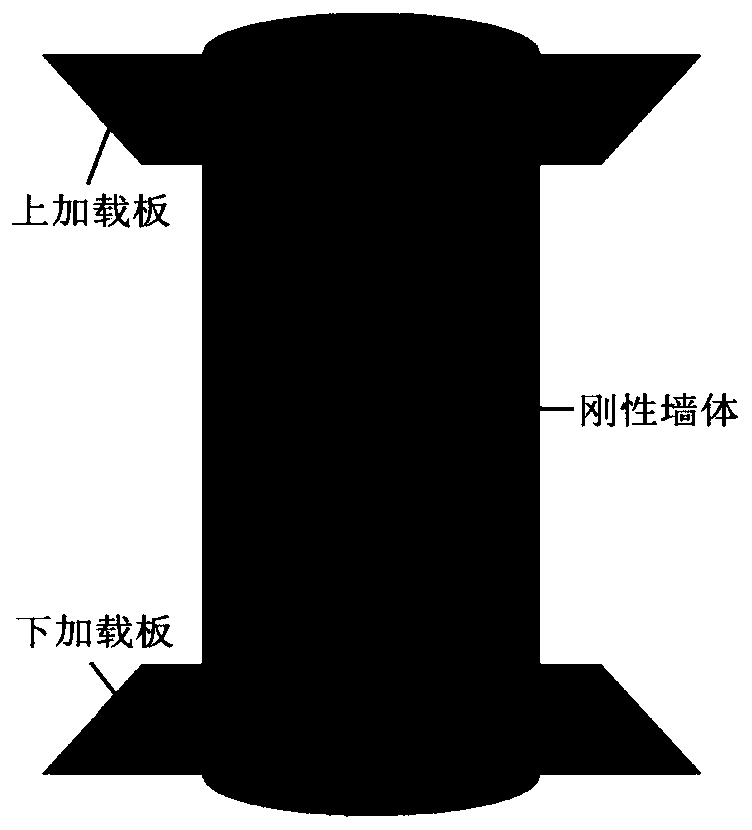

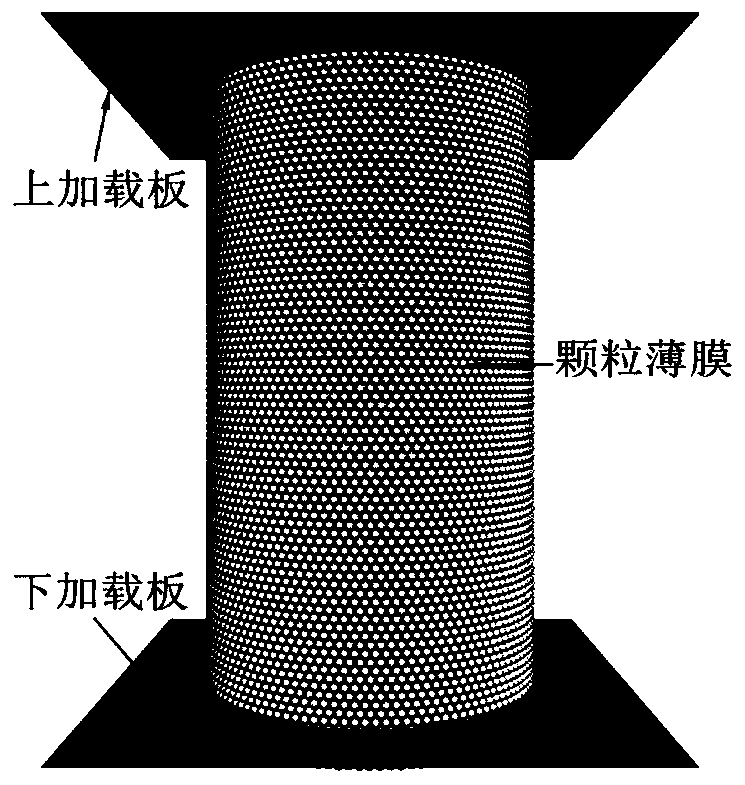

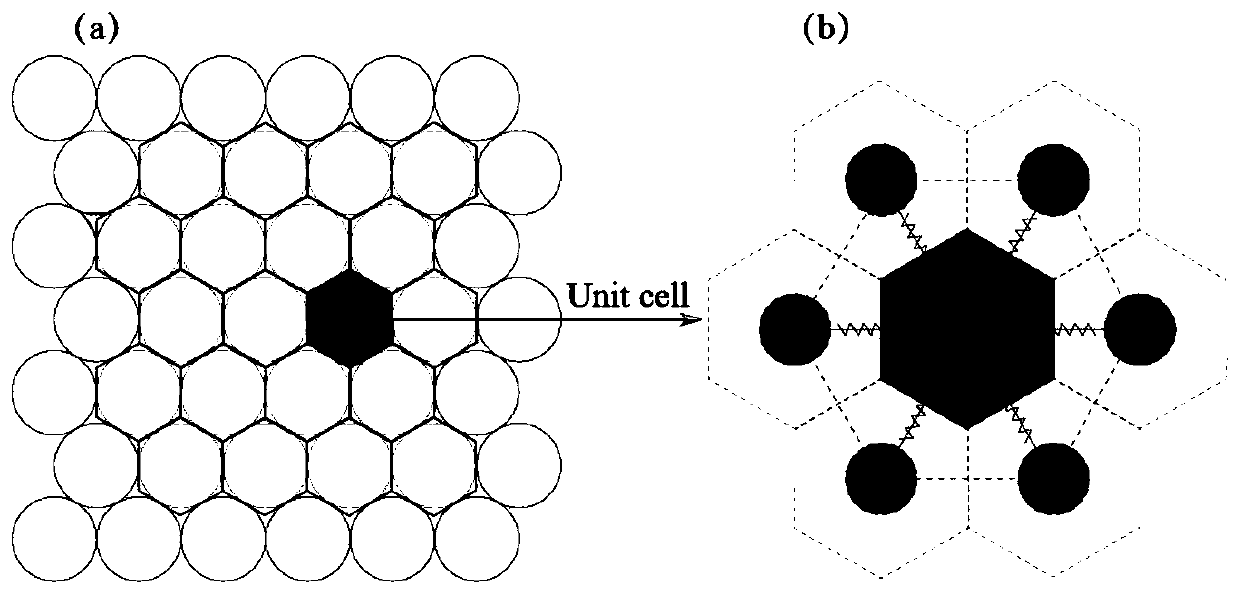

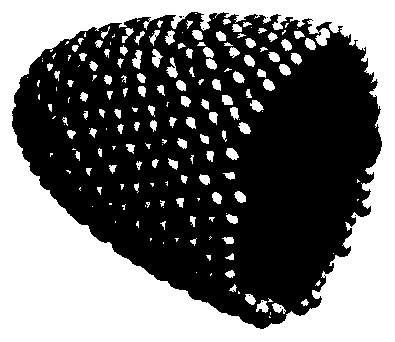

Discrete element simulation method for rock-soil triaxial test flexible film boundary

PendingCN110309536AStable and Accurate LoadingVolumetric deformations of snapping volumesDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationShape change

The invention discloses a discrete element simulation method for a rock-soil triaxial test flexible film boundary. The discrete element simulation method adopts a particle set arranged in a hexagonalhoneycomb structure to represent a flexible film, and a linear bonding model is adopted among particles, and an upper loading plate and a lower loading plate adopt rigid walls. The discrete element simulation method has the outstanding advantages that (1) the film particles can effectively represent parameters such as the elasticity modulus, the Poisson's ratio and the thickness of the physical film; (2) the film can be freely deformed in the sample loading process, and the hydrostatic confining pressure can be stably and accurately transmitted; and (3) the volume deformation of the sample canbe accurately recorded in real time in the loading process. The discrete element simulation method is simple in implementation process and suitable for simulating conventional triaxial tests of various granular materials such as sandy soil and rockfill materials. Practice shows that the discrete element simulation method can accurately simulate the shape change, the stress-strain relationship andthe volume strain condition of the sample in the triaxial test process of the granular material, and can provide powerful support for macroscopic parameter test and mechanical property research of the granular material.

Owner:CENT SOUTH UNIV

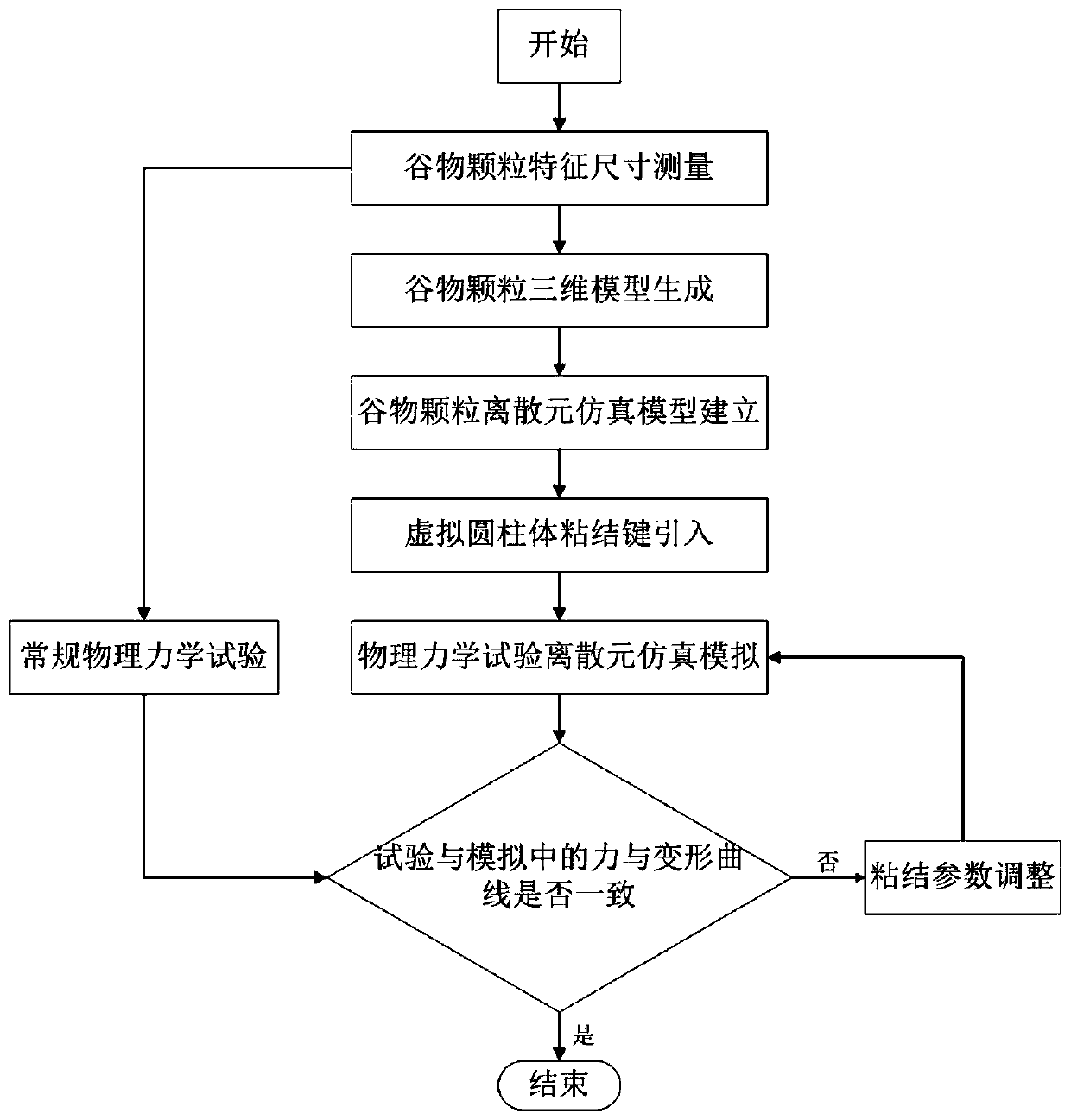

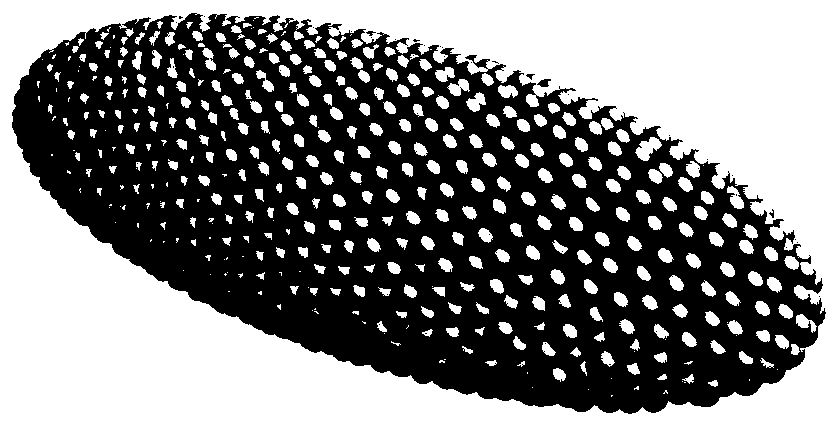

A method for constructing a breakable grain particle discrete element simulation model

InactiveCN109740263AMeet the needs of crushing mechanism researchAccurately respond to stressSpecial data processing applicationsDiscrete element simulationMechanical property

The invention discloses a method for constructing a breakable grain particle discrete element simulation model. The method comprises the following steps that 1, measuring the three-dimensional characteristic size of grain particles; 2, generating a grain particle three-dimensional model by using a computer; 3, preliminarily establishing a grain particle discrete element simulation model through discrete element software; 4, introducing a virtual cylinder bonding key into the discrete element simulation model obtained in the step 3; 5, taking a force and deformation curve obtained by a conventional physical and mechanical test as a target; repeatedly adjusting mesoscopic parameters of the discrete element simulation model; the force obtained by calculation and actual measurement of the simulation model is matched with the deformation curve; according to the method, the characteristic that the cereal grains have crushable and viscoelastic mechanical properties is considered at the same time, so that the discrete element simulation model of the cereal grains is closer to actual cereal grains, and the method can be widely applied to cereal grain crushing mechanism research in the grainprocessing process.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

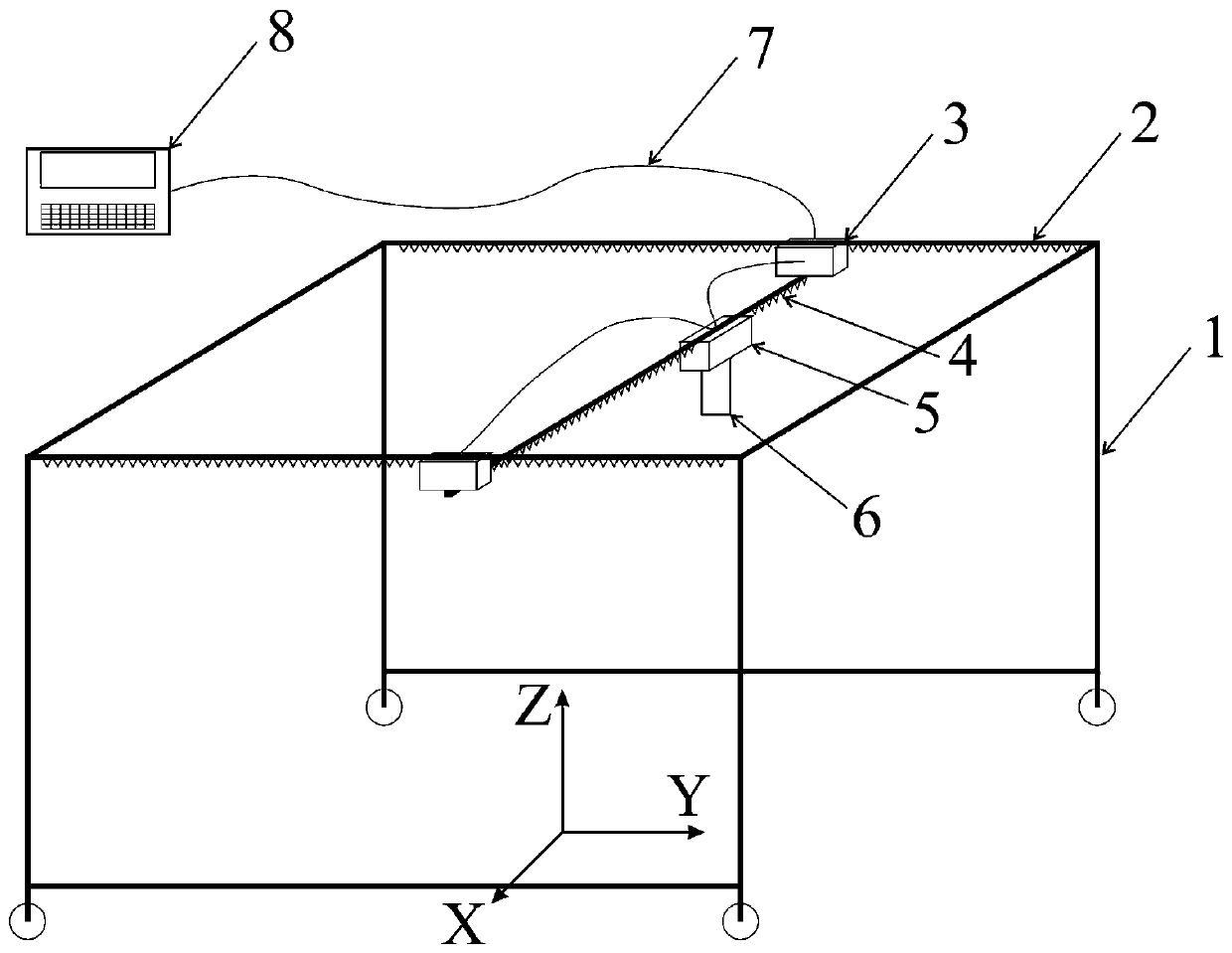

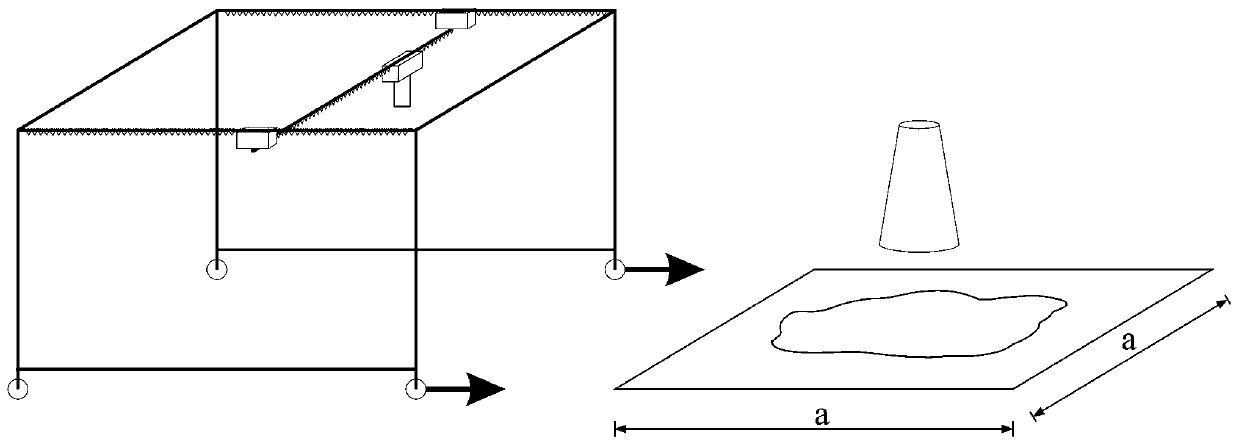

Verification device and method for simulating concrete slump form by discrete elements

ActiveCN110046432AThe result is accurateQuantitative evaluation indicators are reasonableNuclear energy generationDesign optimisation/simulationDiscrete element simulationMeasuring instrument

The invention discloses a verification device and method for simulating a concrete slump form by discrete elements, and belongs to the technical field of building material performance detection. The verification device comprises a supporting frame, a pair of Y-direction guide rails arranged on the supporting frame in parallel, a first driving brake assembly arranged on the Y-direction guide rails,an X-direction guide rail of which the two ends are fixedly connected with the first driving brake assembly, a second driving brake assembly arranged on the X-direction guide rail, and a distance measuring instrument arranged below the second driving brake assembly and a control terminal which comprises a control module, a data acquisition and calculation module and a data processing module. According to the verification device and method, by measuring the distance of a surface measuring point after the concrete slump, calculating the three-dimensional coordinate of the measuring point, converting the three-dimensional coordinate of the measuring point into a polar coordinate, fitting the polar coordinate into a longitudinal section diagram of the concrete slump form simulated by discreteelements, the concrete slump form simulated by the discrete elements is verified, and a quantitative evaluation index has the reasonability.

Owner:SHANGHAI CONSTRUCTION GROUP

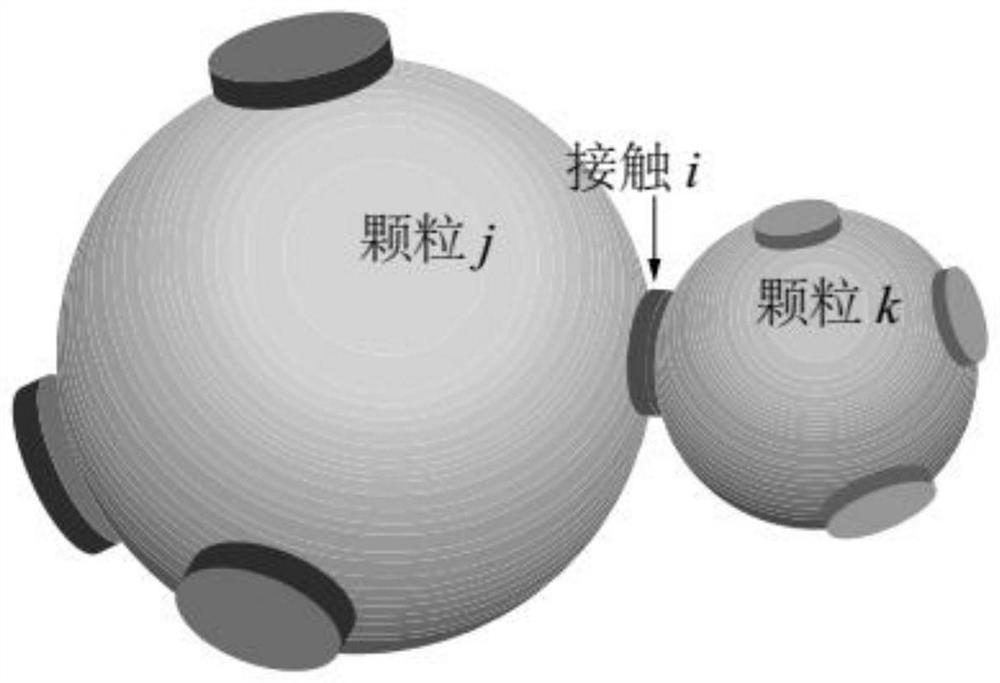

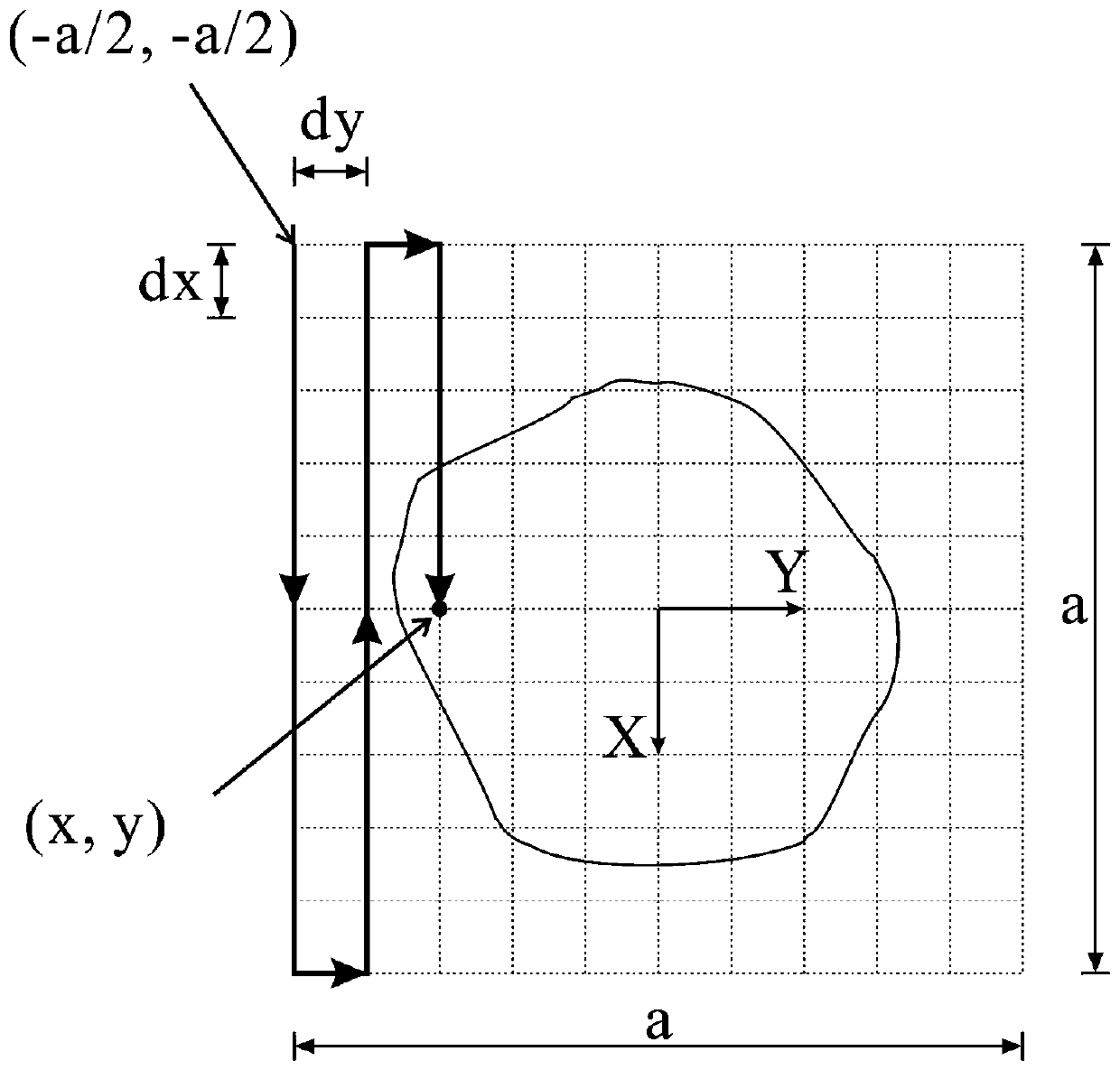

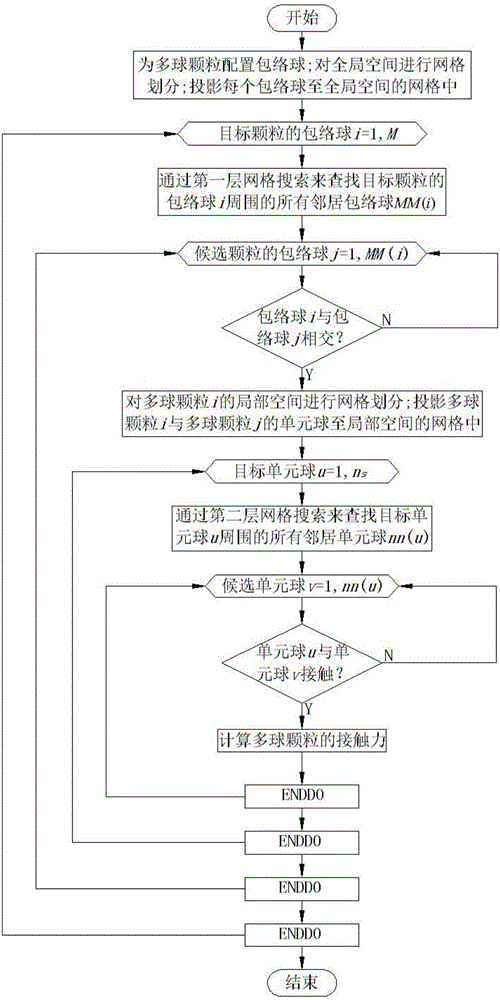

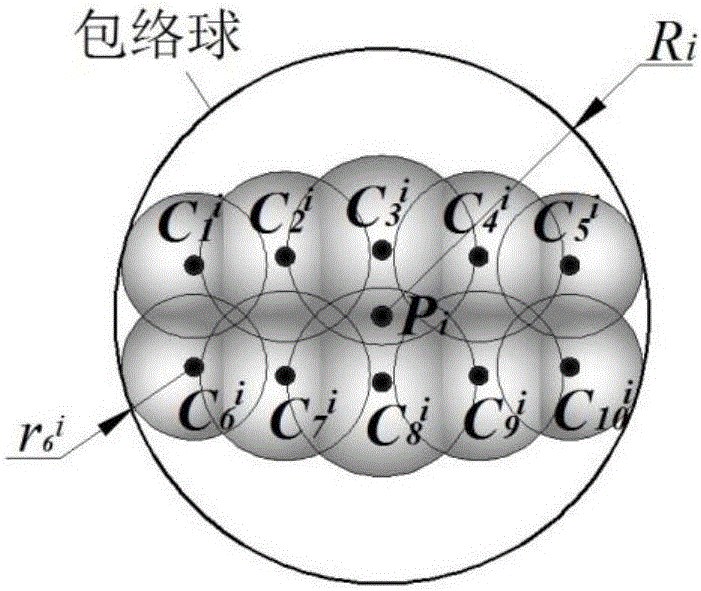

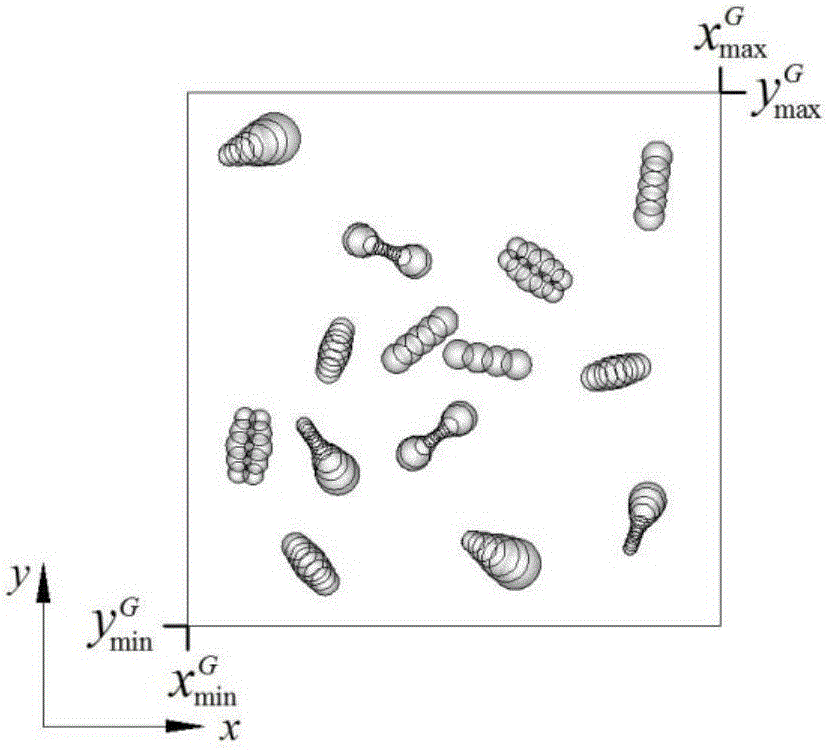

Multi-ball particle two-layer grid search contact detection method in discrete element simulation

ActiveCN105787998AAvoid contact detectionReduce memory consumptionDetails involving 3D image data3D modellingDiscrete element simulationComputer science

The present invention relates to a multi-ball particle two-layer grid search contact detection method in discrete element simulation. The method comprises the following steps: a global space is divided into square or cube girds with the size of D; performing a first layer grid search, if the enveloping ball of a target particle is intersected with the enveloping ball of a certain candidate particle, the first layer grid search is completed, or else, the intersection detection between the enveloping ball of the target particle and the enveloping balls of other candidate particles is performed; and when the enveloping ball of the target particle and the enveloping balls of other candidate particles are intersected, a square or cube local space with the size of D+d is divided into square or cube grids with the size of d for the usage of a second layer grid search, and the contact between the cell ball of the target particle and the cell balls of the candidate particles is detected. The multi-ball particle two-layer grid search contact detection method in discrete element simulation keeps the time consuming of the contact detection without increasing while significantly decreasing memory consumption of the contact detection and provides an effective technological means for the large-scale application of the multi-ball particle discrete element simulation in the industrial field.

Owner:WUHAN UNIV

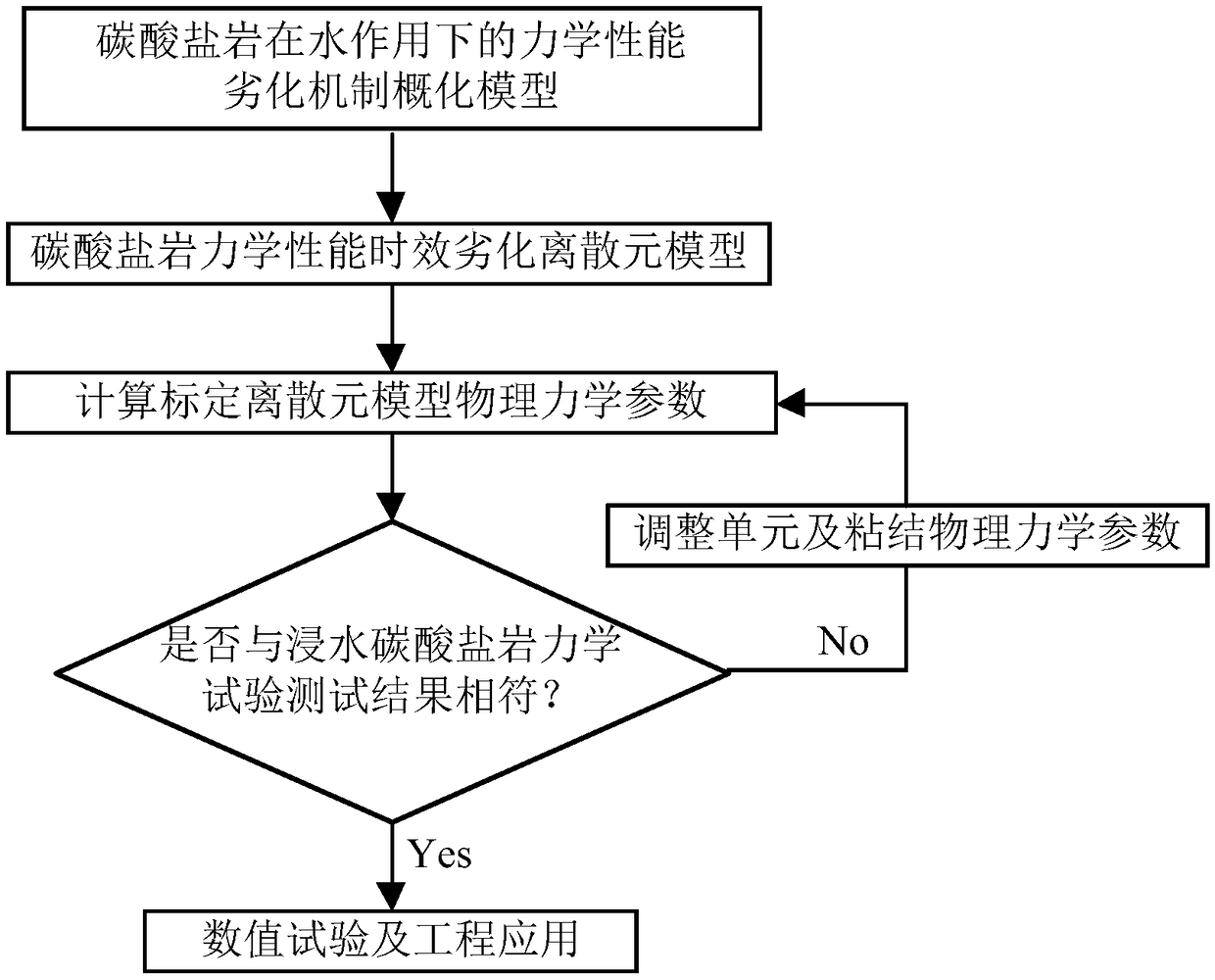

A numerical simulation method for aging degradation of mechanical properties of carbonate rock under water action

ActiveCN109344482ALow costStrong expandabilityDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationGeomorphology

the invention discloses a numerical simulation method for aging degradation of mechanical properties of carbonate rock under water action which includes such step as establishing a generalized model of mechanical property deterioration mechanism of carbonate rock under the action of water, setting up the generalized model of mechanical property deterioration mechanism of carbonate rock under the action of water, setting up the generalized model of mechanical property degradation mechanism of carbonate rock under the action of water. Step 22, establishing a discrete element model of aging deterioration of mechanical properties of carbonate rock under different immersion conditions according to the mechanism generalization model obtained in the step 1, and obtaining a quantitative correlation of mechanical properties with time of bonding between blocks of polygonal blocks under different immersion conditions; step 3, calibrating that mechanical parameters of the discrete element model; Carbonate rock mechanics tests under different immersion conditions and immersion time were carried out to calibrate the mechanical parameters of the discrete element model in step 2. Step 4, simulating the mechanical properties of carbonate rock under different immersion conditions by using the calibrated parameters of the discrete element model. The invention truly reflects the carbonate rock-water water interaction principle, a two-stage deterioration model and its discrete element simulation method are proposed.

Owner:HEBEI UNIV OF TECH

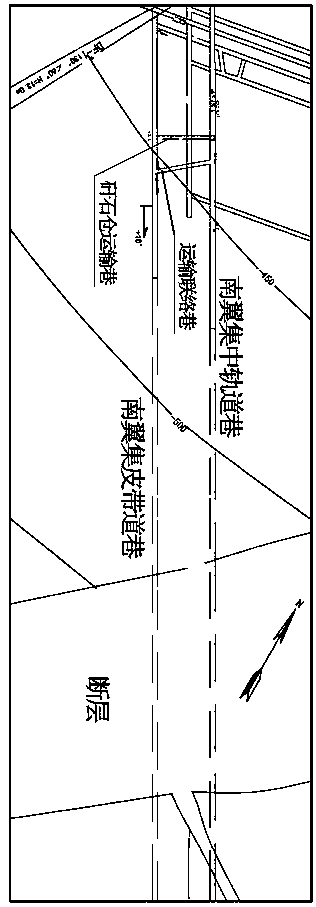

Accurate control method for surrounding rock of coal mine tunnel crossing fault area

ActiveCN110162882AEasy to controlReduce support costsMaterial strength using tensile/compressive forcesUsing mechanical meansLithologyFracture zone

The invention discloses an accurate control method for surrounding rock of a coal mine tunnel crossing fault area, which comprises the following steps of: (1) carrying out ground stress inversion on afault damage area to determine a ground stress distribution rule of the tunnel crossing fault area; (2) taking mudstone of the surrounding rock fault zone of the roadway, carrying out a remolding test, and determining the physical and mechanical properties of the surrounding rock by adopting a geological strength index (GSI) method; (3) adopting a discrete element simulation method to preferablyselect a fault zone surrounding rock control scheme, and determining a precise surrounding rock control method for a fracture zone of the coal mine tunnel crossing fault ; and (4) observing the mine pressure of the roadway surrounding rock. Aiming at the characteristics of quick rock stratum lithology change and rock stratum crushing of a fault fracture zone, the stress distribution rule and the surrounding rock type of the roadway are mastered through geomechanics and a numerical simulation method, and accurate control over the surrounding rock of the roadway is achieved.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD +1

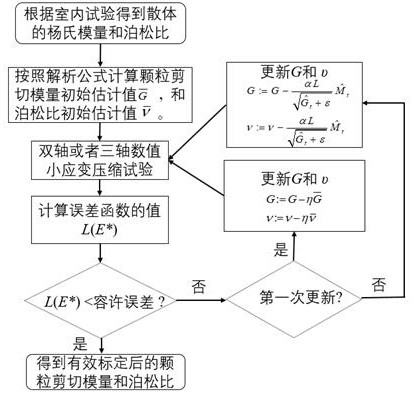

Automatic calibration method for discrete element hertz contact parameters during geotechnical material simulation

InactiveCN111610091AEasy to analyzeConvenient researchMaterial strength using tensile/compressive forcesDesign optimisation/simulationDiscrete element simulationShear modulus

The invention discloses an automatic calibration method for discrete element hertz contact parameters during geotechnical material simulation, and the method comprises the following steps: substituting a target macroscopic parameter calibrated by a discrete element into an analytical formula to calculate a particle shear modulus and a Poisson's ratio, taking the particle shear modulus and the Poisson's ratio as initial estimation values of particle parameters, and establishing a numerical triaxial or biaxial test to obtain a macroscopic Young modulus and a Poisson's ratio; calculating the sizeof an error function, and judging whether particle parameters are updated or not; adopting different strategies according to different iteration times; during primary iteration, manually giving smalldisturbance in direct proportion to an initial estimated value; and adopting an adaptive moment estimation strategy to update parameters in multiple iterations. An embodiment shows that after finiteiteration of a single-particle-size or multi-particle-size discrete element sample, errors of calibration parameters are effectively controlled within a certain range. The calibration method has the advantages of automatic calibration capability, strong convergence capability and high calibration efficiency, and can effectively solve the calibration problem of the Hertz deformation parameter whenthe discrete element simulates the rock-soil body material.

Owner:TAIYUAN UNIV OF TECH

Discrete element modeling of rock destruction under high pressure conditions

ActiveUS8150667B2Way accurateSimple designDrill bitsConstructionsDiscrete element simulationWell drilling

Discrete Element Modeling (DEM) of rock subject to high confining pressures, such as in a subterranean drilling environment, may be used to predict performance of cutting structures used in drill bits and other drilling tools, as well as of the tools themselves. DEM may also be used to create “virtual” rock exhibiting specific drillability characteristics with or without specific reference to any actual rock, for purposes of assessing cutting efficiency of various cutting structure configurations and orientations, as well as of drilling tools incorporating same.

Owner:BAKER HUGHES INC

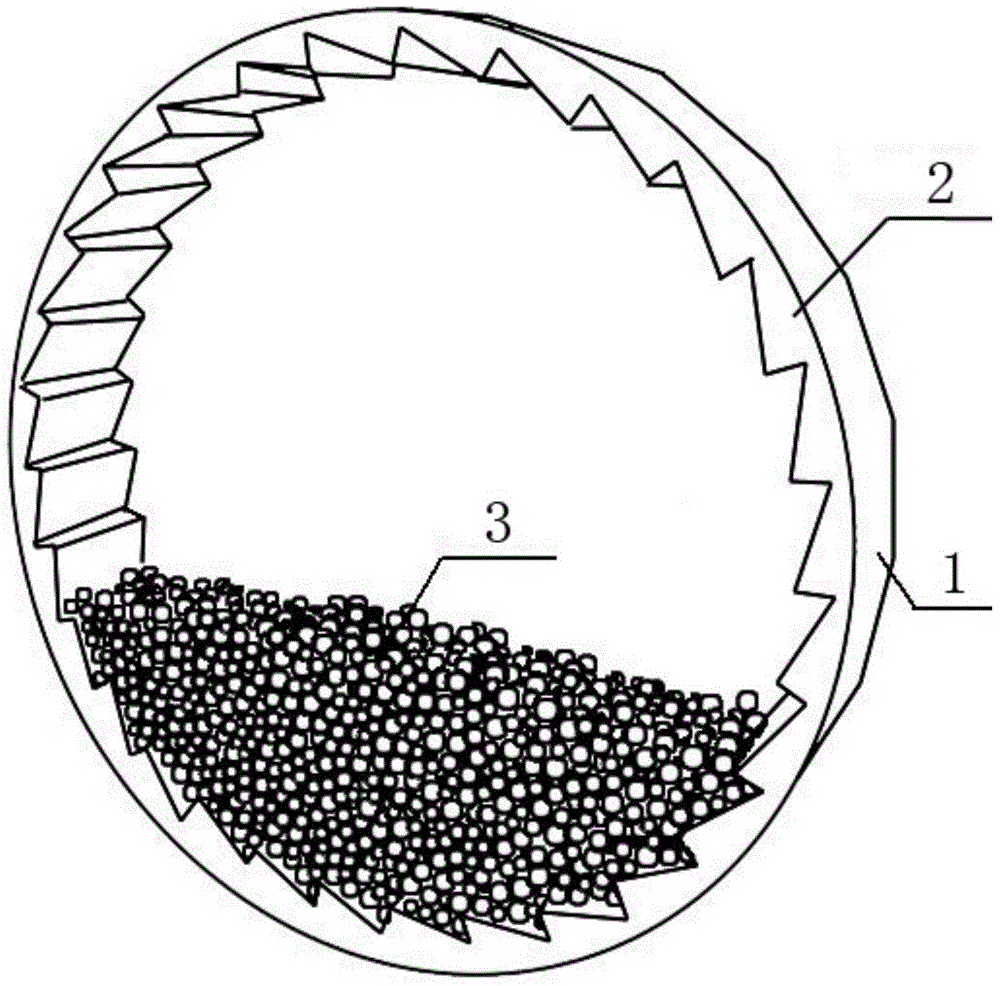

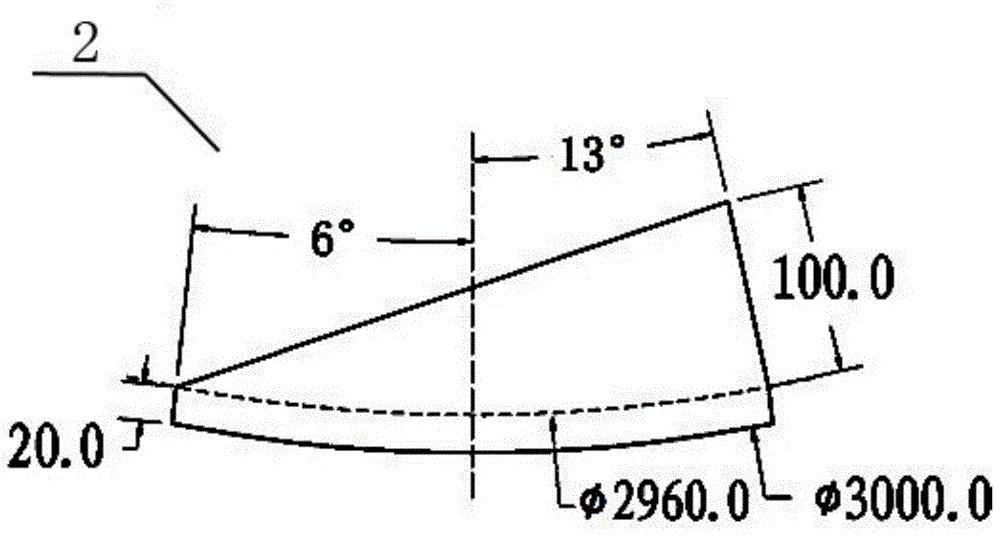

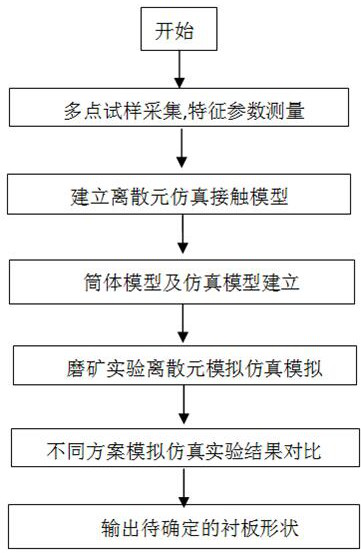

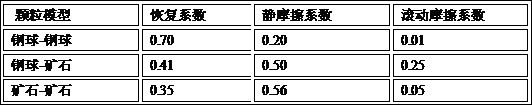

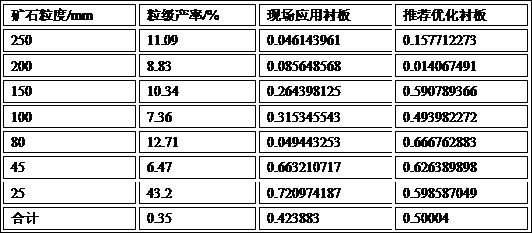

Semi-autogenous mill lining plate shape optimization method based on discrete element method

PendingCN112347689AGuaranteed accuracyGuaranteed reasonablenessDesign optimisation/simulationGrain treatmentsDiscrete element simulationDielectric

The invention relates to a semi-autogenous mill lining plate shape optimization method based on a discrete element method, and belongs to the technical field of mineral processing equipment. The method includes: carrying out multi-point sample collection and parameter measurement on characteristic parameters of physical and mechanical properties of ore to be ground, steel ball dielectric materialcharacteristics, material characteristics of a semi-autogenous mill cylinder lining plate and structural characteristics of the ore to be ground entering the semi-autogenous mill; establishing an irregular ore model and a medium particle model, and establishing a discrete element simulation contact model; establishing a semi-autogenous mill cylinder three-dimensional solid model, and establishinga discrete element simulation model; adopting a discrete element simulation model to carry out different semi-autogenous mill lining plate shape analog simulation experiments, and obtaining collisionenergy loss, collision probability and motion conditions of a semi-autogenous mill load under different lining plate shape conditions; and determining proper shape parameters of the lining plate of the semi-autogenous mill. An effective technical means is provided for large-scale application of semi-autogenous mill lining plate shape optimization and discrete element simulation in the industrial field.

Owner:KUNMING UNIV OF SCI & TECH +1

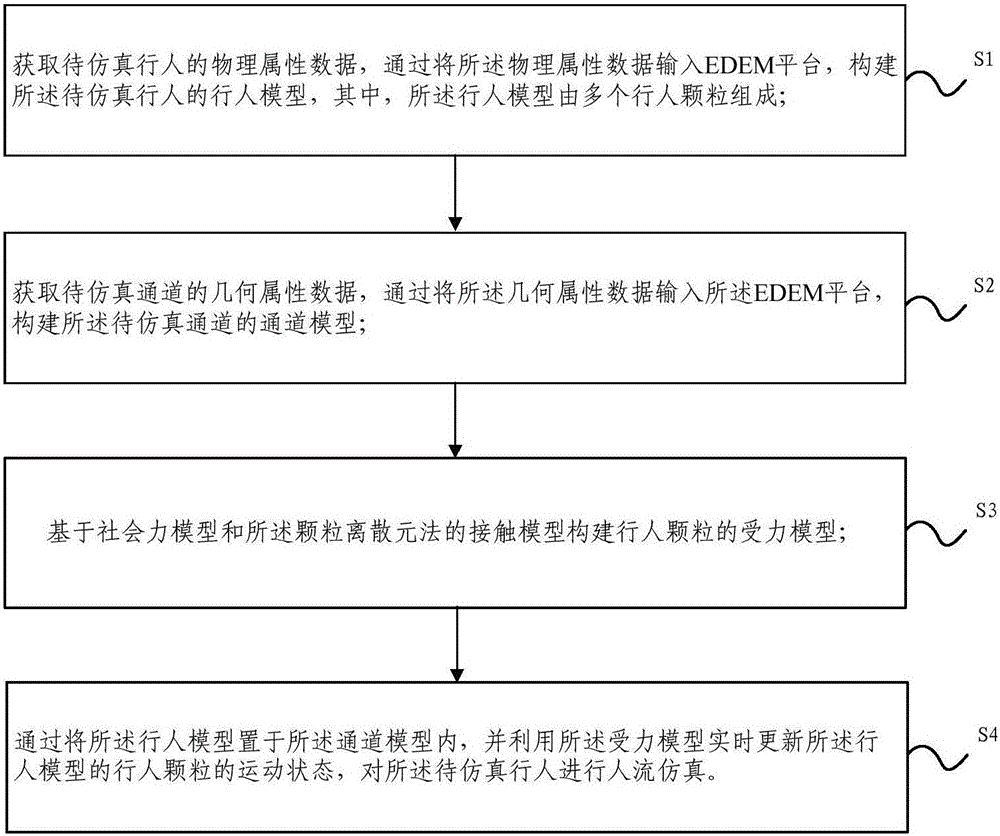

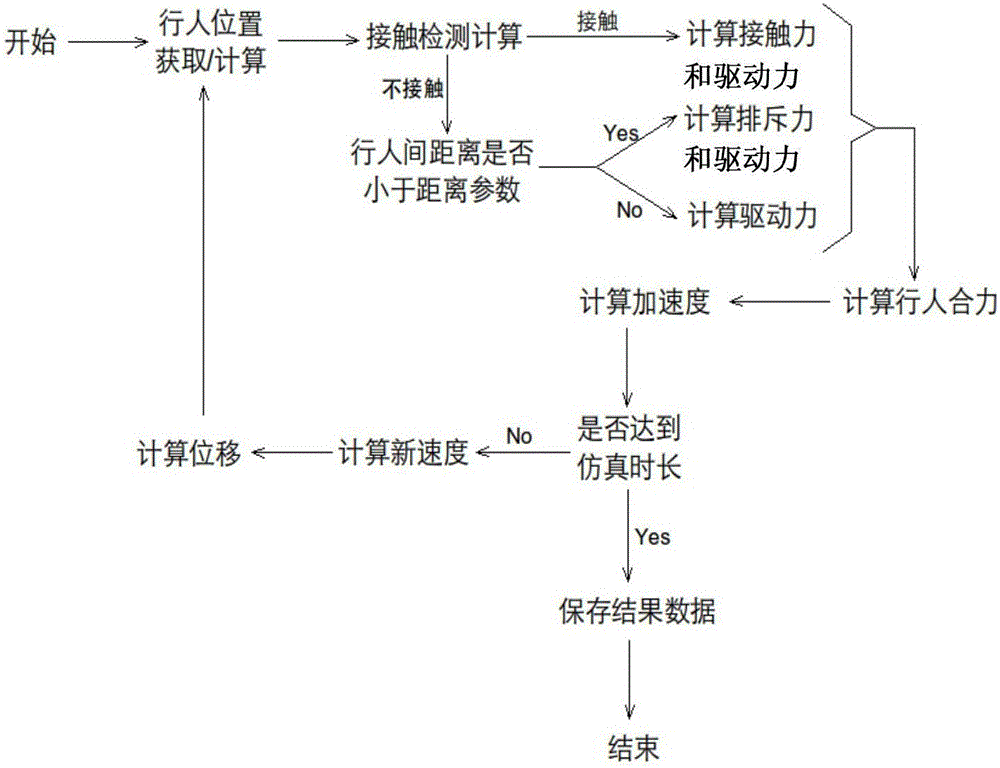

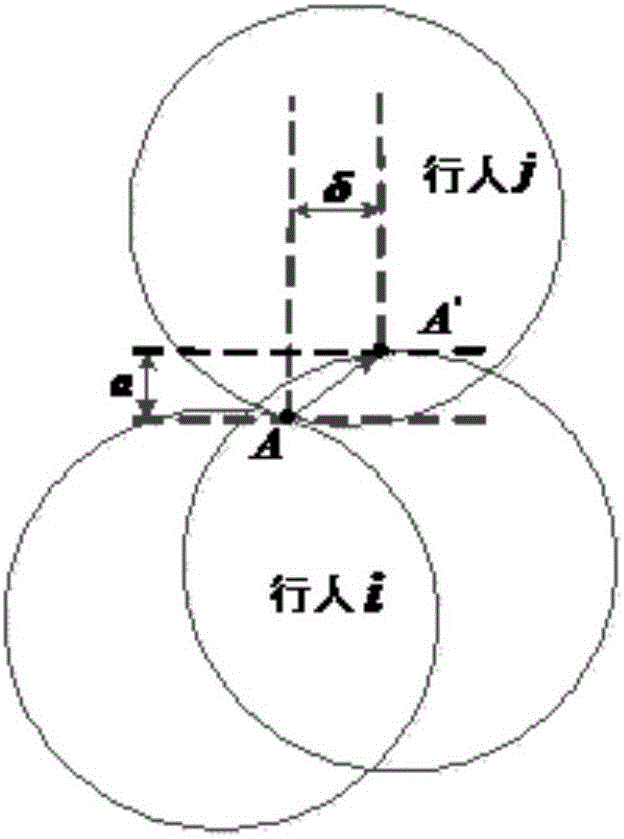

Pedestrian simulation method and device based on discrete element simulation platform

The invention discloses a pedestrian simulation method and device based on a discrete element simulation platform. Large-scale pedestrian movement can be simulated, and deep research and development on the large-scale pedestrian movement by related personnel are supported. The method comprises the steps that firstly, physical attribute data of pedestrians to be simulated are obtained, and the physical attribute data are input into the discrete element simulation platform to structure a pedestrian model of the pedestrians to be simulated; secondly, geometric attribute data of a channel to be simulated are obtained, and the geometric attribute data are input into the discrete element simulation platform to structure a channel model of the channel to be simulated; thirdly, a pedestrian particle stress model is structured based on a social force model and a contact model of a particle discrete element method; fourthly, the pedestrian model is arranged in the channel model, the stress model is used for updating the movement state of pedestrian particles of the pedestrian model in real time, and thus pedestrian stream simulation is carried out on the pedestrian to be simulated.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

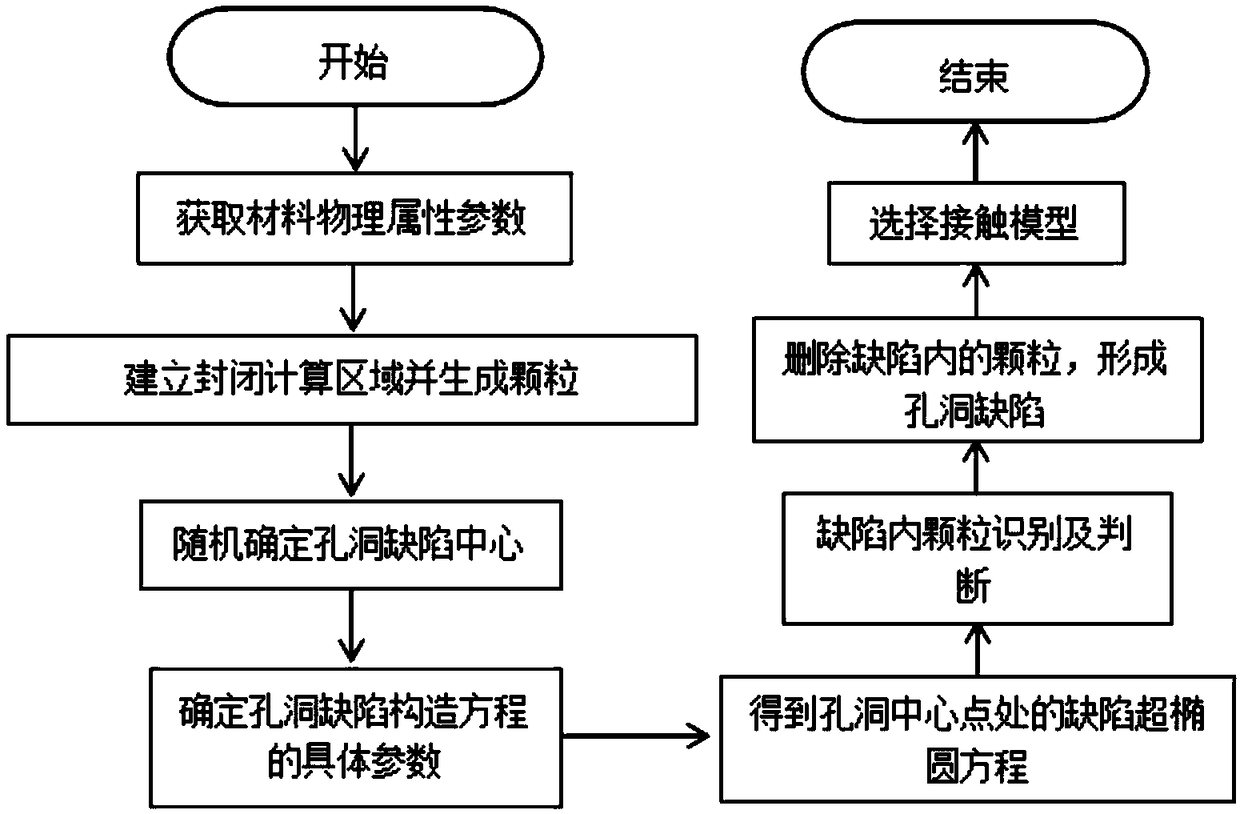

A discrete element modeling method for stochastic void defect materials based on hyperelliptic equation

ActiveCN109376454ADesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationGraphics

The invention provides a discrete element modeling method for stochastic void defect materials based on hyperelliptic equation, which can randomly generate ellipse, rhombus, star or rectangular cavitydefects with different flatness by controlling parameters, and is used for discrete element simulation research of hard and brittle materials. The concrete steps are as follows: defining the main physical parameters of the material, generating particles in a closed calculation area and assigning microscopic contact property parameters to the particles, and randomly determining a certain number ofvoid defect centers with random positions; Based on the hyperelliptic equation, the hole defect patterns with different shapes are constructed at each center point. Delete the particles in each holedefect pattern, select the appropriate contact model, delete the wall of the closed area, and form the discrete element model of the hole defect. The method of the invention is simple and feasible, and the size, shape, angle and flatness of the formed hole defects are controllable, so that the generated material model is closer to the reality, so that the simulation calculation result is more accurate, and the simulation effectiveness is improved.

Owner:XIANGTAN UNIV

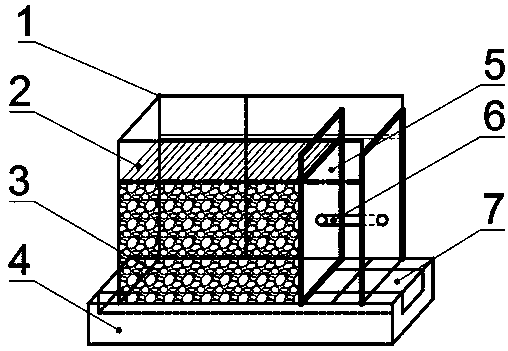

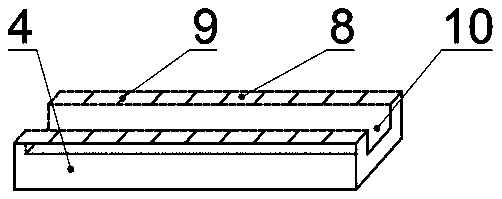

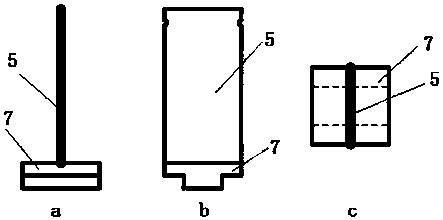

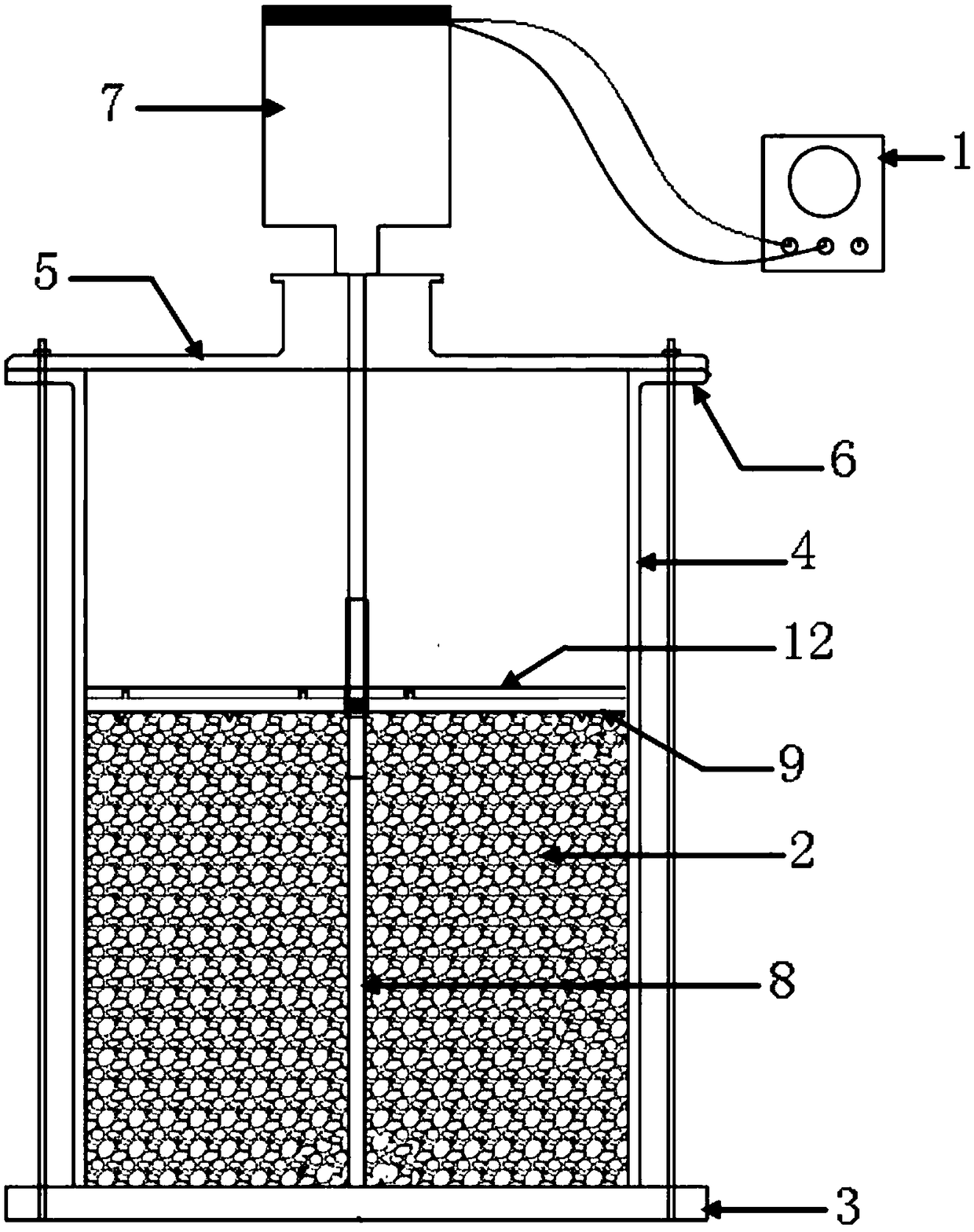

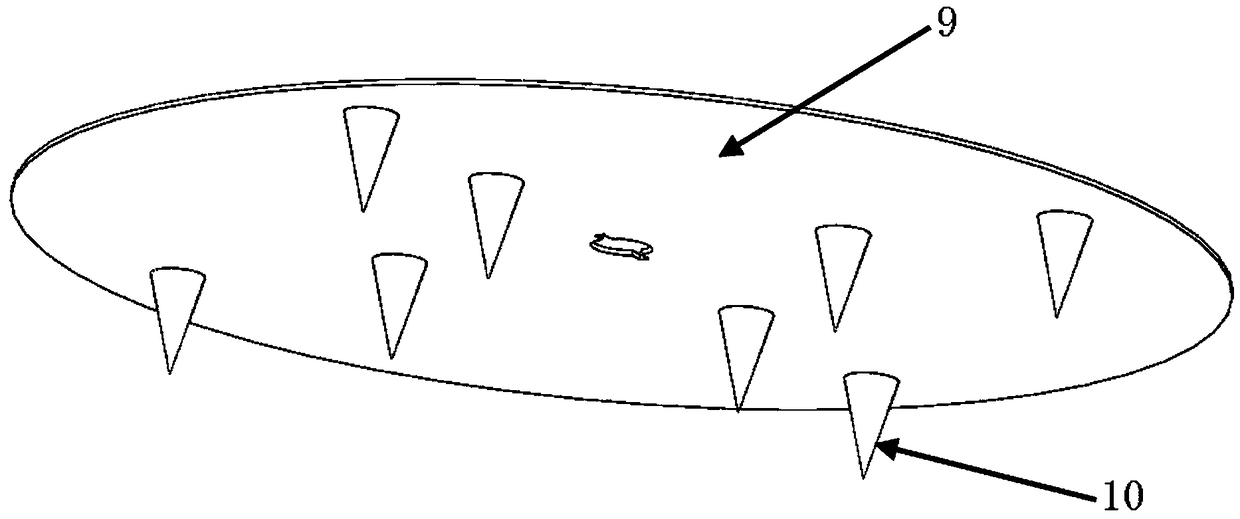

Testing device and testing method for two-dimensional similar soil model

PendingCN110468892AIncrease resistance momentFoundation testingDiscrete element simulationSoil model

The invention discloses a testing device and a testing method for a two-dimensional similar soil model. The testing device comprises a two-dimensional similar soil model box and similar soil. The two-dimensional similar soil model box comprises an outer frame, a fixed baffle plate system, similar soil, a model box bearing table, a movable baffle plate system, a jack, a T-shaped plate, double nosegirders, a T-shaped plate limiting groove and a chute. The multifunctional model box can change the dimension of a box body by changing the position of the T-shaped plate and different members can beprefabricated on the upper part of the T-shaped plate to simulate different tests. Filler similar soil adopts an oval cross section of a bar body to increase the resistant torque, so that the similarsoil is closer to a real soil body. Different soil body weights can be simulated by adjusting the proportioning ratio of different materials. The testing device can be widely applied to a two-dimensional discrete element simulation test.

Owner:ZHONGBEI UNIV

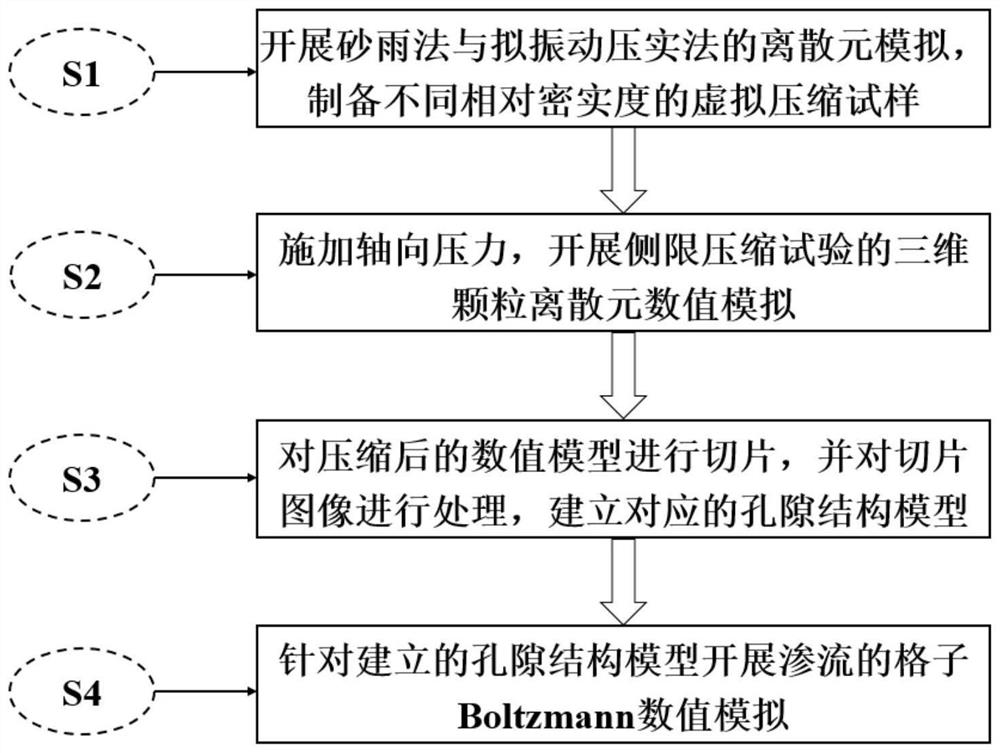

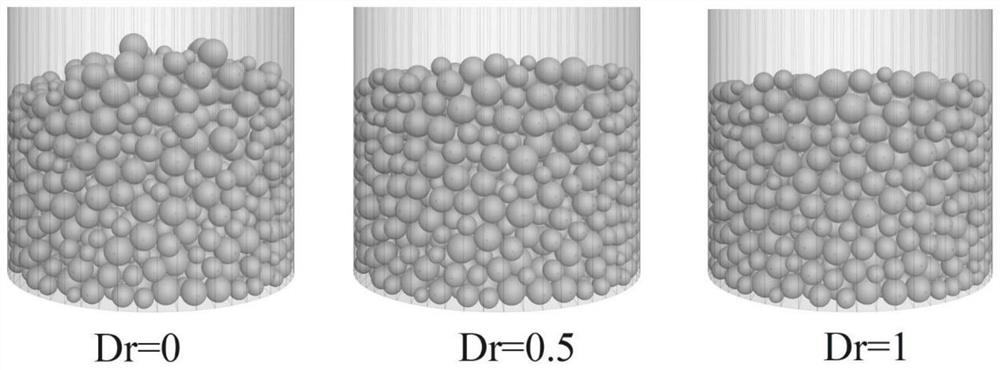

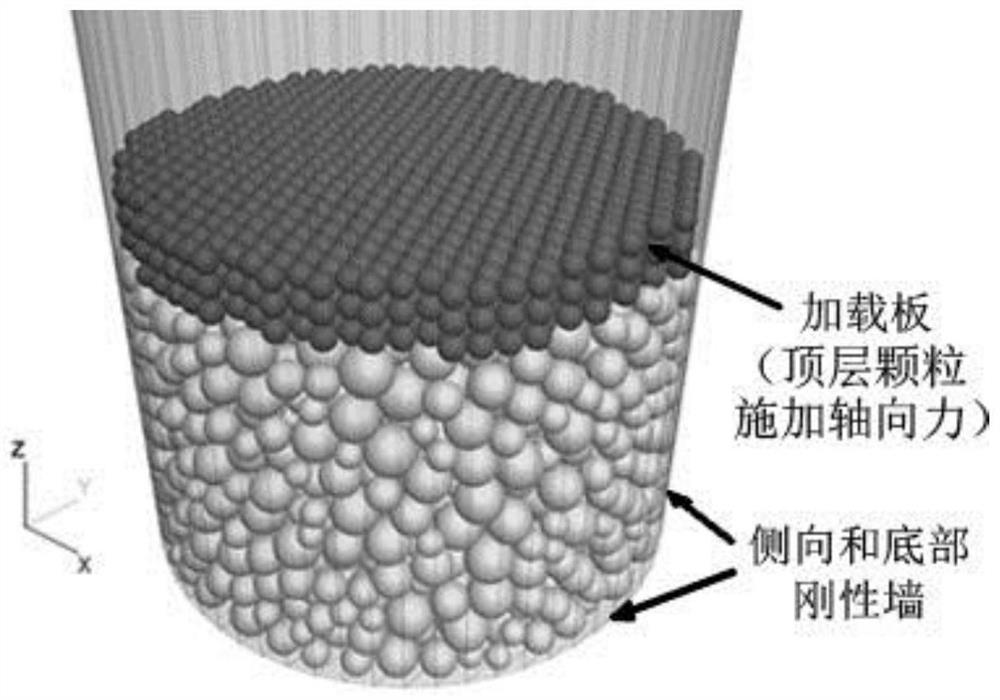

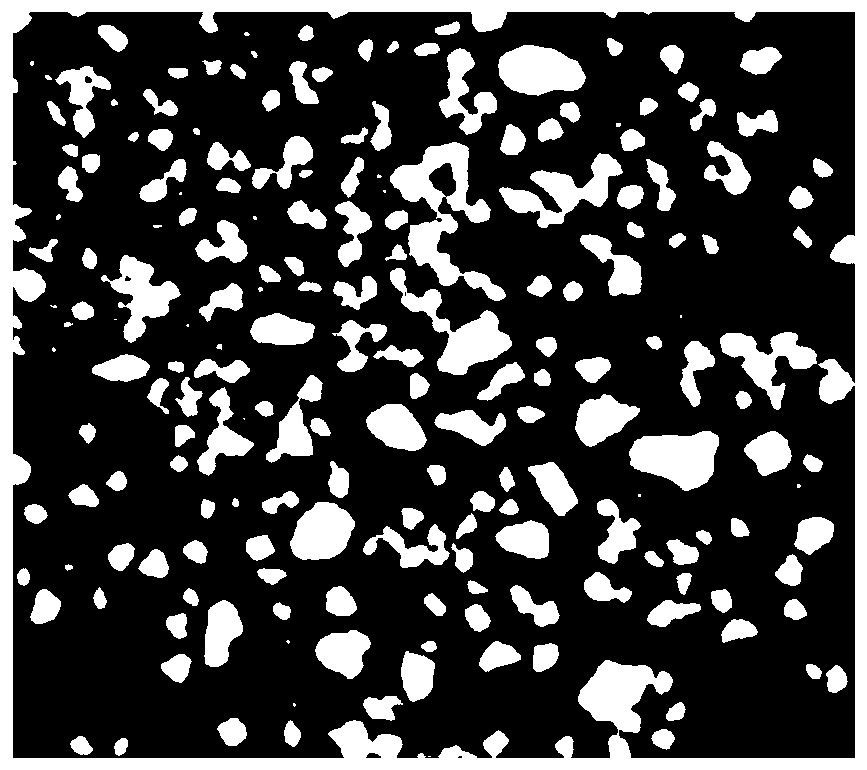

Compression penetration test numerical simulation method based on particle discrete element and lattice Boltzmann

ActiveCN113221431AEasy accessUniform compression ratioDesign optimisation/simulationCAD numerical modellingDiscrete element simulationAxial pressure

The invention discloses a compression penetration test numerical simulation method based on particle discrete elements and lattice Boltzmann, and the method comprises the following steps: S1, carrying out three-dimensional particle discrete element simulation of a sand rain method and a quasi-vibration compaction method, and preparing virtual compression samples with different relative densities; s2, applying axial pressure to the virtual compression sample step by step, and performing three-dimensional particle discrete element numerical simulation of a lateral confinement compression test to obtain a discrete element numerical model after compression stabilization under each stage of pressure; s3, respectively slicing the discrete element numerical model after pressure compression at each stage, processing a slice image, and establishing a corresponding pore structure model; and S4, carrying out lattice Boltzmann numerical simulation of seepage aiming at the established pore structure model. According to the invention, the defects of the existing indoor compression penetration test technology are overcome, the principle is simple, the implementation is convenient, the calculation efficiency is high, the application effect is good, and the feasibility and superiority of the compression penetration test numerical simulation method based on the particle discrete element and the lattice Boltzmann are verified.

Owner:HUBEI POLYTECHNIC UNIV

Method for constructing an irregular sand particle model based on discrete element simulation

InactiveCN108710769AVerify validityHigh precision characteristicsDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationRegular pattern

A method for constructing an irregular sand particle model based on discrete element simulation includes the steps of: carrying out statistical analysis on sand particles with particle size greater than 4.75 mm, obtaining a statistical law related to sand particle shape characteristics, establishing a statistical model, and determining relevant parameter value of sand particle shape distribution;according to the random distribution law of sand particles in the actual embankment filling, obtaining the distribution characteristics of sand particles such as azimuth angle and center position coordinate; performing secondary development on PFC2D3.0 by FISH language according to the parameters of sand particle shape distribution and the characteristics of sand particle distribution, and realizing the establishment of the random sand particle model. The invention uses the built-in FISH language programming to realize that the two-dimensional model of the sand particle is more in line with the actual sand particle shape when simulating, and the large-grain sand particle discrete element modeling is determined by the sand shape rule, so as to achieve the purpose of adopting the discrete element method to analyze the meso-mechanical characteristics of the sand particle.

Owner:HUBEI UNIV OF TECH

Sand abradability test experimental device and calibration experiment method of sand abrasion coefficient

InactiveCN108645738AAccurate calibration of wear coefficientInvestigating abrasion/wear resistanceDiscrete element simulationEngineering

The invention discloses a sand abradability test experimental device and a calibration experiment method of a sand abrasion coefficient. The device comprises a soil body bearing barrel, a driving mechanism, an abrasion mechanism, a loading mechanism and a servo control device, wherein the driving mechanism is controlled by the servo control device to supply different revolving speeds for the abrasion mechanism, loading force is supplied for the abrasion mechanism through the loading mechanism, so that sand in the soil body bearing barrel is used for abrading the abrasion mechanism, and the abrasion loss data is measured. The device can be used for researching the abrasion law and influence effect of sand, which has different water contents and different grain gradations, on a shield cuttermaterial; the cutter abrasion loss at different revolving speeds and bearing pressure can be measured to draw an abrasive characteristic curve, by adjusting an abrasion coefficient in discrete element simulation software, the abrasive tests under different conditions can be simulated to obtain the same characteristic curves, the corresponding abrasion coefficient of the sand for experiments to acutter can be accurately calibrated, and necessary data can be provided for subsequent discrete elements for emulating, simulating and researching shield cutter abrasion.

Owner:BEIJING JIAOTONG UNIV

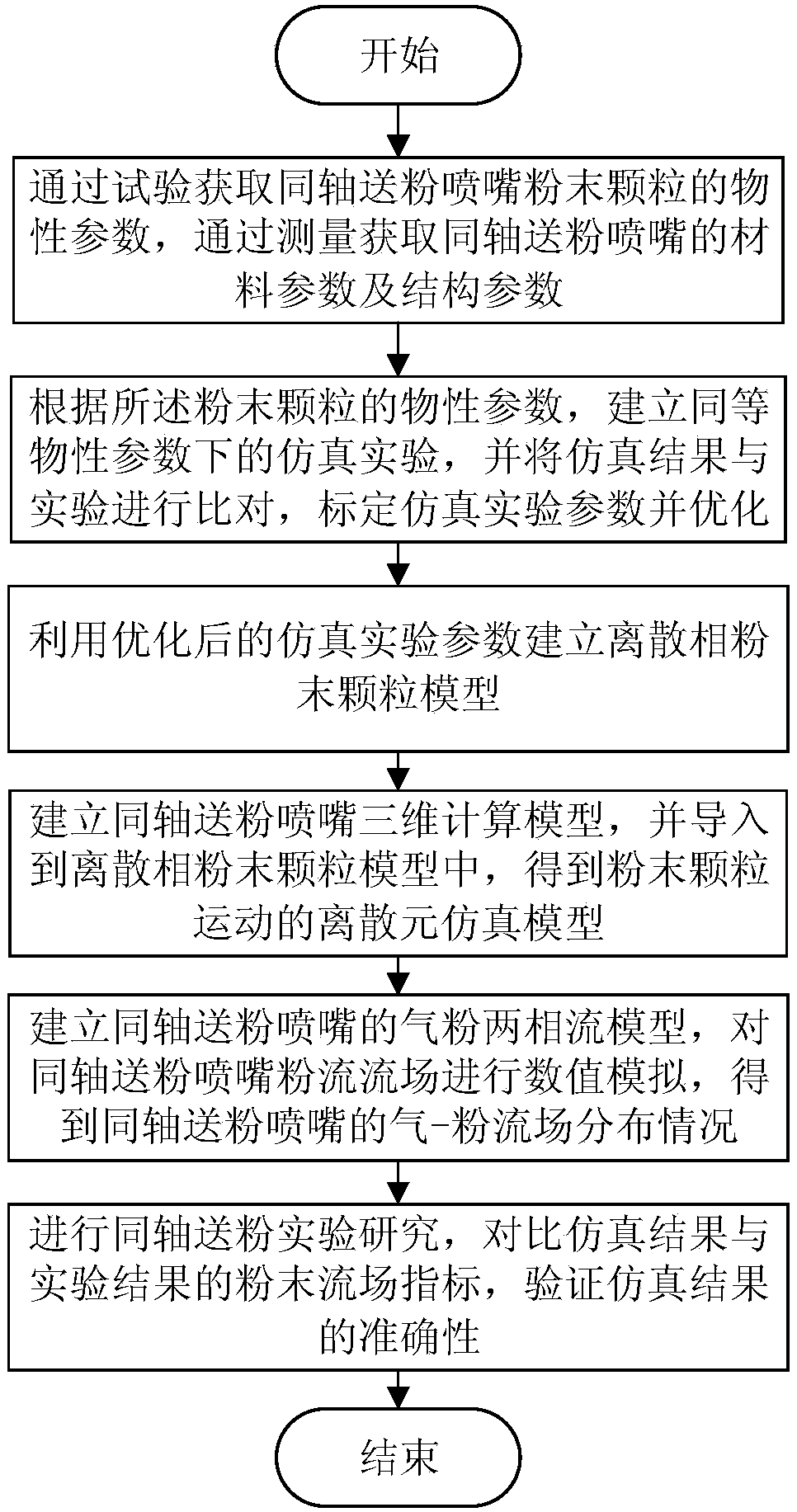

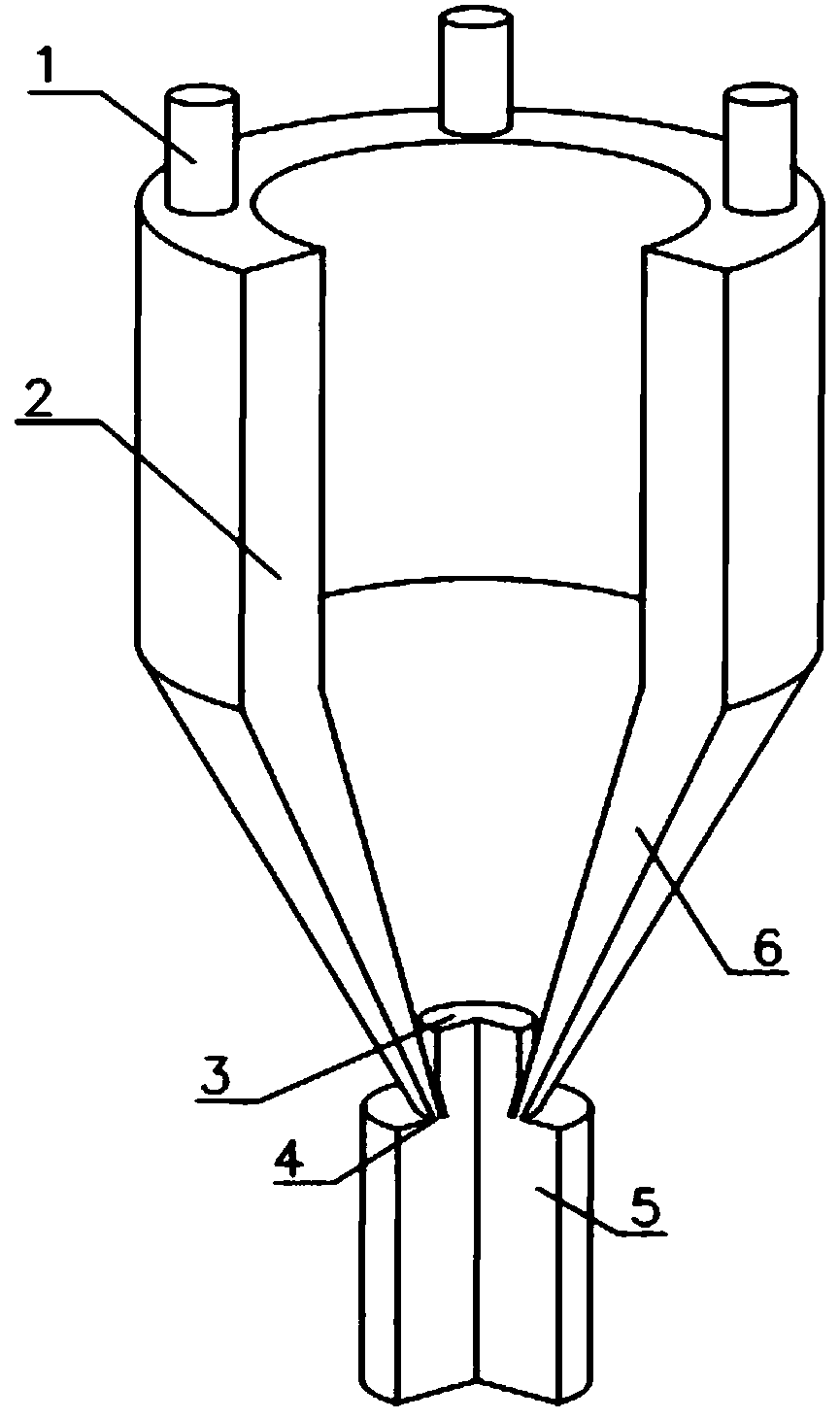

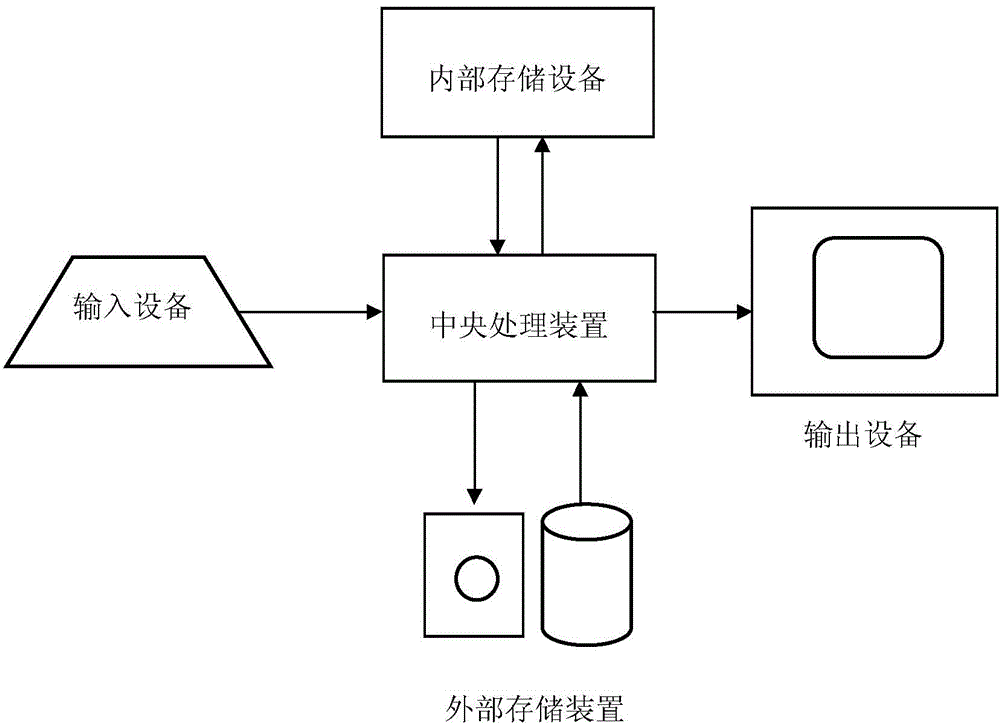

Numerical simulation method of powder flow field of coaxial powder feeding nozzle of laser additive re-manufacturing

ActiveCN108829960AImprove forming qualityAccurate distributionDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationManufacturing technology

The invention provides a numerical simulation method of a powder flow field of a coaxial powder feeding nozzle of laser additive re-manufacturing, and relates to the technical field of laser manufacturing. The method comprises the following steps: firstly, obtaining physical powder parameters and material parameters and structural parameters of the coaxial powder feeding nozzle; and secondly, performing parameter calibration to obtain simulation experimental parameters, establishing a three-dimensional calculation model of the coaxial powder feeding nozzle according to the structural parameters of the coaxial powder feeding nozzle, establishing a powder particle model and a discrete element simulation model of powder particle motion of the coaxial powder feeding nozzle by using a discreteelement method, then establishing a gas-powder two-phase model of the coaxial powder feeding nozzle by using a computational fluid mechanics method, and then obtaining a gas-powder flow field distribution condition of the coaxial powder feeding nozzle. According to the numerical simulation method of the powder flow field of the coaxial powder feeding nozzle of laser additive re-manufacturing provided by the invention, the influence of the action relationship between the gas-powder two-phase, the physical properties of the discrete phase powder particles, and other factors on the powder flow field is fully considered, so that the powder flow field distribution condition of the coaxial powder feeding nozzle is accurately obtained.

Owner:LIAONING TECHNICAL UNIVERSITY

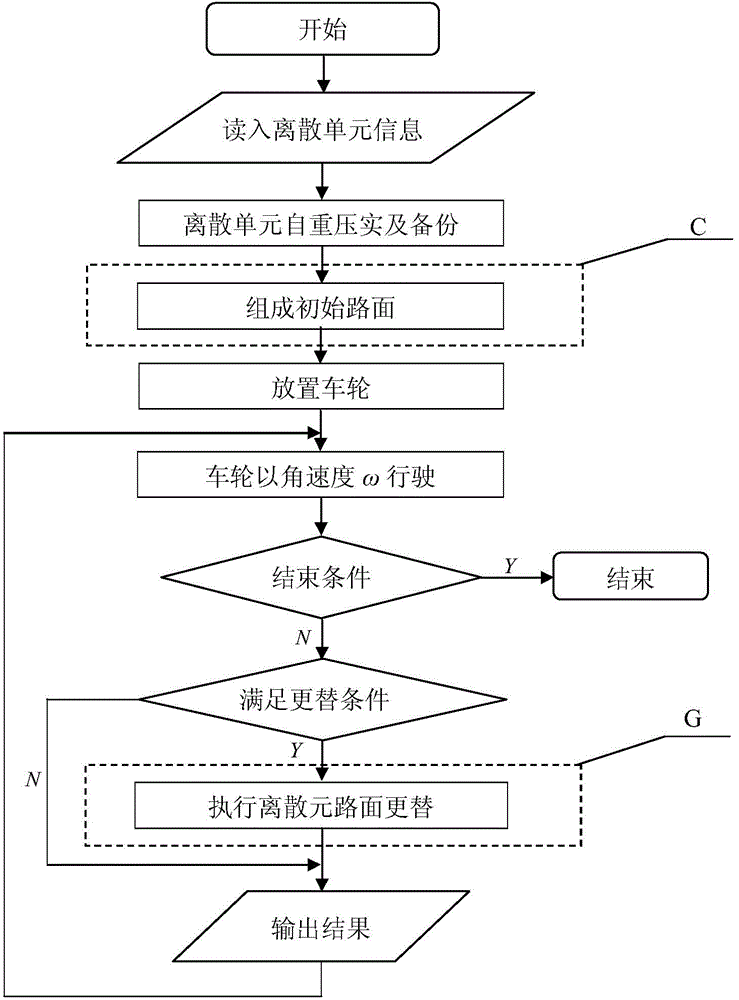

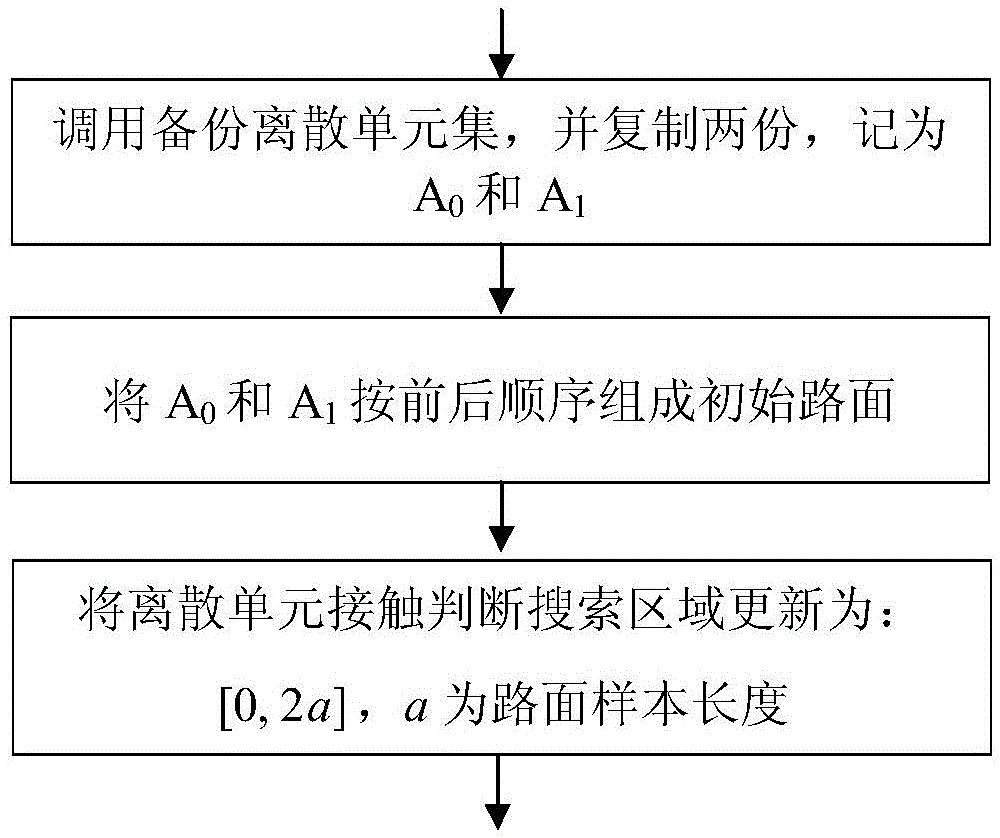

Discrete element pavement replacement method for analyzing driving performance of wheel on sand and stone pavement

InactiveCN103955560AHas engineering application valueSpecial data processing applicationsDiscrete element simulationStable state

The invention provides a discrete element pavement replacement method for analyzing the driving performance of a wheel on a sandstone pavement. The method comprises the steps of generating a discrete element set within a given space range, enabling the discrete element set to reach a stable state under the dead weight effect of the discrete element set, then backuping the discrete element set which is of a pavement sample block; copying the well backuped pavement sample block for two, forming an initial pavement in front and rear sequence and keeping the length of the initial pavement to be 2 times that of the pavement sample block; enabling the initial position of the wheel to be in the middle of the pavement sample block, and enabling the wheel to drive to a second pavement sample block from the first pavement sample block, when the driving distance of the wheel equals to the length of the pavement sample block, deleting the first pavement sample block, and meanwhile paving the same pavement sample block in front of the wheel driving direction. According to the discrete element pavement replacement method, discrete element simulation to sandstone pavement in the wheel driving performance analysis can be achieved, and the model scale is always kept within 2N discrete elements. Therefore, the discrete element analysis is enabled to have an engineering application value.

Owner:SOUTH CHINA UNIV OF TECH

Discrete element method-based double-layer porous asphalt pavement drainage characteristic analysis method

PendingCN112131805AExpress adhesionPerformance graininessDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationSoil science

The invention relates to a discrete element method-based double-layer porous asphalt pavement drainage characteristic analysis method, and belongs to the technical field of double-layer porous asphaltpavement drainage characteristics. By means of the discrete element simulation technology, the problems that irregular geometrical shapes and surface textures of aggregate are difficult to explain bya continuous medium pavement model, and adhesive force, viscoelastic plasticity, pore microstructure and drainage performance between an upper surface layer and a lower surface layer in a porous asphalt pavement influence each other are solved. According to the method, a double-layer porous asphalt pavement model is established mainly through discrete element software, coupling calculation is conducted on the double-layer porous asphalt pavement model and fluid dynamics software, and the double-layer porous asphalt pavement drainage characteristic rule is obtained through analysis. Accordingto the method, the irregular geometrical shape of the aggregate, the asphalt adhesive force and the granularity and the viscoelastic plasticity of the mixture can be well expressed, the asphalt mortarand gap three-phase structure formed by the drainage asphalt mixture serving as coarse aggregate, fine aggregate and an asphalt cementing material is effectively simulated, and the improvement of a model and drainage characteristic research accuracy is facilitated.

Owner:NANJING FORESTRY UNIV

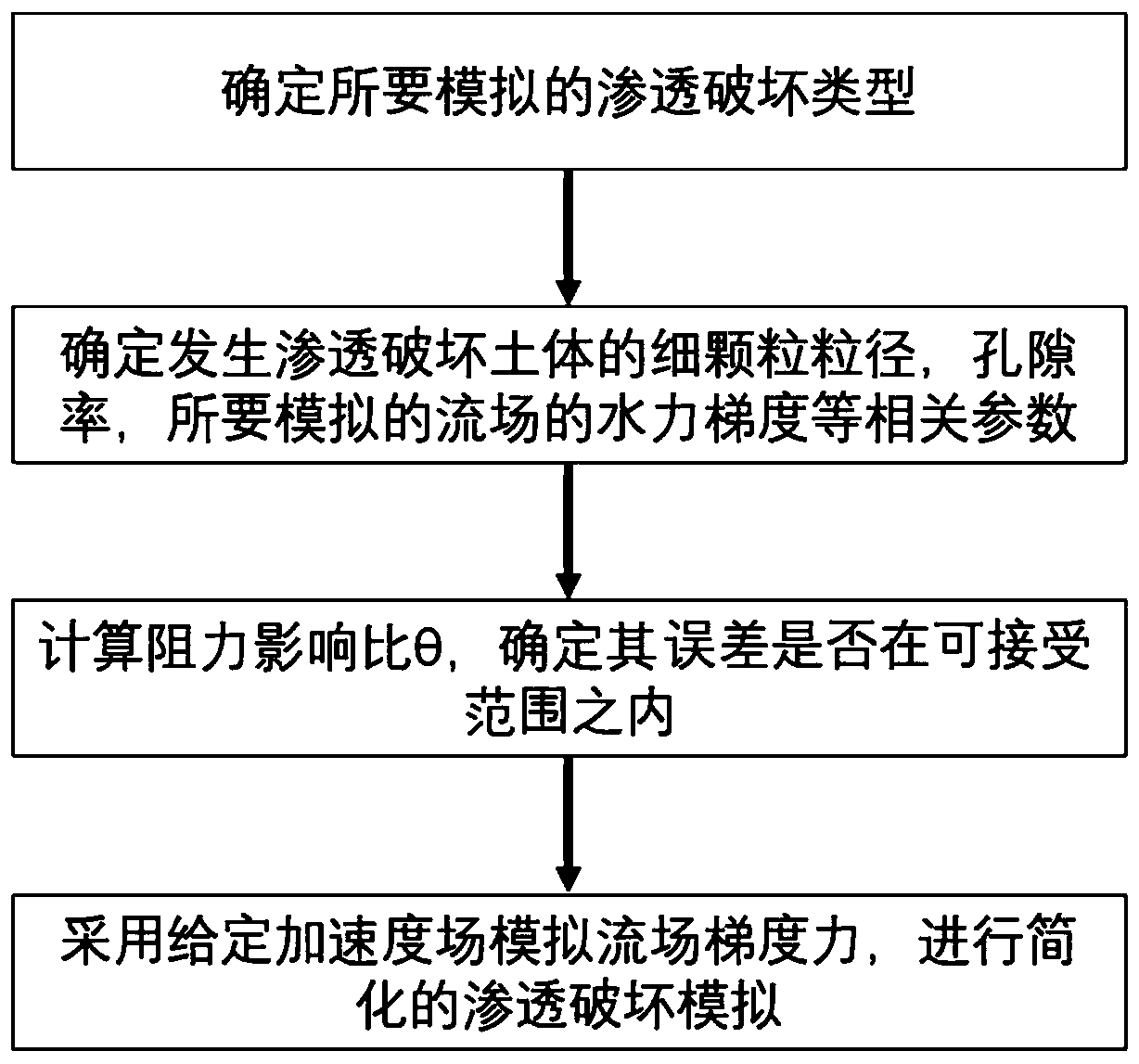

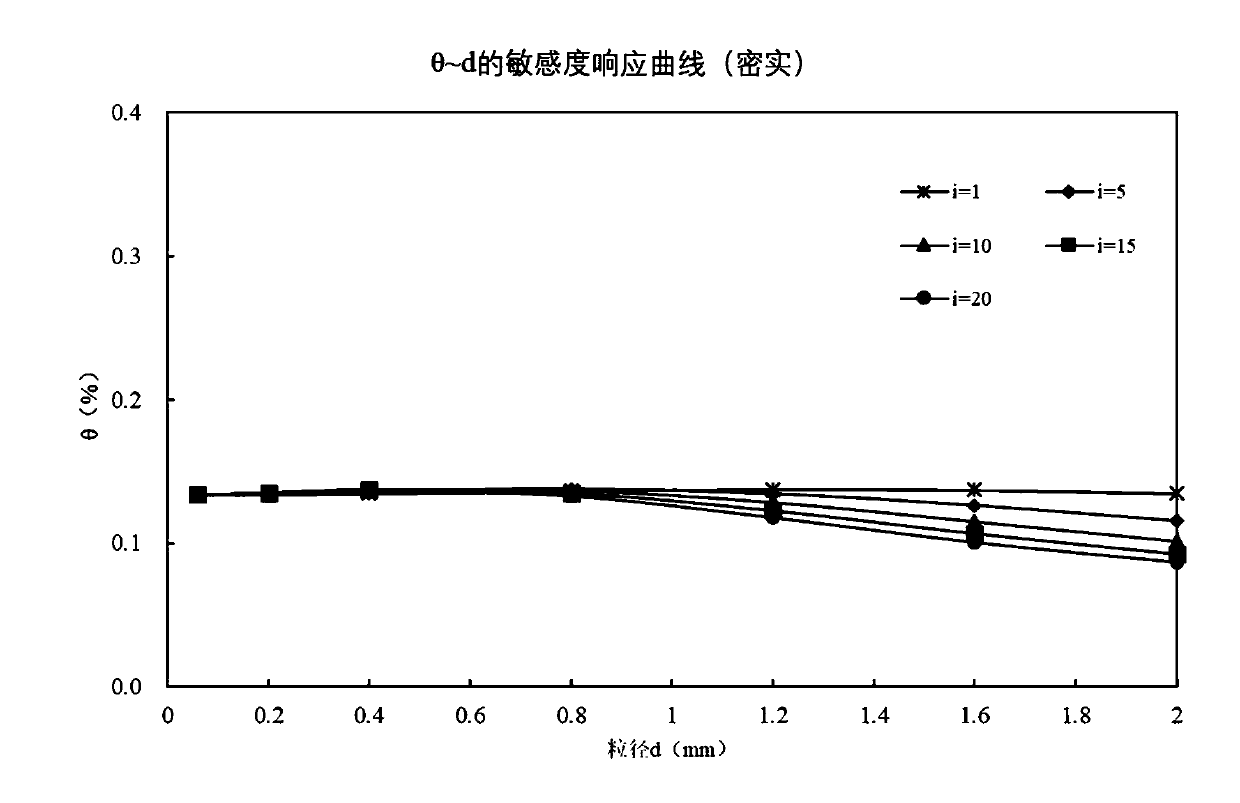

Seepage failure discrete element simulation method

ActiveCN110598323AOmit the fluid-solid coupling calculation processImprove simulation calculation speedSpecial data processing applicationsDiscrete element simulationSolid particle

The invention provides a seepage failure discrete element simulation method which comprises the following steps: in fluid-free solid particle simulation, applying a force related to the hydraulic gradient of a flow field, namely a gradient force, to replace the acting force of a fluid on particles so as to perform simplified simulation on a seepage failure phenomenon. On the basis of achieving thefluid-solid coupling effect, the fluid-solid coupling calculation process can be omitted, and the simulation calculation speed is increased.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

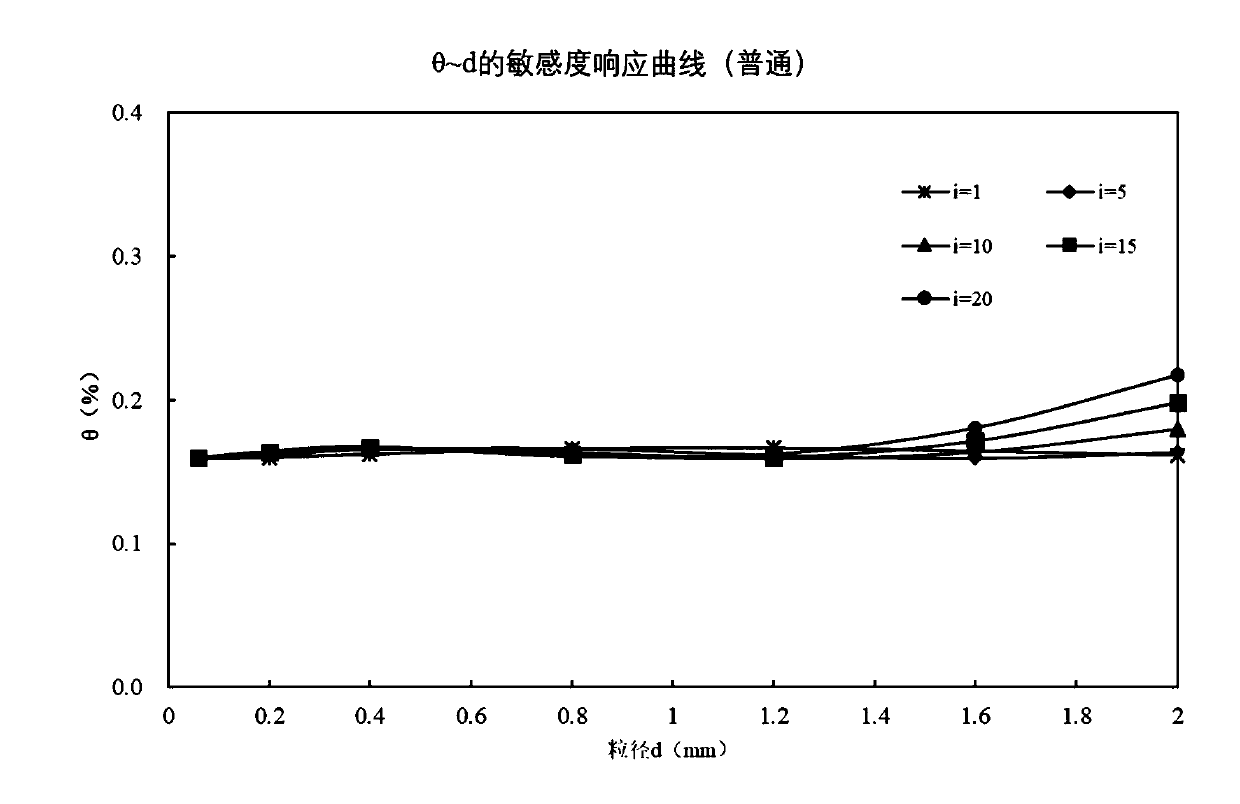

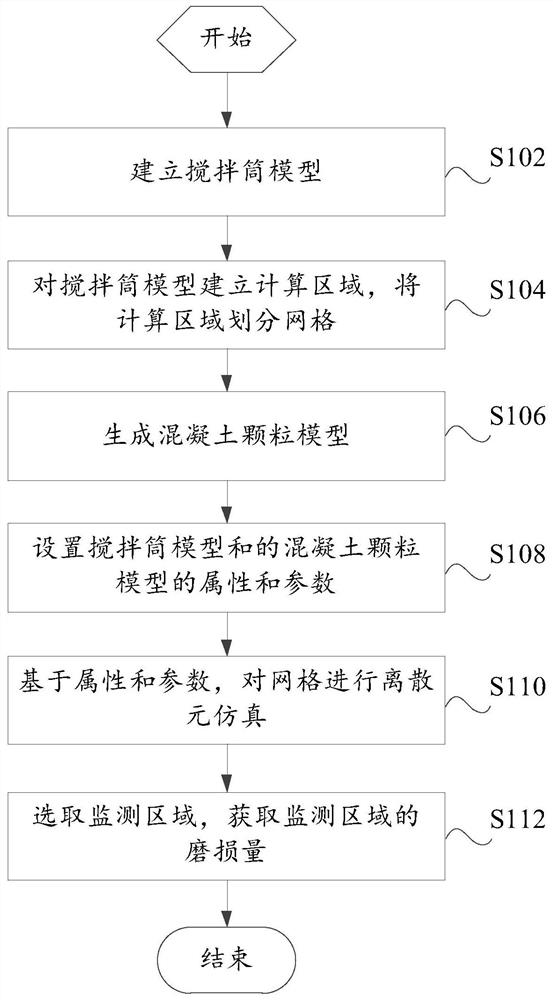

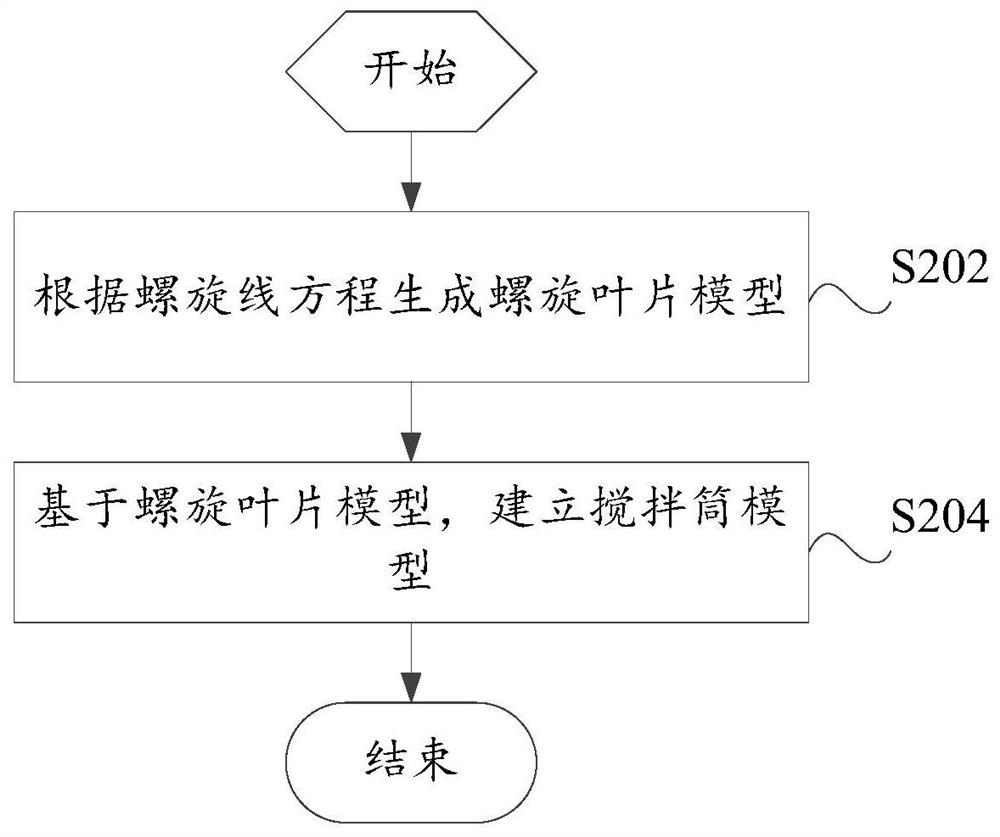

Mixing drum abrasion loss prediction method and device thereof and readable storage medium

PendingCN112699587ADesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationProcess engineering

The invention provides a method and device for predicting the abrasion loss of a mixing drum and a readable storage medium. The mixing drum abrasion loss prediction method comprises the following steps: establishing a mixing drum model; establishing a calculation area for the mixing drum model, and dividing the calculation area into grids; generating a concrete particle model; setting attributes and parameters of the mixing drum model and the concrete particle model; based on the attributes and the parameters, performing discrete element simulation on the grids; selecting a monitoring area, and obtaining the abrasion loss of the monitoring area. In the technical scheme of the invention, the wear condition of the mixing drum is predicted by adopting a discrete element simulation method, the calculation speed is high, the setting is simple and convenient, the time and labor are saved, and the wear condition of the mixing drum can be predicted in advance.

Owner:SANY SPECIAL PURPOSE VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com