Digital image-forming tube bar material defect nondestructive flaw detection system

A digital imaging and non-destructive testing technology, applied in the analysis of materials, instruments, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as high technical requirements for analysts, inability to intuitively characterize defects, and insufficient intuitive display methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

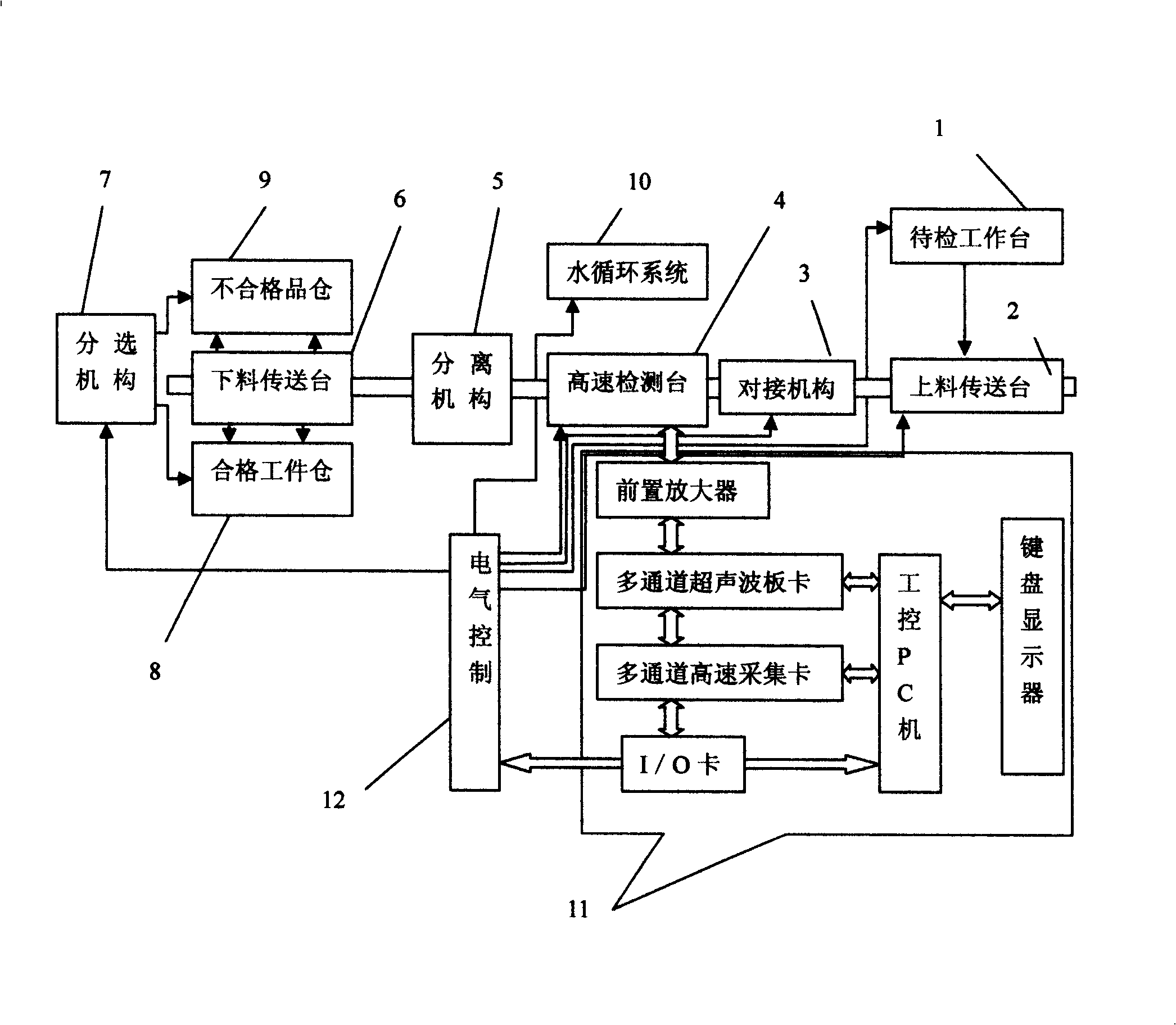

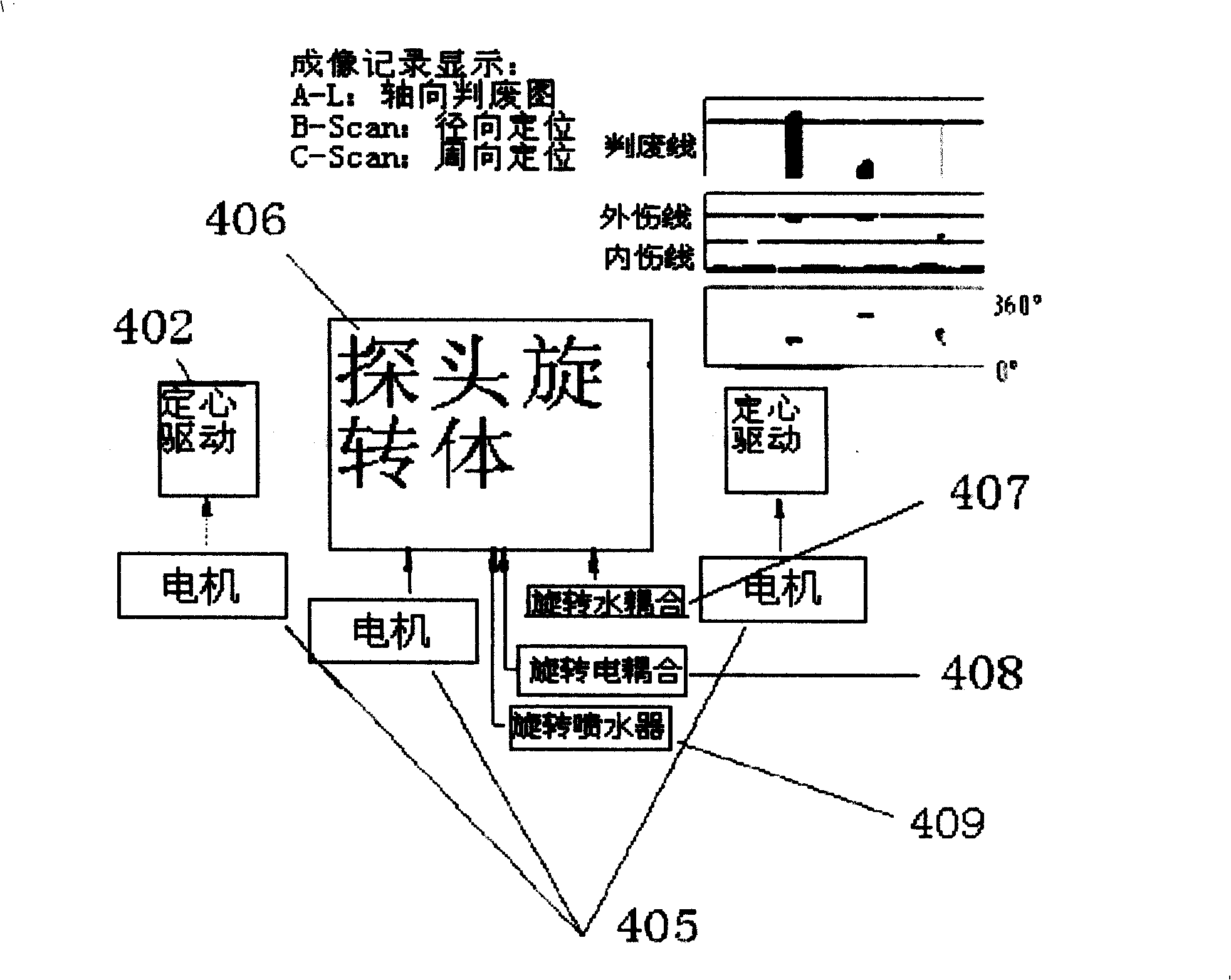

[0040] This embodiment mainly describes the ultrasonic flaw detection detection part in the pipe ultrasonic flaw detection system, a digital imaging tube rod defect non-destructive detection detection system, which is characterized in that: the digital imaging tube rod defect non-destructive detection detection system includes the workpiece to be inspected Table (1), feeding transfer table (2), docking mechanism (3), high-speed detection table (4), separation mechanism (5), unloading transfer table (6), sorting mechanism (7), qualified workpiece warehouse (8), unqualified product warehouse (9), water circulation system (10), non-destructive testing instrument system (11) and electrical control system (12);

[0041] Among them: the feeding transfer table (2) is connected with the workpiece table (1) to be inspected, the docking mechanism (3) is connected with the high-speed inspection table (4) and the feeding transfer table (2), and the high-speed inspection table (4) is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com