Patents

Literature

138results about How to "High simulation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

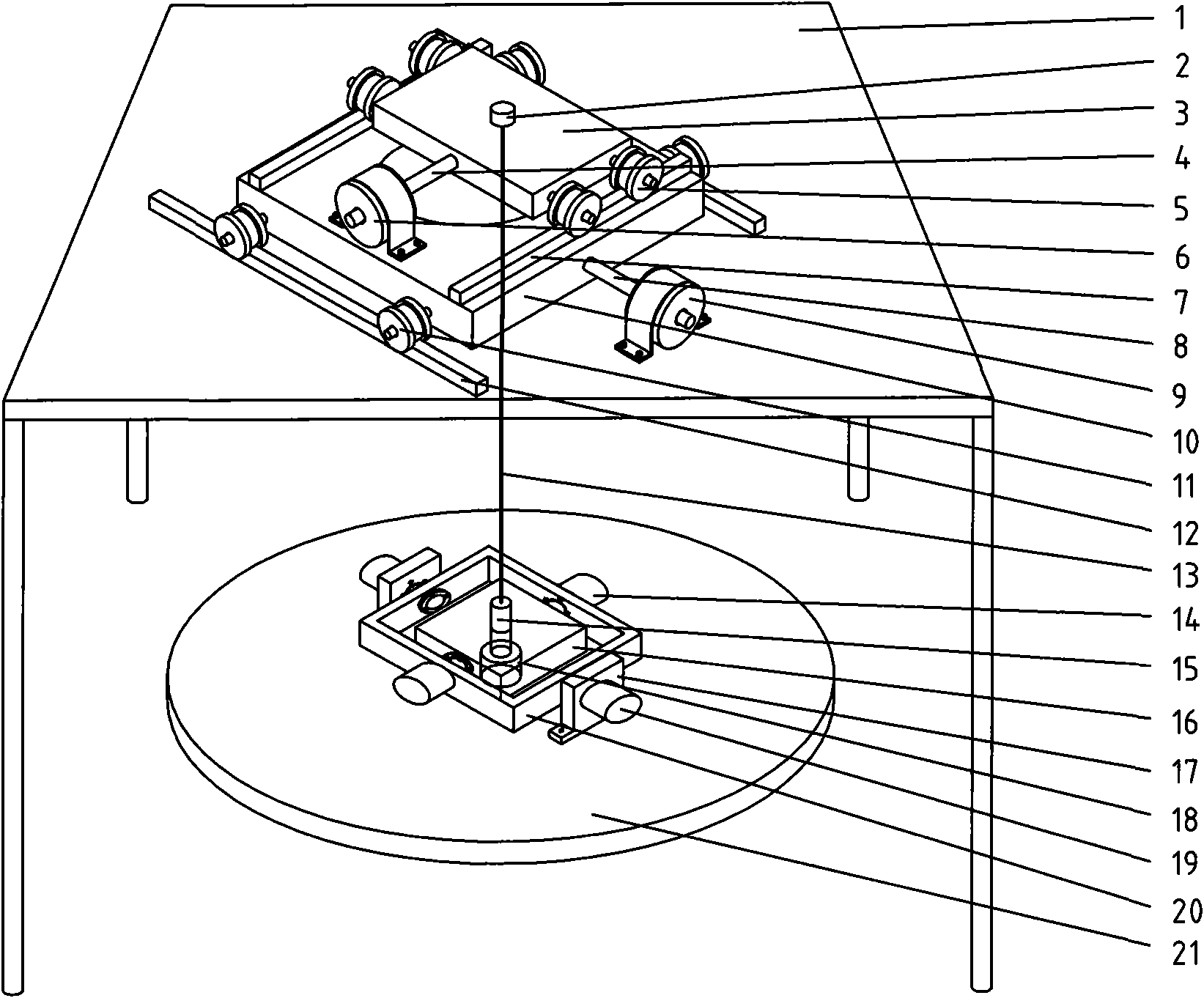

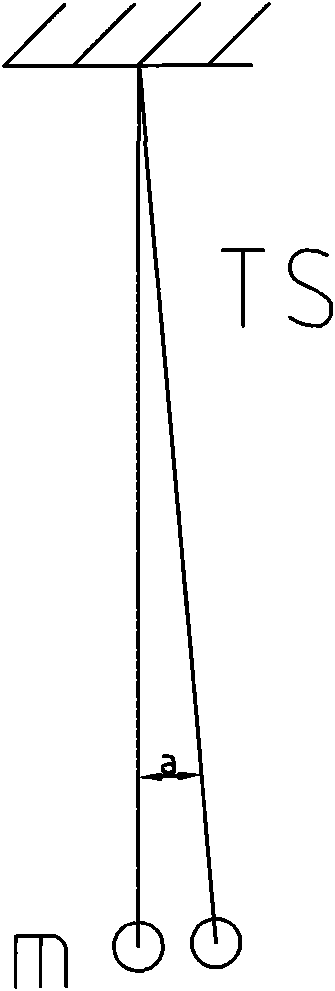

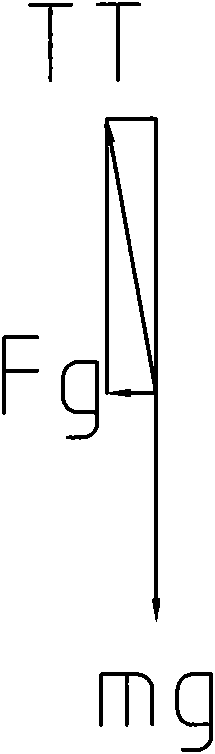

Ground simulation test device for space vehicle

InactiveCN101596940ASimple structureLow costCosmonautic condition simulationsFlight vehicleEngineering

The invention relates to a test device, in particular to a ground simulation test device for space vehicle. The test device is characterized in that a driving mechanism is arranged above a support platform 1 and a space vehicle simulation mechanism is arranged below the support platform 1. One end of a flexible rope 13 is connected with the driving mechanism, and the other end is connected with a space vehicle simulator 21 by a three-axle table. One end of the flexible rope is fixedly connected with an upper trolley 3 on the support platform 1 at a flexible rope fixed point 2, and the other end of the flexible rope 13 is connected with a three-axle table inner shaft 15. A suspension corner formed by rotating motion of the space vehicle is eliminated, so as to cause suspension to be closed to an angle equilibrium position all the time, thus reducing suspension torsion stress; and meanwhile the method also can eliminate that suspension deviates a gravitational equilibrium position caused by translation motion of the space vehicle, so as to cause the suspension to be closed to the gravitational equilibrium position all the time, thus reducing suspension restoring force and ensuring disturbing force of the space vehicle simulator to be minimum.

Owner:葛升民

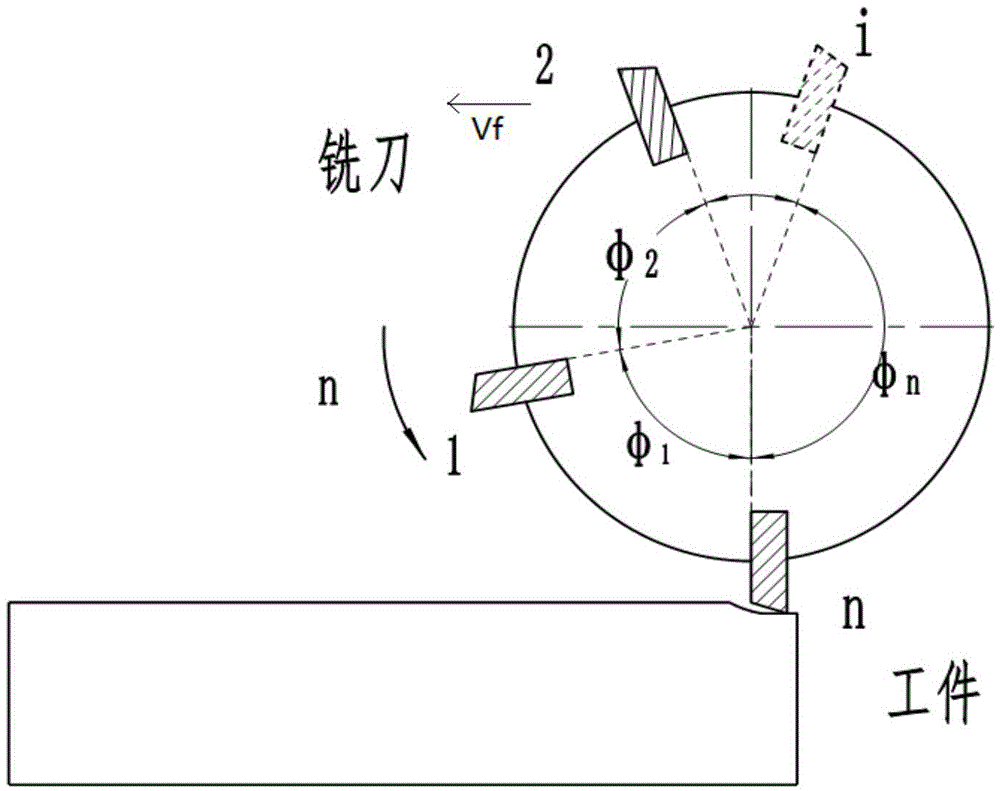

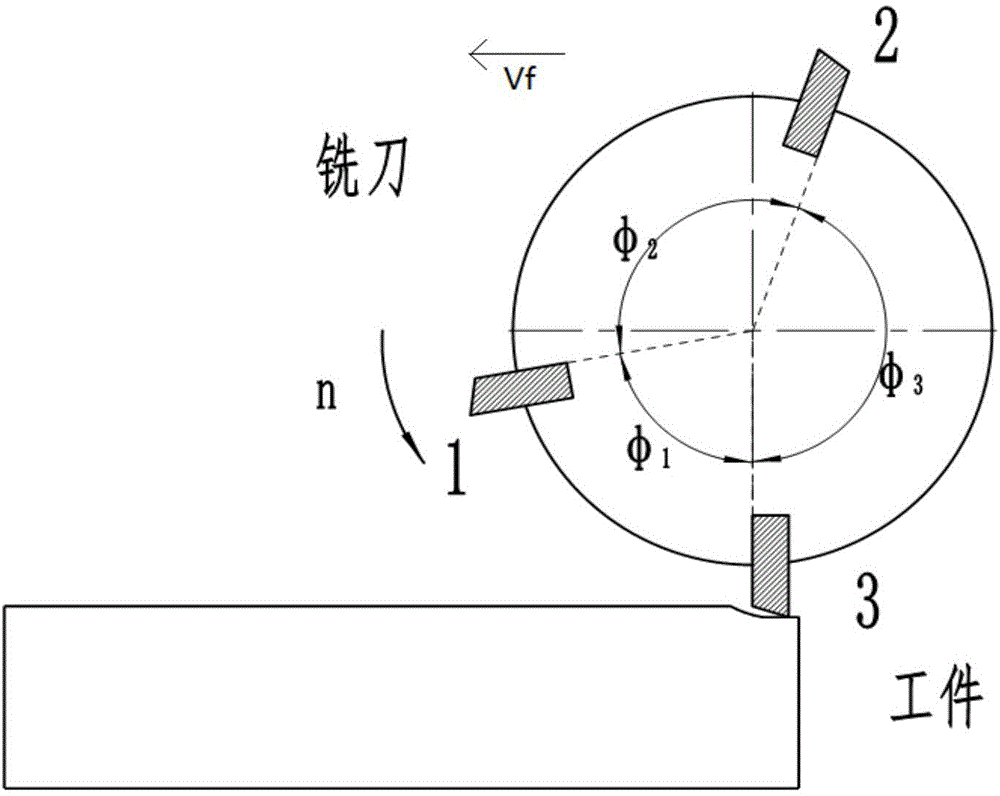

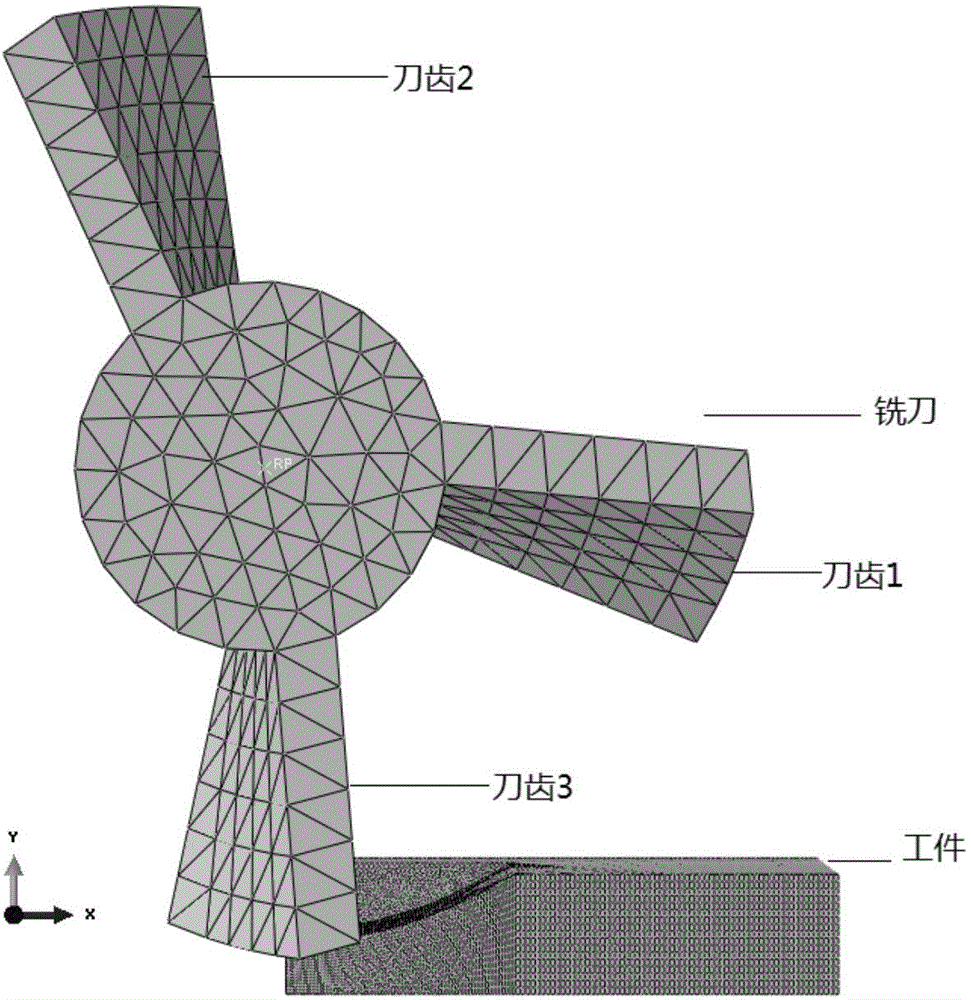

Titanium alloy variable-pitch milling three-dimensional modeling method based on finite elements

ActiveCN104484515AImprove accuracyImprove modeling efficiencySpecial data processing applications3D modellingFinite element methodPhysical model

The invention discloses a titanium alloy variable-pitch milling three-dimensional modeling method based on finite elements. The titanium alloy variable-pitch milling three-dimensional modeling method includes steps of firstly acquiring tool system parameters and material parameters of workpieces and a tool and devising technical cutting parameters; modeling a milling tool geometrically according to the technical parameters and the principle that the radial included angle ratio of various tool teeth to a former tool tooth of the milling tool is equal to the corresponding ratio of feed engagement per tooth; modeling physical models of the milling tool and the workpieces as well as the contact relation and the kinematic relation; submitting operations to an ABAQUS / Explicit solver; drawing a milling force-time curve, a milling temperature-time curve, or a stress and strain figure of a certain specific joint set after the solution is obtained. The helical angle of the milling tool is considered, so that modeling can be closer to the real machining condition; by adopting geometric variable-pitch modeling, different working conditions of feed engagement per tooth can be simulated at one time, and modeling and computing time is saved.

Owner:HUAZHONG UNIV OF SCI & TECH

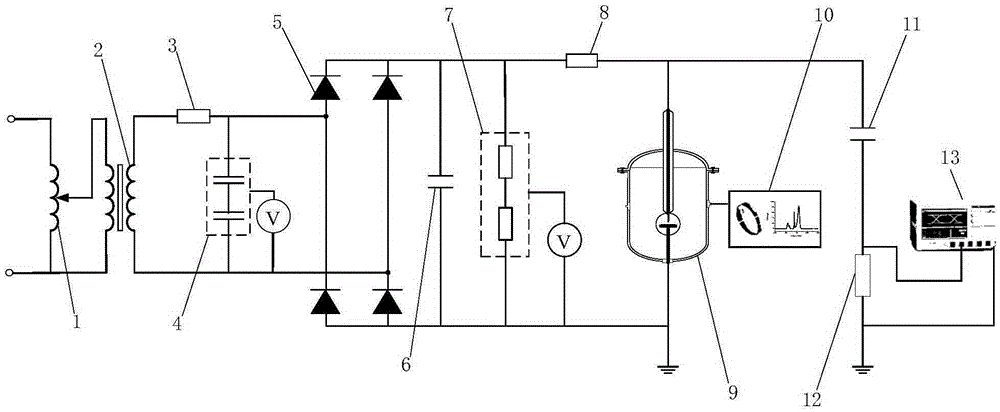

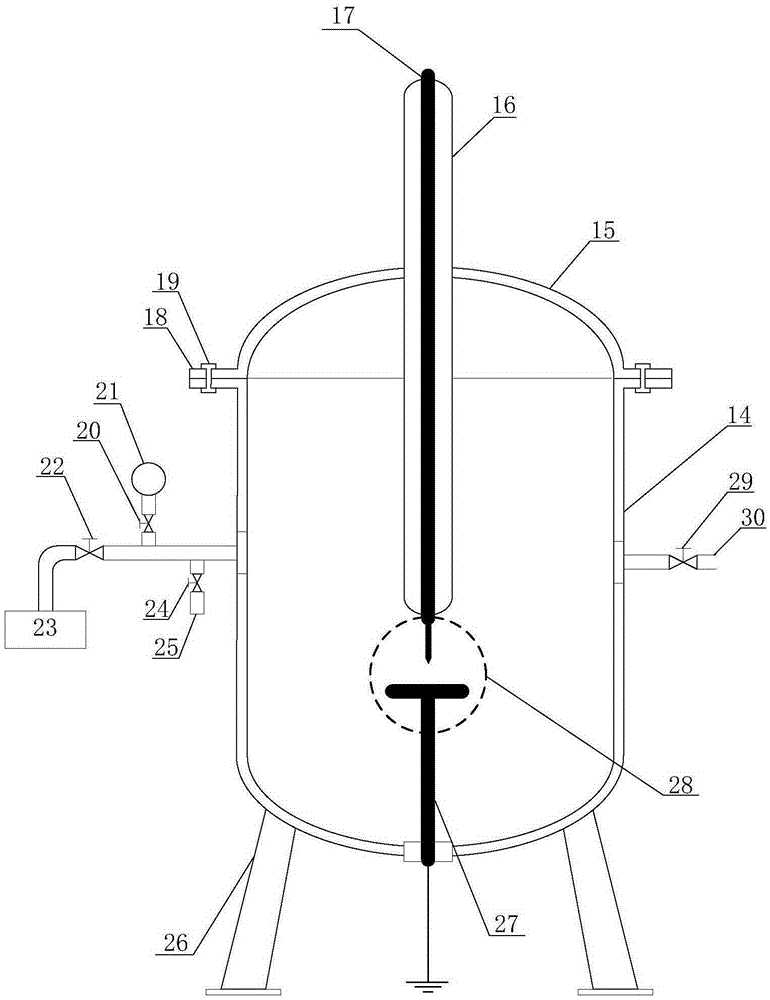

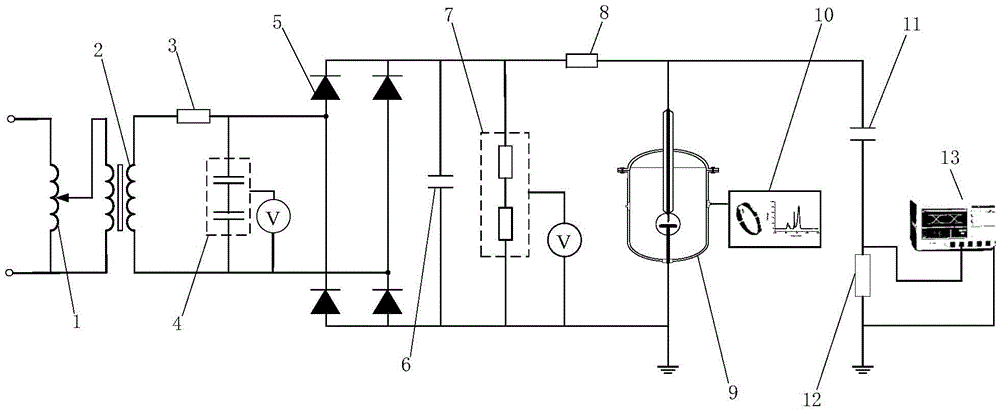

Direct current gas insulation electrical equipment partial discharge decomposition simulation experiment apparatus

ActiveCN105301465AHigh simulation accuracyAdjustable distanceTesting dielectric strengthComponent separationGas phaseDecomposition

The invention relates to a direct current gas insulation electrical equipment partial discharge decomposition simulation experiment apparatus and belongs to the technical field of direct current gas insulation electrical equipment insulation state on-line monitoring. The direct current gas insulation electrical equipment partial discharge decomposition simulation experiment apparatus comprises a direct current power supply system, a gas discharge enclosed air chamber, a detection system and a typical insulation defect physical model, wherein the direct current power supply system comprises a voltage regulation console, a test transformer, a protection resistor, a capacitive voltage divider and a high voltage rectification silicon stack lamp; the detection system comprises a pulse current detection system and a gas chromatography-mass spectrometry detection system; and the typical insulation defect physical model comprises a metal protrusion insulation defect model, a free metal particle insulation defect model, an insulator metal pollution insulation defect model, an insulator air gap insulation defect model and the like. The invention can effectively simulate a typical insulation PD fault and the decomposition process of SF6 under the action of a typical insulation defect PD in direct current gas insulation electrical equipment, thereby providing a solid basis for a system to research direct current PD characteristics, SF6 direct current PD decomposition characteristics and decomposition theories. The invention can be widely used for simulating direct current gas insulation electrical equipment partial discharge.

Owner:WUHAN UNIV +6

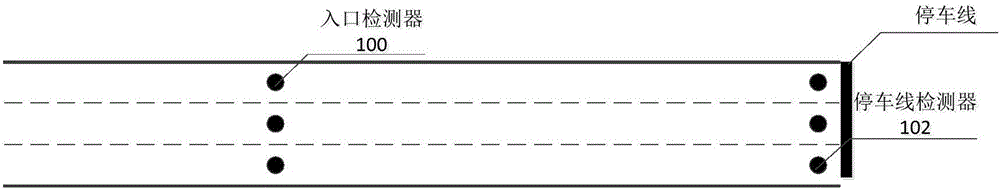

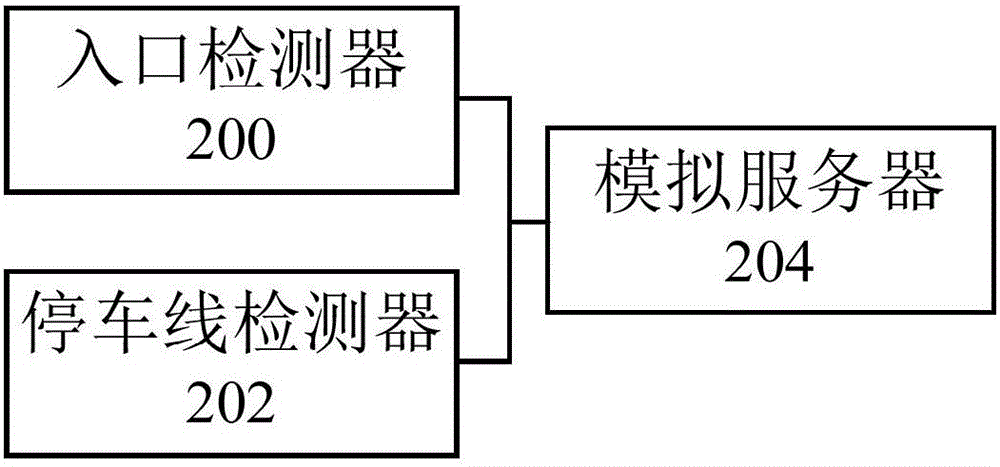

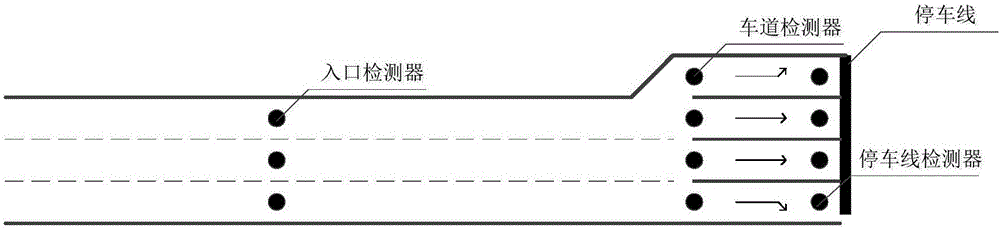

Vehicle queuing length simulation system, method and device

ActiveCN106781493AHigh simulation accuracyImprove timelinessDetection of traffic movementTraffic signalIn vehicle

The invention provides a vehicle queuing length simulation system, method and device. An entrance detector and a stop line detector are respectively arranged at an entrance and a stop line of a detection road section, and a simulation server interacting with the entrance detector and the stop line detector is arranged, enabling the simulation server to simulate a vehicle traveling track in the detection road section by acquiring driving-in vehicle information detected by the entrance detector and driving-away vehicle information detected by the stop line detector according to a collected signal change period of traffic lights, and determine a vehicle queuing length according to the vehicle traveling track; the simulation server carries out dynamic calculation based on acquired traffic road condition data, so that the accuracy of the vehicle queuing length is greatly improved.

Owner:迈锐数据(北京)有限公司

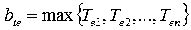

Time sequence probability modeling method for output power of solar photovoltaic power supply

InactiveCN103106314ASimulation is accurateImprove accuracySpecial data processing applicationsInformation technology support systemNormal densityElectric power system

The invention discloses a time sequence probability modeling method for output power of solar photovoltaic power supply and belongs to the technical field of probability modeling for output power of the power supply of an electric power system. The time sequence probability modeling method comprises the following steps of: firstly inputting measured data of the output power of the photovoltaic power supply and daily power output begin-end time by utilizing a computer through a program; then estimating a probability density function of the daily power output begin-end time of the photovoltaic power supply based on a nonparametric kernel density estimation theory, and generating a random sample; and then sequentially estimating the probability density function of the output power of the photovoltaic power supply at each time based on nonparametric kernel density estimation and conditional probability theories, and generating a random sample. The time sequence probability modeling method provided by the invention has the advantages of simplicity, strong practicality, high estimation accuracy, strong commonality, and convenience in popularization and application. The time sequence probability modeling method can be widely used for establishing a time sequence probability model of the output power of the photovoltaic power supply in the electric power system.

Owner:CHONGQING UNIV

Partial discharge decomposition simulation experiment method of direct current gas insulation electrical device

ActiveCN105548823AHigh simulation accuracyAdjustable distanceTesting dielectric strengthDecompositionSulfur hexafluoride

The present invention belongs to the field of on-line monitoring technology of the insulation state of a sulfur hexafluoride (SF6) gas insulation electrical device, and specifically relates to a partial discharge decomposition simulation experiment method of a direct current gas insulation electrical device. The method mainly comprises a SF6 direct current PD decomposition experiment method and methods of pulse current detection and collection and analysis testing of discharge decomposition gas, etc. The method provided by the invention is simple, easy to grasp and convenient for popularization, is widely applicable to the simulation and monitoring of a SF6 gas insulation electrical device direct current PD, and provides a scientific and effective method for insulation state monitoring of a direct current gas insulation electrical device and the SP6 PD decomposition test and decomposition mechanism research.

Owner:WUHAN UNIV +6

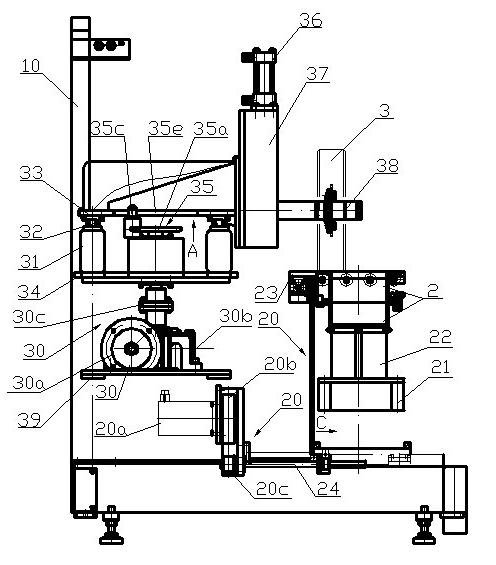

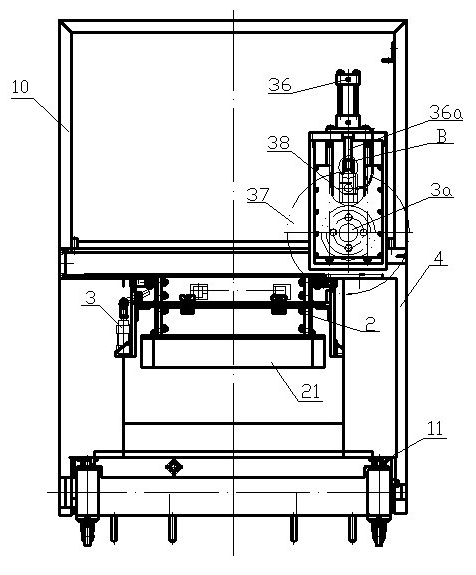

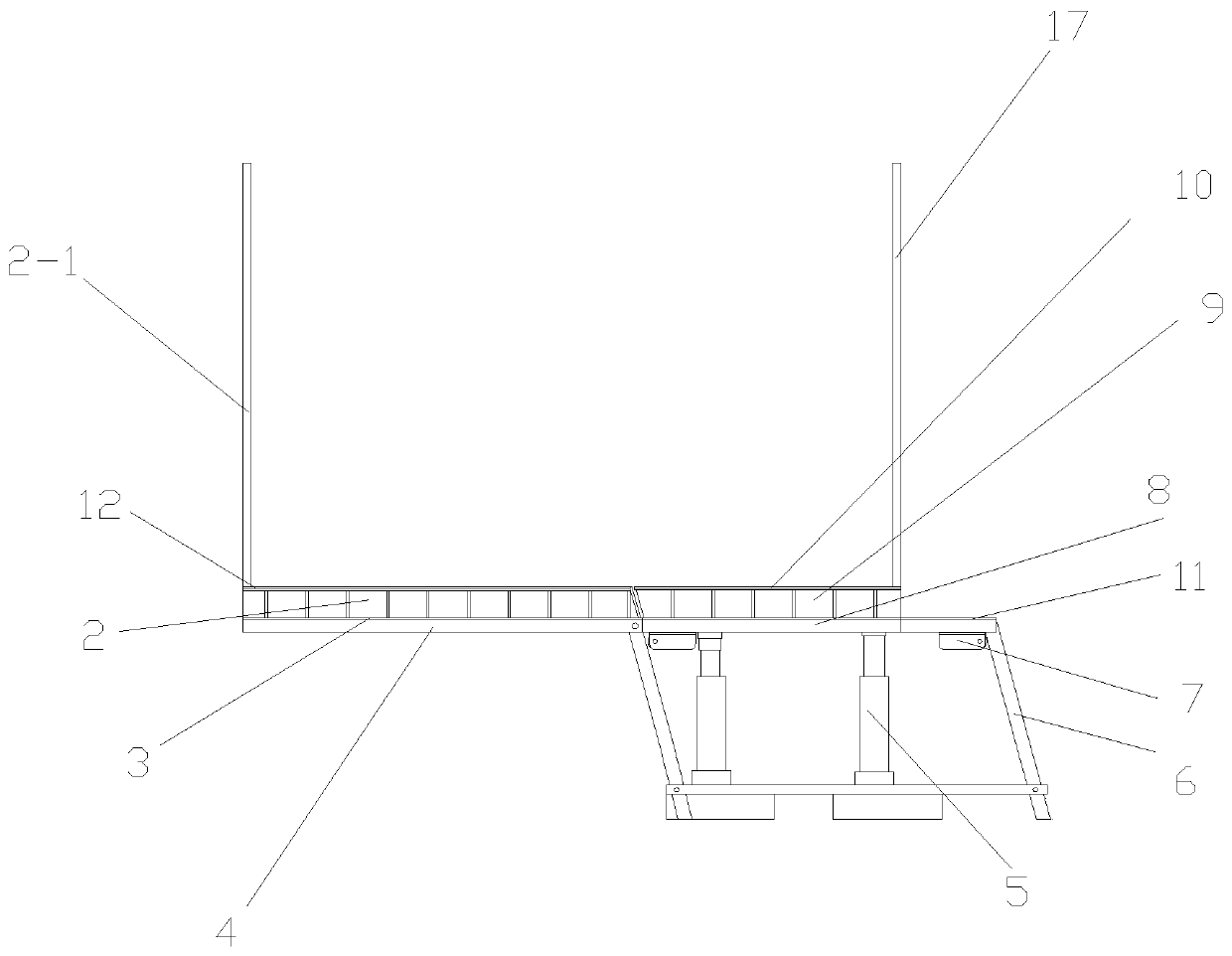

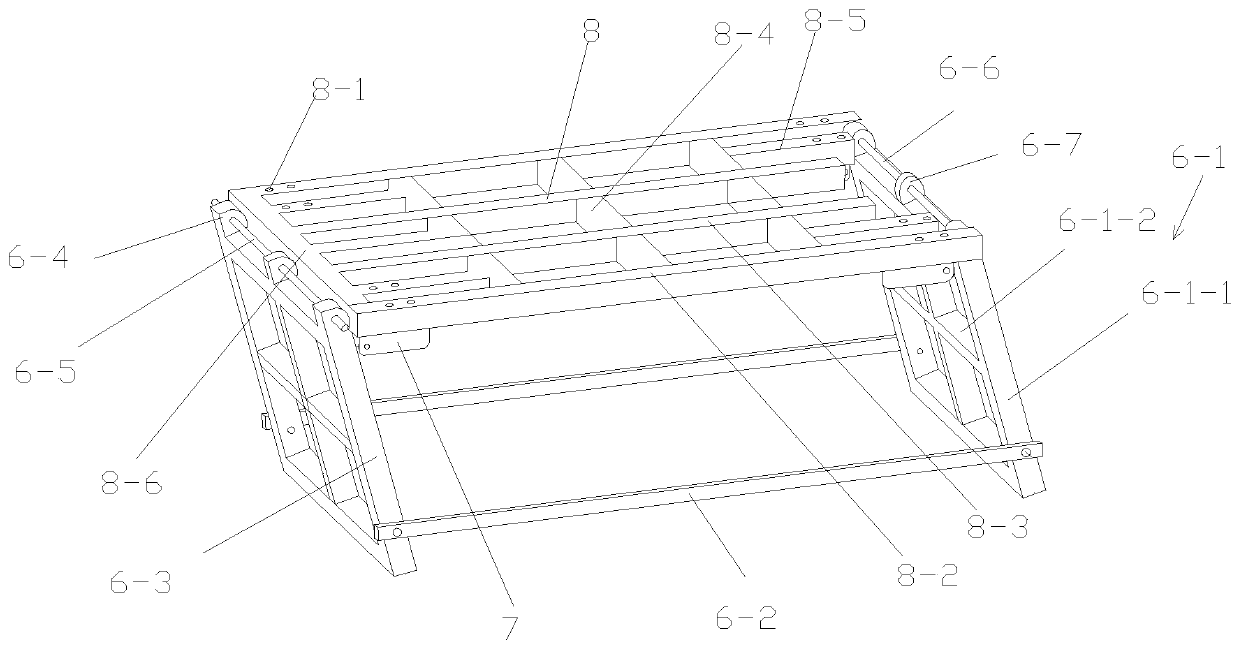

Indoor grinding and forming instrument of bituminous mixture test specimen and forming control method thereof

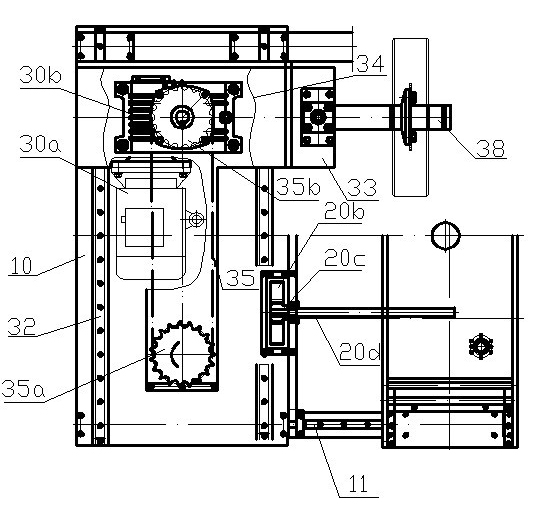

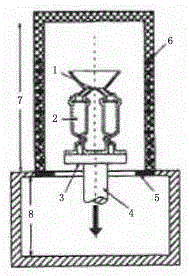

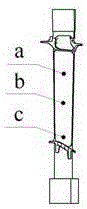

InactiveCN102042923ASmooth rollingUniform densityPreparing sample for investigationHydraulic ramGrinding wheel

The invention relates to an indoor grinding and forming instrument of a bituminous mixture test specimen and a forming control method thereof. The forming instrument comprises a rack, a grinding wheel, a mould and a mould drive device, and also comprises a grinding wheel drive device; the device mainly comprises a first reducing gear, a grinding wheel support, a hydraulic ram, a first guide rail and a driving chain; the mould drive device mainly comprises a mould driving support, a second guide rail, a second reducing gear, a speed reducing elevator mechanism, an elevating platform and a horizontal screw; the grinding wheel is arranged on the grinding wheel support, the grinding wheel support is connected with the first reducing gear, the mould drive support is connected with the second reducing gear through the horizontal screw, and the speed reducing elevator mechanism is fixed on the mould driving support and connected with the elevating platform. The method comprises the steps of:setting parameters, judging whether a starting position is reached or not, applying a grinding force, comparing a pressure value with a set value, grinding with the grinding wheel, judging whether one round of grinding is ended or not, and the like. The grinding and forming instrument has the advantages of high simulation degree, high automation degree and wide application range.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD +1

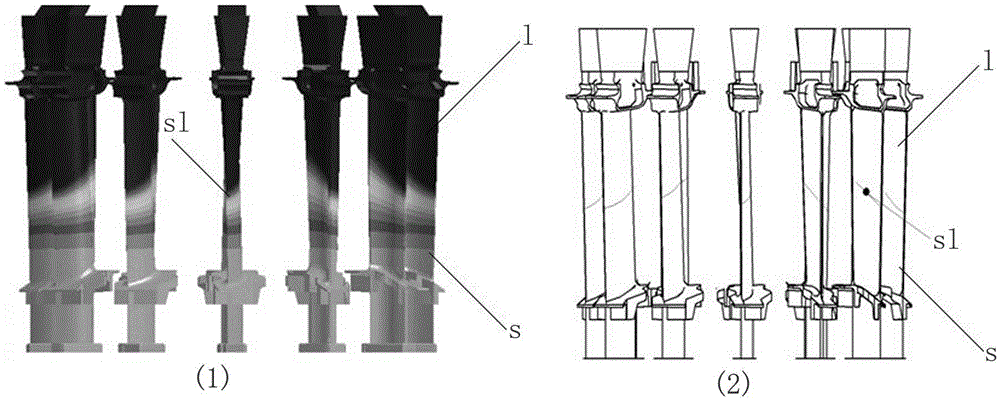

Design method of internal baffle for directional solidification blade casting system

The invention belongs to the field of precision casting, and particularly relates to a design method of an internal baffle for a directional solidification blade casting system. The internal baffle is designed in the manner of combining a casting test and ProCAST software simulation analysis, the grow state of a grain structure is virtualized through a CAFE module, and the part subjected to distortion in the growth direction without a baffle blade structure is predicted. Then, a temperature field is analyzed, pre-judgment is carried out on the influence of the internal baffle on the shape of the front edge of solid liquid, the relation between the inclination angle and the diameter of the baffle is measured to determine the size of the baffle, and finally whether the blade grain growth orientation and grain size meet production standards or not is preliminarily evaluated. The casting system is designed, a large number of trial-manufacture expenses can be saved, test sequences are clearer, and the activity of technicians in design of the internal baffle of the directional solidification blade casting system is fully brought into play.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Crack grouting simulation testing device based on visual detection and testing method

InactiveCN109541182AHigh simulation accuracySimple structureEarth material testingDiffusion analysisCoalRelief valve

The invention provides a crack grouting simulation testing device based on visual detection and a testing method, and belongs to the field of stratum crack grouting technology. The simulation testingdevice comprises a grouting tank, a high pressure grouting pump, a monitoring system, a check valve, a relief valve, a pressure limiting valve, a coal seam floor simulated crack, and a test box. The grouting tank is connected to an inlet of the high pressure grouting pump through a first high pressure pipeline. The test box is made of a transparent plexiglass plate. A grouting circular hole is formed at the upper end of the test box. The bottom end of the side wall of the test box is provided with a displacement scale. A grouting pipe is provided in the grouting circular hole. The lower end ofthe grouting pipe is inserted into the coal seam floor simulated crack, and the upper end of the grouting pipe is located above the test box. An outlet of the high pressure grouting pump is connectedto the upper end of the grouting pipe through a second high pressure pipe. The monitoring system, the one-way valve and the pressure limiting valve are sequentially arranged on the second high pressure pipeline along the flow direction of a slurry. The relief valve is placed on the grouting pipe. The crack grouting simulation testing device based on the visual detection and the testing method usethe plexiglass test box as an accommodating space, and inject a grout into the coal seam floor simulated crack through the high pressure grouting pump, so as to realize the simulation of a high pressure grouting effect of a coal seam floor crack, which has high practical performance and high simulation precision.

Owner:SHANDONG UNIV OF SCI & TECH

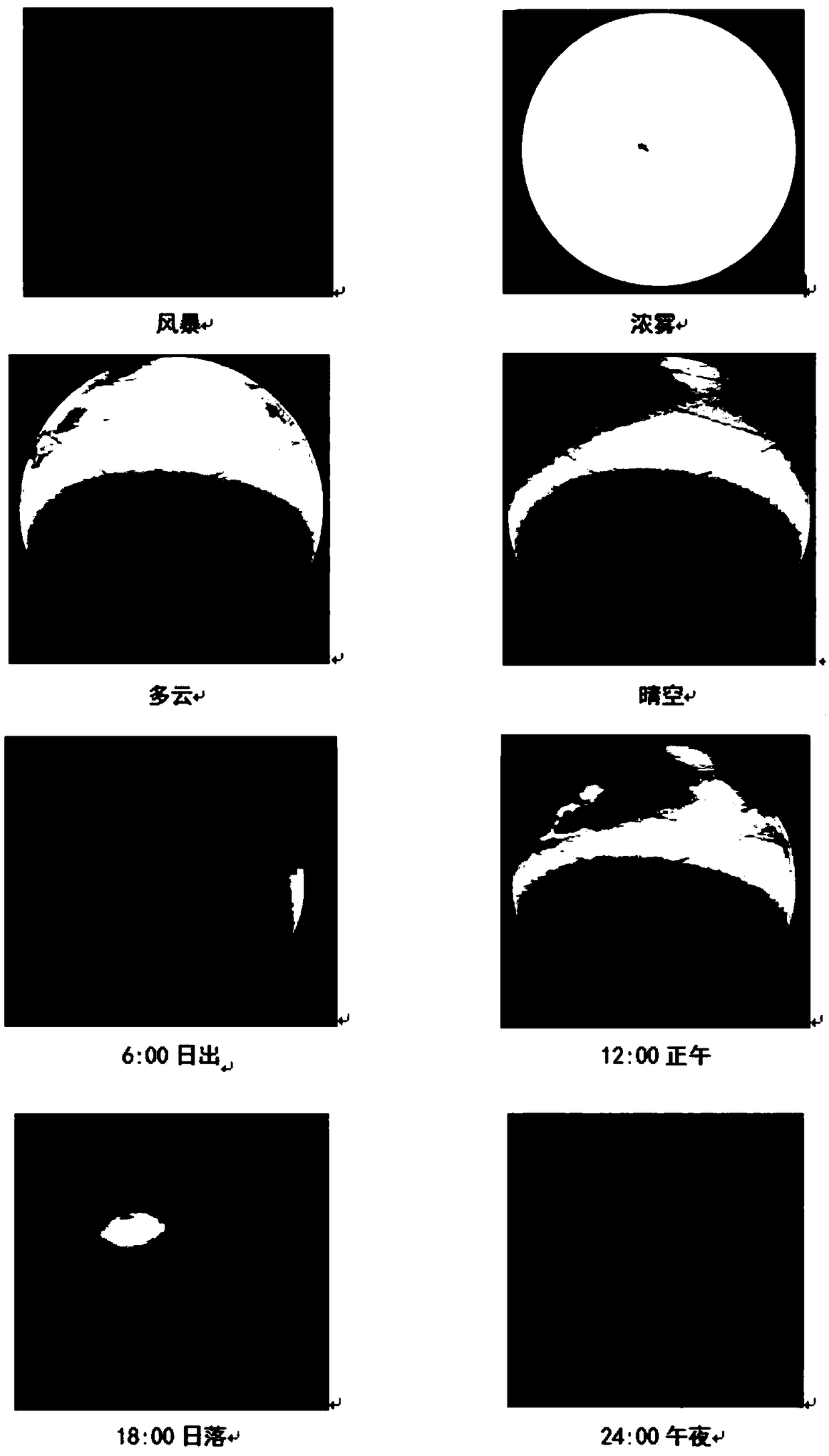

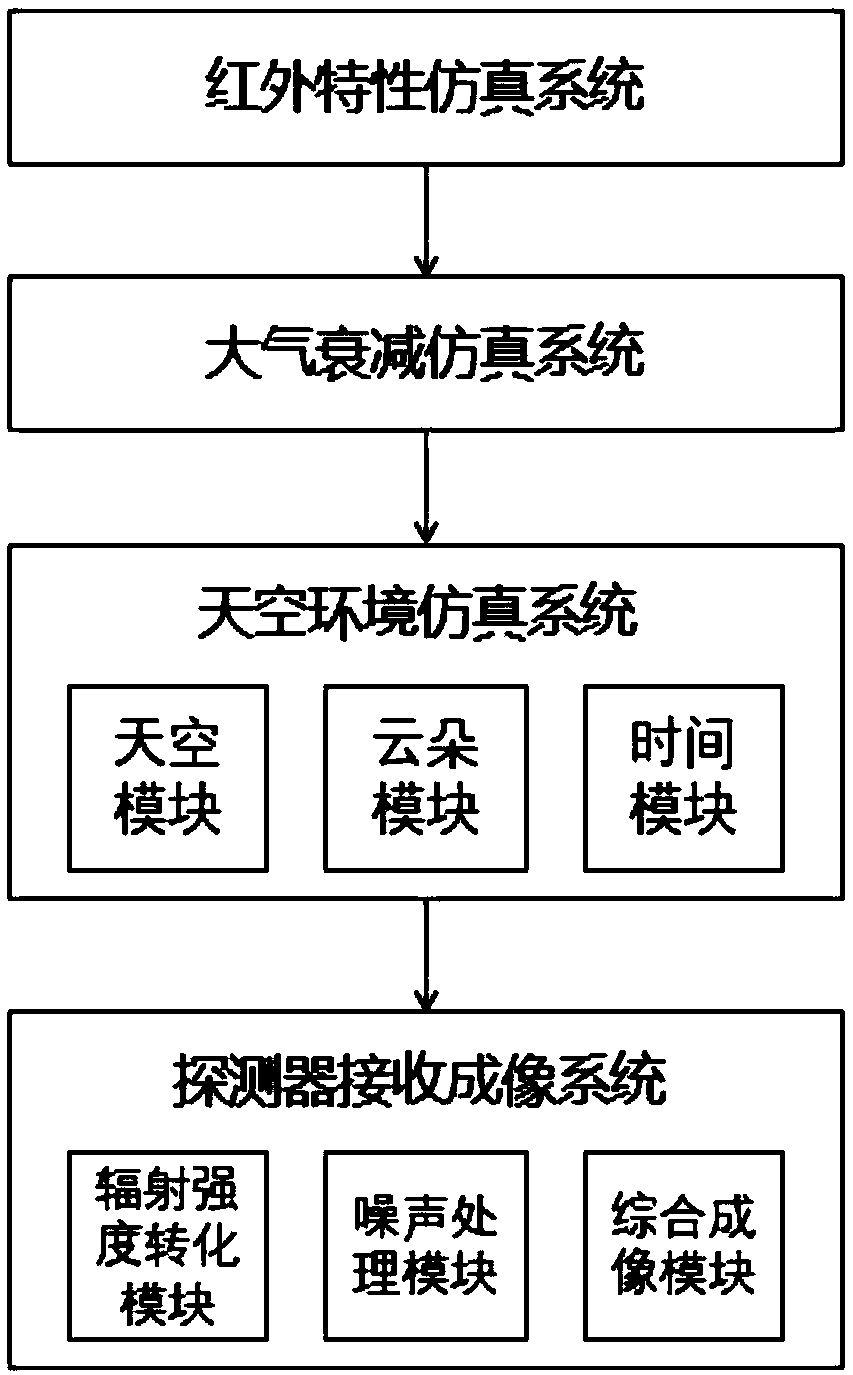

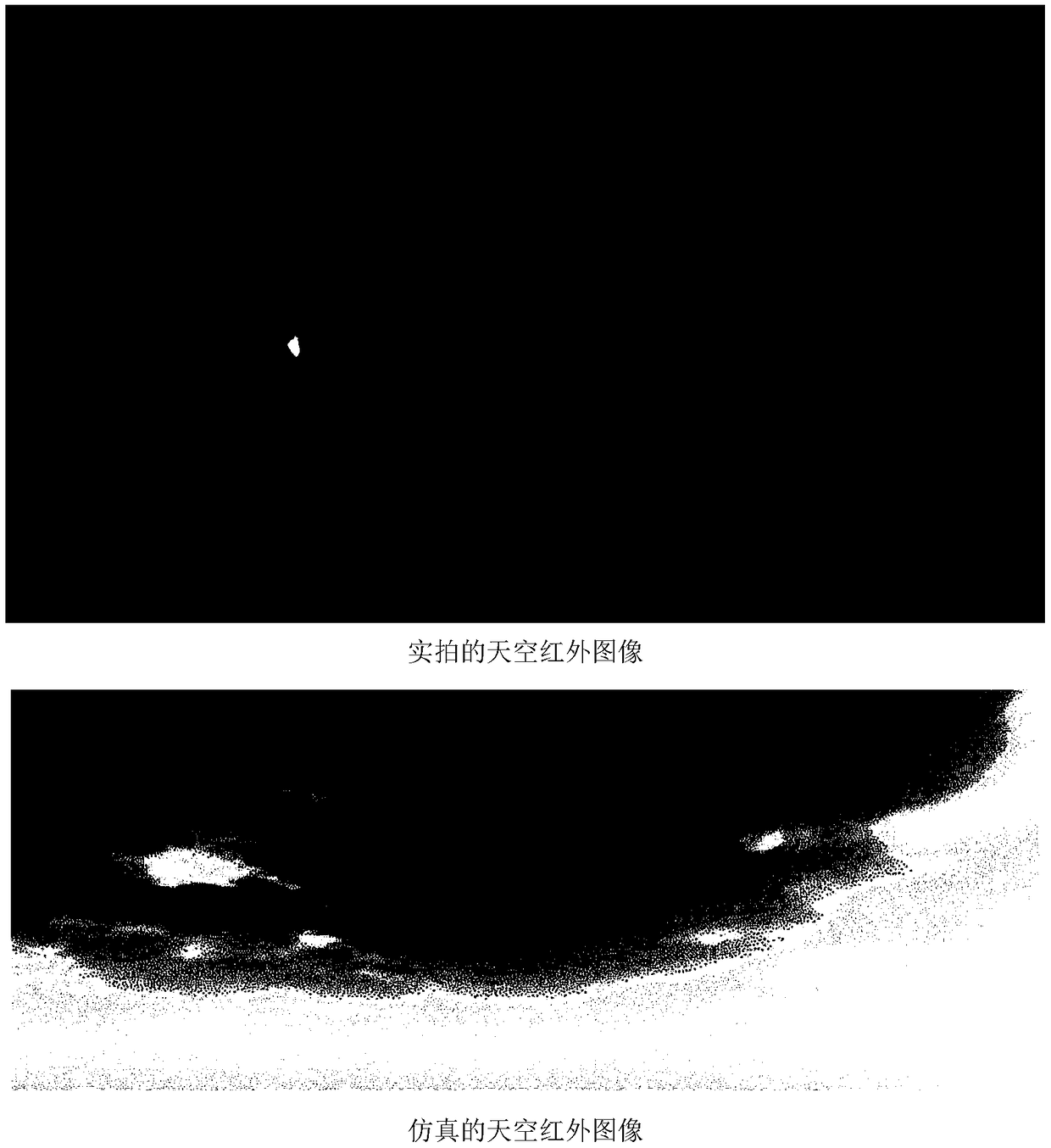

An aerial dynamic infrared scene simulation system based on Unity3D

PendingCN109446553AHigh simulation accuracyImprove real-time performanceSensing radiation from moving bodiesDesign optimisation/simulationUltrasound attenuationGraphics

The invention relates to the field of infrared imaging and computer simulation, and discloses an air dynamic infrared scene simulation system based on Unity3D. The system comprises an infrared characteristic simulation system, an atmospheric attenuation simulation system, a sky environment simulation system and a detector receiving imaging system. The sky environment simulation system comprises asky module, a cloud module and a time module. The detector receiving imaging system comprises a radiation intensity conversion module, a noise processing module and an integrated imaging module. The realization methods of the simulation system comprise 1 creating a three-dimensional model and calculate the infrared radiation characteristics; 2 creating an atmospheric transmittance database; 3 creating a dynamic sky environment; 4, visualizing that receiving unit and the simulation system of the analog detector. The present invention accurately calculates the infrared characteristics of a high-speed flying missile, combines a new generation graphics engine Unity3D, fuses a complex sky model, simulates and generates infrared video closer to real shooting, and generates a large number of testvideo for subsequent infrared target detection and tracking.

Owner:TSINGHUA UNIV

Hierarchical-extension discrete element simulation method

ActiveCN107808030AAccurately reflectHigh simulation accuracyDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationBasement

The invention provides a hierarchical-extension discrete element simulation method. The method comprises the steps that based on formation rock mechanical properties and basement fault positions of areal formation, a discrete element numerical simulation formation is constructed, wherein the discrete element numerical simulation formation comprises a simulation formation, and the simulation formulation has a hierarchical-extension superposed deformation structure of an intermediate ductile layer; and the simulation formulation accurately simulates the rock mechanical properties of the real formation through adjustment of filling material properties, construction and / or structures. Through the hierarchical-extension discrete element simulation method, the model construction mode is simple,the simulation mode is easy to realize, and the simulation result has good accuracy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

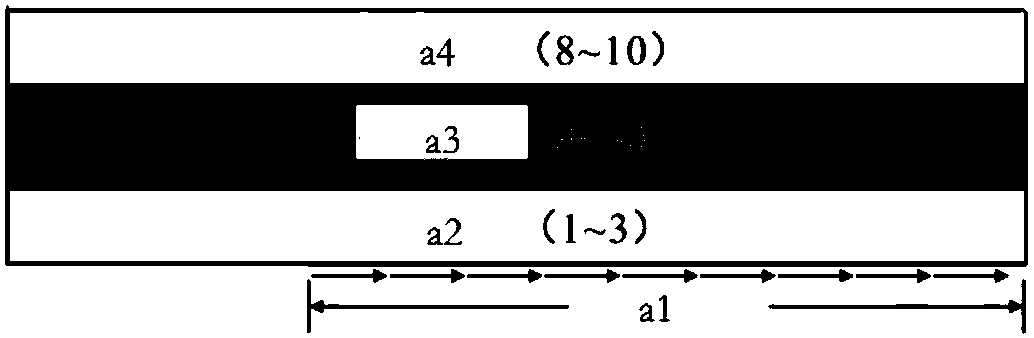

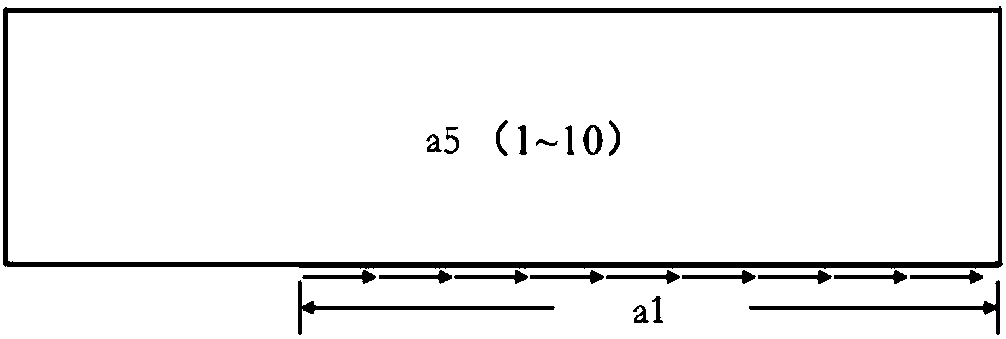

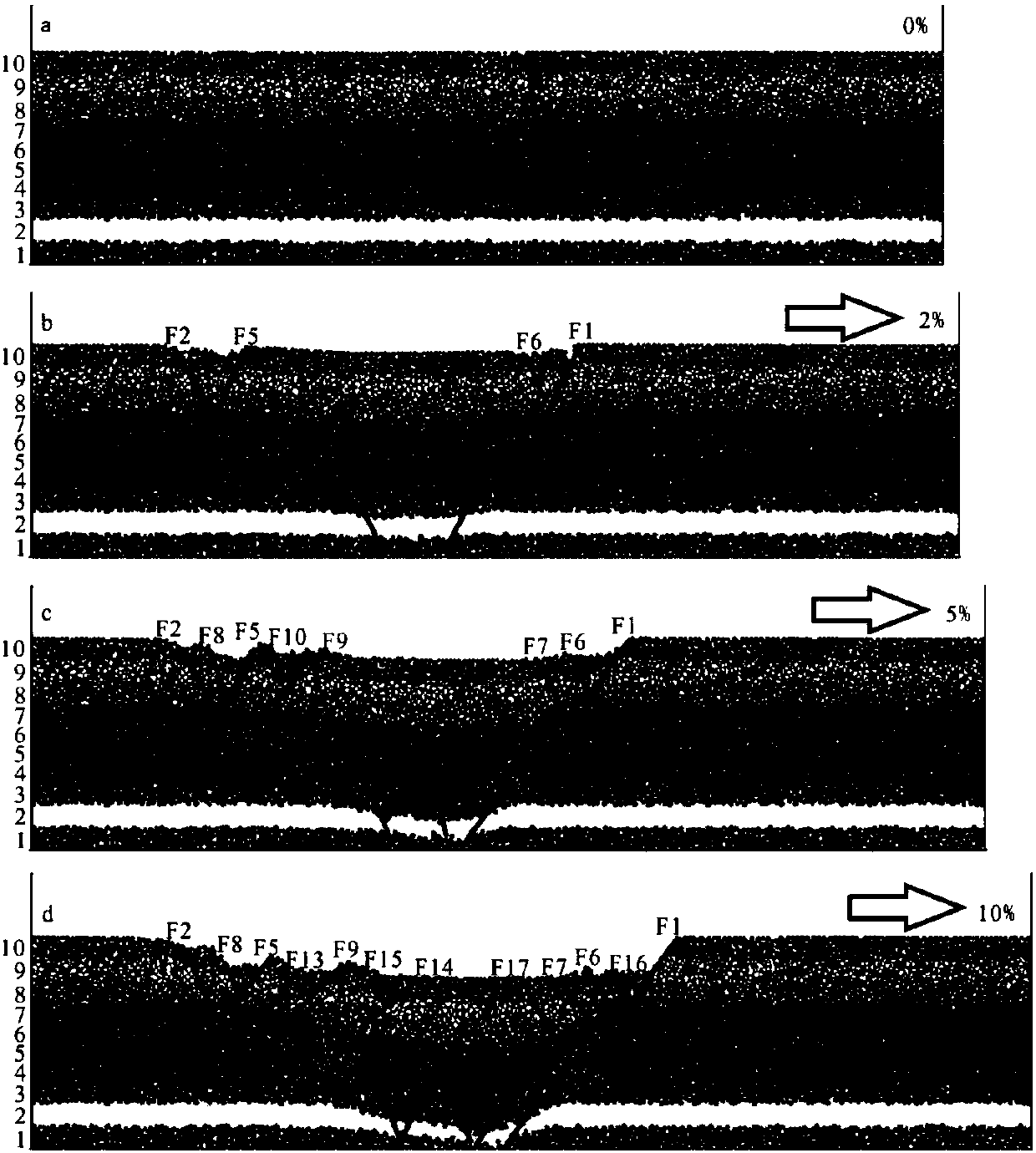

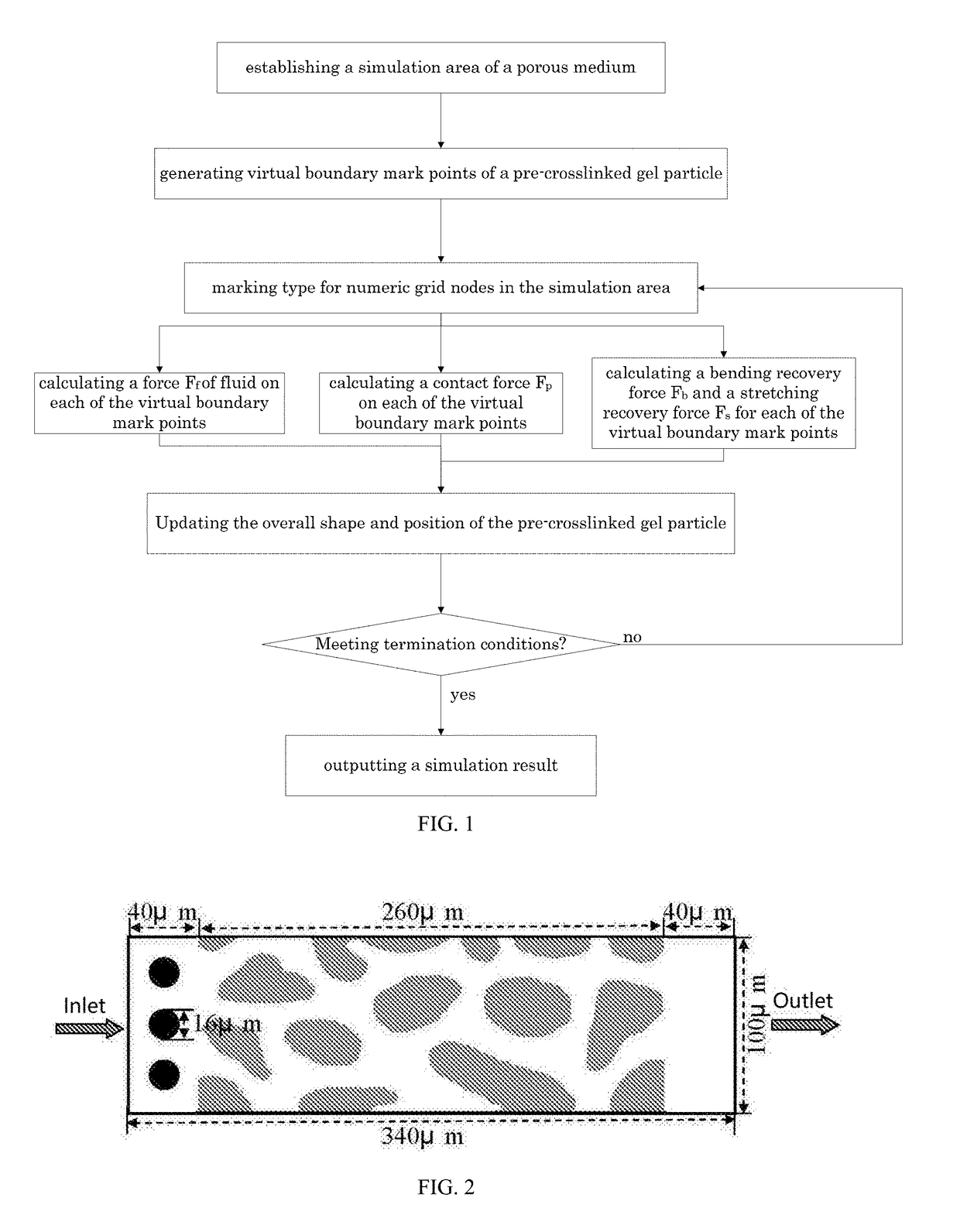

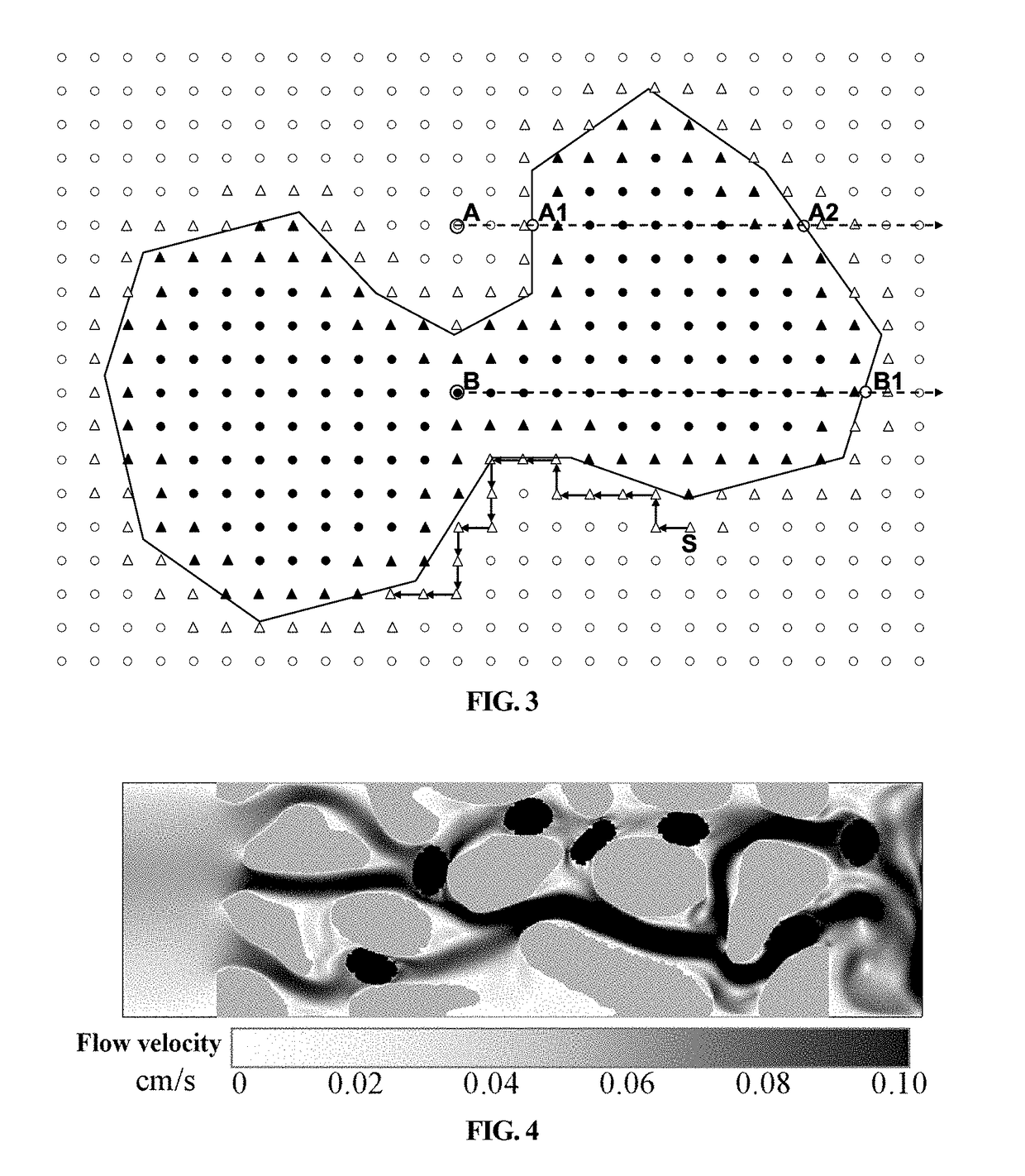

Method for simulation of microscopic flow of pre-crosslinked gel suspension liquid in porous medium

ActiveUS20180341727A1Effective numerical simulationHigh fluid-solid coupling simulation accuracySeismologyGeomodellingNumerical gridPorous medium

Disclosed is a method for simulation of a microscopic flow of pre-crosslinked gel suspension liquid in a porous medium, including the steps of: establishing a simulation area of the porous medium based on a two-dimensional core CT slice image and subjecting the simulation area to numerical grid discretization; setting initial position and original shape of pre-crosslinked gel particles to generate virtual boundary mark points; marking the type of numeric grid nodes; calculating the force of the fluid on each virtual boundary mark point according to the momentum change of the numerical grid nodes on the boundary of the pre-crosslinked gel particles; calculating the contact force on each virtual boundary mark point using a particle contact action model; calculating the bending recovery force and the stretching recovery force for each virtual boundary mark point based on the current shape and original shape of the pre-crosslinked gel particles; and calculating the velocity and displacement of each virtual boundary mark point based on Newton's second law, wherein the respective virtual boundary mark points are connected to obtain the overall shape and position of the pre-crosslinked gel particles.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

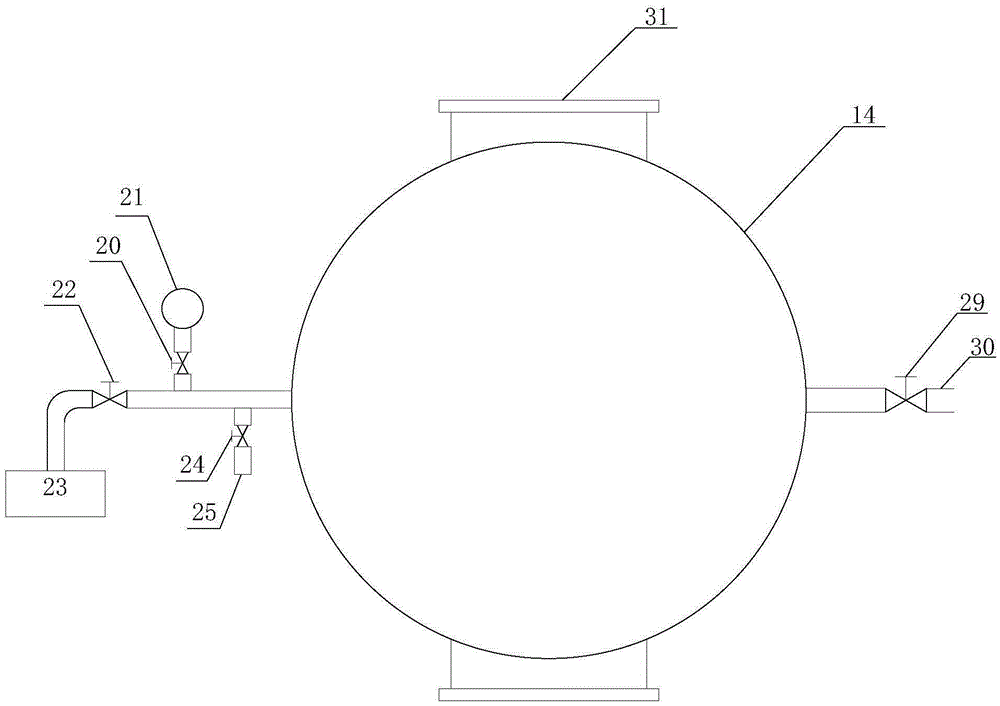

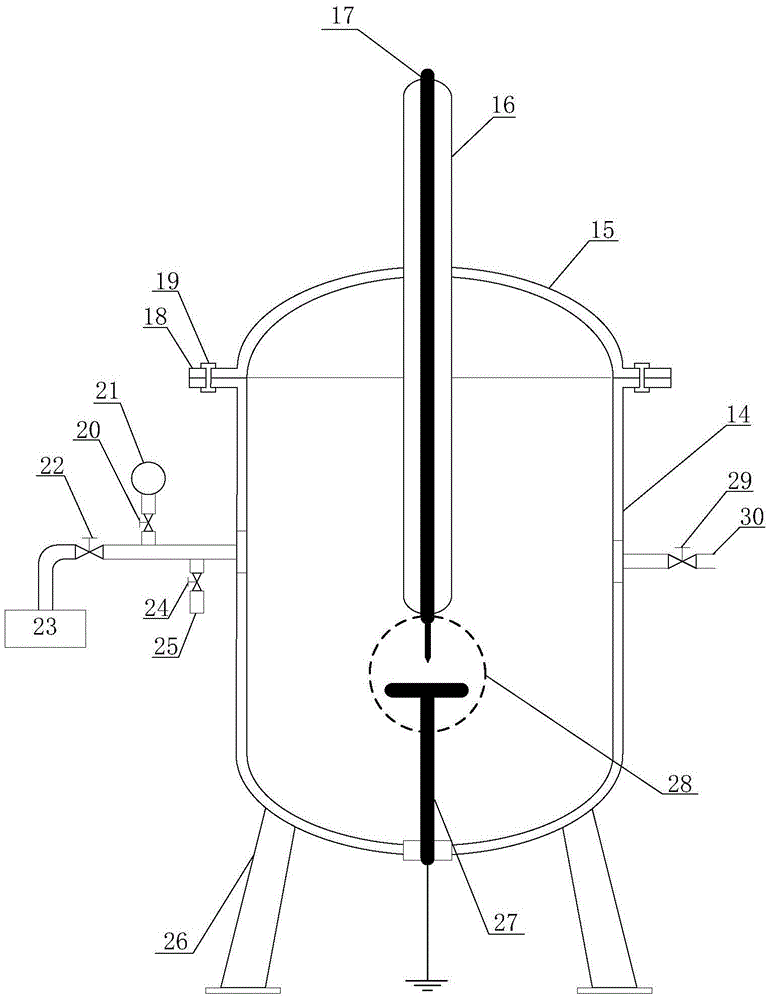

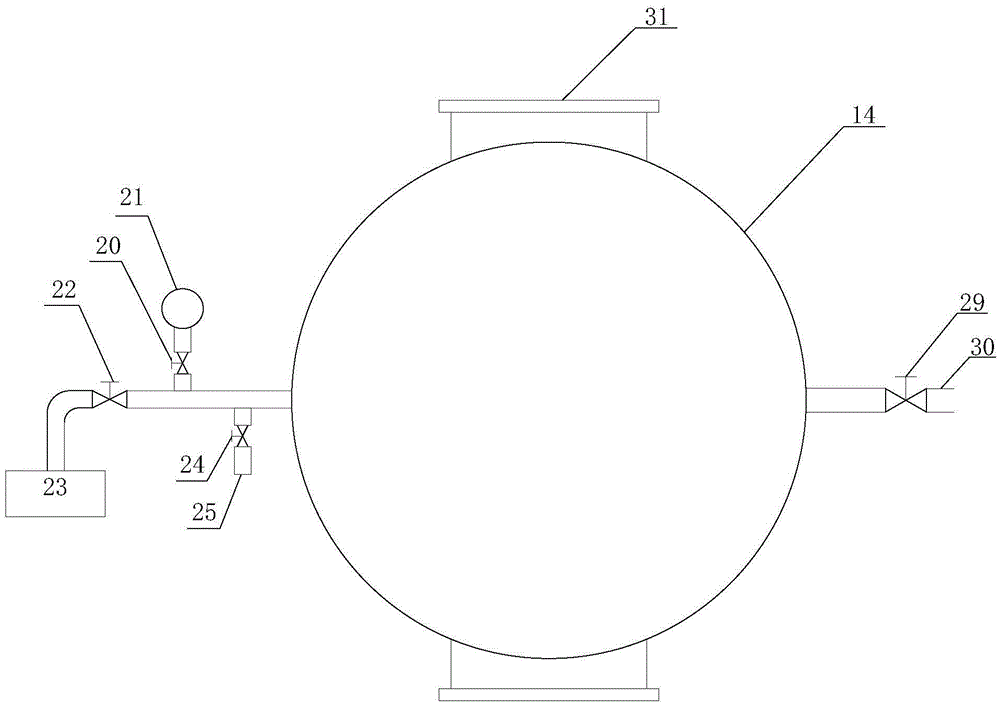

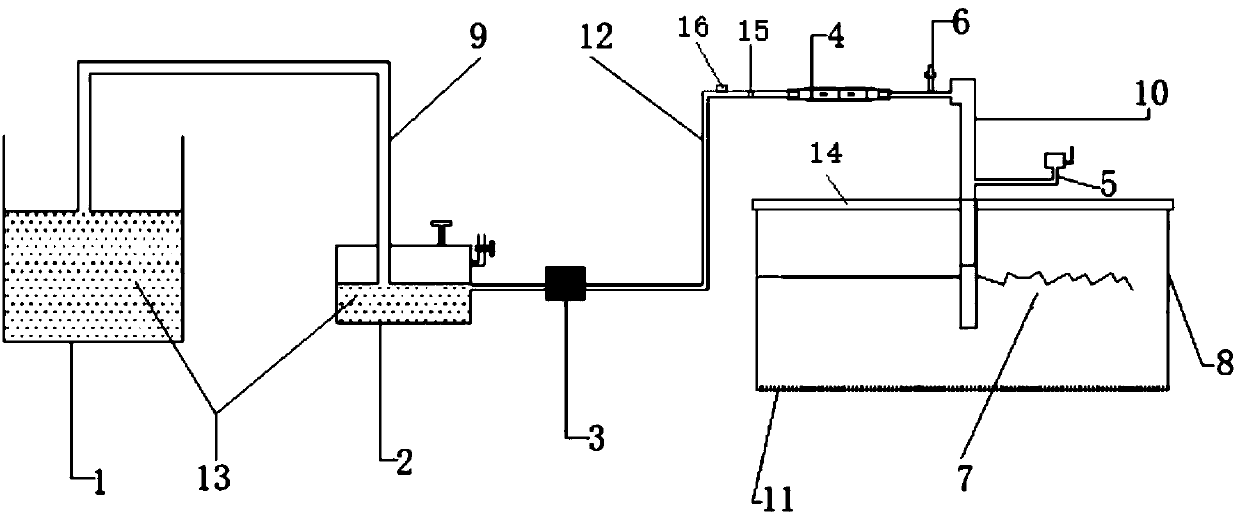

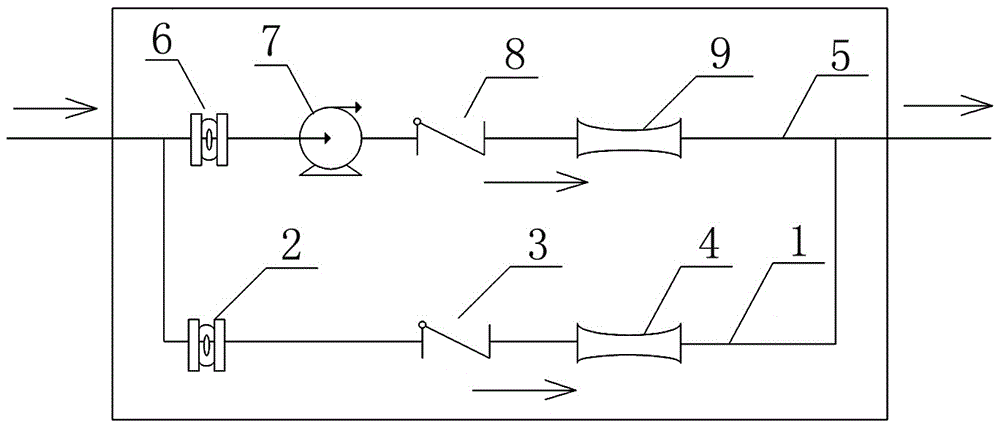

Simulation system and calibration method for hydrodynamic power of parallel pump system of primary coolant circuit of reactor

ActiveCN105788679ALow costGuaranteed Simulation AccuracyNuclear energy generationNuclear monitoringEngineeringCheck valve

The invention discloses a simulation system and a calibration method for hydrodynamic power of a parallel pump system of a primary coolant circuit of a reactor and aims to solve the problem of inaccurate simulation result when an existing simulation pump path is used for simulating flow distribution manners and hydraulic characteristics under working conditions of forced circulation, natural circulation and interconversion between forced circulation and natural circulation. The simulation system comprises a main pump simulating branch and a spare pump simulating branch in parallel connection with the main pump simulating branch, wherein the spare pump simulating branch comprises a parallel connection pipeline (1) and a first resistance adjusting piece (2), a first check valve (3) and a first flow meter (4) which are arranged on the parallel connection pipeline (1). The simulation system provided by the invention has the advantages that the hydraulic characteristics of a parallel pump path under various conditions can be completely and accurately simulated, the test cost can be effectively reduced and the simulation accuracy can be effectively increased.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

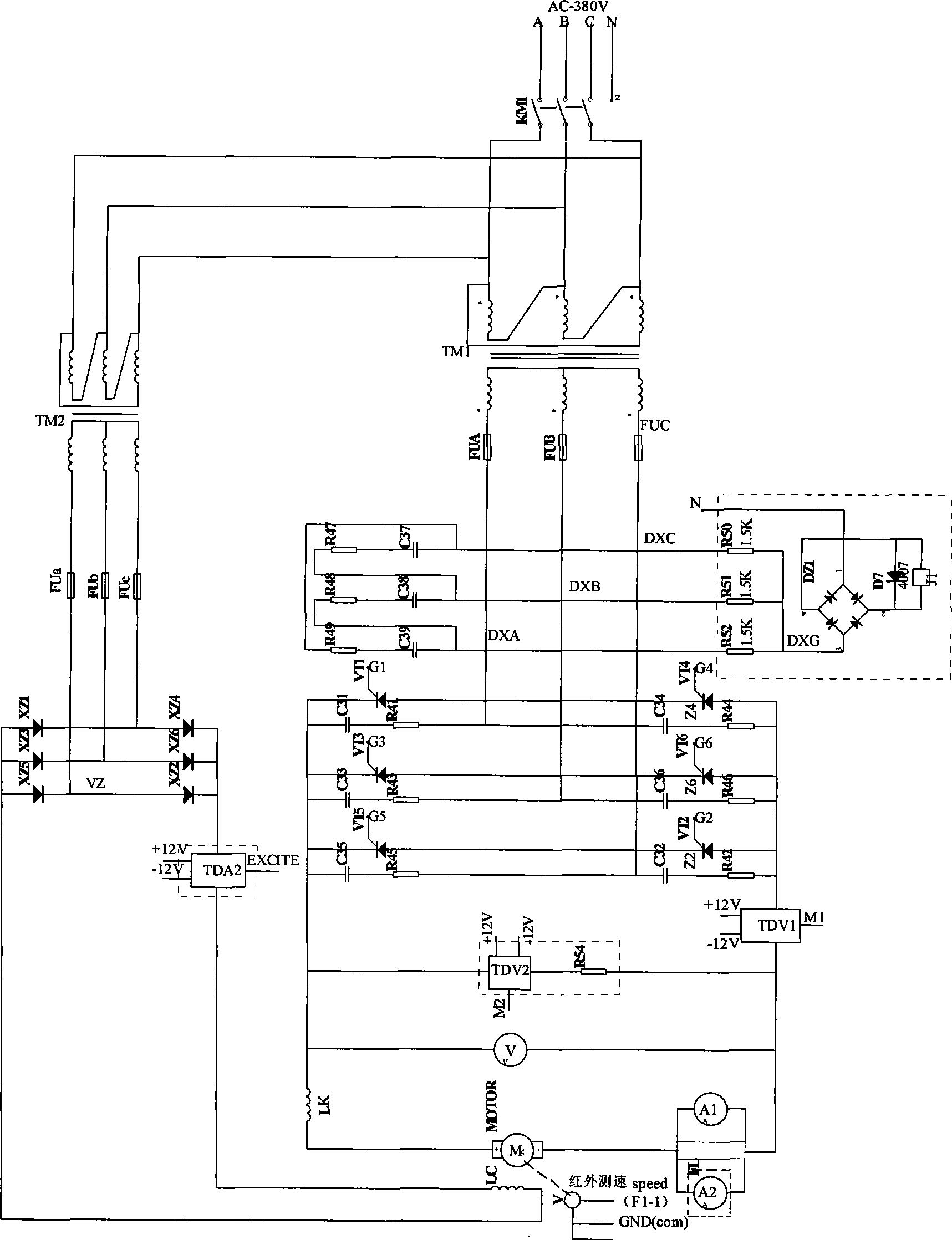

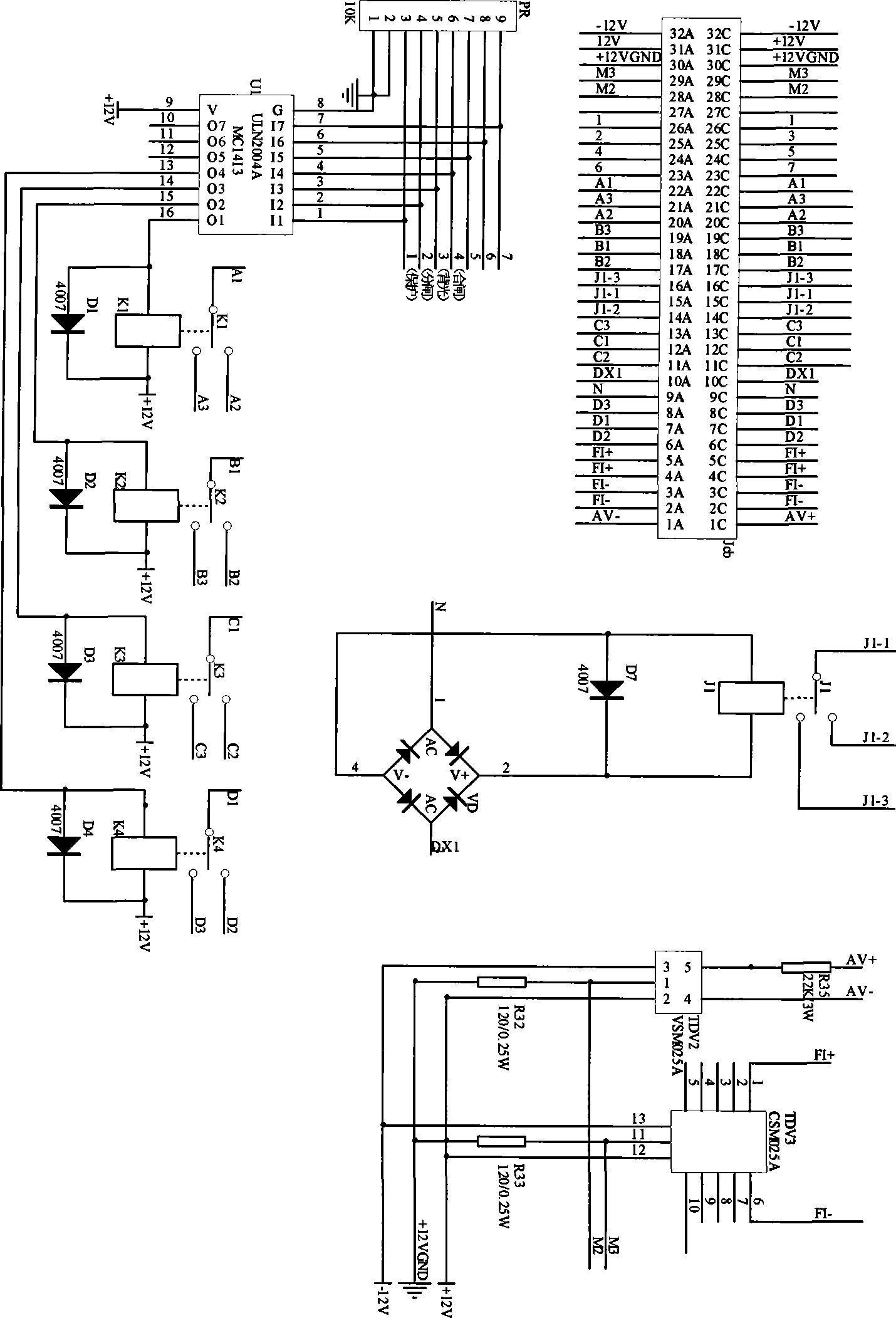

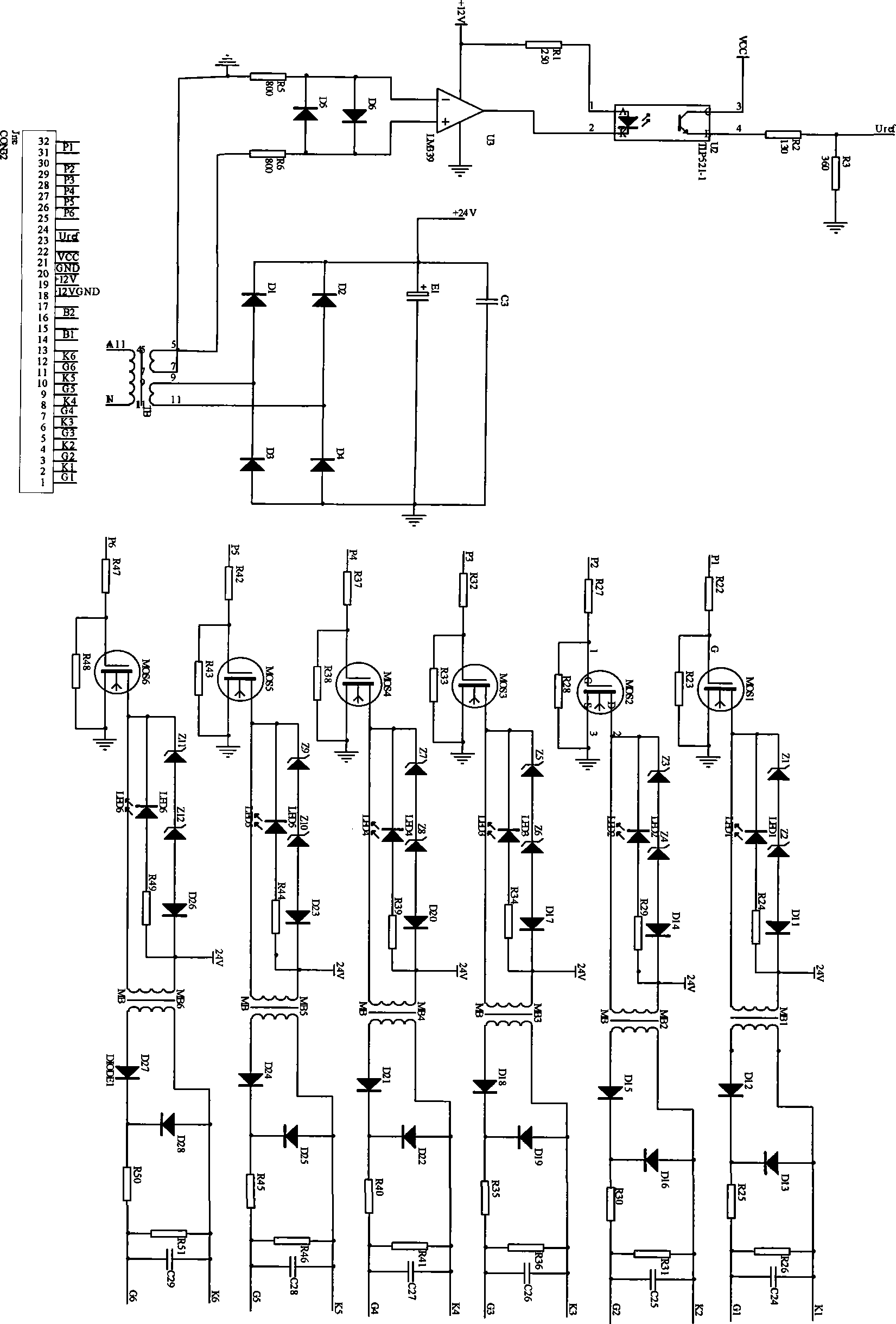

Dynamic simulation apparatus for generator prime system

InactiveCN101425773AImprove the ability to process information quicklyHigh simulation accuracyEducational modelsElectric generator controlData treatmentIsochronous signal

The invention discloses a dynamic emulating device of a motor prime system, which comprises a main loop, an operative loop and a control circuit, wherein the main loop comprises a three-phase controllable rectifier providing electricity for a DC motor, and a switch for switching on or off a controllable rectifier; the operative loop drives the switch on the main loop and is simultaneously and electrically connected with the control circuit; the control circuit comprises a microprocessor, a signal acquiring circuit, a triggering circuit used for providing triggering pulses for each thyristor of the three-phase controllable rectifier, and a relay protecting and switch signal outputting circuit connected with the operative loop; the signal acquiring circuit, the triggering circuit and the relay protecting and switch signal outputting circuit are connected with the microprocessor; and the signal acquiring circuit comprises an armature current acquiring circuit, an armature voltage acquiring circuit, an excitation current acquiring circuit, a synchronous signal generating circuit and a speed measuring pulse acquiring circuit. The dynamic emulating device of a motor prime system has strong data processing function and high simulating accuracy of the motor prime system.

Owner:HUNAN UNIV

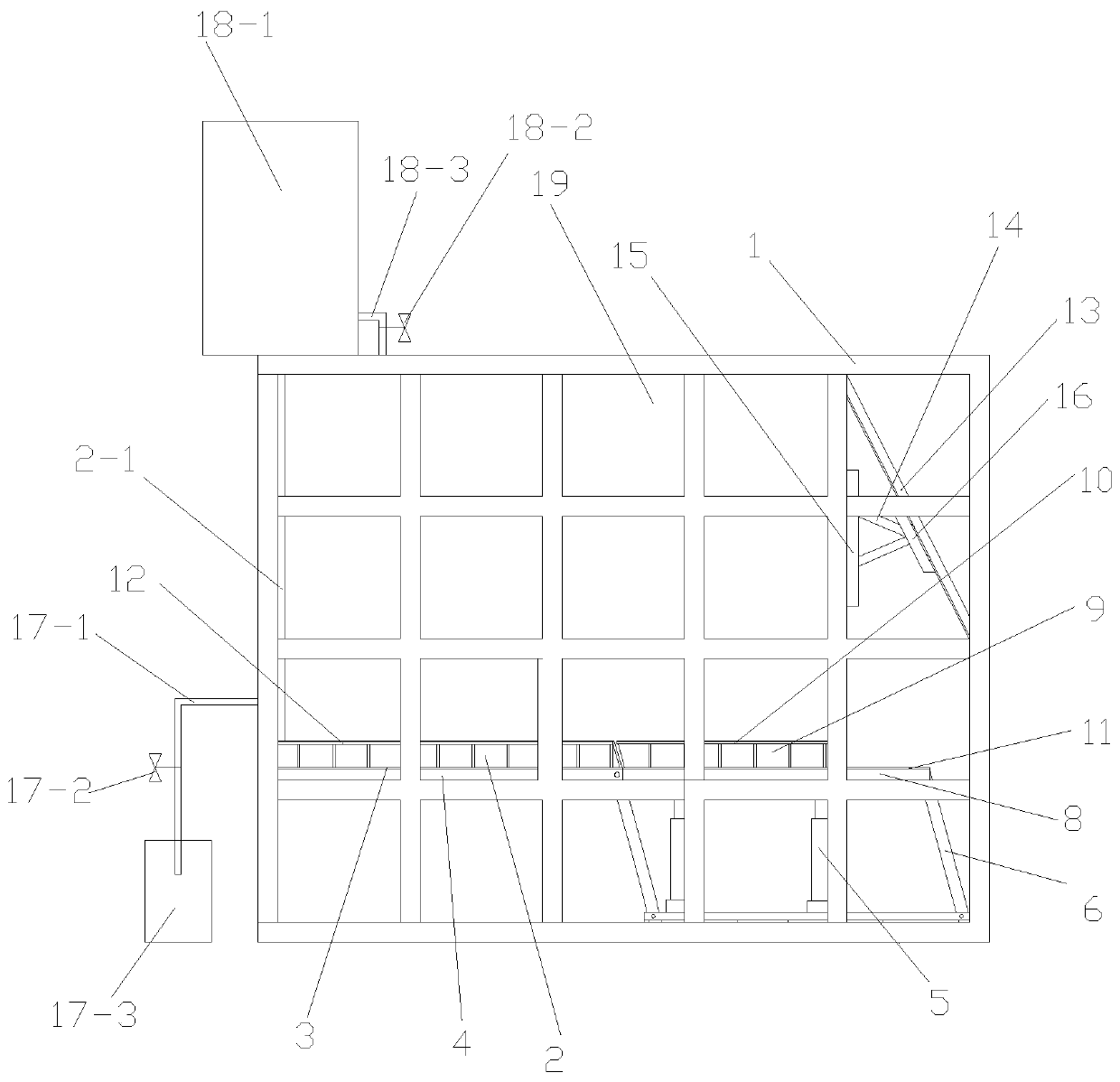

Ground fracture test device and method for simulating fracture dislocation and underground water change

ActiveCN110954680ASimple structureReasonable designEarth material testingFracture DislocationsSoil science

The invention discloses a ground fracture test device and a method for simulating fracture dislocation and underground water change. The device comprises a test model box, a fixed platform and a movable platform, a dislocation adjusting mechanism is arranged at the bottom of the moving platform; a first bottom plate, a first waterproof plate and a first water stop plate are sequentially arranged on the fixed platform from bottom to top, a second bottom plate, a second waterproof plate and a second water stop plate are sequentially arranged on the movable platform from bottom to top, and the dislocation adjusting mechanism comprises a support, a jack and a sliding limiting component. The method comprises the following steps: 1, performing preparation before a test; 2, laying a model soil layer in the model box, burying a sensor and connecting the sensor with a data acquisition instrument; 3, injecting water into the model soil layer; 4, simulating soil layer fracture dislocation of thesimulation model; and 5, simulating underground water level change by model soil layer drainage. The device can simulate the development condition of the ground fissures under the conditions of fracture dislocation and underground water change, and is high in simulation accuracy.

Owner:CHANGAN UNIV

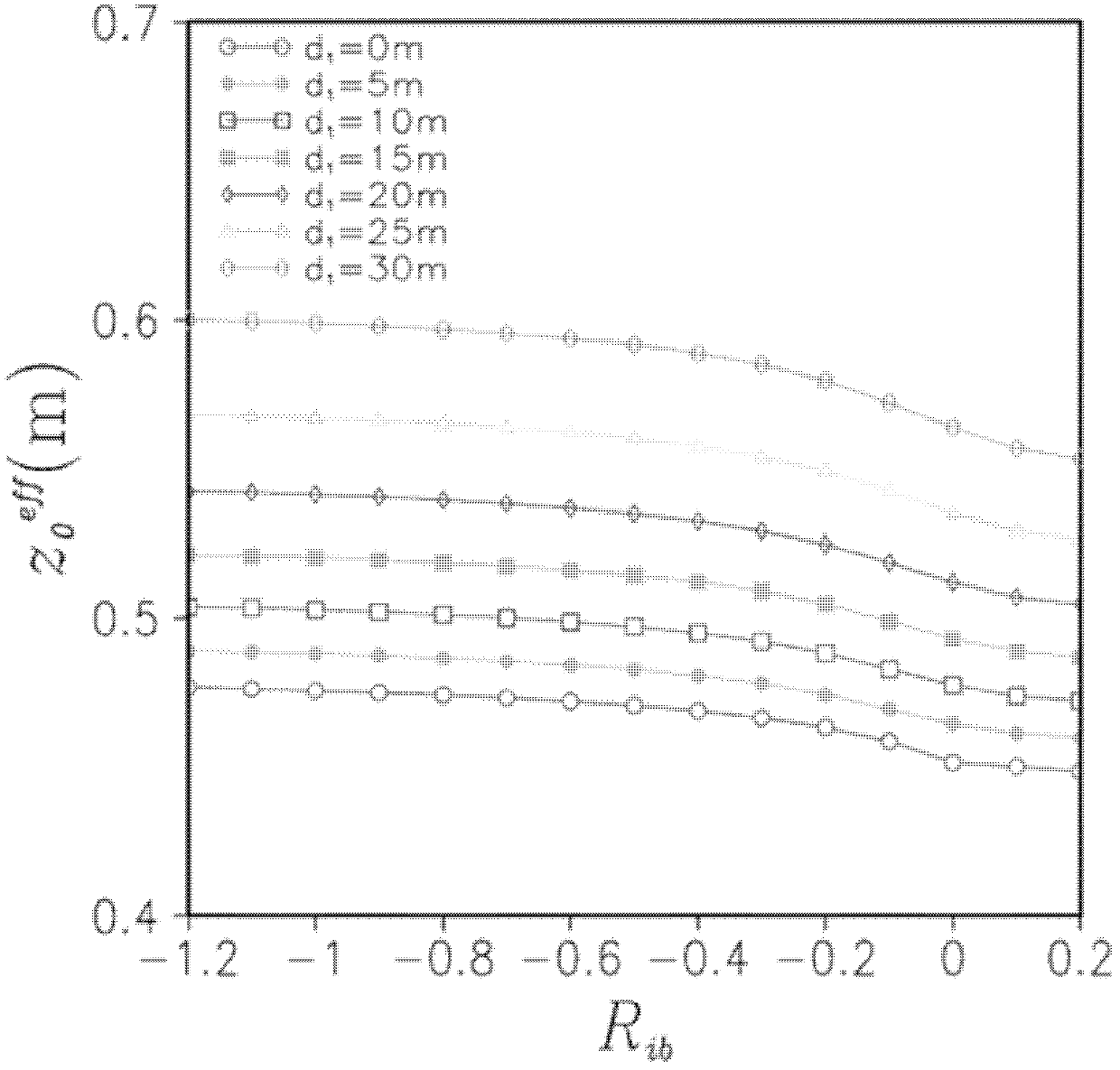

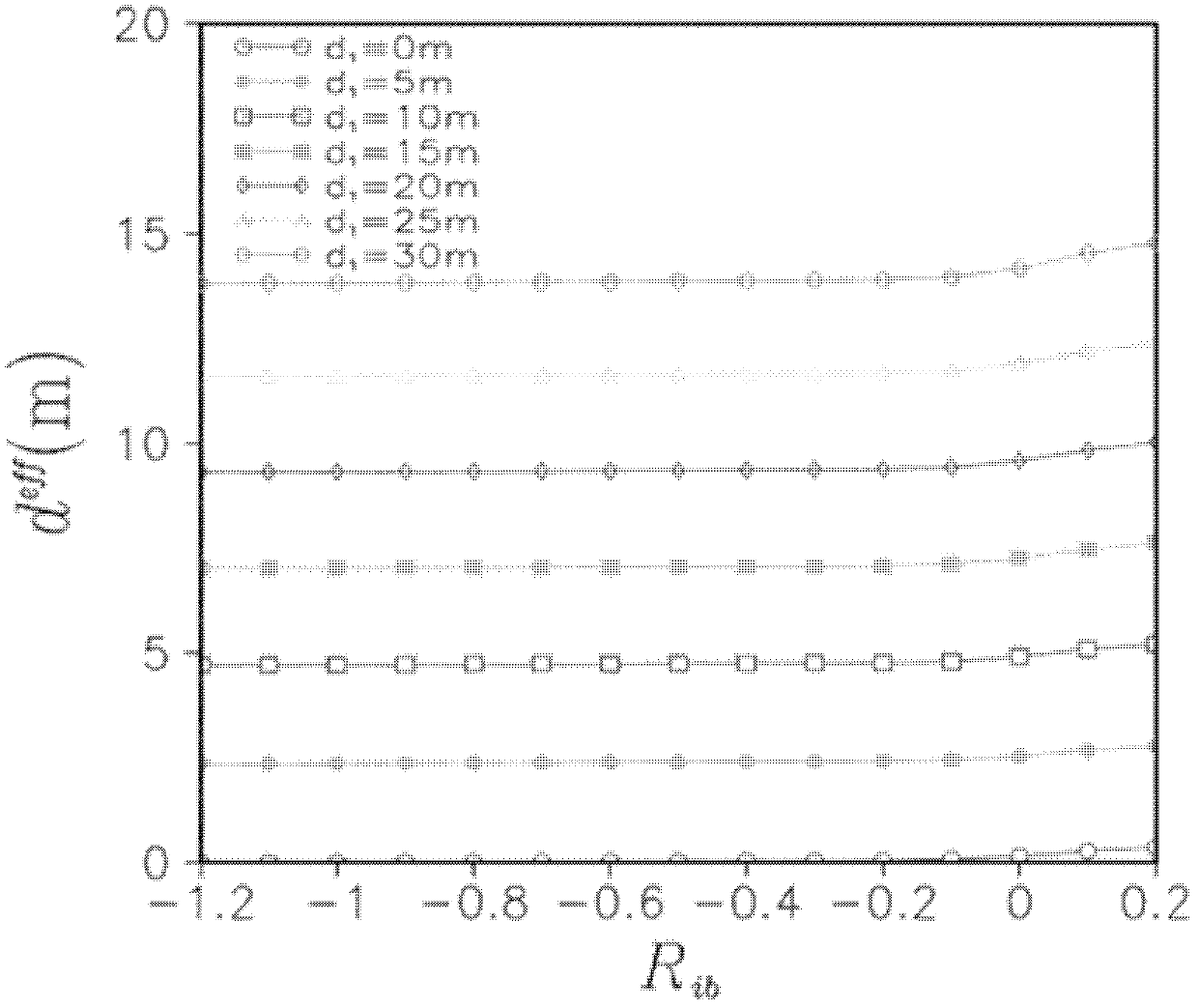

Method for improving accuracy rate of meteorological environment numerical simulation

InactiveCN102521487AGuaranteed conservationHigh simulation accuracySpecial data processing applicationsNumerical modelsEarth surface

The invention discloses a method for improving the accuracy rate of meteorological environment numerical simulation. The method comprises the following steps of: enabling the turbulent flux calculated by using the roughness and the effective null plane displacement in a meteorological environment numerical model net region to be equal to the sum of the turbulent fluxes calculated by using each underlying surface earth service type in the numerical model net region, obtaining a formula (11); enabling the total air mass calculated by using the roughness and the effective null plane displacement in the numerical model net region to be equal to the weighted sum of the air mass calculated by using each underlying surface earth service type in the numerical model net region, obtaining a formula (12), and obtaining an original functional form (13) from the formula (12) by integration; resolving the effective roughness and the effective null plane displacement of the non-uniform earth surface in the numerical model net region, importing an atmosphere initial field and a lateral boundary forcing field into the meteorological environment numerical model, and then, importing the sum into the numerical model to get the numerical simulation result. The method improves the accuracy rate of meteorological environment numerical simulation, and can be used in environmental assessment and wind power utilization.

Owner:PLA UNIV OF SCI & TECH

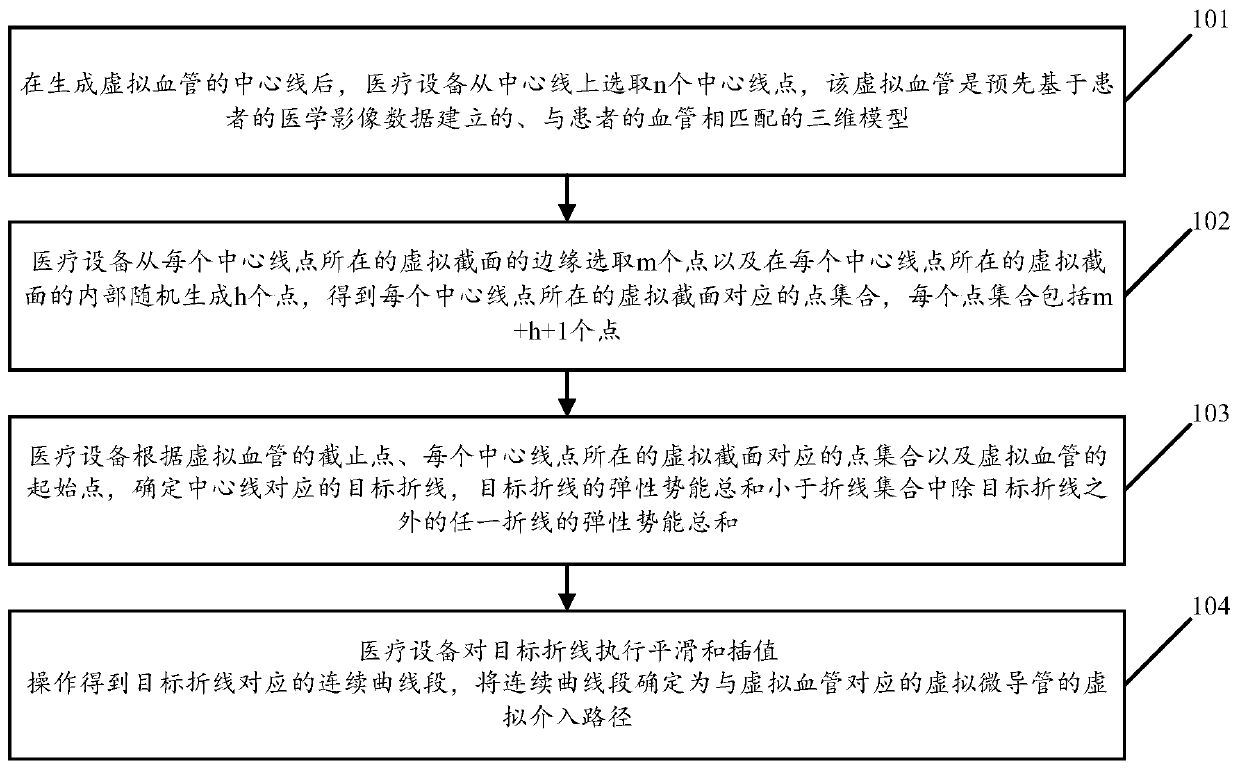

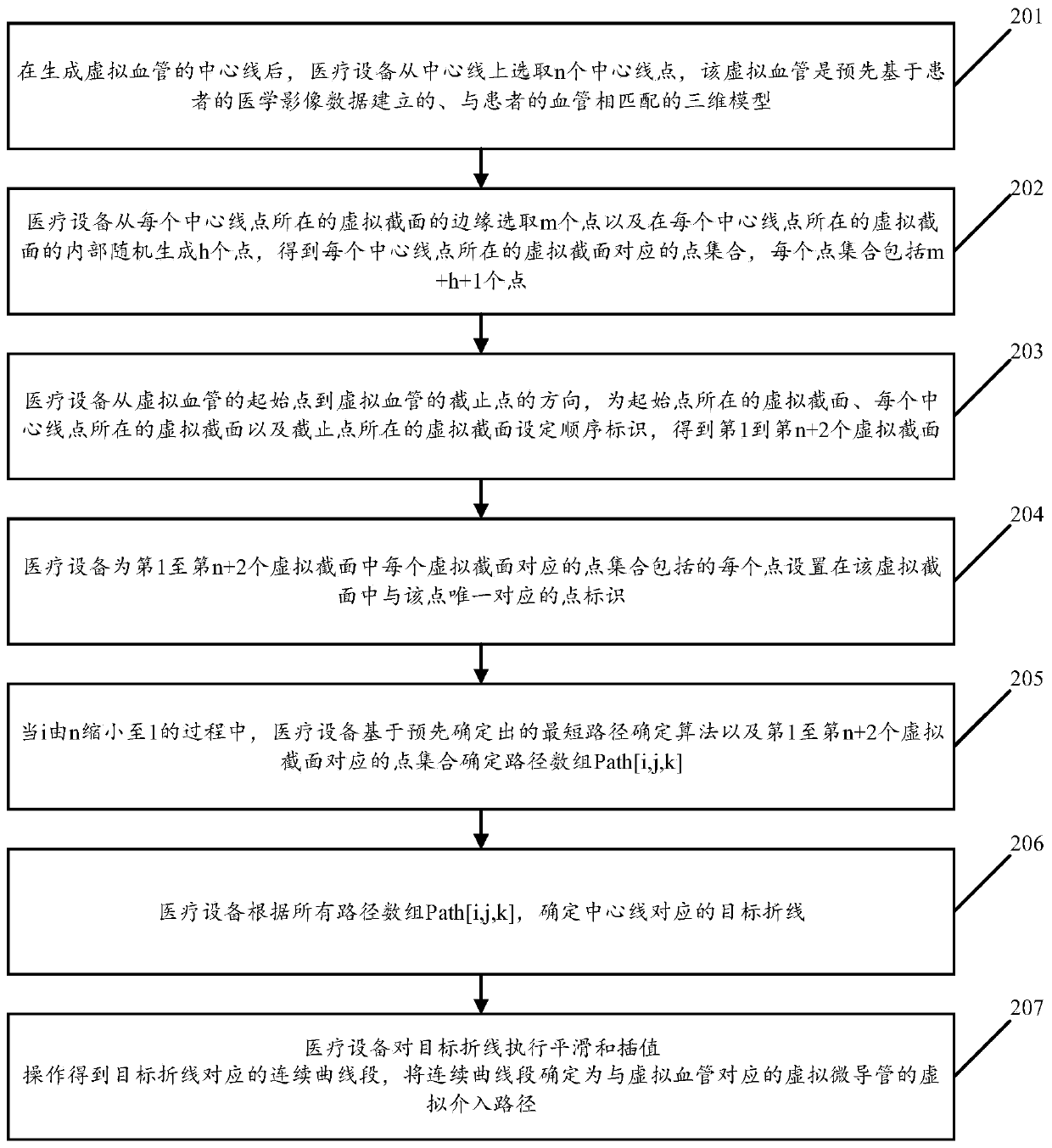

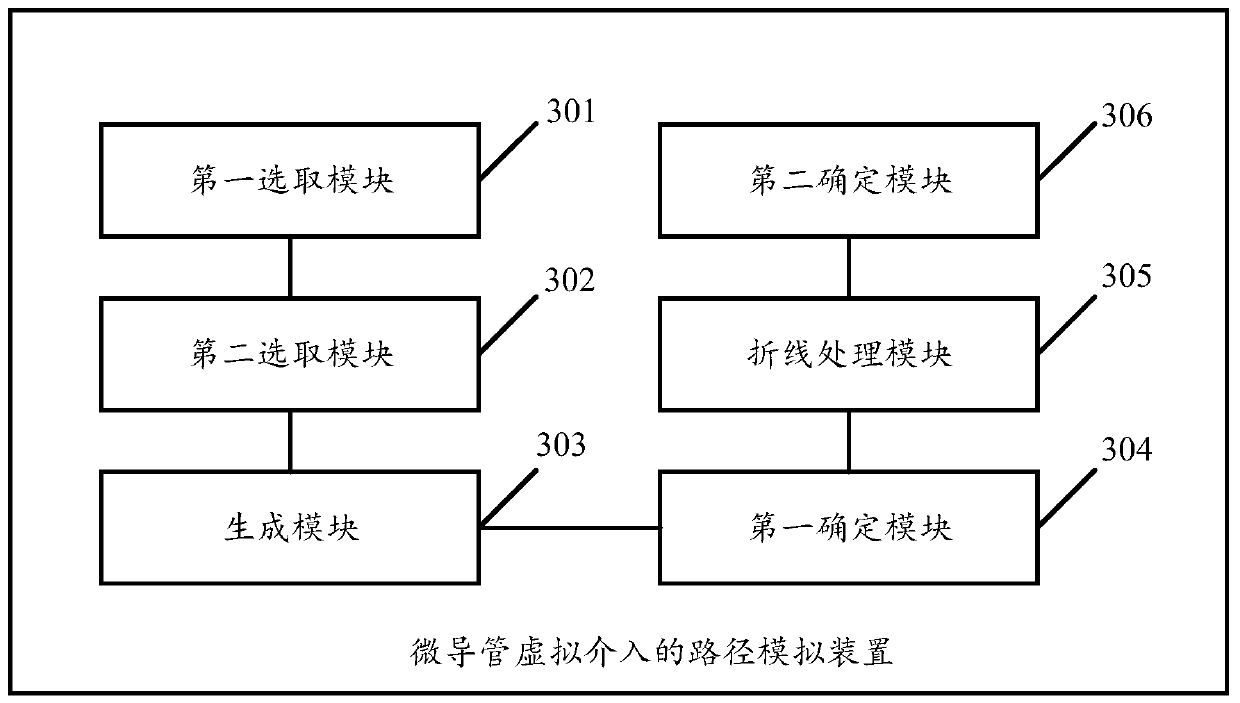

Micro-catheter virtual intervention path simulation method and device thereof

ActiveCN110507415AImprove accuracyWon't penetrateComputer-aided planning/modellingSimulationCatheter

The invention discloses a micro-catheter virtual intervention path simulation method and device thereof, and the method comprises the steps: n central line points are selected from a central line after the central line of a virtual blood vessel is generated; m points are selected from the edge of a virtual cross section where each center line point is located, h points are randomly generated inside the virtual cross section, and a point set corresponding to the virtual cross section where each center line point is located is obtained; according to the cut-off point of the virtual blood vessel,each point set and a starting point of the virtual blood vessel, a target broken line corresponding to the center line is determined, and the elastic potential energy sum of the target broken lines is smaller than the elastic potential energy sum of any broken line except the target broken line in the broken line set; and smoothing and interpolation operation can be performed on the target brokenline to obtain a continuous curve segment, and the continuous curve segment is determined as a virtual intervention path of the virtual micro-catheter corresponding to the virtual blood vessel. Therefore, the simulation accuracy of the interventional path of the micro-catheter can be improved, and then the plasticity of the micro-catheter and the accuracy of the micro-catheter entering the affected part can be improved.

Owner:唯智医疗科技佛山有限公司

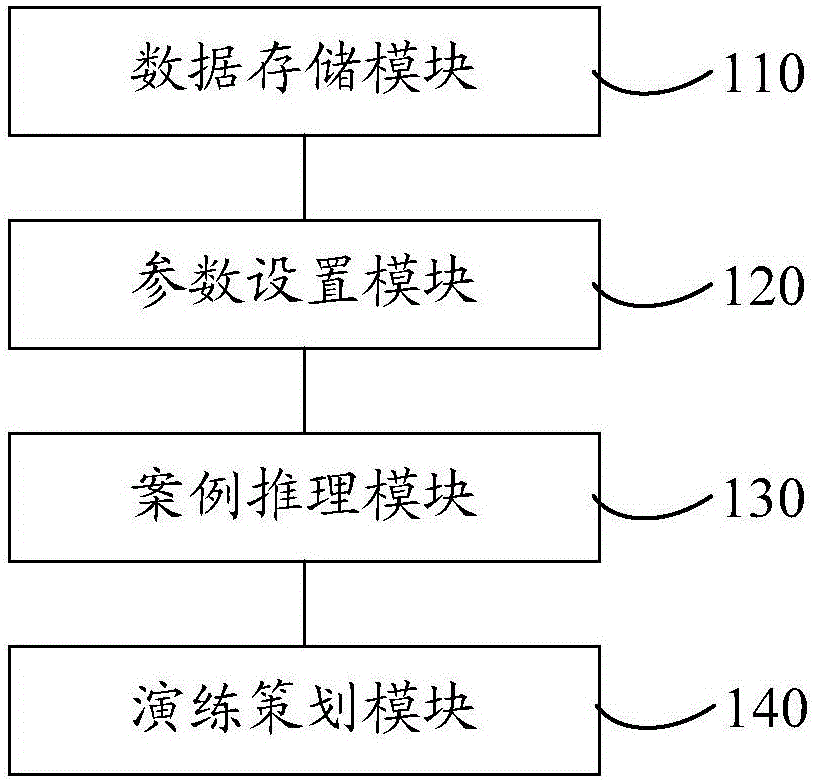

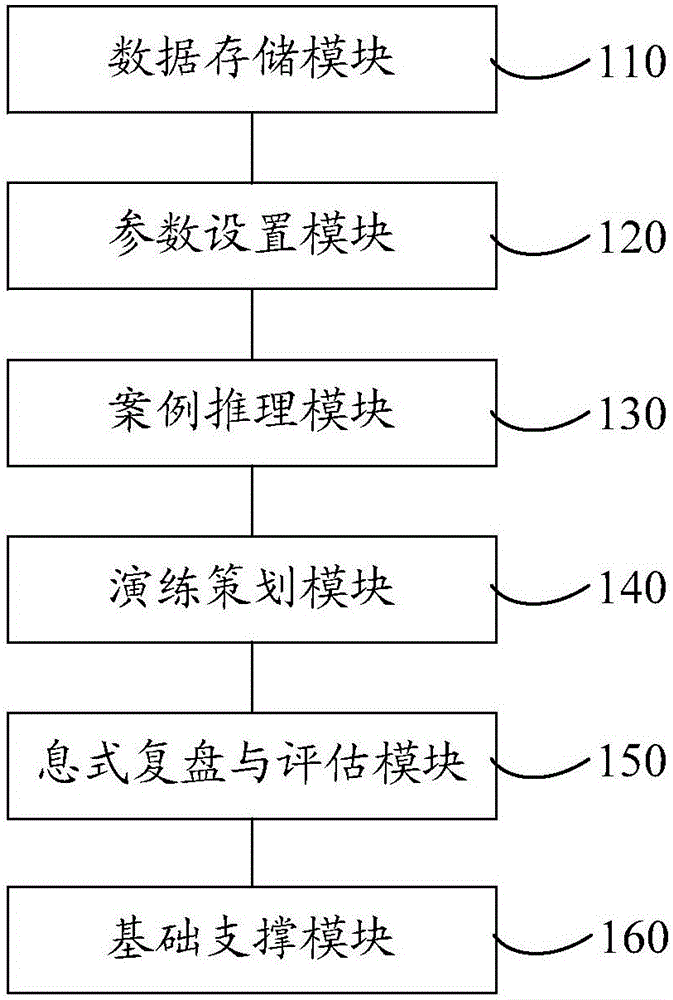

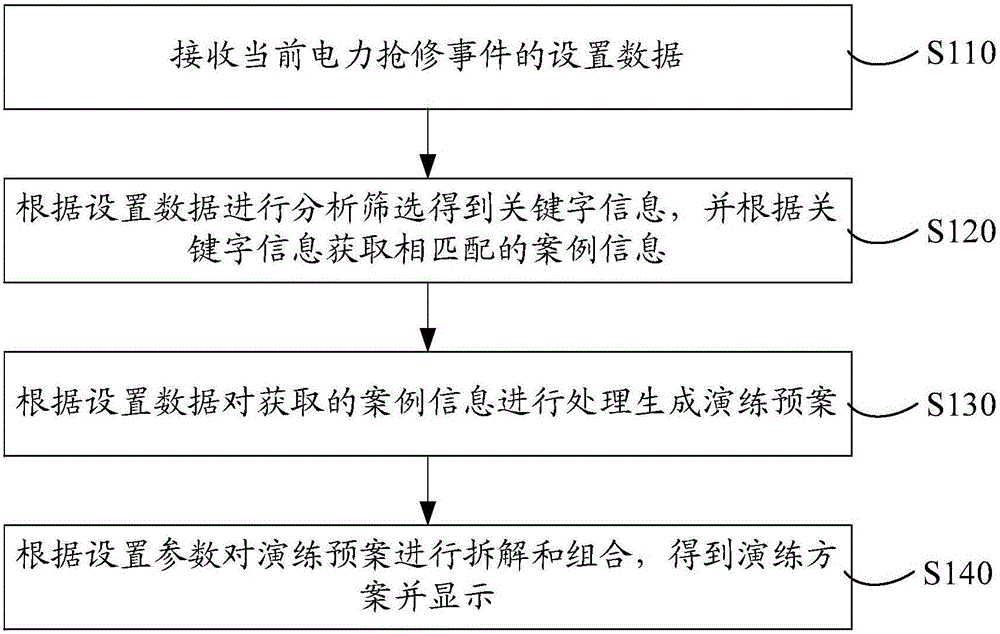

Electricity first-aid repair practice simulation system and method

InactiveCN106202507ASolve intelligent generationSolve the problem of dynamic evolutionData processing applicationsOther databases retrievalElectricityData retrieval

The invention relates to an electricity first-aid repair practice simulation system and method. The method comprises the steps that set data of a current electricity first-aid repair event is received, analysis selection is conducted on the set data to obtain keyword information, and matched case information is obtained from a data storage module according to the keyword information; the obtained case information is processed according to the set data to generate a practice scheme, a practice pre-arranged scheme is decomposed and combined according to set parameters, and a practice scheme is obtained and displayed. A similar case is found through retrieving according to the received set data, the practice pre-arranged scheme is generated, and the practice scheme is obtained by conducting effective case-based reasoning according to the set parameters and displayed, the practice scheme is supplied to a participating unit for practice, the problems of intelligent generation and dynamic evolution of simulation scenarios are solved, the simulation practice scenarios better accord with on-site reality of emergency events, and the simulation accuracy is improved.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

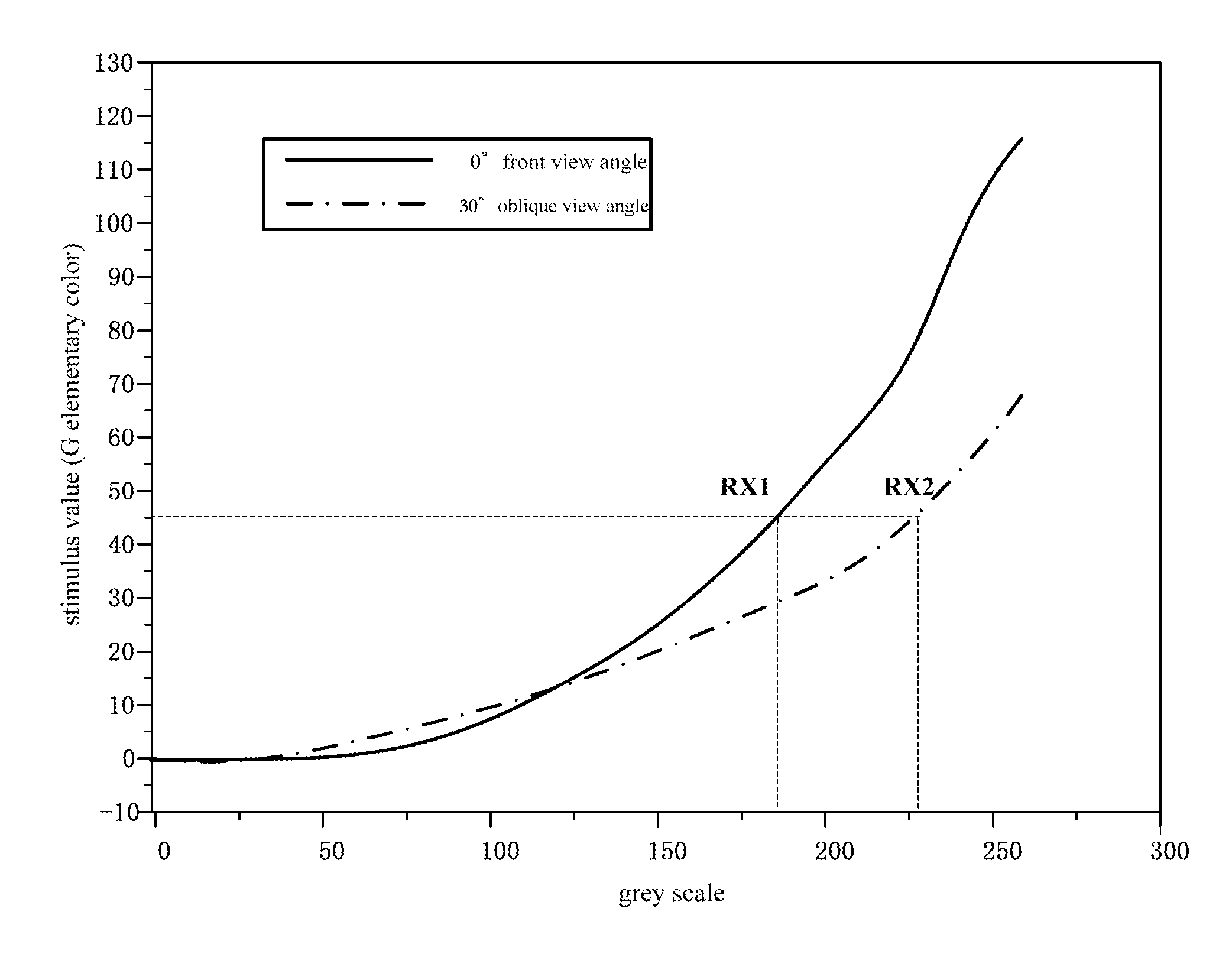

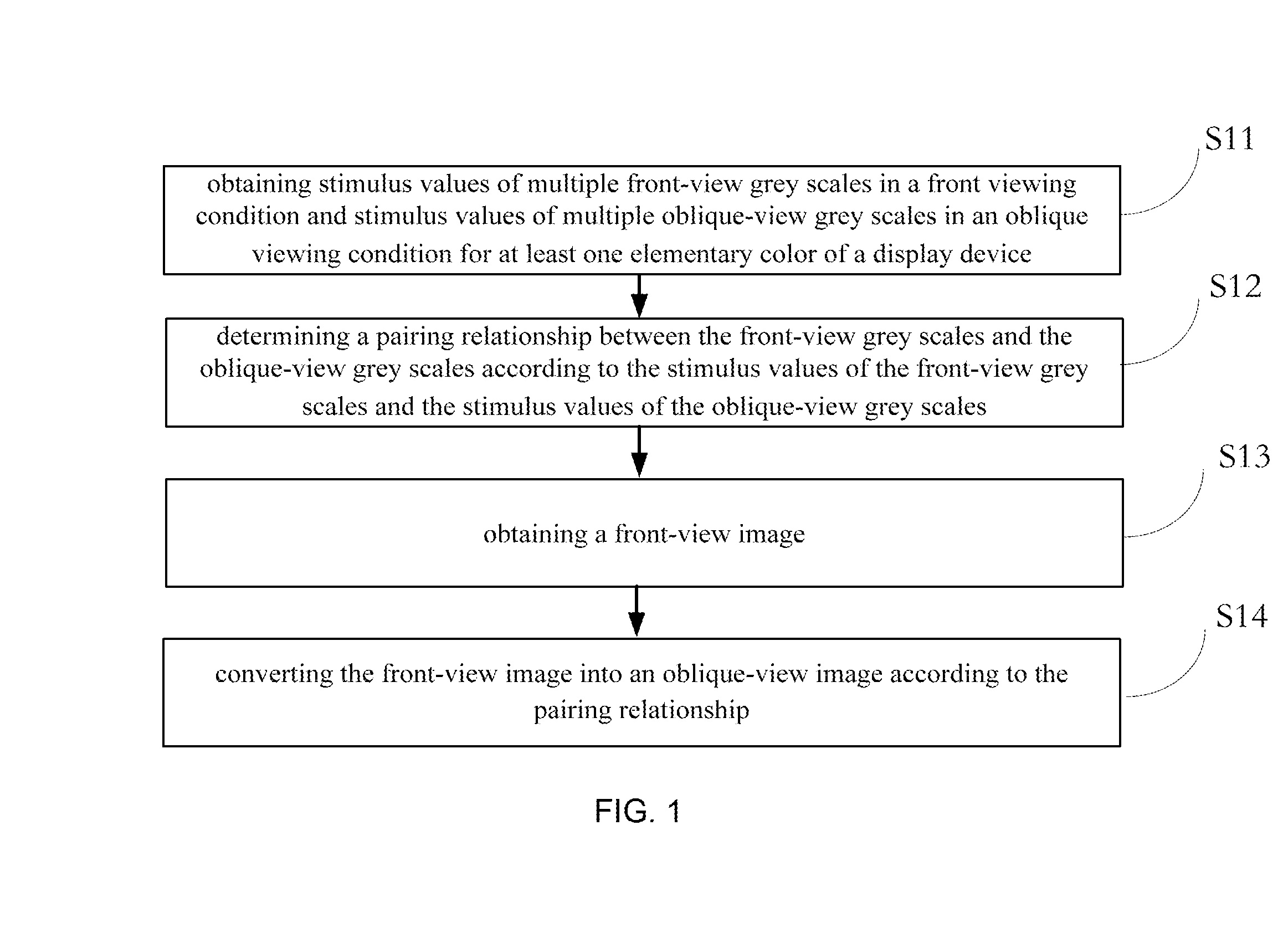

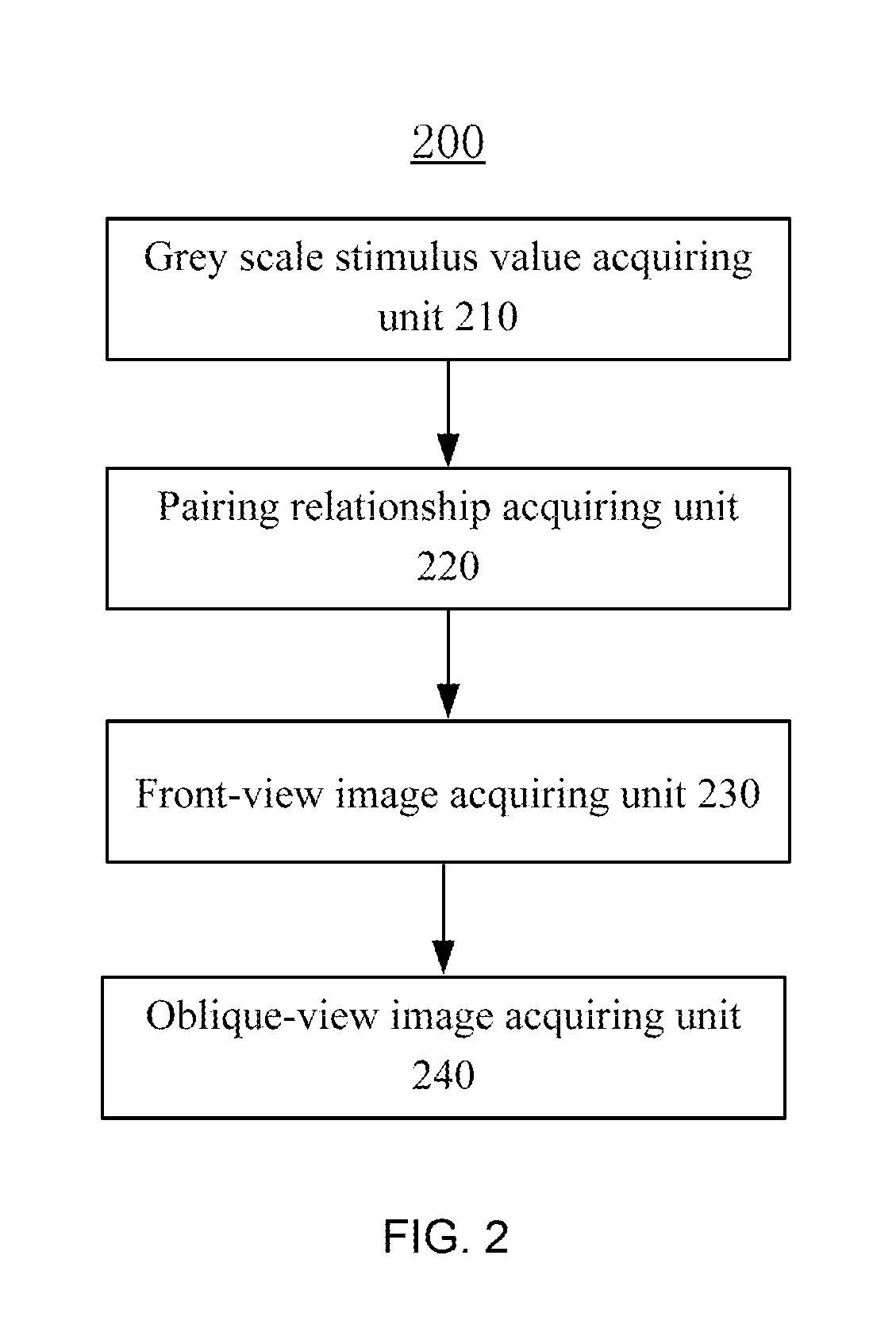

Method and device for simulation of image at oblique view angle

InactiveUS20130229430A1Improve accuracyRemove colorCathode-ray tube indicatorsComputer graphics (images)Display device

The present invention discloses a method and a device for simulation of image at oblique view angle. The method includes: obtaining stimulus values of multiple front-view grey scales in a front viewing condition and stimulus values of multiple oblique-view grey scales in an oblique viewing condition for at least one elementary color of a display device; determining a pairing relationship between the front-view grey scales and the oblique-view grey scales according to the stimulus values of the front-view grey scales and the stimulus values of the oblique-view grey scales; obtaining a front-view image; and converting the front-view image into an oblique-view image according to the pairing relationship. The present invention can directly obtain an image of oblique view angle in a real-time manner without making any measurement. The process is simple and may provide high accuracy of oblique view image simulation and eliminate color shifting in simulating oblique view image.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

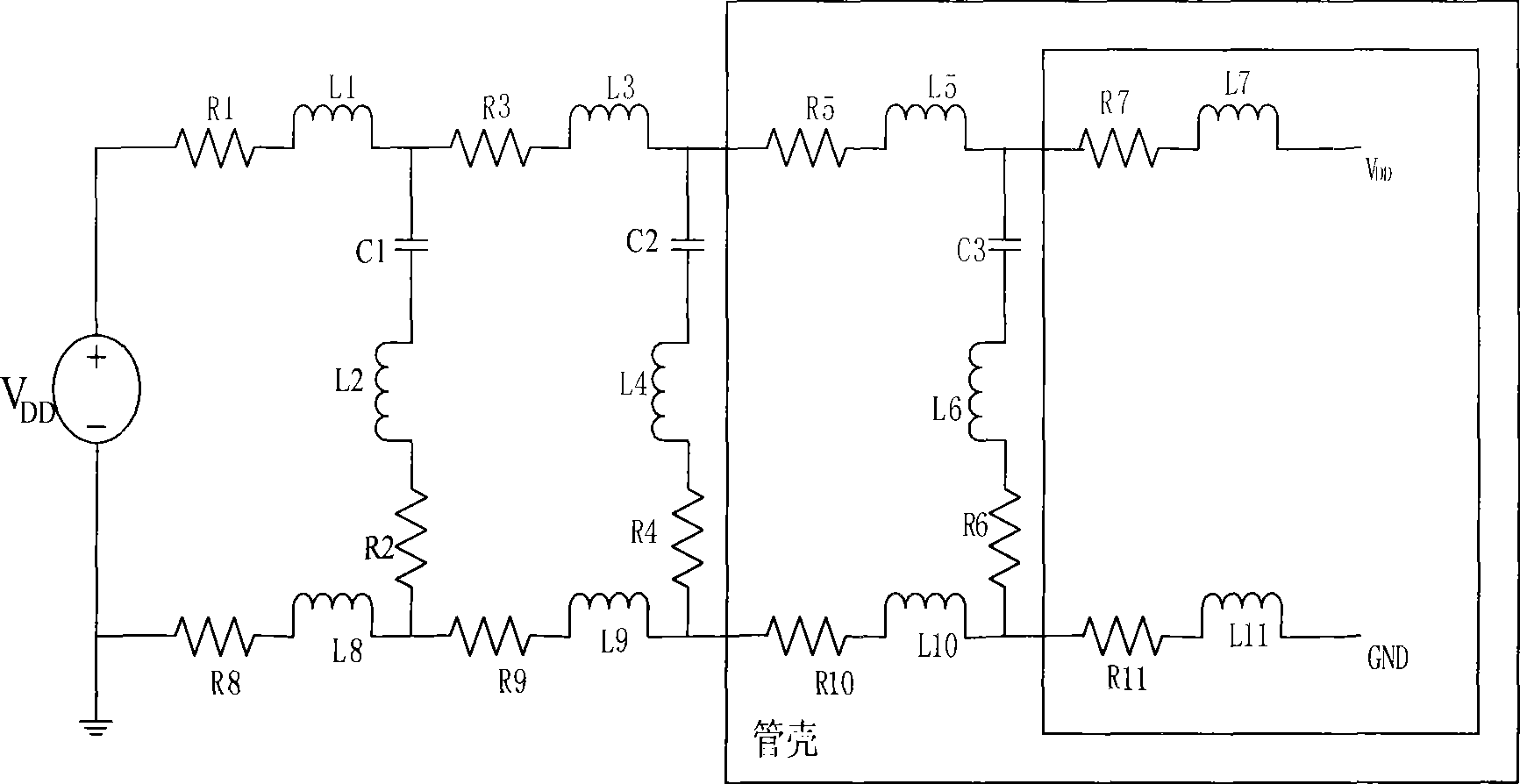

Three-dimensional NoC noise model and simulating method thereof

InactiveCN101377791ARealize all-round simulationSolve problems that cannot be simulatedSpecial data processing applicationsPower parameterEngineering

The invention discloses a tridimensional NoC noise model, which consists of a system power supply encapsulation equivalent model, a power supply distribution network equivalent model, a signal line pi-mode equivalent model and a tridimensional crosstalk model. The invention further discloses a simulation method for the tridimensional NoC noise model based on the tridimensional NoC noise model. The simulation method comprises the following steps: (1) the parasitic parameters and the driving power parameters of the system power supply encapsulation equivalent model, the power supply distribution network equivalent model, the signal line pi-mode equivalent model and the tridimensional crosstalk model are acquired; (2) an artificial circuit is established according to the tridimensional NoC noise model; (3) the constraint conditions of the exotic environment are set; (4) a simulation tool is operated for simulation; (5) the sampling result at an hour is acquired according to the simulation, thus acquiring the equivalent distribution of all noise. By adopting the tridimensional NoC noise model, not only a noise source subject to Gaussian distribution is simulated; but also a noise source not subject to Gaussian distribution is simulated. The tridimensional NoC noise model is mainly applied on network on chip.

Owner:成都成电电子信息技术工程有限公司

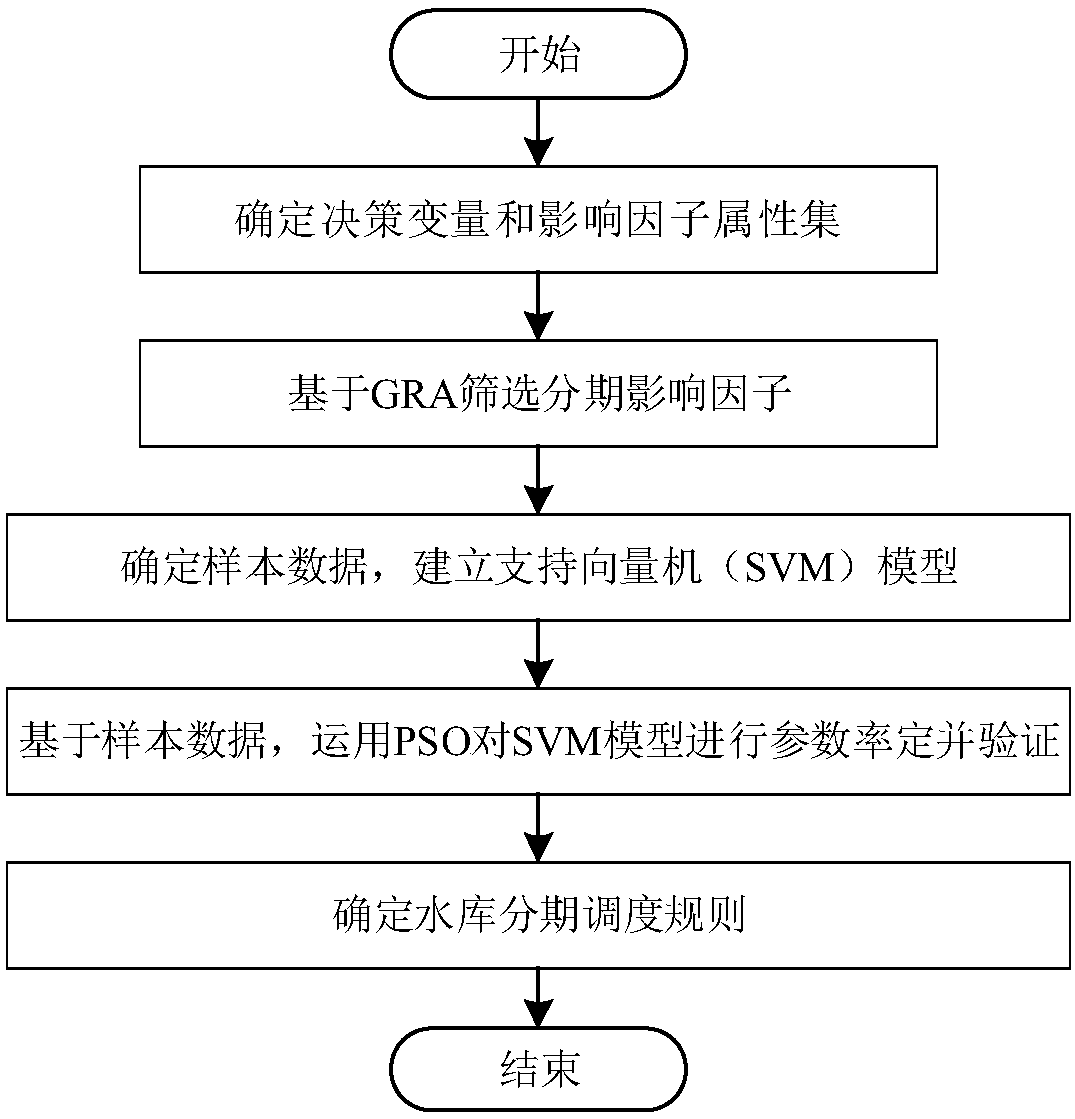

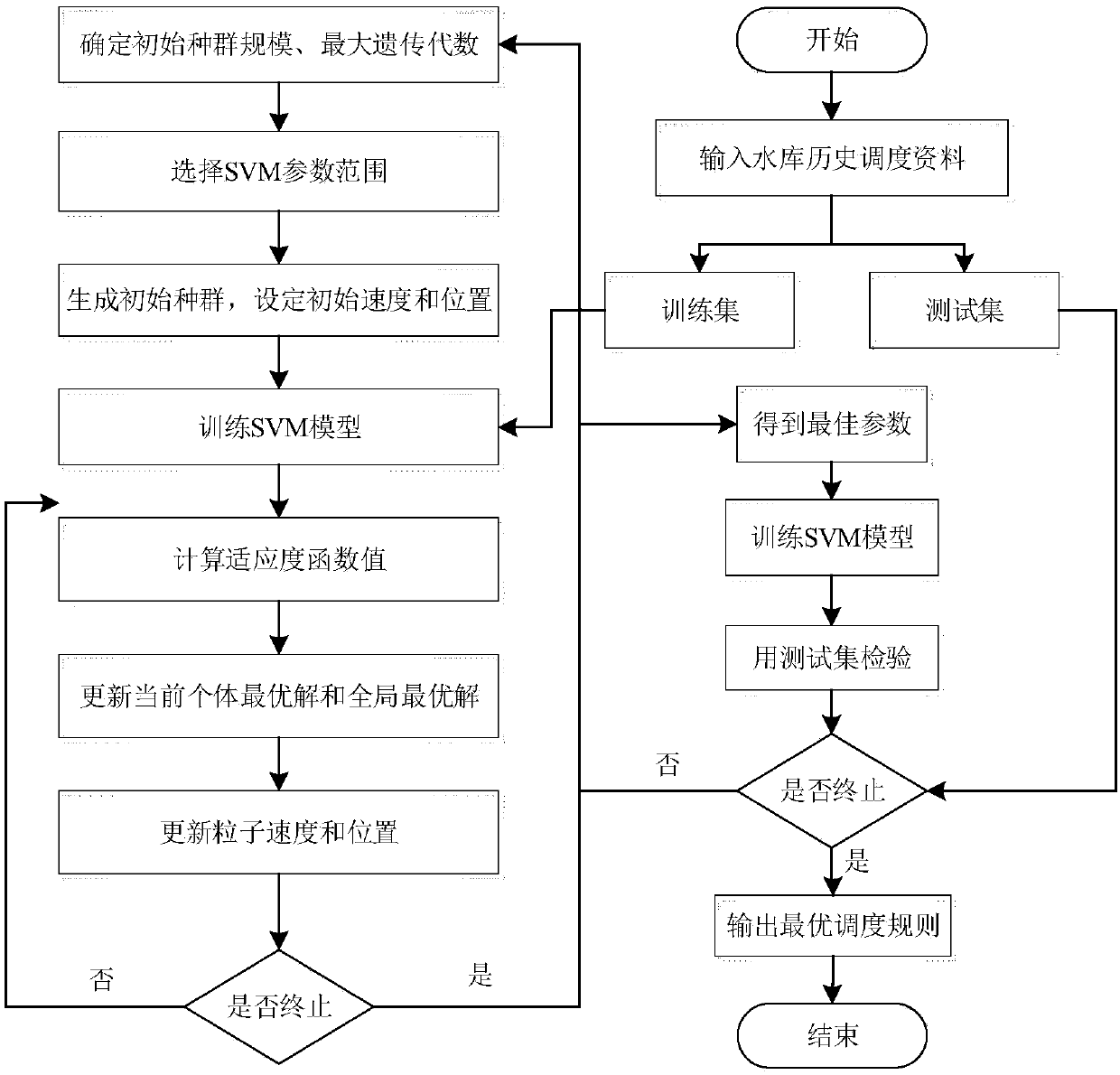

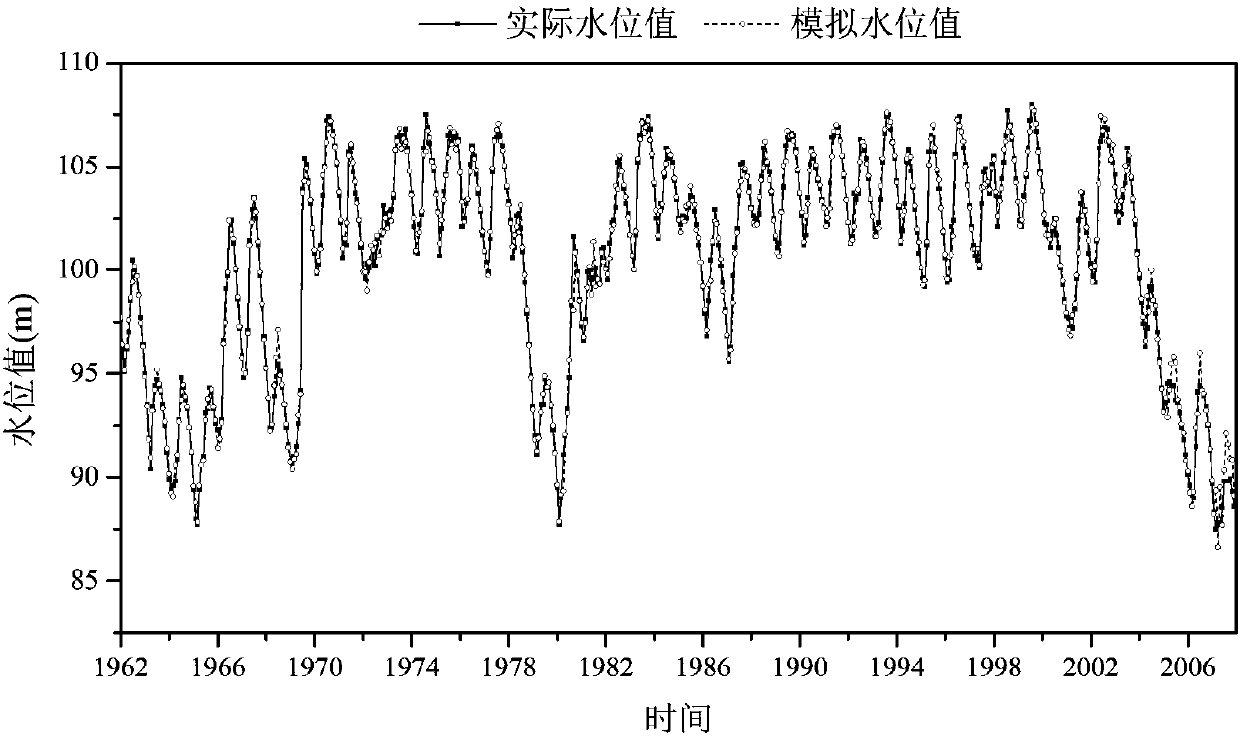

Method for extracting staged scheduling rule of reservoir

ActiveCN107862457AAchieving the purpose of the instruction in actual operationTo achieve the purpose of guidanceResourcesMachine learningPreconditionInfluence factor

The invention discloses a method for extracting a stage scheduling rule of a reservoir based on GRA and PSO-SVM. The method comprises the following steps of based on a historical actual scheduling result, firstly determining a decision variable and an influence factor attribute set, screening a staged influence factor based on GRA; determining a training sample and a testing sample, and constructing an SVM model; establishing a PSO-SVM simulating model based on the sample data, performing parameter calibration and verification on the SVM model by means of PSO; and determining a reservoir staged scheduling rule. The method has advantages of well inheriting a comprehensive benefit in an actual scheduling process, realizing a purpose of guiding the actual operation of the reservoir under a precondition of uncertain incoming water, and supplying theoretical basis and scientific supporting for actual operation of the reservoir.

Owner:HOHAI UNIV

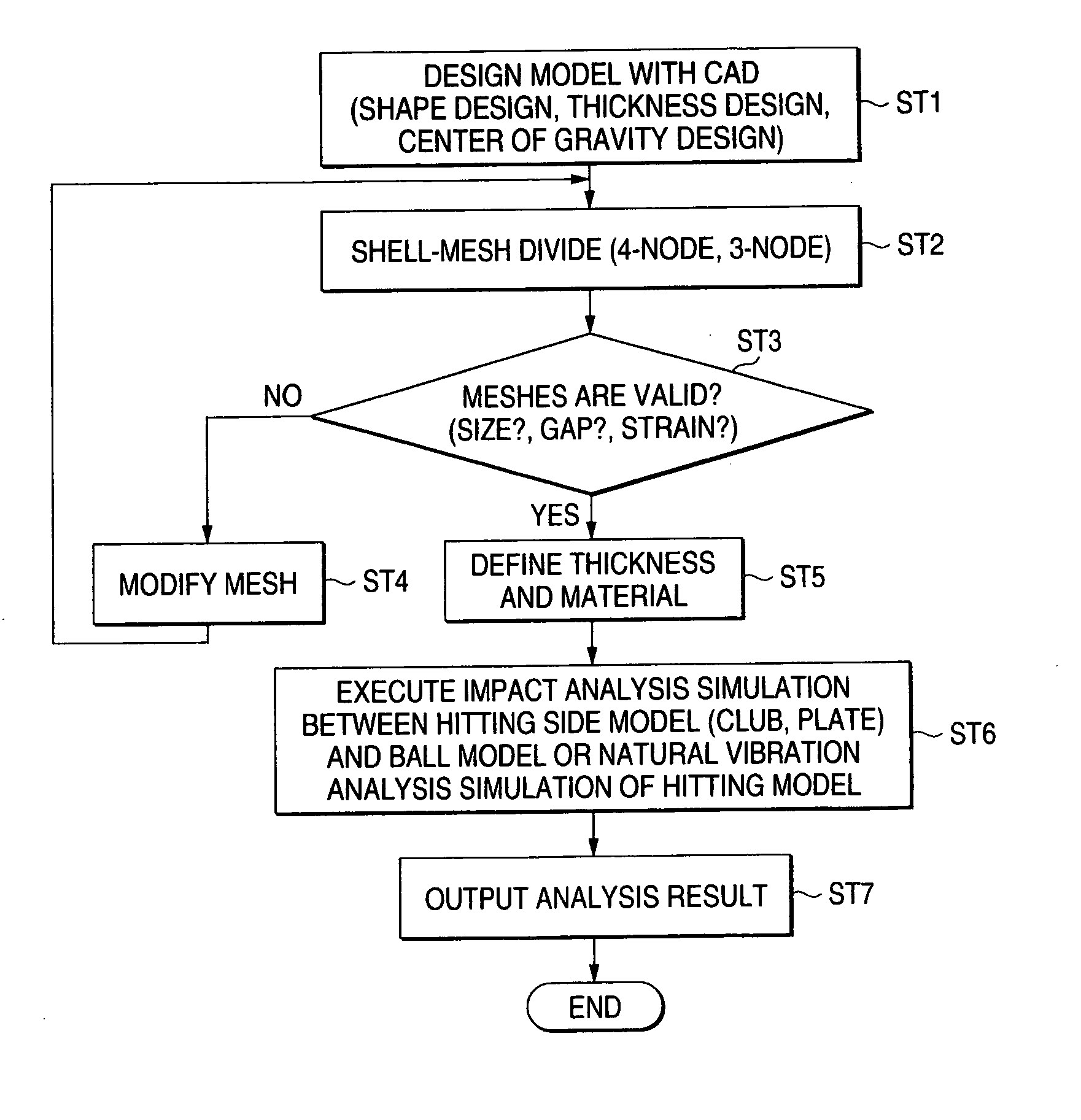

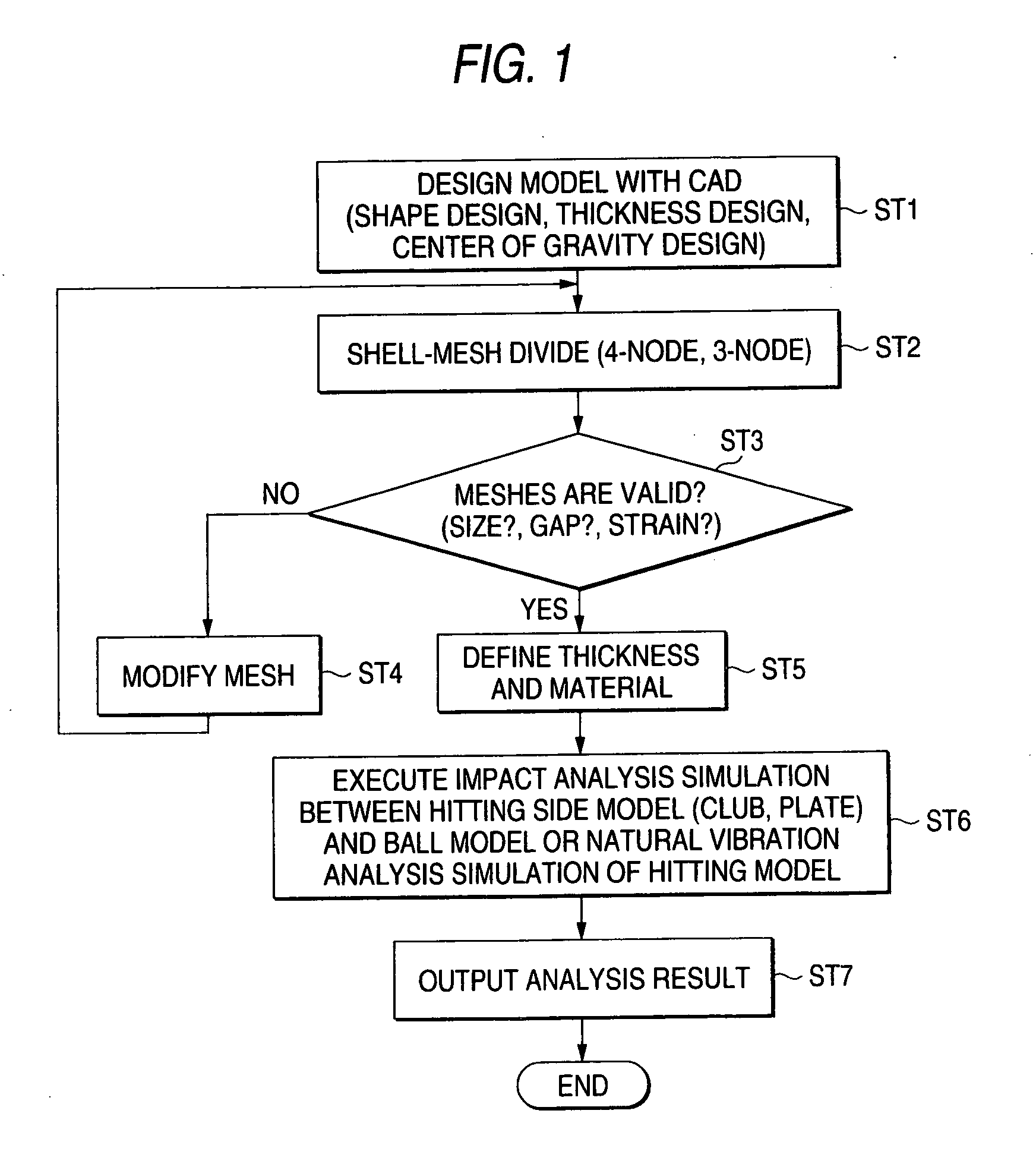

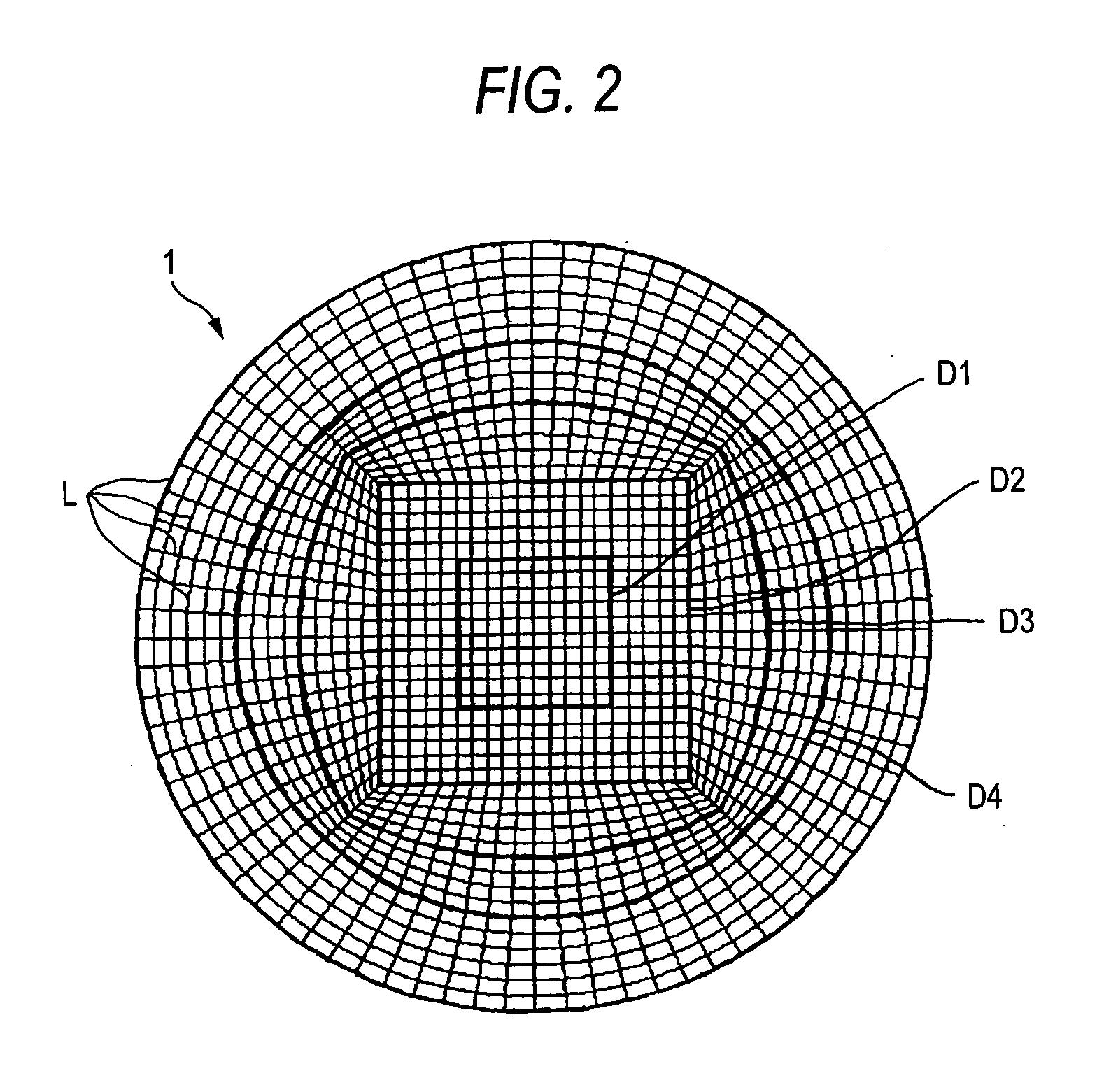

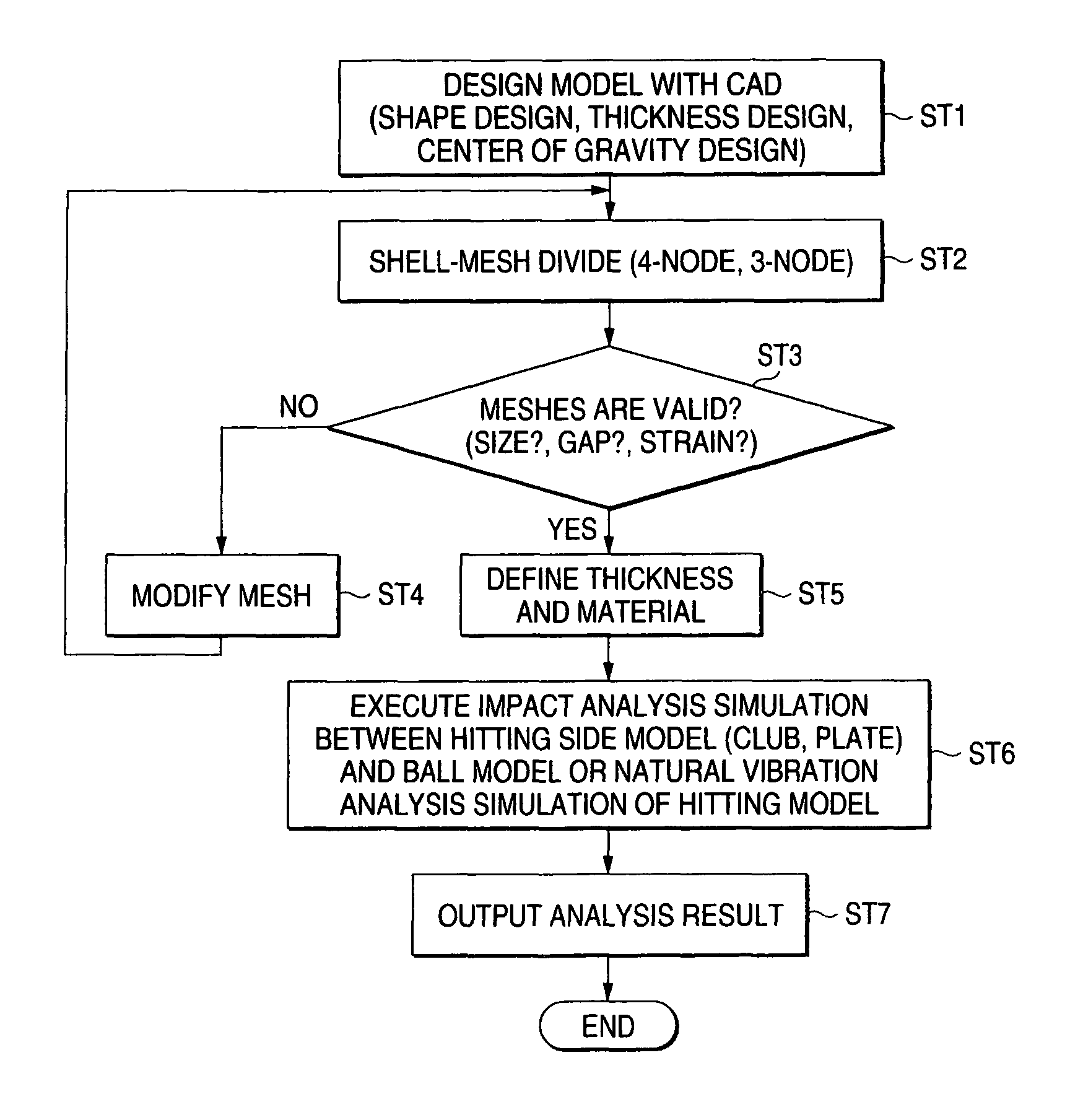

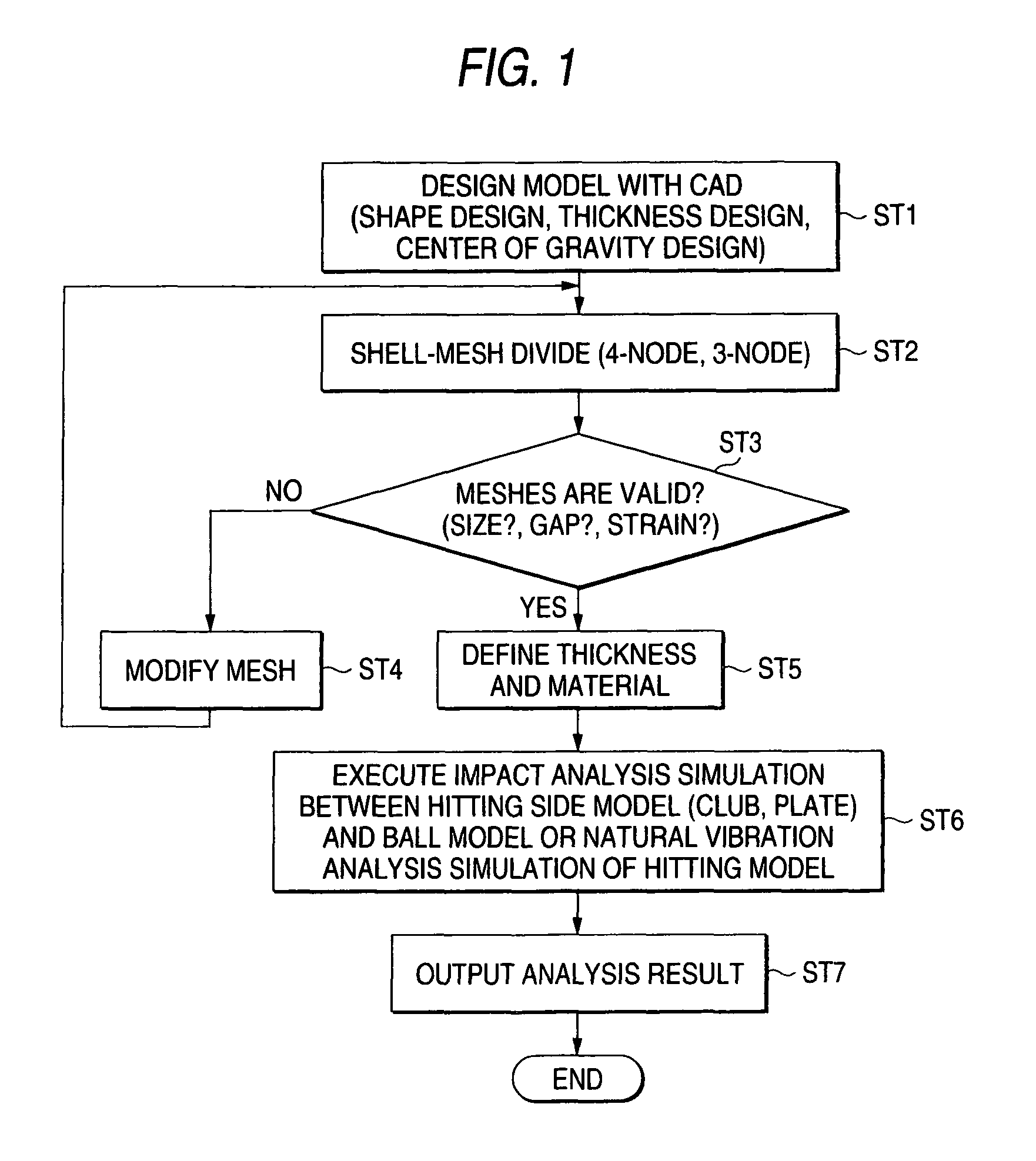

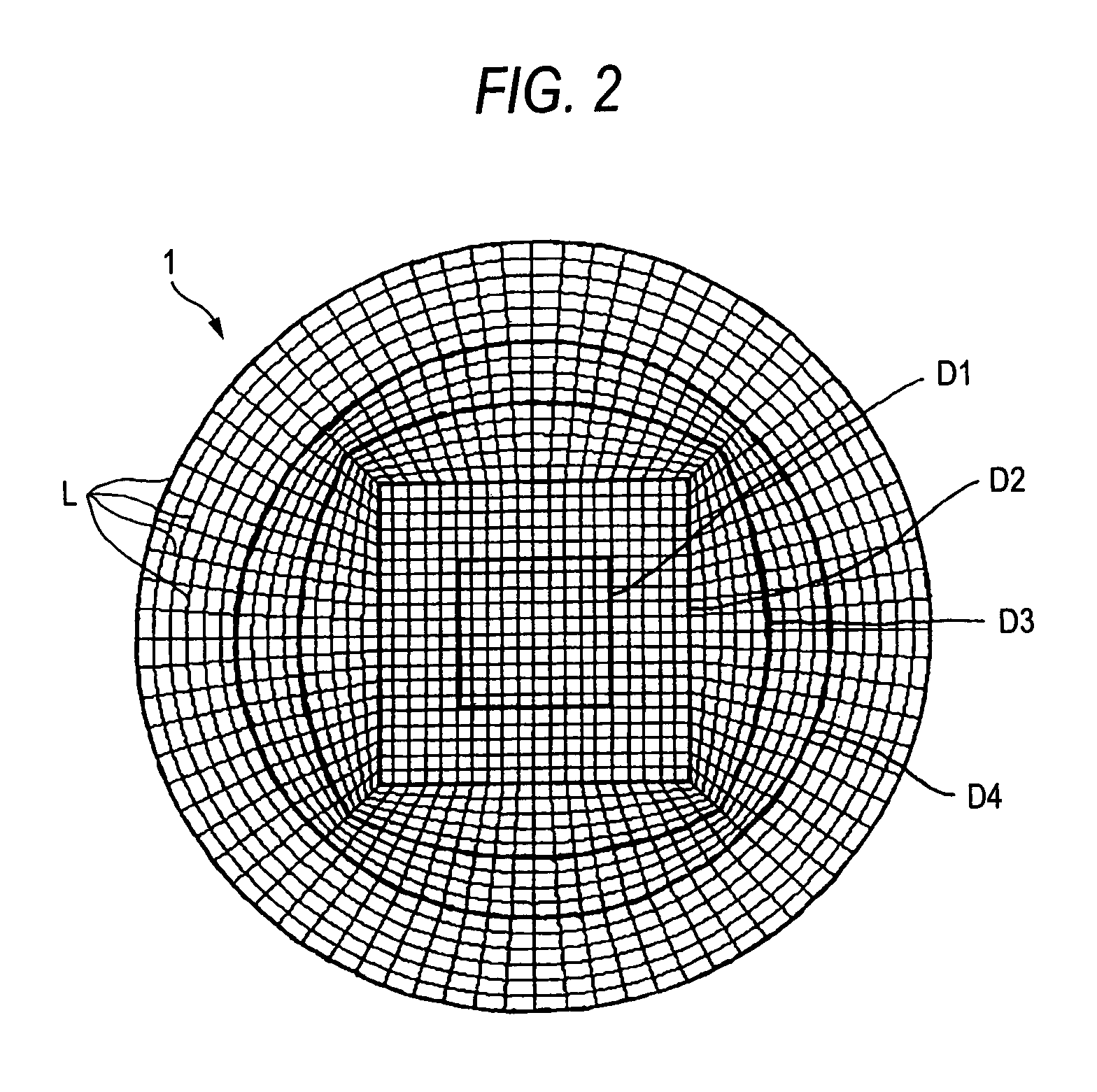

Method for simulating performance of golf club head

InactiveUS20060160637A1Improve accuracyShort calculation timeDesign optimisation/simulationSpecial data processing applicationsEngineeringGolf Ball

Owner:BRIDGESTONE SPORTS

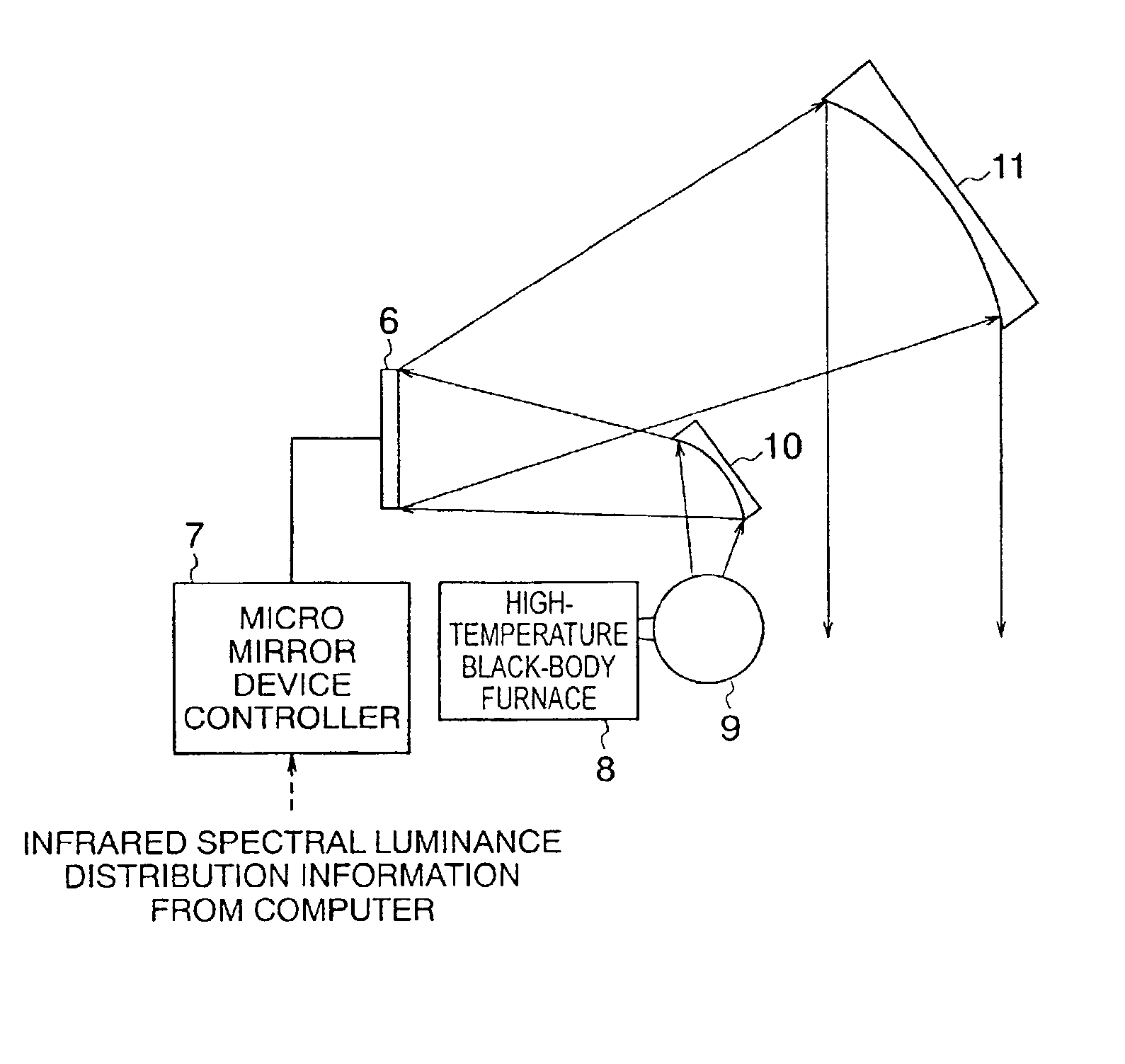

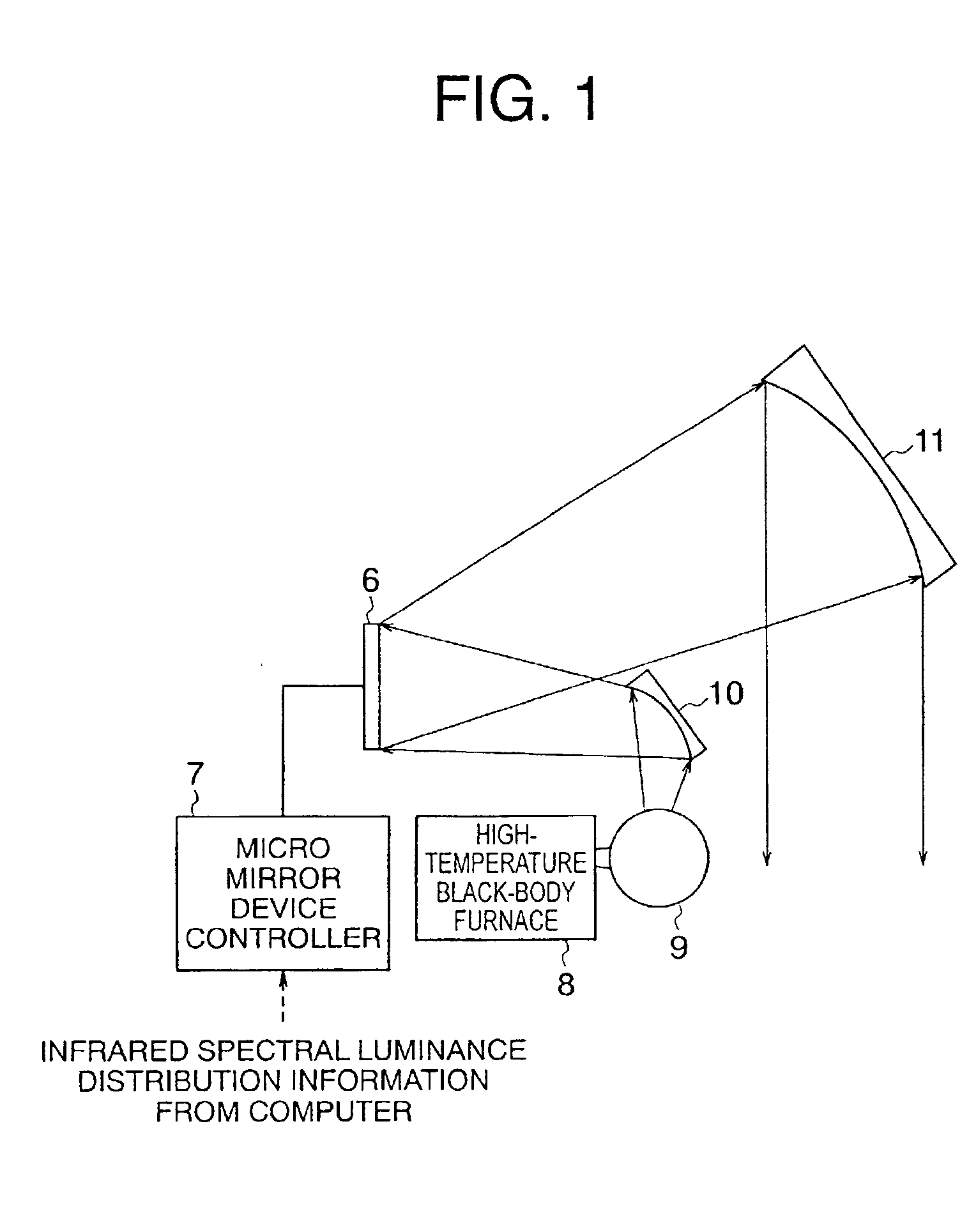

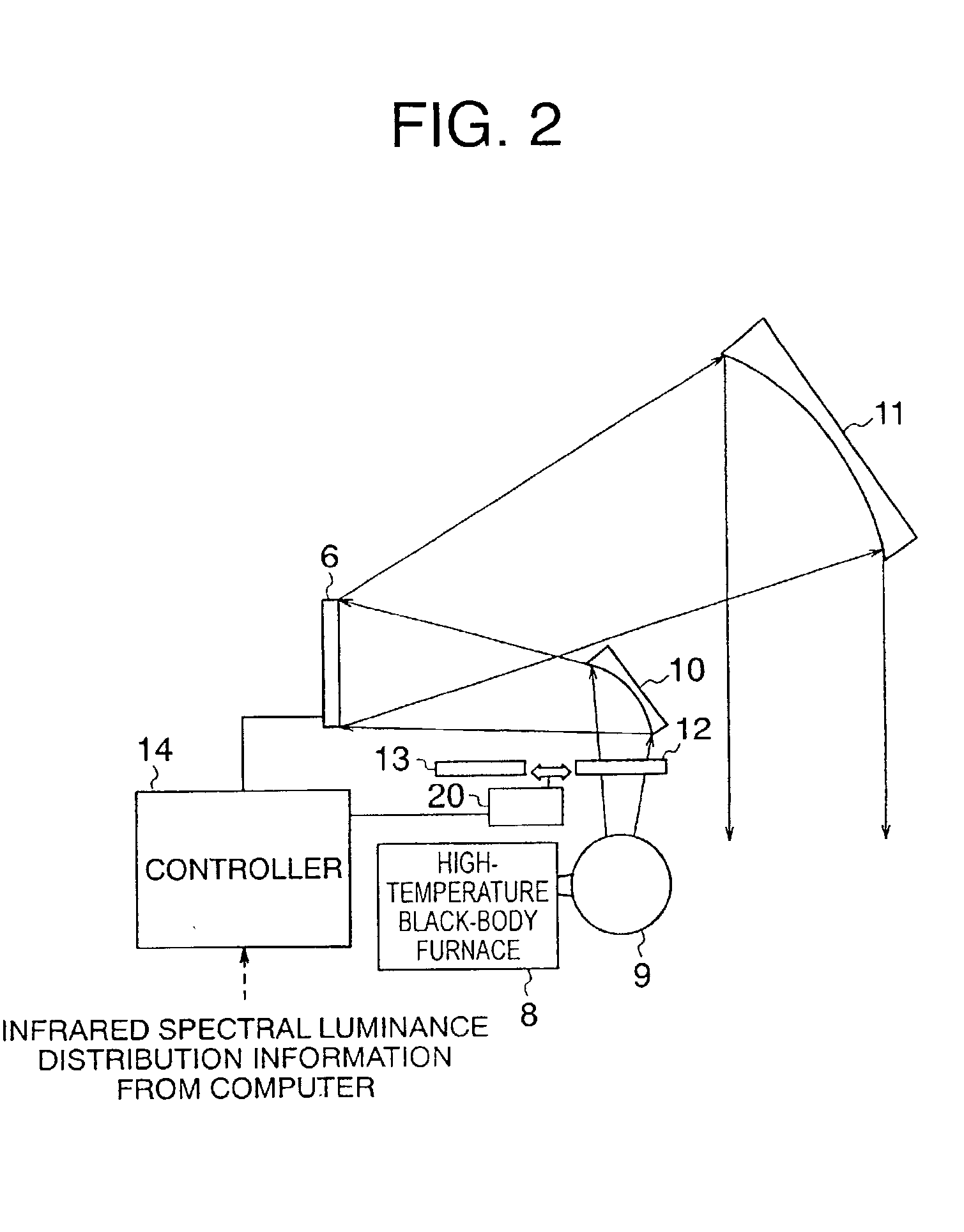

Infrared projector

InactiveUS20020158210A1High resolutionImprove spatial resolutionPrismsMaterial analysis using wave/particle radiationTemporal resolutionArray element

To provide an infrared projector in which it is not necessary to develop arrayed elements radiating infrared radiation, a high temporal resolution and a high spatial resolution are made available, the simulation of a high-temperature body is made possible, the wavelength and luminance characteristics are controlled, a high contrast and a high simulation accuracy are made available, and so on. A micromirror device (6) as an optical modulator for changing the direction of reflection by providing a plurality of mirrors and changing the direction of each of the plurality of mirrors independently, a controller (7) for controlling the direction of each mirror of the micromirror device, and infrared light sources (8, 9, and 10) for irradiating the micromirror device with infrared light are provided.

Owner:MITSUBISHI ELECTRIC CORP

Method for simulating performance of golf club head

InactiveUS8190413B2Improve accuracyShort calculation timeDesign optimisation/simulationSpecial data processing applicationsEngineeringGolf Ball

Owner:BRIDGESTONE SPORTS

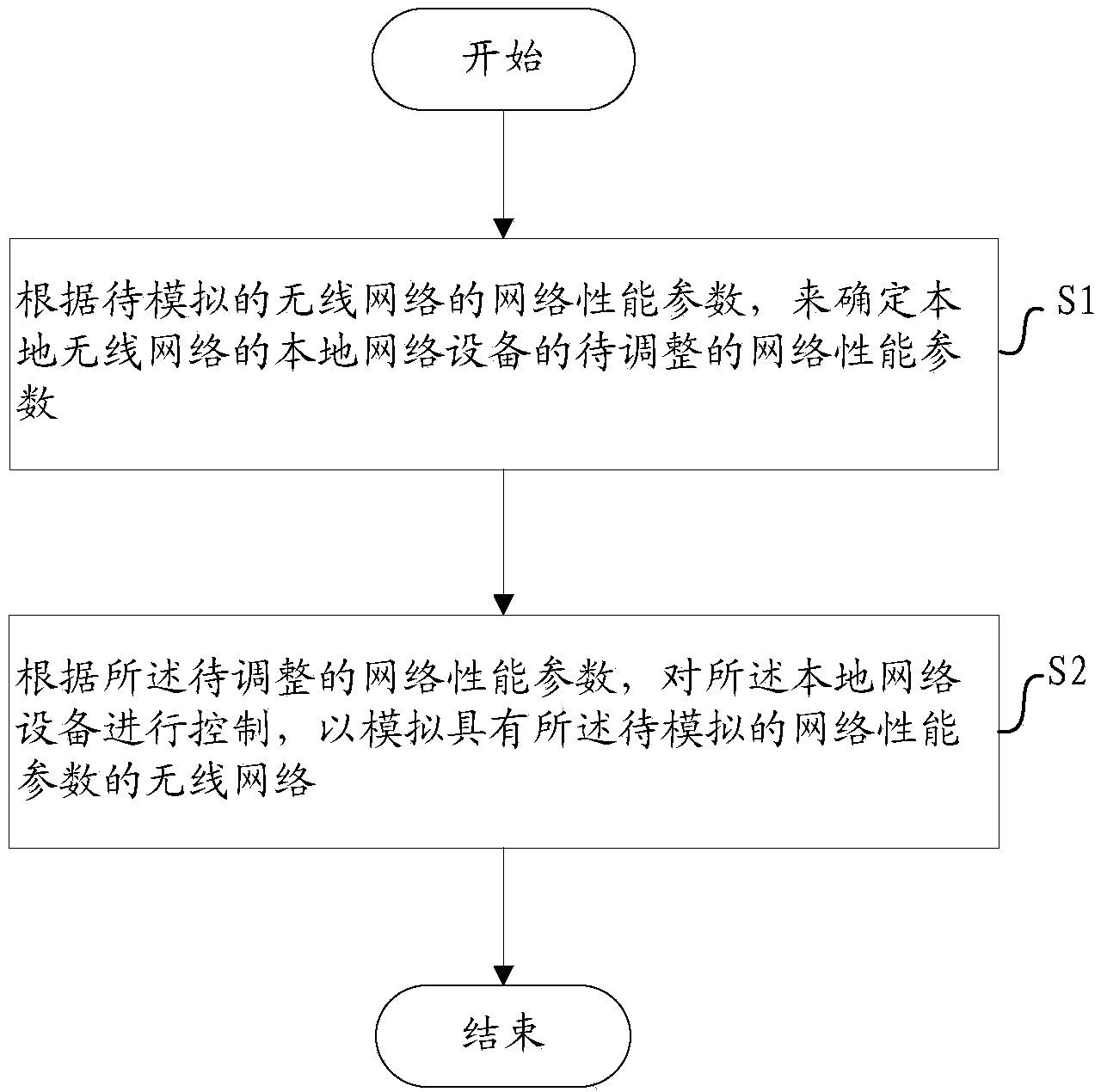

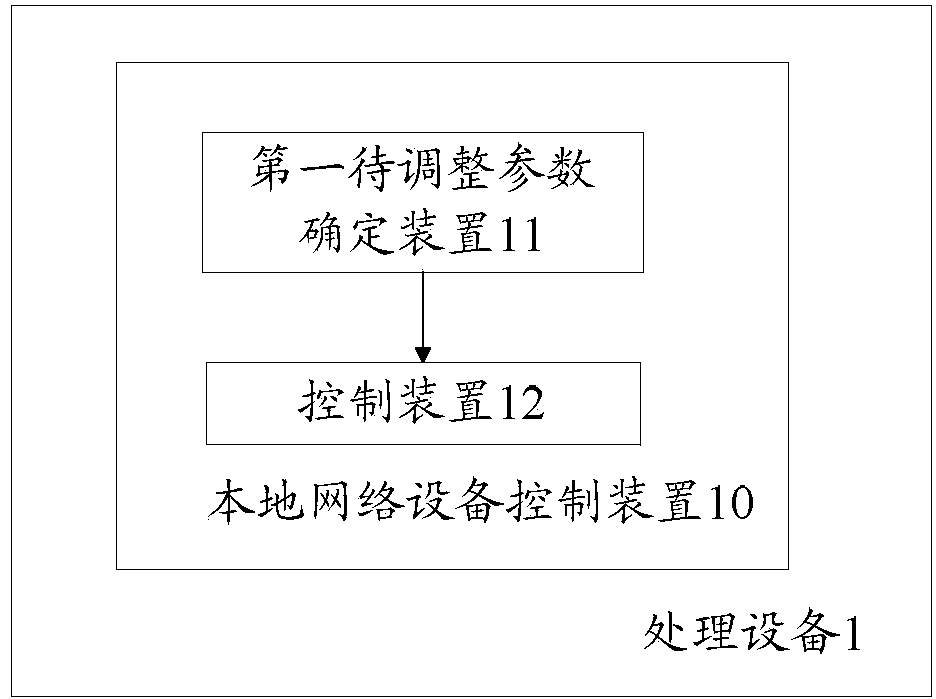

Method and device simulating wireless network

The invention aims to provide a method and a device simulating a wireless network. According to the method and the device, to-be-adjusted network performance parameters of local network equipment of a local wireless network are determined according to network performance parameters of the wireless network to be simulated, then the local network equipment is controlled according to the to-be-adjusted network performance parameters for simulating the wireless network with the network performance parameters to be simulated, and therefore users can simulate the wireless network with the specified network performance parameters, and the time and the money cost for setting up a general mobile system are saved. Furthermore, the detection efficiency of detecting whether mobile application has problems under different wireless network environments can be improved. Meanwhile, according to the method and the device, the wireless network with the network performance parameters to be simulated can be simulated according to the to-be-adjusted network performance parameters required by the users so that various wireless network environments can be provided.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

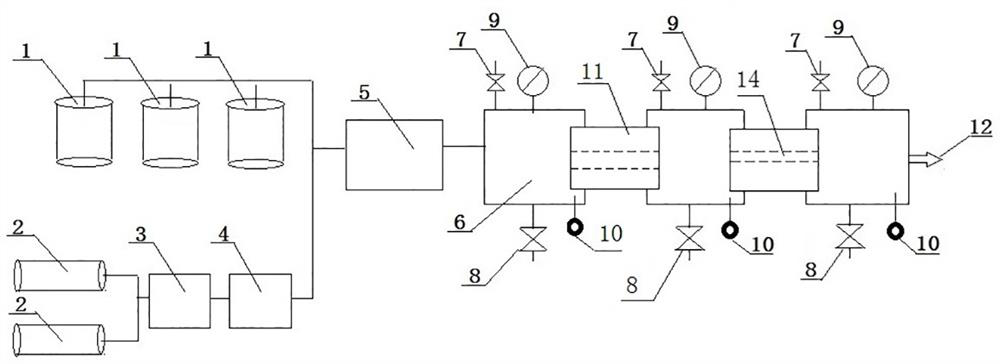

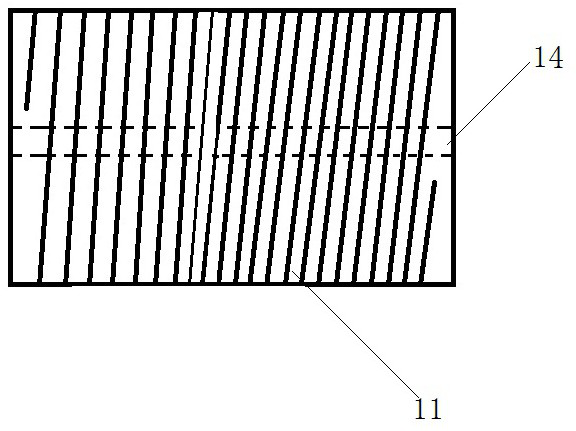

Gas well scaling simulation device and simulation method

PendingCN113006768AHigh simulation accuracyImprove heating efficiencySurveyMaterial thermal analysisThermodynamicsEngineering

The invention relates to a gas well scaling simulation device and simulation method. The gas well scaling simulation device comprises a gas storage device used for providing simulative gas, a liquid storage device used for providing simulative liquid, a gas-liquid mixer used for mixing the simulative gas and the simulative liquid to obtain experimental fluid and scaling simulation pipes; at least two scaling simulation pipes are sequentially connected in series to simulate a gas well; a throttling structure is arranged on any two corresponding adjacent scaling simulation pipes; the two corresponding adjacent scaling simulation pipes are in communication through a throttling channel to simulate the change that the pressure of gas well fluid is gradually reduced in the flowing direction of the gas well fluid; and each scaling simulation pipe is provided with a heating device used for adjusting the temperature of the scaling simulation pipe so as to simulate the change that the corresponding formation temperature is gradually reduced in the flowing direction of the gas well fluid. According to the technical scheme, the influence of the fluid pressure change in the gas well and the formation temperature change on gas well scaling is considered, and the environment in the whole gas well can be simulated from the overall macroscopic aspect.

Owner:CHINA PETROLEUM & CHEM CORP +1

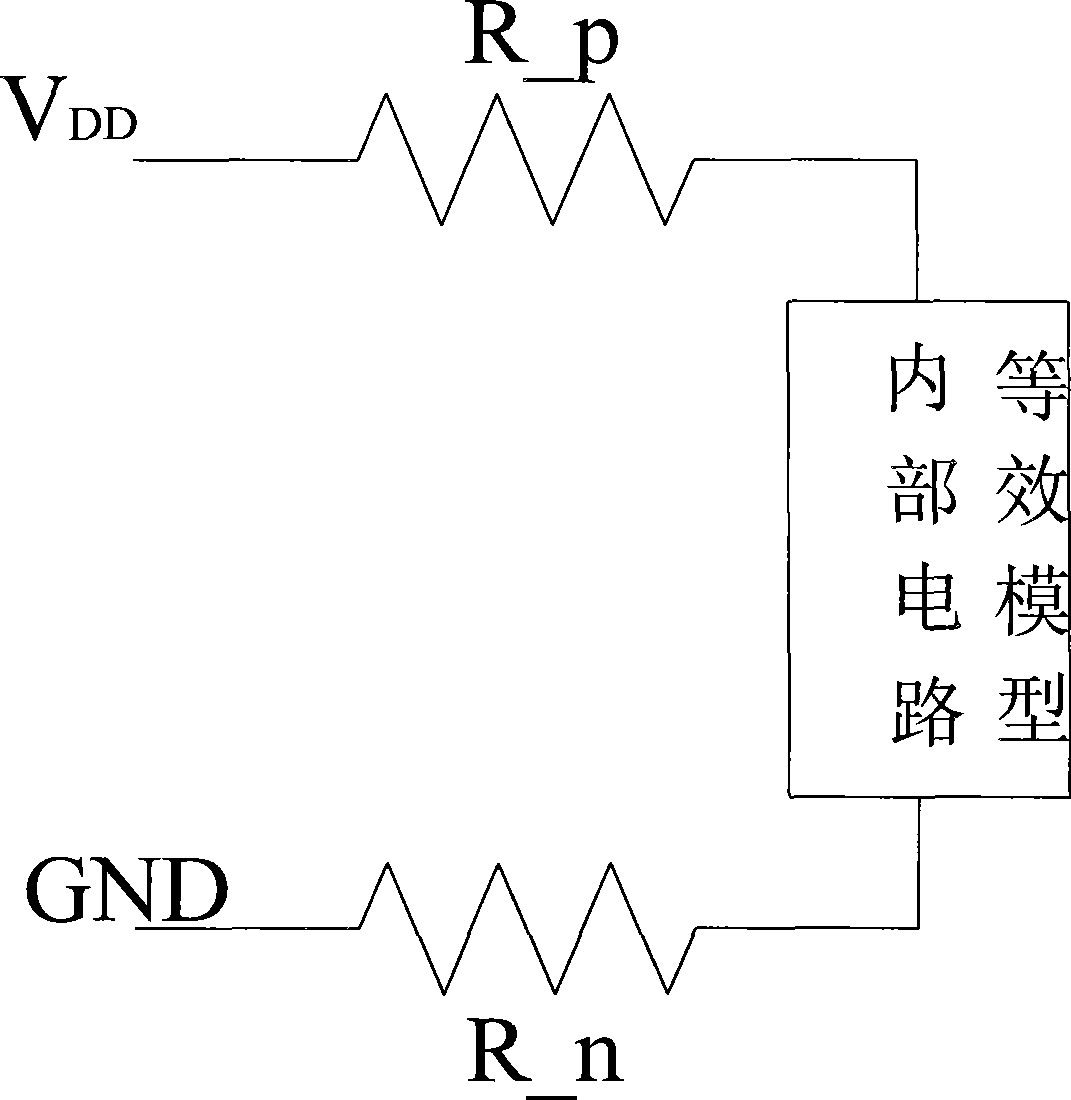

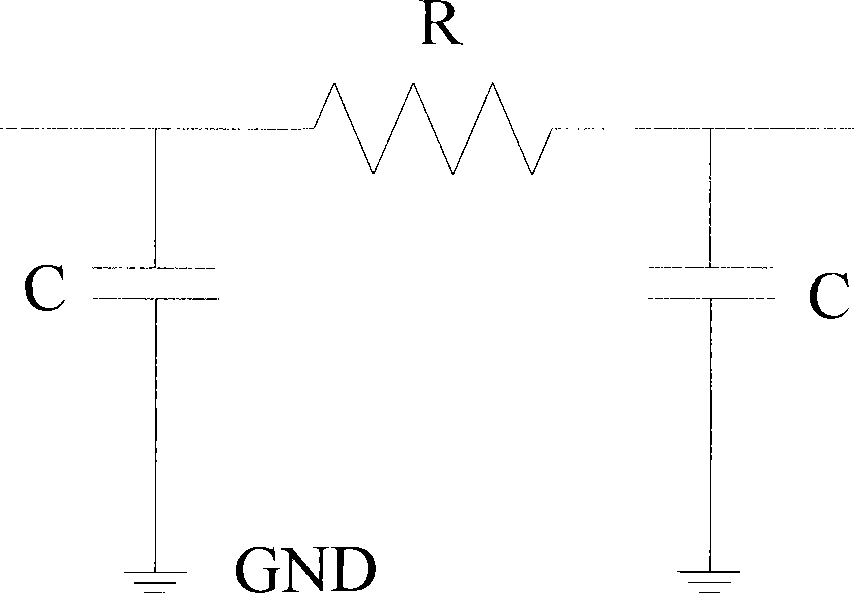

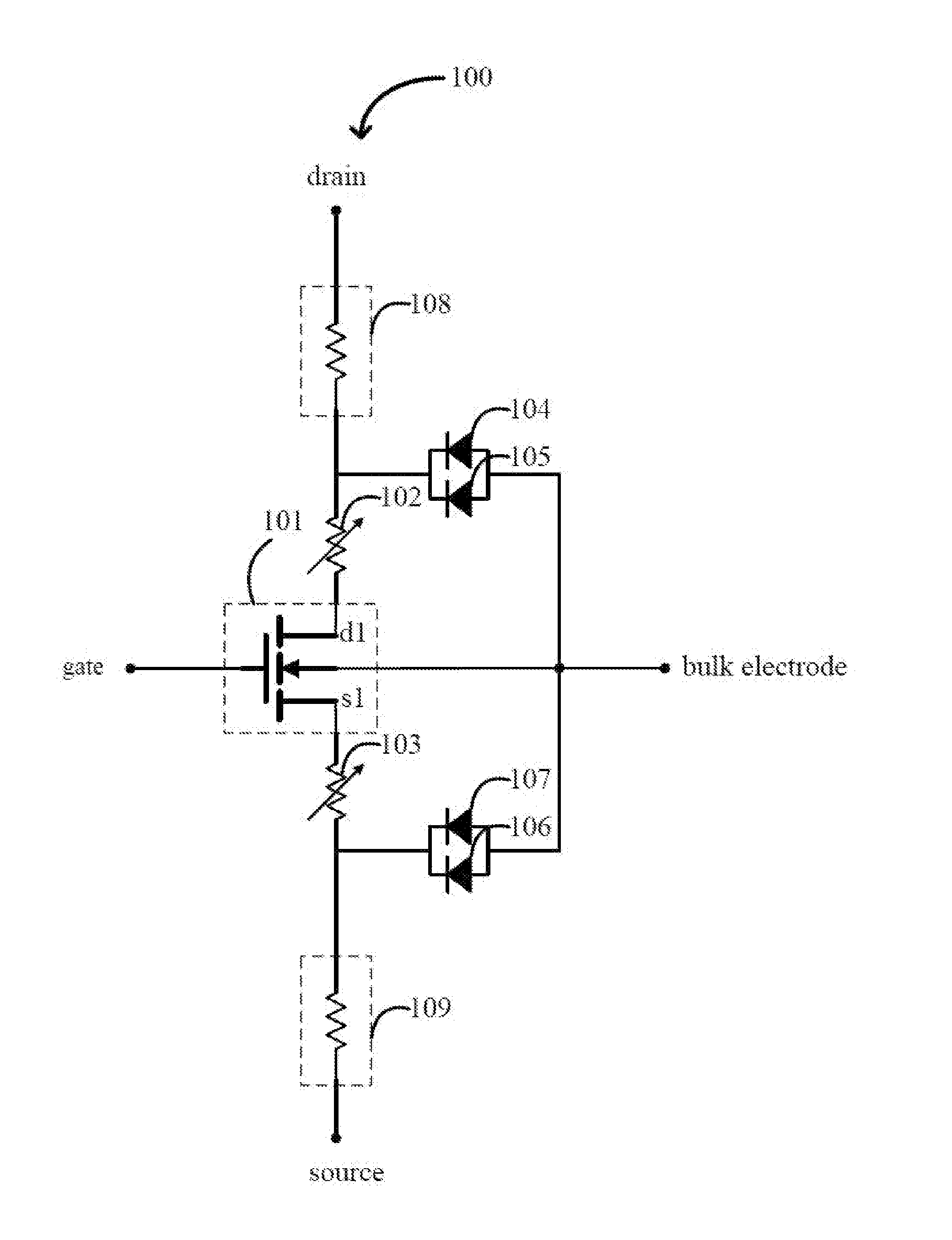

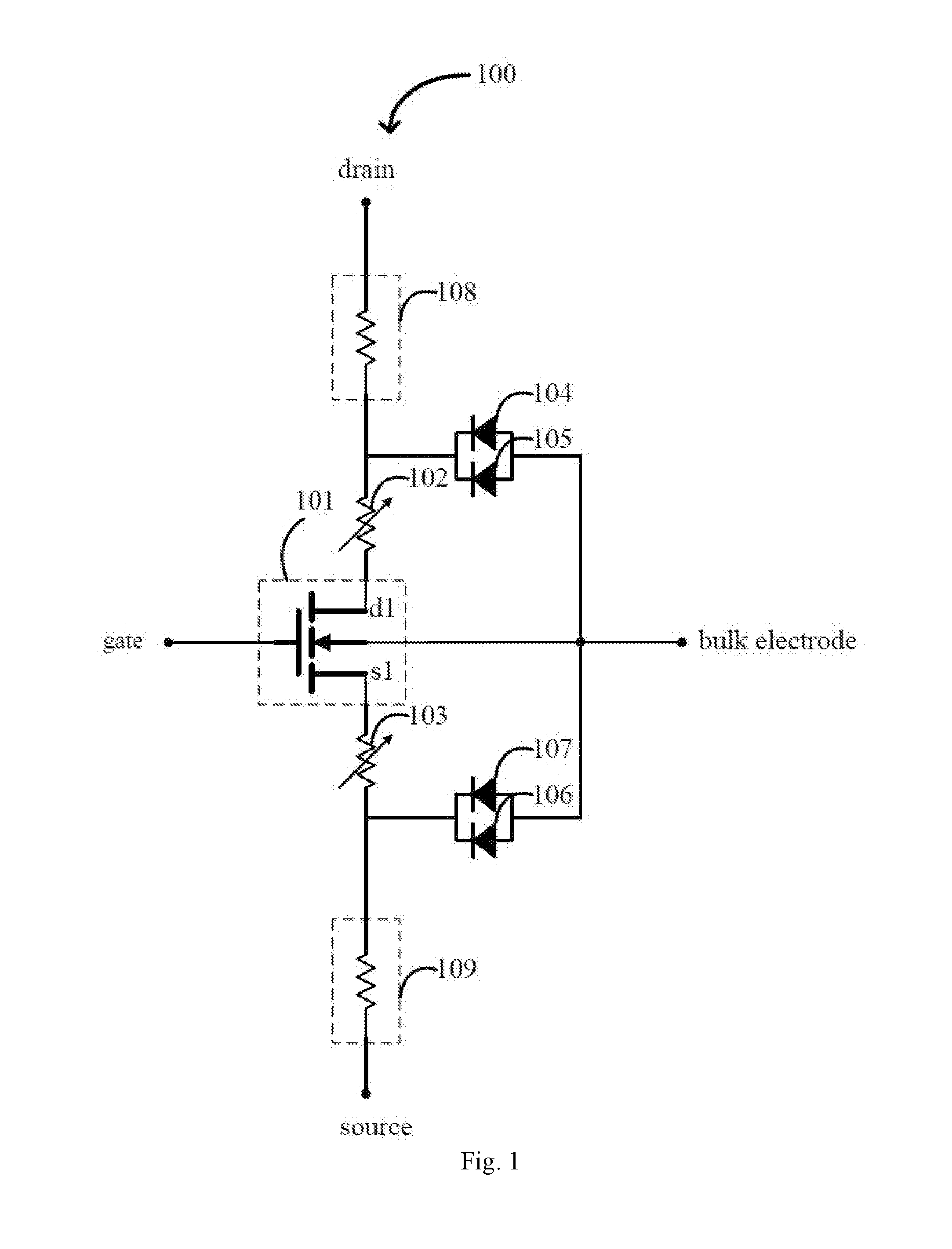

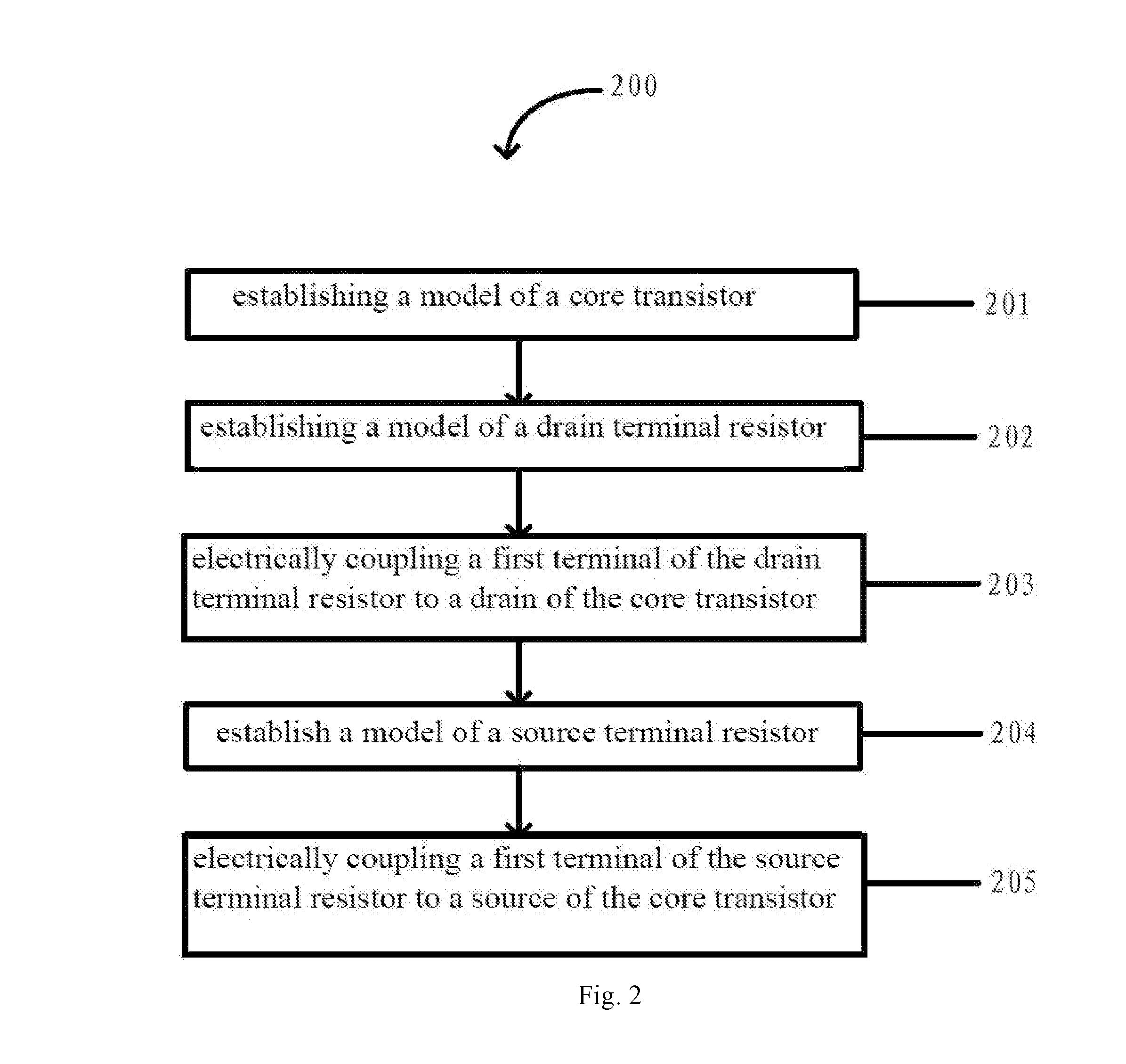

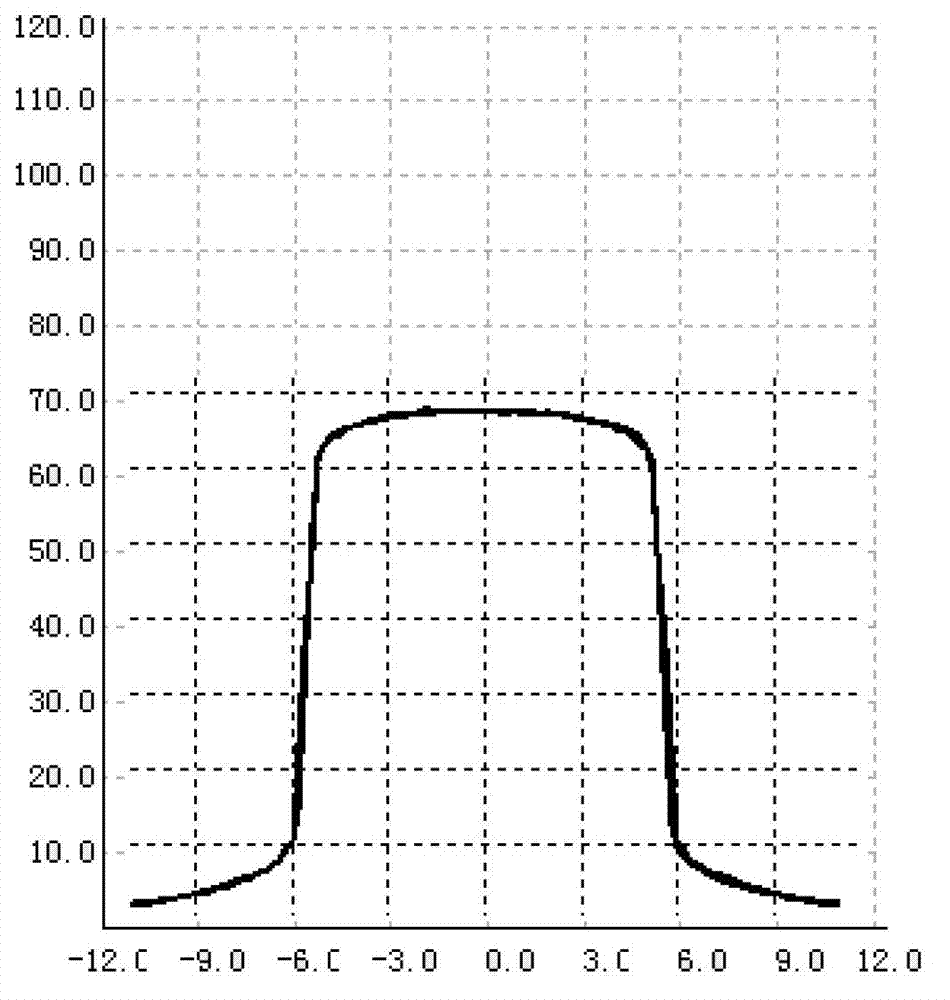

High-voltage device simulation model and modeling method therefor

InactiveUS20170011144A1Improve efficiencyHigh voltageSolid-state devicesDesign optimisation/simulationElectricityDevice simulation

A high-voltage device simulation model and a modeling method thereof are provided. The simulation model comprises: a core transistor (101), a drain terminal resistor (102) and a source terminal resistor (103), wherein a first terminal of the drain terminal resistor (102) is electrically connected to a drain (d1) of the core transistor (101) and a second terminal of the drain terminal resistor (102) serves as the drain of the high voltage device; a first terminal of the source terminal resistor (103) is electrically connected to a source (s1) of the core transistor (101) and a second terminal of the source terminal resistor (103) serves as the source of the high voltage device. The relations of the resistance value of the drain terminal resistor (102) are as follows: RD=(RD0 / W)*(1+CRD*VDERDD+1 / (1+PRWDD*VDERDD))*TFAC_RD, and TFAC_RD=(1+TCRD1*(TEMP−25)+TCRD2*(TEMP−25)*(TEMP−25)).

Owner:CSMC TECH FAB1

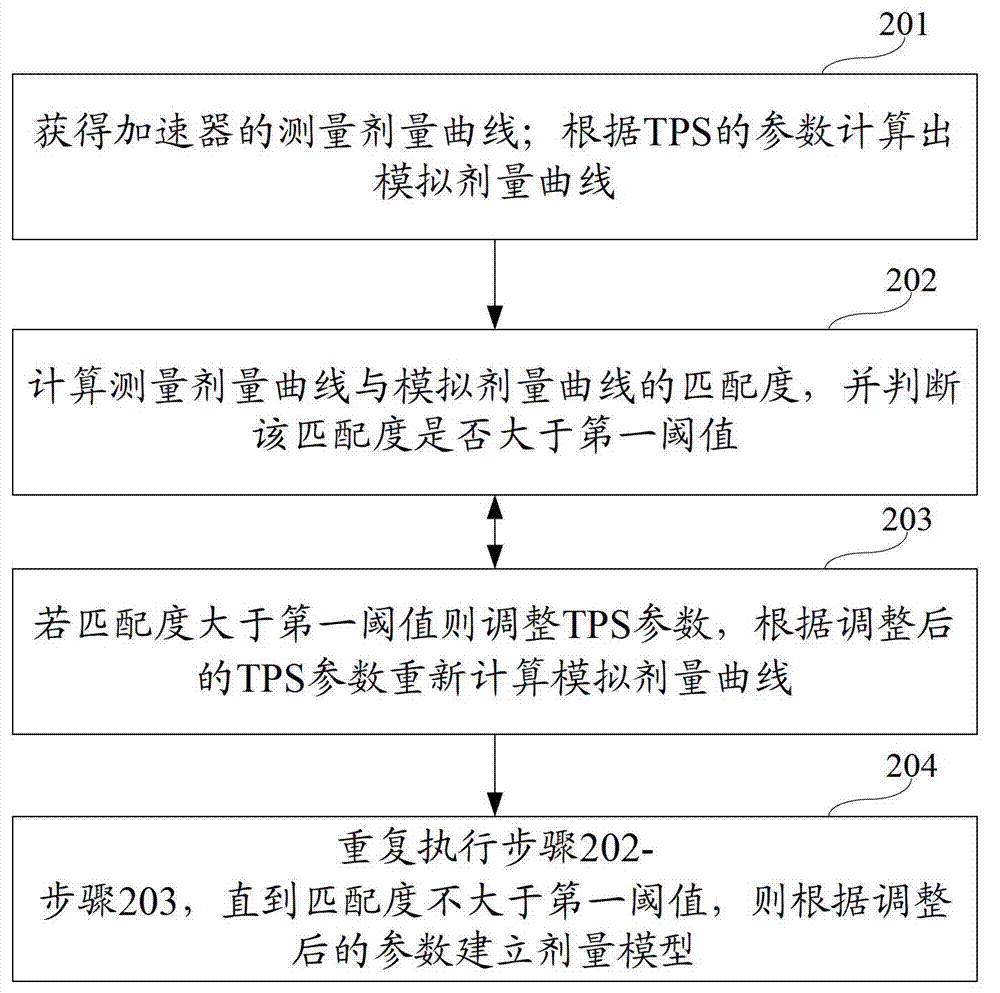

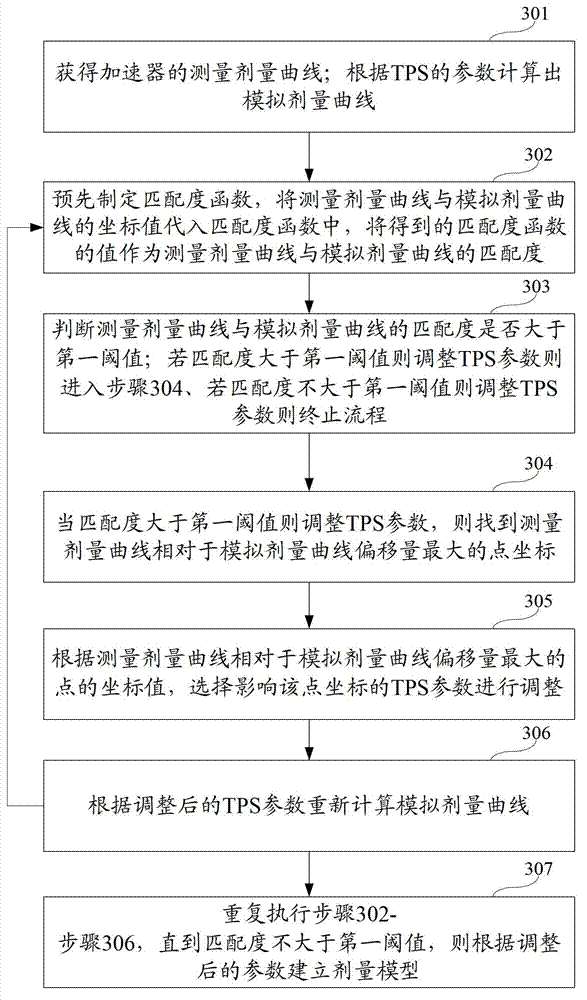

Dose model matching method and system

ActiveCN102930109AImprove efficiencyReduced commissioning timeSpecial data processing applicationsTransactions per secondMedicine

Owner:SHENYANG NEUSOFT ZHIRUI RADIOTHERAPY TECH CO LTD

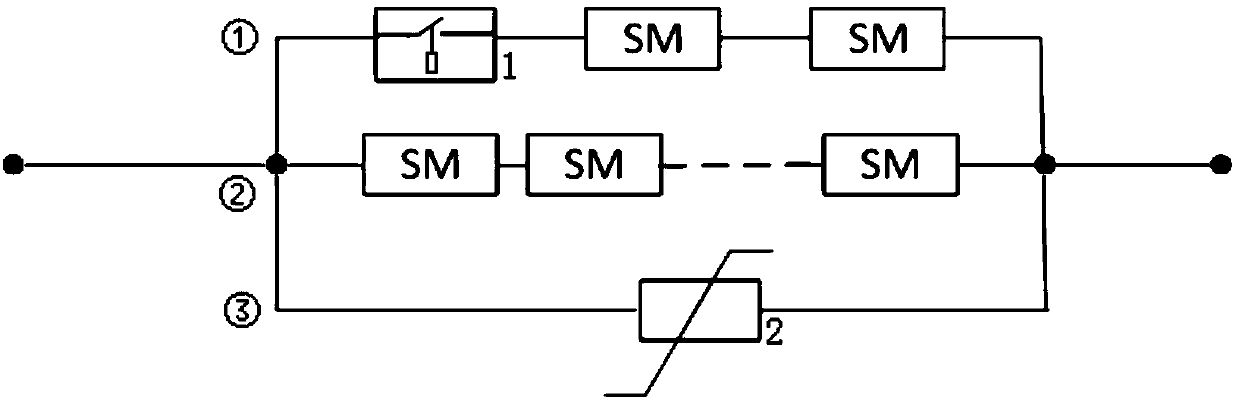

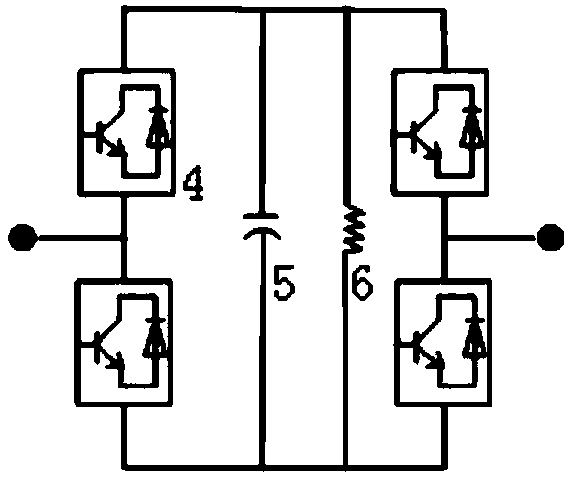

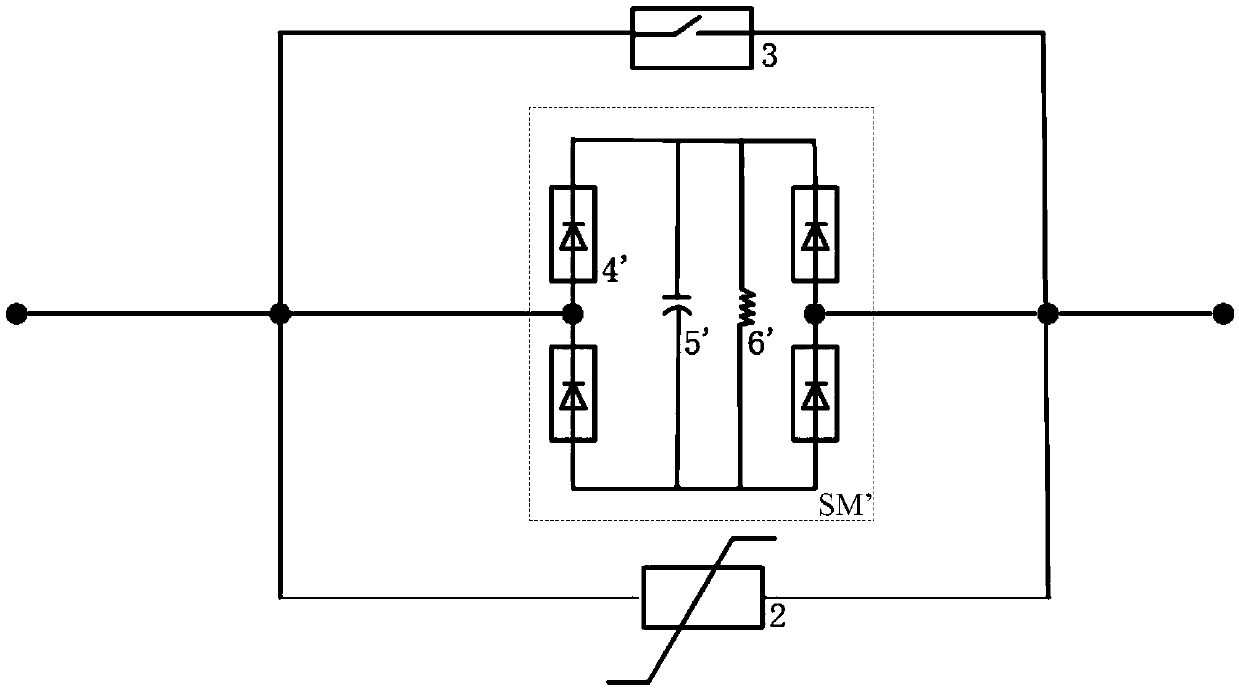

Direct current circuit breaker simulation method and device

ActiveCN109687412ASmall amount of calculationImprove simulation speedElectric power transfer ac networkEmergency protective arrangements for limiting excess voltage/currentFull bridgeEngineering

The invention relates to a direct current circuit breaker simulation method and device. The direct current circuit breaker simulation method comprises the steps that a diode full-bridge module is usedfor simulating all full-bridge sub-modules of a transfer branch; and four bridge arms of the diode full-bridge module are each composed of one diode, and the upper and lower bridge arms are connectedin parallel with an equivalent capacitor and an equivalent discharge resistor. According to the characteristics of a cascaded full-bridge type direct current circuit breaker, the transfer branch is simplified by removing an IGBT, only four diodes are reserved to ensure bidirectional charging of the parallel capacitor, equivalent circuit impedance is achieved, the calculated amount is effectivelyreduced in real-time simulation, and the simulation speed is increased.

Owner:XJ ELECTRIC +3

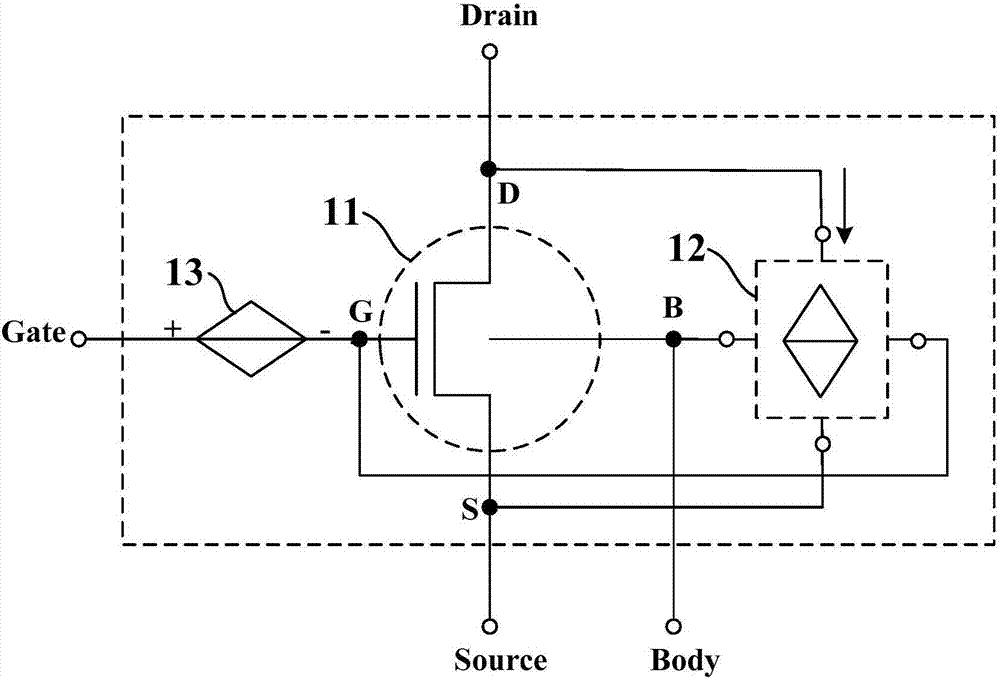

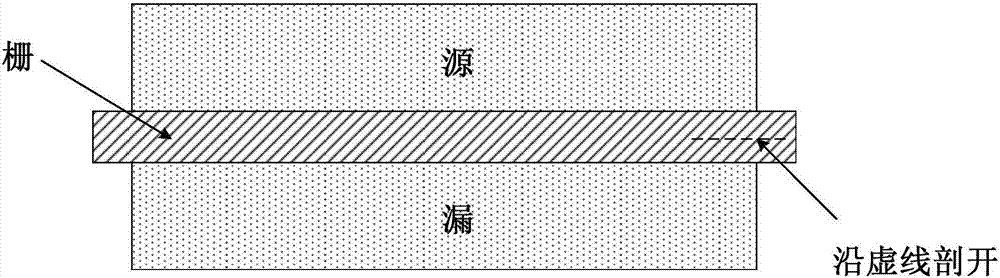

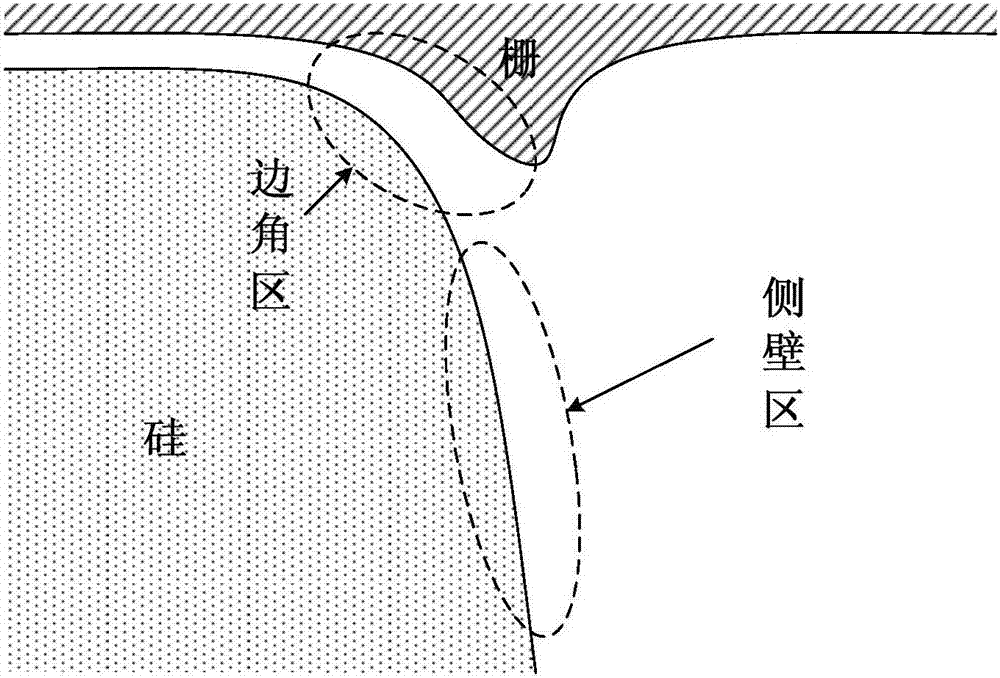

SOI MOSFET total dose radiation model building method

The invention provides an SOI MOSFET total dose radiation model building method. The method comprises the steps of establishing a controlled current source, wherein the controlled current source is connected in parallel between the source end and the drain end of an MOSFET device, and the current magnitude of the controlled current source is controlled by the gate end, the source end, the body end and the drain end of the MOSFET device and the total dose; establishing a controlled voltage source, wherein the controlled voltage source is connected in series to the gate end of the MOSFET device, and the voltage size of the controlled voltage source is controlled by the total dose; and packaging the controlled current source, the controlled voltage source and the MOSFET device to form an SOI MOSFET total dose radiation model. According to the SOI MOSFET total dose radiation model building method, an NMOS and a PMOS can be simulated at the same time; the drift of a threshold voltage can be simulated; and the characteristics of MOSFETs with all sizes and all radiation doses can be simulated, so that the simulation accuracy is greatly improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com