Indoor grinding and forming instrument of bituminous mixture test specimen and forming control method thereof

A technology of asphalt mixture and forming instrument, which is applied in the preparation of test samples, etc., can solve the problems of inability to accurately simulate the rolling condition of road rollers, difficulty in precise and arbitrary settings, poor reliability of test data, etc., and achieve automation The effect of high degree, uniform density and uniform rutting test plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

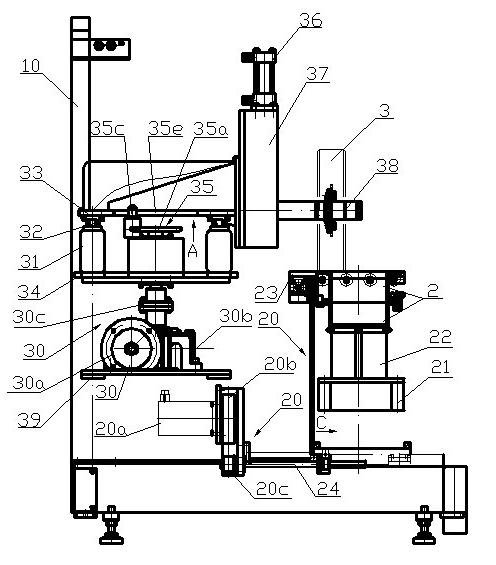

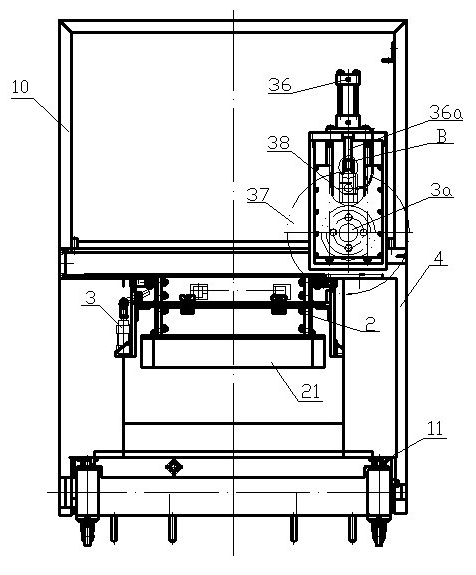

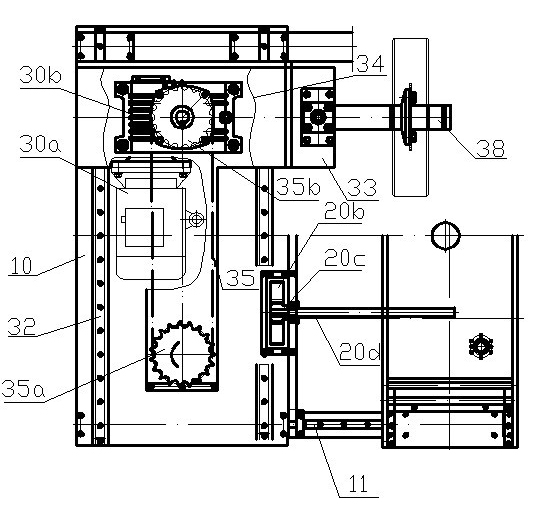

[0036] Contrast figure 1 , figure 2 , image 3 , The wheel roller forming apparatus of the present invention is mainly composed of a frame 10, a roller roller 3, a mold 2, a mold drive device and a roller roller drive device. The rolling wheel drive device and the mold drive device are respectively placed inside and outside of the frame (relative to the operating position, figure 1 The left side is the inside and the right side is the outside).

[0037] The rolling wheel drive device is mainly composed of a first speed reduction mechanism 30, a rolling wheel support 33, a hydraulic cylinder 36, a first guide rail 32 and a transmission chain. The first reduction mechanism 30 is composed of a first motor 30a, a sprocket drive chain 35, a worm gear reducer 30b and a drive pin 30c. The sprocket drive chain 35 includes a sprocket 35a, a sprocket 35b, and a chain that meshes with the two sprockets. The roller support 33 is slidably connected to the first guide rail 32 through two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com