Infrared coherent thermal wave imaging system and detection method based on system

A technology of thermal wave imaging and detection method, which is applied in the field of infrared coherent thermal wave imaging system, can solve the problems of low signal-to-noise ratio and insensitivity of test piece detection, and achieve the effect of improving the effect of material defects and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

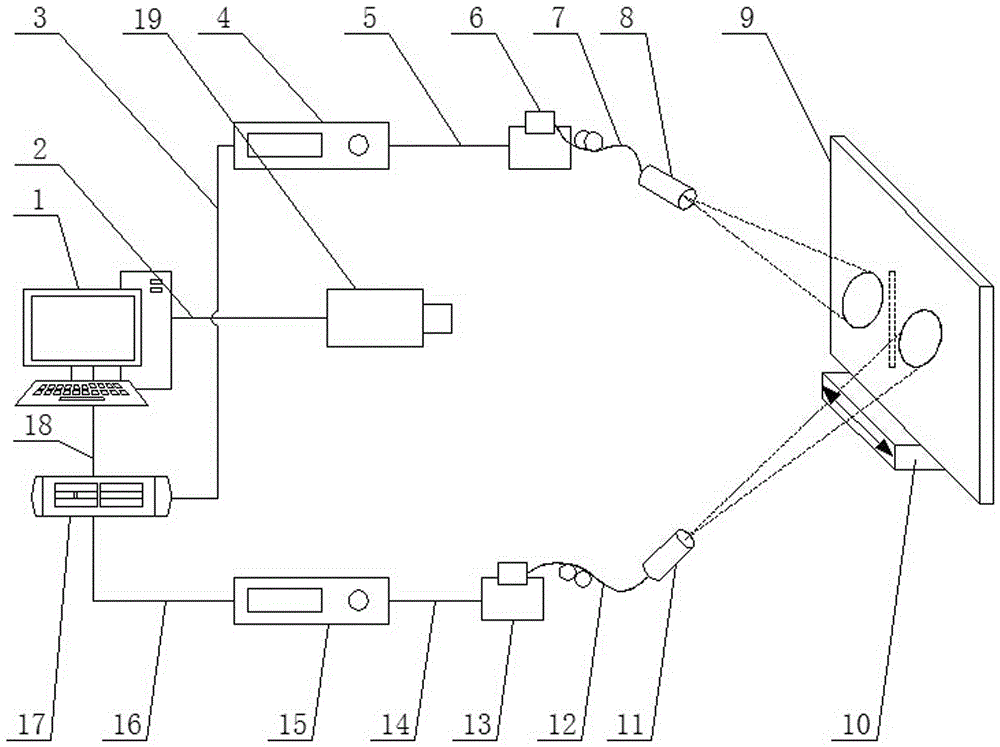

[0026] Specific implementation manner one: such as figure 1 As shown, an infrared coherent thermal wave imaging system is composed of a computer 1, an Ethernet cable 2, a first BNC data line 3, a first laser power supply 4, a first laser power supply line 5, a first laser 6, and a first optical fiber 7. The first collimator 8, the mobile station 10, the second collimator 11, the second optical fiber 12, the second laser 13, the second laser power line 14, the second laser power supply 15, the second BNC data line 16, Function generator 17, USB data cable 18 and infrared thermal imager 19;

[0027] The computer 1 is provided with two signal output terminals. One of the signal output terminals of the computer 1 is connected to the signal input terminal of the infrared camera 19 through the Ethernet cable 2, and the other signal output terminal of the computer 1 is through USB The data line 18 is connected to the signal input end of the function generator 17. The function generator...

specific Embodiment approach 2

[0029] Specific implementation manner two: such as figure 1 As shown, according to an infrared coherent thermal wave imaging system according to the first embodiment, the first laser 6 and the second laser 13 are both 808nm semiconductor lasers; the first laser power supply 4 and the second laser The power supplies 15 are all 808nm semiconductor laser power supplies.

specific Embodiment approach 3

[0030] Specific implementation manner three: such as figure 1 As shown, a detection method based on an infrared coherent thermal wave imaging system described in Embodiment 1 or 2, the detection method includes the following steps:

[0031] Step 1: Fix the tested sample 9 on the mobile platform 10 (the mobile platform 10 can control the vertical and horizontal movement of the tested sample 9); in this embodiment, the thickness of the tested sample 9 is 4 mm , Take a square block with a size of 10cm×10cm as an example, the tested specimen 9 is made of CFRP material, and the tested specimen 9 is prefabricated with micro-crack defects;

[0032] Step 2: Turn on the computer 1, the first laser power supply 4, the first laser 6, the second laser 13, the second laser power supply 15, the function generator 17, and the infrared thermal imager 19 in the infrared coherent thermal wave imaging system ;

[0033] Step 3: Set the peak power of the first laser and the second laser to 30W respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com