Mixing drum abrasion loss prediction method and device thereof and readable storage medium

A prediction method and mixing drum technology, applied in the field of measurement, can solve problems such as low improvement efficiency and inability to accurately predict the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

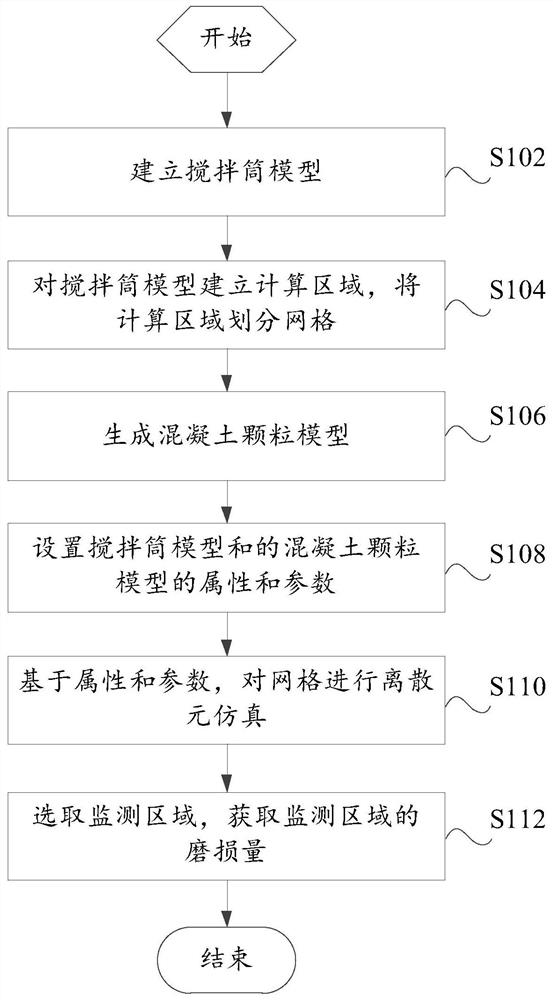

[0061] Such as figure 1 As shown, the present embodiment provides a method for predicting the amount of wear of the mixing drum, comprising the following steps:

[0062] Step S102, establishing a mixing drum model;

[0063] Step S104, establishing a calculation area for the mixing drum model, and dividing the calculation area into grids;

[0064] Step S106, generating a concrete particle model;

[0065] Step S108, setting the attributes and parameters of the mixing drum model and the concrete particle model;

[0066] Step S110, based on attributes and parameters, perform discrete element simulation on the grid;

[0067] Step S112, selecting a monitoring area, and obtaining the wear amount of the monitoring area.

[0068] In the existing technology, the concrete is centralized mixing and supplied on demand. The concrete is produced by the mixing station and then transported to the destination by the concrete truck. The service life of the mixing drum is affected by the wear...

Embodiment 2

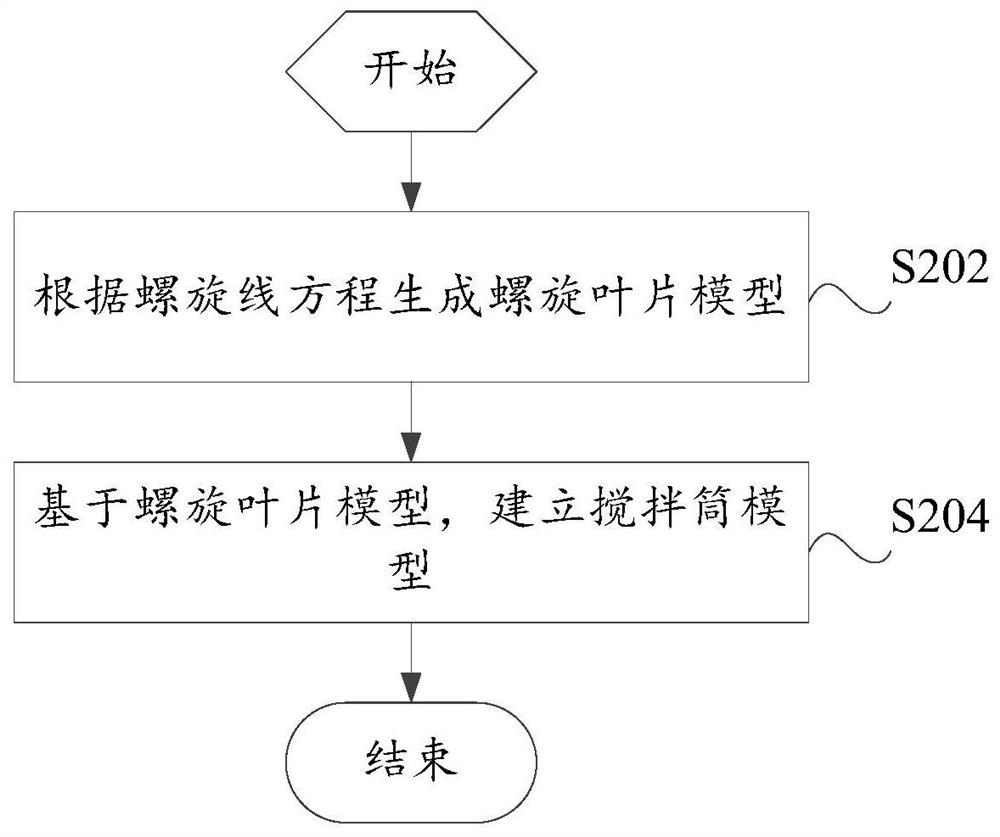

[0072] Such as figure 2 As shown, this embodiment provides a method for predicting the amount of wear of the mixing drum. In addition to the technical features of the above-mentioned embodiments, this embodiment further includes the following technical features:

[0073] Establish a mixing drum model, specifically including the following steps:

[0074] Step S202, generating a helical blade model according to the helix equation;

[0075] Step S204, establishing a mixing drum model based on the helical blade model.

[0076] In this embodiment, the helical blade model is generated based on the helical line equation, and then the mixing drum model is obtained. The setting process is simple and conforms to the characteristics of the mixing drum.

Embodiment 3

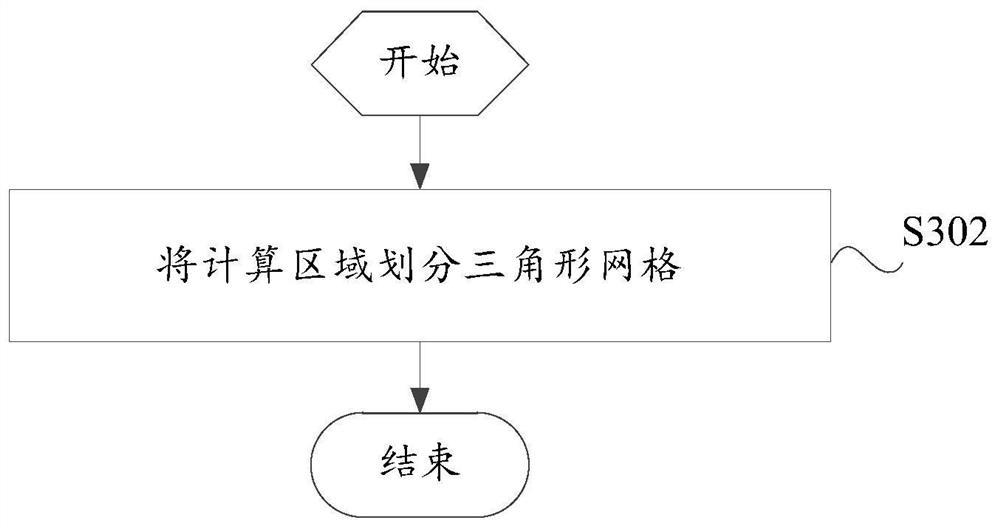

[0078] Such as image 3 As shown, this embodiment provides a method for predicting the amount of wear of the mixing drum. In addition to the technical features of the above-mentioned embodiments, this embodiment further includes the following technical features:

[0079] Divide the calculation area into grids, including:

[0080] Step S302, dividing the calculation area into triangular meshes.

[0081] The grid can be a triangular grid, a rectangular grid, etc. In this embodiment, the calculation area is divided into a triangular grid, so that the model can achieve a better simulation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com