Semi-autogenous mill lining plate shape optimization method based on discrete element method

A semi-autogenous mill and optimization method technology, applied in design optimization/simulation, grain processing, etc., can solve problems such as the inability to theoretically obtain the particle movement state inside the equipment, achieve high practical application value, ensure accuracy and reasonableness performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

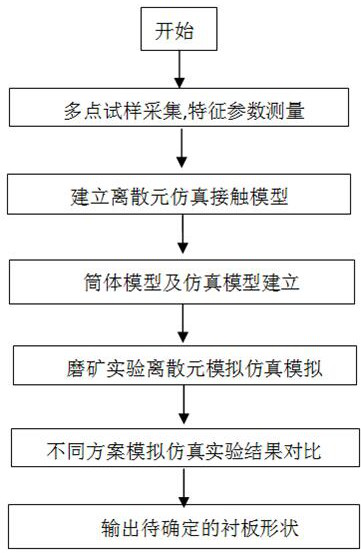

[0022] Such as figure 1 As shown, the discrete element method-based SAG mill liner shape optimization method specifically includes the following steps:

[0023] (1) Select 6 standard regular ore samples with a length, width and height of about 200 mm at each mining point, and measure the mechanical properties of the ore, including the ore hardness coefficient (7.93), ore elastic modulus (3.11×10 4 MPa), ore uniaxial compressive strength (793kg / mm 2 ), ore Poisson's ratio (0.26).

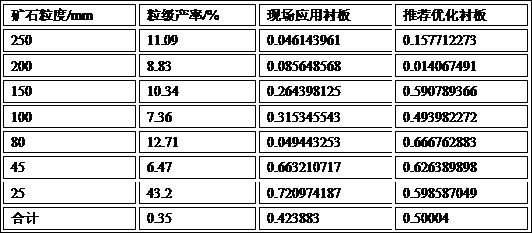

[0024] Synthesize an irregular geometric body with multiple regular geometric bodies, and the proportion of each regular sphere is determined according to the particle size composition. Sampling 1 ton at the feed place of the semi-autogenous mill, and determining the ore particle size composition as 250mm (11.09%), 200mm (8.83%), 150mm (10.34%), 100mm (7.36%), 80mm (12.71%), 45mm ( 6.47%), and 25mm (43.20%).

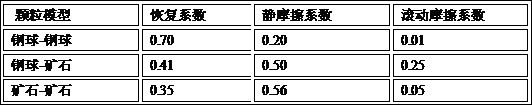

[0025] The medium size of the steel ball is 120mm and 150mm, the impact toughness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com