Brittle material discrete element modeling method considering shape of hole defect and distribution randomness thereof

A technology of brittle materials and modeling methods, applied in instrumentation, design optimization/simulation, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

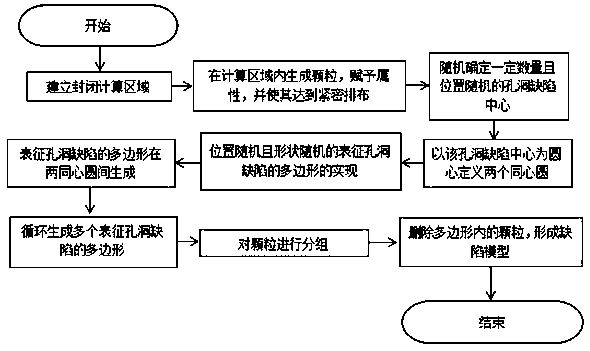

[0028] A discrete element modeling method for brittle materials considering the shape of hole defects and the randomness of their distribution is characterized in that the steps of establishing a discrete element model of hole defects are as follows:

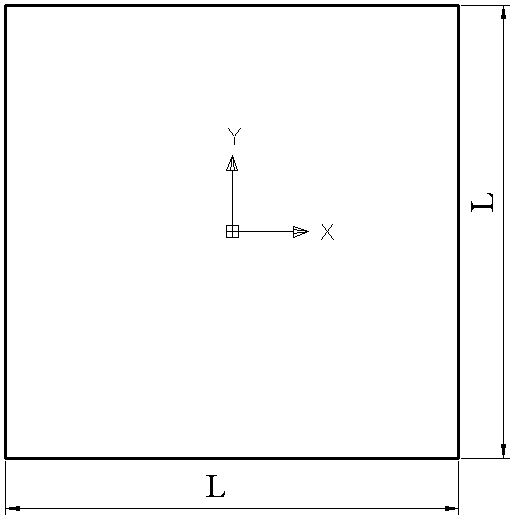

[0029] (1) Enclosing a closed calculation area by establishing a boundary wall;

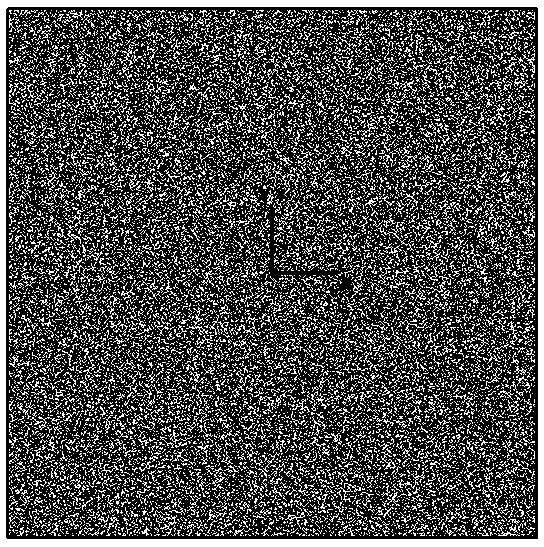

[0030] (2) Generate particles in the closed calculation area, whose particle radius obeys the uniform distribution or normal distribution and the position is randomly generated, assign values to the particle density, damping, stiffness attributes and the attributes of the contact model between particles, and through the interaction of particles The effect makes it reach a stable and densely arranged state, and the basic material model is obtained;

[0031] (3) Generate polygons representing hole defects with random positions and random shapes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com